Reliability-Based Design Optimization for Polymer Electrolyte Membrane Fuel Cells: Tackling Dimensional Uncertainties in Manufacturing and Their Effects on Costs of Cathode Gas Diffusion Layer and Bipolar Plates

Abstract

1. Introduction

2. Numerical PEMFC Model

2.1. Model Assumptions

- The operating pressure is low, and hence, ideal gas mixtures are assumed in the gas phase.

- The velocity of flow is low and laminar.

- The effect of gravity is neglected.

- In the porous region, immobile liquid saturation is neglected.

2.2. Governing Equations and Source Terms

| Governing Equations | ||

|---|---|---|

| Mass | (1) | |

| Momentum | (2) | |

| Species | Flow channels and porous media: | (3) |

| Water transport in membrane: | (4) | |

| Charge | Proton transport: | (5) |

| Electron transport: | (6) | |

| Energy | (7) | |

| Description | Expressions | |

|---|---|---|

| Momentum | ||

| Porous media | ||

| Species | ||

| H2 in anode CL | ||

| O2 in cathode CL | ||

| Water in anode CL | ||

| Water in cathode CL | ||

| Energy | ||

| In anode CL | ||

| In cathode CL | ||

| In membrane | ||

| Charge | ||

| In CLs | ||

| Electrochemical reactions | ||

| General form | ||

| In the anode side (HOR) | ||

| In the cathode side (ORR) | ||

| Transfer current density, | ||

| In anode CL (HOR) | (8) | |

| In cathode CL (ORR) | (9) | |

| Overpotential | ||

| General form | where, | (10) |

| Description | Value/Expression | |

|---|---|---|

| Exchange current density of HOR × ECSA per unit CL volume, | 1.2 × 1010 A/m3 | [34] |

| Exchange current density for the ORR, | 2.0 × 10−4 A/cm2-Pt | [34] |

| Activation energy of the anode, | 10.0 kJ/mol | [38] |

| Activation energy of the cathode, | 70.0 kJ/mol | [39] |

| Transfer coefficient of the HOR, | 1 | [40] |

| Transfer coefficient of the ORR, | 1 | [40] |

| Reference H2/O2 molar concentration, | 40.88 mol/m3 | [34] |

| Permeability of the GDL, | 1.0 × 10−12 m2 | [41] |

| Permeability of the CL, | 1.0 × 10−13 m2 | [41] |

| Porosity of the GDL, | 0.64 | [42] |

| Porosity of the CL, | 0.4 | [43] |

| Equivalent weight of electrolyte in the membrane, | 1.1 kg/mol | [44] |

| Youngs modulus of the GDL | 6.16MPa | [45] |

| Poisson ratio of the GDL | 0.09 | [36] |

| Faraday’s constant, | 96,485 C/mol | |

| Universal gas constant, | 8.314 | |

| H2 diffusivity in the anode gas channel, | 1.1028 × 10−4 m2/s | [46] |

| H2O diffusivity in the anode gas channel, | 1.1028 × 10−4 m2/s | [46] |

| O2 diffusivity in the cathode gas channel, | 3.2348 × 10−4 m2/s | [46] |

| H2O diffusivity in the cathode gas channel, | 7.35 × 10−5 m2/s | [46] |

| Multi component gas diffusivity ( | For nonporous regions | [47] |

| , . where, | (11) | |

| Effective diffusivity ( | For porous regions | (12) |

| Description | Expression | |

|---|---|---|

| Mixture density | (13) | |

| Gas mixture density | (14) | |

| Mixture velocity | (15) | |

| Mixture mass fraction | (16) | |

| Relative permeability | (17) | |

| (18) | ||

| Kinematic viscosity of the two-phase mixture | (19) | |

| Kinematic viscosity of the gas mixture | (20) | |

| where | (21) | |

| and , T in kelvin | (22) | |

| Relative mobility | (23) | |

| (24) | ||

| Diffusive mass flux | (25) | |

| Capillary pressure Pc | (26) | |

| Leverett function J(s) | (27) |

| Description | Expression | |

|---|---|---|

| Water activity | (28) | |

| Membrane water content | (29) | |

| Electro-osmotic drag (EOD) coefficient of water | (30) | |

| Proton conductivity | (31) | |

| Water diffusion coefficient | (32) | |

| Interfacial resistance of the water film | (33) |

2.3. Boundary Conditions and Numerical Implementation

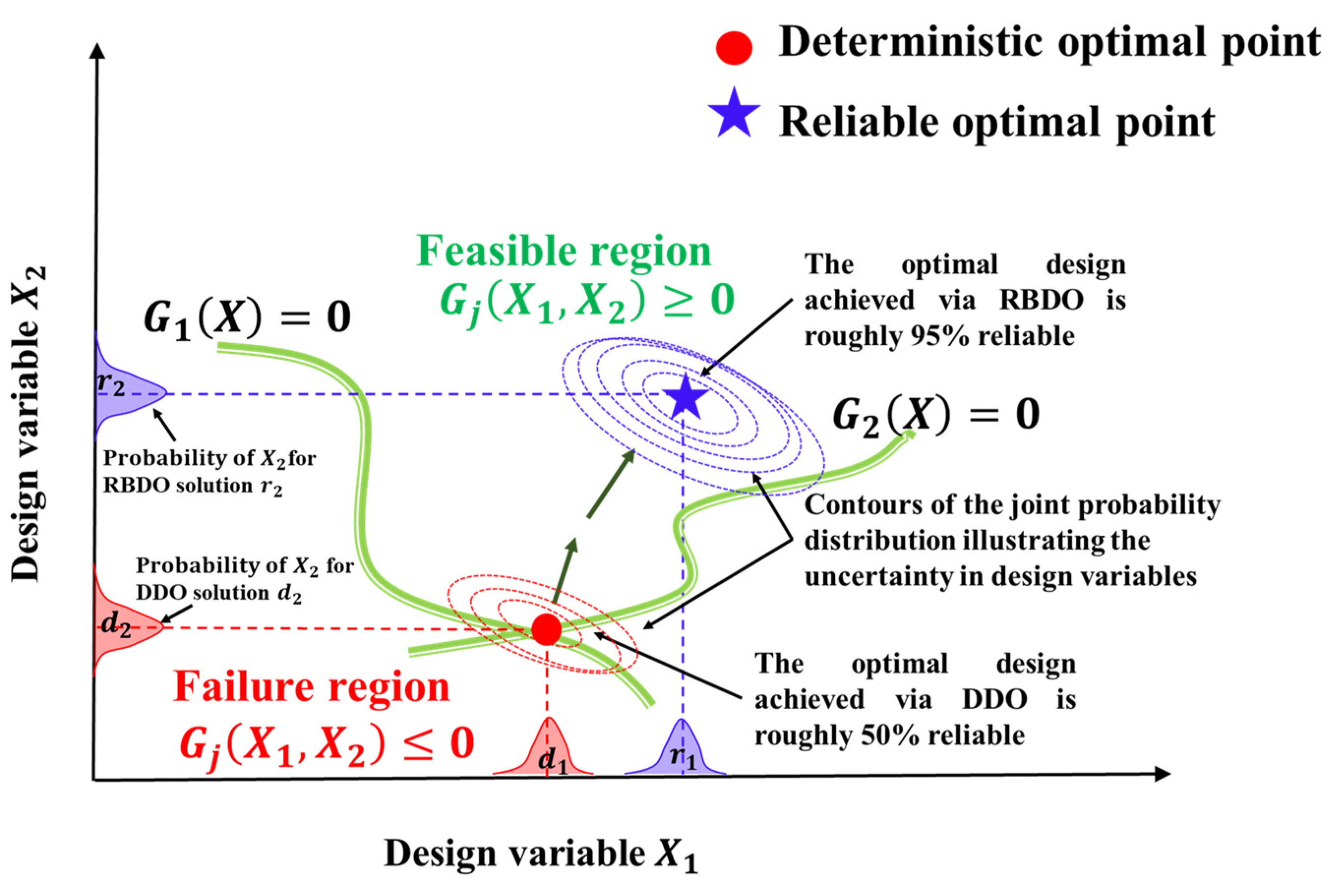

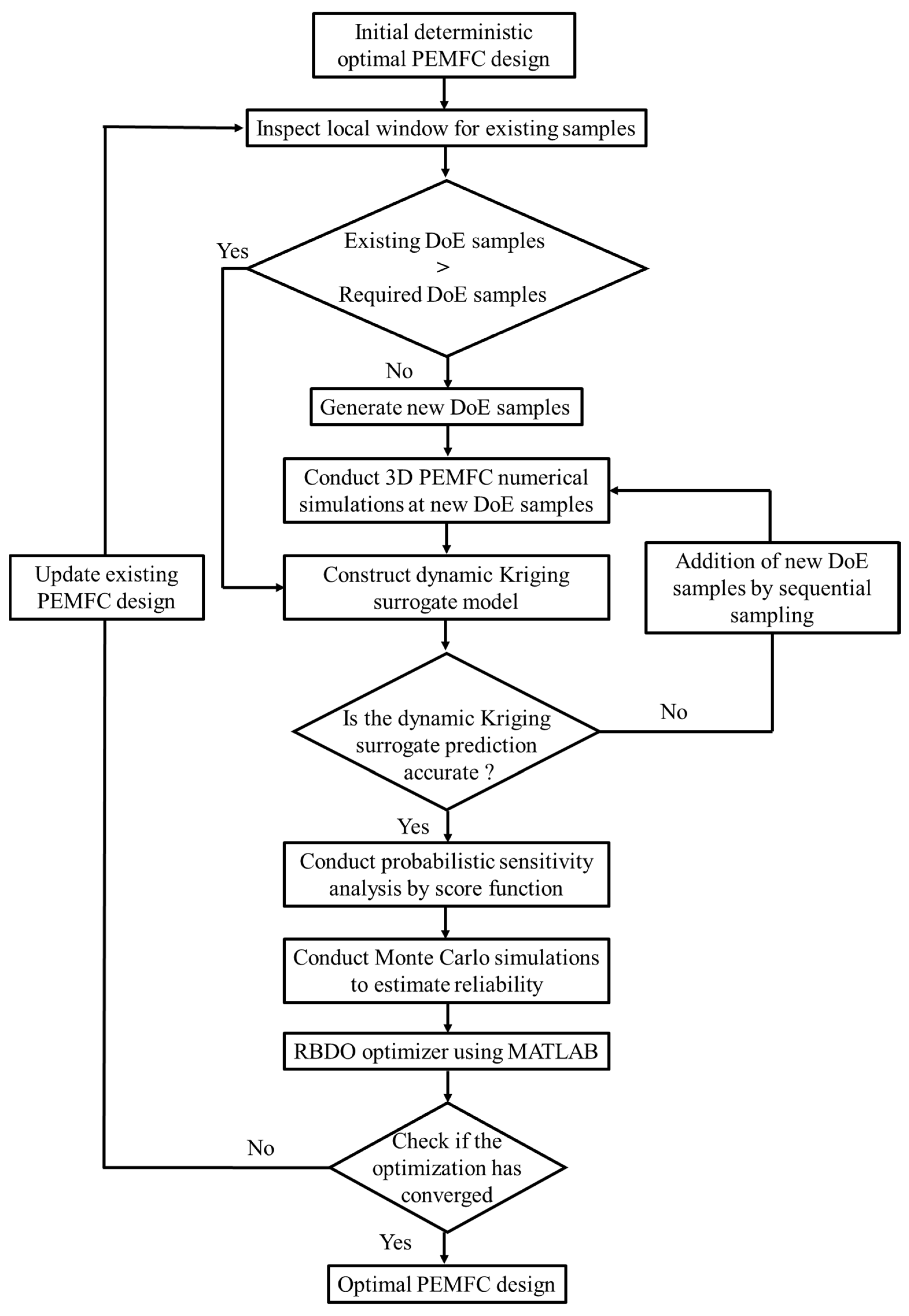

3. Overview of Design Optimization Strategies for Engineering Applications

4. Estimating the Material Costs of the Cathode GDL and BP in PEMFCs

5. Formulation of the Optimization Problem

6. Results and Discussion

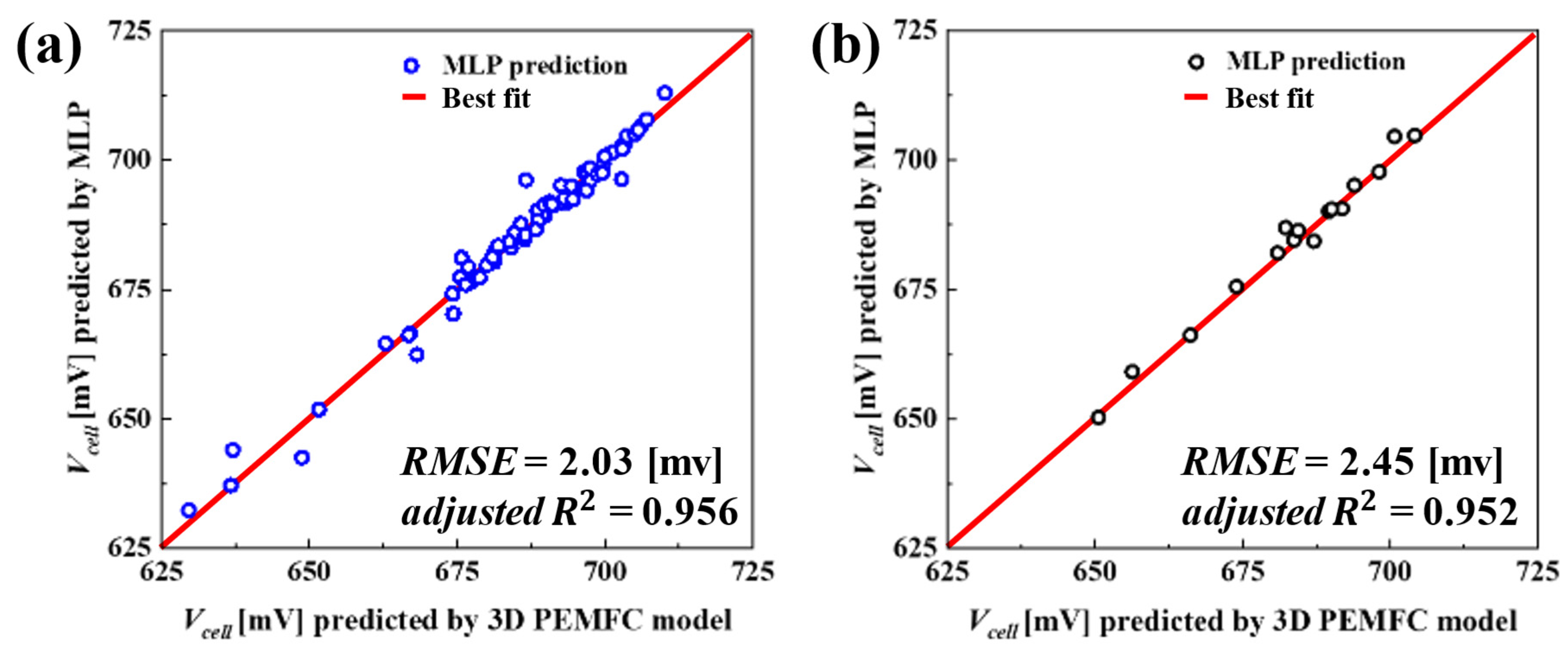

6.1. Evaluation of Predictive Capability of the MLP Surrogate

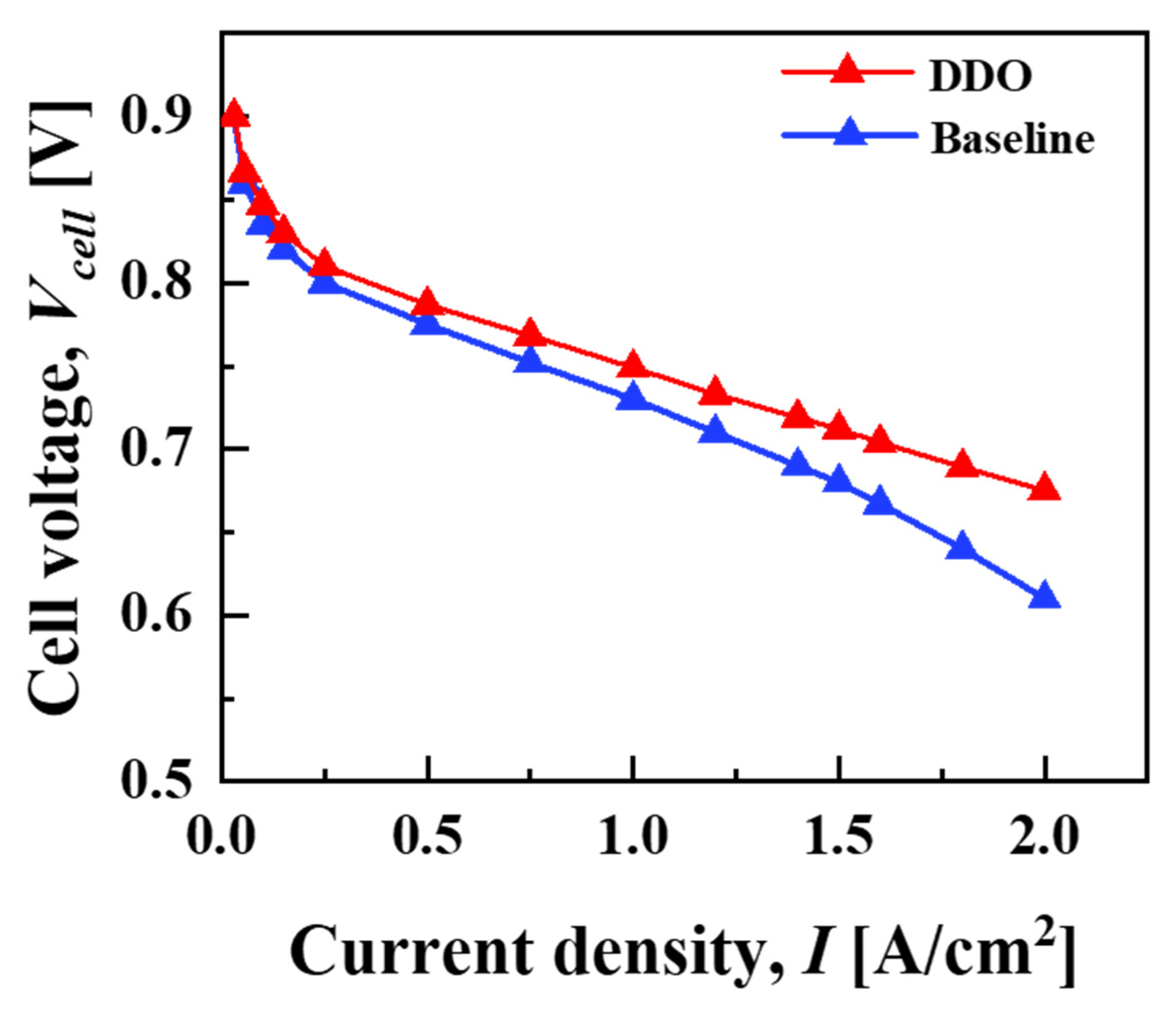

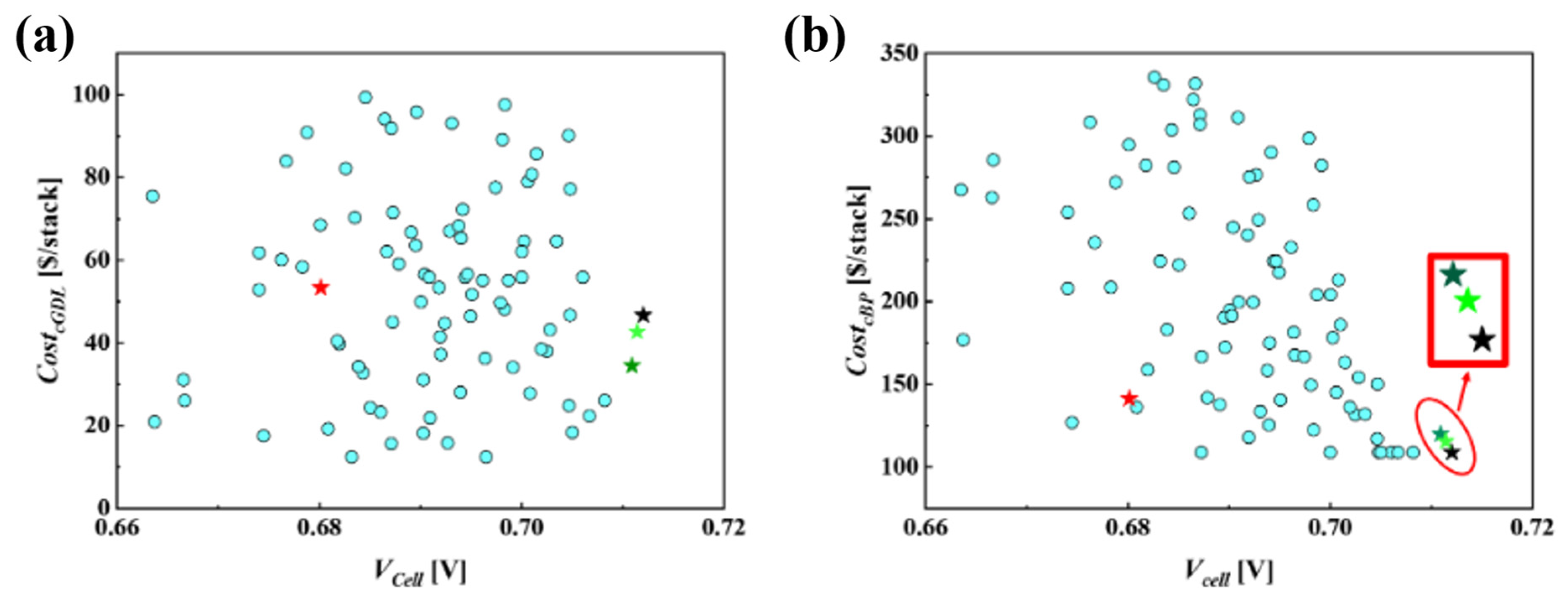

6.2. DDO to Access Superior PEMFC Performance

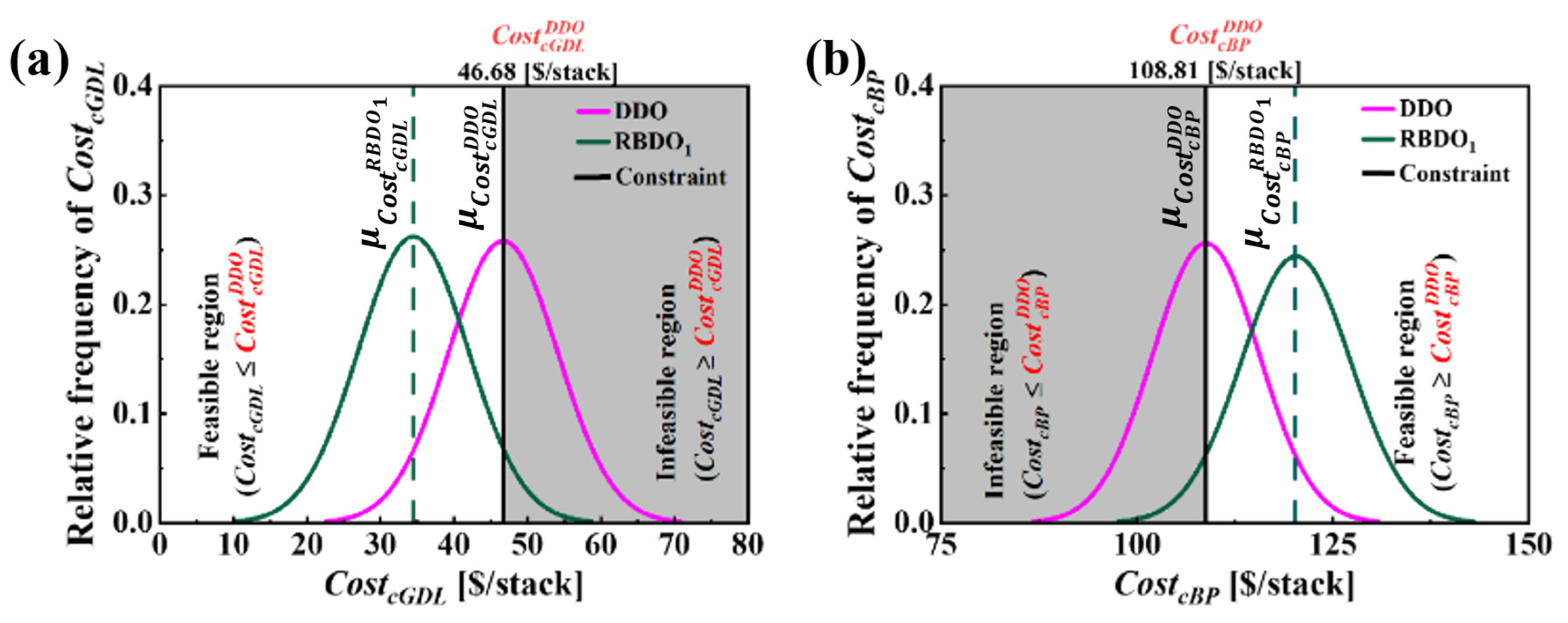

6.3. RBDO for Cathode, GDL and BP Material Costs

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| a | Ratio of active surface area per unit electrode volume: m2/m3 or water activity |

| A | Area, m2 |

| C | Molar concentration of species, mol/m3 |

| d | Vector of design variables or solution of a deterministic optimization problem; |

| D | Species diffusivity, m2/s |

| E | Activation energy, kJ/mol |

| EW | Equivalent weight of a dry membrane, kg/mol |

| f | Objective function that needs to be minimized or maximized in the optimization problem |

| F | Faraday’s constant, 96,487 C/mol |

| G(X) | Constraint condition for the -th constraint; the design is considered “fail” if G(X) fails to meet the constraint condition |

| i0 | Exchange current density, A/cm2 |

| id | Density estimation parameter |

| I | Operating current density, A/cm2 |

| j | Transfer current density, A/cm3, |

| Total number of constraint functions in the optimization problem | |

| k | Thermal conductivity, W/m·K, or Relative permeability, or index representing the specific objective function in the optimization problem |

| K | Hydraulic permeability, m2 |

| L | Amount of loading, |

| n | Number of electrons transferred in the electrode reaction |

| N | Number of design variables |

| MW | Molecular weight, kg/mol |

| MSE | Mean squared error |

| P | Pressure, Pa, |

| P(●) | Probability function |

| RMSE | Root mean squared error |

| s | Liquid saturation |

| S | Source term in the transport equation |

| t | Time |

| T | Temperature, K |

| Fluid velocity and superficial velocity in a porous medium, m/s | |

| V | Voltage, V or Volume, |

| X | Vector of the design variables in the optimization problem |

| Lower or upper bound of the i-th design variable | |

| Input variable | |

| Observed response | |

| Predicted response | |

| Mean value of the observed data | |

| z | Transport resistance coefficient |

Greek Symbols

| α | Transfer coefficient |

| Weight coefficient | |

| γ | Reaction order |

| δ | Thickness, m |

| ε | Volume fraction or error |

| η | Surface overpotential, V |

| Contact angle of the gas diffusion layer | |

| Water content | |

| Mean value of random design variables X, | |

| κ | Proton conductivity, S/m |

| Phase potential, V | |

| ρ | Density, kg/m |

| σ | Electronic conductivity, S/m |

| τ | Viscous shear stress, N/m2 |

| ξ | Stoichiometry flow ratio |

| Ω | Oxygen transport resistance |

Superscripts

| a | Anode |

| aCL | Anode catalyst layer |

| c | Cathode |

| C | Carbon |

| CL | Catalyst layer |

| cCL | Cathode catalyst layer |

| ch | Gas channel |

| e | Electrolyte |

| ECSA | Electro chemical active surface area |

| gdl | Gas diffusion layer |

| Index representing the failure of the -th constraint | |

| I/C | Ionomer to carbon weight ratio |

| i | Species or index representing the lower or upper bound of the N-th design variable |

| in | Channel inlet |

| int | Interface |

| j | Index representing the specific constraint function in a problem with multiple constraints |

| k | Index representing the specific objective function in the optimization problem |

| MEA | Membrane electrode assembly |

| mem | Membrane |

| min | Minimum |

| N | Number of design variables |

| nd | n-th random design variable |

| Pt/C | Weight ratio of platinum to carbon |

| Pt | Platinum |

| s | Solid, surface |

| T | Temperature |

| u | Momentum equation |

| w | Water |

| 0 | Initial conditions or standard conditions, i.e., 298.15 K and 101.3 kPa (1 atm) |

Abbreviations

| BP | Bipolar plate |

| CFD | Computational fluid dynamics |

| CL | Catalyst layer |

| DDO | Deterministic design optimization |

| DKG | Dynamic Kriging |

| DoE | Design of experiments |

| EMS | Energy management strategy |

| FC | Fuel cell |

| FCHEV | Fuel cell hybrid electric vehicle |

| GDL | Gas diffusion layer |

| HOR | Hydrogen oxidation reaction |

| MLP | Multi-layer perceptron |

| ORR | Oxygen reduction reaction |

| PSO | Particle swarm optimization |

| Multiphase mixture | |

| MCS | Monte Carlo simulation |

| MEA | Membrane electrode assembly |

| MSE | Mean square error |

| RAMDO | Reliability Analysis & Multidisciplinary Design Optimization |

| RBDO | Reliability-based design optimization |

| RMSE | Root mean square error |

| USA | United States of America |

References

- Parra, D.; Valverde, L.; Pino, F.J.; Patel, M.K. A Review on the Role, Cost and Value of Hydrogen Energy Systems for Deep Decarbonisation. Renew. Sustain. Energy Rev. 2019, 101, 279–294. [Google Scholar] [CrossRef]

- Sundén, B. Fuel Cell Types—Overview. Hydrog. Batter. Fuel Cells 2019, 101, 123–144. [Google Scholar] [CrossRef]

- Wang, Y.; Yuan, H.; Martinez, A.; Hong, P.; Xu, H.; Bockmiller, F.R. Polymer Electrolyte Membrane Fuel Cell and Hydrogen Station Networks for Automobiles: Status, Technology, and Perspectives. Adv. Appl. Energy 2021, 2, 100011. [Google Scholar] [CrossRef]

- Chugh, S.; Chaudhari, C.; Sonkar, K.; Sharma, A.; Kapur, G.S.; Ramakumar, S.S.V. Experimental and Modelling Studies of Low Temperature PEMFC Performance. Int. J. Hydrogen Energy 2020, 45, 8866–8874. [Google Scholar] [CrossRef]

- Wee, J.H. Applications of Proton Exchange Membrane Fuel Cell Systems. Renew. Sustain. Energy Rev. 2007, 11, 1720–1738. [Google Scholar] [CrossRef]

- Ponnusamy, P.; Pullithadathil, B.; Panthalingal, M.K. Technological Risks and Durability Issues for the Proton Exchange Membrane Fuel Cell Technology. PEM Fuel Cells Fundam. Adv. Technol. Pract. Appl. 2022, 279–314. [Google Scholar] [CrossRef]

- Mustain, W.E.; Chatenet, M.; Page, M.; Kim, Y.S. Durability Challenges of Anion Exchange Membrane Fuel Cells. Energy Environ. Sci. 2020, 13, 2805–2838. [Google Scholar] [CrossRef]

- Mei, J.; Meng, X.; Tang, X.; Li, H.; Hasanien, H.; Alharbi, M.; Dong, Z.; Shen, J.; Sun, C.; Fan, F.; et al. An Accurate Parameter Estimation Method of the Voltage Model for Proton Exchange Membrane Fuel Cells. Energies 2024, 17, 2917. [Google Scholar] [CrossRef]

- Müller, P. Simulation Based Optimal Design. Handb. Stat. 2005, 25, 509–518. [Google Scholar] [CrossRef]

- Song, D.; Wang, Q.; Liu, Z.; Navessin, T.; Eikerling, M.; Holdcroft, S. Numerical Optimization Study of the Catalyst Layer of PEM Fuel Cell Cathode. J. Power Sources 2004, 126, 104–111. [Google Scholar] [CrossRef]

- Grigoriev, S.A.; Kalinnikov, A.A.; Kuleshov, N.V.; Millet, P. Numerical Optimization of Bipolar Plates and Gas Diffusion Electrodes for PBI-Based PEM Fuel Cells. Int. J. Hydrogen Energy 2013, 38, 8557–8567. [Google Scholar] [CrossRef]

- Kim, A.R.; Jung, H.M.; Um, S. An Engineering Approach to Optimal Metallic Bipolar Plate Designs Reflecting Gas Diffusion Layer Compression Effects. Energy 2014, 66, 50–55. [Google Scholar] [CrossRef]

- Tang, X.; Shi, L.; Zhang, Y.; Li, B.; Xu, S.; Song, Z. Degradation Adaptive Energy Management Strategy for FCHEV Based on the Rule-DDPG Method: Tailored to the Current SOH of the Powertrain. IEEE Trans. Transp. Electrif. 2024. [Google Scholar] [CrossRef]

- Tu, J.; Choi, K.K.; Park, Y.H. A New Study on Reliability- Based Design Optimization. J. Mech. Des. 1999, 121, 557–564. [Google Scholar] [CrossRef]

- Ling, C.; Kuo, W.; Xie, M. An Overview of Adaptive-Surrogate-Model-Assisted Methods for Reliability-Based Design Optimization. IEEE Trans. Reliab. 2022, 72, 1–22. [Google Scholar] [CrossRef]

- Cho, H.; Choi, K.K.; Lee, I.; Lamb, D. Design Sensitivity Method for Sampling-Based RBDO with Varying Standard Deviation. J. Mech. Des. 2016, 138, 011405. [Google Scholar] [CrossRef]

- Managers, D.O.E.; Garland, N.; Adams, J. Final Technical Report: Metrology for Fuel Cell Manufacturing; 2010 DOE Annual Merit Review Project ID# MN00; NIST: Gaithersburg, MD, USA, 2010.

- Morse, E.; Dantan, J.Y.; Anwer, N.; Söderberg, R.; Moroni, G.; Qureshi, A.; Jiang, X.; Mathieu, L. Tolerancing: Managing Uncertainty from Conceptual Design to Final Product. CIRP Ann. 2018, 67, 695–717. [Google Scholar] [CrossRef]

- Hoffenson, S.; Söderberg, R. Systems Thinking in Tolerance and Quality-Related Design Decision-Making. Procedia CIRP 2015, 27, 59–64. [Google Scholar] [CrossRef]

- Peng, L.; Wan, Y.; Qiu, D.; Yi, P.; Lai, X. Dimensional Tolerance Analysis of Proton Exchange Membrane Fuel Cells with Metallic Bipolar Plates. J. Power Sources 2021, 481, 228927. [Google Scholar] [CrossRef]

- Bates, A.; Mukherjee, S.; Hwang, S.; Lee, S.C.; Kwon, O.; Choi, G.H.; Park, S. Simulation and Experimental Analysis of the Clamping Pressure Distribution in a PEM Fuel Cell Stack. Int. J. Hydrogen Energy 2013, 38, 6481–6493. [Google Scholar] [CrossRef]

- Qiu, D.; Peng, L.; Lai, X.; Ni, M.; Lehnert, W. Mechanical Failure and Mitigation Strategies for the Membrane in a Proton Exchange Membrane Fuel Cell. Renew. Sustain. Energy Rev. 2019, 113, 109289. [Google Scholar] [CrossRef]

- Irmscher, P.; Qui, D.; Janßen, H.; Lehnert, W.; Stolten, D. Impact of Gas Diffusion Layer Mechanics on PEM Fuel Cell Performance. Int. J. Hydrogen Energy 2019, 44, 23406–23415. [Google Scholar] [CrossRef]

- Tang, A.; Crisci, L.; Bonville, L.; Jankovic, J. An Overview of Bipolar Plates in Proton Exchange Membrane Fuel Cells. J. Renew. Sustain. Energy 2021, 13, 022701. [Google Scholar] [CrossRef]

- Porstmann, S.; Wannemacher, T.; Drossel, W.G. A Comprehensive Comparison of State-of-the-Art Manufacturing Methods for Fuel Cell Bipolar Plates Including Anticipated Future Industry Trends. J. Manuf. Process. 2020, 60, 366–383. [Google Scholar] [CrossRef]

- Turan, C.; Cora, Ö.N.; Koç, M. Effect of Manufacturing Processes on Contact Resistance Characteristics of Metallic Bipolar Plates in PEM Fuel Cells. Int. J. Hydrogen Energy 2011, 36, 12370–12380. [Google Scholar] [CrossRef]

- Barzegari, M.M.; Khatir, F.A. Study of Thickness Distribution and Dimensional Accuracy of Stamped Metallic Bipolar Plates. Int. J. Hydrogen Energy 2019, 44, 31360–31371. [Google Scholar] [CrossRef]

- Liu, D.; Peng, L.; Lai, X. Effect of Assembly Error of Bipolar Plate on the Contact Pressure Distribution and Stress Failure of Membrane Electrode Assembly in Proton Exchange Membrane Fuel Cell. J. Power Sources 2010, 195, 4213–4221. [Google Scholar] [CrossRef]

- Vaz, N.; Choi, J.; Cha, Y.; Kong, J.; Park, Y.; Ju, H. Multi-Objective Optimization of the Cathode Catalyst Layer Micro-Composition of Polymer Electrolyte Membrane Fuel Cells Using a Multi-Scale, Two-Phase Fuel Cell Model and Data-Driven Surrogates. J. Energy Chem. 2023, 81, 28–41. [Google Scholar] [CrossRef]

- Chinannai, M.F.; Lee, J.; Ju, H. Numerical Study for Diagnosing Various Malfunctioning Modes in PEM Fuel Cell Systems. Int. J. Hydrogen Energy 2020, 45, 11714–11732. [Google Scholar] [CrossRef]

- Choi, J.; Kim, E.; Cha, Y.; Ghasemi, M.; Ju, H. Probing the Influence of Nonuniform Pt Particle Size Distribution Using a Full Three-Dimensional, Multiscale, Multiphase Polymer Electrolyte Membrane Fuel Cell Model. Electrochim. Acta 2022, 405, 139811. [Google Scholar] [CrossRef]

- Chippar, P.; Kyeongmin, O.; Kang, K.; Ju, H. A Numerical Investigation of the Effects of GDL Compression and Intrusion in Polymer Electrolyte Fuel Cells (PEFCs). Int. J. Hydrogen Energy 2012, 37, 6326–6338. [Google Scholar] [CrossRef]

- Wang, C.Y.; Cheng, P. Multiphase Flow and Heat Transfer in Porous Media. Adv. Heat Transf. 1997, 30, 93–196. [Google Scholar] [CrossRef]

- Jo, A.; Ju, H. Numerical Study on Applicability of Metal Foam as Flow Distributor in Polymer Electrolyte Fuel Cells (PEFCs). Int. J. Hydrogen Energy 2018, 43, 14012–14026. [Google Scholar] [CrossRef]

- Lim, K.; Vaz, N.; Lee, J.; Ju, H. Advantages and Disadvantages of Various Cathode Flow Field Designs for a Polymer Electrolyte Membrane Fuel Cell. Int. J. Heat Mass Transf. 2020, 163, 120497. [Google Scholar] [CrossRef]

- Chippar, P.; Oh, K.; Kim, D.; Hong, T.W.; Kim, W.; Ju, H. Coupled Mechanical Stress and Multi-Dimensional CFD Analysis for High Temperature Proton Exchange Membrane Fuel Cells (HT-PEMFCs). Int. J. Hydrogen Energy 2013, 38, 7715–7724. [Google Scholar] [CrossRef]

- Springer, T.E. Polymer Electrolyte Fuel Cell Model. J. Electrochem. Soc. 1991, 138, 2334. [Google Scholar] [CrossRef]

- Hao, L.; Moriyama, K.; Gu, W.; Wang, C.-Y. Modeling and Experimental Validation of Pt Loading and Electrode Composition Effects in PEM Fuel Cells. J. Electrochem. Soc. 2015, 169, 014503. [Google Scholar] [CrossRef]

- Gerling, C.; Hanauer, M.; Berner, U.; Andreas Friedrich, K. PEM Single Cells under Differential Conditions: Full Factorial Parameterization of the ORR and HOR Kinetics and Loss Analysis. J. Electrochem. Soc. 2022, 169, 014503. [Google Scholar] [CrossRef]

- Kang, K.; Ju, H. Numerical Modeling and Analysis of Micro-Porous Layer Effects in Polymer Electrolyte Fuel Cells. J. Power Sources 2009, 194, 763–773. [Google Scholar] [CrossRef]

- Basu, S.; Wang, C.Y.; Chen, K.S. Analytical Model of Flow Maldistribution in Polymer Electrolyte Fuel Cell Channels. Chem. Eng. Sci. 2010, 65, 6145–6154. [Google Scholar] [CrossRef]

- Aquah, G.E.E.; Niblett, D.; Shokri, J.; Niasar, V. Characterisation of Hydraulic Properties of Commercial Gas Diffusion Layers: Toray, SGL, MGL, Woven Carbon Cloth. Sci. Rep. 2024, 14, 18812. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, A.; Hattori, T.; Miura, R.; Tsuboi, H.; Hatakeyama, N.; Takaba, H.; Williams, M.C.; Miyamoto, A. Porosity and Pt Content in the Catalyst Layer of PEMFC: Effects on Diffusion and Polarization Characteristics. Int. J. Electrochem. Sci. 2010, 5, 1948–1961. [Google Scholar] [CrossRef]

- Ju, H.; Meng, H.; Wang, C.Y. A Single-Phase, Non-Isothermal Model for PEM Fuel Cells. Int. J. Heat Mass Transf. 2005, 48, 1303–1315. [Google Scholar] [CrossRef]

- Xing, X.Q.; Lum, K.W.; Poh, H.J.; Wu, Y.L. Optimization of Assembly Clamping Pressure on Performance of Proton-Exchange Membrane Fuel Cells. J. Power Sources 2010, 195, 62–68. [Google Scholar] [CrossRef]

- Jo, A.; Ahn, S.; Oh, K.; Kim, W.; Ju, H. Effects of Metal Foam Properties on Flow and Water Distribution in Polymer Electrolyte Fuel Cells (PEFCs). Int. J. Hydrogen Energy 2018, 43, 14034–14046. [Google Scholar] [CrossRef]

- Bird, R.B.; Warren, E.; Stewart, E.N.L. Transport Phenomena, 3rd ed.; Wiley: Hoboken, NJ, USA, 2006; Volume 1, ISBN 0470606924/9780470606926. [Google Scholar]

- Heo, S.; Choi, J.; Park, Y.; Vaz, N.; Ju, H. Reliability-Based Design Optimization of the PEMFC Flow Field with Consideration of Statistical Uncertainty of Design Variables. Energies 2024, 17, 1882. [Google Scholar] [CrossRef]

- Thompson, S.T.; James, B.D.; Huya-Kouadio, J.M.; Houchins, C.; DeSantis, D.A.; Ahluwalia, R.; Wilson, A.R.; Kleen, G.; Papageorgopoulos, D. Direct Hydrogen Fuel Cell Electric Vehicle Cost Analysis: System and High-Volume Manufacturing Description, Validation, and Outlook. J. Power Sources 2018, 399, 304–313. [Google Scholar] [CrossRef]

- Sinha, J.; Lasher, S.; Yang, Y.; Kopf, P. Direct Hydrogen PEMFC Manufacturing Cost Estimation for Automotive Applications Fuel Cell Tech Team Review Acknowledgement and Disclaimer; TIAX: Lexington, MA, USA, 2008. [Google Scholar]

- James, B.D.; Moton, J.M.; Colella, W.G. Mass Production Cost Estimation of Direct H2 PEM Fuel Cell Systems for Transportation Applications: 2013 Update. In Proceedings of the ASME 2014 8th International Conference on Energy Sustainability, ES 2014 Collocated with the ASME 2014 12th International Conference on Fuel Cell Science, Engineering and Technology, Boston, MA, USA, 30 June 30–2 July 2014; p. V001T07A002. [Google Scholar]

- James, B.D.; DeSantis, D.A. Manufacturing Cost and Installed Price Analysis of Stationary Fuel Cell Systems; Strategic Analysis: Arlington, VA, USA, 2015; pp. 1–143. [Google Scholar]

- Ju, H. Investigation of the Effects of the Anisotropy of Gas-Diffusion Layers on Heat and Water Transport in Polymer Electrolyte Fuel Cells. J. Power Sources 2009, 191, 259–268. [Google Scholar] [CrossRef]

- Lim, K.; Kim, C.; Park, R.; Alam, A.; Ju, H. Enhancing PEMFC Performance through Orifice-Shaped Cathode Flow Field Designs: A Multiscale, Multiphase Simulation Study on Oxygen Supply and Water Removal. Chem. Eng. J. 2023, 475, 146147. [Google Scholar] [CrossRef]

- Yan, S.; Yang, M.; Sun, C.; Xu, S. Liquid Water Characteristics in the Compressed Gradient Porosity Gas Diffusion Layer of Proton Exchange Membrane Fuel Cells Using the Lattice Boltzmann Method. Energies 2023, 16, 6010. [Google Scholar] [CrossRef]

| Parameters | Baseline Design | Optimization Approach | ||

|---|---|---|---|---|

| DDO | ||||

| , [mm] | 0.215 | 0.188 | 0.139 | 0.172 |

| , [mm] | 0.54 | 0.300 | 0.382 | 0.349 |

| , [mm] | 1 | 0.614 | 0.855 | 0.687 |

| , [mm] | 1 | 0.310 | 0.300 | 0.300 |

| 0.681 | 0.712 | 0.710 | 0.711 | |

| [$/stack] | 53.38 | 46.68 | 34.43 | 42.59 |

| [$/stack] | 141.45 | 108.81 | 119.99 | 115.52 |

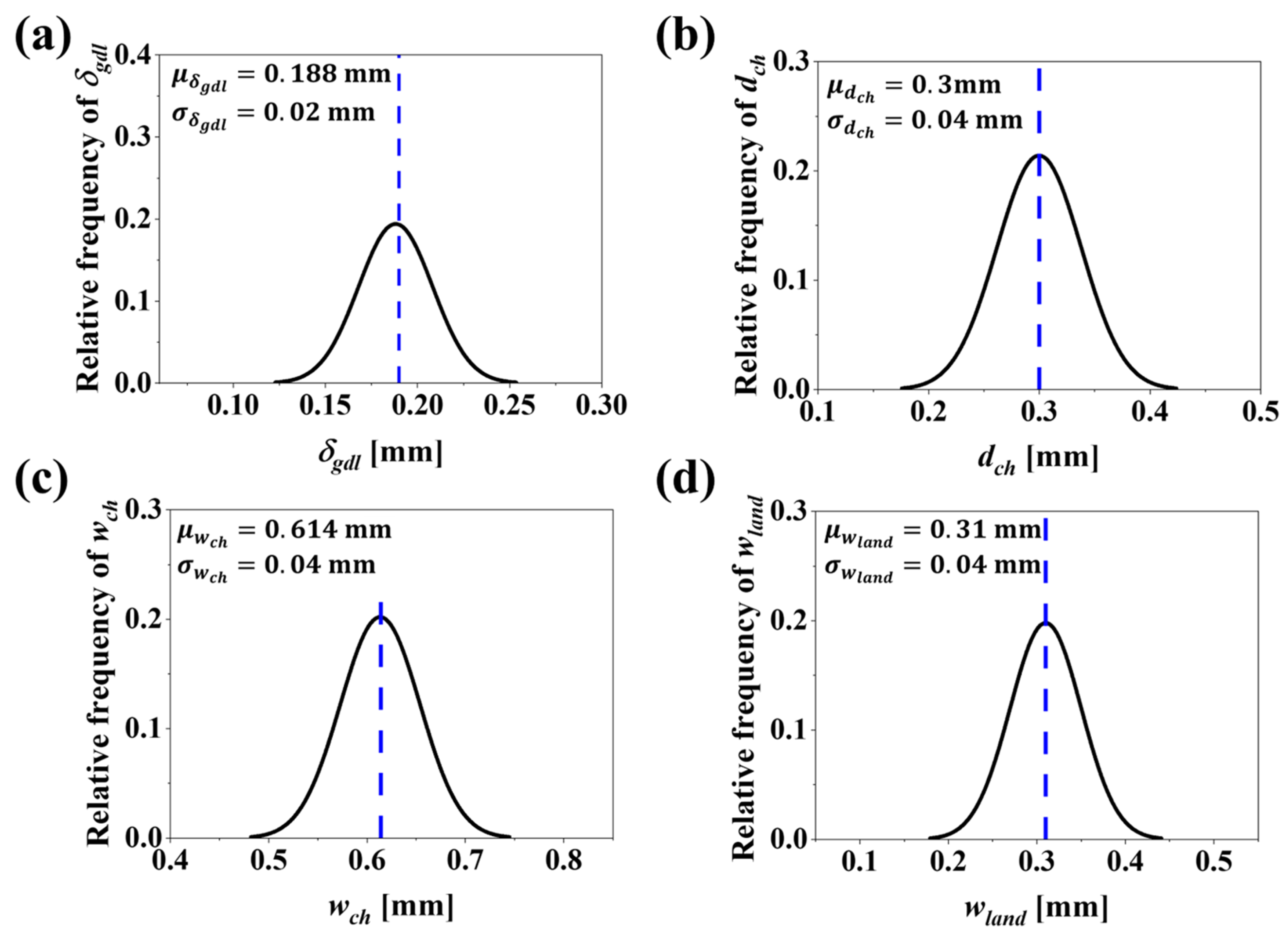

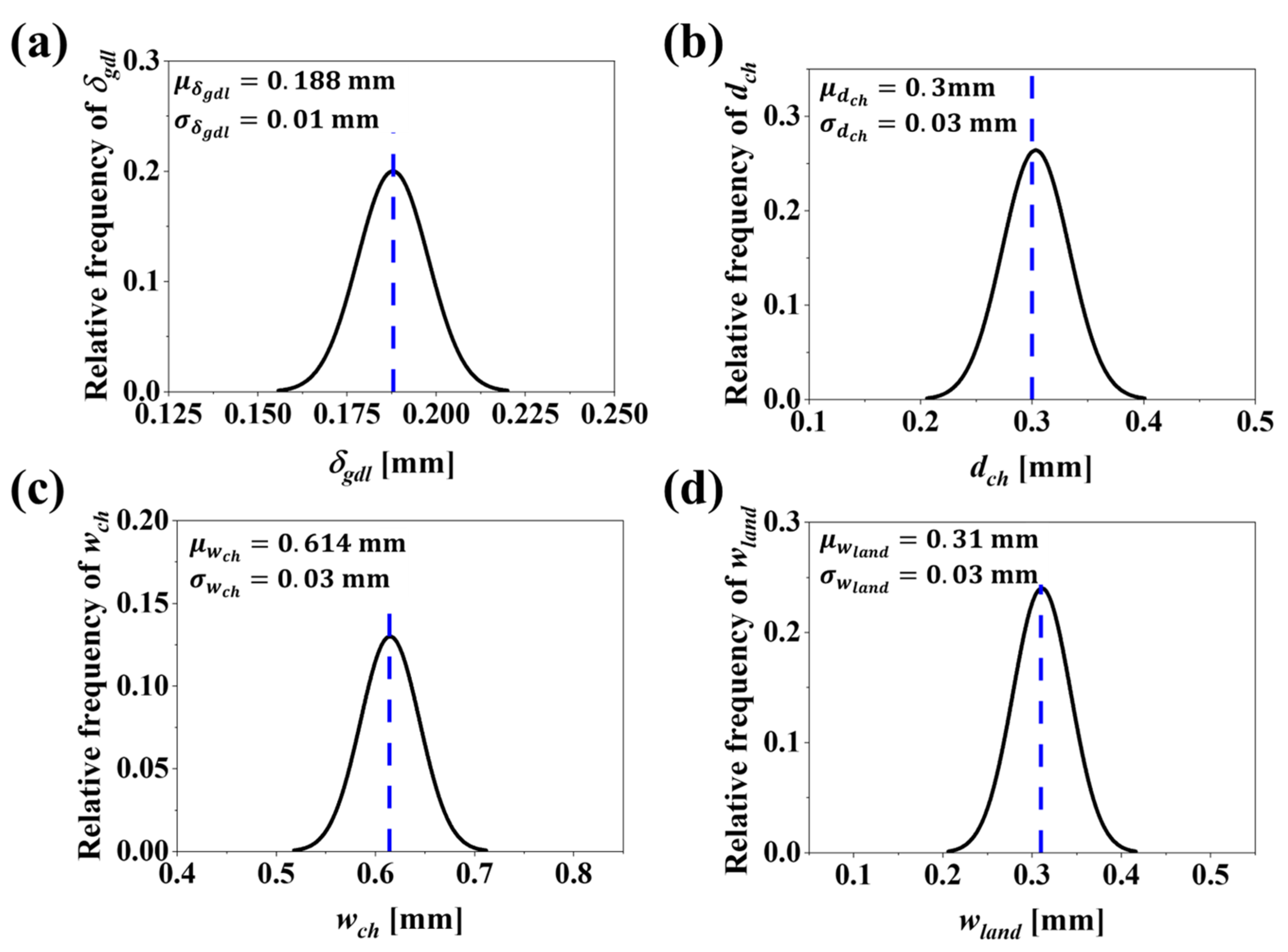

| Design Variables | Distribution | Mean (μ) [mm] | Standard Deviation (), [mm] | |

|---|---|---|---|---|

| DDO | ||||

| GDL thickness (), [mm] | Normal | 0.188 | 0.03 | 0.01 |

| Channel depth (), [mm] | Normal | 0.3 | 0.05 | 0.03 |

| Channel width (), [mm] | Normal | 0.614 | 0.05 | 0.03 |

| Land width (), [mm] | Normal | 0.310 | 0.05 | 0.03 |

| Case | Parameter | Optimization Approach | |||||||

|---|---|---|---|---|---|---|---|---|---|

| RBDO | |||||||||

| Reliability [%] | Nominal Value [$/Stack] | Mean Value () [$/Stack] | Standard Deviation [$/Stack] | Reliability [%] | Nominal Value [$/Stack] | Mean Value [$/Stack] | Standard Deviation [$/Stack] | ||

| 1 | [$/stack] | 49.87 | 46.68 | 46.68 | 7.45 | 95.00 | 34.43 | 34.42 | 7.44 |

[$/stack] | 50.00 | 108.81 | 108.81 | 6.78 | 94.99 | 119.99 | 120.0 | 6.80 | |

| 2 | [$/stack] | 49.87 | 46.68 | 46.68 | 2.48 | 95.02 | 42.59 | 42.58 | 2.48 |

[$/stack] | 50.00 | 108.81 | 108.81 | 4.07 | 94.99 | 115.52 | 115.51 | 4.08 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vaz, N.; Lim, K.; Choi, J.; Ju, H. Reliability-Based Design Optimization for Polymer Electrolyte Membrane Fuel Cells: Tackling Dimensional Uncertainties in Manufacturing and Their Effects on Costs of Cathode Gas Diffusion Layer and Bipolar Plates. Molecules 2024, 29, 4381. https://doi.org/10.3390/molecules29184381

Vaz N, Lim K, Choi J, Ju H. Reliability-Based Design Optimization for Polymer Electrolyte Membrane Fuel Cells: Tackling Dimensional Uncertainties in Manufacturing and Their Effects on Costs of Cathode Gas Diffusion Layer and Bipolar Plates. Molecules. 2024; 29(18):4381. https://doi.org/10.3390/molecules29184381

Chicago/Turabian StyleVaz, Neil, Kisung Lim, Jaeyoo Choi, and Hyunchul Ju. 2024. "Reliability-Based Design Optimization for Polymer Electrolyte Membrane Fuel Cells: Tackling Dimensional Uncertainties in Manufacturing and Their Effects on Costs of Cathode Gas Diffusion Layer and Bipolar Plates" Molecules 29, no. 18: 4381. https://doi.org/10.3390/molecules29184381

APA StyleVaz, N., Lim, K., Choi, J., & Ju, H. (2024). Reliability-Based Design Optimization for Polymer Electrolyte Membrane Fuel Cells: Tackling Dimensional Uncertainties in Manufacturing and Their Effects on Costs of Cathode Gas Diffusion Layer and Bipolar Plates. Molecules, 29(18), 4381. https://doi.org/10.3390/molecules29184381