1. Introduction

According to UNESCO, in 2023, globally, approximately 2 billion people (26% of the population) do not have access to safe drinking water [

1]. Furthermore, a study released in 2017 called

Global Burden of Disease discovered that polluted water is responsible for 1.2 million deaths each year [

2]. Due to the rise in the levels of human and industrial activities, heavy metals in drinking water are still not at the recommended limits. Such heavy metals found commonly in water include arsenic, chromium, lead, manganese and copper, and when ingested in small quantities, these heavy metals can be toxic.

Chromium is naturally found in rocks, plants, soil and volcanic dust. However, due to its heavy use in industrial activities such as metal finishing, leather tanning, textile production and dyeing, chromium in various forms is found in the atmosphere and in water bodies. This leads to a serious threat to human life and environmental toxicity [

3]. Chromium exists in the following two main forms: hexavalent chromium (Cr (VI)) and trivalent chromium (Cr (III)). Trivalent chromium is found to cause damage to the brain, liver and kidneys in large amounts when ingested orally. However, hexavalent chromium is more toxic to soil, plants, animals and humans than trivalent chromium. Cr (VI) exposure causes reduced soil fertility and affects plant enzyme and photosynthesis, and when directly exposed to humans, it results in poisoning, cancer and cellular damage [

3]. Hence, proactive measures are imperative for attaining and upholding the Environmental Protection Agency’s (EPA’s) stipulated maximum limit of 100 µg/L for chromium in drinking water.

Several methods have been conventionally used to remove heavy metals from wastewater such as membrane-based filtration, precipitation, coagulation and electric-based separation methods such as ion exchange. However, many of these methods incur high costs and produce large volumes of sludge [

4]. Therefore, adsorption is becoming an increasingly popular heavy metal removal method due to its higher sustainability and the lower costs associated with the process. Biosorption is a type of adsorption process in which contaminants bind onto the surface of a biomass such as food waste [

5,

6,

7], wood, wood residues [

8], agricultural residues [

9] and household wastes. According to Statista, bananas are one of the most widely produced and consumed fruits in the world, with production levels as high as ~125 million metric tons for the year 2021 [

10]. Bananas are known as a tropical fruit which is grown in the tropical regions of Africa, Latin America, the Caribbean and the Pacific. In 2020, the top three countries exporting bananas were Ecuador (33%), the Philippines (18%) and Costa Rica (12.5%) [

11] due to their ideal climates for banana growth, which include sunshine between 9 and 15 months of the year and temperatures near 27 °C. However, due to the high production and consumption of bananas, large volumes of banana waste are produced annually. Banana peels, which make up ~35% of bananas by weight, produce 3.5 million tons of waste per year. This is detrimental to the environmental as this waste is usually sent to landfills and/or burnt, which results in the release of greenhouse gases which include methane and carbon dioxide, contributing to global warming [

6]. However, banana peels are rich in nutrients and minerals, containing 6–9% protein and 20–30% fiber, and green banana peels contain ~15% starch while ripe banana peels contain up to 30% free sugars [

12]. This makes banana peels an ideal feedstock for several applications such as agricultural feedstock for cattle, goats and other animals; culinary use in recipes in parts of the world such as Southeast Asia; water purification; and use as a fertilizer.

Banana peel use for wastewater treatment is becoming increasingly popular, and several researchers have studied this subject, such as Varney Edwin Johnson et al., who modified banana peels via hydrothermal synthesis for Pb(ii) and As(V) removal from wastewater [

13], Adhi Setiawan et al., who used banana peels to develop Fe-impregnated activated carbon for the removal of methylene blue from wastewater [

14], and K.M. Lavanya et al., who used raw and alkali metal-free banana peels to remove Hg

2+ ions from wastewater [

15]. Pristine banana peel has also been applied as an adsorbent for the removal of chromium, achieving capacities ranging from 90 to 130 mg/g [

16,

17]. Chen et al. carried out a preliminary investigation on the effects of activation methods on the chromium removal capacity of the resultant adsorbent, and their study proved that acid treatment increased from 90 to 163 mg/g (approximately 77%) [

16]. The objective of this research is to extend earlier work—in [

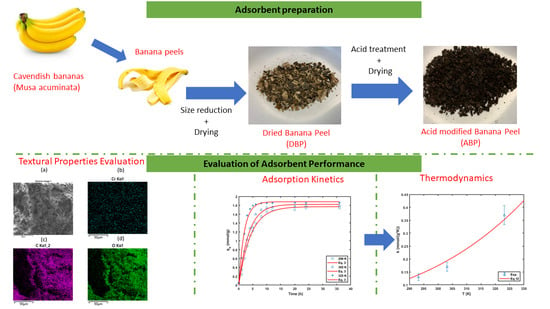

16]—which acid treatment was used to enhance the adsorption capacity of banana peel adsorbent. The current work includes a detailed study on the kinetics of the process and investigated the effect of temperature on the kinetics of the removal process, with a detailed characterization of the adsorbent before and after removal of the chromium to elucidate on the chromium removal mechanism. In this work, the adsorbent from banana peel was synthesized and surface morphological studies were conducted using FTIR and SEM to relate the adsorbent’s characteristics to its adsorption ability.

2. Results and Discussion

2.1. Characterization

2.1.1. BET Analysis

The surface area of both the untreated banana peel and the banana peel subjected to sulfuric acid modification was determined through BET analysis, with the results summarized in

Table 1. Remarkably, the surface area of the banana peel significantly increased by nearly 1.5 times after modification with sulfuric acid. The increase in the surface area may have partially contributed to the observed increase in the removal capacity of the acid-modified banana peel adsorbent. This notable enhancement could be attributed to the composition of a natural banana peel, which is rich in cellulose, lignin and pectin, all of which feature abundant hydroxyl groups. These macromolecular structures foster the formation of numerous hydrogen bonds, both intermolecular and intramolecular.

The mechanism behind this transformation involves the impact of sulfuric acid at elevated temperatures. Firstly, the acid disrupts the hydrogen bonds between molecules in the banana peel, causing the separation of lignin and cellulose into distinct entities. Simultaneously, the acidic conditions facilitate the condensation of tannins, leading to solidification and the formation of larger cage-like molecules within the banana peel [

18]. This dual action underlined the significant increase in surface area observed in the acid-modified banana peel.

2.1.2. Elemental Analysis

The elemental analysis results for the banana peel samples subjected to varying concentrations of sulfuric acid are presented in

Table 2. Notably, no significant disparity was observed in the hydrogen and carbon contents between the two samples. Nevertheless, the nitrogen content in the acid-modified banana peel (ABP) was markedly lower than that in the unmodified banana peel (BP). The sulfuric acid treatment resulted in a substantial increase in the sulfur content in the ABP sample. It is noteworthy that the carbon and nitrogen contents of both samples closely aligned with previously reported values in the literature, specifically, 35.65% for carbon and 1.94% for nitrogen [

19].

2.1.3. Functional Group Analysis Using FTIR

The impact of acid modification on the presence of functional groups in the sample was assessed through FTIR analysis, and the findings are presented in

Figure 1. Examination of the results shown in

Figure 1 reveals a significant peak variation within the 1000–2000 cm

−1 range, indicating that the modification primarily influenced the methoxy groups (-OCH

3) in lignin molecules and the hydroxyl groups in phenolic compounds (-OH). These two functional groups play a crucial role in the formation of hydrogen bonds, both intermolecular and intramolecular. Consequently, it could be tentatively concluded that the modification had achieved its intended purpose. Detailed changes in specific peaks are provided in

Table 3.

2.1.4. Textural Analysis

The SEM measurements allowed for an investigation of the morphology of the adsorbent synthesized from the banana peel (ABP) before adsorption.

Figure 2a,b shows that at magnifications of 1000 and 30,000, respectively, the surfaces of the adsorbents appeared to be rough and sponge-like, with visible pores, which made them ideal for adsorption. It also shows that the surface of the adsorbent was rough.

The textural properties of the adsorbent after adsorption of the Cr were also evaluated through SEM. The surface structure of the adsorbent did not significantly change after the adsorption process.

Figure 3a,b shows SEM images of the ABP sample after Cr adsorption at magnifications of 1000 and 30,000, respectively.

The distribution of the elements on the surface of the adsorbent before and after adsorption is shown in

Figure 4a,b. The XPS results of the sample before adsorption showed no presence of chromium, and approximately 0.6% Cr was observed on the surface of the sample after adsorption. This confirmed the successful loading of the chromium. However, it was noted that the Cr content was low. This could have been due to most of the Cr being loaded into the pore structure of the adsorbent. To further the successful loading of the chromium, the spent adsorbent collected after the adsorption process was digested in acid and the concentration of Cr present in the solution was analyzed using ICP. Higher levels of chromium were detected in the digested spent adsorbent. A comparison of the elemental composition of the sample before and after adsorption is presented in

Table 4.

2.2. Determination of the Optimum Dose of ABP

The removal efficiency was calculated from the residual concentration, and the results are presented in

Figure 5.

The removal percentage of the Cr (VI) was close to 100% when 0.02 g or more of the ABP sample was used. Increasing the mass of the ABP beyond 0.02 g did not result in further increases in removal efficiency, implying that the optimum dosage was 1 g/L (i.e., 0.02 g in 0.02 L). The optimum dosage obtained here was comparable to results in the literature [

20,

21].

2.3. Evaluation of the Adsorption Capacity

Non-linear regression fits of Equations (3)–(7) were performed using a custom-written MATLAB code. The parameters of the various isotherms are summarized in

Table 5, and the fit of the model to the experimental data is shown in

Figure 6.

Based on the preliminary experiments, the BP had a Langmuir adsorption capacity of approximately 90 mg/g, and the adsorption capacity increased to over 163 mg/g after modification [

16]. Therefore, it could be concluded that the adsorption capacity of the banana peel could be enhanced by acid modification. A comparison of the adsorption capacities of Cr

6+ adsorbed onto different bio-adsorbents reported by other researchers is shown in

Table 6.

The results suggested that the modified banana peels had high adsorption capacities for Cr6+; therefore, they could be used as low-cost bio-adsorbents for the treatment of Cr6+-contaminated wastewater. From the FT-IR results, it was found that −OH, −C=O’ and −COO− were the main functional groups in all the BP and ABP samples. Therefore, the differences in the adsorption capacities could have been related to the quantities of these functional groups.

2.4. Adsorption Kinetics at Different Temperatures

The adsorption kinetic study was conducted at three different temperatures (20, 30 and 50 °C), respectively, at the same initial pH, feed amount and Cr (VI) concentration. The results are shown in

Figure 7, and it could be concluded that the rise in temperature accelerated the adsorption time to equilibrium. The results showed that a higher temperature was more conducive to Cr

6+ reduction and adsorption in the adsorption process, as this was an endothermic reaction. The agreed with previously reported results [

23,

25,

26]. The removal process was initially rapid, followed by a second-stage rate that gradually reduced to zero due to increased resistance to diffusion. The plots show that the initial removal rate of the Cr (VI) increased as the temperature increased. Different kinetic models were evaluated for their effectiveness in describing the removal of the Cr (VI) from the solution.

The removal of the Cr (VI) was examined using kinetic models, i.e., pseudo-first-order (PFO) and pseudo-second-order (PFO) kinetics. The pseudo-first-order kinetics model is expressed as follows:

where

qt is the amount of solute adsorbed at the time

t (min),

qe is the amount of solute (mg g

−1) adsorbed at saturation and

k1 is the pseudo-first-order rate constant (h

−1).

The pseudo-second-order kinetics model is generally expressed as follows:

where

qe is the amount adsorbed at equilibrium (mg/g) and

k2 (g min

−1 mg

−1) is the pseudo-second-order rate constant.

The appropriateness of the models was evaluated using R

2 and RSME. A custom written MATLAB code was written to obtain the non-linear regression fit, and the model’s parameters are reported in

Table 7.

The curve-fitting results showed that both PFO and PSO were appropriate for describing the removal kinetics of the Cr (VI); however, the PFO had better goodness of fit values. The results also showed that increasing the temperature from 293 to 323 K did not have a significant effect on the removal capacity as the q

max values were not significantly different. However, the initial removal rate of the Cr(V), h, was significantly influenced by the temperature. The initial removal rate increased from 0.562 to 1.585 as the temperature of the adsorption was increased from 20 to 50 °C. The trends reported here are similar to what has been reported in the literature. For instance, in recent work on the removal of arsenic by adsorption onto magnetic bleached biochars (MBBC), increasing the temperature from 40 to 60 °C resulted in an increase in the initial rate of adsorption from 3.29 to 7.23 mmol g

−1 min

−1 [

26]. A similar trend was also reported by Jaiyoela et al. in their work on the removal of Cr(VI) ions from an aqueous solution by CeO

2@starch nanoparticles [

23].

2.4.1. Thermodynamics

To assess the potential adsorption mechanism of the Cr(VI) on the adsorbent ABP material, we utilized the adsorption data collected at the various temperatures. These data were employed to determine the thermodynamic parameters for the removal of the Cr(VI) by ABP, including the standard Gibbs free-energy change (Δ

G°), enthalpy change (Δ

H°) and entropy change (Δ

S°). These parameters were calculated using the following equations:

In these equations,

(8.314 J/mol K) represents the universal gas constant,

(K) denotes the absolute temperature and

stands for the equilibrium constant at the temperature

, which is given by the following [

27]:

where

(mol/L) signifies the equilibrium concentration of the Cr(VI) solution,

(mmol/g) represents the amount of Cr(VI) removed by the ABP at equilibrium,

(mmol/g) is the maximum adsorption capacity and

(1 mol/L) is the reference standard concentration.

All the calculated thermodynamic parameters are provided in

Table 8. As indicated in the table, both ΔH° and ΔS° exhibited positive values during the removal of the Cr (VI) by the ABP. The positive ΔH° values indicated an endothermic removal process, while the positive ΔS° values suggested an increase in disorder or randomness at the solid–solution interface [

28]. Because the value of the enthalpy of the adsorption was within the range of 20 to 40 kJ/mol, it could be postulated that the removal of the Cr (VI) from the solution may have been mainly due to the physical adsorption of the di-chromate ions onto the solid surface by weak Van der Waals forces [

29].

In the case of Cr (VI) removal by the ABP, all ΔG° values were found to be negative, and these values decreased as the adsorption temperature increased. This observation implied that the process was spontaneous, and its spontaneity was further enhanced at higher temperatures. This trend aligns with findings reported in the literature for various materials [

24,

28,

30,

31]. It has been shown in the literature that a ΔG value of below 18 kJ/mol (absolute values) indicates that the removal mechanism is dominated by physisorption [

32].

2.4.2. Determination of the Activation Energy

The temperature dependence of the rate of chromium removal can be described by the Arrhenius equation, which is expressed as follows:

where

is the activation energy (J/mol),

is the rate constant of the adsorption,

is the frequency factor,

is the universal gas constant (8.134 J/mol) and

is the adsorption temperature (K). The rate constant from the PSO equation was plotted as function of the temperature, and the Arrhenius equation was fitted to the data using non-linear regression to obtain the activation energy for the Cr (VI) removal process (see

Figure 8). The activation energy for the adsorption process was found to be 24.5 kJ/mol, which was almost half the value reported by Cantu et al. in their work on the removal of Cr (VI) from a solution by manganese oxide particles [

33]. Based on the obtained value of the activation energy, it could be deduced that physisorption could be one of the possible removal mechanisms since the activation energy was less than 40 kJ/mol [

33].

2.5. Adsorption Mechanism Discussion

Banana peel comprises insoluble components such as hemicellulose, lignin, cellulose and pectin [

34,

35], along with some reductants capable of reducing Cr (VI) to Cr (III) under acidic conditions [

17,

36]. These reductants include polysaccharides, glycoproteins, glucolipids and nucleic acids. The lignin within banana peel may play a role in Cr

3+ removal, as depicted in the schematic reaction shown in

Figure 9. The changes in the functional groups after adsorption are shown

Figure 10.

Figure 10 indicates that the main functional group changes before and after adsorption are concentrated between the hydroxyl group, methoxy group and carbonyl group, with partial peaks shifting and disappearing and new peaks forming, indicating that during the adsorption process, the reduction in Cr (VI) causes the oxidation of some functional groups on the adsorbent and the increases in -C=O and –COOH (the peaks near 1730 cm

−1). The peaks near 940 cm

−1 and 1147 cm

−1 represent the Cr-O-Cr bond, which provides further confirmation of the interaction of Cr with the adsorbent after adsorption [

37,

38,

39].

This shift signifies alterations in functional groups due to Cr (VI) adsorption, involving the reduction in Cr (VI) causing the oxidation of certain functional groups on the adsorbent. The increased presence of -C=O and –COOH suggests a subsequent combination of reduced Cr (III) with carboxyl hydroxyl groups, leading to adsorption on the adsorbent’s surface.

In summary, chromium removal by the ABP adsorbent involves: (1) the direct adsorption of Cr(VI) in the form of hydrated anions at positively charged sites; (2) the reduction of Cr(VI) to Cr(III) by lignin and other reductive molecules under acidic conditions; and (3) the adsorption of Cr(III) on the adsorbent surface as a complex. The reduced Cr (III) is combined with the carboxyl hydroxyl group and adsorbed on the surface of the adsorbent.

2.6. Desorption Study

No chromium was detected in the distilled water; however, in the acidic conditions, only trivalent chromium was detected, with no hexavalent chromium. The desorption rate under acidic conditions was found to be 36%. The results showed that adsorption of the Cr (VI) was irreversible under neutral pH conditions. This was a good result as it implied that there was no chance of the Cr (VI) leaching back into the aqueous phase without pH adjustment once it was removed. On the other hand, the low desorption rate would have implications about the recyclability of the adsorbent material.