Influence of Polytetrafluoroethylene Content, Compaction Pressure, and Annealing Treatment on the Magnetic Properties of Iron-Based Soft Magnetic Composites

Abstract

1. Introduction

2. Results and Discussion

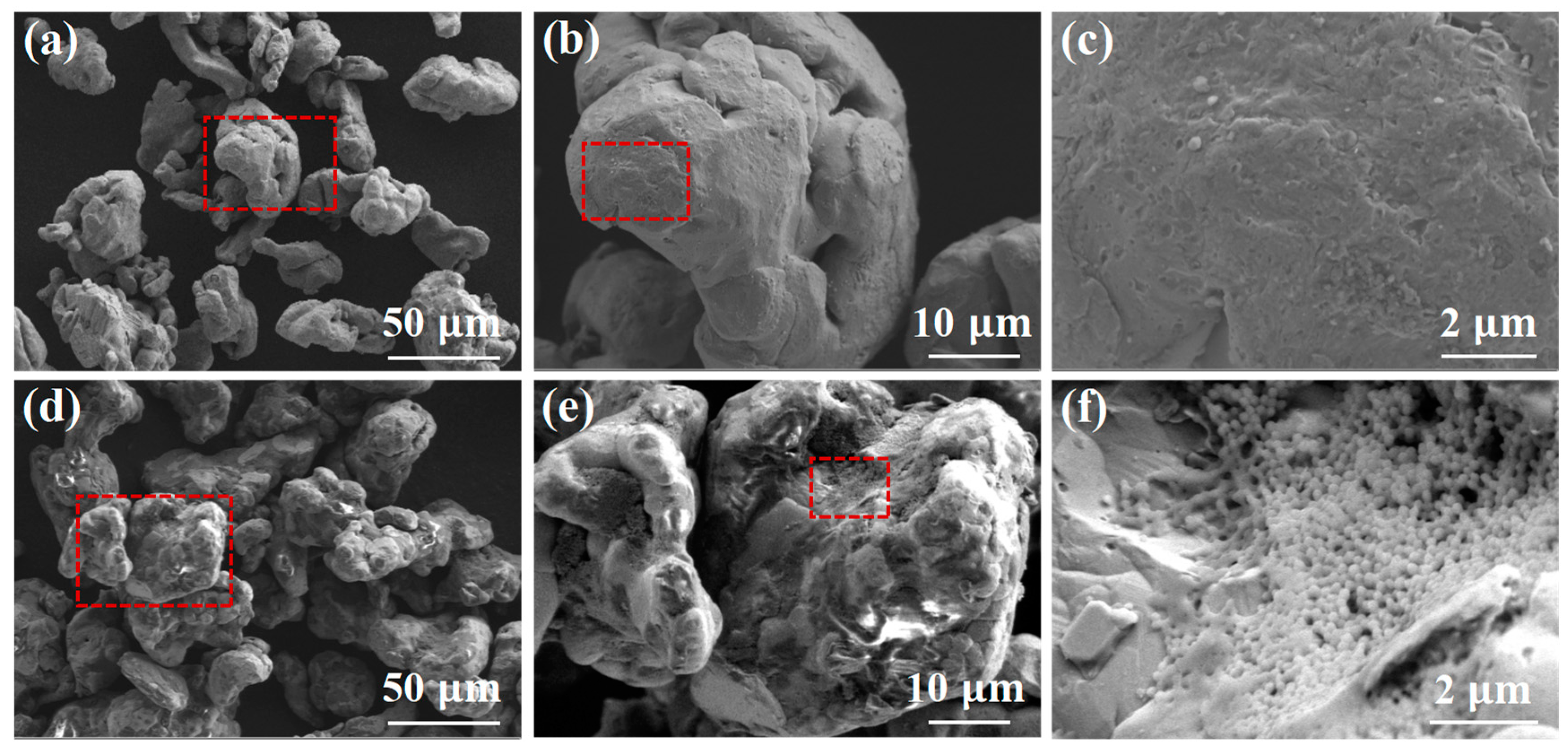

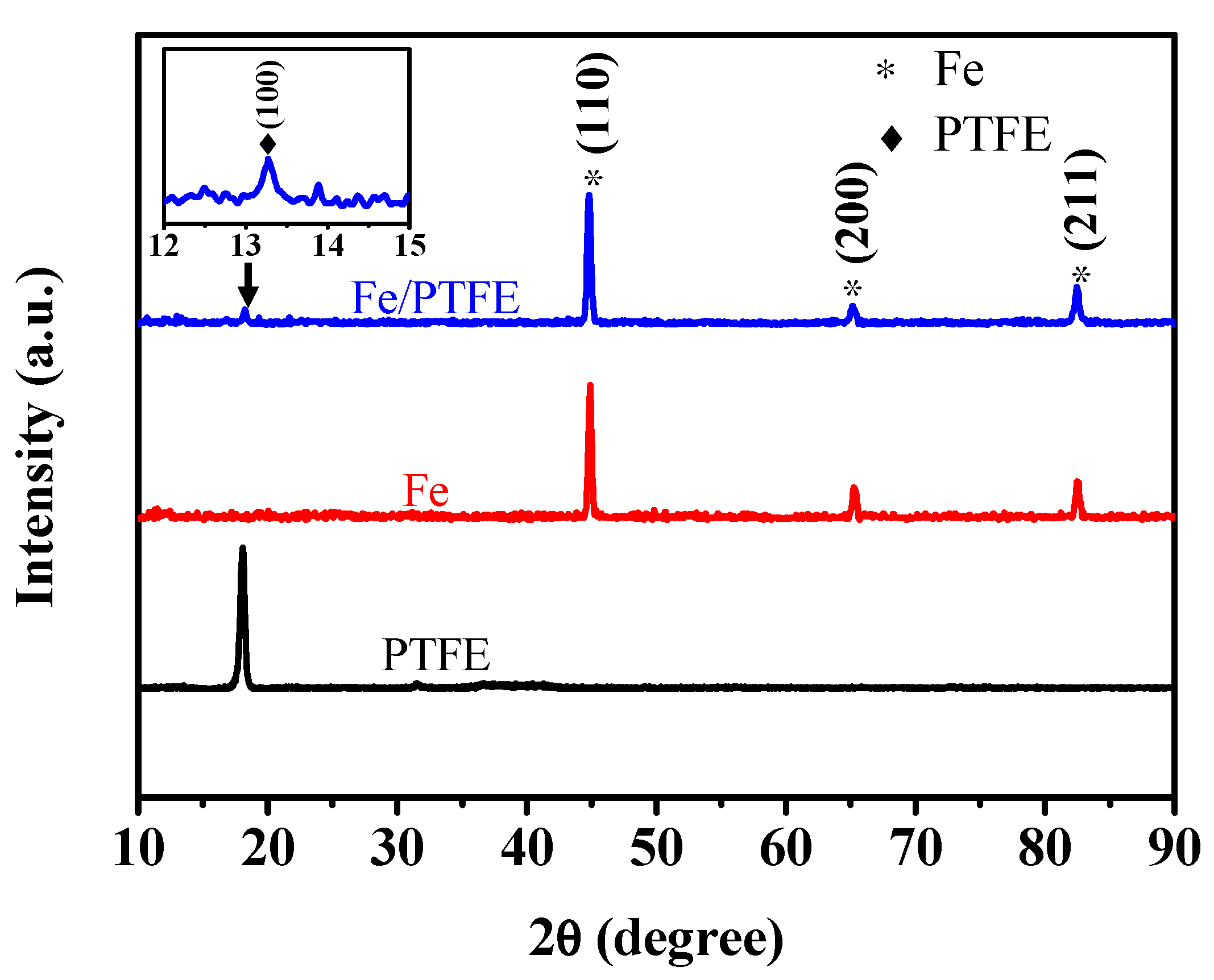

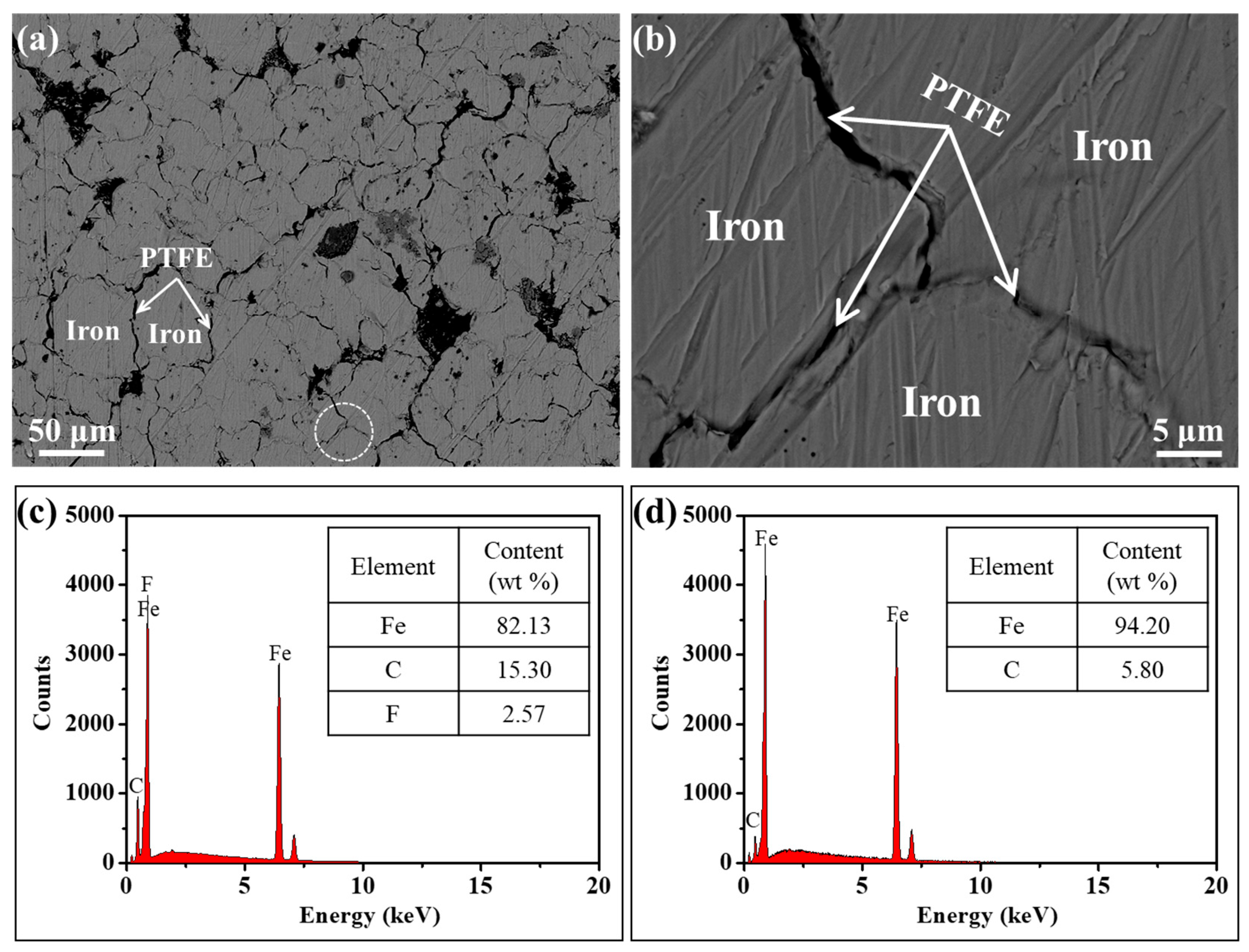

2.1. Characterization of the Fe/PTFE Composite Powders and Corresponding SMCs

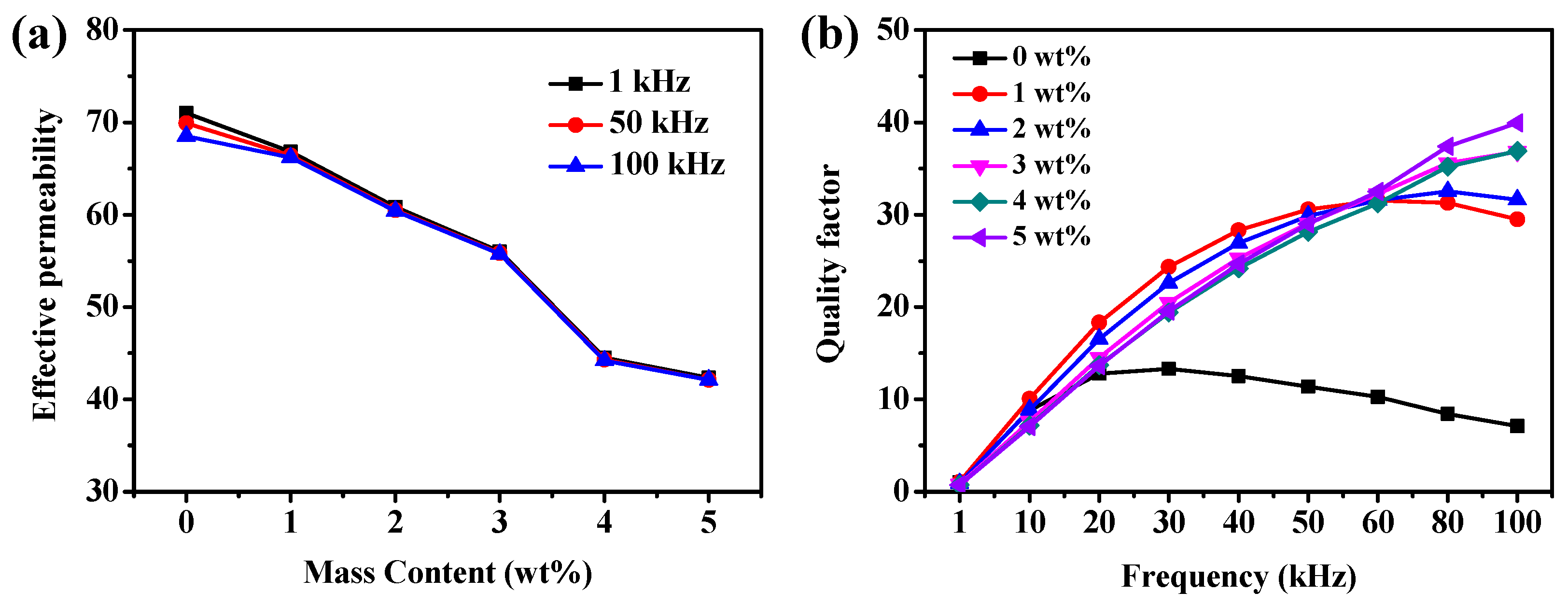

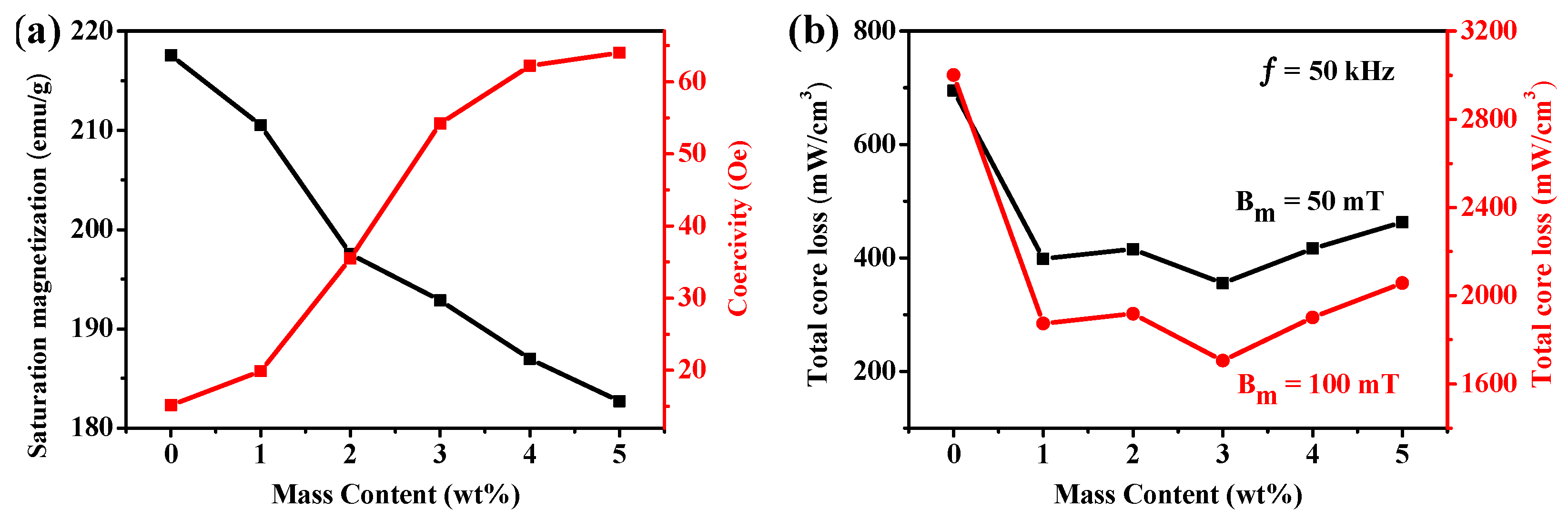

2.2. Effect of PTFE Content on the Magnetic Properties of Fe/PTFE SMCs

2.3. Effect of Compaction Pressure on the Magnetic Properties of Fe/PTFE SMCs

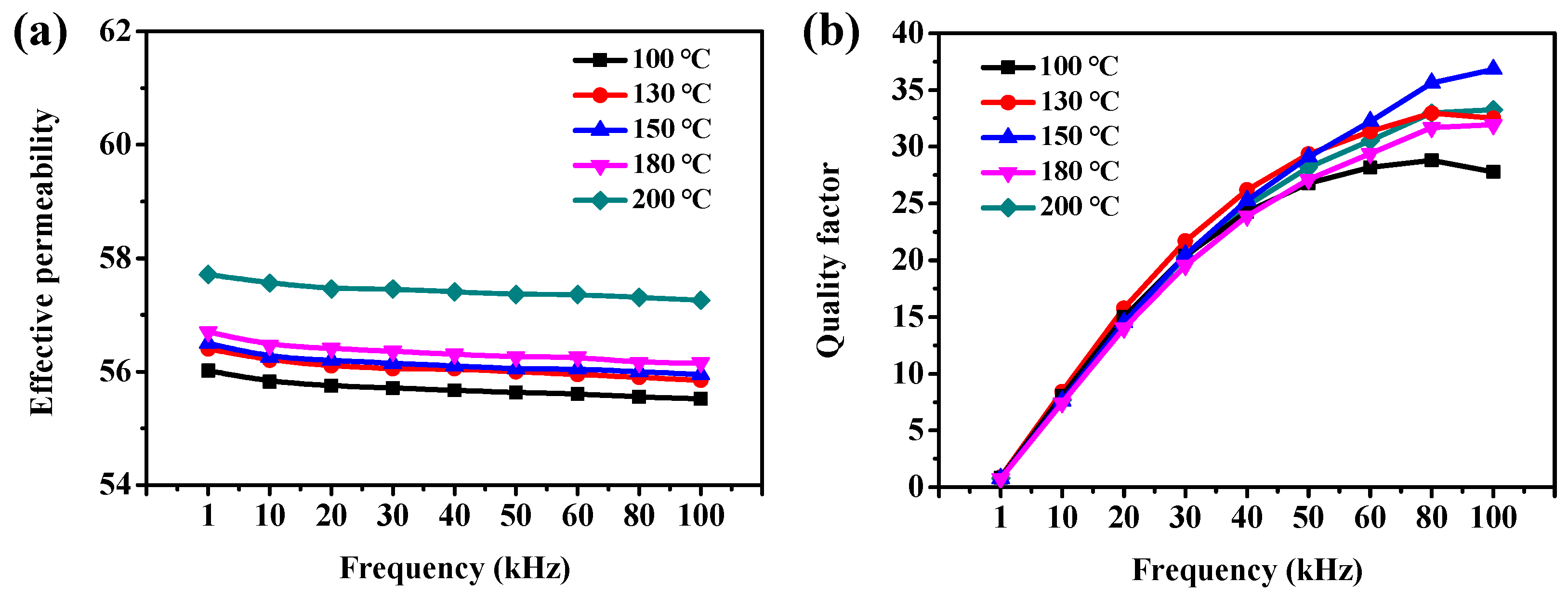

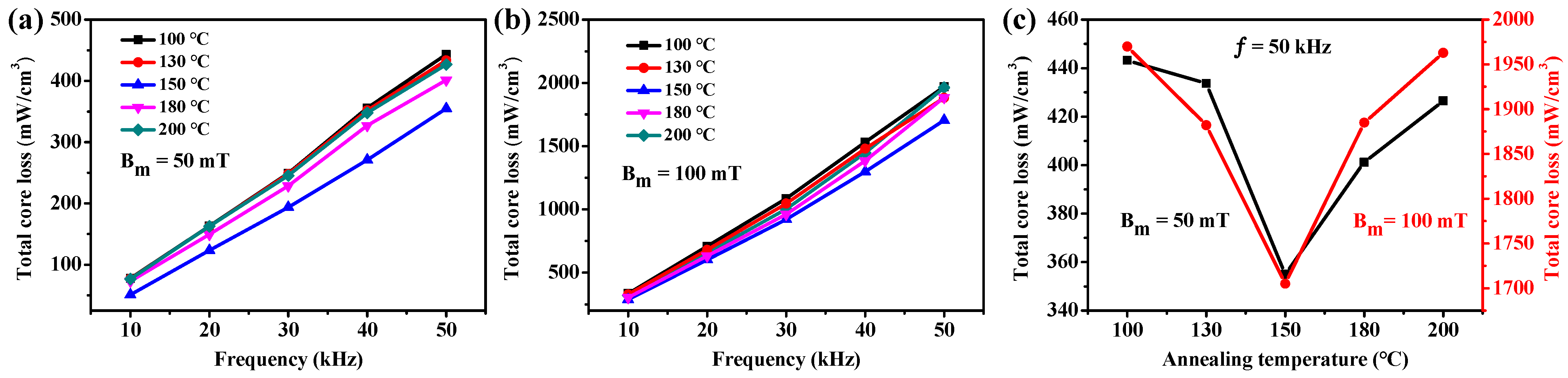

2.4. Effect of Annealing Treatment on the Magnetic Properties of Fe/PTFE SMCs

3. Materials and Methods

3.1. Materials

3.2. Preparation of the Fe/PTFE SMCs

3.3. Characterizations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shokrollahi, H.; Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Talaat, A.; Suraj, M.V.; Byerly, K.; Wang, A.; Wang, Y.; Lee, J.K.; Ohodnicki, P.R. Review on soft magnetic metal and inorganic oxide nanocomposites for power applications. J. Alloys Compd. 2021, 870, 159500. [Google Scholar] [CrossRef]

- Périgo, E.A.; Weidenfeller, B.; Kollár, P.; Füzer, J. Past, present, and future of soft magnetic composites. Appl. Phys. Rev. 2018, 5, 031301. [Google Scholar] [CrossRef]

- Sunday, K.J.; Taheri, M.L. Soft magnetic composites: Recent advancements in the technology. Met. Powder Rep. 2017, 72, 425–429. [Google Scholar] [CrossRef]

- Schoppa, A.; Delarbre, P. Soft magnetic powder composites and potential applications in modern electric machines and devices. IEEE Trans. Magn. 2014, 50, 2004304. [Google Scholar] [CrossRef]

- Peng, Y.; Yi, Y.; Li, L.; Yi, J.; Nie, J.; Bao, C. Iron-based soft magnetic composites with Al2O3 insulation coating produced using sol–gel method. Mater. Des. 2016, 109, 390–395. [Google Scholar] [CrossRef]

- Li, W.; Li, W.; Ying, Y.; Yu, J.; Zheng, J.; Qiao, L.; Li, J.; Zhang, L.; Fan, L.; Wakiya, N.; et al. Magnetic and mechanical properties of iron-based soft magnetic composites coated with silane synergized by Bi2O3. J. Electron. Mater. 2021, 50, 2425–2435. [Google Scholar] [CrossRef]

- Yaghtin, M.; Taghvaei, A.H.; Hashemi, B.; Janghorban, K. Structural and magnetic properties of Fe–Al2O3 soft magnetic composites prepared using the sol–gel method. Int. J. Mater. Res. 2014, 105, 474–479. [Google Scholar] [CrossRef]

- Li, K.; Cheng, D.; Yu, H.; Liu, Z. Process optimization and magnetic properties of soft magnetic composite cores based on phosphated and mixed resin coated Fe powders. J. Magn. Magn. Mater. 2020, 501, 166455. [Google Scholar] [CrossRef]

- Peng, Y.; Chen, L. Research progress on insulation coating technology for soft magnetic composites. Recent Pat. Mater. Sci. 2015, 8, 239–246. [Google Scholar] [CrossRef]

- Zhao, G.; Wu, C.; Yan, M. Enhanced magnetic properties of Fe soft magnetic composites by surface oxidation. J. Magn. Magn. Mater. 2016, 399, 51–57. [Google Scholar] [CrossRef]

- Wu, S.; Sun, A.; Lu, Z.; Cheng, C. Fabrication and properties of iron-based soft magnetic composites coated with parylene via chemical vapor deposition polymerization. Mater. Chem. Phys. 2015, 153, 359–364. [Google Scholar] [CrossRef]

- Matsushita, N.; Hatanaka, S.; Abe, M. Fe/ferrite composite magnetic cores far exceeding snoek’s limit fabricated by simplified ferrite plating in open air. IEEE Trans. Magn. 2004, 40, 2011–2013. [Google Scholar] [CrossRef]

- Dias, M.M.; Mozetic, H.J.; Barboza, J.S.; Martins, R.M.; Pelegrini, L.; Schaeffer, L. Influence of resin type and content on electrical and magnetic properties of soft magnetic composites (SMCs). Powder Technol. 2013, 237, 213–220. [Google Scholar] [CrossRef]

- Wu, S.; Pan, S.; Liu, J.; Fan, J.; Zhou, X.; Gao, H.; Zhang, D.; Wang, Y.; Li, Y.; Sun, A. Effect of compaction parameters on the magnetic and corrosive properties of soft magnetic composites with parylene insulation. J. Supercond. Novel Magn. 2019, 32, 4033–4041. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, S.; Zhang, W.; Peng, K. Influence of processed parameters on the magnetic properties of Fe/Fe3O4 composite cores. J. Mater. Sci. Mater. Electron. 2021, 32, 1233–1241. [Google Scholar] [CrossRef]

- Yaghtin, M.; Taghvaei, A.H.; Hashemi, B.; Janghorban, K. Effect of heat treatment on magnetic properties of iron-based soft magnetic composites with Al2O3 insulation coating produced by sol–gel method. J. Alloys Compd. 2013, 581, 293–297. [Google Scholar] [CrossRef]

- Zhao, G.; Wu, C.; Yan, M. Evolution of the insulation matrix and influences on the magnetic performance of Fe soft magnetic composites during annealing. J. Alloys Compd. 2016, 685, 231–236. [Google Scholar] [CrossRef]

- Yi, Y.; Peng, Y.; Xia, C.; Wu, L.; Ke, X.; Nie, J. Influence of heat treatment on microstructures and magnetic properties of Fe-based soft magnetic composites prepared by co-precipitation method. J. Magn. Magn. Mater. 2019, 476, 100–105. [Google Scholar] [CrossRef]

- Ren, L.; Zhao, J.; Wang, S.-J.; Han, B.-Z.; Dang, Z.-M. Dielectric and magnetic properties of Fe@FexOy/epoxy resin nanocomposites as high-performance electromagnetic insulating materials. Compos. Sci. Technol. 2015, 114, 57–63. [Google Scholar] [CrossRef]

- Birčáková, Z.; Kollár, P.; Füzer, J.; Bureš, R.; Fáberová, M. Analytical expression for initial magnetization curve of Fe-based soft magnetic composite material. J. Magn. Magn. Mater. 2017, 423, 140–144. [Google Scholar] [CrossRef]

- Wu, S.; Sun, A.; Zhai, F.; Wang, J.; Zhang, Q.; Xu, W.; Logan, P.; Volinsky, A.A. Annealing effects on magnetic properties of silicone-coated iron-based soft magnetic composites. J. Magn. Magn. Mater. 2012, 324, 818–822. [Google Scholar] [CrossRef]

- Wang, J.; He, Y.; Li, G.; Xu, J.; Liu, X. Effect of annealing treatment on the magnetic properties with wide temperature range of co-doped FeSi soft magnetic composites. J. Magn. Magn. Mater. 2023, 567, 170343. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, L.; Chen, Y.; Chen, F.; Qu, X.; Xie, C.; Zhang, L. Magnetic properties of iron-based soft magnetic composites prepared by utilizing polyimide insulating layer. J. Magn. Magn. Mater. 2019, 486, 165287. [Google Scholar] [CrossRef]

- Huang, M.; Wu, C.; Jiang, Y.; Yan, M. Evolution of phosphate coatings during high-temperature annealing and its influence on the Fe and FeSiAl soft magnetic composites. J. Alloys Compd. 2015, 644, 124–130. [Google Scholar] [CrossRef]

- Li, W.; Wang, Z.; Ying, Y.; Yu, J.; Zheng, J.; Qiao, L.; Che, S. In-situ formation of Fe3O4 and ZrO2 coated Fe-based soft magnetic composites by hydrothermal method. Ceram. Int. 2019, 45, 3864–3870. [Google Scholar] [CrossRef]

- Luo, Z.; Fan, X.; Hu, W.; Luo, F.; Li, G.; Li, Y.; Liu, X.; Wang, J. Controllable SiO2 insulating layer and magnetic properties for intergranular insulating Fe-6.5wt.%Si/SiO2 composites. Adv. Powder Technol. 2019, 30, 538–543. [Google Scholar] [CrossRef]

- Luo, Z.; Fan, X.; Hu, W.; Luo, F.; Li, G.; Li, Y.; Wang, J.; Liu, X. Effect of sintering temperature on microstructure and magnetic properties for Fe-Si soft magnetic composites prepared by water oxidation combined with spark plasma sintering. J. Magn. Magn. Mater. 2019, 491, 165615. [Google Scholar] [CrossRef]

- Lei, J.; Zheng, J.; Zheng, H.; Qiao, L.; Ying, Y.; Cai, W.; Li, W.; Yu, J.; Lin, M.; Che, S. Effects of heat treatment and lubricant on magnetic properties of iron-based soft magnetic composites with Al2O3 insulating layer by one-pot synthesis method. J. Magn. Magn. Mater. 2019, 472, 7–13. [Google Scholar] [CrossRef]

- Zhou, B.; Dong, Y.; Liu, L.; Chang, L.; Bi, F.; Wang, X. Enhanced soft magnetic properties of the Fe-based amorphous powder cores with novel TiO2 insulation coating layer. J. Magn. Magn. Mater. 2019, 474, 1–8. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, X.; Hu, W.; Luo, Z.; Yang, Z.; Li, G.; Li, Y. Microstructure and magnetic properties of MnO2 coated iron soft magnetic composites prepared by ball milling. J. Magn. Magn. Mater. 2020, 514, 167295. [Google Scholar] [CrossRef]

- Peng, Y.; Yi, Y.; Li, L.; Ai, H.; Wang, X.; Chen, L. Fe-based soft magnetic composites coated with NiZn ferrite prepared by a co-precipitation method. J. Magn. Magn. Mater. 2017, 428, 148–153. [Google Scholar] [CrossRef]

- Lauda, M.; Fuzer, J.; Kollar, P.; Streckova, M.; Bures, R.; Kovac, J.; Bat’kova, M.; Bat’ko, I. Magnetic properties and loss separation in FeSi/MnZnFe2O4 soft magnetic composites. J. Magn. Magn. Mater. 2016, 411, 12–17. [Google Scholar] [CrossRef]

- Yang, B.; Li, X.; Yang, X.; Yu, R. Chemical synthesis of Fe/Fe3O4 core-shell composites with enhanced soft magnetic performances. J. Magn. Magn. Mater. 2017, 428, 6–11. [Google Scholar] [CrossRef]

- Shokrollahi, H.; Janghorban, K.; Mazaleyrat, F.; Bue, M.L.; Ji, V.; Tcharkhtchi, A. Investigation of magnetic properties, residual stress and densification in compacted iron powder specimens coated with polyepoxy. Mater. Chem. Phys. 2009, 114, 588–594. [Google Scholar] [CrossRef]

- Shokrollahi, H.; Janghorban, K. Different annealing treatments for improvement of magnetic and electrical properties of soft magnetic composites. J. Magn. Magn. Mater. 2007, 317, 61–67. [Google Scholar] [CrossRef]

- Hemmati, I.; Madaah Hosseini, H.R.; Kianvash, A. The correlations between processing parameters and magnetic properties of an iron–resin soft magnetic composite. J. Magn. Magn. Mater. 2006, 305, 147–151. [Google Scholar] [CrossRef]

- Hira, S.-I.; Yoshioka, M. Micro-cutting of polytetrafluoroetylene (PTFE) for application of micro-fluidic devices. Key Eng. Mater. 2007, 329, 577–582. [Google Scholar] [CrossRef]

- Fang, S.A. Modification and application situation of PTFE in anticorrosive heat exchanger. Mater. Mech. Eng. 2007, 31, 1–4. [Google Scholar]

- Hong, W.P.; Zhang, H. Application of PTFE heat exchanger in low temperature waste heat of big coal-fired power plants. Appl. Mech. Mater. 2015, 789–790, 503–507. [Google Scholar] [CrossRef]

- Müller, J.; Illek, R.; Michos, G.; Faust, K.; Hubert, M.; Franke, J. A system embracing observation of different PTFE-compounds in the sealing application of rotary manifolds. Appl. Mech. Mater. 2015, 805, 123–130. [Google Scholar] [CrossRef]

- Kollár, P.; Birčáková, Z.; Füzer, J.; Bureš, R.; Fáberová, M. Power loss separation in Fe-based composite materials. J. Magn. Magn. Mater. 2013, 327, 146–150. [Google Scholar] [CrossRef]

- Kollár, P.; Olekšáková, D.; Vojtek, V.; Füzer, J.; Fáberová, M.; Bureš, R. Steinmetz law for AC magnetized iron-phenolformaldehyde resin soft magnetic composites. J. Magn. Magn. Mater. 2017, 424, 245–250. [Google Scholar] [CrossRef]

- Taghvaei, A.H.; Shokrollahi, H.; Janghorban, K.; Abiri, H. Eddy current and total power loss separation in the iron–phosphate–polyepoxy soft magnetic composites. Mater. Des. 2009, 30, 3989–3995. [Google Scholar] [CrossRef]

- Zhang, Y.; Jin, H.; Shi, Y. General properties of low-frequency power losses in Fe-based nanocrystalline soft magnetic alloys. J. Mater. Sci. Technol. 2000, 16, 37–44. [Google Scholar]

- Dobák, S.; Füzer, J.; Kollár, P.; Fáberová, M.; Bureš, R. Interplay of domain walls and magnetization rotation on dynamic magnetization process in iron/polymer–matrix soft magnetic composites. J. Magn. Magn. Mater. 2017, 426, 320–327. [Google Scholar] [CrossRef]

- Xiao, L.; Li, M.; Cheng, W.; Fan, H.; Liu, G.; Sun, Y. Magnetic properties and eddy current losses in Fe-based soft magnetic composites. Int. J. Appl. Electrom. 2016, 52, 1433–1441. [Google Scholar] [CrossRef]

- Blyskun, P.; Kowalczyk, M.; Lukaszewicz, G.; Cieslak, G.; Ferenc, J.; Zackiewicz, P.; Kolano-Burian, A. Influence of particles size fraction on magnetic properties of soft magnetic composites prepared from a soft magnetic nanocrystalline powder with no synthetic oxide layer. Mater. Sci. Eng. B 2021, 272, 115357. [Google Scholar] [CrossRef]

- Wang, J.; Guo, Z.; Zeng, Q.; Hang, G.; Xue, Z.; Chen, D.; Liang, Z.; Sun, H. Magnetic properties regulation and loss contribution analysis for Fe-based amorphous powder cores doped with micron-sized FeSi powders. J. Magn. Magn. Mater. 2020, 510, 166931. [Google Scholar] [CrossRef]

- Liu, D.; Liu, X.; Wang, J.; Mao, X.; Xu, X.; Fan, X. The influence of Fe nanoparticles on microstructure and magnetic properties of Fe-6.5wt%Si soft magnetic composites. J. Alloys Compd. 2020, 835, 155215. [Google Scholar] [CrossRef]

- Xu, H.; He, K.; Qiu, Y.; Wang, Z.; Cheng, L.; Dong, Y.; Xiao, X.; Wang, Q. Investigation of the magnetic properties of Fe73.5Cu1Nb3Si13.5B9 nanocrystalline dust core. J. Funct. Mater. 2000, 42–44. [Google Scholar]

- Tian, M.; Xu, J.; Yang, S.; Wang, J.; Yang, T.; Li, G.; Chen, Q.; Liu, X. Effects of heat treatment and compaction pressure on the microstructure and magnetic properties of core-shell structured FeSiBNbCu/SiO2 soft magnetic composites. J. Alloys Compd. 2022, 923, 166394. [Google Scholar] [CrossRef]

| PTFE Contents (wt%) | Effective Permeability | Saturation Magnetization (emu/g) | Coercivity (Oe) | Total Core Loss (mW/cm3) | Resistivity (mΩ·m) | ||

|---|---|---|---|---|---|---|---|

| Bm = 50 mT | Bm = 100 mT | ||||||

| 1 kHz | 100 kHz | 50 kHz | 50 kHz | ||||

| 0 | 71.0 | 68.5 | 217.6 | 15.2 | 695.1 | 3001 | 0.4 |

| 1 | 66.8 | 66.2 | 210.5 | 19.9 | 398.5 | 1874 | 4.3 |

| 2 | 60.8 | 60.4 | 197.5 | 35.5 | 415.4 | 1918 | 4.5 |

| 3 | 56.0 | 55.8 | 192.9 | 54.2 | 355 | 1705 | 19.9 |

| 4 | 44.5 | 44.2 | 187.0 | 62.2 | 416.5 | 1901 | 25.8 |

| 5 | 42.4 | 42.1 | 182.7 | 64 | 463.1 | 2057 | 97.3 |

| Compaction Pressure (MPa) | Density (g/cm3) | Resistivity (mΩ·m) |

|---|---|---|

| 540 | 6.53 | 9.4 |

| 594 | 6.61 | 12.9 |

| 648 | 6.74 | 19.9 |

| 702 | 6.79 | 10.8 |

| 756 | 6.85 | 7.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, M.; Luo, F.; Shang, Y.; Duan, Z. Influence of Polytetrafluoroethylene Content, Compaction Pressure, and Annealing Treatment on the Magnetic Properties of Iron-Based Soft Magnetic Composites. Molecules 2024, 29, 4019. https://doi.org/10.3390/molecules29174019

Song M, Luo F, Shang Y, Duan Z. Influence of Polytetrafluoroethylene Content, Compaction Pressure, and Annealing Treatment on the Magnetic Properties of Iron-Based Soft Magnetic Composites. Molecules. 2024; 29(17):4019. https://doi.org/10.3390/molecules29174019

Chicago/Turabian StyleSong, Mei, Fan Luo, Yajing Shang, and Zhongxia Duan. 2024. "Influence of Polytetrafluoroethylene Content, Compaction Pressure, and Annealing Treatment on the Magnetic Properties of Iron-Based Soft Magnetic Composites" Molecules 29, no. 17: 4019. https://doi.org/10.3390/molecules29174019

APA StyleSong, M., Luo, F., Shang, Y., & Duan, Z. (2024). Influence of Polytetrafluoroethylene Content, Compaction Pressure, and Annealing Treatment on the Magnetic Properties of Iron-Based Soft Magnetic Composites. Molecules, 29(17), 4019. https://doi.org/10.3390/molecules29174019