FDM 3D Printing and Properties of WF/PBAT/PLA Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Testing and Characterization

2.3.1. Mechanical Testing

2.3.2. Microscopic Morphology Observation

2.3.3. Thermal Stability Characterization

2.3.4. Melting and Crystallization Behavior Analysis

2.3.5. Contact Angle Testing

2.3.6. Melt Flow Rate Testing

3. Results

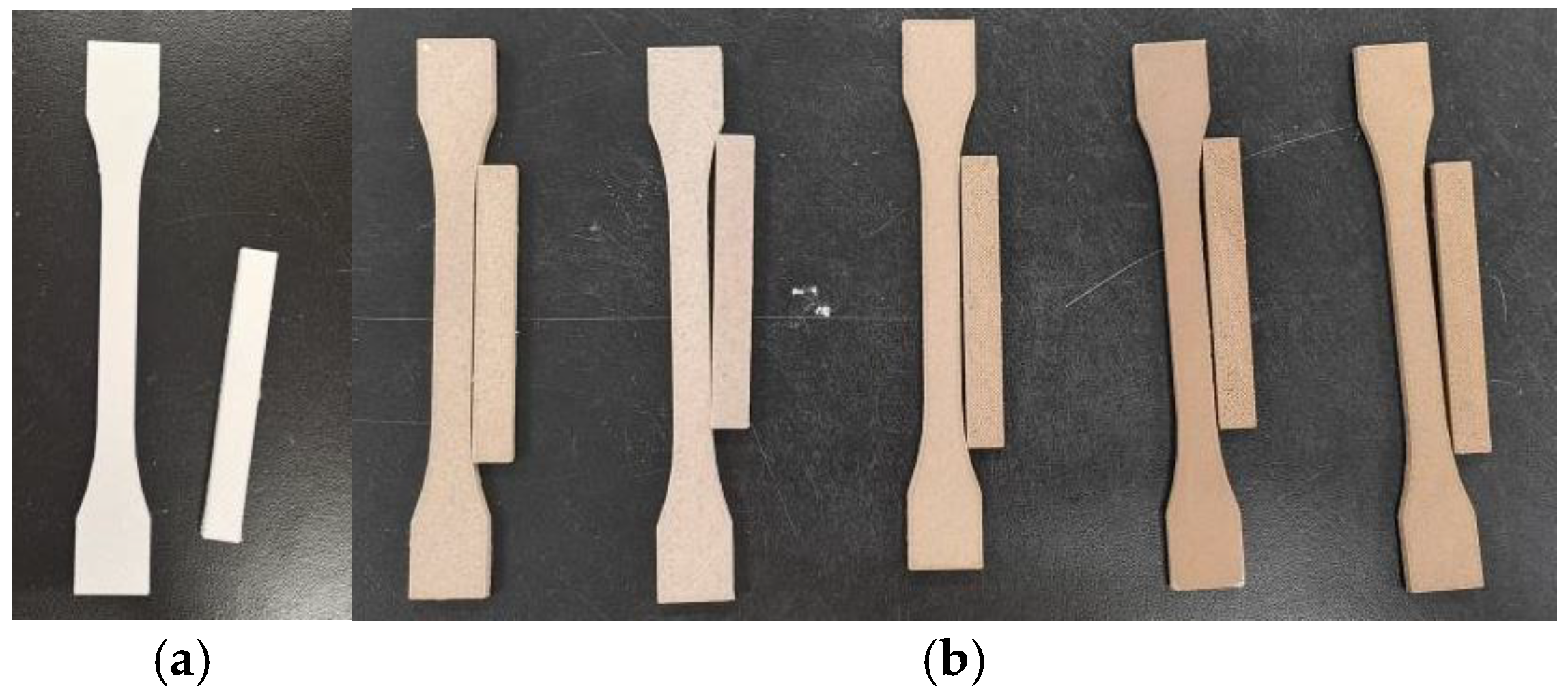

3.1. Appearance Quality

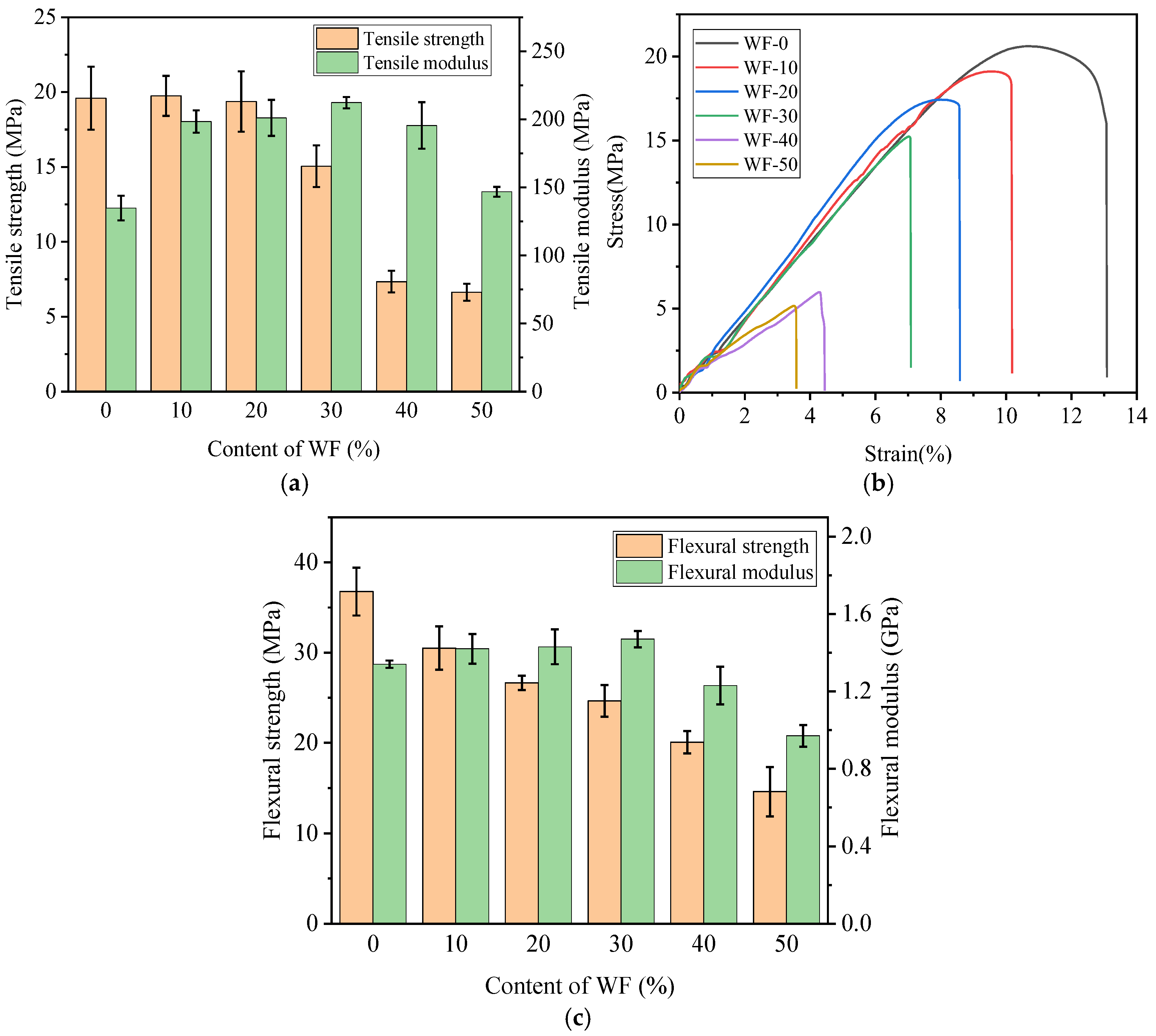

3.2. Mechanical Properties

3.3. Microscopic Morphology

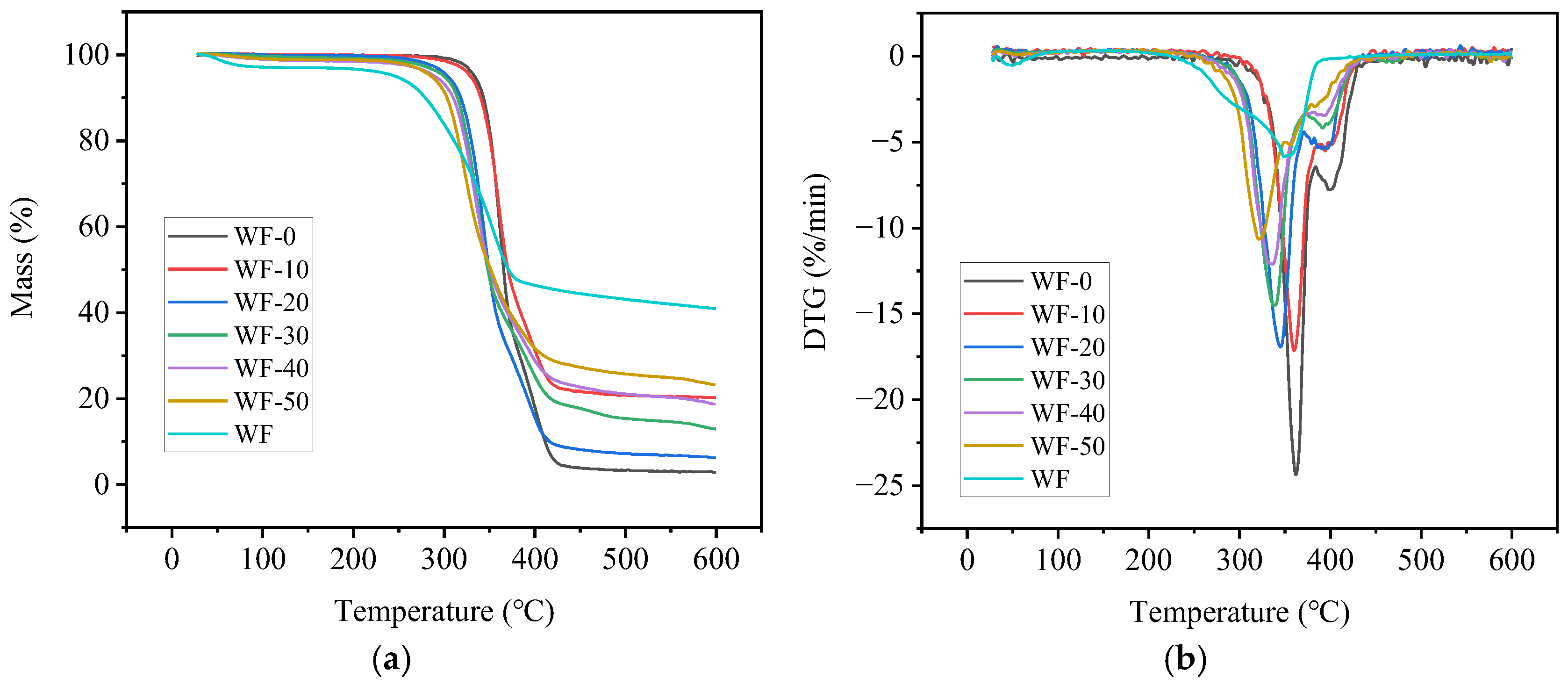

3.4. Thermal Stability

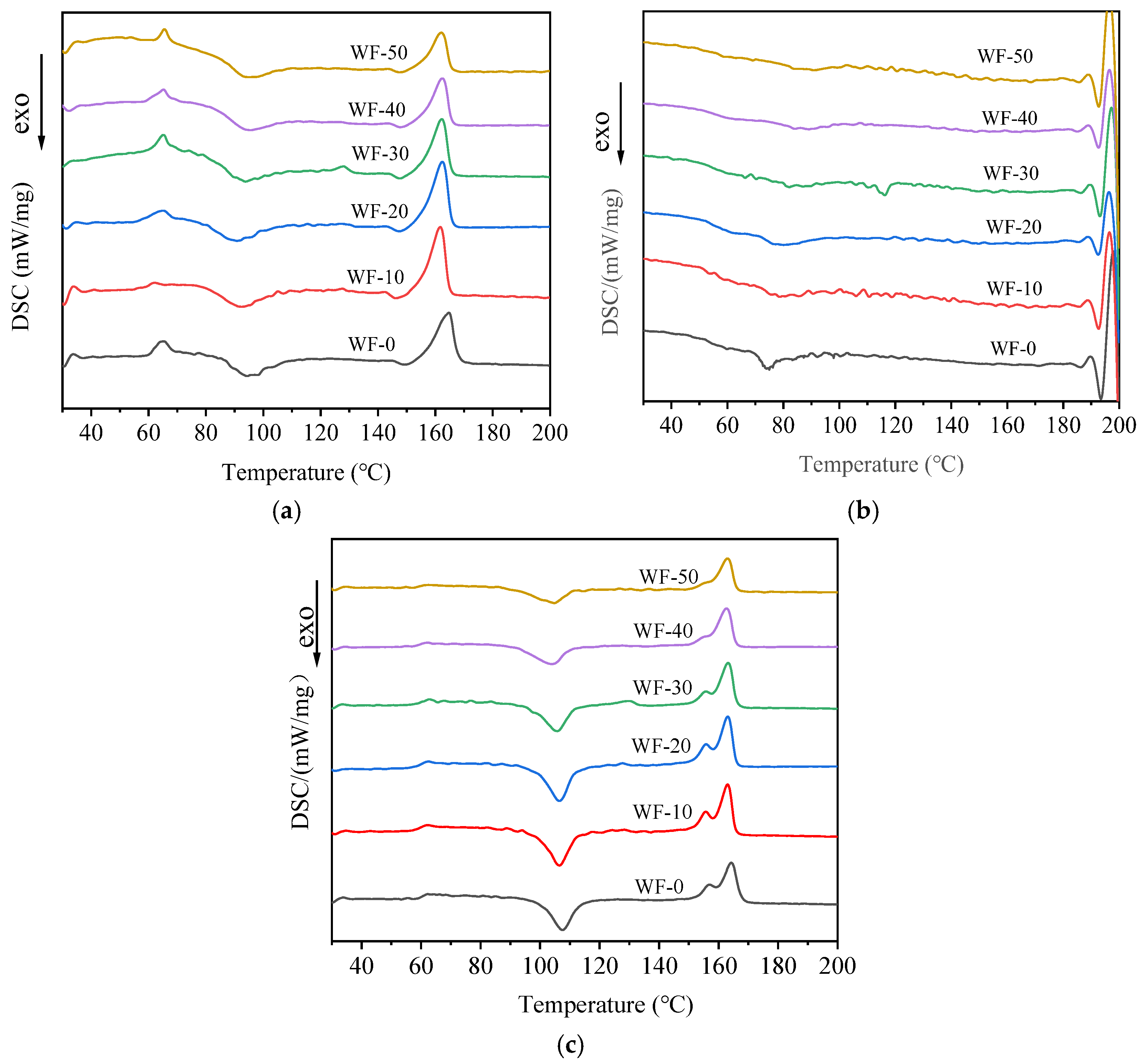

3.5. Melting and Crystallization Behavior

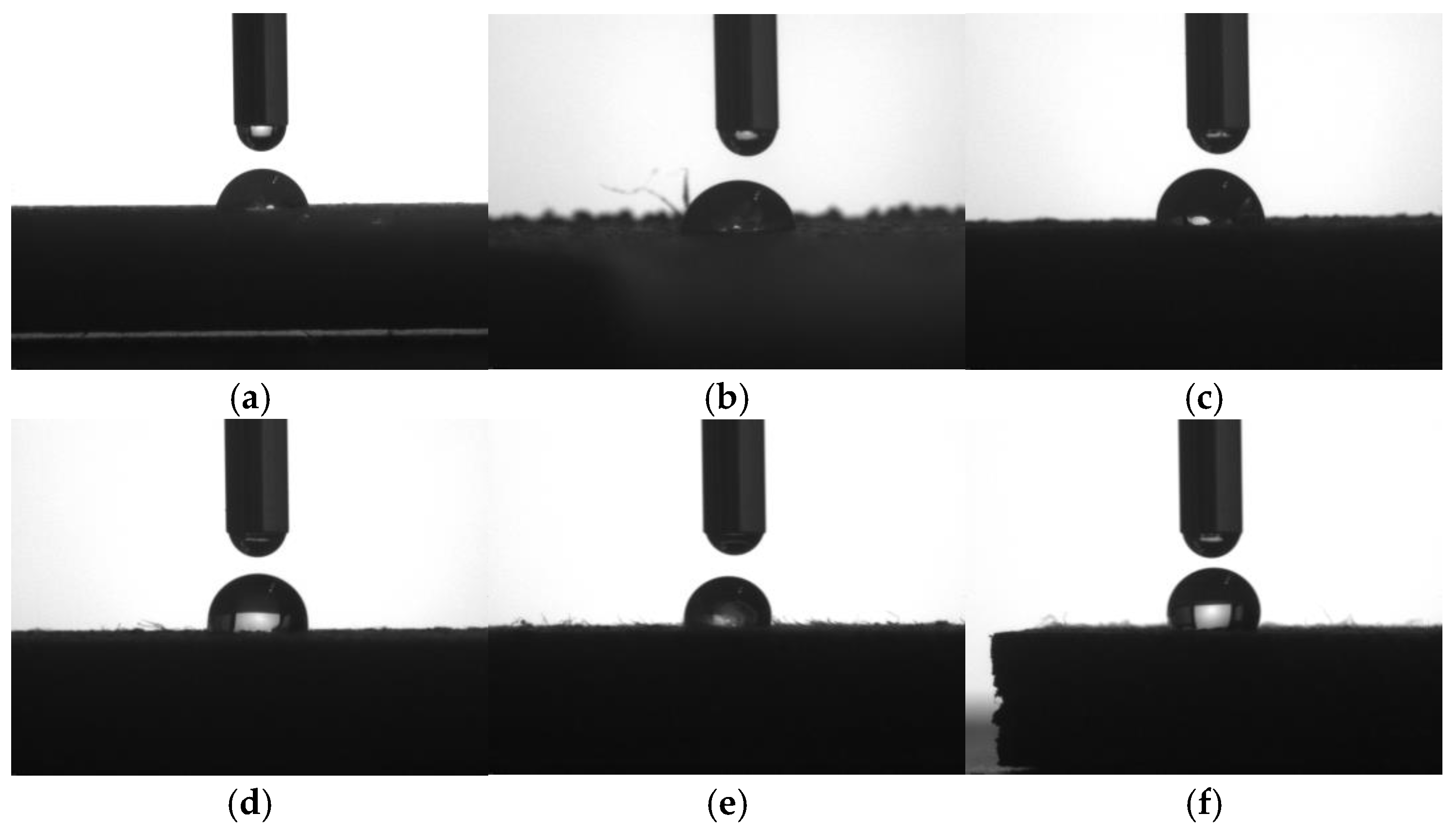

3.6. Wettability

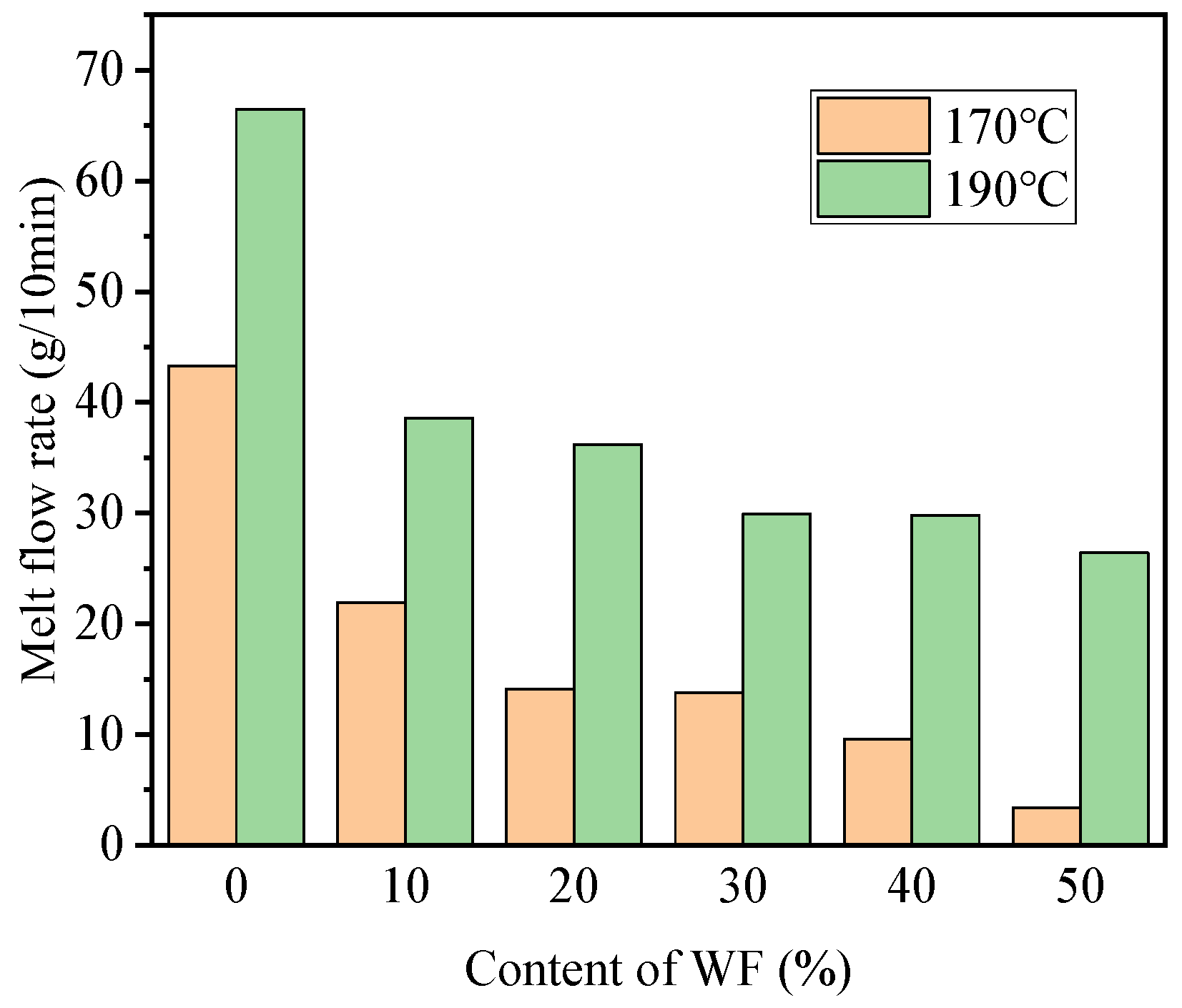

3.7. Melt Flow Rate

3.8. Cost Analysis

4. Discussions

5. Conclusions

- (1)

- The addition of WF decreased the tensile and flexural strengths of PBAT/PLA, and the tensile and flexural moduli showed a tendency to increase first and then decrease with the increase of WF content. Among them, WF-20 had the best overall mechanical properties, whose tensile strength, tensile modulus, flexural strength, and modulus were 19.4 MPa, 201.1 MPa, 26.7 MPa, and 1.4 GPa, respectively.

- (2)

- Both the T95 and Tp of the printed samples decreased gradually with the increased WF dosage while the char residue rate increased; the thermal stability of the printed specimens worsened when WF was introduced, and the degradation process was retarded. Among all the printed composites, WF-20 had proper thermal stability and decomposition speed.

- (3)

- WF content had little effect on the glass transition temperature and cold crystallization temperature, while it had a positive correlation with the crystallinity of the printed composite samples, WF-20 had the greatest cold crystallization enthalpy and melting enthalpy, showing a perfect crystal structure compared to the composite samples.

- (4)

- As the WF content increased, the hydrophilicity of the composite was enhanced, and the sample turned from surface hydrophilicity to hydrophobicity when the WF content was greater than 20 wt.%.

- (5)

- The MFR of the printed specimens decreased with the increasing dosage of WF, and all the samples had a greater MFR at 190 °C than that at 170 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef] [PubMed]

- Azlin, M.N.M.; Ilyas, R.A.; Zuhri, M.Y.M.; Sapuan, S.M.; Harussani, M.M.; Sharma, S.; Nordin, A.H.; Nurazzi, N.M.; Afiqah, A.N. 3D Printing and Shaping Polymers, Composites, and Nanocomposites: A Review. Polymers 2022, 14, 180. [Google Scholar] [CrossRef]

- Jiang, Z.; Diggle, B.; Tan, M.L.; Viktorova, J.; Bennett, C.W.; Connal, L.A. Extrusion 3D Printing of Polymeric Materials with Advanced Properties. Adv. Sci. 2020, 7, 2001379. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.G.; Wang, Y.Q.; Wu, B.C.; Cui, C.Z.; Guo, Y.; Yan, C. A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Alba, C.V.; Murtaza, M.; Tambuwala, S.K.; Sarif, H.; Debmalya, B.; Alaa, A.A. Fused deposition modelling: Current status, methodology, applications and future prospects. Addit. Manuf. 2021, 47, 2214–8604. [Google Scholar] [CrossRef]

- Rajan, K.; Samykano, M.; Kadirgama, K.; Harun, W.S.W.; Rahman, W.W. Fused deposition modeling: Process, materials, parameters, properties, and applications. Int. J. Adv. Manuf. Technol. 2022, 120, 1531–1570. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Abbasali, B.; Mohammad, S.A.P.; Abdolvahed, K.; Mohammad, A.; Vahid, A. Fatigue testing on rotary friction-welded joints between solid ABS and 3D-printed PLA and ABS. Eur. J. Mech. A-Solids 2022, 96, 104713. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, W.; Liu, T.X. Fused deposition modeling 3D printing of polyamide-based composites and its applications. Compos. Commun. 2020, 21, 100413. [Google Scholar] [CrossRef]

- Shinhyeong, C.; Yujin, K.; Geunyong, P.; Do, H.L.; Jehee, P.; Ayantu, T.M.; Sumin, L.; Jaewook, M. Biodegradation of 3D-Printed Biodegradable/Non-biodegradable Plastic Blends. ACS Appl. Polym. Mater. 2022, 4, 5077–5090. [Google Scholar] [CrossRef]

- Weng, Z.X.; Wang, J.L.; Senthil, T.; Wu, L.X. Mechanical and thermal properties of ABS/montmorillonite nanocomposites for fused deposition modeling 3D printing. Mater. Des. 2016, 102, 276–283. [Google Scholar] [CrossRef]

- Seong, J.P.; Ji, E.L.; Han, B.L.; Jeanho, P.; Nak-Kyu, L.; Yong, S.; Suk-Hee, P. 3D printing of bio-based polycarbonate and its potential applications in ecofriendly indoor manufacturing. Addit. Manuf. 2020, 31, 100974. [Google Scholar] [CrossRef]

- Bahar, A.; Belhabib, S.; Guessasma, S.; Benmahiddine, F.; Hamami, A.E.A.; Belarbi, R. Mechanical and Thermal Properties of 3D Printed Polycarbonate. Energies 2022, 15, 3686. [Google Scholar] [CrossRef]

- Cody, W.W.; John, W.W.; Katherine, V.H. 3D-Printing of Poly(arylene ether sulfone)s: Functional High-Performance Polymers for Vat Photopolymerization. Macromol. Chem. Phys. 2023, 224, 2200240. [Google Scholar] [CrossRef]

- Tümer, E.H.; Erbil, H.Y. Extrusion-Based 3D Printing Applications of PLA Composites: A Review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Bardot, M.; Schulz, M.D. Biodegradable Poly(Lactic Acid) Nanocomposites for Fused Deposition Modeling 3D Printing. Nanomaterials 2020, 10, 2567. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.; Liu, L.W.; Liu, J.J.; Leng, J.S. 4D printing of shape memory polybutylene succinate/polylactic acid (PBS/PLA) and its potential applications. Compos. Struct. 2022, 279, 114729. [Google Scholar] [CrossRef]

- Atsuki, T.; Hsu, Y.I.; Hiroshi, U. Biodegradable poly(lactic acid) and polycaprolactone alternating multiblock copolymers with controllable mechanical properties. Polym. Degrad. Stabil. 2023, 218, 110564. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, X.; Fu, Y.; Jin, Y.; Weng, Y.; Bian, X.; Chen, X. Degradation Behaviors of Polylactic Acid, Polyglycolic Acid, and Their Copolymer Films in Simulated Marine Environments. Polymers 2024, 16, 1765. [Google Scholar] [CrossRef]

- Li, G.Z.; Xia, Y.; Mu, G.Q.; Yang, Q.; Zhou, H.M.; Lin, X.J.; Gao, Y.M.; Qian, F. Phase Structure Analysis and Composition Optimization of Poly(Lactic Acid)/Poly(Butylene Adipate-co-terephthalate) Blends. J. Macromol. Sci. B 2022, 61, 413–424. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, Z.S.; Long, Y.; Fu, K.K.; Li, Y. Process optimization of continuous flax fiber/polylactic acid prepreg filaments toward high performance 3D-printed composites. Polym. Compos. 2023, 44, 6242–6253. [Google Scholar] [CrossRef]

- Bundit, I.; Chootrakul, S.; Kreetha, S.; Patcharaporn, A.; Thanya, K.; Vittaya, P.; Chinnathan, A. Biocomposite fabrication from pilot-scale steam-exploded coconut fiber and PLA/PBS with mechanical and thermal characterizations. J. Clean. Prod. 2022, 379, 134517. [Google Scholar] [CrossRef]

- Ehsan, E.; Armin, M.; Larry, L.; Abdolhamid, A. 3D printed wood-fiber reinforced architected cellular composite beams with engineered flexural properties. Addit. Manuf. 2023, 78, 103800. [Google Scholar] [CrossRef]

- Dönitz, A.; Köllner, A.; Richter, T.; Löschke, O.; Auhl, D.; Völlmecke, C. Additive Manufacturing of Biodegradable Hemp-Reinforced Polybutylene Succinate (PBS) and Its Mechanical Characterization. Polymers 2023, 15, 2271. [Google Scholar] [CrossRef] [PubMed]

- Binh, M.; Trinh, E.O.; Ogunsona, T.H.M. Thin-structured and compostable wood fiber-polymer biocomposites: Fabrication and performance evaluation. Compos. Part A-Appl. S 2021, 140, 106150. [Google Scholar] [CrossRef]

- Yu, W.; Li, M.; Lei, W.; Pu, Y.; Sun, K.; Ma, Y. Effects of Wood Flour (WF) Pretreatment and the Addition of a Toughening Agent on the Properties of FDM 3D-Printed WF/Poly(lactic acid) Biocomposites. Molecules 2022, 27, 2985. [Google Scholar] [CrossRef]

- Chaiwutthinan, P.; Chuayjuljit, S.; Srasomsub, S.; Boonmahitthisud, A. Composites of poly(lactic acid)/poly(butylene adipate-co-terephthalate) blend with wood fiber and wollastonite: Physical properties, morphology, and biodegradability. J. Appl. Polym. 2019, 136, 47543. [Google Scholar] [CrossRef]

- Dou, Q.; Cai, J. Investigation on Polylactide (PLA)/Poly(butylene adipate-co-terephthalate) (PBAT)/Bark Flour of Plane Tree (PF) Eco-Composites. Materials 2016, 9, 393. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, X.L.; Jin, X.; Nie, S.J.; Yang, R. Study on Mechanical and Thermal Properties of Poly(Lactic acid)/Poly(Butylene adipate-co-terephthalate)/Office Wastepaper Fiber Biodegradable Composites. J. Polym. Environ. 2019, 27, 1273–1284. [Google Scholar] [CrossRef]

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM International (ASTM): West Conshohocken, PA, USA, 2022.

- ASTM D 790-2010; ASTM D790-2010 Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International (ASTM): West Conshohocken, PA, USA, 2010.

- Deng, H.W.; Yu, J.S.; Liu, C.K.; Zhao, Y.; Pan, H.W.; Ni, H.Z.; Wang, Z.; Bian, J.J.; Han, L.J.; Zhang, H.L. Crystallization and heat resistance properties of poly(glycolic acid) reinforced poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends. Thermochim. Acta 2024, 731, 179628. [Google Scholar] [CrossRef]

- Dylan, J.; Costas, T.; Tizazu, H.M. Recycled PLA-Wood flour based biocomposites: Effect of wood flour surface modification, PLA recycling, and maleation. Constr. Build. Mater. 2022, 352, 129026. [Google Scholar] [CrossRef]

- Phuong, L.X.; Shida, S.; Saito, Y. Effects of heat treatment on brittleness of Styrax tonkinensis wood. J. Wood Sci. 2007, 53, 181–186. [Google Scholar] [CrossRef]

- Yue, Z.; Wang, H.; Zhang, M.; Wang, M. Mechanical, thermal and rheological properties of polylactic acid (PLA)/epichlorohydrin modified pine wood flour (EWF) composites. Eur. J. Wood Prod. 2022, 80, 1111–1120. [Google Scholar] [CrossRef]

- Lu, W.; Zhang, Y.H. Jointly modified mechanical properties and accelerated hydrolytic degradation of PLA by interface reinforcement of PLA-WF. J. Mech. Behav. Biomed. Mater. 2018, 88, 223–230. [Google Scholar] [CrossRef]

- Chen, F.; Ni, X.; Liu, Y.; Xia, X.; Gao, X. Preparation and properties of heat-treated esterified wood flour/polylactic acid composites for FDM 3D printing. J. Mater. Sci. 2022, 57, 14819–14834. [Google Scholar] [CrossRef]

- Guo, R.; Ren, Z.C.; Bi, H.J.; Song, Y.M.; Xu, M. Effect of toughening agents on the properties of poplar wood flour/poly (lactic acid) composites fabricated with Fused Deposition Modeling. Eur. Polym. J. 2018, 107, 34–45. [Google Scholar] [CrossRef]

- Wu, W.; Wu, G.; Zhang, H. Effect of wood flour as nucleating agent on the isothermal crystallization of poly(lactic acid). Polym. Adv. Technol. 2016, 28, 252–260. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kariž, M.; Kitek Kuzman, M. Effect of wood flour content on surface properties of 3D printed materials produced from wood flour/PLA filament. Int. J. Polym. Anal. Charact. 2019, 24, 659–666. [Google Scholar] [CrossRef]

- Liu, L.; Lin, M.; Xu, Z.; Lin, M. Polylactic acid-based wood-plastic 3D printing composite and its properties. BioRes 2019, 14, 8484–8498. [Google Scholar] [CrossRef]

| Sample Codes | WF-0 | WF-10 | WF-20 | WF-30 | WF-40 | WF-50 |

|---|---|---|---|---|---|---|

| PLA/wt.% | 70 | 63 | 56 | 49 | 42 | 35 |

| PBAT/wt.% | 30 | 27 | 24 | 21 | 18 | 15 |

| WF/wt.% | 0 | 10 | 20 | 30 | 40 | 50 |

| Parameter | Nozzle Temperature/°C | Platform Temperature/°C | Printing Speed/ mm/s | Layer Thickness/ mm |

|---|---|---|---|---|

| Value | 220 | 50 | 50 | 0.1 |

| Sample Code | T95/°C | Tp,1/°C | Tp,2 | W/% |

|---|---|---|---|---|

| WF-0 | 333.3 | 361.9 | 400.3 | 4.3 |

| WF-10 | 329.2 | 360.1 | 394.2 | 9.7 |

| WF-20 | 304.2 | 345.2 | 391.1 | 22.0 |

| WF-30 | 299.5 | 338.8 | 392.5 | 24.1 |

| WF-40 | 290.0 | 336.2 | 394.0 | 28.3 |

| WF-50 | 285.8 | 321.3 | 33.1 | |

| WF | 245.4 | 349.2 | 53.5 |

| Sample Code | Tg/°C | Tcc/°C | Tm/°C | ∆Hcc (J/g) | ∆Hm (J/g) | Xc (%) |

|---|---|---|---|---|---|---|

| WF-0 | 61.4 | 107.6 | 164.2 | −17.5 | 19.5 | 3.11 |

| WF-10 | 59.3 | 106.5 | 163.0 | −16.6 | 19.3 | 4.49 |

| WF-20 | 59.6 | 106.5 | 163.1 | −19.8 | 22.3 | 4.50 |

| WF-30 | 60.7 | 105.6 | 162.9 | −16.5 | 18.8 | 4.54 |

| WF-40 | 60.0 | 104.5 | 162.7 | −11.9 | 14.4 | 5.34 |

| WF-50 | 59.2 | 103.8 | 162.8 | −9.5 | 12.5 | 6.33 |

| Sample Code | WF-0 | WF-10 | WF-20 | WF-30 | WF-40 | WF-50 |

|---|---|---|---|---|---|---|

| Contact angle/° | 76.1 ± 4.7 | 82.7 ± 4.2 | 88.5 ± 2.9 | 96.9 ± 4.6 | 100.1 ± 5.7 | 106.6 ± 4.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Lei, W.; Yu, W. FDM 3D Printing and Properties of WF/PBAT/PLA Composites. Molecules 2024, 29, 5087. https://doi.org/10.3390/molecules29215087

Li M, Lei W, Yu W. FDM 3D Printing and Properties of WF/PBAT/PLA Composites. Molecules. 2024; 29(21):5087. https://doi.org/10.3390/molecules29215087

Chicago/Turabian StyleLi, Mengya, Wen Lei, and Wangwang Yu. 2024. "FDM 3D Printing and Properties of WF/PBAT/PLA Composites" Molecules 29, no. 21: 5087. https://doi.org/10.3390/molecules29215087

APA StyleLi, M., Lei, W., & Yu, W. (2024). FDM 3D Printing and Properties of WF/PBAT/PLA Composites. Molecules, 29(21), 5087. https://doi.org/10.3390/molecules29215087