Sustainable Assessment of Bio-Colorant from Bakain Bark (Melia azedarach L.) for Dyeing of Cellulosic and Proteinous Fabric

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Extraction of Bio-Colorant

2.3. Optimization of Different Parameters

2.4. Bio-Mordanting

2.5. Computation of K/S Value and Fastness Attributes

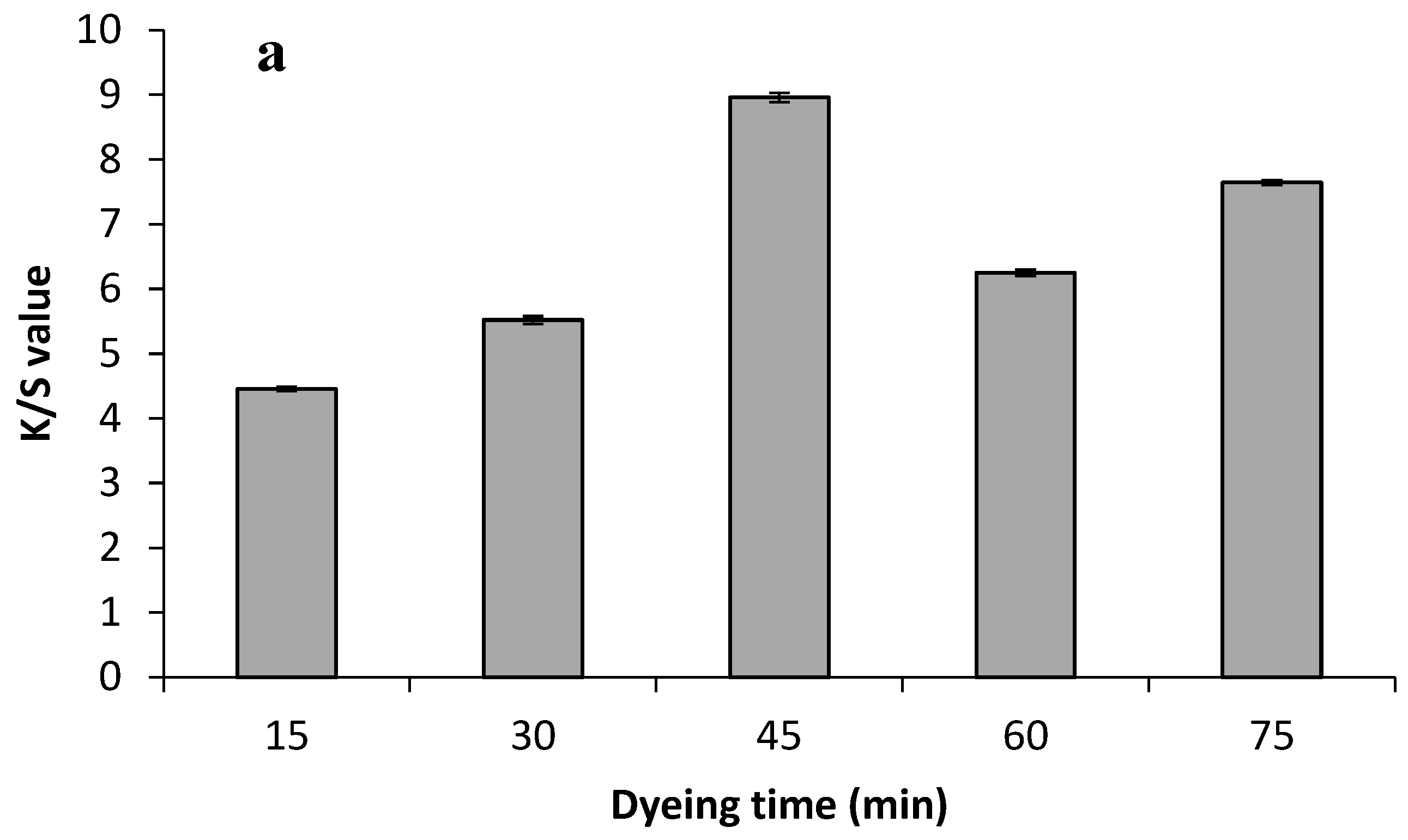

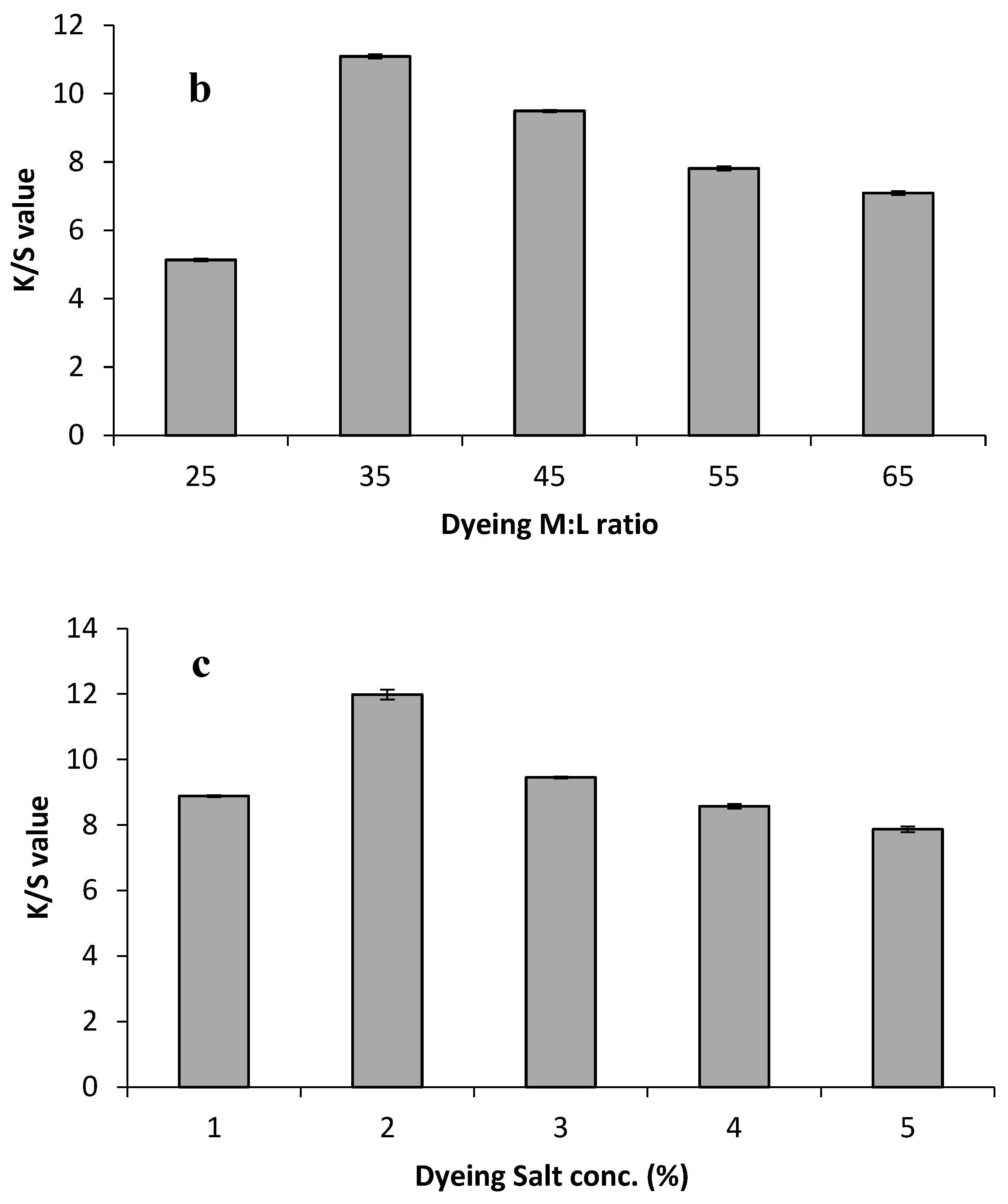

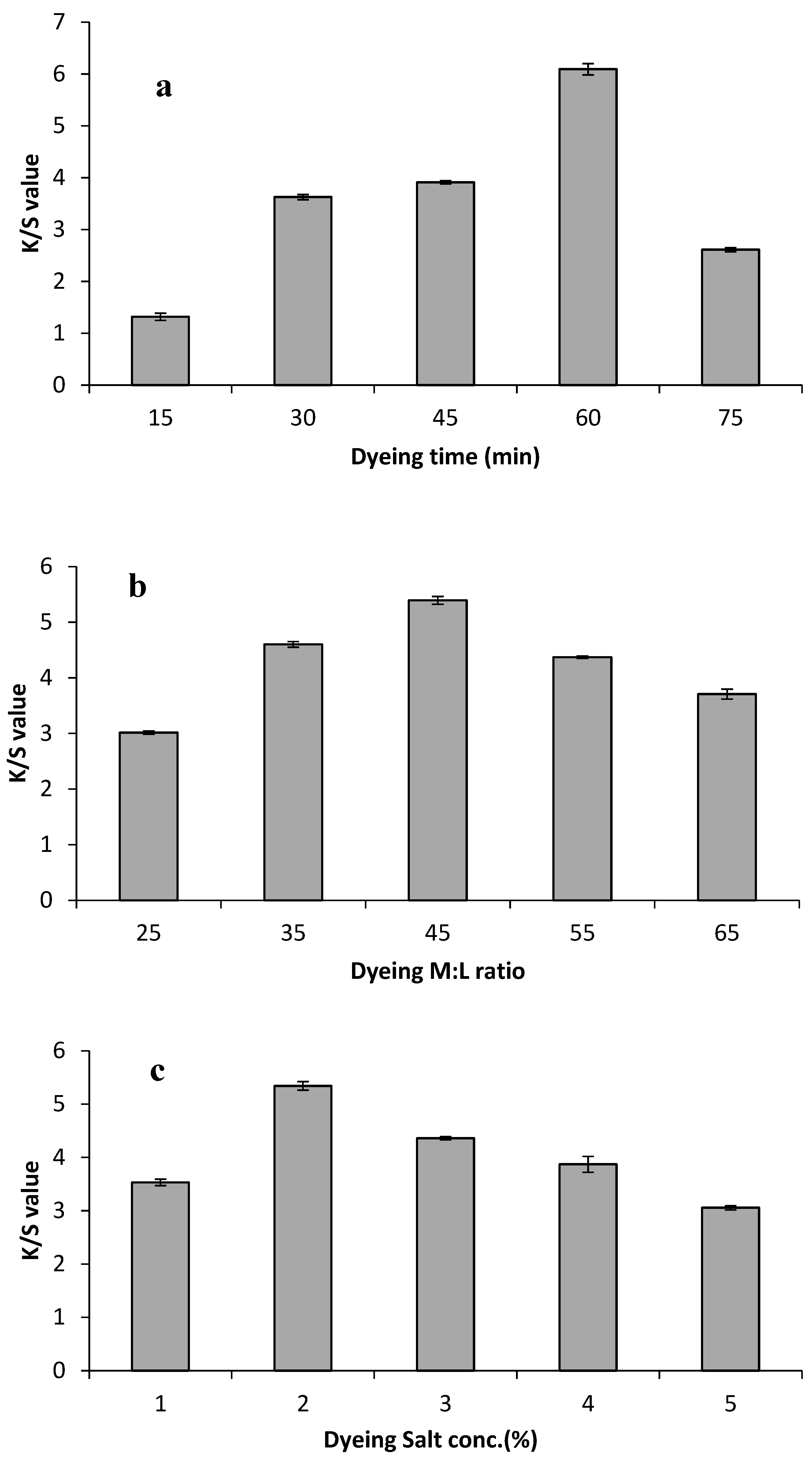

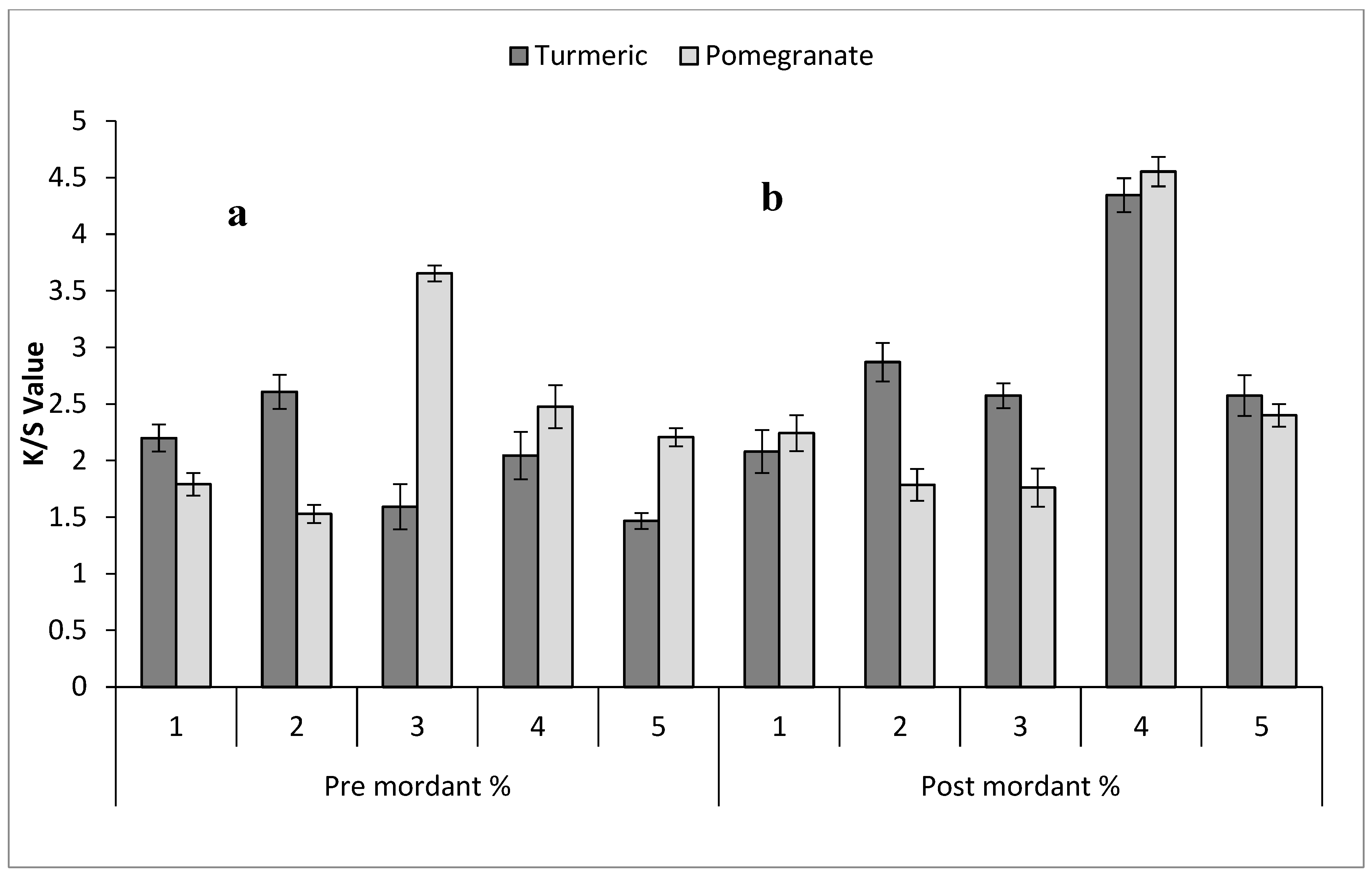

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shahrajabian, M.H.; Sun, W.; Cheng, Q. The Importance of Flavonoids and Phytochemicals of Medicinal Plants with Antiviral Activities. Mini Rev. Org. Chem. 2022, 19, 293–318. [Google Scholar] [CrossRef]

- Boshra, Y.R.; Fahim, J.R.; Hamed, A.N.E.; Desoukey, S.Y. Phytochemical and Biological Attributes of Narcissus pseudonarcissus L. (Amaryllidaceae): A Review. S. Afr. J. Bot. 2022, 146, 437–458. [Google Scholar] [CrossRef]

- Rana, R.; Dhiman, K.; Ashawat, M.S. Natural Coloring Agents for Fibers and Their Medicinal Values: A Review. J. Nat. Fibers 2022, 19, 14755–14770. [Google Scholar] [CrossRef]

- Rizwanullah; Rauf, A.; Hussain, F.; Ali, I.; Muhammad, J.; Gul, A.; Hussain, H.; Gondal, M.A.; Ilyas, M.; Kamil, M.; et al. Biological Investigation on Novel Natural Dye Extracted from the Bark of Calligonum polygonoides L. and Their Application on Cotton Fiber. Pol. J. Environ. Stud. 2022, 31, 3789–3796. [Google Scholar] [CrossRef]

- Asif, N.; Shehzadi, S.; Fatima, S.; Fatma, T. Photocatalytic Degradation of Synthetic Dyes Using Cyanobacteria-Derived Zinc Oxide Nanoparticles. Bionanoscience 2023, 13, 365–375. [Google Scholar] [CrossRef]

- Uddin, F. Environmental Hazard in Textile Dyeing Wastewater from Local Textile Industry. Cellulose 2021, 28, 10715–10739. [Google Scholar] [CrossRef]

- Khattab, T.A.; Abdelrahman, M.S.; Rehan, M. Textile Dyeing Industry: Environmental Impacts and Remediation. Environ. Sci. Pollut. Res. 2020, 27, 3803–3818. [Google Scholar] [CrossRef]

- Dutta, S.; Adhikary, S.; Bhattacharya, S.; Roy, D.; Chatterjee, S.; Chakraborty, A.; Rajak, P. Contamination of textile dyes in aquatic environment: Adverse impacts on aquatic ecosystem and human health, and its management using bioremediation. J. Environ. Manag. 2024, 353, 120103. [Google Scholar] [CrossRef]

- Al-Tohamy, R.; Ali, S.S.; Li, F.; Okasha, K.M.; Mahmoud, Y.A.G.; Elsamahy, T.; Jiao, H.; Fu, Y.; Sun, J. A Critical Review on the Treatment of Dye-Containing Wastewater: Ecotoxicological and Health Concerns of Textile Dyes and Possible Remediation Approaches for Environmental Safety. Ecotoxicol. Environ. Saf. 2022, 231, 113160. [Google Scholar] [CrossRef]

- Lellis, B.; Fávaro-Polonio, C.Z.; Pamphile, J.A.; Polonio, J.C. Effects of Textile Dyes on Health and the Environment and Bioremediation Potential of Living Organisms. Biotechnol. Res. Innov. 2019, 3, 275–290. [Google Scholar] [CrossRef]

- Rosyida, A.; Suranto; Masykuri, M.; Margono. Minimisation of Pollution in the Cotton Fabric Dyeing Process with Natural Dyes by the Selection of Mordant Type. Res. J. Text. Appar. 2022, 26, 41–56. [Google Scholar] [CrossRef]

- Nambela, L. The Potentials of Plant-Based Colorants for Sustainable Textile Dyeing Industry. Res. J. Text. Appar. 2023; ahead of print. [Google Scholar] [CrossRef]

- Zhu, T.; Ren, K.; Sheng, J.; Zhang, Q.; Li, J.; Lin, J. Natural dye extracted from Dalbergia cochinchinensis residue with water fastness mildew resistance and permeability properties for wood staining. Wood Sci. Technol. 2022, 56, 969–988. [Google Scholar] [CrossRef]

- Rehman, A.; Irfan, M.; Hameed, A.; Saif, M.J.; Qayyum, M.A.; Farooq, T. Chemical-free dyeing of cotton with functional natural dye: A pollution-free and cleaner production approach. Front. Environ. Sci. 2022, 10, 848245. [Google Scholar] [CrossRef]

- Amutha, K.; Annapoorani, S.G.; Sakthivel, P.; Sudhapriya, N. Ecofriendly Dyeing of Textiles with Natural Dyes Extracted from Commercial Food Processing Waste Materials. J. Nat. Fibers 2022, 19, 10394–10411. [Google Scholar] [CrossRef]

- Tian, Y.; Lu, Y.; Zhang, Y.; Hou, X.; Zhang, Y. Extraction and Characterization of Natural Colorant from Melia Azedarach Bark and Its Utilization in Dyeing and Finishing of Wool. Sustain. Chem. Pharm. 2022, 27, 100647. [Google Scholar] [CrossRef]

- Li, N.; Wang, Q.; Zhou, J.; Li, S.; Liu, J.; Chen, H. Insight into the Progress on Natural Dyes: Sources, Structural Features, Health Effects, Challenges, and Potential. Molecules 2022, 27, 3291. [Google Scholar] [CrossRef]

- Jabar, J.M.; Ogunsade, A.F.; Odusote, Y.A.; Yılmaz, M. Utilization of Nigerian Mango (Mangifera indica L.) Leaves Dye Extract for Silk Fabric Coloration: Influence of Extraction Technique, Mordant and Mordanting Type on the Fabric Color Attributes. Ind. Crops Prod. 2023, 193, 116235. [Google Scholar] [CrossRef]

- Rahman, M.M.; Kim, M.; Youm, K.; Kumar, S.; Koh, J.; Hong, K.H. Sustainable One-Bath Natural Dyeing of Cotton Fabric Using Turmeric Root Extract and Chitosan Biomordant. J. Clean. Prod. 2023, 382, 135303. [Google Scholar] [CrossRef]

- Kandasamy, N.; Kaliappan, K.; Palanisamy, T. Upcycling Sawdust into Colorant: Ecofriendly Natural Dyeing of Fabrics with Ultrasound Assisted Dye Extract of Pterocarpus Indicus Willd. Ind. Crops Prod. 2021, 171, 113969. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Q.; Rather, L.J.; Li, Q. Agricultural Waste of Eriobotrya Japonica L. (Loquat) Seeds and Flora Leaves as Source of Natural Dye and Bio-Mordant for Coloration and Bio-Functional Finishing of Wool Textile. Ind. Crops Prod. 2021, 169, 113633. [Google Scholar] [CrossRef]

- Sun, R.; Lou, J.; Fan, X.; Gao, W.; Gu, Z. Dyeing and Functionalization of Wool Fabric with Alizarin Red S via Covalent Combination Catalyzed by Horseradish Peroxidase and Hydrogen Peroxide. Fibers Polym. 2023, 24, 4311–4321. [Google Scholar] [CrossRef]

- Pinheiro, L.; Kohan, L.; Duarte, L.O.; Garavello, M.E.D.P.E.; Baruque-Ramos, J. Biomordants and new alternatives to the sustainable natural fiber dyeings. SN Appl. Sci. 2019, 1, 1356. [Google Scholar] [CrossRef]

- Kushwaha, A.; Singh, S.; Chaudhary, K. Eco-Friendly Multifunctional Dyeing of Pineapple Using Nyctanthes Arbortristis Dye and Acacia Nilotica Bio-Mordant. Sustain. Chem. Pharm. 2023, 34, 101146. [Google Scholar] [CrossRef]

- Che, J.; Yang, X. A recent (2009–2021) perspective on sustainable color and textile coloration using natural plant resources. Heliyon 2022, 8, e10979. [Google Scholar]

- Hosen, M.D.; Rabbi, M.F.; Raihan, M.A.; Al Mamun, M.A. Effect of turmeric dye and biomordants on knitted cotton fabric coloration: A promising alternative to metallic mordanting. Clean. Eng. Technol. 2021, 3, 100124. [Google Scholar] [CrossRef]

- Mwamatope, B.; Tembo, D.; Chikowe, I.; Kampira, E.; Nyirenda, C. Total Phenolic Contents and Antioxidant Activity of Senna Singueana, Melia Azedarach, Moringa Oleifera and Lannea Discolor Herbal Plants. Sci. Afr. 2020, 9, e00481. [Google Scholar] [CrossRef]

- Qureshi, H.; Arshad, M.; Akram, A.; Iqbal, N.; Fatima, S.; Amjad, M.S. Ethnopharmacological and Phytochemical Account of Paradise Tree (Melia azedarach L.: Meliaceae). Pure Appl. Biol. 2016, 5, 5–14. [Google Scholar] [CrossRef]

- Turker, A.U.; Camper, N.D. Biological Activity of Common Mullein, a Medicinal Plant. J. Ethnopharmacol. 2002, 82, 117–125. [Google Scholar] [CrossRef]

- Touzout, S.N.; Merghni, A.; Laouani, A.; Boukhibar, H.; Alenazy, R.; Alobaid, A.; El-Bok, S. Antibacterial properties of methanolic leaf extracts of Melia azedarach L. against gram-positive and gram-negative pathogenic bacteria. Microorganisms 2023, 11, 2062. [Google Scholar] [CrossRef]

- Alché, L.E.; Ferek, G.A.; Meo, M.; Coto, C.E.; Maier, M.S. An Antiviral Meliacarpin from Leaves of Melia azedarach L. Z. Fur Naturforsch.-Sect. C J. Biosci. 2003, 58, 215–219. [Google Scholar] [CrossRef]

- Jahan, N.; Makbul, S.A.A. Phytochemical and Pharmacological Appraisal of Barks from Unani Medicinal Plants. In Plant-Derived Bioactives: Production, Properties and Therapeutic Applications; Swamy, M.K., Ed.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 523–548. [Google Scholar]

- Adeel, S.; Mumtaz, A.; Mia, R.; Aftab, M.; Hussaan, M.; Amin, N.; Khan, S.R.; Khattak, S.P. Microwave-Assisted Sustainable Coloration of Wool Fabric Using Rheum Emodi-Based Natural Dye. Surf. Innov. 2024, 12, 147–158. [Google Scholar] [CrossRef]

- Mahboob, M.; Adeel, S.; Barkaat, S.; Ahmad, T.; Özomay, M.; Mia, R.; Mirnezhad, S.; Zuber, M. Microwave-Assisted Santalin Extraction from Pterocarpus Santalinus for Mordanted Woolen Yarn Dyeing. Sustain. Chem. Pharm. 2023, 35, 101224. [Google Scholar] [CrossRef]

- ISO 105-B02:2014; Textiles—Tests for Colour Fastness-Part B02: Colour Fastness to Artificial Light: Xenon Arc Fading Lamp Test. International Organization for Standardization: Geneva, Switzerland, 2020.

- ISO 105-X12:2016; Textiles—Tests for Colour Fastness-Part X12: Colour Fastness to Rubbing. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 105-C10:2006; Textiles—Tests for Colour Fastness-Part C10: Colour Fastness to Washing with Soap or Soap and Soda. International Organization for Standardization: Geneva, Switzerland, 2020.

- Raza, A.; Iqbal, N.; Mahmood, S.; Parveen, S.; Azeem, M.; Nawaz, M.; Javed, M.T.; Noman, A. Harnessing Natural Colorants For Sustainable Textile Dyeing An Eco-Friendly Approach Using Sweet Cane (Saccharum Bengalense Retz.) Inflorescence. Braz. Arch. Biol. Technol. 2018, 61, 1–10. [Google Scholar] [CrossRef]

- Velmurugan, P.; Shim, J.; Seo, S.K.; Oh, B.T. Extraction of natural dye from Coreopsis tinctoria flower petals for leather dyeing−An ecofriendly approach. Fibers Polym. 2016, 17, 1875–1883. [Google Scholar] [CrossRef]

- Rani, N.; Jajpura, L.; Butola, B.S. Sustainable Coloration of Protein Fibers Using Kalanchoe-Pinnata Leaf Extract. J. Nat. Fibers 2022, 19, 115–130. [Google Scholar] [CrossRef]

- Dhanania, Y.; Singhee, D.; Samanta, A.K. Optimization of dyeing process variables for eco-friendly dyeing of cotton fabric with babul bark extract as a natural dye and gallnut extract as a biomordant. J. Nat. Fibers 2021, 19, 5478–5495. [Google Scholar] [CrossRef]

- Iqbal, W.; Qi, Y.; Jiang, Y.; Siddiqui, M.O.R.; Khalid, R.; Iqbal, A.; Munir, M.U.; Hussain, A.; Xu, S. Antimicrobial Property of Functional Viscose Fibre by Using Mint Extract. Ind. Textila 2023, 74, 464–469. [Google Scholar] [CrossRef]

| Extraction Medium | Conc.% | (Silk Fabric) K/S Value | (Cotton Fabric) K/S Value |

|---|---|---|---|

| Tap water | 100% | 2.8213 | 2.0112 |

| Acid (Vinegar) | 4% | 1.1932 | 0.2731 |

| Fabric Types | Mordanted Fabrics | Shade |

|---|---|---|

| Silk | Control sample |  |

| Pomegranate peel 3% pre-mordanted silk |  | |

| Pomegranate peel 2% post-mordanted silk |  | |

| Turmeric 2% pre-mordanted fabric |  | |

| Turmeric 3%post-mordanted fabric |  | |

| Cotton | Control |  |

| Pomegranate peel 3% pre-mordanted cotton |  | |

| Pomegranate peel 4% post-mordanted sample |  | |

| 2% turmeric pre-mordanted cotton |  | |

| 4% Turmeric post-mordanted cotton |  |

| Mordant | Mordant Ratio % | Turmeric | Pomegranate Peel | ||||

|---|---|---|---|---|---|---|---|

| LF | WF | RF | LF | WF | RF | ||

| Pre-mordant (Silk) | 1 | 4/5 | 4/5 | 3/4 | 3/4 | 3/4 | 5 |

| 2 | 5 | 4/5 | 4/5 | 4/5 | 4/5 | 4/5 | |

| 3 | 4/5 | 4 | 3/4 | 3/4 | 4/5 | 4 | |

| 4 | 4 | 3/4 | 5 | 4/5 | 5 | 4/5 | |

| 5 | 3/4 | 4/5 | 4/5 | 3/4 | 3/4 | 4/5 | |

| Post-mordant (Silk) | 1 | 3/4 | 5 | 4/5 | 4 | 3/4 | 5 |

| 2 | 4/5 | 3/4 | 5 | 3/4 | 5 | 3/4 | |

| 3 | 4/5 | 4/5 | 4/5 | 4/5 | 4/5 | 3 | |

| 4 | 4 | 3/4 | 4/5 | 3/4 | 3/4 | 4/5 | |

| 5 | 3/4 | 4 | 3/4 | 4 | 4/5 | ¾ | |

| Pre-mordant (Cotton) | 1 | 4/5 | 3/4 | 4/5 | 3/4 | 4 | 4/5 |

| 2 | 4 | 5 | 3/4 | 4 | 3/4 | 5 | |

| 3 | 3/4 | 4/5 | 5 | 3/4 | 4/5 | 4/5 | |

| 4 | 4/5 | 3 | 4/5 | 4/5 | 4 | 4/5 | |

| 5 | 3/4 | 3/4 | 5 | 4/5 | 4/5 | 4 | |

| Post-mordant (Cotton) | 1 | 5 | 4/5 | 3/4 | 3/4 | 4 | 4/5 |

| 2 | 4/5 | 3/4 | 5 | 3/4 | 4/5 | 5 | |

| 3 | 3/4 | 5 | 3/4 | 5 | 3/4 | 4 | |

| 4 | 4 | 4/5 | 4/5 | 4/5 | 4 | ¾ | |

| 5 | 3/4 | 3/4 | 4/5 | 4 | 5 | 3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Batool, F.; Fatima, M.; Adeel, S.; Ahmad, S.A.; Repon, M.R.; Haji, A. Sustainable Assessment of Bio-Colorant from Bakain Bark (Melia azedarach L.) for Dyeing of Cellulosic and Proteinous Fabric. Molecules 2024, 29, 4392. https://doi.org/10.3390/molecules29184392

Batool F, Fatima M, Adeel S, Ahmad SA, Repon MR, Haji A. Sustainable Assessment of Bio-Colorant from Bakain Bark (Melia azedarach L.) for Dyeing of Cellulosic and Proteinous Fabric. Molecules. 2024; 29(18):4392. https://doi.org/10.3390/molecules29184392

Chicago/Turabian StyleBatool, Fatima, Maheen Fatima, Shahid Adeel, Sheikh Asrar Ahmad, Md. Reazuddin Repon, and Aminoddin Haji. 2024. "Sustainable Assessment of Bio-Colorant from Bakain Bark (Melia azedarach L.) for Dyeing of Cellulosic and Proteinous Fabric" Molecules 29, no. 18: 4392. https://doi.org/10.3390/molecules29184392

APA StyleBatool, F., Fatima, M., Adeel, S., Ahmad, S. A., Repon, M. R., & Haji, A. (2024). Sustainable Assessment of Bio-Colorant from Bakain Bark (Melia azedarach L.) for Dyeing of Cellulosic and Proteinous Fabric. Molecules, 29(18), 4392. https://doi.org/10.3390/molecules29184392