Chemical-Assisted CO2 Water-Alternating-Gas Injection for Enhanced Sweep Efficiency in CO2-EOR

Abstract

:1. Introduction

2. Key Factors Influencing Sweep Efficiency in WAG Flooding

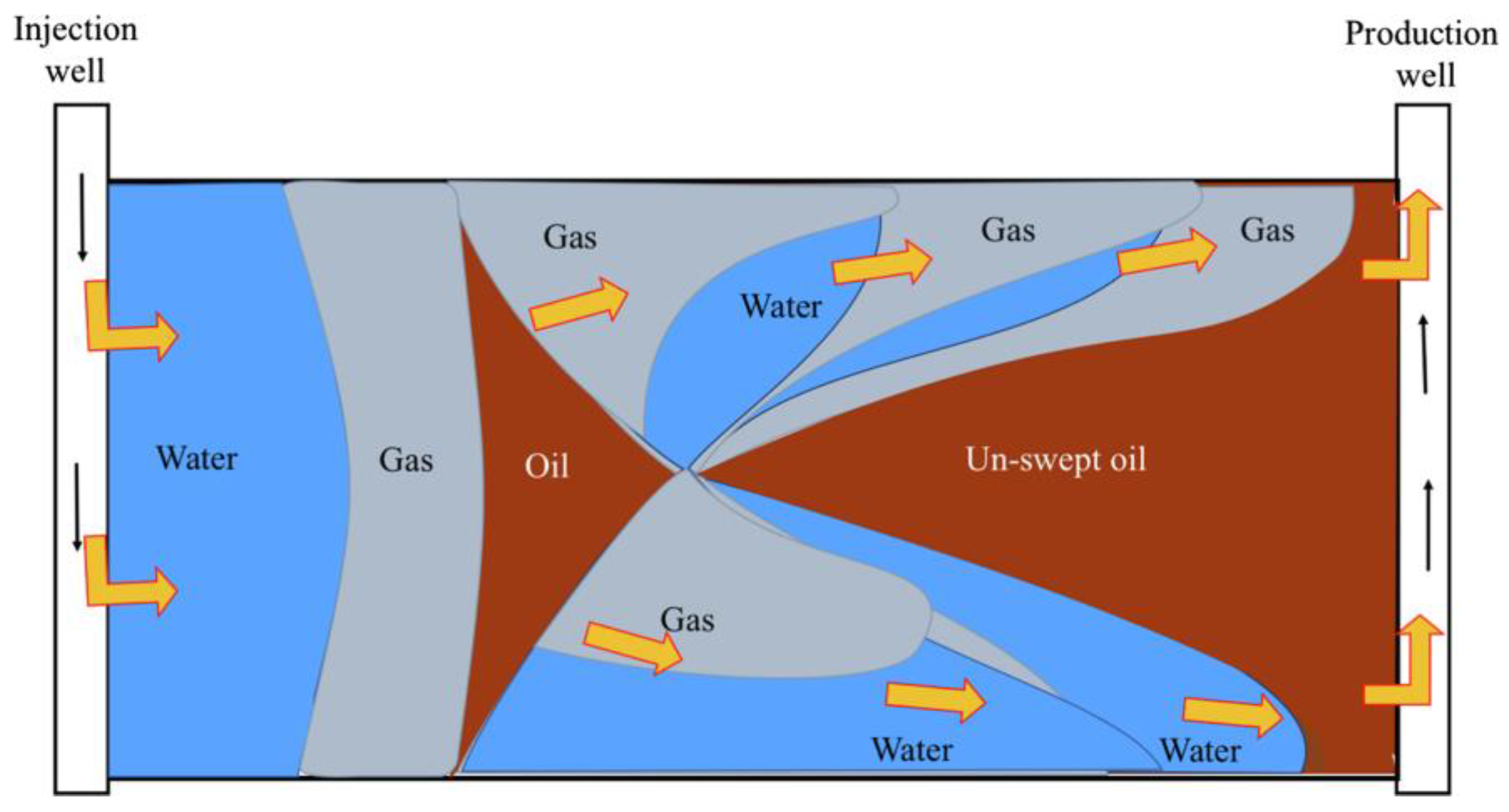

2.1. Mobility Ratio

2.2. Reservoir Properties and Gravity Segregation

2.3. Hysteresis and Relative Permeability

2.4. WAG Field Injection-Production Scheme

3. Establishment of WAG Flooding Mathematical Models and Hysteresis Models

3.1. Two-Phase Relative Permeability Hysteresis Models

3.2. Three-Phase Relative Permeability Hysteresis Models

4. Techniques to Expand CO2-WAG Sweep Volume

4.1. Simultaneous Water and Gas Injection (SWAG) for Enhanced Sweep Volume

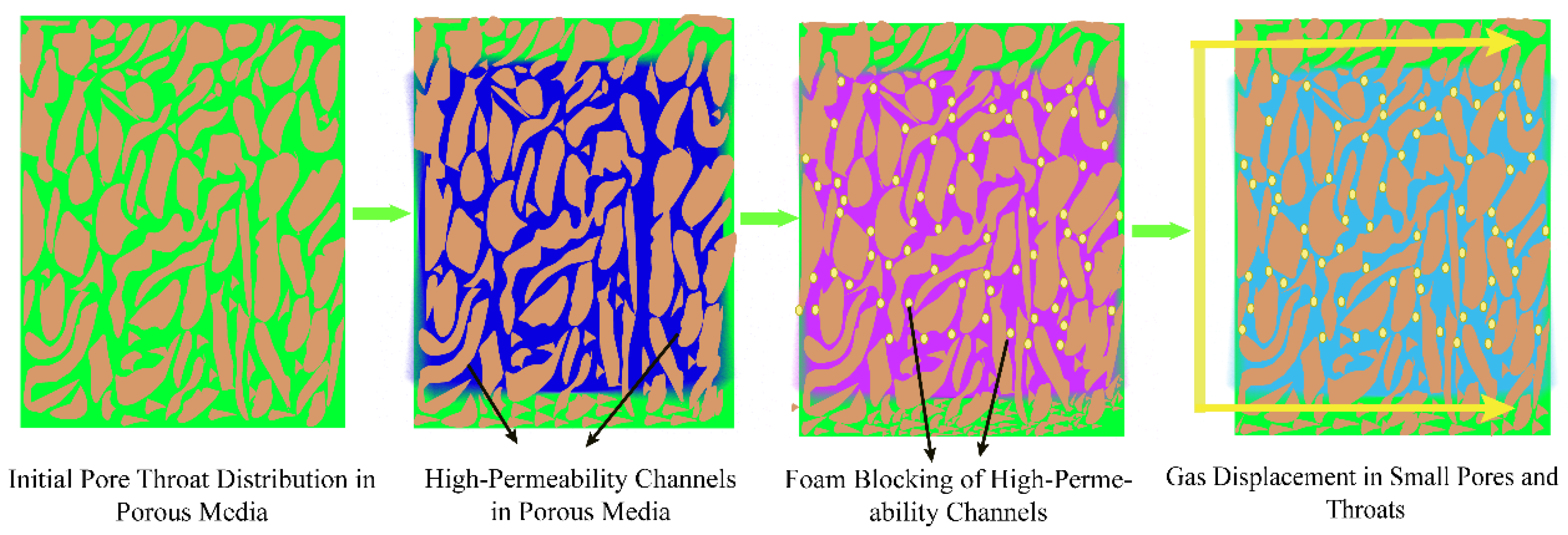

4.2. Foam-Assisted WAG (FAWAG) for Enhanced Sweep Efficiency

4.3. Polymer and Gel-Assisted WAG for Enhanced Sweep Efficiency

4.3.1. Polymer-Assisted WAG (PWAG) for Enhanced Sweep Efficiency

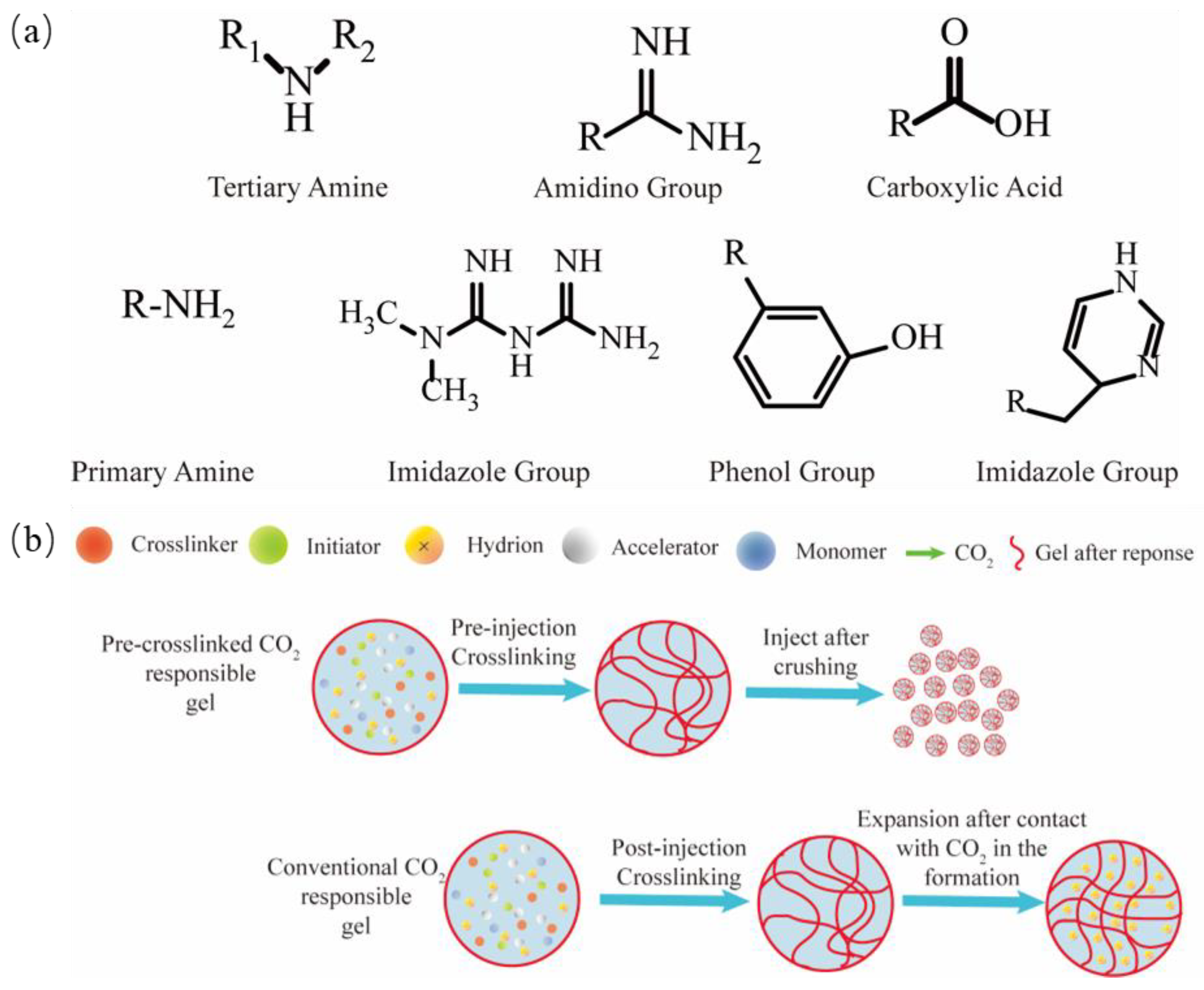

4.3.2. Gel-Assisted WAG (GWAG) for Enhanced Sweep Efficiency

4.4. Nanoparticle-Assisted WAG (NWAG) for Enhanced Sweep Efficiency

5. Current Problems and Challenges

6. Conclusions

- WAG injection technology is a crucial method for addressing significant gas channeling and viscous fingering issues. However, in the context of highly heterogeneous domestic reservoirs, it continues to face challenges, including insufficient control over gas channeling and a low sweep efficiency of CO2 flooding. Therefore, new and improved techniques are required to enhance the sweep volume and utilization rate of CO2 flooding, thereby maximizing both oil recovery and CO2 storage.

- The swept volume of CO2-WAG is influenced not only by its viscosity and the heterogeneity of the reservoir, but also by factors such as the mobility ratio, reservoir properties, gravity segregation, production and injection techniques, and the hysteresis effect. From the perspectives of regulatory complexity and economic viability, reducing the water–gas mobility ratio is the primary method to address CO2 gas channeling and viscous fingering. This can be achieved by introducing chemicals to physically or chemically block fractures and high-permeability channels, thereby improving reservoir heterogeneity and the water–gas mobility ratio. Additionally, optimizing appropriate production and injection regimes (e.g., the water–gas slug ratio, injection pressure, injection rate, and injection methods) and well pattern designs (e.g., horizontal wells and well spacing) can enhance gas hysteresis effects and mitigate the adverse impacts of gas bypassing and gravity segregation on the sweep efficiency of CO2 flooding. These measures collectively improve the overall utilization and storage efficiency of CO2 flooding.

- The saturation history during individual drainage and imbibition processes, along with the chronological cycle of water and gas injections in WAG, significantly influence fluid distribution in three-phase flow. Most phase permeability models for WAG flooding neglect three-phase hysteresis effects or are influenced by two-phase hysteresis models, leading to a substantial overestimation of gas phase permeability. This overestimation reduces the accuracy of realistic predictions in WAG flooding models.

- Chemical-assisted CO2-WAG for Enhanced Sweep Efficiency techniques demonstrate significant advantages over conventional CO2-WAG methods. They possess advantages such as enhancing the mobility ratio to mitigate gas channeling, sealing fractures, and high-permeability channels to improve reservoir heterogeneity, lowering the oil–water interfacial tension and capillary forces, and enhancing reservoir wettability. These technologies have been validated through laboratory experiments and field applications, achieving recovery rates which are more than 5% higher than those achieved with traditional CO2-WAG methods. With ongoing advancements in CO2-WAG flooding and volumetric expansion techniques, these methods are crucial for economically developing heterogeneous reservoirs and play a pivotal role in geological storage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| K | permeability |

| krg | gas relative permeability |

| kro | oil relative permeability |

| krow | oil relative permeability in oil–water flow |

| krw | water relative permeability |

| krog | equivalent two-phase (oil–gas) oil relative permeability in three-phase flow |

| oil relative permeability at connate water saturation | |

| equivalent two-phase (oil–gas) oil relative permeability in three-phase flow | |

| equivalent two-phase (oil–water) oil relative permeability in three-phase flow | |

| drainage non-wetting-phase relative permeability | |

| imbibition non-wetting-phase relative permeability | |

| experimental non-wetting-phase relative permeability | |

| normalized relative permeability to water | |

| normalized imbibition relative permeability to water | |

| normalized drainage relative permeability to water | |

| normalized relative permeability to water when saturation reversal occurs | |

| normalized drainage relative permeability to water when saturation reversal occurs | |

| normalized imbibition relative permeability to water when saturation reversal occurs | |

| normalized relative permeability to water | |

| normalized imbibition relative permeability to oil | |

| normalized drainage relative permeability to oil | |

| normalized relative permeability to oil when saturation reversal occurs | |

| normalized drainage relative permeability to oil when saturation reversal occurs | |

| normalized imbibition relative permeability to oil when saturation reversal occurs | |

| krwi[j] | imbibition relative permeability to water when saturation reversal occurs |

| imbibition relative permeability to water at zero point when saturation reversal occurs | |

| imbibition relative permeability to water associated with bounding scanning curves of first reversal at Sw = 1 point when saturation reversal occurs | |

| imbibition relative permeability to water at threshold when saturation reversal occurs | |

| kroi[j] | imbibition relative permeability to oil when saturation reversal occurs |

| imbibition relative permeability to oil at zero point when saturation reversal occurs | |

| imbibition relative permeability to water associated with bounding scanning curves of first reversal at So =1 point when saturation reversal occurs | |

| imbibition relative permeability to oil at threshold when saturation reversal occurs | |

| maximum non-wetting residual saturation | |

| the non-wetting-phase saturation | |

| SNr | residual or trapped non-wetting saturation |

| maximum historical non-wetting saturation | |

| normalized non-wetting-phase saturation | |

| Snwr | residual non-wetting-phase saturation trapped after complete imbibition of wetting phase |

| Snwi | historical maximum non-wetting-phase saturation reached before the change of process from drainage to imbibition, fraction of pore space |

| Snwf | “free” or continuous non-wetting-phase saturation, fraction of pore space |

| Snw | total non-wetting-phase saturation present independent of direction of saturation change, fraction of pore space |

| normalized water saturation, fraction | |

| normalized water saturation, fraction when saturation reversal occurs | |

| Sg | gas saturation |

| Sgc | critical gas saturation |

| So | oil saturation |

| equivalent two-phase (oil–gas) gas saturation in three-phase flow | |

| Sor | the residual oil saturation in three-phase flow |

| equivalent two-phase (oil–water) water saturation in three-phase flow | |

| Sw | water saturation |

| Swc | connate water saturation |

| Sg | normalized gas saturation |

| So | normalized oil saturation |

| Sw | normalized water saturation |

| Sof | flowing oil saturation |

| Sot | ultimate trapped oil saturation |

| Soi | initial oil saturation |

| α | initial slope of IR curve in new trapping model |

| β | curvature of the IR curve in new trapping model |

| C | Land trapping coefficient |

References

- IPCC Climate Change 2007 Comprehensive Report, Report of Working Groups I, II, and III of the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Switzerland, Geneva, 2008.

- Zhang, L.; Li, X.; Ren, B.; Cui, G.; Zhang, Y.; Ren, S. CO2 Storage Potential and Trapping Mechanisms in the H-59 Block of Jilin Oilfield, China. Int. J. Greenh. Gas Control 2016, 49, 267–280. [Google Scholar] [CrossRef]

- Li, L.; Zhou, X.; Su, Y.; Xiao, P.; Chen, Z.; Zheng, J. Influence of heterogeneity and fracture conductivity on supercritical CO2 miscible flooding enhancing oil recovery and gas channeling in tight oil reservoirs. Energy Fuels 2022, 36, 8199–8209. [Google Scholar] [CrossRef]

- Hustad, O.S.; Holt, T. Gravity stable displacement of oil by hydrocarbon gas after waterflooding. In Proceedings of the SPE/DOE Enhanced Oil Recovery Symposium, Tulsa, OK, 16–18 April 1992; Society of Petroleum Engineers: Houston, TX, USA, 1992. [Google Scholar]

- Touray, S. Effect of Water Alternating Gas Injection on Ultimate Oil Recovery. Master’s Thesis, Dalhousie University, Halifax, NS, Canada, 2013; p. 25. [Google Scholar]

- Holm, L.W. CO2 flooding: Its time has come. J. Pet. Technol. 1982, 34, 2739–2745. [Google Scholar] [CrossRef]

- Christensen, J.R.; Stenby, E.H.; Skauge, A. Review of WAG field experience. SPE Reserv. Eval. Eng. 2001, 4, 97–106. [Google Scholar] [CrossRef]

- Skauge, A.; Stensen, J.Å. Review of WAG field experience. In Oil Recovery-2003, 1st International Conference and Exhibition, Modern Challenges in Oil Recovery; Gubkin University: Moscow, Russia, 2003; pp. 19–23. [Google Scholar]

- Panda, M.N.; Ambrose, J.G.; Beuhler, G.; McGuire, P.L. Optimized EOR design for the Eileen west end area, Greater Prudhoe bay. SPE Reserv. Eval. Eng. 2009, 12, 25–32. [Google Scholar] [CrossRef]

- Bahagio, D.N.T. Ensemble Optimization of CO2 wag EOR. Master Thesis, Delft University of Technology, Delft, The Netherlands, 2013. [Google Scholar]

- Chen, S.; Li, H.; Yang, D.; Tontiwachwuthikul, P. Optimal parametric design for water-alternating-gas process in a CO2-miscible flooding reservoir. J. Can. Pet. Technol. 2010, 49, 75–82. [Google Scholar] [CrossRef]

- Rogers, J.D.; Grigg, R.B. A literature analysis of the WAG injectivity abnormalities in the CO2 process. SPE Reserv. Eval. Eng. 2001, 4, 375–386. [Google Scholar] [CrossRef]

- Christensen, J.R.; Stenby, E.H.; Skauge, A. Review of WAG field experience. In Proceedings of the SPE International Petroleum Conference and Exhibition of Mexico, Villahermosa, Mexico, 3–5 March 1998; p. SPE 39883. [Google Scholar]

- Kumar, S.; Mandal, A. A comprehensive review on chemically enhanced water alternating gas/CO2 (CEWAG) injection for enhanced oil recovery. J. Pet. Sci. Eng. 2017, 157, 696–715. [Google Scholar] [CrossRef]

- Stephenson, D.J.; Graham, A.G.; Luhning, R.W. Mobility control experience in the Joffre Viking miscible CO2 flood. SPE Reserv. Eng. 1993, 8, 183–188. [Google Scholar] [CrossRef]

- Hu, Y. Optimization Study of CO2 Flooding Systems for Gas Channeling Prevention in Ultra-Low Permeability Reservoirs. Ph.D. Thesis, Yangtze University, Jingzhou, China, 2021. [Google Scholar]

- Afzali, S.; Rezaei, N.; Zendehboudi, S. A comprehensive review on enhanced oil recovery by water alternating gas (WAG) injection. Fuel 2018, 227, 218–246. [Google Scholar] [CrossRef]

- Sedaralit, M.F.; Saaid, I.M.; Awang, M. Design and Evaluation of In-Situ Chemical Regeneration of Foam for Enhanced Oil Recovery EOR, 1D Foam Modelling-Malaysia’s Offshore Oilfield. In Proceedings of the Offshore Technology Conference Asia, OTC, Kuala Lumpur, Malaysia, 20–23 March 2018; OnePetro: Richardson, TX, USA, 2018. [Google Scholar]

- Li, W.; Schechter, D.S. Using polymer alternating gas to maximize CO2 flooding performance. In Proceedings of the Energy Resources Conference, Port of Spain, Trinidad and Tobago, 9–11 June 2014; OnePetro: Richardson, TX, USA, 2014; p. D021S008R001. [Google Scholar]

- Speight, J.G. Enhanced Recovery Methods for Heavy Oil and Tar Sands; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Ahmed, T. Reservoir Engineering Handbook; Gulf Professional Publishing: Houston, TX, USA, 2006. [Google Scholar]

- Thakur, G.C.; Satter, A. Integrated Waterflood Asset Management; PennWell Books: Tulsa, OK, USA, 1998. [Google Scholar]

- Shahverdi, H.; Sohrabi, M.; Fatemi, M.; Jamiolahmady, M. Three-phase relative permeability and hysteresis effect during WAG process in mixed wet and low IFT systems. J. Pet. Sci. Eng. 2011, 78, 732–739. [Google Scholar] [CrossRef]

- Latil, M. Enhanced Oil Recovery; Editions Technip: Paris, France, 1980. [Google Scholar]

- Campbell, B.T. Flow Visualization for CO2/Crude Displacements. SPEJ 1985, 25, 665–687. [Google Scholar] [CrossRef]

- AlOtaibi, F.M.; Kokal, S.L.; Chang, Y.C.; AlQahtani, J.F.; AlAbdulwahab, A.M. Gelled emulsions of CO2-water nanoparticles. In Proceedings of the SPE Annual Technical Conference and Exhibition 2013, New Orleans, LA, USA, 30 September–2 October 2013; p. D021S020R002. [Google Scholar]

- Tovar, F.D.; Barrufet, M.A.; Schechter, D.S. Experimental investigation of polymer assisted WAG for mobility control in the highly heterogeneous north burbank unit in Oklahoma, using anthropogenic CO2. In Proceedings of the Latin American and Caribbean Petroleum Engineering Conference, Quito, Ecuador, 18–20 November 2015; OnePetro: Richardson, TX, USA, 2015; p. D011S004R004. [Google Scholar]

- Chakravarthy, D.; Muralidharan, V.; Putra, E.; Schechter, D.S. Application of X-ray CT for investigation of CO2 and WAG injection in fractured reservoirs. In Proceedings of the PETSOC Canadian International Petroleum Conference, Calgary, Alberta, 8–10 June 2004; p. PETSOC-2004. [Google Scholar]

- Masalmeh, S.K.; Hillgartner, H.; Al Mjeni, R.; Jing, X.D. Simultaneous injection of miscible gas and polymer (SIMGAP) to improve oil recovery and sweep efficiency from layered carbonate reservoirs. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 11–13 April 2010; p. SPE-129645. [Google Scholar]

- Gharbi, R.; Peters, E.; Elkamel, A. Scaling miscible fluid displacements in porous media. Energy Fuels 1998, 12, 801–811. [Google Scholar] [CrossRef]

- Arogundade, O.A.; Shahverdi, H.-R.; Sohrabi, M. A study of three-phase relative permeability and hysteresis in water alternating gas (WAG) injection. In Proceedings of the SPE Asia Pacific Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 2–4 July 2013; p. SPE-165218. [Google Scholar]

- Jeong, M.S.; Cho, J.; Choi, J.; Lee, J.H.; Lee, K.S. Compositional simulation on the flow of polymeric solution alternating CO2 through heavy oil reservoir. Adv. Mech. Eng. 2014, 6, 978465. [Google Scholar] [CrossRef]

- Donaldson, E.C.; Chilingarian, G.V.; Yen, T.F. Enhanced oil recovery, II. In Processes and Operations; Elsevier: Amsterdam, The Netherlands, 1989. [Google Scholar]

- Ilyushin, Y.V.; Novozhilov, I.M. Temperature Field Control of a Metal Oil-well Tubing for Producing of High-Paraffin Oil. In Proceedings of the 2020 XXIII International Conference on Soft Computing and Measurements (SCM), St. Petersburg, Russia, 27–29 May 2020; pp. 149–152. [Google Scholar]

- Li, L.; Jia, C.; Yao, J.; Sepehrnoori, K.; Abushaikha, A.; Liu, Y. An Investigation of Gas-Fingering Behavior during CO2 Flooding in Acid Stimulation Formations. SPE J. 2024, 29, 3369–3386. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Q. Research Progress on CO2 Gel Blocking System for Channeling Prevention. Pet. Geol. Recovery Effic. 2022, 1–13. [Google Scholar]

- Bai, F.; Jia, C.; Hu, J.; Alsousy, A.; Lu, Y.; Sepehrnoori, K. Storage Capacity Comparison of Hydrogen and Carbon Dioxide in Heterogeneous Aquifers. Gas Sci. Eng. 2024, 121, 205182. [Google Scholar] [CrossRef]

- Juanes, R.; Spiteri, E.J.; Orr, F.M., Jr.; Blunt, M.J. Impact of relative permeability hysteresis on geological CO2 storage. Water Resour. Res. 2006, 42. [Google Scholar] [CrossRef]

- Skauge, A.; Larsen, J.A. Three-phase relative permeabilities and trapped gas measurements related to WAG processes. In Proceedings of the International Symposium of the Society of Core Analysts, Stavanger, Norway, 12–14 September 1994; p. SCA 9421. [Google Scholar]

- Sohrabi, M.; Jamiolahmady, M. Mechanism of injectivity loss during water-alter-nating-gas (WAG) injection. Gas 2005, 5, 00209. [Google Scholar]

- Foroudi, S.; Gharavi, A.; Fatemi, M. Assessment of two-phase relative permeability hysteresis models for oil/water, gas/water and gas/oil systems in mixed-wet porous media. Fuel 2022, 309, 122150. [Google Scholar] [CrossRef]

- Karkooti, H.; Masoudi, R.; Arif, A.M.; Darman, N.H.; Othman, M.B. Evaluation of the Impact of Relative Permeability Hysteresis and Three Phase Modeling on the Performance of Water Alternative Gas EOR Processes. In Proceedings of the SPE Asia Pacific Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 19–20 July 2011; p. SPE-143982. [Google Scholar]

- Aladasani, A.; Bai, B. Recent developments and updated screening criteria of enhanced oil recovery techniques. In Proceedings of the SPE International Oil and Gas Conference and Exhibition in China, Beijing, China, 8–10 June 2010; p. SPE-130726. [Google Scholar]

- Nuryaningsih, L.; Jiang, H.; Adidharma, H. Experimental study on optimum half-cycle slug size of water alternating gas under tertiary miscible carbon dioxide flooding. In Proceedings of the SPE International Conference on CO2 Capture, Storage, and Utilization, New Orleans, LA, USA, 10–12 November 2010; p. SPE-139580. [Google Scholar]

- Claridge, E.L. CO2 flooding strategy in a communicating layered reservoir. J. Pet. Technol. 1982, 34, 2746–2756. [Google Scholar] [CrossRef]

- Barkhan, M.H.; Zargar, G.; Zakariyaei, S.; Jamal, S. Studying the effect of injectionpattern on water alternating gas (WAG) injection process using eclipse simulator software in an oil reservoir in Iran. Pet. Coal 2015, 57, 234–240. [Google Scholar]

- Redman, R.S. Horizontal miscible water alternating gas development of the Alpine field, Alaska. In Proceedings of the SPE Western Regional Meeting, Anchorage, Alaska, 20–22 May 2002; p. SPE-76819. [Google Scholar]

- Surguchev, L.M.; Korbøl, R.; Haugen, S.; Krakstad, O.S. Screening of WAG injection strategies for heterogeneous reservoirs. In Proceedings of the SPE Europec Featured at EAGE Conference and Exhibition, Cannes, France, 16–18 November 1992; p. SPE-25075. [Google Scholar]

- Ding, S.; Xi, Y.; Liu, G.; Liu, Q.; Yu, H. Adaptability of Different CO2 Injection Methods in Enhancing Oil Recovery and Geological Sequestration in Low-Permeability Reservoirs. Oil Gas Geol. Recovery 2022, 30, 104–111. [Google Scholar]

- Muskat, M. Physical Principles of Oil Production; U.S. Department of Energy Office of Scientific and Technical Information: Washington, DC, USA, 1981. [Google Scholar]

- Chen, Z.; Ewing, R.E. Comparison of various formulations of three-phase flow in porous media. J. Comput. Phys. 1997, 132, 362–373. [Google Scholar] [CrossRef]

- Larsen, J.; Skauge, A. Methodology for numerical simulation with cycle-dependent relative permeabilities. SPE J. 1998, 3, 163–173. [Google Scholar] [CrossRef]

- Kumar, J.; Agrawal, P.; Draoui, E. A case study on miscible and immiscible gas-injection pilots in a Middle East carbonate reservoir in an offshore environment. SPE Reserv. Eval. Eng. 2017, 20, 019–029. [Google Scholar] [CrossRef]

- Spiteri, E.J.; Juanes, R. Impact of relative permeability hysteresis on the numerical simulation of WAG injection. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26–29 September 2004; p. SPE-89921. [Google Scholar]

- Fatemi, S.M.; Sohrabi, M. Experimental and theoretical investigation of water/gas relative permeability hysteresis: Applicable to water alternating gas (WAG) injection and gas storage processes. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 2–5 October 2012; p. SPE-161827-MS. [Google Scholar]

- Avraam, D.G.; Payatakes, A.C. Flow mechanisms, relative permeabilities, and coupling effects in steady-state two-phase flow through porous media. The case of strong wettability. Ind. Eng. Chem. Res. 1999, 38, 778–786. [Google Scholar] [CrossRef]

- Geffen, T.M.; Owens, W.W.; Parrish, D.R.; Morse, R.A. Experimental investigation of factors affecting laboratory relative permeability measurements. J. Pet. Technol. 1951, 3, 99–110. [Google Scholar] [CrossRef]

- Batycky, J.P.; McCaffery, F.G.; Hodgins, P.K.; Fisher, D.B. Interpreting Relative Permeability and Wettability From Unsteady-State Displacement Measurements. Soc. Pet. Eng. J. 1981, 21, 296–308. [Google Scholar] [CrossRef]

- Fulcher, R.A., Jr.; Ertekin, T.; Stahl, C.D. Effect of capillary number and its constituents on two-phase relative permeability curves. J. Pet. Technol. 1985, 37, 249–260. [Google Scholar] [CrossRef]

- Bouchard, A.J.; Hawkins, J.T. Reservoir-engineering implications of capillary-pressure and relative-permeability hysteresis. Log Anal. 1992, 33, SPWLA-1992-v33n4a6. [Google Scholar]

- Morrow, N.R. Wettability and its effect on oil recovery. J. Pet. Technol. 1990, 42, 1476–1484. [Google Scholar] [CrossRef]

- Rao, D.N.; Girard, M.; Sayegh, S.G.G. The Influence Of Reservoir Wettability On Waterflood And Miscible Flood Performance. J. Can. Pet. Technol. 1992, 31, 47–51. [Google Scholar] [CrossRef]

- Land, C.S. Calculation of imbibition relative permeability for two-and three-phase flow from rock properties. Soc. Pet. Eng. J. 1968, 8, 149–156. [Google Scholar] [CrossRef]

- Killough, J.E. Reservoir simulation with history-dependent saturation functions. Soc. Pet. Eng. J. 1976, 16, 37–48. [Google Scholar] [CrossRef]

- Carlson, F.M. Simulation of relative permeability hysteresis to the nonwetting phase. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 4–7 October 1981; p. SPE-10157. [Google Scholar]

- Salathiel, R.A. Oil recovery by surface film drainage in mixed-wettability rocks. J. Pet. Technol. 1973, 25, 1216–1224. [Google Scholar] [CrossRef]

- Delshad, M.; Lenhard, R.J.; Oostrom, M.; Pope, G.A. A Mixed-Wet Hysteretic Relative Permeability and Capillary Pressure Model for Reservoir Simulations. SPE Reserv. Eval. Eng. 2012, 6, 328–334. [Google Scholar] [CrossRef]

- Kjosavik, A.; Ringen, J.K.; Skjaeveland, S.M. Relative Permeability Correlation for Mixed-Wet Reservoirs. SPE J. 2002, 7, 49–58. [Google Scholar] [CrossRef]

- Guzman, R.E.; Domenico, G.; Fayers, F.J.; Aziz, K.; Godi, A. Three-phase flow in field-scale simulations of gas and WAG injections. In Proceedings of the SPE Europe Featured at EAGE Conference and Exhibition, New Orleans, LA, USA, 25–28 September 1994; p. SPE-28897. [Google Scholar]

- Spiteri, E.J.; Juanes, R.; Blunt, M.J.; Orr, F.M. A new model of trapping and relative permeability hysteresis for all wettability characteristics. SPE J. 2008, 13, 277–288. [Google Scholar] [CrossRef]

- Vivek, R.; Suresh Kumar, G. An Improved Brine-Relative Permeability Model with Hysteresis and Its Significance to Sequestrated CO2 in a Deep Saline Aquifer. Env. Earth 2019, 78, 151. [Google Scholar] [CrossRef]

- Land, C.S. The optimum gas saturation for maximum oil recovery from displacement by water. In Proceedings of the Fall Meeting of the Society of Petroleum Engineers of AIME, Houston, TX, USA, 29 September–2 October 1968. [Google Scholar]

- Beattie, C.; Boberg, T.; McNab, G. Reservoir simulation of cyclic steam stimulation in the Cold Lake oil sands. SPE Reserv. Eng. 1989, 6, 200–206. [Google Scholar] [CrossRef]

- Beygi, M.R.; Delshad, M.; Pudugramam, V.S.; Pope, G.A.; Wheeler, M.F. A new approach to model hysteresis and its impact on CO2-EOR processes with mobility control strategies. In Proceedings of the SPE Western Regional Meeting, Monterey, CA, USA, 19–25 April 2013; p. SPE-165324. [Google Scholar]

- Zuo, L.; Chen, Y.; Zhou, D.; Kamath, J. Three-phase relative permeability modeling in the simulation of WAG injection. SPE Reserv. Eval. Eng. 2014, 17, 326–339. [Google Scholar] [CrossRef]

- Shahrokhi, O.; Fatemi, M.; Sohrabi, M.; Ireland, S.; Ahmed, K. Assessment of three-phase relative permeability and hysteresis models for simulation of water-alternating-gas WAG injection in water-wet and mixed-wet systems. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OA, USA, 12–16 April 2014; p. SPE-169170. [Google Scholar]

- Stone, H.L. Probability model for estimating three-phase relative permeability. J. Pet. Technol. 1970, 22, 214–218. [Google Scholar] [CrossRef]

- Stone, H.L. Estimation of three-phase relative permeability and residual oil data. J. Can. Pet. Technol. 1973, 12, PETSOC-73-04-06. [Google Scholar] [CrossRef]

- Baker, L.E. Three-Phase Relative Permeability Correlations. In Proceedings of the SPE/DOE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 17–20 April 1988. [Google Scholar]

- Dyer, S.B.; Farouq Ali, S.M. Linear Model Studies of the Immiscible CO2 WAG Process for Heavy-Oil Recovery. SPE Res. Eng. 1994, 9, 107–111. [Google Scholar] [CrossRef]

- Larsen, J.A.; Skauge, A.A. Simulation of the immiscible WAG process using cycle-dependent three-phase relative permeabilities. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 3–6 October 1999; p. SPE-56475. [Google Scholar]

- Jamshidnezhad, M. Oil recovery by miscible SWAG injection. In Proceedings of the SPE Russian Petroleum Technology Conference, Moscow, Russia, 28–30 October 2008; p. SPE-115710. [Google Scholar]

- Sohrabi, M.; Danesh, A.; Tehrani, D.H. Oil recovery by near-miscible SWAG injection. In Proceedings of the SPE Europe Featured at EAGE Conference and Exhibition, Turin, Italy, 26–28 June 2005; p. SPE-94073. [Google Scholar]

- Ma, Y.; Zhao, F.; Hou, J.; Duan, X.; Li, S. Physical Simulation of Enhanced Oil Recovery Using Gas-Water Co-Injection Techniques. Pet. Geol. Recovery Effic. 2015, 22. [Google Scholar]

- Attanucci, V.; Aslesen, K.S.; Hejl, K.A.; Wright, C.A. WAG process optimization in the Rangely CO2 miscible flood. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 3–6 October 1993; p. SPE-26622. [Google Scholar]

- Stephenson, D.J.; Graham, A.G.; Luhning, R.W. Mobility control experience in the Joffre Viking miscible carbon dioxide flood. In Proceedings of the IOR 1991-6th European Symposium on Improved Oil Recovery, European Association of Geoscientists & Engineers, Stavanger, Norway, 21–23 May 1991; p. cp-44. [Google Scholar]

- Berge, L.I.; Stensen, J.Å.; Crapez, B.; Quale, E.A. SWAG Injectivity Behavior Based on Siri Field Data. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, Oklahoma, 13–17 April 2002; p. SPE-75126. [Google Scholar]

- Stone, H.L. A simultaneous water and gas flood design with extraordinary vertical gas sweep. In Proceedings of the SPE International Oil Conference and Exhibition in Mexico, Puebla Pue, Mexico, 7–9 November 2004; p. SPE-91724. [Google Scholar]

- Shetty, S.; Hughes, R.G.; Afonja, G. Experimental evaluation of simultaneous water and gas injection using carbon dioxide. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 31 March–2 April 2014; p. SPE-169690. [Google Scholar]

- Stoisits, R.F.; Krist, G.J.; Ma, T.D.; Rugen, J.A.; Kolpak, M.M.; Payne, R.L. Simultaneous water and gas injection pilot at the Kuparuk River field, surface line impact. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 22–25 October 1995; p. SPE-30645. [Google Scholar]

- Hosseini-Nasab, S.M.; Zitha, P.L.J. Investigation of certain physical-chemical features of oil recovery by an optimized alkali-surfactant-foam (ASF) system. Colloid Polym. Sci. 2017, 295, 1873–1886. [Google Scholar] [CrossRef]

- Massarweh, O.; Abushaikha, A.S. The use of surfactants in enhanced oil recovery: A review of recent advances. Energy Rep. 2020, 6, 3150–3178. [Google Scholar] [CrossRef]

- Dalland, M.; Hanssen, J.E.; Kristiansen, T.S. Oil interaction with foams under static and flowing conditions in porous media. Colloids Surf. A Physicochem. Eng. Asp. 1994, 82, 129–140. [Google Scholar] [CrossRef]

- Zuta, J.; Fjelde, I. Mechanistic modeling of CO2-foam processes in fractured chalk rock: Effect of foam strength and gravity forces on oil recovery. In Proceedings of the SPE Asia Pacific Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 19–20 July 2011; p. SPE-144807. [Google Scholar]

- Yue, X.; Wang, Y.; Wang, K. Fundamentals of Enhanced Oil Recovery; Petroleum Industry Press: Beijing, China, 2007; pp. 151–171. [Google Scholar]

- Aarra, M.G.; Skauge, A.; Martinsen, H.A. FAWAG: A Breakthrough for EOR in the North Sea. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 29 September–2 October 2002; p. SPE-77695. [Google Scholar]

- Turta, A.T.; Singhal, A.K. Petroleum Recovery Institute (PRI)/Alberta Research Council (ARC). Field Foam Applications in Enhanced Oil Recovery Projects: Screening and Design Aspects. J. Can. Pet. Technol. 2002, 41. [Google Scholar] [CrossRef]

- Tunio, S.Q.; Chandio, T.A.; Memon, M.K. Comparative study of FAWAG and swag as an effective EOR technique for a Malaysian field. Res. J. Appl. Sci. Eng. Technol. 2012, 4, 645–648. [Google Scholar]

- Kharrat, R.; Mahdavi, S.; Ghorbani, D. A comprehensive EOR study of a highly fractured matured field-case study. In Proceedings of the SPE Europe Featured at EAGE Conference and Exhibition, Copenhagen, Denmark, 4–7 June 2012; p. SPE-153311. [Google Scholar]

- Zhang, C.; Li, S. Study on Enhanced Oil Recovery by CO2 Foam and CO2 Alternating Injection in Heterogeneous Reservoirs. J. Petrochem. Univ. 2011, 24, 1–5. [Google Scholar]

- Osei-Bonsu, K.; Shokri, N.; Grassia, P. Foam stability in the presence and absence of hydrocarbons: From bubble-to bulk-scale. Colloids Surf. A Physicochem. Eng. Asp. 2015, 481, 514–526. [Google Scholar] [CrossRef]

- Simjoo, M.; Rezaei, T.; Andrianov, A.; Zitha, P. Foam stability in the presence of oil: Effect of surfactant concentration and oil type. Colloids Surf. A Physicochem. Eng. Asp. 2013, 438, 148–158. [Google Scholar] [CrossRef]

- Salehi, M.M.; Omidvar, P.; Naeimi, F. Salinity of injection water and its impact on oil recovery absolute permeability, residual oil saturation, interfacial tension and capillary pressure. Egypt. J. Pet. 2017, 26, 301–312. [Google Scholar] [CrossRef]

- Morrow, N.R.; Buckley, J. Wettability and oil recovery by imbibition and viscous displacement from fractured and heterogeneous carbonates. In Chemical & Petroleum Engineering; U.S. Department of Energy Office of Scientific and Technical Information: Washington, DC, USA, 2006. [Google Scholar]

- Hassan, A.M.; Ayoub, M.; Eissa, M.; Bruining, H.; Al-Mansour, A.; Al-Quraishi, A. A New Hybrid Improved and Enhanced Oil Recovery IOR/EOR Process Using Smart Water Assisted Foam SWAF Flooding in Carbonate Rocks; A Laboratory Study Approach. In Proceedings of the International Petroleum Technology Conference, IPTC, Virtual, 23 March–1 April 2021; p. D012S045R087. [Google Scholar]

- Hassan, A.M.; Ayoub, M.A.; Mohyaldinn, M.E.; Al-Shalabi, E.W. Insights into Hybrid Smart Water Assisted Foam (SWAF) Flooding in Carbonate Reservoirs: A Combined Numerical and Experimental Approach. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 31 October–3 November 2022; p. D041S129R002. [Google Scholar]

- Qu, H.; Liu, Q.; Peng, B.; Luo, D.; Liu, S.; Liu, J. Influence of Nanoparticles on the Stability of CO2 Foam Systems. Pet. Geol. Recovery Effic. 2019, 26. [Google Scholar]

- Wang, J.; Wang, H. Laboratory Study and Evaluation of a New Foam Profile Control Agent. Sci. Technol. Eng. 2009, 9, 6159–6162. [Google Scholar]

- Luo, Z. Development and Performance Evaluation of Temperature-Resistant Foam Gel. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2019. [Google Scholar]

- Wang, P. Experimental Study and Application of SiO2 Nanoparticles for Enhancing CO2 Foam Stability; China University of Petroleum (East China): Dongyin, China, 2015. [Google Scholar]

- Yang, Z.; Luo, Z.; Lin, M.; Lü, Q.; Li, X. Construction of a Temperature-Resistant Foam Gel System to Improve CO2 Flooding Efficiency in Low-Permeability Reservoirs. Oilfield Chem. 2020, 37. [Google Scholar]

- Li, D. Study on Leakage and Gas Channeling Mechanisms and Chemical Control Methods during CO2 Flooding; China University of Petroleum (East China)): Dongyin, China, 2017. [Google Scholar]

- Enick, R.M.; Olsen, D.; Ammer, J.; Schuller, W. Mobility and conformance control for CO2 EOR via thickeners, foams, and gels-a literature review of 40 years of research and pilot tests. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OA, USA, 14–18 April 2012; p. SPE-154122. [Google Scholar]

- Sydansk, R.D. Polymers, gels, foams, and resins. Pet. Eng. Handb. 2007, 5, 1219–1224. [Google Scholar]

- Li, W.; Dong, Z.; Sun, J.; Schechter, D.S. Polymer-alternating-gas simulation—A case study. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 31 March–2 April 2014; p. SPE-169734. [Google Scholar]

- Zhang, Y.; Huang, S.; Luo, P. Coupling immiscible CO2 technology and polymer injection to maximize EOR performance for heavy oils. J. Can. Pet. Technol. 2010, 49, 27–33. [Google Scholar]

- Lee, J.J.; Cummings, S.; Dhuwe, A.; Enick, R.; Beckman, E.J.; Perry, R.M.; Doherty, M.; O’Brien, M. Development of small molecule CO2 thickeners for EOR and fracturing. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 12–16 April 2014; OnePetro: Richardson, TX, USA, 2014. [Google Scholar]

- Lee, J.J.; Cummings, S.D.; Beckman, E.J.; Robert, M.E.; Ward, A.B.; Mark, D.D.; Michael, J.O.; Robert, J.P. The solubility of low molecular weight Poly (Dimethyl siloxane) in dense CO2 and its use as a CO2-philic segment. J. Supercrit. Fluids 2017, 119, 17–25. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.; Liang, L. Preparation and performance of supercritical carbon dioxide thickener. Polymers 2020, 13, 78. [Google Scholar] [CrossRef] [PubMed]

- Dai, C.; Liu, P.; Gao, M.; Liu, Z.; Liu, C.; Wu, Y.; Yan, H. Preparation and thickening mechanism of copolymer fluorinated thickeners in supercritical CO2. J. Mol. Liq. 2022, 360, 119563. [Google Scholar] [CrossRef]

- Bac, J.H.; Irani, C.A. Laboratory investigation of viscosified CO2 process. SPE Adv. Technol. Ser. 1993, 1, 166–169. [Google Scholar]

- Zhou, M.; Tu, H.; He, Y.; Peng, P.; Liao, M.; Zhang, J.; Guo, X. Synthesis of an oligomeric thickener for supercritical carbon dioxide and its properties. J. Mol. Liq. 2020, 312, 113090. [Google Scholar] [CrossRef]

- Al-Ali, A.H.; Schechter, D.S.; Lane, R.H. Application of polymer gels as conformance control agents for carbon dioxide EOR WAG floods. In Proceedings of the SPE International Conference on Oilfield Chemistry, The Woodlands, TX, USA, 8–10 April 2013; p. SPE-164096. [Google Scholar]

- Panthi, K.; Mohanty, K.K. pH-insensitive polymeric particles for enhanced oil recovery in reservoirs with fractures. SPE J. 2018, 23, 34–47. [Google Scholar] [CrossRef]

- Ding, Y.; Zhao, Y.; Wen, X.; Liu, Y.; Feng, M.; Rui, Z. Development and Applications of CO2-Responsive Gels in CO2 Flooding and Geological Storage. Gels 2023, 9, 936. [Google Scholar] [CrossRef]

- Yang, Y.; Li, W.; Zhou, T.; Dong, Z. Using polymer alternating gas to enhance oil recovery in heavy oil. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Zhao, F.; Hao, H.; Hou, J.; Hou, L.; Song, Z. CO2 mobility control and sweep efficiency improvement using starch gel or ethylenediamine in ultra-low permeability oil layers with different types of heterogeneity. J. Pet. Sci. Eng. 2015, 133, 52–65. [Google Scholar] [CrossRef]

- Hao, H.; Hou, J.; Zhao, F.; Song, Z.; Hou, L.; Wang, Z. Gas channeling control during CO2 immiscible flooding in 3D radial flow model with complex fractures and heterogeneity. J. Pet. Sci. Eng. 2016, 146, 890–901. [Google Scholar] [CrossRef]

- Luo, X.J.; Wei, B.; Gao, K.; Jing, B.; Huang, B.; Guo, P.; Yin, H.; Feng, Y.; Zhang, X. Gas channeling control with an in-situ smart surfactant gel during water-alternating-CO2 enhanced oil recovery. Pet. Sci. 2023, 20, 2835–2851. [Google Scholar] [CrossRef]

- Luo, X.; Zheng, P.; Gao, K.; Wei, B.; Feng, Y. Thermo-and CO2-triggered viscosifying of aqueous copolymer solutions for gas channeling control during water-alternating-CO2 flooding. Fuel 2021, 291, 120171. [Google Scholar] [CrossRef]

- Zhao, M.; Yan, X.; Wang, X.; Yan, R.; Dai, C. The development of a smart gel for CO2 mobility control in heterogeneity reservoir. Fuel 2023, 342, 127844. [Google Scholar] [CrossRef]

- Xu, T.; Wei, Y.; Ma, T.T. Experiment and Simulation of Gas Channeling Control Technique During CO2 Flooding in Normal Pressure Tight Oil Reservoir of South Ordos Basin. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 9–12 November 2020; p. D012S116R157. [Google Scholar]

- Zhao, F.; Wang, P.; Huang, S.; Hao, H.; Zhang, M.; Lu, G. Performance and applicable limits of a multi-stage gas channeling control system for CO2 flooding in ultra-low permeability reservoirs. J. Pet. Sci. Eng. 2020, 192, 107336. [Google Scholar] [CrossRef]

- Auffan, M.; Rose, J.; Bottero, J.Y.; Lowry, J.P.; Jolivet, J.P.; Wiesner, M.R. Towards a definition of inorganic nanoparticles from an environmental, health and safety perspective. Nat. Nanotechnol. 2009, 4, 634–641. [Google Scholar] [CrossRef]

- Jeevanandam, J.; Barhoum, A.; Chan, Y.S.; Dufresne, A.; Danquah, M.K. Review on nanoparticles and nanostructured materials: History, sources, toxicity, and regulations. Beilstein J. Nanotechnol. 2018, 9, 1050–1074. [Google Scholar] [CrossRef] [PubMed]

- Kanj, M.Y.; Funk, J.J.; Al-Yousif, Z. Nanofluid coreflood experiments in the ARAB-D, SPE Saudi Arabia Section Technical Symposium. In Proceedings of the SPE Saudi Arabia Section Technical Symposium, Al-Khobar, Saudi Arabia, 9–11 May 2009. [Google Scholar]

- Shen, H.; Xiong, Y.; Wang, Y.; Zhang, F.; Yang, Z.; Dong, Z. Current Status of Research on Janus Platelet Nanomaterials for Enhanced Oil Recovery. Pet. Geol. Recovery Effic. 2023, 1–10. [Google Scholar]

- Jafari, S.; Khezrnejad, A.; Shahrokhi, O.; Ghazanfari, M.H.; Vossoughi, M. Experimental investigation of heavy oil recovery by continuous/WAG injection of CO2 saturated with silica nanoparticles. Int. J. Oil Gas Coal Technol. 2015, 9, 169–179. [Google Scholar] [CrossRef]

- Kazemzadeh, Y.; Malayeri, M.R.; Riazi, M.; Parsaei, R.R. Impact of Fe3O4 nanoparticles on asphaltene precipitation during CO2 injection. J. Nat. Gas Sci. Eng. 2015, 22, 227–234. [Google Scholar] [CrossRef]

- Al Matroushi, M.; Pourafshary, P.; Al Wahaibi, Y. Possibility of nanofluid/gas alternating injection as an EOR method in an oil field. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 13–16 October 2015; p. D031S054R002. [Google Scholar]

- Moradi, B.; Pourafshary, P.; Farahani, F.J.; Mohammadi, M.; Emadi, M.A. Application of SiO2 nanoparticles to improve the performance of water alternating gas EOR process. In Proceedings of the SPE Oil and Gas India Conference and Exhibition, Mumbai, India, 24–26 November 2015; p. SPE-178040. [Google Scholar]

- Zhang, K.; Li, Y.; Hong, A.; Wu, K.; Jing, G.; Torsæter, O.; Chen, Z. Nanofluid alternating gas for tight oil exploitation. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Nusa Dua, Bali, Indonesia, 20–22 October 2015; p. SPE-176241. [Google Scholar]

- Agada, S.; Geiger, S.; Elsheikh, A.; Oladyshkin, S. Data-driven surrogates for rapid simulation and optimization of WAG injection in fractured carbonate reservoirs. Pet. Geosci. 2017, 23, 270–283. [Google Scholar] [CrossRef]

- Mäkel, G.H. The modelling of fractured reservoirs: Constraints and potential for fracture network geometry and hydraulics analysis. Geol. Soc. Lond. Spec. Publ. 2007, 292, 375–403. [Google Scholar] [CrossRef]

- Agada, S.; Geiger, S.; Doster, F. Wettability, hysteresis, and fracture-matrix interaction during CO2 EOR and storage in fractured carbonate reservoirs. Int. J. Greenh. Gas Control 2016, 46, 57–75. [Google Scholar] [CrossRef]

- Agada, S.; Geiger, S. Wettability, trapping and fracture-matrix interaction during WAG injection in fractured carbonate reservoirs. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OA, USA, 12–16 April 2014; p. SPE-169054. [Google Scholar]

| Key Factors | Difficulty of Control | Sequence and Importance of Control | Main Control Methods | Control Mechanisms |

|---|---|---|---|---|

| Mobility ratio | Easy | Critical and prioritized control | Adding chemicals or altering injection methods in water–gas | Lowering the mobility ratio and stabilizing displacement fronts |

| Reservoir properties | Moderately challenging | Significant and targeted control | Adding chemicals to water–gas or adjusting injection-production regimes | Physically or chemically blocking fractures or high-permeability channels |

| Field injection-production regime | Relatively easy | Significant and targeted control | Modifying water–gas slug ratio, injection pressure, injection rate, and injection method | Reducing water–gas mobility ratio, stabilizing displacement front, and improving heterogeneity |

| Hysteresis and relative permeability | Moderately difficult | Significant and generally applicable control | Introducing chemical agents or adjusting injection-production regimes | Altering wettability, reducing gas phase permeability |

| Gravity segregation | Moderately difficult | Significant and generally applicable control | Control of injection-production regimes | Blocking vertical high-permeability channels to reduce vertical gas migration |

| Two-Phase Hysteresis Models | Applicability to Fluid Phases and Rock Systems | Rock Wettability | Reversibility of Hysteresis Curves | Limitations and Drawbacks | Key Formulas | Ref |

|---|---|---|---|---|---|---|

| Killough model | Gas–water systems | Water-wet system | reversible | It performs well in predicting hysteresis effects in gas–water systems but fails to accurately predict hysteresis effects in gas–oil systems. As petroleum saturation increases, it underestimates gas relative permeability due to the internal inclusion of the Land model, resulting in poor hysteresis predictions for oil–water mixed-wet systems. | [64] | |

| Carlson model | Oil–water systems | Water-wet system | reversible | It performs well in predicting hysteresis in oil–water mixed-wet systems, but shows poorer predictions for hysteresis effects in gas–oil and gas–water systems during the imbibition process of the non-wetting phase. Additionally, the model’s prediction performance is affected by the absence of hysteresis effects in the wetting phase. | [65] | |

| Beattie model | Gas–oil systems | Water-wet system | irreversible | The model performs well in predicting hysteresis effects in gas–oil systems. However, the uncertainty and multiplicity of parameter (n) arise from fitting curves to estimate it through the first imbibition and drainage cycles. Additionally, a major drawback of the model is the absence of a trapping model. | [73] | |

| Kjosavik model | Gas–oil systems | Mixed-wet system | irreversible | The model extends relative permeability relationships for water-wet and oil-wet systems to mixed-wet rocks. However, due to its inclusion of the Land trapping model, the model has inherent limitations for non-water-wet systems. | [68] | |

| Spiteri model | Pore network model | Mixed-wet system | irreversible | This trapping model is applicable to multiple wetting systems and performs well in predicting hysteresis effects in oil–water systems. | [70] |

| Three-Phase Hysteresis Models | Analysis | Rock Wettability | Limitations and Drawbacks | Key Formulas | Ref |

|---|---|---|---|---|---|

| Stone 1 model | The model does not account for hysteresis effects, and while it accurately predicts relative permeability at high oil saturations, it tends to overestimate the relative permeability of the oil phase as the oil saturation decreases. | Water-wet system | The model predictions are based on imbibition hysteresis curves under different initial conditions, rather than on drainage and imbibition hysteresis curves during cyclic periods. In mixed-wet or weakly water-wet systems, the prevailing models’ assumption that the relative permeabilities of the wetting phase (water) and the non-wetting phase (gas) are exclusively determined by their own saturations is not reflective of actual reservoir conditions. In these systems, krw and krg are dependent on both saturations. This fundamental discrepancy results in a significant divergence between the model predictions and the experimental outcomes for mixed-wet or weakly water-wet systems. | [77] | |

| Stone 2 model | The model does not account for hysteresis effects, and it may underestimate the relative permeability of the oil phase when predicting three-phase permeability. | Water-wet system | [78] | ||

| Baker model | The model assumes that water and gas are completely segregated within the porous medium, while the oil phase is uniformly distributed. | Water-wet system | [79] | ||

| Linear model | The model assumes a linear relationship between the permeabilities of the oil–water and oil–gas curves, allowing for the determination of the three-phase oil relative permeability. | Water-wet system | [80] |

| Researchers, Year | Porous Medium Type | Research Method | Key Findings | Ref |

|---|---|---|---|---|

| Stephenson DJ, 1993 | sandstone | Joffre Viking oil field | SWAG in a 1:1 ratio enhances sweep efficiency compared to conventional CO2-WAG and continuous CO2 injection. | [15] |

| Ma Yunfei, 2015 | sandstone | laboratory core displacement experiment. | The coefficient of fluid mobility reduction in SWAG is inversely proportional to core permeability, which is a key indicator of SWAG’s capability to expand sweep volume. | [84] |

| Berge L I, 2002 | sandstone | Siri oil field field experiments and numerical simulation (Eclipse) | The swept volume of SWAG is influenced by injection and production system parameters, specifically injection pressure and the gas-to-water ratio. Decreased injection capacity reduces the range of gas displacement, with injection capacity dependent on the gas-to-water ratio under fracturing pressures. | [87] |

| Stone, 2004 | limestone | Laboratory model experiments and numerical simulation (UTCOMP) | SWAG is superior to conventional CO2-WAG and continuous CO2 injection modes because it better controls gas mobility, resulting in relatively higher oil recovery rates. | [88] |

| M.Jamshidnezhad, 2008 | porous network model | numerical simulation (CMG). | Factors such as injection rates of water and gas, the placement of injection wells, and reservoir heterogeneity significantly influence gas mobility and sweep range, with minimal impact on oil recovery rates. | [82] |

| Researchers, Year | Porous Medium Type | Synthetic Ingredient | Research Methods | Key Findings | Ref |

|---|---|---|---|---|---|

| W. Li, 2014 | Pore Network Mode | Not mentioned | Numerical Simulation (CMG) of TR59 Block in North Burbank Oilfield | A case study of the TR59 block demonstrates that the incremental recovery rate using PWAG is 20%, which is 12% higher than that achieved with WAG. Heterogeneous formations with high permeability variation coefficients are the optimal choice for PWAG flooding. | [19] |

| Yang Y, 2018 | Pore Network Mode | Not mentioned | Numerical Simulation (CMG) of Heterogeneous Heavy Oil Reservoirs in Liaohe Oilfiel | The recovery rate using PWAG technology is 45% higher than that of polymer flooding and 57% higher than that of WAG. It significantly reduces the water cut and gas–oil ratio. | [126] |

| ZHAO, 2015 | sandstone | Modified Starch Gel and Ethylenediamine | Core Flooding Experiments and Field Trials | When the permeability ratio is less than or equal to 100, the in situ gel generated from the reaction of ethylenediamine with CO2 effectively seals high-permeability layers. This process enhances CO2 flooding efficiency and boosts the total recovery rate by over 20%. | [127] |

| Hao H, 2016 | sandstone | Modified Starch Gel, Acrylamide Monomer Crosslinker, and Ethylenediamine | Three-dimensional radial flow model and core displacement experiments | Injection of high-strength gel and ethylenediamine combined with CO2-WAG flooding effectively mitigates gas channeling in large fractures and high-permeability channels. This integrated approach results in a substantial 15.09% increase in overall recovery rates | [128] |

| Luo et al., 2022 | sandstone | N-erucamidopropyl- N, N-Dimethylamine | numerical simulation (CMG). | The recovery rate of UC22AMPM solution WAG increased by 8% compared to WAG. | [129] |

| Luo X et al., 2021 | sandstone | F127-g-PDMAEMA | Core flooding test | Compared to conventional WAG, HAPM solution WAG increases total recovery by 21% and expands the gas displacement volume. | [130] |

| Mingwei Zhao, 2023 | sandstone | Sodium salicylate, acetone, sodium fluoride, erucic acid N, N-dimethyl-1,3- propane diamine (99%). | Dual-tube core parallel flooding test and CO2 plugging experiment | Low permeability, high surfactant concentration, and high injection volume are positively correlated with improved plugging performance. Gel systems enhance reservoir conformance, resulting in an 18.7% increase in recovery rate for low-permeability reservoirs. | [131] |

| Method | Influencing Factor | Advantage | Disadvantage | Field Application |

|---|---|---|---|---|

| WAG | Reservoir factors (temperature, pressure, thickness, porosity, permeability, saturation, and heterogeneity); CO2 rheological properties and density; composition and viscosity of crude oil; hysteresis, Gravity Segregation Injection parameters (injection rate, injection pressure, and slug ratio); injection scheme; and spacing between injection and production wells. | It enhances CO2 utilization and increases crude oil recovery, controls the mobility ratio, reduces gas channeling, expands sweep efficiency, reduces the mobility ratio, and maintains CO2 mixing with crude oil. | Controlling gas channeling in strong heterogeneous and fractured oil reservoirs may prove ineffective; corroded pipelines are unable to alleviate the phenomenon of gravitational differentiation, which causes the water lock effect. | Yes |

| SWAG | Reservoir factors (temperature, pressure, thickness, porosity, permeability, saturation, and heterogeneity); CO2 rheological properties and density; composition and viscosity of crude oil; hysteresis effect and gravity segregation; injection parameters (injection rate and injection pressure); injection scheme; and spacing between injection and production wells. | It enhances CO2 utilization and increases crude oil recovery; controlling gas channeling and fingering has shown significant effects. | Corrosion of the casing and wellbore, instability of the water–gas front, inability to alleviate the phenomenon of gravitational differentiation, and causing the water lock effect. | Yes |

| FWAG | CO2 rheological properties and density; composition and viscosity of crude oil; injection scheme; type and concentration of surfactants; molecular structure; injection parameters (injection rate and injection pressure); reservoir factors (temperature, pressure, thickness, porosity, permeability, saturation, and heterogeneity); and chemical agent formulation and system. | Relieves sticky fingering; relieves gravity differentiation; relieves early breakthroughs; reduces interfacial tension; changes wettability; easy to inject; and prevents and controls sedimentation. | The cost is high, the foam stability is poor and prone to defoaming, it is sensitive to temperature and pressure, and its effective range is short. | Yes |

| PWAG | Reservoir factors (temperature, pressure, thickness, porosity, permeability, saturation, and heterogeneity); CO2 rheological properties and density; composition and viscosity of crude oil; injection scheme; injection parameters (injection pressure, injection rate, and injection fluid concentration), and chemical agent formulation and system. | It can effectively block large fractures and high-permeability channels in highly heterogeneous oil reservoirs. | The high cost, difficulty in injecting, limited effective range, and potential damage to the reservoir pose significant concerns. | Yes |

| GWAG | Reservoir factors (temperature, pressure, thickness, porosity, permeability, saturation, and heterogeneity); CO2 rheological properties and density; composition and viscosity of crude oil; injection scheme; injection parameters (injection pressure, injection rate, and injection fluid concentration); and chemical agent formulation and system. | Good injectivity can improve reservoir heterogeneity, control mobility ratio, and mitigate gas channeling. | Sensitive to reservoir conditions, and strict chemical agent formulation and system | No |

| NWAG | Reservoir factors (temperature, pressure, thickness, porosity, permeability, saturation, and heterogeneity); CO2 rheological properties and density; composition and viscosity of crude oil; injection scheme; nanoparticle type; particle size; hydrophilicity; and concentration. | Reduces the mobility ratio; prevents and controls asphaltene precipitation; changes the wettability of rocks; reduces interfacial tension; and improves CO2 rheological properties. | Nanoparticles are prone to coalescence, blocking the roar channel, and failing; large particle sizes can damage the reservoir. | No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, P.; Zhang, Q.; Zhou, C.; Yang, Z.; Yu, H.; Du, M.; Chen, X.; Song, Y.; Wang, S.; Gao, Y.; et al. Chemical-Assisted CO2 Water-Alternating-Gas Injection for Enhanced Sweep Efficiency in CO2-EOR. Molecules 2024, 29, 3978. https://doi.org/10.3390/molecules29163978

Fang P, Zhang Q, Zhou C, Yang Z, Yu H, Du M, Chen X, Song Y, Wang S, Gao Y, et al. Chemical-Assisted CO2 Water-Alternating-Gas Injection for Enhanced Sweep Efficiency in CO2-EOR. Molecules. 2024; 29(16):3978. https://doi.org/10.3390/molecules29163978

Chicago/Turabian StyleFang, Pengwei, Qun Zhang, Can Zhou, Zhengming Yang, Hongwei Yu, Meng Du, Xinliang Chen, Yuxuan Song, Sicai Wang, Yuan Gao, and et al. 2024. "Chemical-Assisted CO2 Water-Alternating-Gas Injection for Enhanced Sweep Efficiency in CO2-EOR" Molecules 29, no. 16: 3978. https://doi.org/10.3390/molecules29163978