Abstract

The synthesis and structural analysis of (Me3SiC5H4)TiCl2(OAr) [OAr = O-2,6-iPr2-4-RC6H2; R = H, SiEt3] revealed that it exhibits higher catalytic activities than (tBuC5H4)TiCl2(OAr), Cp*TiCl2(OAr), with efficient comonomer incorporation in ethylene/styrene copolymerization in the presence of a methylaluminoxane (MAO) cocatalyst. The catalytic activity in the copolymerization increased upon increasing the charged styrene concentration along with the increase in the styrene content in the copolymers, whereas the activities of other catalysts showed the opposite trend. (Me3SiC5H4)TiCl2(O-2,6-iPr2C6H3) displayed the most suitable catalyst performance in terms of its activity and styrene incorporation, affording amorphous copolymers with styrene contents higher than 50 mol% (up to 63.6 mol%) and with random styrene incorporation confirmed by 13C-NMR spectra.

1. Introduction

Olefin coordination polymerization using transition metal catalysts is the core technology for the production of polyolefins, and the development of new polymeric materials, especially copolymers consisting of ethylene or propylene with monomers which have never been used by conventional catalysts (Ziegler–Natta, metallocene catalysts, etc.), is a long-term interest in this research field. Catalyst development has been considered to play an important key role in the success of this research area [1,2,3,4,5,6,7,8,9,10]. Ethylene copolymers with aromatic vinyl monomers exemplified as ethylene/styrene copolymers are known to be interesting materials whose thermo-mechanical and viscoelastic properties can be modified through the incorporation of a comonomer (styrene) [11]. Half-titanocene complexes [5,6,7,8,9,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28] have been known as efficient catalysts in terms of having a better capacity for styrene incorporation than ordinary metallocene catalysts [11,29,30].

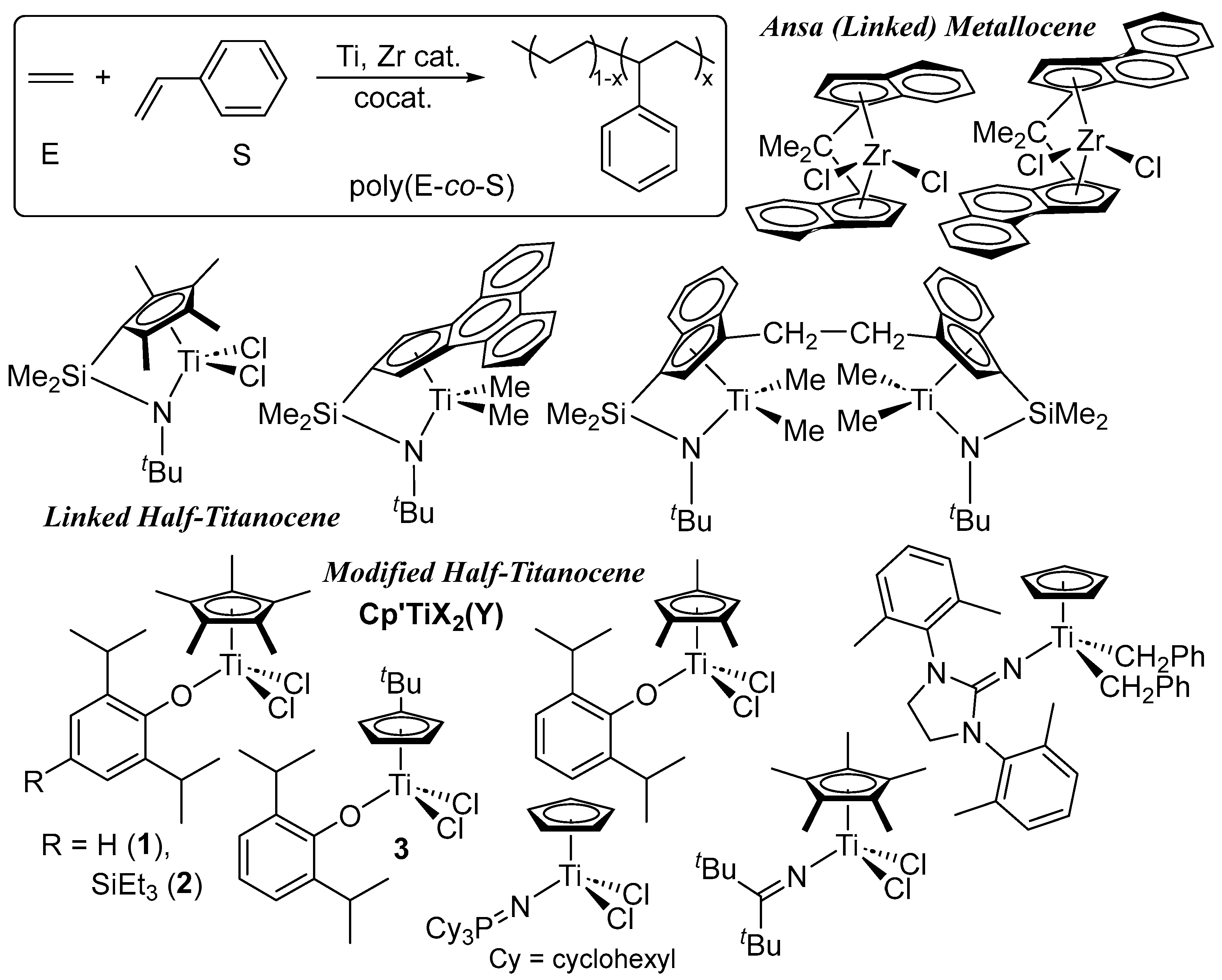

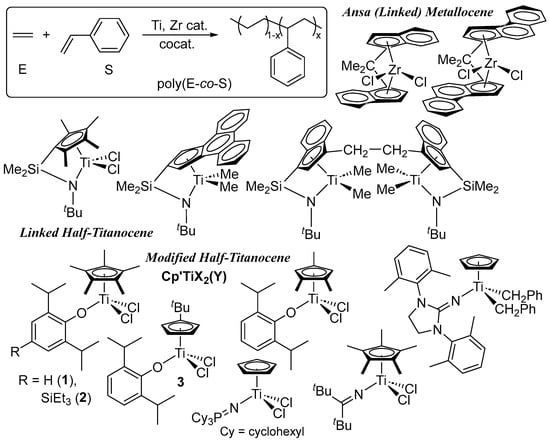

Linked (ansa) half-titanocenes (called “constrained geometry type”) [5,6,7,12,13,14,15,16,17,18,19], certain ansa-metallocenes [29,30], and non-bridged modified half-titanocenes (exemplified in Scheme 1) [20,21,22,23,24,25,26,27,28] are known to be effective transition metal catalysts in ethylene/styrene copolymerization [11]. In particular, the bimetallic linked half-titanocene, (CH2CH2)[Me2Si(indenyl)(NtBu)TiMe2]2 [17,19], and the phenoxide-modified half-titanocene, Cp’TiCl2(O-2,6-iPr2C6H3) [Cp’ = tBuC5H4 (3), 1,2,4-Me3C5H2] [20,21], have been recognized as effective catalysts in terms of the synthesis of copolymers with high styrene contents (>50 mol%) [17,19,20,21]. The resultant copolymers with high styrene contents (ca. >30 mol%) are amorphous, and the glass transition temperature (Tg) increases with the increase in the styrene content (shown below) [21]. However, as described above, catalysts affording copolymers with high styrene contents (especially >50 mol%) are still limited. Moreover, these phenoxide-modified catalysts (shown above) also exhibited remarkable catalytic activities for syndio-specific styrene polymerization [20,31], whereas the bimetallic linked half-titanocene gave atactic polystyrene [17]. In contrast, the C5Me5 (Cp*) analogues, Cp*TiCl2(O-2,6-iPr2-4-RC6H2) [R = H (1), SiEt3 (2), Scheme 1], exhibited remarkable catalytic activities for ethylene copolymerization with α-olefins [3,8,9]; the SiEt3 analogue (2) was effective for ethylene copolymerization with alken-1-ol [32]. These results also suggest that modification of the cyclopentadienyl fragment plays a role in the success of efficient catalysts for the desired ethylene copolymerization [3,8,9]; an introduction of the SiEt3 group would lead to higher activity as a result of better π-donation [32].

Scheme 1.

Selected titanium and zirconium catalysts for ethylene/styrene copolymerization.

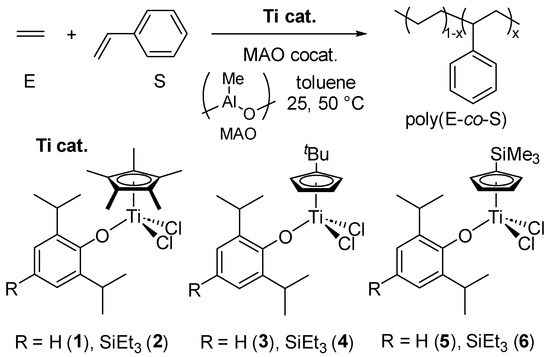

In this paper, we focus on the phenoxide−modified half−titanocene catalysts for ethylene/styrene copolymerization. We recently realized that the complexes containing the trimethylsilyl-cyclopentadienyl ligand, (Me3SiC5H4)TiCl2(O-2,6-iPr2C6H3), showed better catalyst performance than the tert-BuC5H4 analogue (3) [20,21] in the copolymerization. We thus herein report our results concerning the synthesis of (Me3SiC5H4)TiCl2(O-2,6-iPr2-4-RC6H2) [R = H (5), SiEt3 (6)] and its use as a catalyst for ethylene/styrene copolymerization in the presence of a methylaluminoxane (MAO) cocatalyst (Scheme 2).

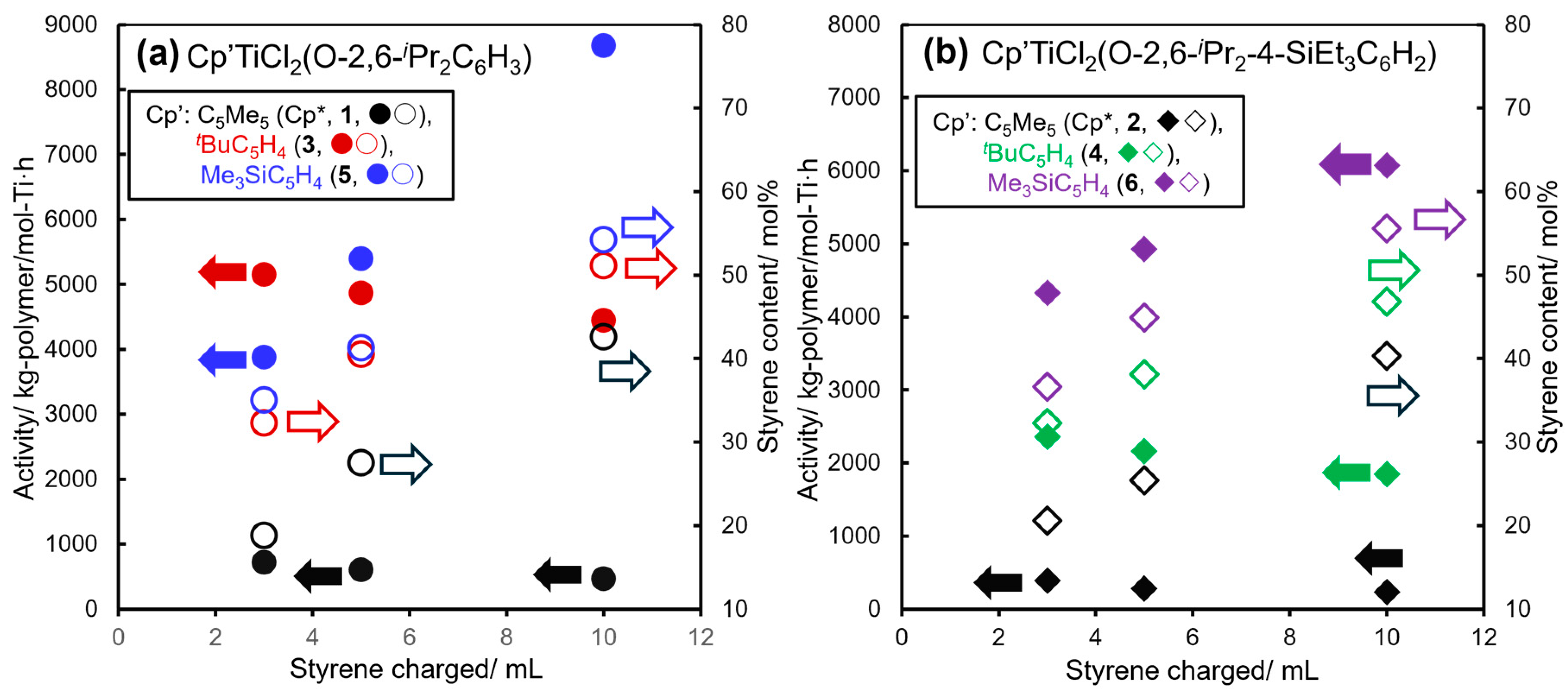

Scheme 2.

Ethylene/styrene copolymerization by phenoxide−modified half−titanocene catalysts.

2. Results and Discussion

2.1. Synthesis and Structural Analysis of (Me3SiC5H4)TiCl2(O-2,6-iPr2-4-RC6H2) (R = H, SiEt3)

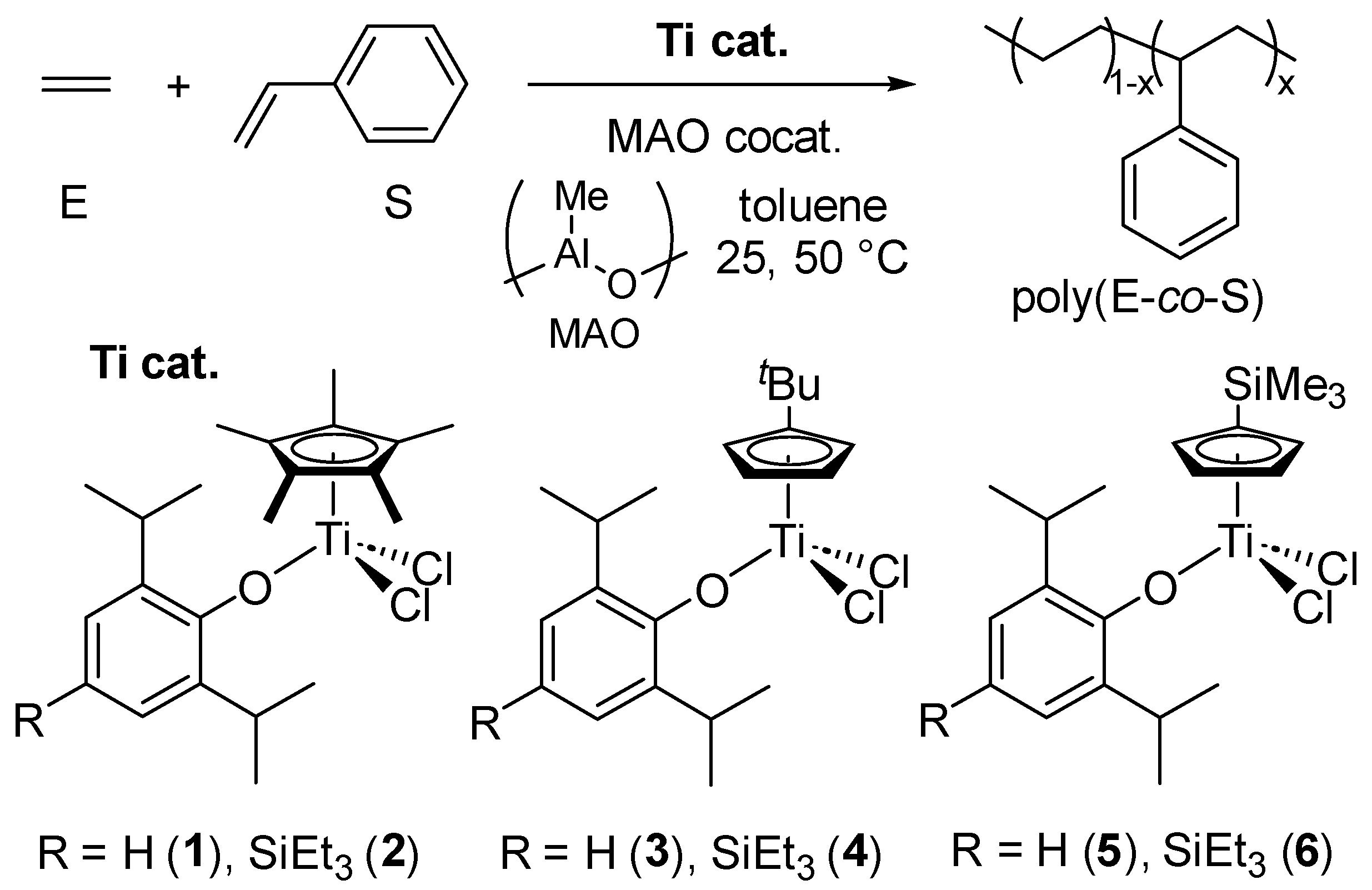

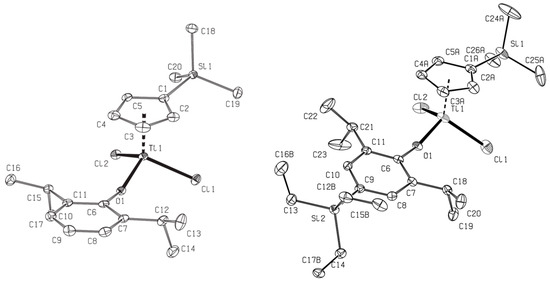

The phenoxide-modified half-titanocenes containing the Me3SiC5H4 ligand, (Me3SiC5H4)TiCl2(O-2,6-iPr2-4-RC6H2) [R = H (5), SiEt3 (6)] were prepared according to the previous report by treating (Me3SiC5H4)TiCl3 [33,34] with Li(O-2,6-iPr2C6H3) or 2,6-iPr2-4-SiEt3-C6H2OH (in the presence of NEt3) in diethyl ether. (tBuC5H4)TiCl2(O-2,6-iPr2-4-SiEt3-C6H2) (4) was also prepared in the same manner (as described in the Experimental Procedures Section). These complexes were identified by NMR spectra and elemental analysis, and the structures of 5 and 6 were determined by X-ray crystallography (Figure 1, CCDC 2378274, 2378275; the table for the crystal data and the collection parameters are shown in the Supplementary Material). The selected bond distances and angles are summarized in Table 1. The data for Cp*TiCl2(O-2,6-iPr2-4-RC6H2) [R = H (1) [35], SiEt3 (2) [32]] and CpTiCl2(O-2,6-iPr2C6H3) (7) [35] are inserted for comparison.

Figure 1.

ORTEP drawings for (Me3SiC5H4)TiCl2(O-2,6-iPr2-4-RC6H2) [R = H (5, left), SiEt3 (6, right)]. Thermal ellipsoids are drawn at 30 % probability level, and hydrogen atoms are omitted for clarity. Additional data including crystal data and collection parameters for structural analysis are shown in Supplementary Material.

Table 1.

Selected bond distances (Å) and angles (º) in (Me3SiC5H4)TiCl2(O-2,6-iPr2-4-RC6H2) [R = H (5), SiEt3 (6)], a Cp*TiCl2(O-2,6-iPr2-4-RC6H2) [R = H (1) [35], SiEt3 (2) [32]], and CpTiCl2(O-2,6-iPr2C6H3) (7) [35] a.

The analyses revealed that these complexes fold a distorted tetrahedral geometry around titanium, and no significant differences are observed in Ti–Cl, Ti–O, and O–C (phenyl) bond distances among these complexes. It seems that Ti–C(1) and Ti–C(2) in 5 [2.3678(17), 2.3854(19) Å] and Ti–C(4) and Ti–C(5) in 6 [2.390(6), 2.398(8) Å] are rather longer than the others in the cyclopentadienyl ligands, and these results might lead to an assumption that the cyclopentadienyl group would be coordinated as η3-fashion. However, these phenomena were also seen in complexes 1 [2.438(7) Å in Ti–C(2)] [35], 2 [2.403(3), 2.411(3) Å in Ti–C(1) and Ti–C(2)] [32], and even 7 [2.299(5) Å in Ti–C(2) and Ti–C(5)] [35]. Therefore, it seems more likely that the observed fact could be probably due to crystal packing in the crystallographic analysis. It was revealed that the Ti(1)–O(1)–C(6 in phenyl) angles in 5 [151.41(12)°] and 6 [157.0(2)°] are apparently smaller than those in 1 and 2 [173.0(3), 174.62(19)°, respectively] [32,35] and 7 [163.0(4)°] [35], suggesting that these complexes (5,6) show an inferior π-donation capability from the phenoxide ligand.

2.2. Ethylene/Styrene Copolymerization by Cp′TiCl2(O-2,6-iPr2-4-RC6H2) [Cp’ = Cp*, tBuC5H4, Me3SiC5H4, R = H, SiEt3]–MAO Catalyst Systems

Table 2 summarizes the results of the ethylene/styrene copolymerization using a series of phenoxide-modified half-titanocene catalysts, Cp′TiCl2(O-2,6-iPr2-4-RC6H2) [Cp’ = Cp*, R = H (1), SiEt3 (2); Cp’ = tBuC5H4, R = H (3), SiEt3 (4); Cp’ = Me3SiC5H4, R = H (5), SiEt3 (6)] in the presence of an MAO cocatalyst. MAO was used as the white solid (d-MAO) after the removal of AlMe3 and toluene from the commercially available samples [TMAO-S, 9.5 wt% (Al) toluene solution, Tosoh Finechem Co., Shunan, Japan], because the use of MAO is quite effective for obtaining high-molar-mass polymers efficiently, as shown in the previous reports [8,9,20,21,28,32,35]. The resultant polymers usually contained atactic polystyrene generated by MAO itself, and the polymer yields were described after the removal of atactic polystyrene through extraction with acetone (see Experimental Procedures). As shown in Table 2, the contents (atactic polystyrene) were negligible in most cases (>99%), except when the copolymerization runs were conducted by the Cp* analogues (1,2) under high initial styrene concentrations (runs 2–6) due to low catalytic activities (low copolymer yields). These copolymerization runs were terminated after 10 min to control the comonomer (styrene) conversion so it was less than 10% in order to obtain copolymers with uniform compositions. For instance, the styrene conversions in runs 7–15 are 10%, 6.4%, 3.2%, 4.6%, 2.8%, 1.3%, 7.9%, 7.2%, and 6.5%, respectively.

Table 2.

Ethylene copolymerization with styrene (St) by Cp′TiCl2(O-2,6-iPr2-4-RC6H2) [Cp’ = Cp*, R = H (1), SiEt3 (2); Cp’ = tBuC5H4, R = H (3), SiEt3 (4); Cp’ = Me3SiC5H4, R = H (5), SiEt3 (6)]–MAO catalyst systems (ethylene 4 atm, 20 °C, 10 min) a.

As reported previously [20,21], the tert-BuC5H4 analogue (3) showed higher catalytic activities than the Cp* analogue (1), and the activity based on the polymer yield decreased with the increase in the initial charged styrene concentration along with the decrease in the Mn values (runs 1–3 vs. runs 7–9). The resultant copolymers were amorphous and possessed uniform compositions, confirmed by DSC thermograms [observed as a sole glass transition temperature (Tg)]; their uniform compositions were also confirmed previously by GPC–FT-IR and cross-fractionation (CFC) analyses [21]. The Tg value increased with the increasing styrene content (estimated by 1H NMR spectra according to the reported procedure) [20,21]. It was revealed that the introduction of the SiEt3 group into the para-position in the phenoxide led to a decrease in the catalytic activities. The activities of 2 and 4 were lower than those of 1 and 3, respectively, whereas no remarkable differences were observed in the molecular weight and the styrene contents in the copolymers. There was an opposite trend in the ethylene copolymerization with α-olefin, 2-methyl-1-pentene reported previously for 1 and 2 [32], although we are not sure of the reason for this at this moment. As shown in Table S2 (Supplementary Materials), as reported previously for 1 and 3,21 the catalytic activities based on the polymer yields decreased upon the addition of styrene.

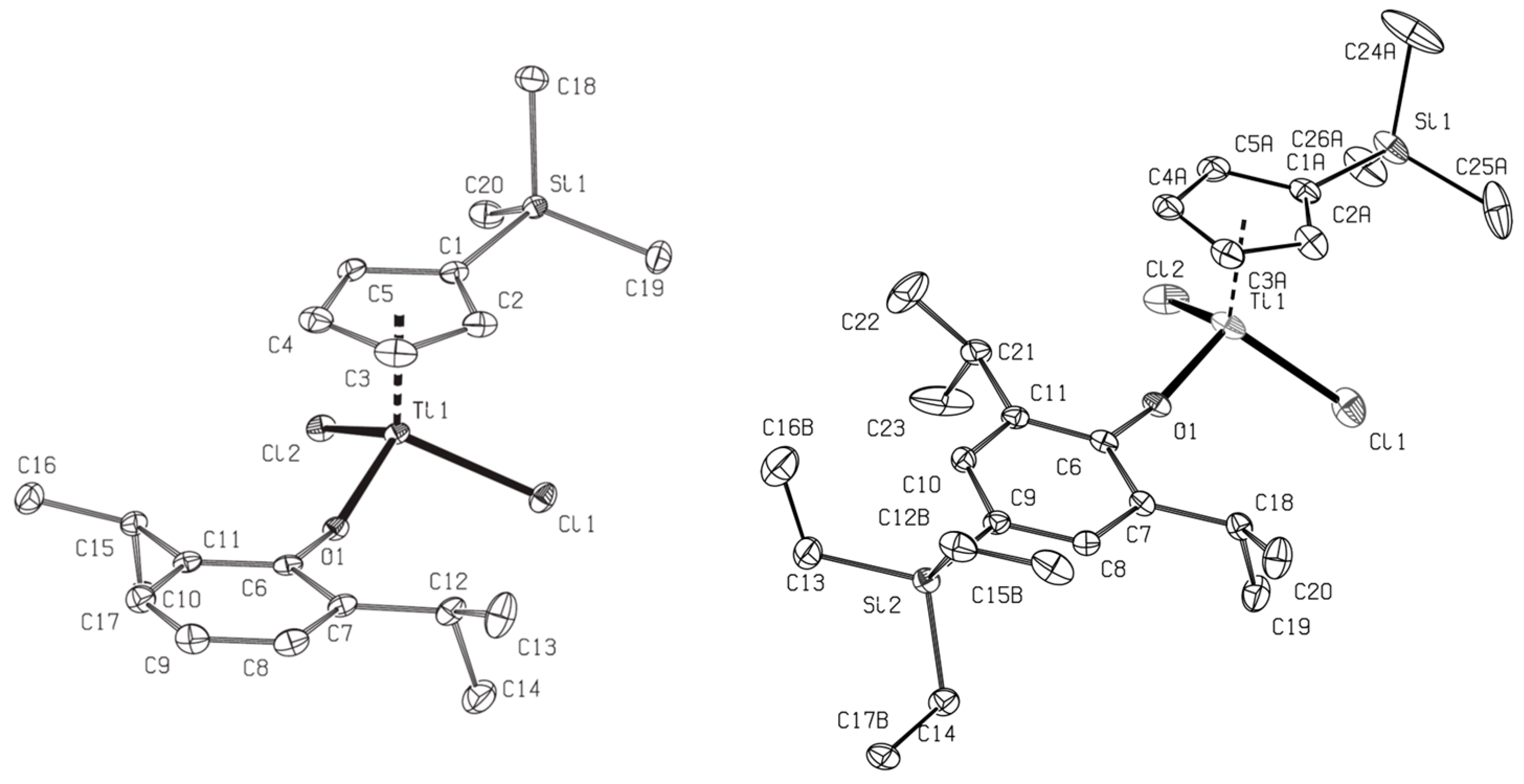

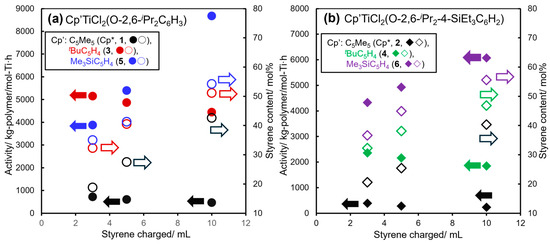

It should be noted that the Me3SiC5H4 analogue (5) showed higher catalytic activity than the others (1–4), and the styrene contents in the copolymers were close to those produced by the tert-BuC5H4 analogue (3) under the same conditions (Table 2, Figure 2). Note that the activity by 5 increased upon increasing the charged styrene concentration along with the increase in the styrene content in the resultant copolymers (runs 13–15, Figure 2); the Mn value in the resultant copolymer decreased with the increase in the styrene content. Similarly to the observed trend for 2 and 4, the introduction of the SiEt3 group into the para-position in the phenoxide (6) led to a decrease in the catalytic activities (runs 16–18). As observed in the copolymerization by 5, the activity of 6 also increased upon increasing the charged styrene concentration along with the increase in the styrene content in the copolymers. It seems that the Mn values in the copolymers prepared with 6 were higher than those prepared with 5.

Figure 2.

The effect of the cyclopentadienyl fragment on the catalytic activity and the styrene contents of the copolymers in ethylene/styrene copolymerization by Cp′TiCl2(O-2,6-iPr2-4-RC6H2) [Cp’ = Cp*, R = H (1), SiEt3 (2); Cp’ = tBuC5H4, R = H (3), SiEt3 (4); Cp’ = Me3SiC5H4, R = H (5), SiEt3 (6)]–MAO catalyst systems. The detailed data are shown in Table 2. The filled circle or square (arrows) expresses activity and the others express the styrene contents.

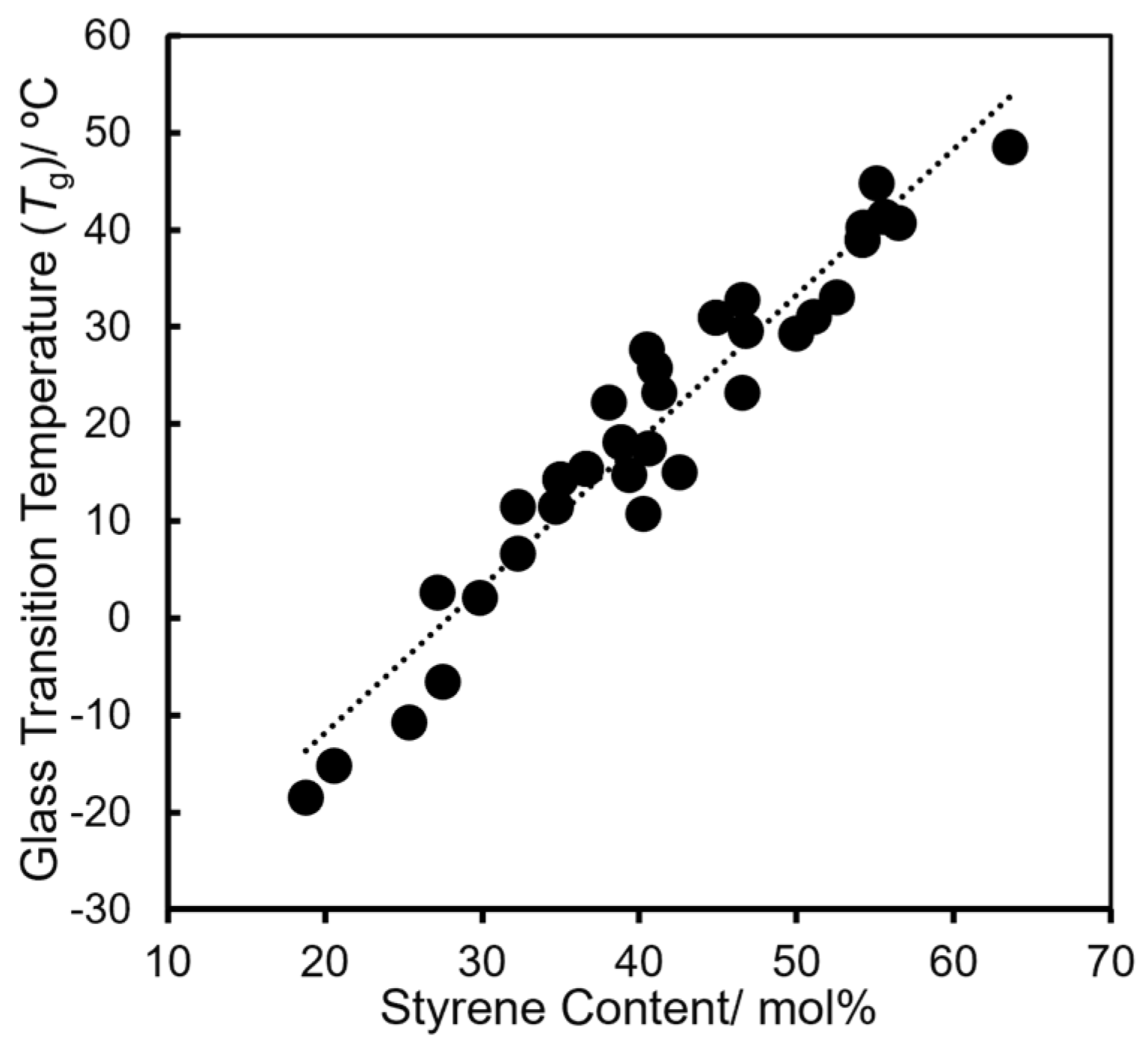

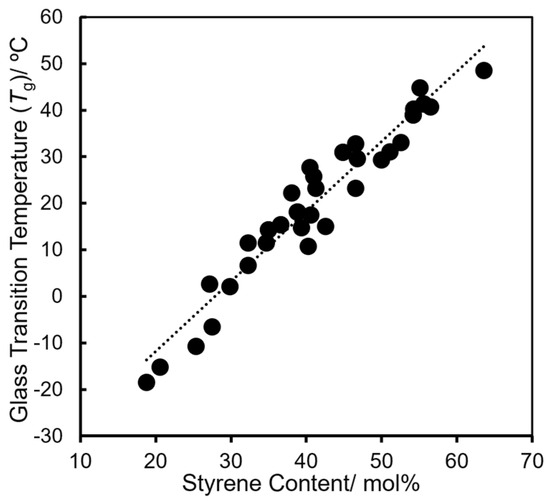

Table 3 summarizes the results of the ethylene/styrene copolymerization by 5 and 6 under various conditions (temperature, ethylene pressure). The activity of 5 was affected by the ethylene pressure employed (runs 13, 19, and 28) and increased upon increasing the ethylene pressure along with the decrease in the styrene content in the resultant copolymer. A decrease in the catalyst concentration (0.50 → 0.30 μmol) did not affect the activity, the Mn values, and the styrene content in the copolymers (runs 13–15, 20–22). The styrene content in the copolymers reached to 63.6 mol% when the copolymerization was conducted under high styrene and low ethylene concentration conditions (run 29). Unfortunately, the activities conducted at 50 °C (runs 23–27) were low compared to those conducted at 20 °C (runs 13–15), and the resultant copolymers possessed low Mn values compared to those conducted at 20 °C. A similar trend was also observed in the copolymerization using the 6–MAO catalyst system (runs 30–33 vs. runs 16–18), whereas the Mn values in the copolymers were higher than those prepared with 5 under the same conditions. As shown in Figure 3, a linear correlation between the Tg values with the styrene contents in the copolymers was observed, as seen in a previous report [11].

Table 3.

Ethylene (E) copolymerization with styrene (St) by (Me3SiC5H4)TiCl2(O-2,6-iPr2-4-RC6H2) [R = H (5), SiEt3 (6)]–MAO catalyst systems: effect of ethylene pressure, styrene concentration, and temperature a.

Figure 3.

Plots of the glass transition temperature (Tg/°C) versus the styrene content (mol%) in the copolymers estimated by 1H NMR spectra (in 1,1,2,2−tetrachloroethane-d2 at 110 °C). The plots were made on the basis of the copolymerization data by catalysts 1–6 in the presence of MAO cocatalyst.

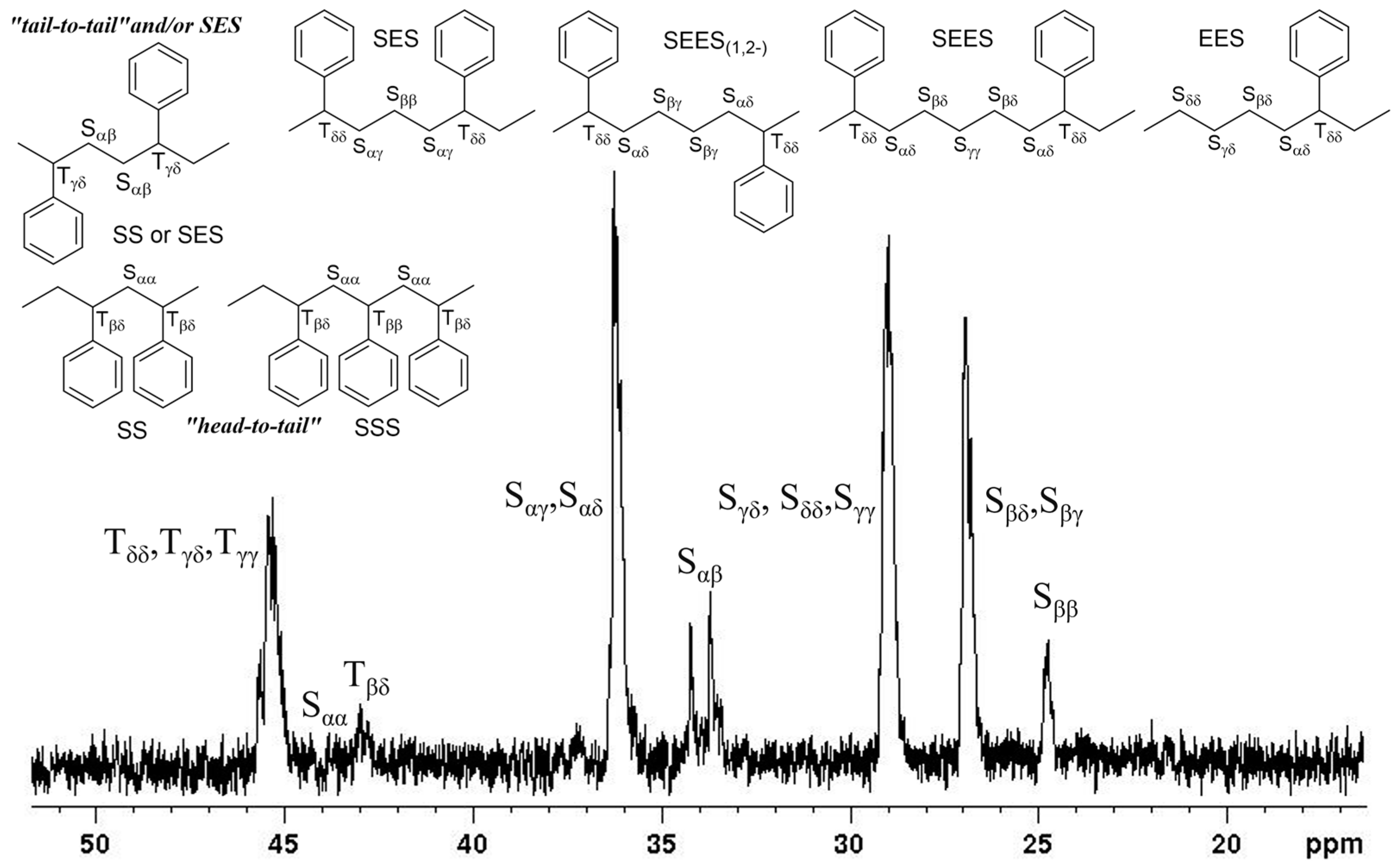

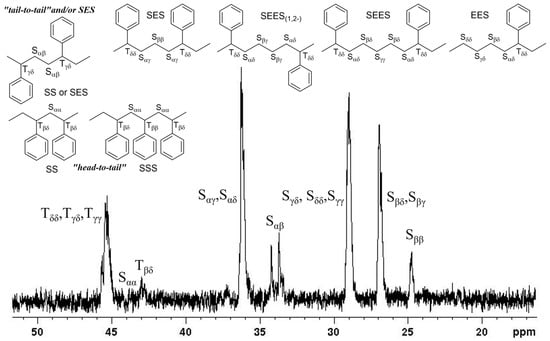

Figure 4 shows a typical 13C NMR spectrum (in 1,1,2,2-tetrachloroethane-d2 at 110 °C) in the ethylene/styrene copolymer prepared by the 5–MAO catalyst system (run 13, styrene 35.0 mol%). As reported previously for catalysts 1 and 3 [11,20,21], the resonances corresponding to styrene head-to-tail incorporation and SES or SS (Sββ, tail-to tail, called pseudo random) were observed in addition to the resonances ascribed to isolated and alternating styrene incorporation (depicted in Figure 4). These results clearly suggest that styrene incorporation was random in this catalysis. No significant differences in the spectra were observed in the resultant copolymers prepared with 6 (the additional data are shown in the Supplementary Material).

Figure 4.

13C NMR spectrum (in C2D2Cl4 at 110 °C, methylene and methine region) of poly(ethylene-co-styrene) prepared by (Me3SiC5H4)TiCl2(O-2,6-iPr2C6H3) (5)–MAO catalyst system; styrene content of 35.0 mol% (run 13).

3. Conclusions

We have demonstrated that newly prepared (Me3SiC5H4)TiCl2(OAr) [OAr = O-2,6-iPr2-4-RC6H2; R = H (5), SiEt3 (6)] exhibited higher catalytic activities than (tBuC5H4)TiCl2(OAr), Cp*TiCl2(OAr), with efficient comonomer incorporation, in ethylene/styrene copolymerization in the presence of an MAO cocatalyst at 20 ºC. The catalytic activity in the copolymerization increased upon increasing the charged styrene concentration along with the increase in the styrene content in the copolymers, whereas the activities of other catalysts showed the opposite trend. Catalyst 5 showed the most suitable catalyst performance in terms of its activity and styrene incorporation, affording amorphous copolymers containing styrene contents higher than 50 mol% (up to 63.6 mol%) with random styrene incorporation. The unique characteristics observed in 5 should be helpful for further designing efficient molecular catalysts for the synthesis of new polyolefins and should provide a new idea for the metal-catalyzed polymerization of various monomers.

4. Materials and Methods

General. All experiments were conducted under a nitrogen atmosphere unless otherwise specified. Anhydrous-grade toluene (Kanto Chemical Co., Inc., Tokyo, Japan) containing a mixture of molecular sieves (3 Å 1/16 and 4 Å 1/8, and 13 × 1/16) was stored in a dry box, and styrene (Tokyo Chemical Industry Co., Ltd., Tokyo, Japan) was stored under nitrogen in a freezer in the dry box and passed through an alumina short column before use. Ethylene (polymerization grade, purity > 99.9%; Sumitomo Seika Co., Ltd., Osaka, Japan) was used as received. According to previous reports [20,21,28,32,35], toluene and AlMe3 in the commercially available MAO solution [TMAO-S, 9.5 wt% (Al) toluene solution, Tosoh Finechem Co.] were removed under reduced pressure (at ca. 50 °C and completion for 1 h at >100 °C) to afford an AlMe3-free MAO white solid (d-MAO) as the cocatalyst employed in this study. Cp′TiCl2(O-2,6-iPr2-C6H3) [Cp′=Cp* (1), tBuC5H4 (3)] [35] and Cp*TiCl2(O-2,6-iPr2-4-SiEt3-C6H2) (2) [32] were prepared according to previous reports. TMAO-S generates flammable gases upon exposure to water and/or air, and should be kept under an inert atmosphere.

All 1H and 13C NMR spectra were recorded on a Bruker AV500 spectrometer (Bruker 500.13 MHz for 1H, 125.77 MHz for 13C, Billerica, MA, USA), and chemical shifts are given in ppm and are referenced to SiMe4. All spectra for the analysis of the titanium complexes were obtained in the solvent indicated at 25 °C, and the resultant poly(ethylene-co-styrene)s were prepared by dissolving them in 1,1,2,2-tetrachloroethane-d2 and were measured at 110 °C. 13C{1H} NMR spectra (90° pulse angle) were measured with the conditions of a pulse interval of 5.2 s and an acquisition time of 0.8 s; number of the transients in the analysis was accumulated, ca. 6000. Gel permeation chromatography (GPC) was performed to estimate the molecular weights (Mw, Mn) and their distributions, and the analysis was conducted by using Tosoh HLC-8321GPC/HT (at 140 °C) in ortho-dichlorobenzene (containing 0.05 wt% 2,6-di-tert-butyl-p-cresol) as the eluent. The molecular weight was estimated with a calibration curve by using polystyrene standard samples. Thermal properties in the resultant poly(ethylene-co-styrene)s were analyzed by differential scanning calorimetric (DSC) thermograms (Hitachi DSC-7000X, Hitachi High-Tech Corp. Tokyo, Japan) under nitrogen atmosphere. The analysis of the copolymer samples was conducted upon heating from −100 to 250 °C at 20 °C/min, after preheating from 30 to 250 °C (20 °C/min) and cooling to −100 °C (10 °C/min). In this heating scan, the melting temperature (Tm) and the glass transition temperature (Tg) were chosen from the middle of the phase transition.

Preparation of (tBuC5H4)TiCl2(O-2,6-iPr2-4-SiEt3C6H2) (4). An Et2O solution (5.0 mL) containing 2,6-iPr2-4-SiEt3-C6H2OH (292 mg, 1.0 mmol) and Et3N (152 mg, 1.5 mmol) was added into an Et2O (20 mL) solution of (tBuC5H4)TiCl3 (233 mg, 0.85 mmol) in one portion at −30 °C. The reaction mixture was warmed slowly to room temperature and was stirred overnight. The mixture was then filtered through a Celite pad, and the filter cake was washed with Et2O. The combined filtrate and the wash were taken to dryness under reduced pressure to give an orange oil. The resultant oil was then dissolved in a small amount of n-hexane. The chilled (−30 °C) solution in the freezer gave orange microcrystals (yield: 76%). 1H NMR (500 MHz, CDCl3): δ = 7.20 (s, 2H, Ar-H), δ = 6.82 (t, 2H, J = 2.8 Hz, Cp-H), δ = 6.23 (t, 2H, J = 2.8 Hz, Cp-H), δ = 3.30–3.22 (m, 2H, Ar-CH(CH3)2), δ = 1.44 (s, 9H, Cp-C(CH3)3), δ = 1.23 (d, 12H, J = 6.9 Hz, Ar-CH(CH3)2), δ = 0.99 (t, 9H, J = 7.9 Hz, Ar-SiCH2CH3), δ = 0.78 (q, 6H, J = 7.9 Hz, Ar-SiCH2CH3). 13C{1H} NMR (125 MHz, CDCl3): δ = 165.4, 151.4, 137.2, 133.3, 129.3, 119.3 (Aromatic group), δ = 34.2 (Cp-C(CH3)3), δ = 31.0 (Cp-C(CH3)3), δ = 27.0 (Ar-CH(CH3)2), δ = 23.9 (Ar-CH(CH3)2), δ = 7.66 (-SiCH2CH3), δ = 3.73 (-SiCH2CH3).

Preparation of (Me3SiC5H4)TiCl2(O-2,6-iPr2-C6H3) (5). Li(O-2,6-iPr2C6H3) (221 mg, 1.2 mmol) was added in one portion to an Et2O solution (30 mL) containing (Me3SiC5H4)TiCl3 (350 mg, 1.2 mmol) precooled at −30 °C. The reaction mixture was warmed slowly to room temperature and was stirred overnight. The mixture was then filtered through a Celite pad, and the filter cake was washed with Et2O. The combined filtrate and the wash were taken to dryness under reduced pressure to give orange solids. The resultant solids were then dissolved in a minimum amount of dichloromethane layered by a small amount of n-hexane. The chilled (−30 °C) solution in the freezer gave orange microcrystals (yield: 82%). 1H NMR (500 MHz, CDCl3): δ = (d, 2H, J = 7.8 Hz, Ar-H), δ = (t, 1H, J = 7.2 Hz, Ar-H), δ = 7.04 (t, 2H, J = 1.9 Hz, Cp-H), δ = 6.40 (t, 2H, J = 2.2 Hz, Cp-H), δ = 3.27–3.19 (m, 2H, Ar-CH(CH3)2), δ = 1.23 (d, 12H, J = 6.8 Hz, Ar-CH(CH3)2), δ = 0.40 (s, 9H, Cp-Si(CH3)3). 13C{1H} NMR (125 MHz, CDCl3): δ = 164.7, 138.3, 136.9, 127.9, 124.5, 123.5, 122.6 (Aromatic group), δ = 27.1 (Ar-CH(CH3)2), δ = 23.7 (Ar-CH(CH3)2), δ = −0.43 (-Si(CH3)3). EA: Found. C 55.52%, H 7.02%; Calcd. for C20H30Cl2OSiTi: C 55.44%, H 6.98%.

Preparation of (Me3SiC5H4)TiCl2(O-2,6-iPr2-4-SiEt3C6H2) (6). An Et2O solution (5.0 mL) containing 2,6-iPr2-4-SiEt3-C6H2OH (292 mg, 1.0 mmol) and Et3N (152 mg, 1.5 mmol) was added in one portion into an Et2O solution (20 mL) containing (Me3SiC5H4)TiCl3 (262 mg, 0.9 mmol) at −30 °C. The reaction mixture was warmed slowly to room temperature and was stirred overnight. The mixture was then filtered through a Celite pad, and the filter cake was washed with Et2O. The combined filtrate and the wash were taken to dryness under reduced pressure to give an orange oil. The oil was then dissolved in a small amount of n-hexane, and the chilled (−30 °C) solution in the freezer gave orange microcrystals (yield: 75%). 1H NMR (500 MHz, CDCl3): δ = 7.20 (s, 2H, Ar-H), δ = 7.04 (t, 2H, J = 2.3 Hz, Cp-H), δ = 6.43 (t, 2H, J = 2.3 Hz, Cp-H), δ = 3.27–3.19 (m, 2H, Ar-CH(CH3)2), δ = 1.23 (d, 12H, J = 6.8 Hz, Ar-CH(CH3)2), δ = 0.99 (t, 9H, J = 7.9 Hz, Ar-SiCH2CH3), δ = 0.78 (q, 6H, J = 7.9 Hz, Ar-SiCH2CH3), δ = 0.40 (s, 9H, Cp-Si(CH3)3). 13C{1H} NMR (125 MHz, CDCl3): δ = 165.5, 137.1, 136.8, 133.4, 129.3, 127.9, 122.5 (Aromatic group), δ = 27.0 (Ar-CH(CH3)2), δ = 23.8 (Ar-CH(CH3)2), δ = 7.66 (-SiCH2CH3), δ = 3.74 (-SiCH2CH3), δ = −0.43 (-Si(CH3)3). EA: Found. C 57.18%, H 8.005%; Calcd. for C26H44Cl2OSi2Ti: C 57.03%, H 8.100%.

Typical Reaction Procedure for Ethylene Copolymerization with Styrene. A typical reaction procedure for the copolymerization of ethylene with styrene by a (Me3SiC5H4)TiCl2(O-2,6-iPr2C6H3) (5)-MAO catalyst (Table 2, run 13) is as follows: Toluene (26.0 mL) and d-MAO (white solid, 174 mg, 3.0 mmol) were added into the autoclave (100 mL, stainless steel) in the dry box, and the reaction apparatus was then filled with ethylene in the fume hood. A toluene solution (1.0 mL) containing 1 was then added into the autoclave after the addition of styrene (3.0 mL), and the reaction apparatus was then immediately pressurized to the prescribed pressure employed. The mixture was stirred for 10 min, and the polymerization was terminated with the addition of MeOH. The solution was then poured into MeOH (100 mL), and the resultant polymer was adequately washed with MeOH and then dried in vacuo for several hours.

According to previous reports [20,21], the resultant polymer mixture was separated into three fractions. Atactic polystyrene prepared by MAO itself (in a cationic manner) was extracted with acetone. Poly(ethylene-co-styrene)s were then extracted with THF from the acetone-insoluble portion, and the polyethylene and syndiotactic polystyrene by-products were separated as the THF-insoluble fraction. The basic experimental procedure is as follows: The resultant polymer solids (after precipitation with MeOH and dried in vacuo) were added to acetone (15.0 mL) in a centrifugal sedimentation tube (50 mL, glass), and the copolymers were separated [with the removal of the atactic polystyrene formed due to MAO] as precipitates by a centrifuge. The procedure was repeated three times. The acetone-insoluble fraction was added into a centrifugal sedimentation tube containing tetrahydrofuran (THF, 15.0 mL), and the THF-soluble and THF-insoluble fractions were separated; the procedure was repeated three times. As reported previously [20,21], the resultant copolymers were soluble in THF and the amount of THF insoluble fractions was negligible in all cases. These fractions were analyzed by 1H- and 13C-NMR spectra, GPC analysis, and DSC thermograms.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/molecules29184473/s1, Crystal data and collection parameters for analysis of (Me3SiC5H4)TiCl2(O-2,6-iPr2-4-RC6H2) [R = H (5), SiEt3 (6)]; ethylene polymerization data for 1–4; selected NMR spectra of poly(ethylene-co-styrene)s and selected DSC thermograms in resultant poly(ethylene-co-styrene)s.

Author Contributions

Conceptualization, methodology, writing—original draft preparation, review, and editing, supervision, project administration, and funding acquisition, K.N.; validation, formal analysis, and investigation, T.H. and T.F. (catalyst synthesis and identification); data curation and visualization, T.H. and K.N.; crystallographic analysis, D.S. All authors have read and agreed to the published version of the manuscript.

Funding

This study was partly funded by a Grant-in-Aid for Scientific Research from the Japan Society for the Promotion of Science (JSPS, No. 21H01942) awarded to K.N.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are contained within the article and the Supplementary Material. The crystallographic analysis data for (Me3SiC5H4)TiCl2(O-2,6-iPr2-4-RC6H2) [R = H (5), SiEt3 (6)] are available as CCDC 2378274 and 2378275, respectively, from The Cambridge Crystallographic Data Centre (CCDC).

Acknowledgments

The authors express their thanks to Tosoh Finechem Co. for providing the MAO samples, and K.N. thanks Youshu Jiang (Tokyo Metropolitan University) for her kind help in preparing the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Osakada, K. (Ed.) Organometallic Reactions and Polymerization. In The Lecture Notes in Chemistry 85; Springer: Berlin, Germany, 2014. [Google Scholar]

- Handbook of Transition Metal Polymerization Catalysts, 2nd ed; Hoff, R., Ed.; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar]

- Nomura, K.; Kitphaitun, S. Catalysis for a Sustainable Environment: Reactions, Processes and Applied Technologies; Pombeiro, A.J.L., Sutradhar, M., Alegria, E.C.B.A., Eds.; John Wiley & Sons, Ltd.: Chichester, West Sussex, UK, 2024; pp. 323–338. [Google Scholar]

- Baier, M.C.; Zuideveld, M.A.; Mecking, S. Post-metallocenes in the industrial production of polyolefins. Angew. Chem. Int. Ed. 2014, 53, 9722–9744. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Marks, T.J. Nuclearity and cooperativity effects in binuclear catalysts and cocatalysts for olefin polymerization. Proc. Nat. Acad. Sci. USA 2006, 103, 15295–15302. [Google Scholar] [CrossRef]

- Delferro, M.; Marks, T.J. Multinuclear olefin polymerization catalysts. Chem. Rev. 2011, 111, 2450–2485. [Google Scholar] [CrossRef]

- McInnis, J.P.; Delferro, M.; Marks, T.J. Multinuclear group 4 catalysis: Olefin polymerization pathways modified by strong metal–metal cooperative effects. Acc. Chem. Res. 2014, 47, 2545–2557. [Google Scholar] [CrossRef] [PubMed]

- Nomura, K. Half-titanocenes containing anionic ancillary donor ligands as promising new catalysts for precise olefin polymerization. Dalton Trans. 2009, 38, 8811–8823. [Google Scholar] [CrossRef] [PubMed]

- Nomura, K.; Liu, J. Half-titanocenes for precise olefin polymerisation: Effects of ligand substituents and some mechanistic aspects. Dalton Trans. 2011, 40, 7666–7682. [Google Scholar] [CrossRef]

- van Doremaele, G.; van Duin, M.; Valla, M.; Berthoud, A. On the development of titanium κ1-amidinate complexes, commercialized as Keltan ACETM technology, enabling the production of an unprecedented large variety of EPDM polymer structures. J. Poly. Sci. Part A Polym. Chem. 2017, 55, 2877–2891. [Google Scholar] [CrossRef]

- Nomura, K. Syndiotactic Polystyrene—Synthesis, Characterization, Processing, and Applications; Schellenberg, J., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; pp. 60–91. [Google Scholar]

- Stevens, J.C.; Timmers, F.J.; Wilson, D.R.; Schmidt, G.F.; Nickias, P.N.; Rosen, R.K.; Knight, G.W.; Lai, S.Y. Constrained Geometry Addition Polymerization Catalysts, Processes for Their Preparation, Precursors Therefor, Methods of Use, and Novel Polymers Formed Therewith. Dow Chemical Co. EP 0416815 A2, 13 August 1997. (Application granted). [Google Scholar]

- Sernetz, F.G.; Mülhaupt, R.; Waymouth, R.M. Influence of polymerization conditions on the copolymerization of styrene with ethylene using Me2Si(Me4Cp)(N-tert-butyl)TiCl2/methylaluminoxane Ziegler-Natta catalysts. Macromol. Chem. Phys. 1996, 197, 1071–1083. [Google Scholar] [CrossRef]

- Sernetz, F.G.; Mülhaupt, R.; Amor, F.; Eberle, T.; Okuda, J. Copolymerization of ethene with styrene using different methylalumoxane activated half-sandwich complexes. J. Polym. Sci. Part A Polym. Chem. 1997, 35, 1571–1578. [Google Scholar] [CrossRef]

- Timmers, F.J. Olefin Polymers Formed by Use of Constrained Geometry Addition Polymerization Catalysts. Dow Chemical Co. U.S. Patent 6670432 B1, 30 December 2003. (Application granted). [Google Scholar]

- Nomura, K.; Okumura, H.; Komatsu, T.; Imanishi, Y. Effect of ligand in ethylene/styrene copolymerization by [Me2Si(C5Me4)(NR)]TiCl2 (R = tert-Bu, cyclohexyl) and (1,3-Me2C5H3)TiCl2(O-2,6-iPr2C6H3)—MAO catalyst systems. J. Mol. Catal. A 2002, 190, 225–234. [Google Scholar] [CrossRef]

- Guo, N.; Li, L.; Marks, T.J. Bimetallic catalysis for styrene homopolymerization and ethylene-styrene copolymerization. Exceptional comonomer selectivity and insertion regiochemistry. J. Am. Chem. Soc. 2004, 126, 6542–6543. [Google Scholar] [CrossRef] [PubMed]

- Arriola, D.J.; Bokota, M.; Campbell, R.E., Jr.; Klosin, J.; LaPointe, R.E.; Redwine, O.D.; Shankar, R.B.; Timmers, F.J.; Abboud, K.A. Penultimate effect in ethylene-styrene copolymerization and the discovery of highly active Ethylene-styrene catalysts with increased styrene reactivity. J. Am. Chem. Soc. 2007, 129, 7065–7076. [Google Scholar] [CrossRef]

- Guo, N.; Stern, C.L.; Marks, T.J. Bimetallic effects in homopolymerization of styrene and copolymerization of ethylene and styrenic comonomers: Scope, kinetics, and mechanism. J. Am. Chem. Soc. 2008, 130, 2246–2261. [Google Scholar] [CrossRef] [PubMed]

- Nomura, K.; Komatsu, T.; Imanishi, Y. Syndiospecific styrene polymerization and efficient ethylene/styrene copolymerization catalyzed by (cyclopentadienyl)(aryloxy)titanium(IV) complexes—MAO system. Macromolecules 2000, 33, 8122–8124. [Google Scholar] [CrossRef]

- Nomura, K.; Okumura, H.; Komatsu, T.; Naga, N. Ethylene/styrene copolymerization by various (cyclopentadienyl)(aryloxy)titanium(IV) complexes—MAO catalyst system. Macromolecules 2002, 35, 5388–5395. [Google Scholar] [CrossRef]

- Kretschmer, W.P.; Dijkhuis, C.; Meetsma, A.; Hessen, B.; Teuben, J.H. A highly efficient titanium-based olefin polymerisation catalyst with a monoanionic iminoimidazolidide π-donor ancillary ligand. Chem. Commun. 2002, 608–609. [Google Scholar] [CrossRef]

- Wang, Q.; Lam, P.; Zhang, Z.; Yamashita, G.; Fan, L. Ethylene styrene interpolymers with double reverse styrene incorporation. U.S. Patent 6579961 B1, 17 June 2003. (Application granted). [Google Scholar]

- Zhang, H.; Nomura, K. Living copolymerization of ethylene with styrene catalyzed by (cyclopentadienyl)(ketimide)titanium(IV) complex—MAO catalyst system. J. Am. Chem. Soc. 2005, 127, 9364–9365. [Google Scholar] [CrossRef]

- Zhang, H.; Nomura, K. Living copolymerization of ethylene with styrene catalyzed by (cyclopentadienyl)(ketimide)titanium(IV) complex—MAO catalyst system: Effect of anionic ancillary donor ligand. Macromolecules 2006, 39, 5266–5274. [Google Scholar] [CrossRef]

- Nomura, K.; Pracha, S.; Phomphrai, K.; Katao, S.; Kim, D.-H.; Kim, H.-J.; Suzuki, N. Synthesis and structural analysis of phenoxy-substituted half-titanocenes with different anionic ligands, Cp*TiX(Y)(O-2,6-iPr2C6H3): Effect of anionic ligands (X,Y) in ethylene/styrene copolymerization. J. Mol. Catal. A Chem. 2012, 365, 136–145. [Google Scholar] [CrossRef]

- Son, K.-S.; Waymouth, R.M. Stereospecific styrene polymerization and ethylene–styrene copolymerization with titanocenes containing a pendant amine donor. J. Polym. Sci. Part A Polym. Chem. 2010, 48, 1579–1585. [Google Scholar] [CrossRef]

- Aoki, H.; Nomura, K. Synthesis of amorphous ethylene copolymers with 2-vinylnaphthalene, 4-vinylbiphenyl and 1-(4-vinylphenyl)naphthalene. Macromolecules 2021, 54, 83–93. [Google Scholar] [CrossRef]

- Arai, T.; Ohtsu, T.; Suzuki, S. Stereoregular and Bernoullian copolymerization of styrene and ethylene by bridged metallocene catalysts. Macromol. Rapid Commun. 1998, 19, 327–331. [Google Scholar] [CrossRef]

- Arai, T.; Suzuki, S.; Ohtsu, T. Olefin Polymerization: Emerging Frontiers; Arjunan, P., Ed.; ACS Symposium Series 749; American Chemical Society: Washington, DC, USA, 2000; pp. 66–80. [Google Scholar]

- Byun, D.-J.; Fudo, A.; Tanaka, A.; Fujiki, M.; Nomura, K. Effect of cyclopentadienyl and anionic ancillary ligand in syndiospecific styrene polymerization catalyzed by nonbridged half-titanocenes containing aryloxo, amide and anilide ligands—cocatalyst systems. Macromolecules 2004, 37, 5520–5530. [Google Scholar] [CrossRef]

- Kitphaitun, S.; Yan, Q.; Nomura, K. Effect of SiMe3, SiEt3 para-substituents for exhibiting high activity, introduction of hydroxy group in ethylene copolymerization catalyzed by phenoxide-modified half-titanocenes. Angew. Chem. Int. Ed. 2020, 59, 23072–23076. [Google Scholar] [CrossRef]

- Miyazawa, A.; Kase, T.; Soga, K. Cis-Specific living polymerization of 1,3-butadiene catalyzed by alkyl and alkylsilyl substituted cyclopentadienyltitanium trichlorides with MAO. Macromolecules 2000, 33, 2796–2800. [Google Scholar] [CrossRef]

- Losio, S.; Bertini, F.; Vignali, A.; Fujioka, T.; Nomura, K.; Tritto, I. Amorphous elastomeric ultra-high molar mass polypropylene in high yield by half-titanocene catalysts. Polymers 2024, 16, 512. [Google Scholar] [CrossRef]

- Nomura, K.; Naga, N.; Miki, M.; Yanagi, K. Olefin Polymerization by (cyclopentadienyl)(aryloxy) titanium(IV) complexes−cocatalyst systems. Macromolecules 1998, 31, 7588–7597. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).