Synthesis of Nitronyl Nitroxide Radical-Modified Multi-Walled Carbon Nanotubes and Oxidative Desulfurization in Fuel

Abstract

:1. Introduction

2. Results and Discussion

2.1. The Characteristic of MWCNTs/NIT Composites

2.1.1. ESR Spectra

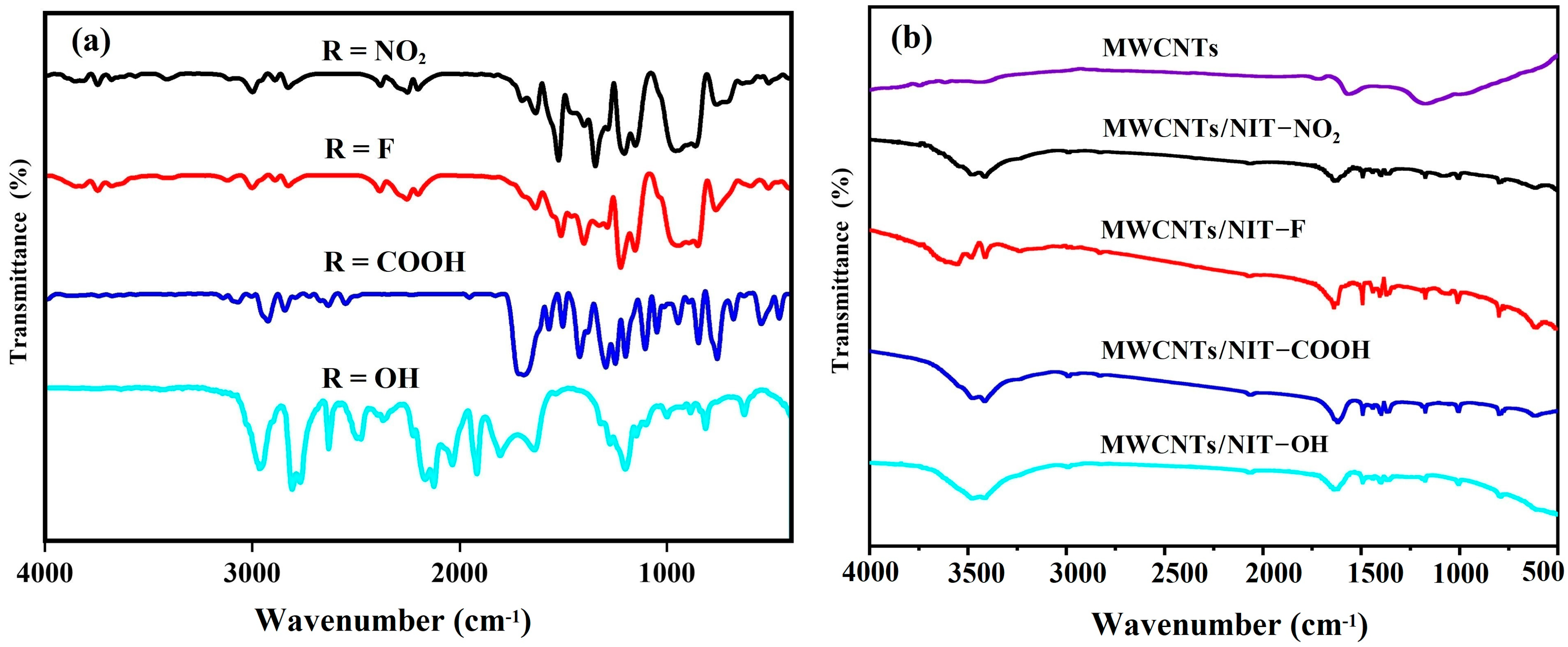

2.1.2. IR Spectra

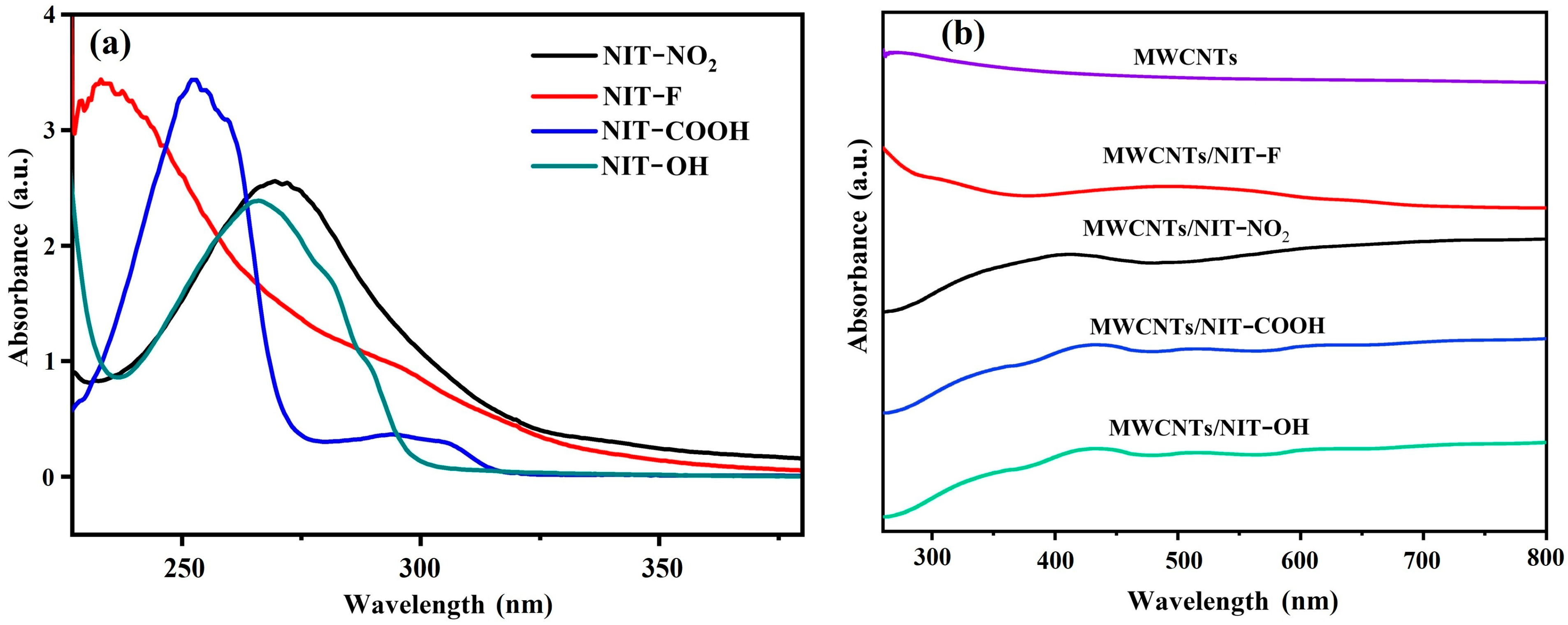

2.1.3. UV-Vis Spectra

2.1.4. XRD Spectrum

2.1.5. Raman Spectrum

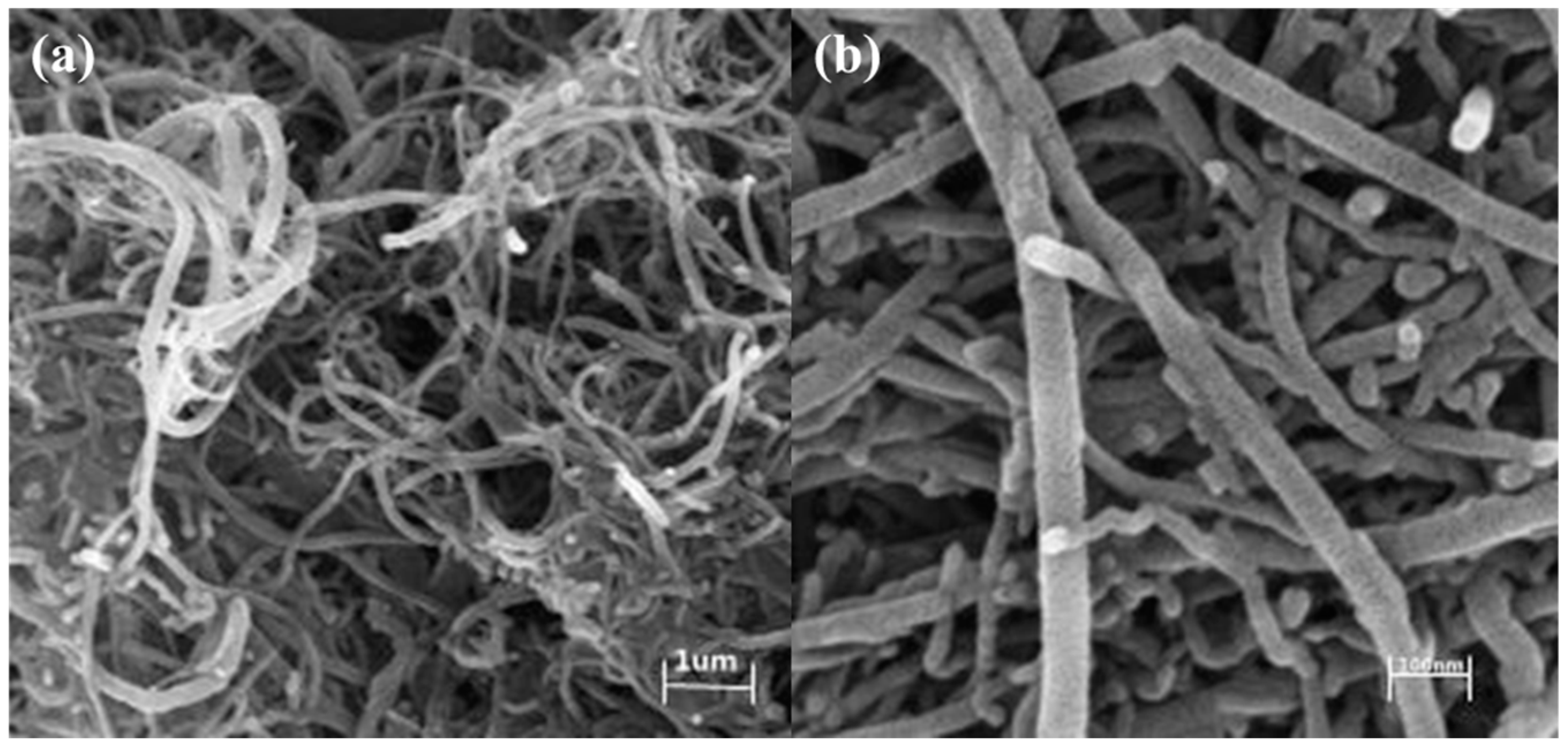

2.1.6. Morphology

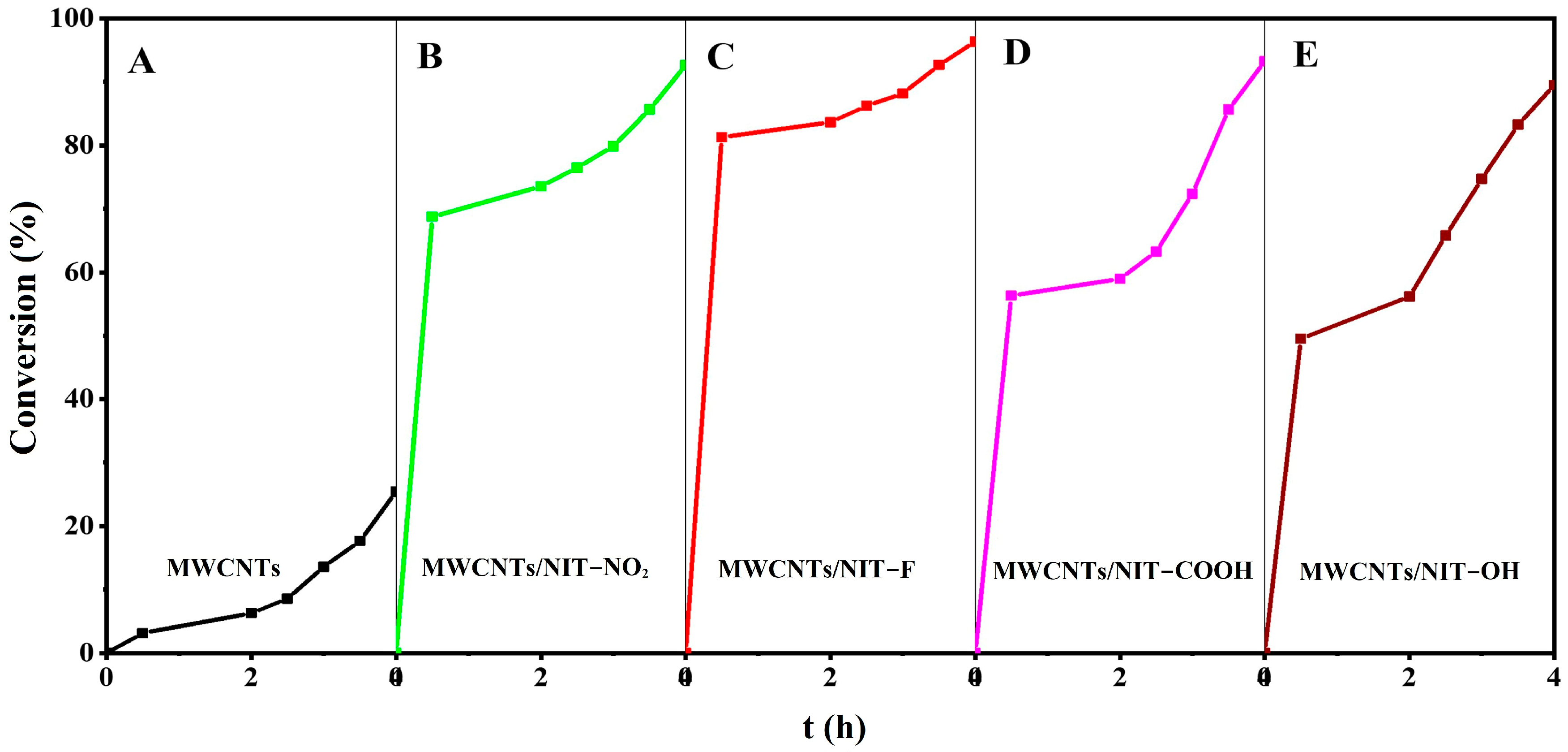

2.2. Desulfurization Effects of NIT and MWCNT/NIT Composites

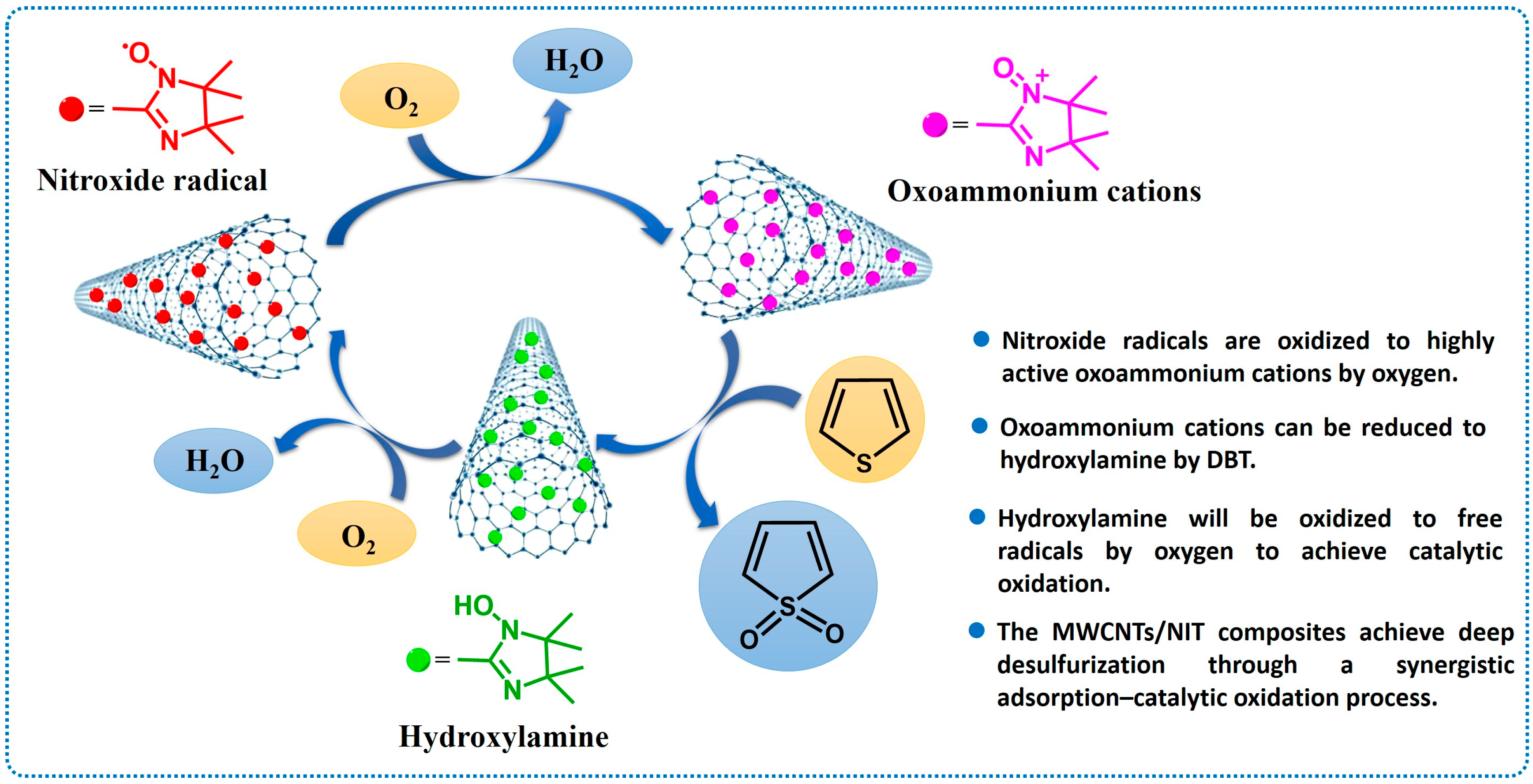

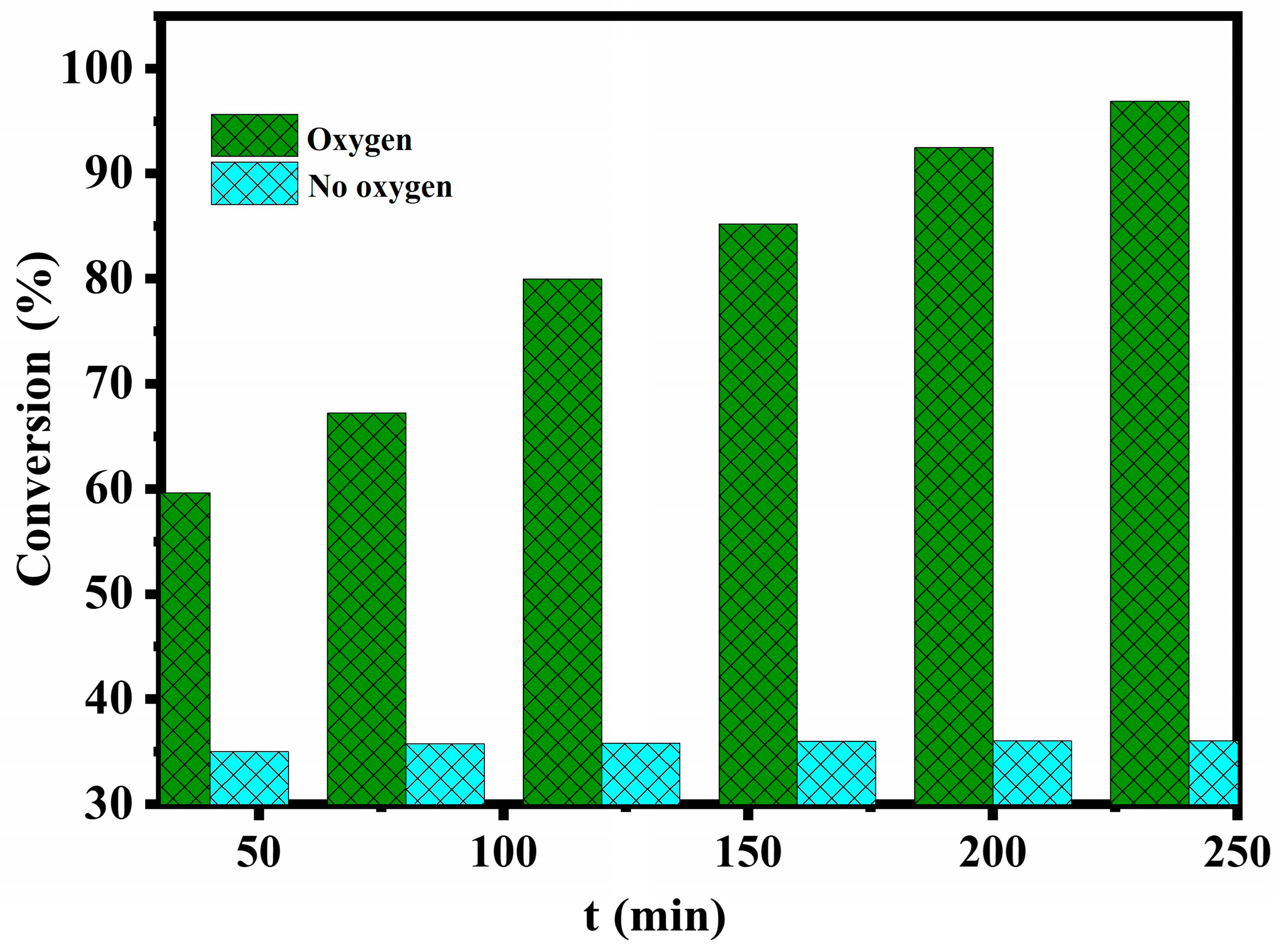

2.3. Catalytic Degradation Mechanism of the MWCNT/NIT Composites

3. Materials and Methods

3.1. Experimental Reagents and Instruments

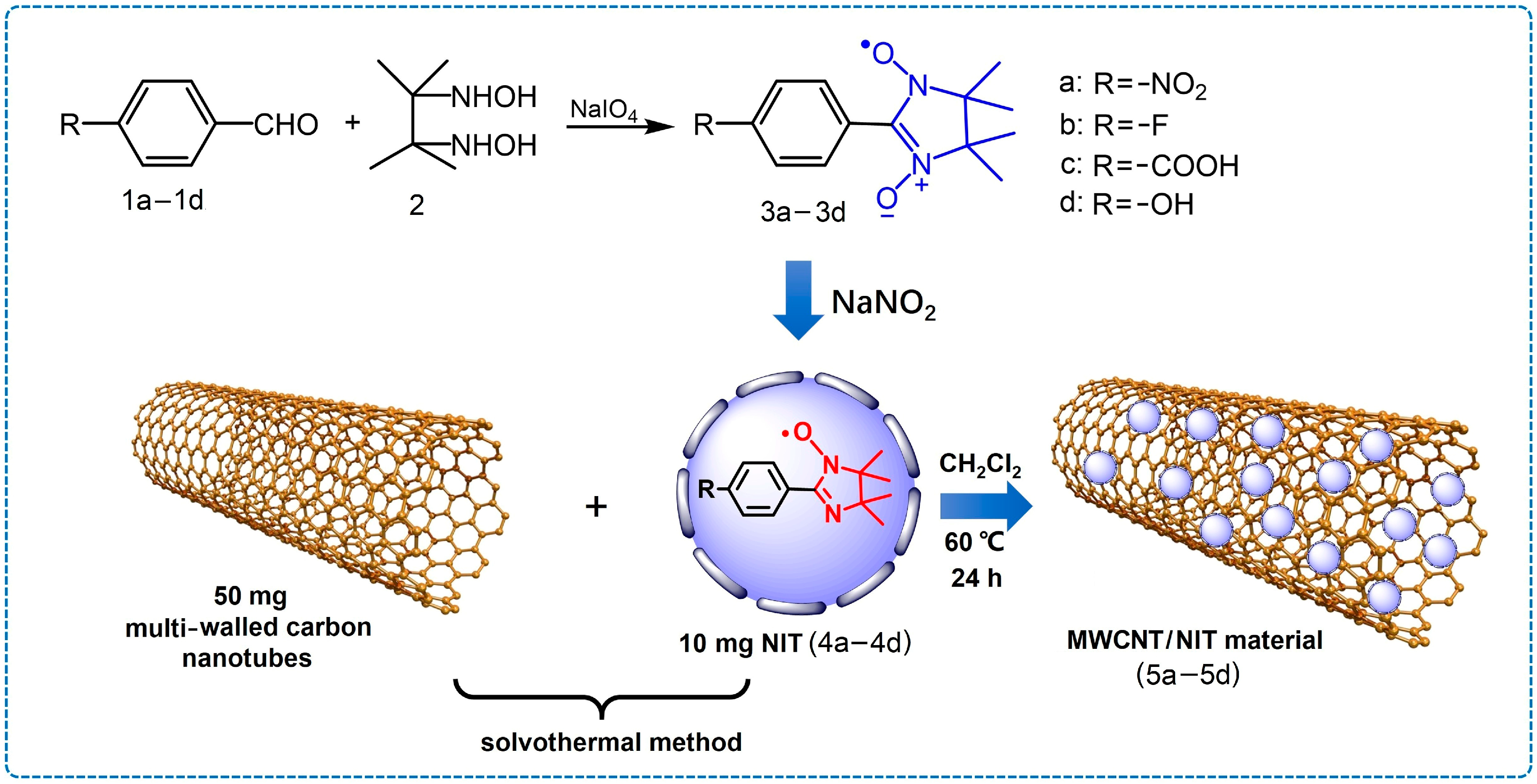

3.2. Synthesis of Nitronyl Nitroxide Radical Derivatives

3.3. Synthesis of MWCNTs/NIT Composites (Nitroxide Radical-Modified Carbon Nanotubes)

3.4. Evaluation of Catalytic Activity

3.5. Evaluation of Catalyst Recycling

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmad, I.; Rehan, M.; Balkhyour, M.A.; Abbas, M.; Ismail, I.M.I. Review of Environmental Pollution and Health Risks at Motor Vehicle Repair Workshops Challenges and Perspectives for Saudi Arabia. Int. J. Agric. Environ. Res. 2016, 2, 1–23. [Google Scholar]

- Qu, Y.; An, J.; He, Y.; Zheng, J. An overview of emissions of SO2 and NOx and the long-range transport of oxidized sulfur and nitrogen pollutants in East Asia. J. Environ. Sci. 2016, 44, 13–25. [Google Scholar] [CrossRef]

- Grennfelt, P.; Engleryd, A.; Forsius, M.; Hov, Ø.; Rodhe, H.; Cowling, E. Acid rain and air pollution: 50 Years of progress in environmental science and policy. Ambio 2020, 4, 849–864. [Google Scholar] [CrossRef] [PubMed]

- Bello, S.S.; Wang, C.; Zhang, M.; Gao, H.; Han, Z.; Shi, L.; Su, F.; Xu, G. A Review on the Reaction Mechanism of Hydrodesulfurization and Hydrodenitrogenation in Heavy Oil Upgrading. Energy Fuels 2021, 35, 10998–11016. [Google Scholar] [CrossRef]

- Wu, Z.; Ondruschka, B. Ultrasound-assisted oxidative desulfurization of liquid fuels and its industrial application. Ultrason. Sonochem. 2010, 6, 1027–1032. [Google Scholar] [CrossRef] [PubMed]

- Rajendran, A.; Cui, T.Y.; Fan, H.X.; Yang, Z.F.; Feng, J.; Li, W.Y. A comprehensive review on oxidative desulfurization catalysts targeting clean energy and environment. J. Mater. Chem. A 2020, 8, 2246–2285. [Google Scholar] [CrossRef]

- Fedorova, E.V.; Zhirkov, N.P.; Tarakanova, A.V.; Ivanov, A.A.; Senyavin, V.M.; Anisimov, A.V.; Tulyakova, E.V.; Surin, S.A. Oxidative desulfurization of diesel fuel with hydrogen peroxide in the presence of vanadium peroxo complexes. Pet. Chem. 2002, 42, 253–256. [Google Scholar]

- Liu, F.; Yu, J.; Qazi, A.B.; Zhang, L.; Liu, X. Metal-Based Ionic Liquids in Oxidative Desulfurization: A Critical Review. Environ. Sci. Technol. 2021, 3, 1419–1435. [Google Scholar] [CrossRef]

- Haghighi, M.; Gooneh-Farahani, S. Insights to the oxidative desulfurization process of fossil fuels over organic and inorganic heterogeneous catalysts: Advantages and issues. Environ. Sci. Pollut. Res. Int. 2020, 32, 39923–39945. [Google Scholar] [CrossRef]

- Chen, L.; Ren, J.T.; Wang, H.Y. Engineering a Local Hydrophilic Environment in Fuel Oil for Efficient Oxidative Desulfurization with Minimum H2O2 Oxidant. ACS Catal. 2023, 18, 12125–12133. [Google Scholar] [CrossRef]

- Ahmad, M.; Liu, Z.; Aslam, S. Fabrication of nanoconfined spaces of KIT-6 with small-sized SnO2 for enhanced oxidative desulfu-rization of fuel: Kinetics and thermodynamics. Sep. Purif. Technol. 2024, 331, 125745–125759. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Z.; Zhu, W.; Wu, P.; Jiang, W.; Zhang, M.; Li, H.; Zhu, W.; Li, H. One-Pot Extraction and Oxidative Desulfurization of Fuels with Molecular Oxygen in Low-Cost Metal-Based Ionic Liquids. Energy Fuels 2017, 31, 1376–1382. [Google Scholar] [CrossRef]

- Luo, H.; Gu, Y.; Liu, D.; Sun, Y. Advances in Oxidative Desulfurization of Fuel Oils over MOFs-Based Heterogeneous Catalysts. Catalysts 2021, 11, 1557. [Google Scholar] [CrossRef]

- Wertz, S.; Studer, A. ChemInform Abstract: Nitroxide-Catalyzed Transition-Metal-Free Aerobic Oxidation Processe. Green Chem. 2013, 11, 3116–3132. [Google Scholar] [CrossRef]

- Tebben, L.; Studer, A. Nitroxides: Applications in Synthesis and in Polymer Chemistry. Angew. Chem. Int. Ed. 2011, 22, 5034–5068. [Google Scholar] [CrossRef] [PubMed]

- Deneuve, A.; Wang, K.; Janowska, I.; Chizari, K.; Pham-Huu, C. Bucky paper with improved mechanical stability made from vertically aligned multi-walled carbon nanotubes for desulfurization process. Appl. Catal. A Gen. 2011, 400, 230–237. [Google Scholar] [CrossRef]

- Saleh, T.A.; Siddiqui, M.N.; Al-Arfaj, A.A. Synthesis of Multiwalled Carbon Nanotubes-Titania Nanomaterial for Desulfurization of Model Fuel. J. Nanomater. 2014, 2014, 940639. [Google Scholar] [CrossRef]

- Larrude, D.G.; de Maia, C.M.E.H.; Freire, F.L. Synthesis and Characterization of Silver Nanoparticle-Multiwalled Carbon Nanotube Composites. J. Nanomater. 2014, 7, 654068. [Google Scholar] [CrossRef]

- Kazemi-Beydokhti, A.; Hassanpour-Souderjani, H. Physical and chemical surface modification of multi-walled carbon nanotubes for adsorptive desulfurization of aromatic impurities in diesel fuel. Environ. Sci. Pollut. Res. 2022, 29, 33558–33571. [Google Scholar] [CrossRef]

- Tian, M.; He, Y.; Zhang, G. Multi-walled carbon nanotubes wrapped phthalocyanine: Enhanced oxidative desulfurization for dibenzothiophene in fuel. J. Nanopart. Res. 2021, 23, 223–232. [Google Scholar] [CrossRef]

- Karousis, N.; Tagmatarchis, N.; Tasis, D. Current Progress on the Chemical Modification of Carbon Nanotubes. Chem. Rev. 2010, 110, 5366–5397. [Google Scholar] [CrossRef] [PubMed]

- Shihab, M.A.; Nawaf, A.T.; Mohamedali, S.A.; Alsalmaney, M.N. Improving Porosity of Activated Multi-Walled Carbon Nanotubes via Alkali Agents for the Enhancement of Adsorptive Desulfurization Process. Mater. Sci. Forum 2020, 1002, 423–434. [Google Scholar] [CrossRef]

- Alwan, H.H. Oxidative desulfurization of a model fuel using MoO3 nanoparticles supported on multi-walled carbon nanotubes catalyst: Examine most significance variables, optimization, kinetics and thermodynamics study. S. Afr. J. Chem. Eng. 2022, 40, 230–239. [Google Scholar] [CrossRef]

- Chronopoulos, D.D.; Kokotos, C.G.; Karousis, N.; Kokotos, G.; Tagmatarchis, N. Functionalized multi-walled carbon nanotubes inan aldol reaction. Nanoscale 2015, 7, 2750–2757. [Google Scholar] [CrossRef]

- McConnell, H.M. Spin Labeling: Theory and Applications; Berliner, L.J., Ed.; Academic Press: New York, NY, USA, 1976; pp. 525–560. [Google Scholar]

- Pierre, G.; Punta, C.; Delattre, C.; Melone, L.; Dubessay, P.; Fiorati, A.; Pastori, N.; Galante, Y.M.; Michaud, P. TEMPO-mediated oxidation of polysaccharides: An ongoing story. Carbohydr. Polym. 2017, 165, 71–85. [Google Scholar] [CrossRef]

- Santos, F.R.; Rossetto, I.M.U.; Montico, F.; Lamas, C.D.A.; Cagnon, V.H.A. Differential tempol effects in prostatic cancer: Angiogenesis and short- and long-term treatments. J. Mol. Histol. 2024, 55, 253–264. [Google Scholar] [CrossRef] [PubMed]

- Ciriminna, R.; Ghahremani, M.; Karimi, B.; Pagliaro, M. Electrochemical Alcohol Oxidation Mediated by TEMPO-like Nitroxyl Radicals. Chem. Open 2017, 1, 5–10. [Google Scholar] [CrossRef]

- Arian, E.J.N.; Arie, C.B.; Herman, V.B. Highly selective nitroxyl radical-mediated oxidation of primary alcohol groups in water-soluble glucans. Carbohydr. Res. 1995, 269, 89–98. [Google Scholar] [CrossRef]

- Yoshida, E.; Takata, T.; Endo, T. Efficient and selective oxidation of a polymeric terminal diol with Cu(II) mediated by nitroxyl radical. J. Polym. Sci. Part A Polym. Chem. 1992, 30, 1193–1197. [Google Scholar] [CrossRef]

- Parlett, C.M.A.; Durndell, L.J.; Machado, A.; Cibin, G.; Bruce, D.W.; Hondow, N.S.; Wilson, K.; Lee, A.F. Alumina-grafted SBA-15 as a high performance support for Pd-catalysed cinnamyl alcohol selective oxidation. Catal. Today 2014, 229, 46–55. [Google Scholar] [CrossRef]

- Mitchell, J.B.; Russo, A.; Kuppusamy, P.; Krishna, M.C. Radiation, radicals, and images, Radiation, Radicals, and Images. Ann. N. Y. Acad. Sci. 2000, 899, 28–43. [Google Scholar] [CrossRef]

- Li, L.; Matsuda, R.; Tanaka, I.; Sato, H.; Kanoo, P.; Jeon, H.J.; Foo, M.L.; Wakamiya, A.; Murata, Y.; Kitagawa, S. A Crystalline Porous Coordination Polymer Decorated with Nitroxyl Radicals Catalyzes Aerobic Oxidation of Alcohols. J. Am. Chem. Soc. 2014, 21, 7543–7546. [Google Scholar] [CrossRef]

- Augusto, O.; Trindade, D.F.; Linares, E.; Vaz, S.M. Cyclic nitroxides inhibit the toxicity of nitric oxide-derived oxidants: Mechanisms and implications. An. Acad. Bras. Cienc. 2008, 80, 179–189. [Google Scholar] [CrossRef]

- Stanislaus, A.; Marafi, A.; Rana, M.S. Recent advances in the science and technology of ultra low sulfur diesel (ULSD) production. Catal. Today 2010, 153, 1–68. [Google Scholar] [CrossRef]

- Htet, Y.; Tennyson, A.G. Catalytic radical reduction in aqueous solution via oxidation of biologically-relevant alcohols. Chem. Sci. 2016, 7, 4052–4058. [Google Scholar] [CrossRef] [PubMed]

- Beejapur, H.A.; Campisciano, V.; Franchi, P.; Lucarini, M.; Giacalone, F.; Gruttadauria, M. Fullerene as a Platform for Recyclable TEMPO Organocatalysts for the Oxidation of Alcohols. ChemCatChem 2014, 6, 2419–2424. [Google Scholar] [CrossRef]

- Afsharpour, M.; Dini, Z. One-Pot Functionalization of Multi-walled carbon nanotubes by WO3/MoO3 Nanoparticles as Oxidative Desulfurization Catalysts. Fuller. Nanotub. Carbon Nanozstruct. 2019, 27, 198–205. [Google Scholar] [CrossRef]

- Sayre, R. The identity of Heilpern’s “pinacolylthiourea” and the preparation of authentic 2-thiono-4,4,5,5-tetramethylimidazolidine. J. Am. Chem. Soc. 1955, 77, 6689–6690. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, M.; Huang, H.; Zhang, G.; Wang, H. Synthesis of Nitronyl Nitroxide Radical-Modified Multi-Walled Carbon Nanotubes and Oxidative Desulfurization in Fuel. Molecules 2024, 29, 3896. https://doi.org/10.3390/molecules29163896

Tian M, Huang H, Zhang G, Wang H. Synthesis of Nitronyl Nitroxide Radical-Modified Multi-Walled Carbon Nanotubes and Oxidative Desulfurization in Fuel. Molecules. 2024; 29(16):3896. https://doi.org/10.3390/molecules29163896

Chicago/Turabian StyleTian, Min, Haokang Huang, Gai Zhang, and Haibo Wang. 2024. "Synthesis of Nitronyl Nitroxide Radical-Modified Multi-Walled Carbon Nanotubes and Oxidative Desulfurization in Fuel" Molecules 29, no. 16: 3896. https://doi.org/10.3390/molecules29163896