Recent Progress in Thermoplastic Polyurethane/MXene Nanocomposites: Preparation, Flame-Retardant Properties and Applications

Abstract

:1. Introduction

2. Flame-Retardant Mechanisms for TPU

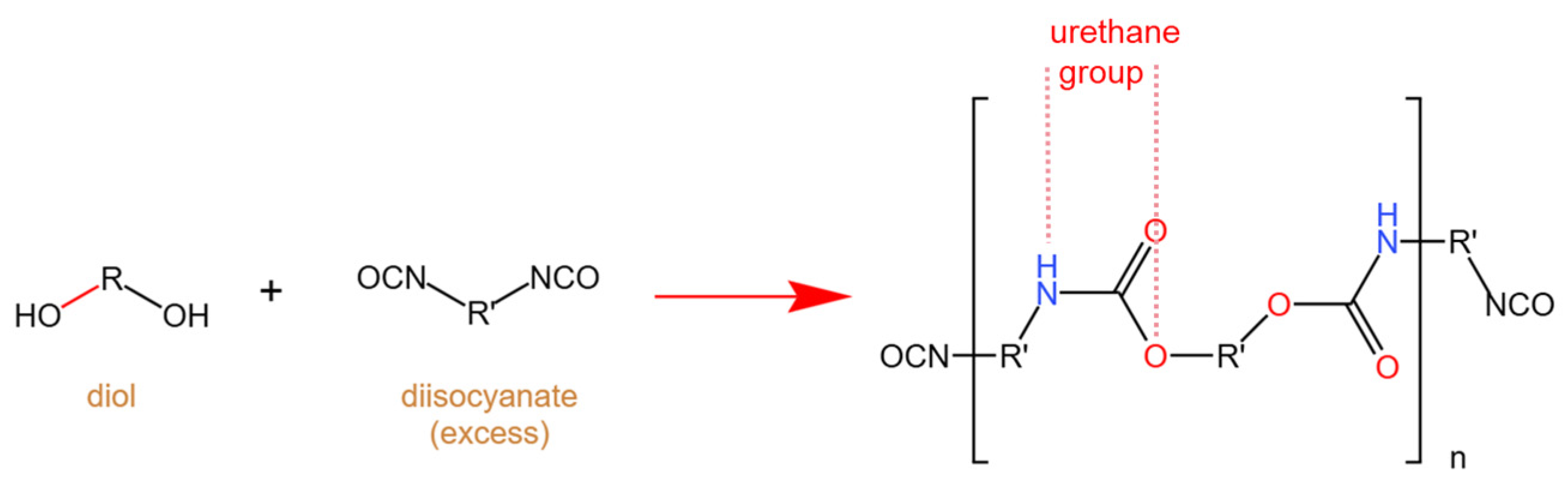

2.1. Synthesis and Combustion Characteristics of Polyurethane

2.2. Condensed-Phase Flame-Retardant Mechanism

2.3. Gas-Phase Flame-Retardant Mechanism

2.4. Synergistic Flame-Retardant Mechanism

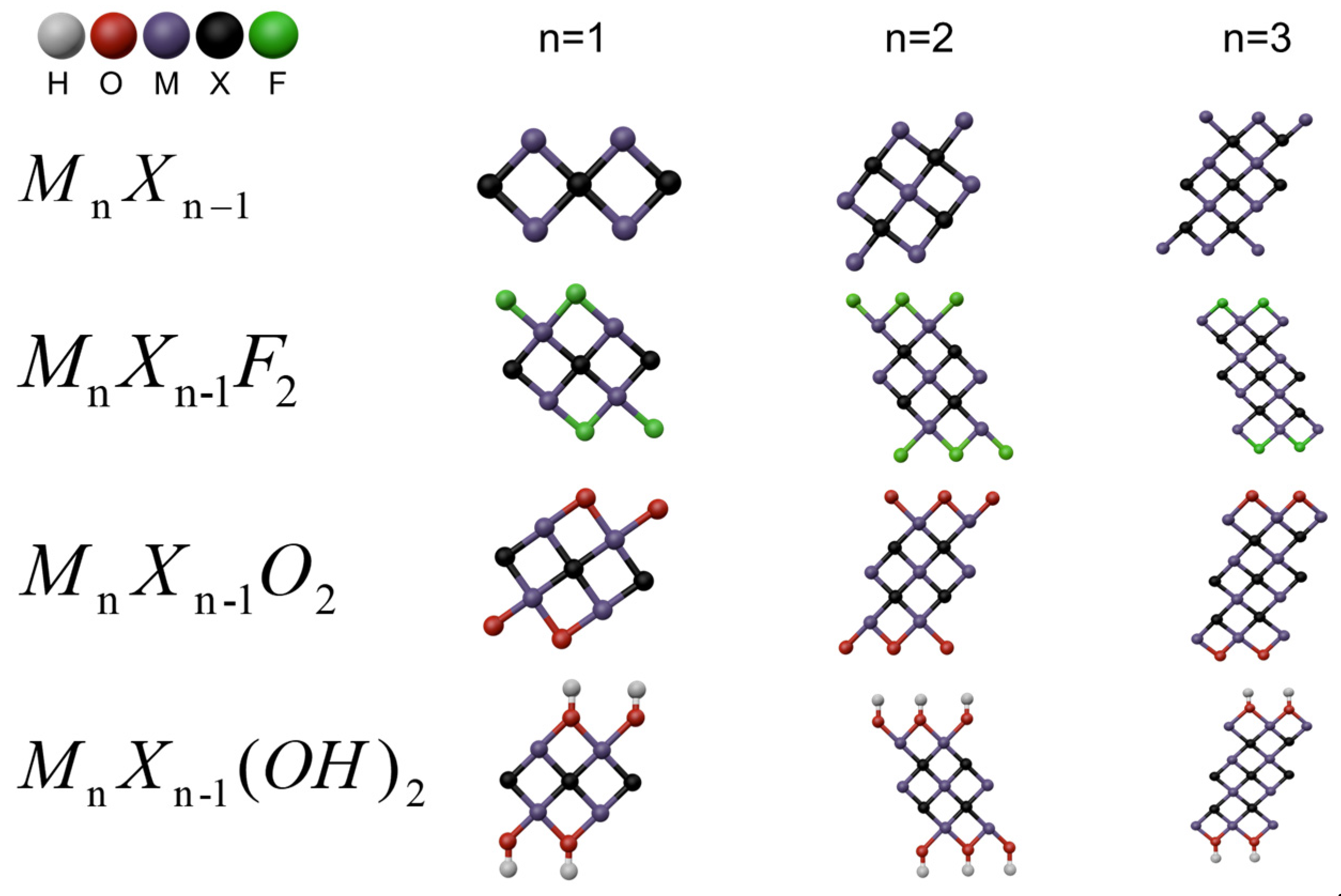

3. Synthesis and Modification of MXenes

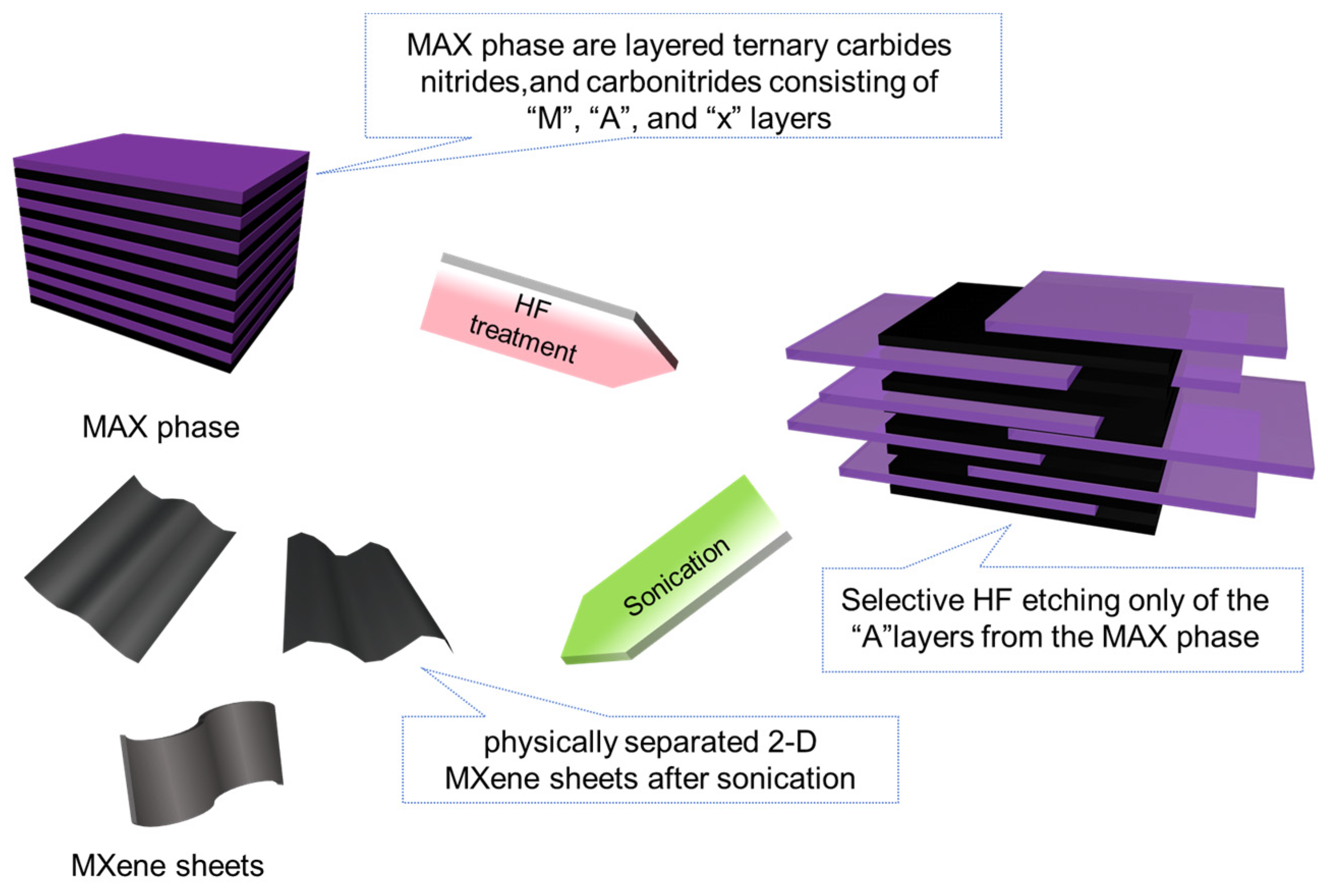

3.1. Synthesis of MXenes

3.1.1. Fluoride-Containing Etching Methods

3.1.2. Alkaline Etching Strategy

3.1.3. Electrochemical Etching Strategy

4. MXene-Based Flame-Retardant Polyurethane Systems

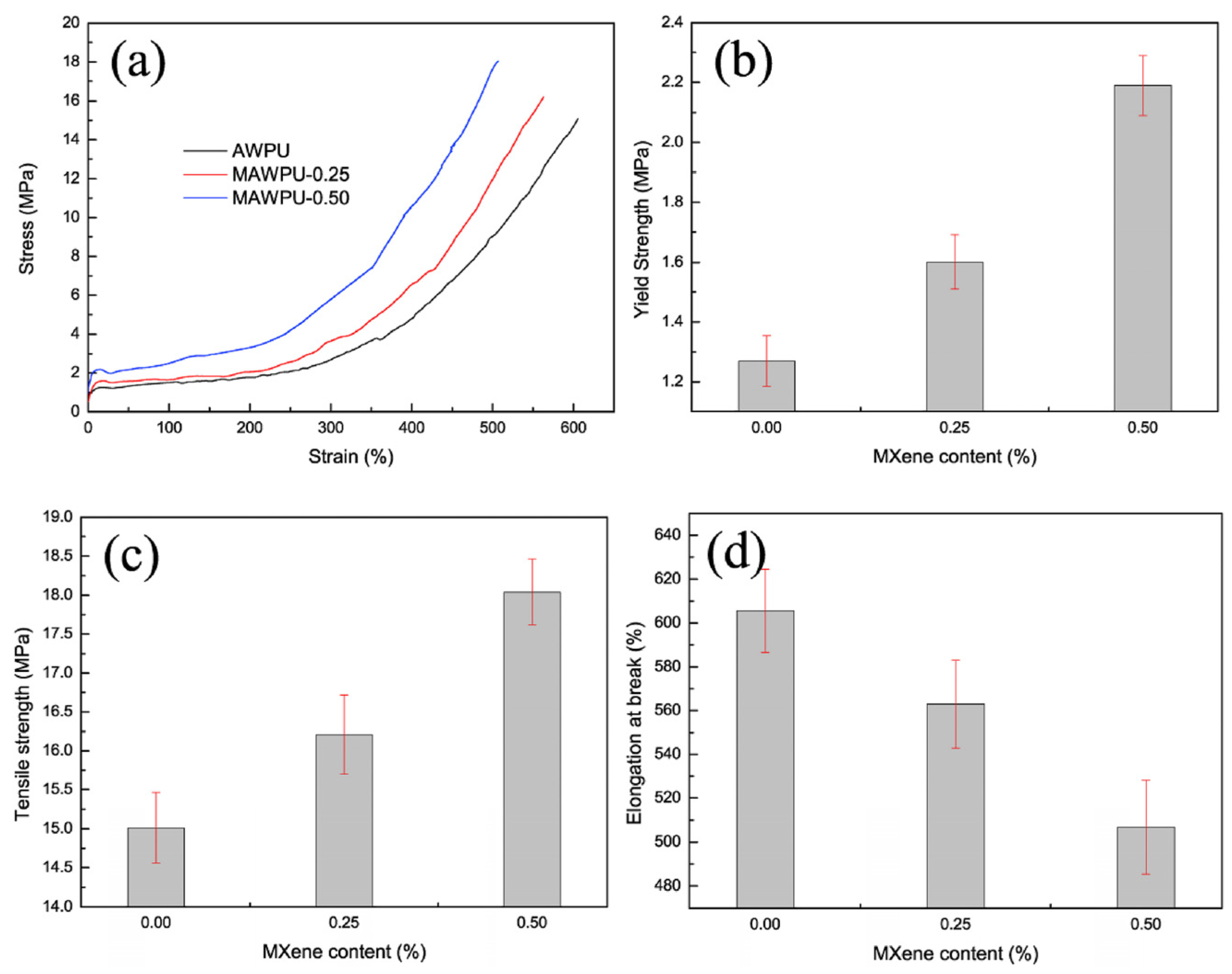

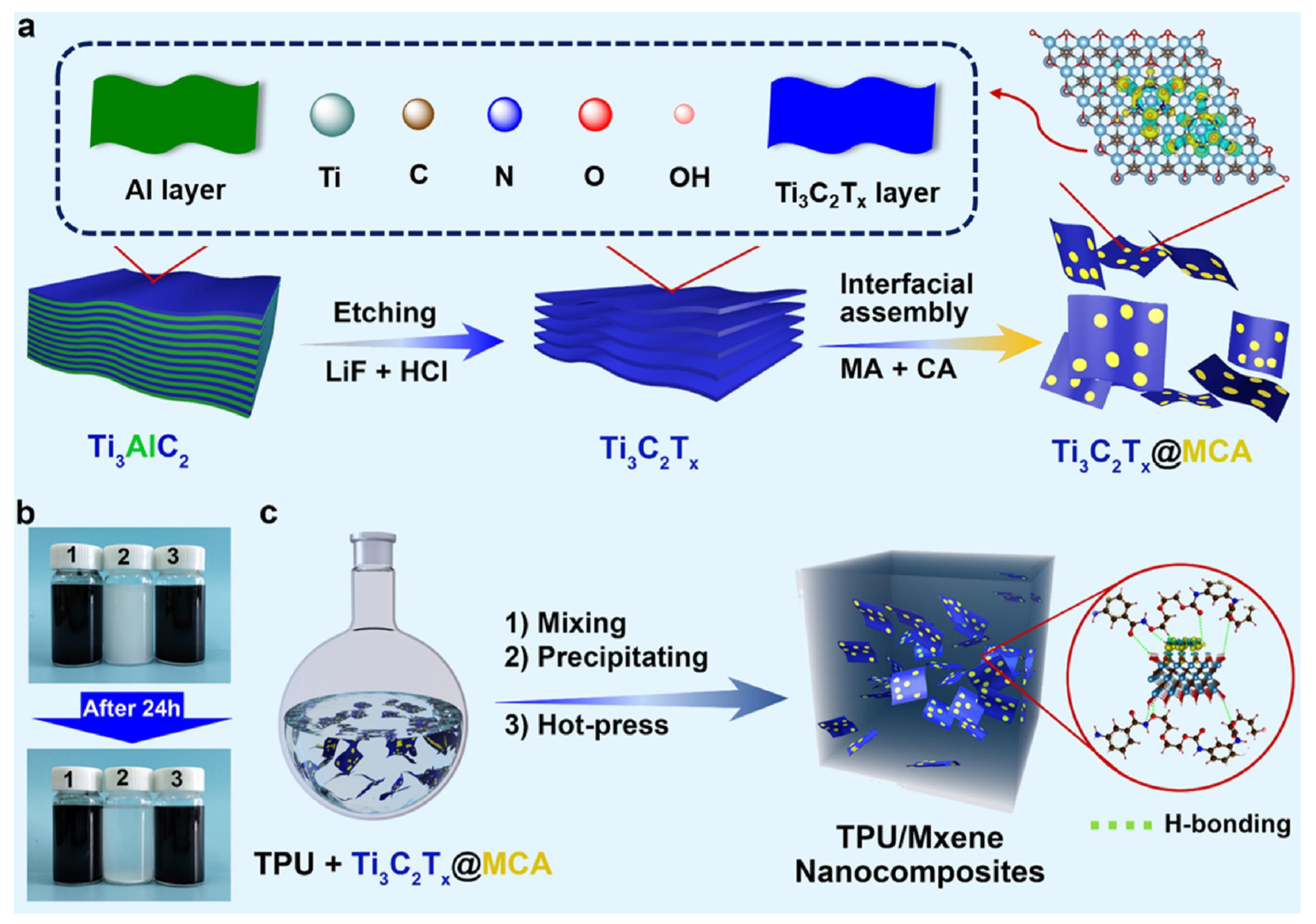

4.1. Preparation of Thermoplastic Polyurethane/MXene Nanocomposites

4.1.1. Solution Casting

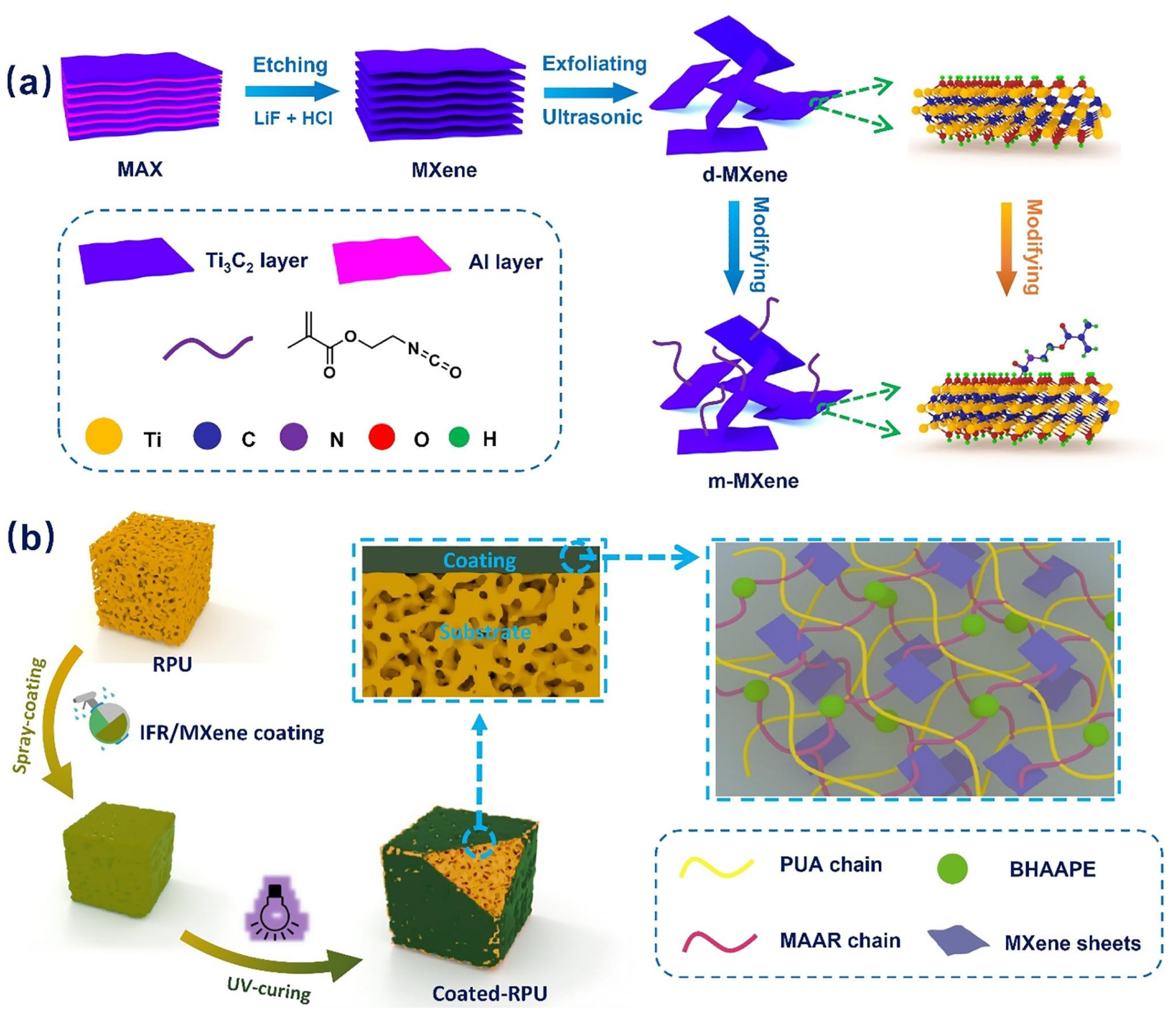

4.1.2. Melt Blending

4.2. Utilization of Pristine MXene

4.3. Utilization of Modified MXene

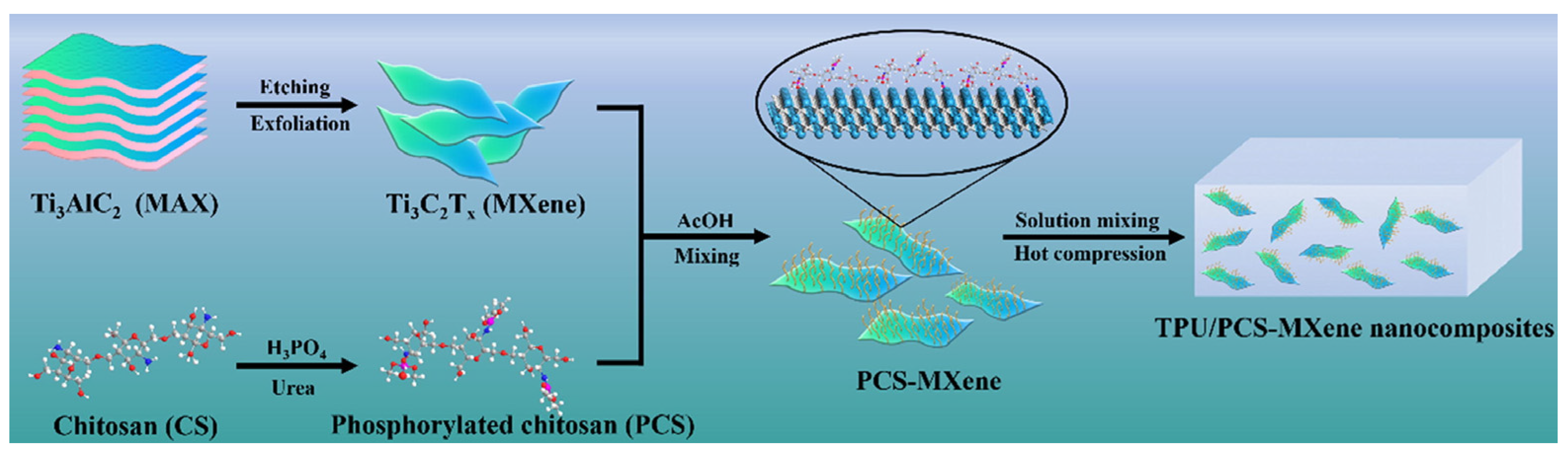

4.3.1. Functionalized MXene by Noncovalent Adhesion

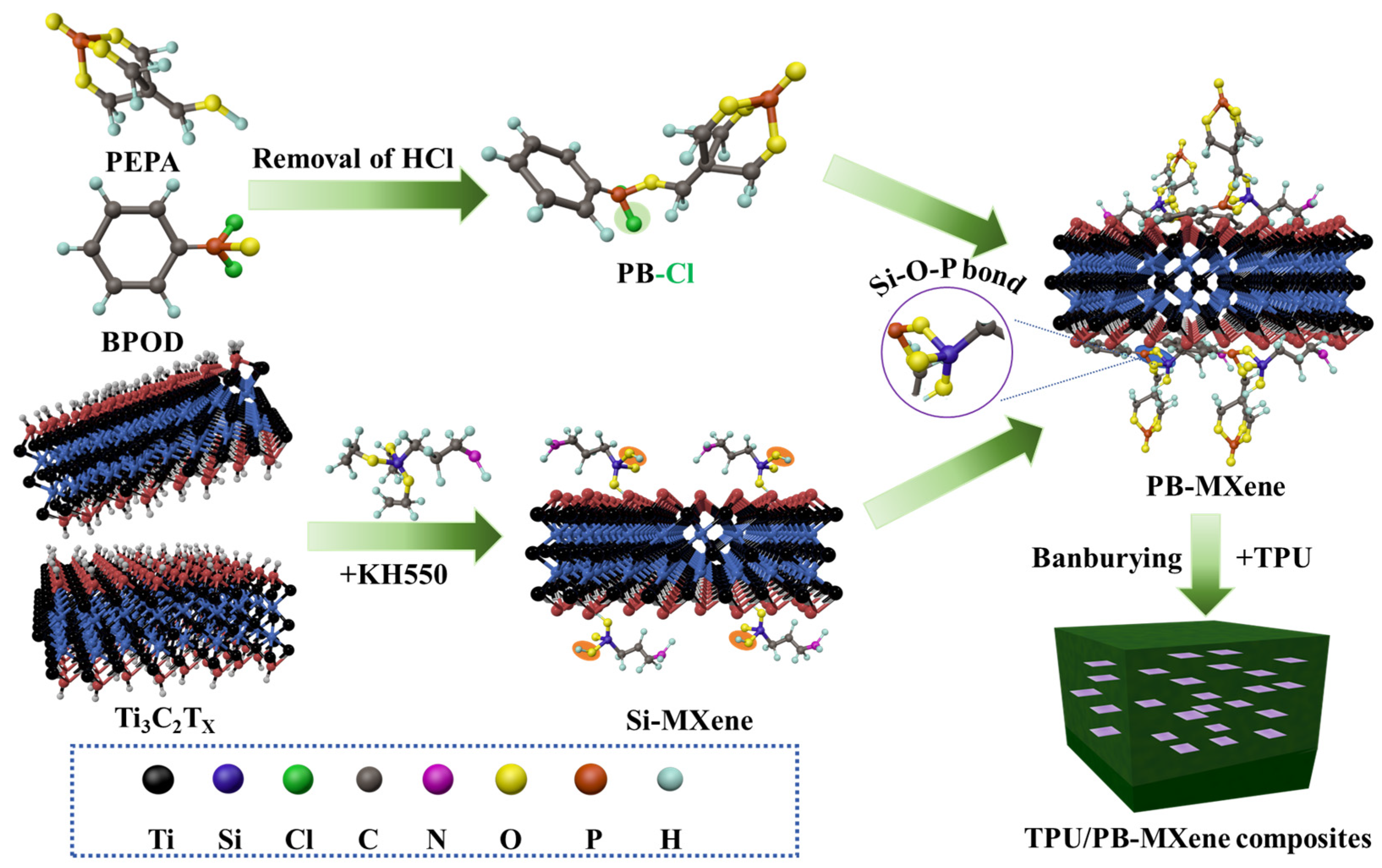

4.3.2. Functionalized MXene by Covalent Bonding

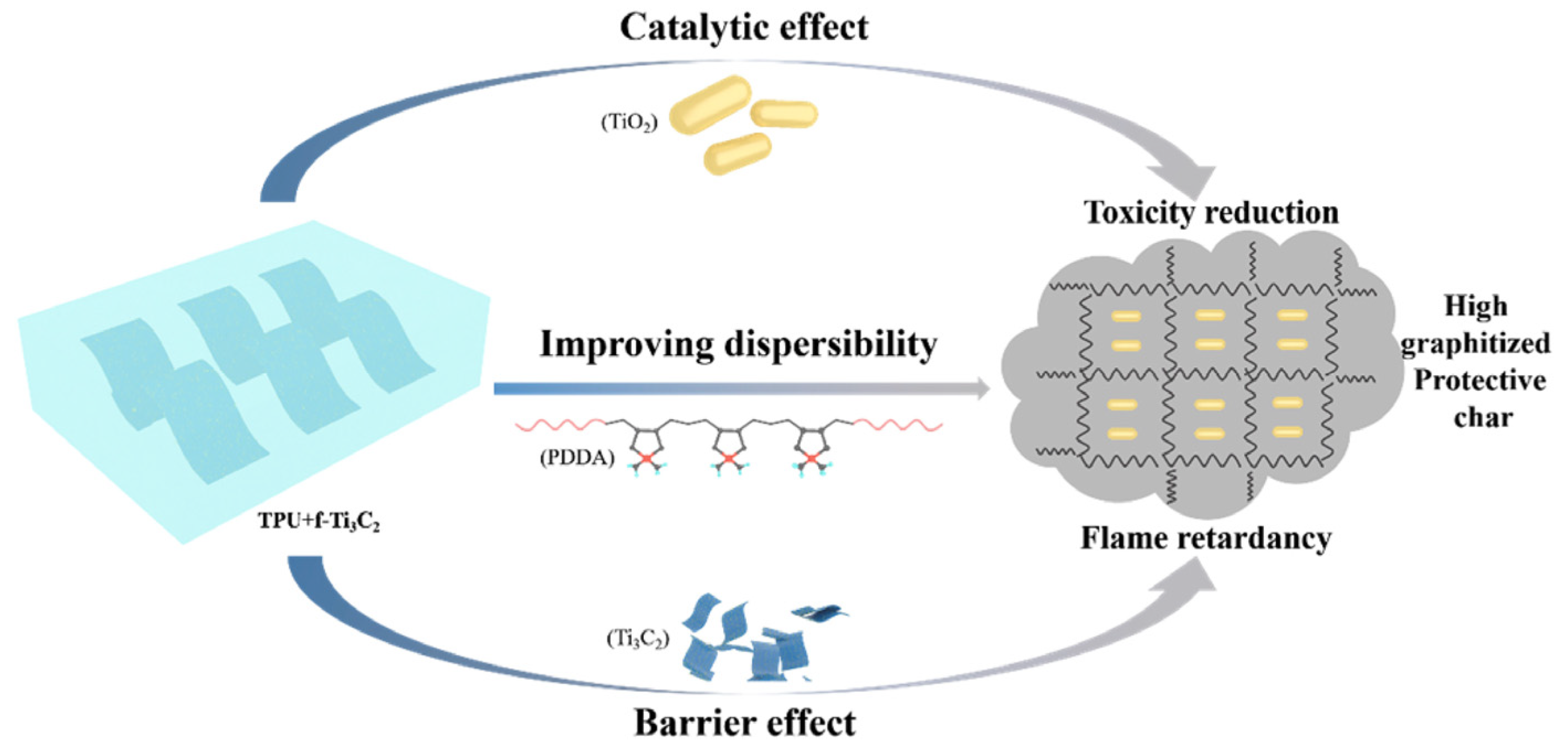

4.3.3. Synergism between MXene and Flame-Retardant Compounds

4.4. MXene-Based Flame-Retardant Polyurethane Foam Systems

4.5. Flame-Retardant Mechanism for MXene

5. Concluding Remarks and Future Aspects

- (i).

- The large-scale production of MXene materials is still a challenge. The current synthesis methods, including the selective etching of MAX phases and subsequent delamination, are often expensive, time-consuming, and involve hazardous chemicals like hydrofluoric acid. These factors limit the commercial viability of MXene. Developing cost-effective, safe, and scalable production techniques is crucial for their widespread adoption in industry.

- (ii).

- MXene materials can be prone to oxidation and degradation when exposed to air and moisture. This instability can compromise their flame-retardant properties over time, reducing their effectiveness in practical applications. Research is needed to improve the long-term stability of MXene, possibly through protective coatings or more stable surface modifications.

- (iii).

- Functionalizing MXene surfaces to enhance their properties, such as compatibility with polymer matrices or improving flame retardancy, often involves complex chemical processes. These processes can lead to the introduction of impurities or defects, potentially having a negative impact on material performance. Developing simple, efficient, and reproducible functionalization methods is necessary to ensure consistent quality and functionality.

- (iv).

- The potential environmental and health impacts of MXene production, use, and disposal are not fully understood. The synthesis process involves hazardous chemicals, raising concerns about safety and environmental contamination. Moreover, the long-term effects of MXene nanoparticles on human health and the environment need to be thoroughly investigated. Life cycle assessments and toxicological studies are necessary to evaluate the sustainability and safety of MXene-based flame retardants. Regulations and guidelines for the handling and disposal of MXene materials should be developed to mitigate potential risks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wan, L.; Deng, C.; Chen, H.; Zhao, Z.-Y.; Huang, S.-C.; Wei, W.-C.; Yang, A.-H.; Zhao, H.-B.; Wang, Y.-Z. Flame-retarded thermoplastic polyurethane elastomer: From organic materials to nanocomposites and new prospects. Chem. Eng. J. 2021, 417, 129314. [Google Scholar] [CrossRef]

- Eom, Y.; Kim, S.-M.; Lee, M.; Jeon, H.; Park, J.; Lee, E.S.; Hwang, S.Y.; Park, J.; Oh, D.X. Mechano-responsive hydrogen-bonding array of thermoplastic polyurethane elastomer captures both strength and self-healing. Nat. Commun. 2021, 12, 621. [Google Scholar] [CrossRef]

- Gallu, R.; Méchin, F.; Dalmas, F.; Gérard, J.-F.; Perrin, R.; Loup, F. On the use of solubility parameters to investigate phase separation-morphology-mechanical behavior relationships of TPU. Polymer 2020, 207, 122882. [Google Scholar] [CrossRef]

- Pedrazzoli, D.; Manas-Zloczower, I. Understanding phase separation and morphology in thermoplastic polyurethanes nanocomposites. Polymer 2016, 90, 256–263. [Google Scholar] [CrossRef]

- Naguib, M.; Barsoum, M.W.; Gogotsi, Y. Ten years of progress in the synthesis and development of MXenes. Adv. Mater. 2021, 33, 2103393. [Google Scholar] [CrossRef]

- VahidMohammadi, A.; Rosen, J.; Gogotsi, Y. The world of two-dimensional carbides and nitrides (MXenes). Science 2021, 372, eabf1581. [Google Scholar] [CrossRef]

- Ho, D.H.; Choi, Y.Y.; Jo, S.B.; Myoung, J.M.; Cho, J.H. Sensing with MXenes: Progress and prospects. Adv. Mater. 2021, 33, 2005846. [Google Scholar] [CrossRef] [PubMed]

- Pang, J.; Mendes, R.G.; Bachmatiuk, A.; Zhao, L.; Ta, H.Q.; Gemming, T.; Liu, H.; Liu, Z.; Rummeli, M.H. Applications of 2D MXenes in energy conversion and storage systems. Chem. Soc. Rev. 2019, 48, 72–133. [Google Scholar] [CrossRef] [PubMed]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Man Hong, S.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, H.B.; Sun, R.; Liu, Y.; Liu, Z.; Zhou, A.; Yu, Z.Z. Hydrophobic, flexible, and lightweight MXene foams for high-performance electromagnetic-interference shielding. Adv. Mater. 2017, 29, 1702367. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yin, X.; Xu, H.; Han, M.; Li, M.; Liang, S.; Cheng, L.; Zhang, L. Ultralight MXene-coated, interconnected SiCnws three-dimensional lamellar foams for efficient microwave absorption in the X-band. ACS Appl. Mater. Interfaces 2018, 10, 34524–34533. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Chen, X.; Zheng, Y.; Zhang, D.; Zhao, Y.; Wang, C.; Pan, C.; Liu, C.; Shen, C. Lightweight, superelastic, and hydrophobic polyimide nanofiber/MXene composite aerogel for wearable piezoresistive sensor and oil/water separation applications. Adv. Funct. Mater. 2021, 31, 2008006. [Google Scholar] [CrossRef]

- Cao, S.; Shen, B.; Tong, T.; Fu, J.; Yu, J. 2D/2D heterojunction of ultrathin MXene/Bi2WO6 nanosheets for improved photocatalytic CO2 reduction. Adv. Funct. Mater. 2018, 28, 1800136. [Google Scholar] [CrossRef]

- Zhan, X.; Si, C.; Zhou, J.; Sun, Z. MXene and MXene-based composites: Synthesis, properties and environment-related applications. Nanoscale Horiz. 2020, 5, 235–258. [Google Scholar] [CrossRef]

- Akhter, R.; Maktedar, S.S. MXenes: Acomprehensive review of synthesis, properties, and progress in supercapacitor applications. J. Materiom. 2023, 9, 1196–1241. [Google Scholar] [CrossRef]

- Li, X.; Huang, Z.; Shuck, C.E.; Liang, G.; Gogotsi, Y.; Zhi, C. MXene chemistry, electrochemistry and energy storage applications. Nat. Rev. Chem. 2022, 6, 389–404. [Google Scholar] [CrossRef] [PubMed]

- Reddy, M.S.B.; Aich, S. Recent progress in surface and heterointerface engineering of 2D MXenes for gas sensing applications. Coord. Chem. Rev. 2024, 500, 215542. [Google Scholar] [CrossRef]

- Ng, V.M.H.; Huang, H.; Zhou, K.; Lee, P.S.; Que, W.; Xu, J.Z.; Kong, L.B. Recent progress in layered transition metal carbides and/or nitrides (MXenes) and their composites: Synthesis and applications. J. Mater. Chem. A 2017, 5, 3039–3068. [Google Scholar]

- Zhang, H.; Wang, L.; Chen, Q.; Li, P.; Zhou, A.; Cao, X.; Hu, Q. Preparation, mechanical and anti-friction performance of MXene/polymer composites. Mater. Des. 2016, 92, 682–689. [Google Scholar] [CrossRef]

- Iqbal, A.; Sambyal, P.; Koo, C.M. 2D MXenes for electromagnetic shielding: A review. Adv. Funct. Mater. 2020, 30, 2000883. [Google Scholar] [CrossRef]

- Kumar, R.; Sahoo, S.; Joanni, E.; Shim, J.-J. Cutting edge composite materials based on MXenes: Synthesis and electromagnetic interference shielding applications. Compos. Part B-Eng. 2023; 110874. [Google Scholar]

- Li, L.; Liu, X.; Wang, J.; Yang, Y.; Cao, Y.; Wang, W. New application of MXene in polymer composites toward remarkable anti-dripping performance for flame retardancy. Compos. Part A-Appl. Sci. Manuf. 2019, 127, 105649. [Google Scholar] [CrossRef]

- He, L.; Jiang, X.; Zhou, X.; Li, Z.; Chu, F.; Wang, X.; Cai, W.; Song, L.; Hu, Y. Integration of black phosphorene and MXene to improve fire safety and mechanical properties of waterborne polyurethane. Appl. Surf. Sci. 2022, 581, 152386. [Google Scholar] [CrossRef]

- Wang, K.; Zhou, Y.; Xu, W.; Huang, D.; Wang, Z.; Hong, M. Fabrication and thermal stability of two-dimensional carbide Ti3C2 nanosheets. Ceram. Int. 2016, 42, 8419–8424. [Google Scholar] [CrossRef]

- Sheng, X.; Zhao, Y.; Zhang, L.; Lu, X. Properties of two-dimensional Ti3C2 MXene/thermoplastic polyurethane nanocomposites with effective reinforcement via melt blending. Compos. Sci. Technol. 2019, 181, 107710. [Google Scholar] [CrossRef]

- Qin, W.; Geng, J.; Lin, C.; Li, G.; Peng, H.; Xue, Y.; Zhou, B.; Liu, G. Flexible multifunctional TPU strain sensors with improved sensitivity and wide sensing range based on MXene/AgNWs. J. Mater. Sci. Mater. Electron. 2023, 34, 564. [Google Scholar] [CrossRef]

- Ronchi, R.M.; Marchiori, C.F.; Araujo, C.M.; Arantes, J.T.; Santos, S.F. Thermoplastic polyurethane–Ti3C2 (Tx) MXene nanocomposite: The influence of functional groups upon the matrix–reinforcement interaction. Appl. Surf. Sci. 2020, 528, 146526. [Google Scholar] [CrossRef]

- Gao, Q.; Pan, Y.; Zheng, G.; Liu, C.; Shen, C.; Liu, X. Flexible multilayered MXene/thermoplastic polyurethane films with excellent electromagnetic interference shielding, thermal conductivity, and management performances. Adv. Compos. Hybrid Mater. 2021, 4, 274–285. [Google Scholar] [CrossRef]

- Xiu, L.; Wang, Z.; Yu, M.; Wu, X.; Qiu, J. Aggregation-resistant 3D MXene-based architecture as efficient bifunctional electrocatalyst for overall water splitting. ACS Nano 2018, 12, 8017–8028. [Google Scholar] [CrossRef]

- Liu, Y.T.; Zhang, P.; Sun, N.; Anasori, B.; Zhu, Q.Z.; Liu, H.; Gogotsi, Y.; Xu, B. Self-assembly of transition metal oxide nanostructures on MXene nanosheets for fast and stable lithium storage. Adv. Mater. 2018, 30, 1707334. [Google Scholar] [CrossRef] [PubMed]

- Chaudhari, N.K.; Jin, H.; Kim, B.; San Baek, D.; Joo, S.H.; Lee, K. MXene: An emerging two-dimensional material for future energy conversion and storage applications. J. Mater. Chem. A 2017, 5, 24564–24579. [Google Scholar] [CrossRef]

- Murali, G.; Reddy Modigunta, J.K.; Park, Y.H.; Lee, J.-H.; Rawal, J.; Lee, S.-Y.; In, I.; Park, S.-J. A review on MXene synthesis, stability, and photocatalytic applications. ACS Nano 2022, 16, 13370–13429. [Google Scholar] [CrossRef] [PubMed]

- Ayodhya, D. A review of recent progress in 2D MXenes: Synthesis, properties, and applications. Diam. Relat. Mater. 2023, 132, 109634. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, W.; Shi, Y.; Song, L.; Ma, C.; Hu, Y. The influence of highly dispersed Cu2O-anchored MoS2 hybrids on reducing smoke toxicity and fire hazards for rigid polyurethane foam. J. Hazard. Mater. 2020, 382, 121028. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Xu, L.; Wang, W. Tri-phase flame retardant system towards advanced energy-saving building materials with highly efficient fire and smoke toxicity reductions. Constr. Build. Mater. 2024, 433, 136719. [Google Scholar] [CrossRef]

- Hou, Y.; Liao, C.; Qiu, S.; Xu, Z.; Mu, X.; Gui, Z.; Song, L.; Hu, Y.; Hu, W. Preparation of soybean root-like CNTs/bimetallic oxides hybrid to enhance fire safety and mechanical performance of thermoplastic polyurethane. Chem. Eng. J. 2022, 428, 132338. [Google Scholar] [CrossRef]

- Ravey, M.; Pearce, E.M. Flexible polyurethane foam. I. Thermal decomposition of a polyether-based, water-blown commercial type of flexible polyurethane foam. J. Appl. Polym. Sci. 1997, 63, 47–74. [Google Scholar] [CrossRef]

- Dyer, E.; Wright, G.C. Thermal degradation of alkyl N-phenylcarbamates. J. Am. Chem. Soc. 1959, 81, 2138–2143. [Google Scholar] [CrossRef]

- Chattopadhyay, D.; Webster, D.C. Thermal stability and flame retardancy of polyurethanes. Prog. Polym. Sci. 2009, 34, 1068–1133. [Google Scholar] [CrossRef]

- Lan, B.; Li, P.; Yang, Q.; Gong, P. Dynamic self generation of hydrogen bonding and relaxation of polymer chain segment in stabilizing thermoplastic polyurethane microcellular foams. Mat. Today Commun. 2020, 24, 101056. [Google Scholar] [CrossRef]

- Piao, J.; Lai, Y.; Ren, J.; Wang, Y.; Feng, T.; Wang, Y.; Liu, W.; Dong, H.; Chen, W.; Jiao, C. Zn-doped carbon microspheres as synergist in intumescent flame-retardant thermoplastic polyurethane composites: Mechanism of char residues layer regulation. Compos. Commun. 2022, 32, 101173. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, W.; Xiao, Y.; Yuen, A.C.Y.; Mao, L.; Pan, H.; Yu, B.; Hu, Y. Surface modification of multi-scale cuprous oxide with tunable catalytic activity towards toxic fumes and smoke suppression of rigid polyurethane foam. Appl. Surf. Sci. 2021, 556, 149792. [Google Scholar] [CrossRef]

- Schartel, B.; Hull, T.R. Development of fire-retarded materials—Interpretation of cone calorimeter data. Fire Mater. 2007, 31, 327–354. [Google Scholar] [CrossRef]

- Yuan, Y.; Yu, B.; Wang, W. The influence of poorly-/well-dispersed organo-montmorillonite on interfacial compatibility, fire retardancy and smoke suppression of polypropylene/intumescent flame retardant composite system. J. Colloid Interface Sci. 2022, 622, 367–377. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Deng, C.; Zhao, Z.-Y.; Wan, L.; Yang, A.-H.; Wang, Y.-Z. Novel piperazine-containing oligomer as flame retardant and crystallization induction additive for thermoplastics polyurethane. Chem. Eng. J. 2020, 400, 125941. [Google Scholar] [CrossRef]

- Liu, L.; Xu, Y.; Li, S.; Xu, M.; He, Y.; Shi, Z.; Li, B. A novel strategy for simultaneously improving the fire safety, water resistance and compatibility of thermoplastic polyurethane composites through the construction of biomimetic hydrophobic structure of intumescent flame retardant synergistic system. Compos. Part B-Eng. 2019, 176, 107218. [Google Scholar] [CrossRef]

- Qiu, S.; Liang, J.; Hou, Y.; Zhou, X.; Zhou, Y.; Wang, J.; Zou, B.; Xing, W.; Hu, Y. Hindered phenolic antioxidant passivation of black phosphorus affords air stability and free radical quenching. J. Colloid Interface Sci. 2022, 606, 1395–1409. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, J.; Wang, L.; Liu, H.; Yang, B.; Guo, J.; Mu, B.; Tian, L. Phosphorus-containing Salen-metal complexes investigated for enhancing the fire safety of thermoplastic polyurethane (TPU). Polym. Adv. Technol. 2020, 31, 1150–1163. [Google Scholar] [CrossRef]

- Hu, W.-J.; Li, Y.-M.; Pang, Y.-Y.; Li, Y.-R.; Wang, D.-Y. The preparation of phosphorus and nitrogen-containing structure towards the enhancement of flame retardancy for thermoplastic polyurethane elastomer. Colloids Surf. A Physicochem. Eng. Asp. 2023, 656, 130375. [Google Scholar] [CrossRef]

- Cui, Y.; Xu, Z.; Li, Y.; Lang, X.; Zong, C.; Cao, L. Synergistic thermodynamic compatibility of polydimethylsiloxane block in thermoplastic polyurethane for flame retardant materials: Super flexible, highly flame retardant and low smoke release. Polymer 2022, 253, 124976. [Google Scholar] [CrossRef]

- Chen, K.; Yang, D.; Shi, Y.; Feng, Y.; Fu, L.; Liu, C.; Chen, M.; Yang, F. Synergistic function of N-P-cu containing supermolecular assembly networks in intumescent flame retardant thermoplastic polyurethane. Polym. Adv. Technol. 2021, 32, 4450–4463. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Kim, S.J.; Seo, D.; Chae, Y.; Anayee, M.; Lee, Y.; Gogotsi, Y.; Ahn, C.W.; Jung, H.-T. Etching mechanism of monoatomic aluminum layers during MXene synthesis. Chem. Mater. 2021, 33, 6346–6355. [Google Scholar] [CrossRef]

- Naguib, M.; Mashtalir, O.; Carle, J.; Presser, V.; Lu, J.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-dimensional transition metal carbides. ACS Nano 2012, 6, 1322–1331. [Google Scholar] [CrossRef]

- Yuan, W.; Cheng, L.; An, Y.; Wu, H.; Yao, N.; Fan, X.; Guo, X. MXene nanofibers as highly active catalysts for hydrogen evolution reaction. ACS Sustain. Chem. Eng. 2018, 6, 8976–8982. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, P.; Soomro, R.A.; Zhu, Q.; Xu, B. Advances in the synthesis of 2D MXenes. Adv. Mater. 2021, 33, 2103148. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S. Fluorine-Free MXenes: Recent Advances, Synthesis Strategies, and Mechanisms. Small 2024, 20, 2308225. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Yao, L.; Liu, Q.; Gu, J.; Luo, R.; Li, J.; Yan, X.; Wang, W.; Liu, P.; Chen, B. Fluorine-free synthesis of high-purity Ti3C2Tx (T= OH, O) via alkali treatment. Angew. Chem. Int. Ed. 2018, 57, 6115–6119. [Google Scholar] [CrossRef] [PubMed]

- Yin, T.; Li, Y.; Wang, R.; Al-Hartomy, O.A.; Al-Ghamdi, A.; Wageh, S.; Luo, X.; Tang, X.; Zhang, H. Synthesis of Ti3C2Fx MXene with controllable fluorination by electrochemical etching for lithium-ion batteries applications. Ceram. Int. 2021, 47, 28642–28649. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, P.; Wang, F.; Ricciardulli, A.G.; Lohe, M.R.; Blom, P.W.; Feng, X. Fluoride-free synthesis of two-dimensional titanium carbide (MXene) using a binary aqueous system. Angew. Chem. 2018, 130, 15717–15721. [Google Scholar] [CrossRef]

- Pokharel, P. High performance polyurethane nanocomposite films prepared from a masterbatch of graphene oxide in polyether polyol. Chem. Eng. J. 2014, 253, 356–365. [Google Scholar] [CrossRef]

- Benedito, A.; Buezas, I.; Giménez, E.; Galindo, B.; Ortega, A. Dispersion and characterization of thermoplastic polyurethane/multiwalled carbon nanotubes by melt mixing. J. Appl. Polym. Sci. 2011, 122, 3744–3750. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, R.; Li, D.; Zhang, L.; Ren, G.; Wang, L.; Liu, J.; Wang, D.; Tang, Z.; Lu, G. High-performance foam-shaped strain sensor based on carbon nanotubes and Ti3C2Tx MXene for the monitoring of human activities. ACS nano 2021, 15, 9690–9700. [Google Scholar] [CrossRef]

- Cai, W.; Li, Z.; Cui, T.; Feng, X.; Song, L.; Hu, Y.; Wang, X. Self-assembly of hierarchical MXene@ SnO2 nanostructure for enhancing the flame retardancy, solar de-icing, and mechanical property of polyurethane resin. Compos. Part B-Eng. 2022, 244, 110204. [Google Scholar] [CrossRef]

- Gao, Q.; Feng, M.; Li, E.; Liu, C.; Shen, C.; Liu, X. Mechanical, thermal, and rheological properties of Ti3C2Tx MXene/thermoplastic polyurethane nanocomposites. Macromol. Mater. Eng. 2020, 305, 2000343. [Google Scholar] [CrossRef]

- Yu, B.; Tawiah, B.; Wang, L.-Q.; Yuen, A.C.Y.; Zhang, Z.-C.; Shen, L.-L.; Lin, B.; Fei, B.; Yang, W.; Li, A. Interface decoration of exfoliated MXene ultra-thin nanosheets for fire and smoke suppressions of thermoplastic polyurethane elastomer. J. Hazard. Mater. 2019, 374, 110–119. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, Y.; Dong, H.; Xu, R.; Jiang, S. Flame-retardant shape memory polyurethane/MXene paper and the application for early fire alarm sensor. Compos. Part B-Eng. 2021, 223, 109149. [Google Scholar] [CrossRef]

- Harito, C.; Bavykin, D.V.; Yuliarto, B.; Dipojono, H.K.; Walsh, F.C. Polymer nanocomposites having a high filler content: Synthesis, structures, properties, and applications. Nanoscale 2019, 11, 4653–4682. [Google Scholar] [CrossRef] [PubMed]

- Zhi, W.; Xiang, S.; Bian, R.; Lin, R.; Wu, K.; Wang, T.; Cai, D. Study of MXene-filled polyurethane nanocomposites prepared via an emulsion method. Compos. Sci. Technol. 2018, 168, 404–411. [Google Scholar] [CrossRef]

- Parra-Muñoz, N.; Soler, M.; Rosenkranz, A. Covalent functionalization of MXenes for tribological purposes-a critical review. Adv. Colloid Interface Sci. 2022, 309, 102792. [Google Scholar] [CrossRef]

- Wang, X.Y.; Liao, S.Y.; Huang, H.P.; Wang, Q.F.; Shi, Y.Y.; Zhu, P.L.; Hu, Y.G.; Sun, R.; Wan, Y.J. Enhancing the chemical stability of MXene through synergy of hydrogen bond and coordination bond in aqueous solution. Small Methods 2023, 7, 2201694. [Google Scholar] [CrossRef]

- Zhu, B.; Wang, K.; Gao, H.; Wang, Q.; Pan, X.; Fan, M. Functional Group Modification and Bonding Characteristics of Ti3C2 MXene-Organic Composites from First-Principles Calculations. ChemPhysChem 2021, 22, 1675–1683. [Google Scholar] [CrossRef]

- Raja Sulaiman, R.R.; Hanan, A.; Wong, W.Y.; Mohamad Yunus, R.; Shyuan Loh, K.; Walvekar, R.; Chaudhary, V.; Khalid, M. Structurally modified MXenes-based catalysts for application in hydrogen evolution reaction: A review. Catalysts 2022, 12, 1576. [Google Scholar] [CrossRef]

- Saha, D.; Dalmieda, J.; Patel, V. Surface-modified MXenes: Simulation to potential applications. ACS Appl. Electron. Mater. 2023, 5, 2933–2955. [Google Scholar] [CrossRef]

- Shi, Y.; Liu, C.; Duan, Z.; Yu, B.; Liu, M.; Song, P. Interface engineering of MXene towards super-tough and strong polymer nanocomposites with high ductility and excellent fire safety. Chem. Eng. J. 2020, 399, 125829. [Google Scholar] [CrossRef]

- Luo, Y.; Xie, Y.; Geng, W.; Dai, G.; Sheng, X.; Xie, D.; Wu, H.; Mei, Y. Fabrication of thermoplastic polyurethane with functionalized MXene towards high mechanical strength, flame-retardant, and smoke suppression properties. J. Colloid Interface Sci. 2022, 606, 223–235. [Google Scholar] [CrossRef]

- Liu, C.; Xu, K.; Shi, Y.; Wang, J.; Ma, S.; Feng, Y.; Lv, Y.; Yang, F.; Liu, M.; Song, P. Fire-safe, mechanically strong and tough thermoplastic Polyurethane/MXene nanocomposites with exceptional smoke suppression. Mater. Today Phys. 2022, 22, 100607. [Google Scholar] [CrossRef]

- Jia, P.; Lu, J.; He, R.; Jiang, G.; Jiang, X.; Wang, B.; Song, L.; Hu, Y. Octopus sucker-inspired hierarchical structure MXene@ carbon nanotubes enhancing the mechanical properties and fire safety of thermoplastic polyurethane composites through the interfacial engineering. Chem. Eng. J. 2022, 450, 138184. [Google Scholar] [CrossRef]

- Liu, C.; Wu, W.; Shi, Y.; Yang, F.; Liu, M.; Chen, Z.; Yu, B.; Feng, Y. Creating MXene/reduced graphene oxide hybrid towards highly fire safe thermoplastic polyurethane nanocomposites. Compos. Part B-Eng. 2020, 203, 108486. [Google Scholar] [CrossRef]

- Liu, C.; Yao, A.; Chen, K.; Shi, Y.; Feng, Y.; Zhang, P.; Yang, F.; Liu, M.; Chen, Z. MXene based core-shell flame retardant towards reducing fire hazards of thermoplastic polyurethane. Compos. Part B-Eng. 2021, 226, 109363. [Google Scholar] [CrossRef]

- Luo, X.; Zhong, J.; Zhou, Q.; Du, S.; Yuan, S.; Liu, Y. Cationic reduced graphene oxide as self-aligned nanofiller in the epoxy nanocomposite coating with excellent anticorrosive performance and its high antibacterial activity. ACS Appl. Mater. Interfaces 2018, 10, 18400–18415. [Google Scholar] [CrossRef]

- Jiang, H.; Xie, Y.; Jiang, Y.; Luo, Y.; Sheng, X.; Mei, Y.; Xie, D. Rationally assembled sandwich structure of MXene-based phosphorous flame retardant at ultra-low loading nanosheets enabling fire-safe thermoplastic polyurethane. Appl. Surf. Sci. 2024, 649, 159111. [Google Scholar] [CrossRef]

- Shi, C.; Wan, M.; Hou, Z.; Qian, X.; Che, H.; Qin, Y.; Jing, J.; Li, J.; Ren, F.; Yu, B. Co-MOF@ MXene hybrids flame retardants for enhancing the fire safety of thermoplastic polyurethanes. Polym. Degrad. Stab. 2022, 204, 110119. [Google Scholar] [CrossRef]

- Nie, C.; Yang, J.; Deng, G.; Feng, Y.; Shi, Y. Supermolecular assembly networks functionalized MXene toward fire-resistant thermoplastic polyurethane nanocomposites. J. Therm. Anal. Calorim. 2023, 148, 10051–10063. [Google Scholar] [CrossRef]

- Chen, W.; Liu, P.; Liu, Y.; Liu, Z. Recent advances in Two-dimensional Ti3C2Tx MXene for flame retardant polymer materials. Chem. Eng. J. 2022, 446, 137239. [Google Scholar] [CrossRef]

- Liu, C.; Yang, D.; Sun, M.; Deng, G.; Jing, B.; Wang, K.; Shi, Y.; Fu, L.; Feng, Y.; Lv, Y. Phosphorous-Nitrogen flame retardants engineering MXene towards highly fire safe thermoplastic polyurethane. Compos. Commun. 2022, 29, 101055. [Google Scholar] [CrossRef]

- Wang, S.; Fang, Q.; Liu, C.; Zhang, J.; Jiang, Y.; Huang, Y.; Yang, M.; Tan, Z.; He, Y.; Ji, B. Biomass tannic acid intermediated surface functionalization of ammonium polyphosphate for enhancing fire safety and smoke suppression of thermoplastic polyurethane. Eur. Polym. J. 2023, 187, 111897. [Google Scholar] [CrossRef]

- Yin, S.; Du, Y.; Liang, X.; Xie, Y.; Xie, D.; Mei, Y. Surface coating of biomass-modified black phosphorus enhances flame retardancy of rigid polyurethane foam and its synergistic mechanism. Appl. Surf. Sci. 2023, 637, 157961. [Google Scholar] [CrossRef]

- Jiang, Q.; Li, P.; Liu, Y.; Zhu, P. Green flame-retardant flexible polyurethane foam based on polyphenol-iron-phytic acid network to improve the fire safety. Compos. Part B-Eng. 2022, 239, 109958. [Google Scholar] [CrossRef]

- Lin, B.; Yuen, A.C.Y.; Li, A.; Zhang, Y.; Chen, T.B.Y.; Yu, B.; Lee, E.W.M.; Peng, S.; Yang, W.; Lu, H.-D. MXene/chitosan nanocoating for flexible polyurethane foam towards remarkable fire hazards reductions. J. Hazard. Mater. 2020, 381, 120952. [Google Scholar] [CrossRef]

- Huang, Y.; Jiang, S.; Liang, R.; Sun, P.; Hai, Y.; Zhang, L. Thermal-triggered insulating fireproof layers: A novel fire-extinguishing MXene composites coating. Chem. Eng. J. 2020, 391, 123621. [Google Scholar] [CrossRef]

- Luo, Y.; Xie, Y.; Geng, W.; Chu, J.; Wu, H.; Xie, D.; Sheng, X.; Mei, Y. Boosting fire safety and mechanical performance of thermoplastic polyurethane by the face-to-face two-dimensional phosphorene/MXene architecture. J. Mater. Sci. Technol. 2022, 129, 27–39. [Google Scholar] [CrossRef]

- He, L.; Wang, J.; Wang, B.; Wang, X.; Zhou, X.; Cai, W.; Mu, X.; Hou, Y.; Hu, Y.; Song, L. Large-scale production of simultaneously exfoliated and Functionalized Mxenes as promising flame retardant for polyurethane. Compos. Part B-Eng. 2019, 179, 107486. [Google Scholar] [CrossRef]

| Composition of Materials | Preparation Method | Fillers Content | Tensile Strength (MPa) | Properties | Ref. |

|---|---|---|---|---|---|

| GO/TPU | In situ polymerization | 1 wt% | ↑40.5% | Mechanical | [60] |

| CNT/TPU | Melt blending | 1 wt% | ↑20% | Mechanical + Thermal | [61] |

| TPU/MWCNTs TPU/MWCNTs@MXene | Pressing Foaming | 10 wt% | TPU/MWCNTs@MXene > TPU/MWCNTs | Mechanical + conductivity | [62] |

| TPU/MXene@SnO2 | Hot pressing | 2% | ↑26.8% | Mechanical + Flame Retardant | [63] |

| Ti3C2Tx/TPU | Melt blending | 0.5 wt% | ↑41.2% | Mechanical + crystalline | [64] |

| Ti3C2Tx/TPU | Melt blending | 0.5 wt% | ↑47.1% | Mechanical + Flame Retardant | [25] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Y.; Lin, W.; Xu, L.; Wang, W. Recent Progress in Thermoplastic Polyurethane/MXene Nanocomposites: Preparation, Flame-Retardant Properties and Applications. Molecules 2024, 29, 3880. https://doi.org/10.3390/molecules29163880

Yuan Y, Lin W, Xu L, Wang W. Recent Progress in Thermoplastic Polyurethane/MXene Nanocomposites: Preparation, Flame-Retardant Properties and Applications. Molecules. 2024; 29(16):3880. https://doi.org/10.3390/molecules29163880

Chicago/Turabian StyleYuan, Yao, Weiliang Lin, Lulu Xu, and Wei Wang. 2024. "Recent Progress in Thermoplastic Polyurethane/MXene Nanocomposites: Preparation, Flame-Retardant Properties and Applications" Molecules 29, no. 16: 3880. https://doi.org/10.3390/molecules29163880