Adsorptive–Photocatalytic Composites of α-Ferrous Oxalate Supported on Activated Carbon for the Removal of Phenol under Visible Irradiation

Abstract

:1. Introduction

2. Results and Discussion

2.1. Synthesis and Characterization of AC/α-FOD Composites

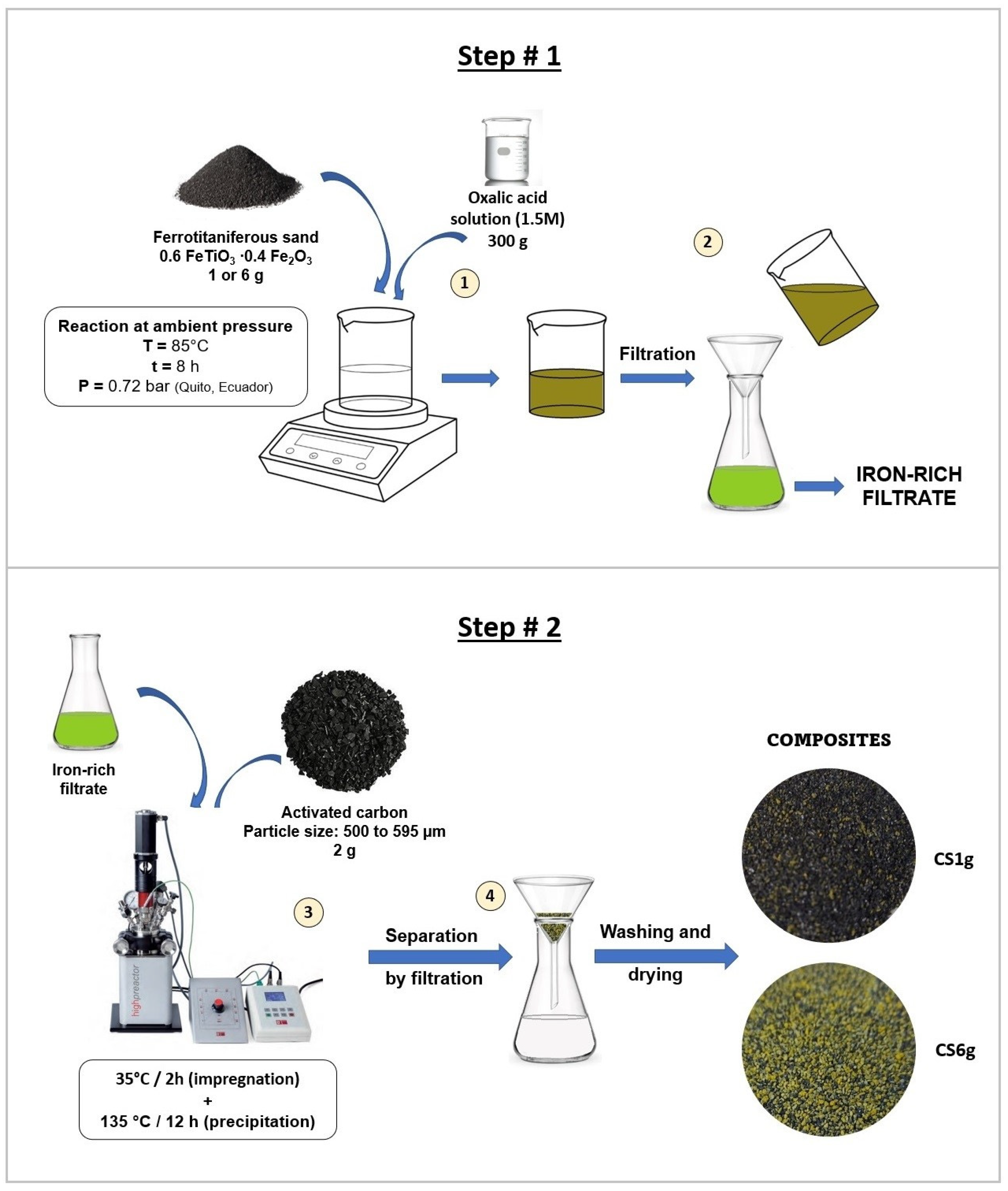

2.1.1. Synthesis

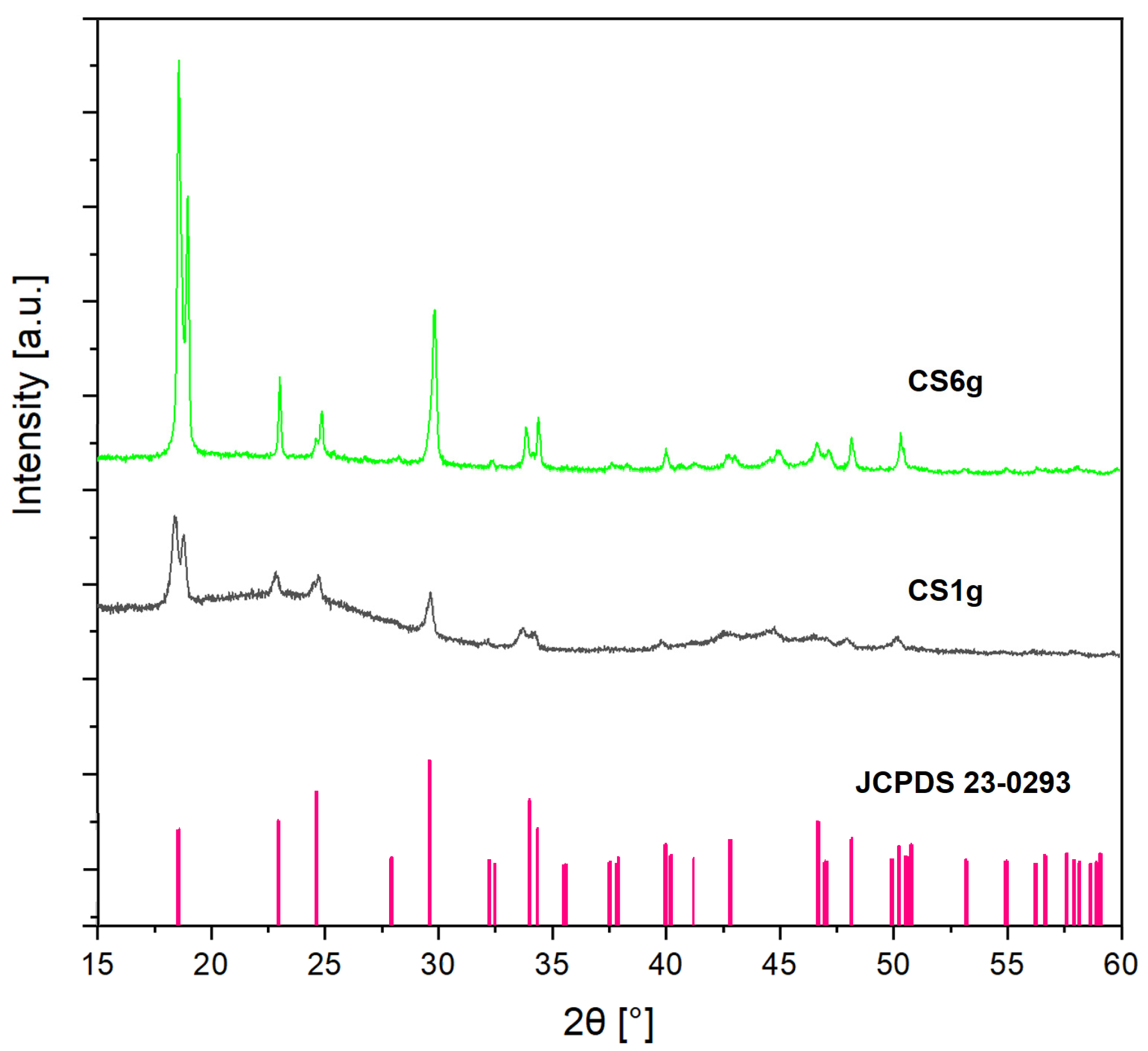

2.1.2. Crystalline Structure

2.1.3. Morphology and Surface Characteristics

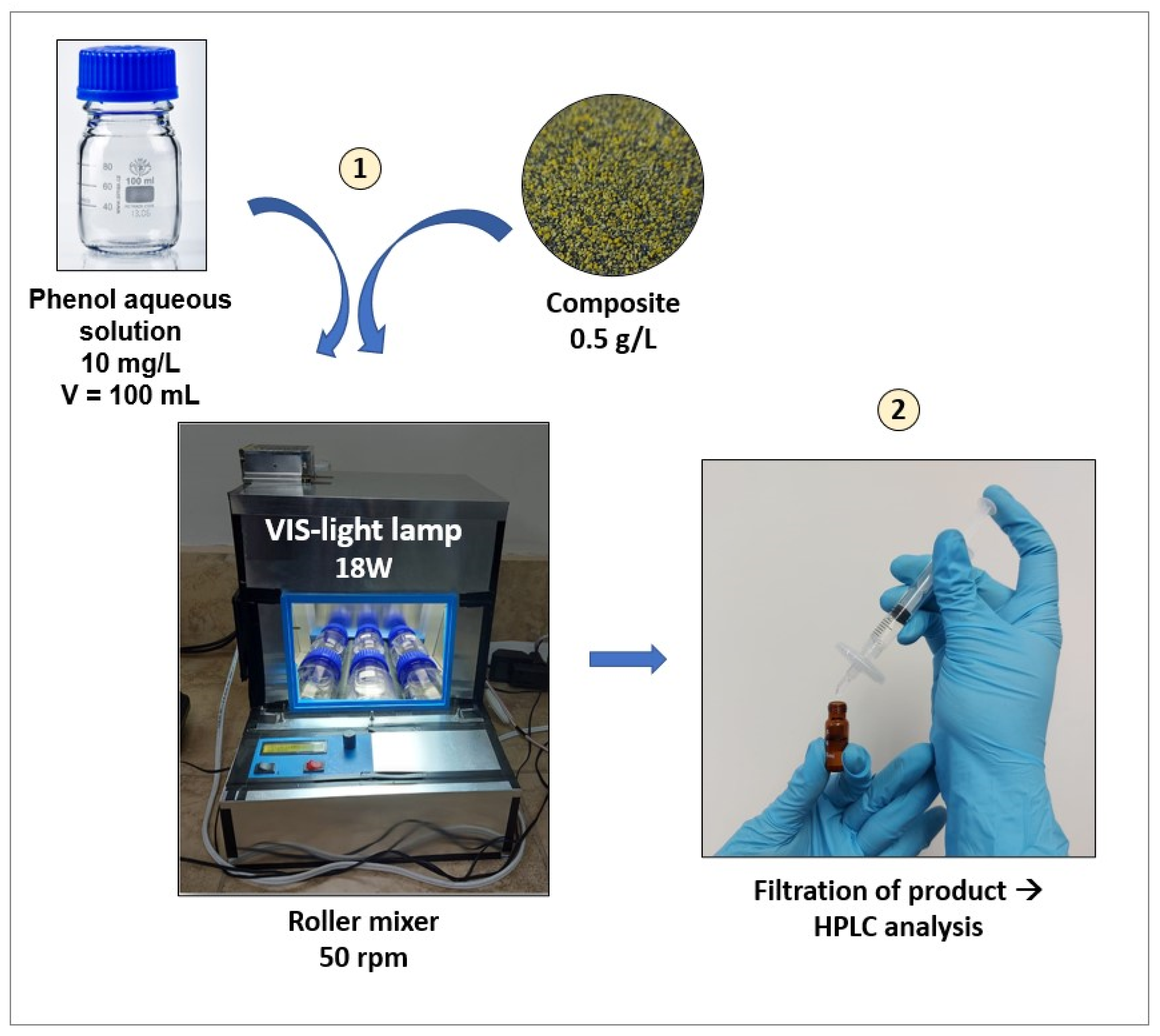

2.2. Adsorption and Photocatalytic Tests

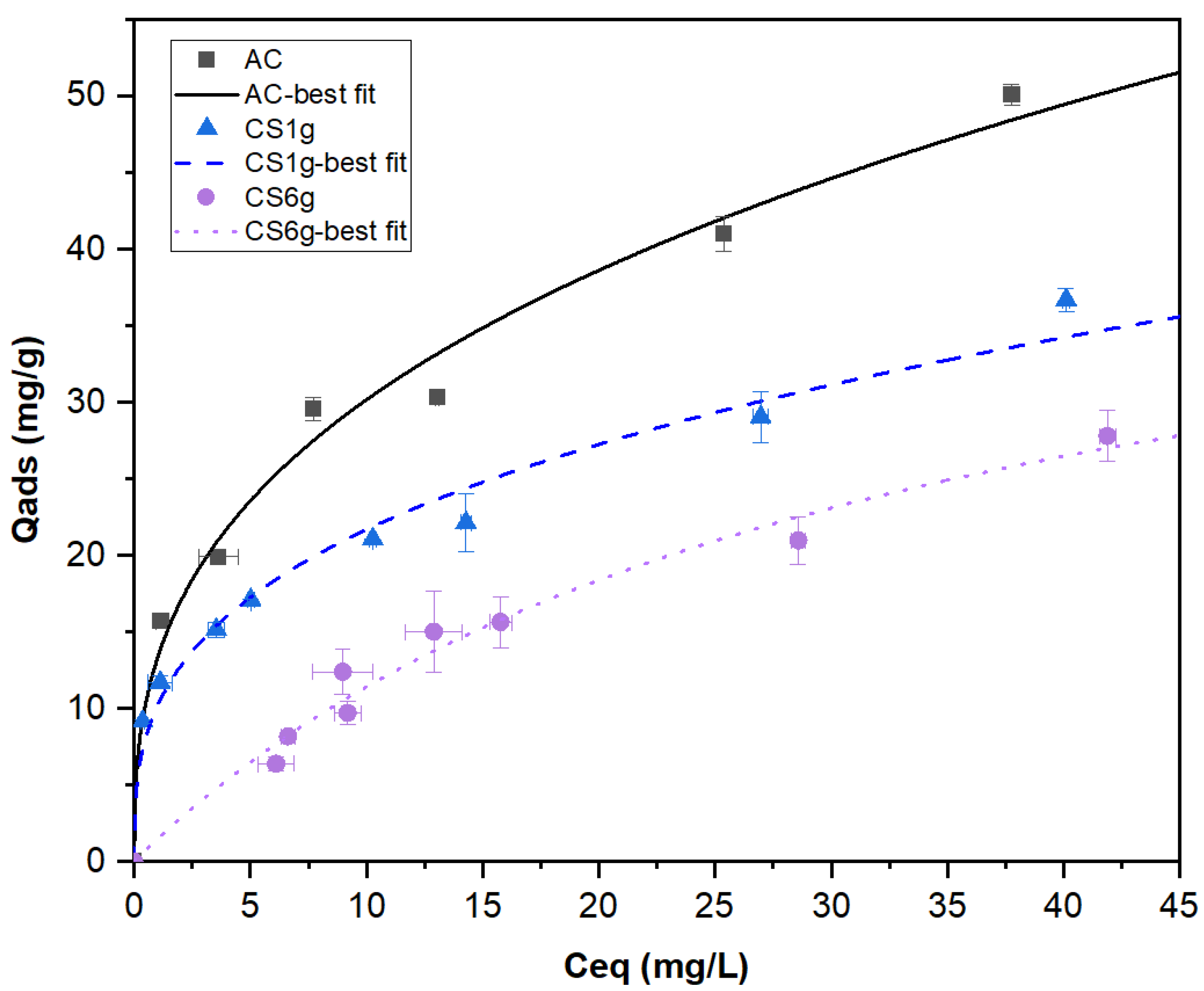

2.2.1. Adsorption Isotherms

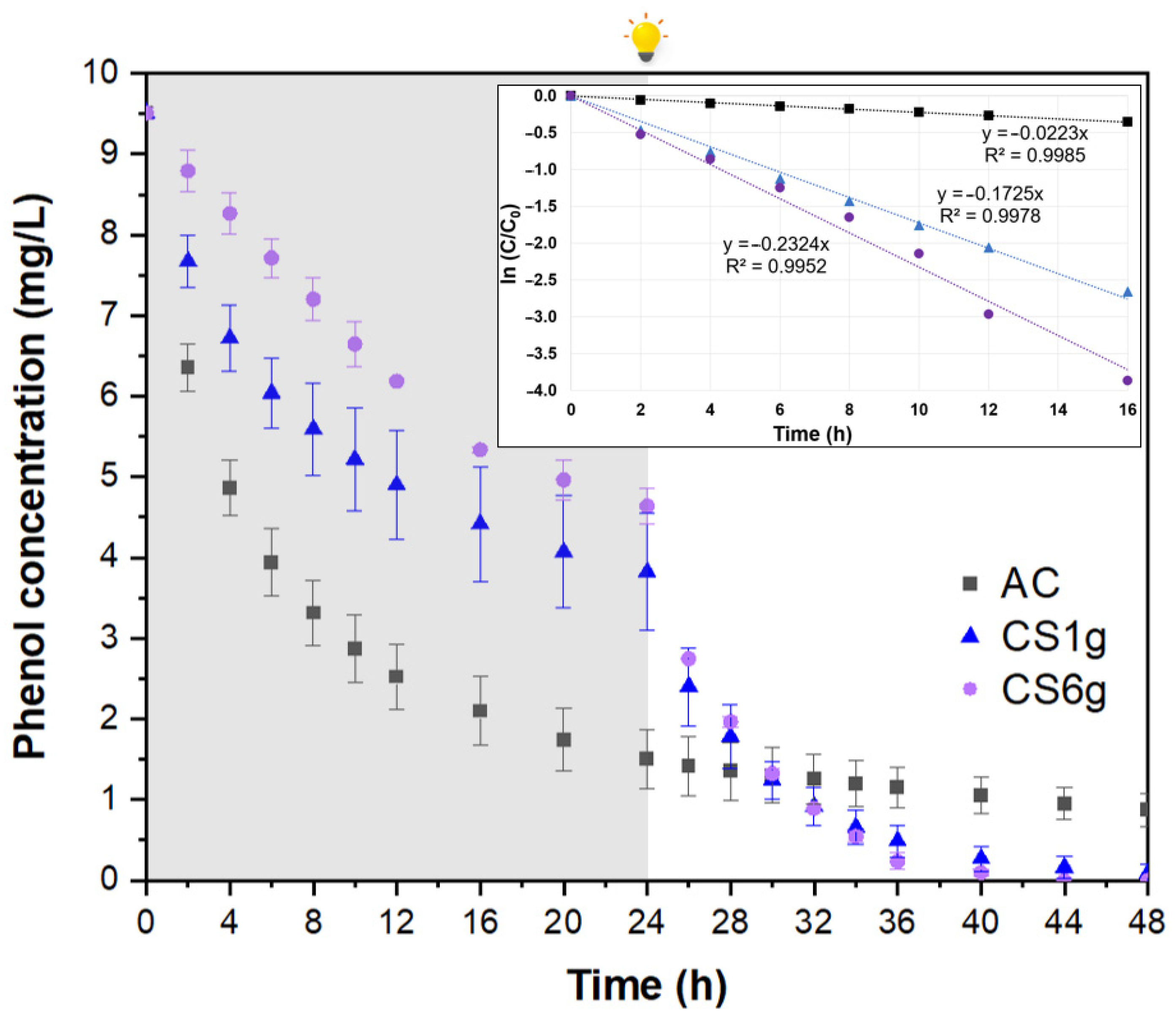

2.2.2. Photocatalytic Tests

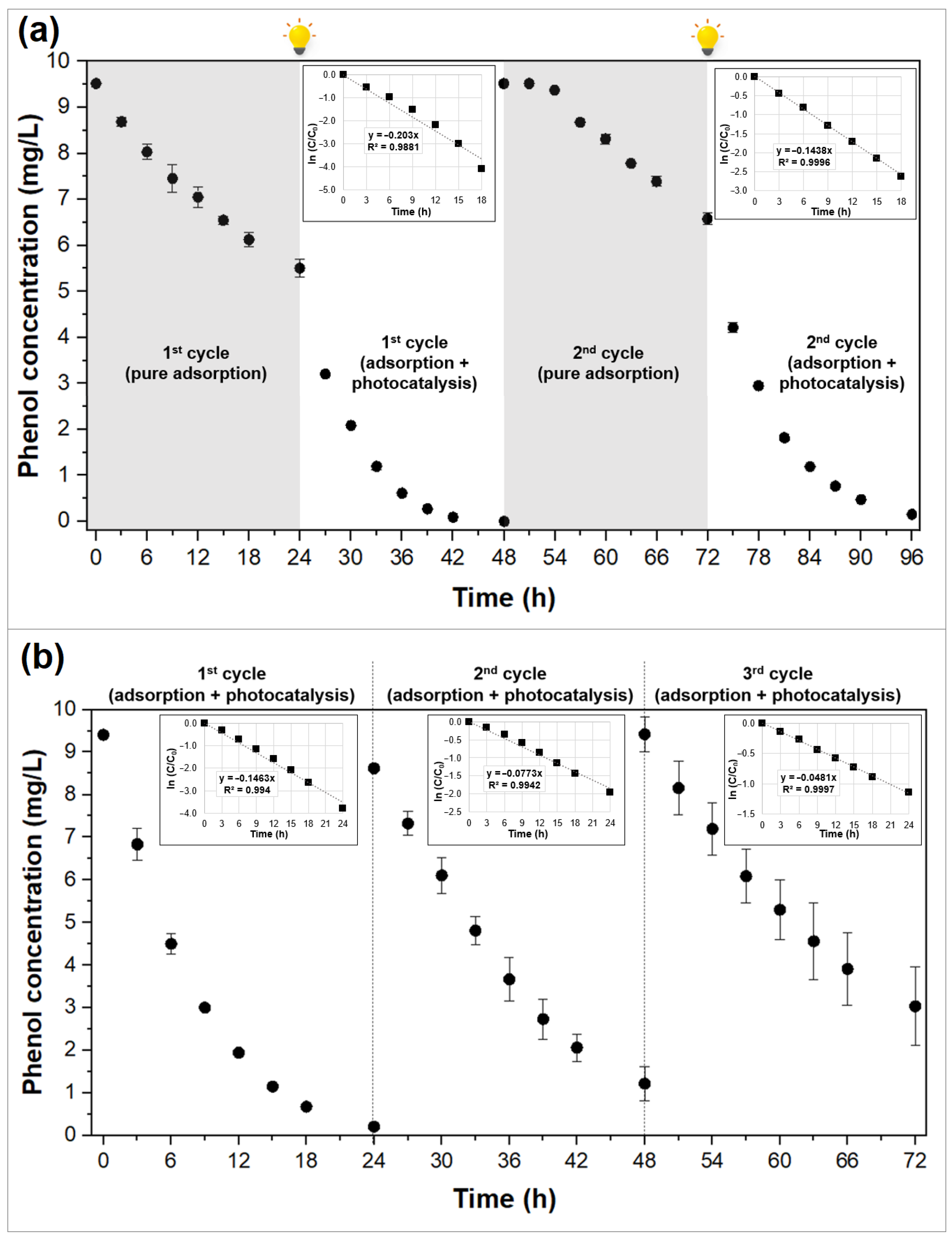

2.2.3. Recycling Tests

3. Materials and Methods

3.1. Materials

3.2. Synthesis of the AC/α-FOD Composites

3.2.1. Conditioning of the AC

3.2.2. Synthesis

3.3. Characterization of the Materials

3.4. Adsorption and Photocatalytic Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jin, H.; Zhang, Y.; Wang, Q.; Chang, Q.; Li, C. Rapid removal of methylene blue and nickel ions and adsorption/desorption mechanism based on geopolymer adsorbent. Colloids Interface Sci. Commun. 2021, 45, 100551. [Google Scholar] [CrossRef]

- Tang, S.; Zhao, M.; Yuan, D.; Li, X.; Zhang, X.; Wang, Z.; Jiao, T.; Wang, K. MnFe2O4 nanoparticles promoted electrochemical oxidation coupling with persulfate activation for tetracycline degradation. Sep. Purif. Technol. 2021, 255, 117690. [Google Scholar] [CrossRef]

- Shi, H.; Zhang, Y.; Wei, Y.; Che, C.; Xia, Z.; Li, G.; Zhang, X.; Shi, Y.; Tang, Z. In situ preparation of biochar/Bi4O5Br2 composite for ibuprofen removal under the synergistic effect of adsorption and photocatalysis and the underlying mechanism. J. Water Process Eng. 2024, 57, 104628. [Google Scholar] [CrossRef]

- Guan, C.; Jiang, J.; Luo, C.; Pang, S.; Yang, Y.; Wang, Z.; Ma, J.; Yu, J.; Zhao, X. Oxidation of bromophenols by carbon nanotube activated peroxymonosulfate (PMS) and formation of brominated products: Comparison to peroxydisulfate (PDS). Chem. Eng. J. 2018, 337, 40–50. [Google Scholar] [CrossRef]

- Wang, T.; Zheng, J.; Cai, J.; Liu, Q.; Zhang, X. Visible-light-driven photocatalytic degradation of dye and antibiotics by activated biochar composited with K+ doped g-C3N4: Effects, mechanisms, actual wastewater treatment and disinfection. Sci. Total Environ. 2022, 839, 155955. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Zou, L.; Wang, L. A novel charge-driven self-assembly method to prepare visible-light sensitive TiO2/activated carbon composites for dissolved organic compound removal. Chem. Eng. J. 2011, 168, 485–492. [Google Scholar] [CrossRef]

- Amaly, N.; EL-Moghazy, A.Y.; Nitin, N.; Sun, G.; Pandey, P.K. Synergistic adsorption-photocatalytic degradation of tetracycline by microcrystalline cellulose composite aerogel dopped with montmorillonite hosted methylene blue. Chem. Eng. J. 2022, 430, 133077. [Google Scholar] [CrossRef]

- El Mouchtari, E.M.; Daou, C.; Rafqah, S.; Najjar, F.; Anane, H.; Piram, A.; Hamade, A.; Briche, S.; Wong-Wah-Chung, P. TiO2 and activated carbon of Argania spinosa tree nutshells composites for the adsorption photocatalysis removal of pharmaceuticals from aqueous solution. J. Photochem. Photobiol. A Chem. 2020, 388, 112183. [Google Scholar] [CrossRef]

- Entezami, N.; Farhadian, M.; Nazar, A.R.S.; Tangestaninejad, S. Synthesis and characterization of Bi2O3/ZIF-67 nanocomposite integration with capacitive deionization system in the degradation tetracycline. Process Saf. Environ. Prot. 2022, 164, 747–760. [Google Scholar] [CrossRef]

- Khasevani, S.G.; Nikjoo, D.; Chaxel, C.; Umeki, K.; Sarmad, S.; Mikkola, J.P.; Concina, I. Empowering Adsorption and Photocatalytic Degradation of Ciprofloxacin on BiOI Composites: A Material-by-Design Investigation. ACS Omega 2023, 8, 44044–44056. [Google Scholar] [CrossRef]

- Xiang, R.; Zhou, C.; Liu, Y.; Qin, T.; Li, D.; Dong, X.; Muddassir, M.; Zhong, A. A new type Co(II)-based photocatalyst for the nitrofurantoin antibiotic degradation. J. Mol. Struct. 2024, 1312, 138501. [Google Scholar] [CrossRef]

- Amornpitoksuk, P.; Suwanboon, S.; Randorn, C. Photocatalytic activities of silver compound modified activated carbon@ZnO: Novel ternary composite visible light-driven photocatalysts. Mater. Sci. Semicond. Process. 2018, 84, 50–57. [Google Scholar] [CrossRef]

- Guo, F.; Chen, Z.; Huang, X.; Cao, L.; Cheng, X.; Shi, W.; Chen, L. Ternary Ni2P/Bi2MoO6/g-C3N4 composite with Z-scheme electron transfer path for enhanced removal broad-spectrum antibiotics by the synergistic effect of adsorption and photocatalysis. Chin. J. Chem. Eng. 2022, 44, 157–168. [Google Scholar] [CrossRef]

- Dai, H.; Xu, S.; Chen, J.; Miao, X.; Zhu, J. Oxalate enhanced degradation of Orange II in heterogeneous UV-Fenton system catalyzed by Fe3O4@Γ-Fe2O3 composite. Chemosphere 2018, 199, 147–153. [Google Scholar] [CrossRef] [PubMed]

- Habibi, M.H.; Habibi, A.H. Photocatalytic degradation of Brilliant Red M5B using four different nanocomposites (ZnFe2O4, porous ZnFe2O4, ZnFe2O4–TiO2, FeTiO3) coated on glass. J. Ind. Eng. Chem. 2014, 20, 2964–2968. [Google Scholar] [CrossRef]

- Karami, K.; Bayat, P.; Javadian, S.; Saraji, M. A novel TMD/MOF (Transition Metal Dichalcogenide/Metalorganic frameworks) composite for highly and selective adsorption of methylene blue dye from aqueous mixture of MB and MO. J. Mol. Liq. 2021, 342, 117520. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, Y.; Du, Y.; Jiang, H.; Zhou, D.; Dong, S. Carbon nanodots/WO3 nanorods Z-scheme composites: Remarkably enhanced photocatalytic performance under broad spectrum. Appl. Catal. B Environ. 2017, 209, 253–264. [Google Scholar] [CrossRef]

- Zhao, J.; Dang, Z.; Muddassir, M.; Raza, S.; Zhong, A.; Wang, X.; Jin, J. A New Cd(II)-Based Coordination Polymer for Efficient Photocatalytic Removal of Organic Dyes. Molecules 2023, 28, 6848. [Google Scholar] [CrossRef] [PubMed]

- Cheng, S.; Zhao, S.; Xing, B.; Liu, Y.; Zhang, C.; Xia, H. Preparation of magnetic adsorbent-photocatalyst composites for dye removal by synergistic effect of adsorption and photocatalysis. J. Clean. Prod. 2022, 348, 131301. [Google Scholar] [CrossRef]

- Liu, H.; Tian, X.; Xiang, X.; Chen, S. Preparation of carboxymethyl cellulose/graphene composite aerogel beads and their adsorption for methylene blue. Int. J. Biol. Macromol. 2022, 202, 632–643. [Google Scholar] [CrossRef]

- Abdullah, M.; Iqbal, J.; Ur Rehman, M.S.; Khalid, U.; Mateen, F.; Arshad, S.N.; Al-Sehemi, A.G.; Algarni, H.; Al-Hartomy, O.A.; Fazal, T. Removal of ceftriaxone sodium antibiotic from pharmaceutical wastewater using an activated carbon based TiO2 composite: Adsorption and photocatalytic degradation evaluation. Chemosphere 2023, 317, 137834. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Cai, Y.; Zhou, B.; Yuan, R.; Chen, Z.; Chen, H. Removal of PFASs from water by carbon-based composite photocatalysis with adsorption and catalytic properties: A review. Sci. Total Environ. 2022, 836, 155652. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, E.; Plantard, G.; Goetz, V. TiO2 grafted activated carbon elaboration by milling: Composition effect on sorption and photocatalytic properties. J. Photochem. Photobiol. A Chem. 2021, 408, 113108. [Google Scholar] [CrossRef]

- Gamage McEvoy, J.; Cui, W.; Zhang, Z. Synthesis and characterization of Ag/AgCl-activated carbon composites for enhanced visible light photocatalysis. Appl. Catal. B Environ. 2014, 144, 702–712. [Google Scholar] [CrossRef]

- Karimi, F.; Altuner, E.E.; Gulbagca, F.; Tiri, R.N.E.; Sen, F.; Javadi, A.; Dragoi, E.N. Facile bio-fabrication of ZnO@AC nanoparticles from chitosan: Characterization, hydrogen generation, and photocatalytic properties. Environ. Res. 2023, 216, 114668. [Google Scholar] [CrossRef] [PubMed]

- Yap, P.S.; Lim, T.T. Solar regeneration of powdered activated carbon impregnated with visible-light responsive photocatalyst: Factors affecting performances and predictive model. Water Res. 2012, 46, 3054–3064. [Google Scholar] [CrossRef] [PubMed]

- Primo, A.; García, H. Chapter 6. Solar Photocatalysis for Environment Remediation. In New and Future Developments in Catalysis: Solar Photocatalysis; Elsevier: Amsterdam, The Netherlands, 2013; pp. 145–165. ISBN 9780444538727. [Google Scholar]

- Hou, D.; Feng, L.; Zhang, J.; Dong, S.; Zhou, D.; Lim, T.T. Preparation, characterization and performance of a novel visible light responsive spherical activated carbon-supported and Er3+:YFeO3-doped TiO2 photocatalyst. J. Hazard. Mater. 2012, 199–200, 301–308. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, X.; Chen, W.; Li, L.; Zen, M.; Qin, S.; Sun, S. Photodecolorization of Rhodamine B on tungsten-doped TiO2/activated carbon under visible-light irradiation. J. Hazard. Mater. 2012, 227–228, 25–33. [Google Scholar] [CrossRef] [PubMed]

- Ma, R.; Wang, X.; Huang, J.; Song, J.; Zhang, J.; Wang, X. Photocatalytic degradation of salicylic acid with magnetic activated carbon-supported F-N codoped TiO2 under visible light. Vacuum 2017, 141, 157–165. [Google Scholar] [CrossRef]

- Xu, J.; Ao, Y.; Fu, D.; Yuan, C. Synthesis of fluorine-doped titania-coated activated carbon under low temperature with high photocatalytic activity under visible light. J. Phys. Chem. Solids 2008, 69, 2366–2370. [Google Scholar] [CrossRef]

- Wang, N.; Li, X.; Yang, Y.; Guo, T.; Zhuang, X.; Ji, S.; Zhang, T.; Shang, Y.; Zhou, Z. Enhanced photocatalytic degradation of sulfamethazine by Bi-doped TiO2 nano-composites supported by powdered activated carbon under visible light irradiation. Sep. Purif. Technol. 2019, 211, 673–683. [Google Scholar] [CrossRef]

- Wang, G.; Zhou, A.; Xu, Q. α-Ferrous oxalate with different micro scale: Synthesis and catalytic degradation effect to rhodamine B. Solid State Sci. 2019, 91, 54–60. [Google Scholar] [CrossRef]

- Chuaicham, C.; Shenoy, S.; Trakulmututa, J.; Balakumar, V.; Santawaja, P.; Kudo, S.; Sekar, K.; Sasaki, K. Preparation of Iron Oxalate from Iron Ore and Its Application in Photocatalytic Rhodamine B Degradation. Separations 2023, 10, 378. [Google Scholar] [CrossRef]

- Fan, X.; Zhang, L.; Li, M.; Wang, M.; Zhou, X.; Cheng, R.; Zhou, Y.; Shi, J. α-Ferrous oxalate dihydrate: A simple coordination polymer featuring photocatalytic and photo-initiated Fenton oxidations. Sci. China Mater. 2016, 59, 574–580. [Google Scholar] [CrossRef]

- Galeas, S.; Valdivieso-Ramírez, C.S.; Pontón, P.I.; Goetz, V.; Guerrero, V.H. Photocatalytic activity of Fe/Ti-based compounds obtained from ferro-titaniferous mineral sands via a simple soft chemistry route. J. Phys. Conf. Ser. 2022, 2238, 012006. [Google Scholar] [CrossRef]

- Galeas, S.; Valdivieso-Ramírez, C.S.; Pontón, P.I.; Guerrero, V.H.; Goetz, V. Photocatalytic degradation of phenol under visible light irradiation by using ferrous oxalate synthesized from iron-rich mineral sands via a green hydrothermal route. Environ. Technol. Innov. 2023, 32, 103325. [Google Scholar] [CrossRef]

- Lagos, K.J.; Marinkovic, B.A.; Dosen, A.; Guamán, M.V.; Guerrero, V.H.; Pardo, E.; Pontón, P.I. Data on phase and chemical compositions of black sands from “El Ostional” beach situated in Mompiche, Ecuador. Data Br. 2020, 32, 106214. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.N.; Song, L.X.; Teng, Y.; Xia, J.; Li, Y.; Wang, W.P. Microspheres of Ferrous Oxalate Dihydrate: Formation, Structure, Physical Properties, and Photocatalytic Activities. J. Phys. Chem. C 2022, 126, 19122–19135. [Google Scholar] [CrossRef]

- Omri, A.; Benzina, M. Characterization Of Activated Carbon Prepared From A New Raw Lignocellulosic Material: Ziziphus Spina-Christi Seeds. J. Soc. Chim. Tunisie 2012, 14, 175–183. [Google Scholar]

- Mani, P.; Kim, Y.; Lakhera, S.K.; Neppolian, B.; Choi, H. Complete arsenite removal from groundwater by UV activated potassium persulfate and iron oxide impregnated granular activated carbon. Chemosphere 2021, 277, 130225. [Google Scholar] [CrossRef]

- Xue, G.; Liu, H.; Chen, Q.; Hills, C.; Tyrer, M.; Innocent, F. Synergy between surface adsorption and photocatalysis during degradation of humic acid on TiO2/activated carbon composites. J. Hazard. Mater. 2011, 186, 765–772. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.J.; Liu, W.; Wang, Y.; Guo, M.L. Preparation of β-ferrous oxalate dihydrate layered nanosheets by mechanochemical method and its visible-light-driven photocatalytic performance. Mater. Lett. 2016, 178, 83–86. [Google Scholar] [CrossRef]

- Ogasawara, H.; Koga, N. Kinetic modeling for thermal dehydration of ferrous oxalate dihydrate polymorphs: A combined model for induction period-surface reaction-phase boundary reaction. J. Phys. Chem. A 2014, 118, 2401–2412. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.I.; Kim, H.R.; Park, J.K.; Oh, W.; Kim, J.; Kim, C.; Lee, J.; Kim, K.C.; Lee, B.C. Precipitation of Ferrous Oxalate from Ferrous Ammonium Sulfate in Oxalic Acid Solution. Processes 2022, 10, 2420. [Google Scholar] [CrossRef]

- Maziarka, P.; Sommersacher, P.; Wang, X.; Kienzl, N.; Retschitzegger, S.; Prins, W.; Hedin, N.; Ronsse, F. Tailoring of the pore structures of wood pyrolysis chars for potential use in energy storage applications. Appl. Energy 2021, 286, 116431. [Google Scholar] [CrossRef]

- Asencios, Y.J.O.; Lourenço, V.S.; Carvalho, W.A. Removal of phenol in seawater by heterogeneous photocatalysis using activated carbon materials modified with TiO2. Catal. Today 2022, 388–389, 247–258. [Google Scholar] [CrossRef]

- Alikhani, N.; Farhadian, M.; Goshadrou, A.; Tangestaninejad, S.; Eskandari, P. Photocatalytic degradation and adsorption of herbicide 2,4-dichlorophenoxyacetic acid from aqueous solution using TiO2/BiOBr/Bi2S3 nanostructure stabilized on the activated carbon under visible light. Environ. Nanotechnol. Monit. Manag. 2021, 15, 100415. [Google Scholar] [CrossRef]

- Minisy, I.M.; Salahuddin, N.A.; Ayad, M.M. Adsorption of methylene blue onto chitosan–montmorillonite/polyaniline nanocomposite. Appl. Clay Sci. 2021, 203, 105993. [Google Scholar] [CrossRef]

- Ahmed, F.S.; AbdulRazak, A.A.; Alsaffar, M.A. Modelling and optimization of methylene blue adsorption from wastewater utilizing magnetic marble dust adsorbent: A response surface methodology approach. Mater. Today Proc. 2022, 60, 1676–1688. [Google Scholar] [CrossRef]

- Guo, T.; Jiang, L.; Wang, K.; Li, Y.; Huang, H.; Wu, X.; Zhang, G. Efficient persulfate activation by hematite nanocrystals for degradation of organic pollutants under visible light irradiation: Facet-dependent catalytic performance and degradation mechanism. Appl. Catal. B Environ. 2021, 286, 119883. [Google Scholar] [CrossRef]

- Frost, R.L. Raman spectroscopy of natural oxalates. Anal. Chim. Acta 2004, 517, 207–214. [Google Scholar] [CrossRef]

- Mohtaram, M.S.; Sabbaghi, S.; Rasouli, J.; Rasouli, K. Photocatalytic degradation of tetracycline using a novel WO3–ZnO/AC under visible light irradiation: Optimization of effective factors by RSM-CCD. Environ. Pollut. 2024, 347, 123746. [Google Scholar] [CrossRef] [PubMed]

- Telegang Chekem, C.; Goetz, V.; Richardson, Y.; Plantard, G.; Blin, J. Modelling of adsorption/photodegradation phenomena on AC-TiO2 composite catalysts for water treatment detoxification. Catal. Today 2019, 328, 183–188. [Google Scholar] [CrossRef]

- Santawaja, P.; Kudo, S.; Mori, A.; Tahara, A.; Asano, S.; Hayashi, J.I. Sustainable Iron-Making Using Oxalic Acid: The Concept, A Brief Review of Key Reactions, and An Experimental Demonstration of the Iron-Making Process. ACS Sustain. Chem. Eng. 2020, 8, 13292–13301. [Google Scholar] [CrossRef]

- Hermankova, P.; Hermanek, M.; Zboril, R. Thermal decomposition of ferric oxalate tetrahydrate in oxidative and inert atmospheres: The role of ferrous oxalate as an intermediate. Eur. J. Inorg. Chem. 2010, 2010, 1110–1118. [Google Scholar] [CrossRef]

- Angermann, A.; Töpfer, J. Synthesis of magnetite nanoparticles by thermal decomposition of ferrous oxalate dihydrate. J. Mater. Sci. 2008, 43, 5123–5130. [Google Scholar] [CrossRef]

- Jia, Y.; Ni, J.; Fang, F. Thermal decomposition of ferrous oxalate nanowires to porous nanowire-like α-Fe2O3 with a good gas-sensing properties. Mater. Sci. Semicond. Process 2021, 125, 105650. [Google Scholar] [CrossRef]

| Adsorbent | Specific Surface Area (m2·g−1) | Average Pore Diameter (nm) |

|---|---|---|

| AC | 314.3 | 1.71 |

| CS1g | 374.8 | 1.81 |

| CS6g | 251.8 | 2.48 |

| Adsorbent | Langmuir | Freundlich | ||||

|---|---|---|---|---|---|---|

| Qmax (mg.g−1) | KL (L·mg−1) | R2 | KF ((mg·g−1)·(L·mg−1)1/n) | n | R2 | |

| AC | 52.28 | 0.17 | 0.957 | 13.29 | 2.81 | 0.988 |

| CS1g | 34.97 | 0.21 | 0.927 | 10.17 | 3.04 | 0.982 |

| CS6g | 47.24 | 0.03 | 0.989 | 2.69 | 1.60 | 0.977 |

| Composite | Composite Dosage (g/L) | Phenol Initial Concentration (mg/L) | Particle Size (µm) | Removal Capacity and Irradiation Time | Irradiation Power (W) | Reference |

|---|---|---|---|---|---|---|

| AC/TiO2 | 0.5 | 50 | NR | 55 mg/g within 1 h (dark) + 4 h vis-irradiation | 90 | [47] |

| AC/Ag-AgCl | 0.5 | 13 | 149 | 23 mg/g within 2 h (dark) + 2.5 h vis-irradiation | 300 | [24] |

| AC/fluorine doped TiO2 | 1 | 25 | NR | 15 mg/g within 30 min (dark + 8 h vis-irradiation) | 250 | [31] |

| AC/α-FOD (CS6g) | 0.5 | 10 | 500–595 | 19 mg/g within 24 h (dark) + 24 h vis-irradiation | 18 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galeas, S.; Guerrero, V.H.; Pontón, P.I.; Valdivieso-Ramírez, C.S.; Vargas-Jentzsch, P.; Zárate, P.; Goetz, V. Adsorptive–Photocatalytic Composites of α-Ferrous Oxalate Supported on Activated Carbon for the Removal of Phenol under Visible Irradiation. Molecules 2024, 29, 3690. https://doi.org/10.3390/molecules29153690

Galeas S, Guerrero VH, Pontón PI, Valdivieso-Ramírez CS, Vargas-Jentzsch P, Zárate P, Goetz V. Adsorptive–Photocatalytic Composites of α-Ferrous Oxalate Supported on Activated Carbon for the Removal of Phenol under Visible Irradiation. Molecules. 2024; 29(15):3690. https://doi.org/10.3390/molecules29153690

Chicago/Turabian StyleGaleas, Salomé, Víctor H. Guerrero, Patricia I. Pontón, Carla S. Valdivieso-Ramírez, Paul Vargas-Jentzsch, Paola Zárate, and Vincent Goetz. 2024. "Adsorptive–Photocatalytic Composites of α-Ferrous Oxalate Supported on Activated Carbon for the Removal of Phenol under Visible Irradiation" Molecules 29, no. 15: 3690. https://doi.org/10.3390/molecules29153690

APA StyleGaleas, S., Guerrero, V. H., Pontón, P. I., Valdivieso-Ramírez, C. S., Vargas-Jentzsch, P., Zárate, P., & Goetz, V. (2024). Adsorptive–Photocatalytic Composites of α-Ferrous Oxalate Supported on Activated Carbon for the Removal of Phenol under Visible Irradiation. Molecules, 29(15), 3690. https://doi.org/10.3390/molecules29153690