Recent Advances in Preparing Transparent Phosphor Ceramics for High-Index Color Rendering and High-Power Lighting

Abstract

1. Introduction

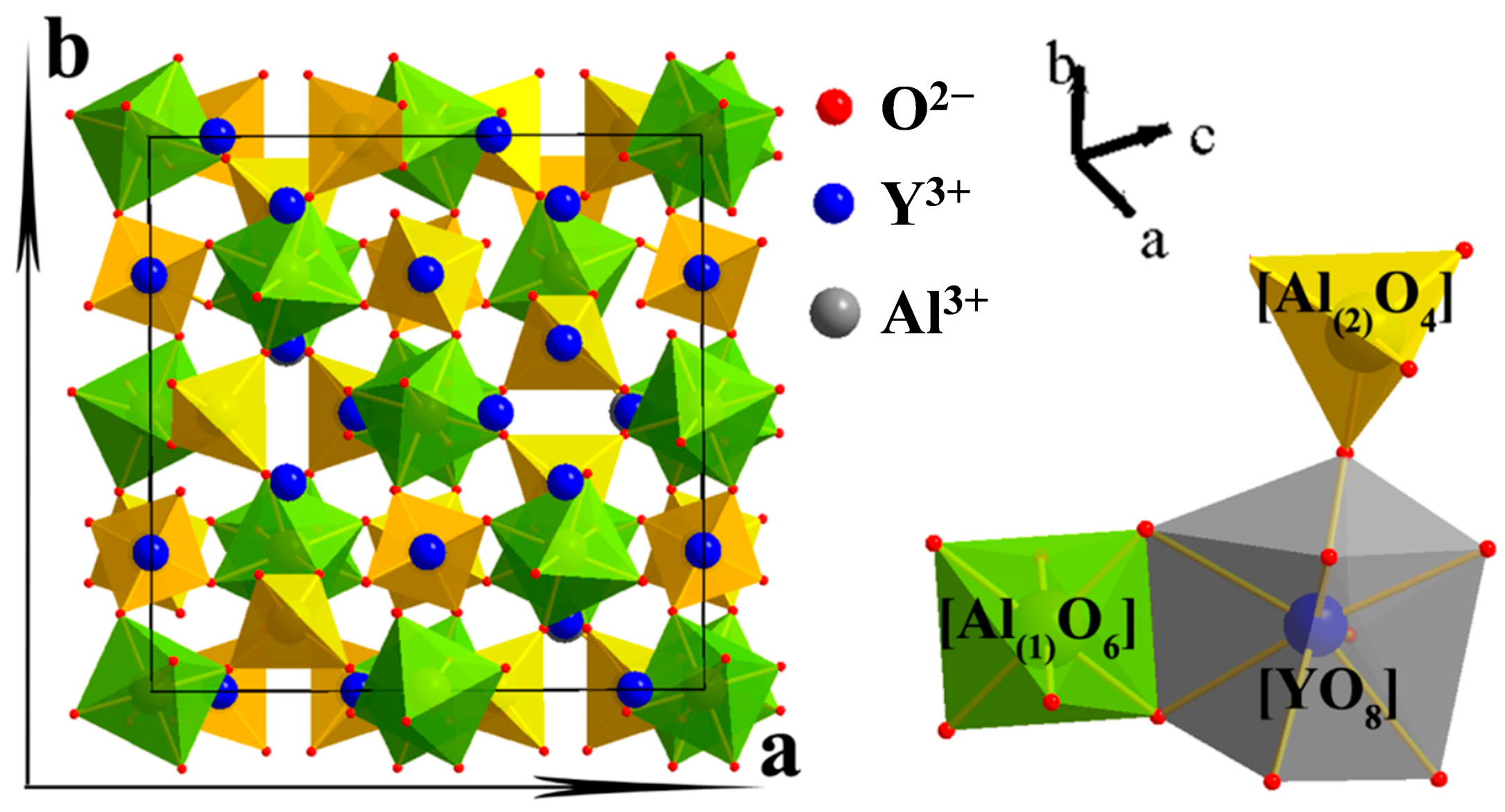

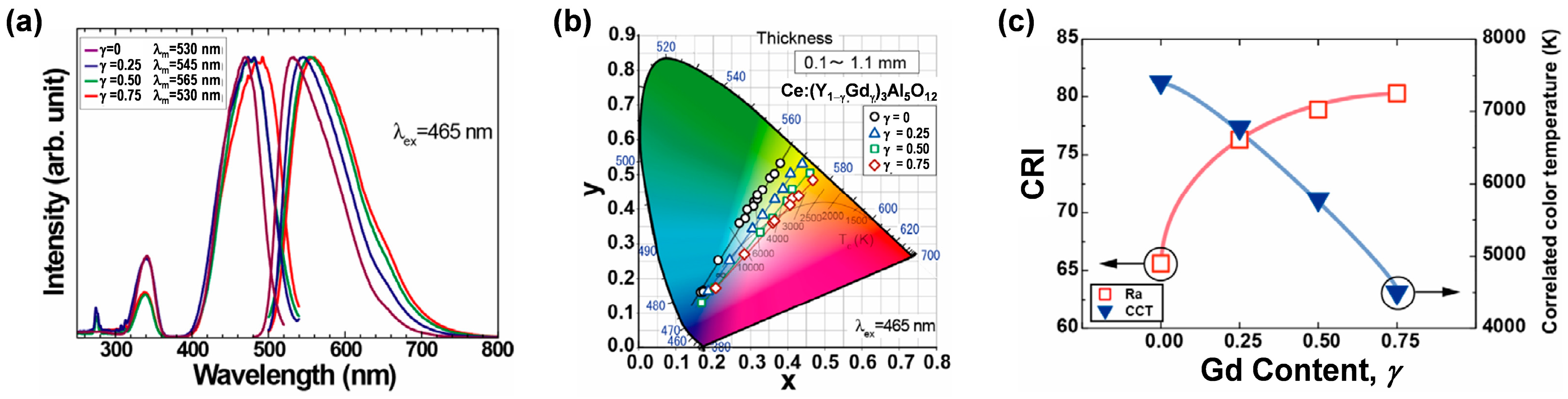

2. Modifying the YAG Host to Redshift the Emission or/and Widen the Emission Band of Ce3+

3. Co-Doping Red-Emitting Cr3+, Pr3+, or Mn2+ Ions into YAG:Ce3+

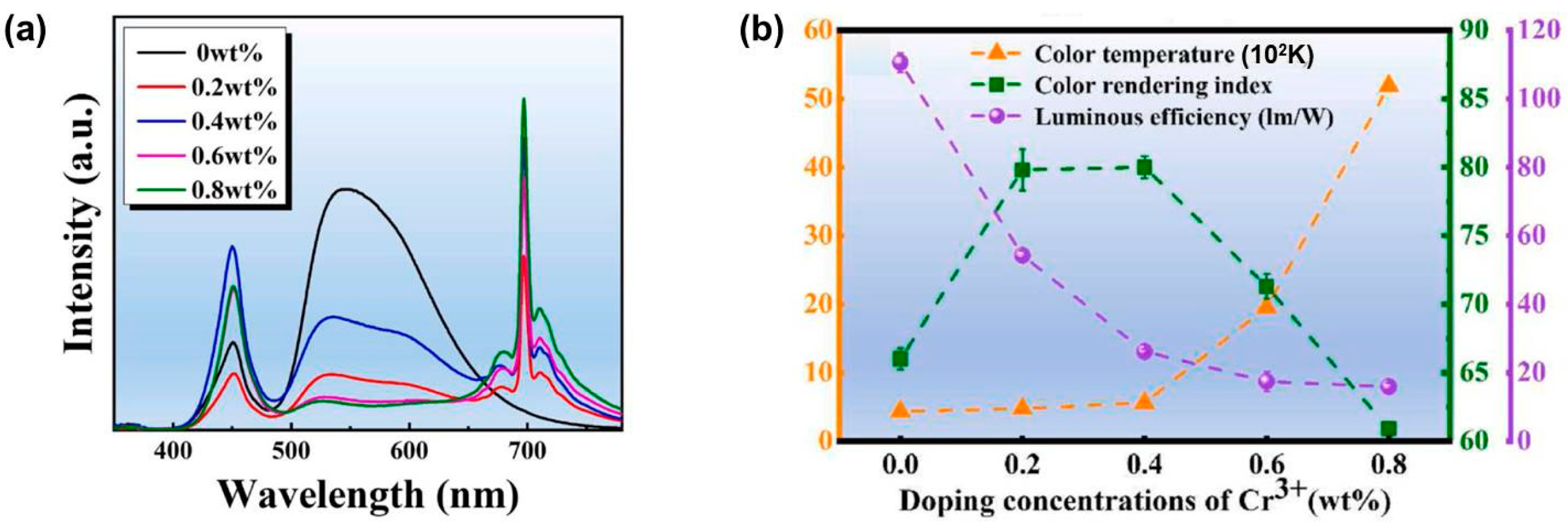

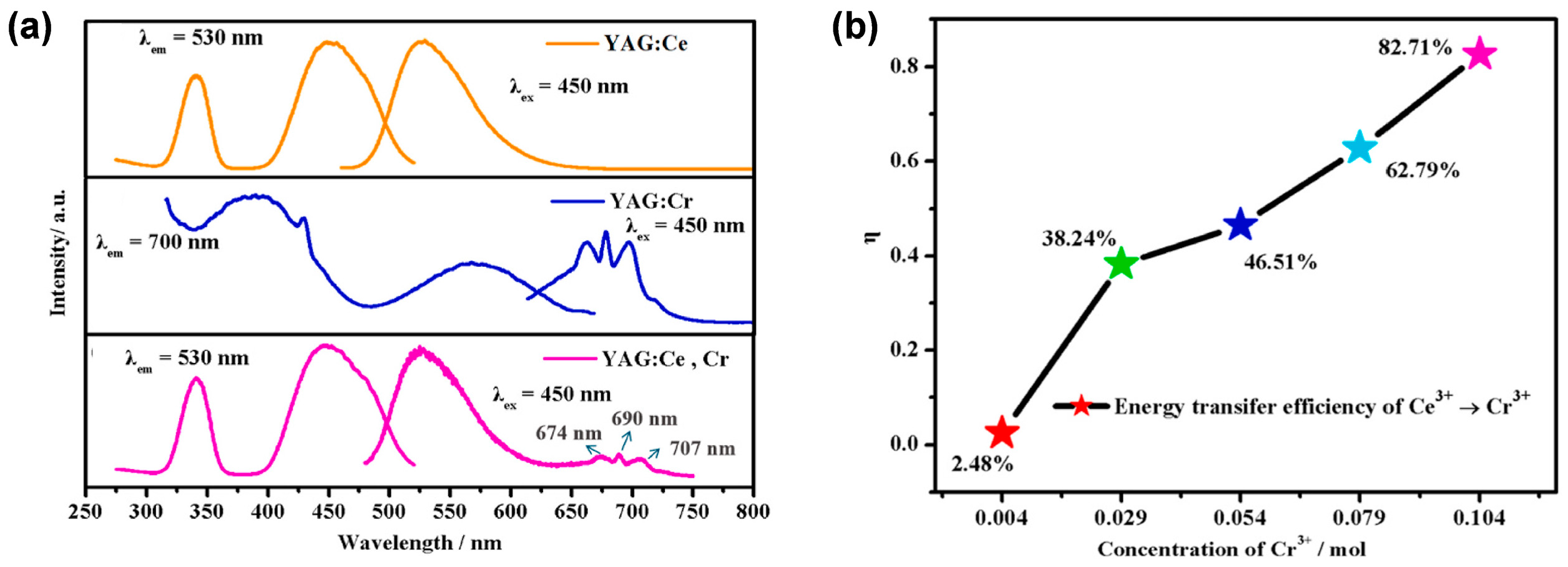

3.1. Co-Doping Cr3+ Ions into YAG:Ce3+

3.2. Co-Doping Mn2+ Ions into YAG:Ce3+

3.3. Co-Doping Cr3+ and Pr3+ Ions into YAG:Ce3+

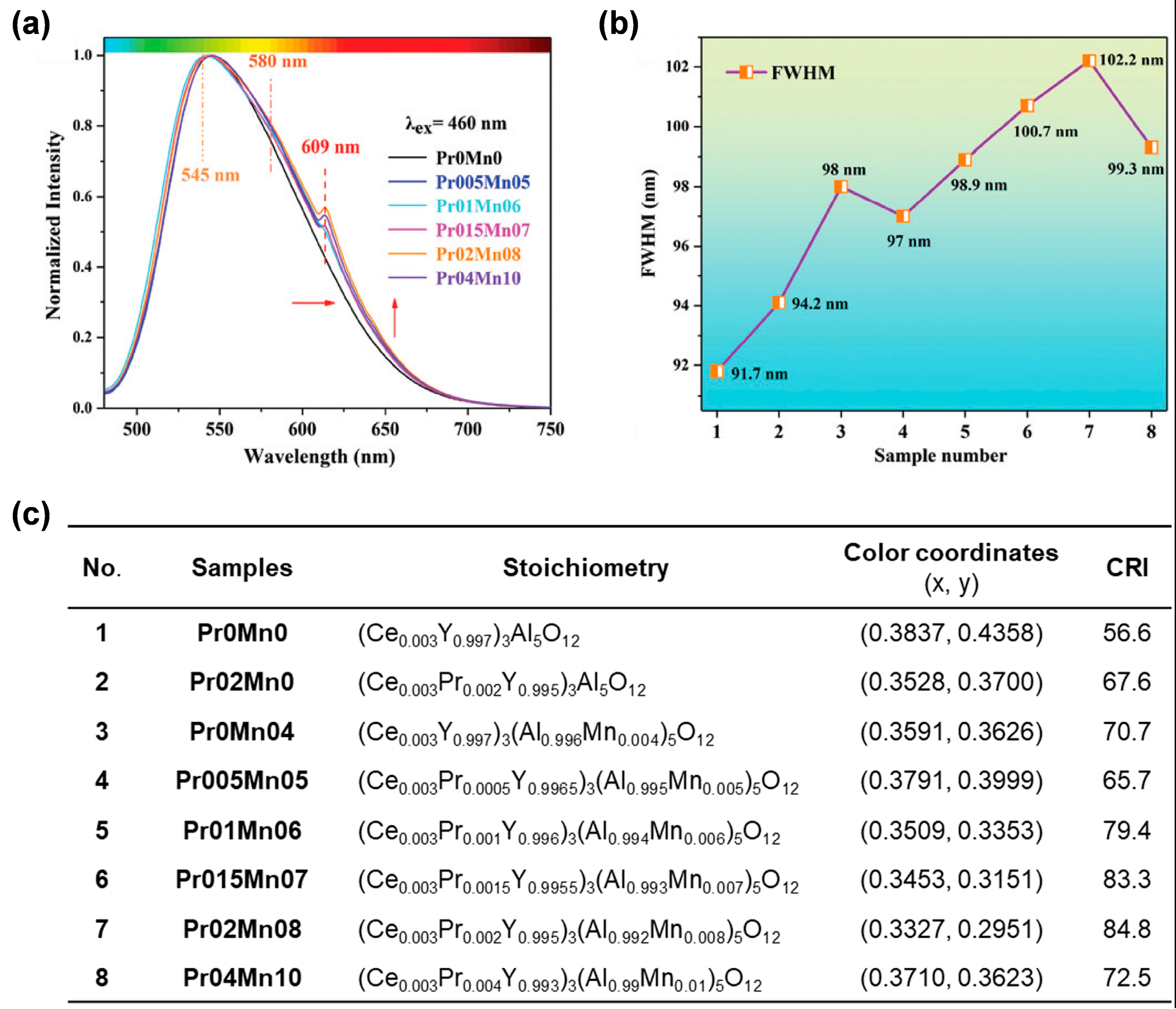

3.4. Co-Doping Pr3+ and Mn2+ Ions into YAG:Ce3+

4. Combining the Strategies of 2 and 3

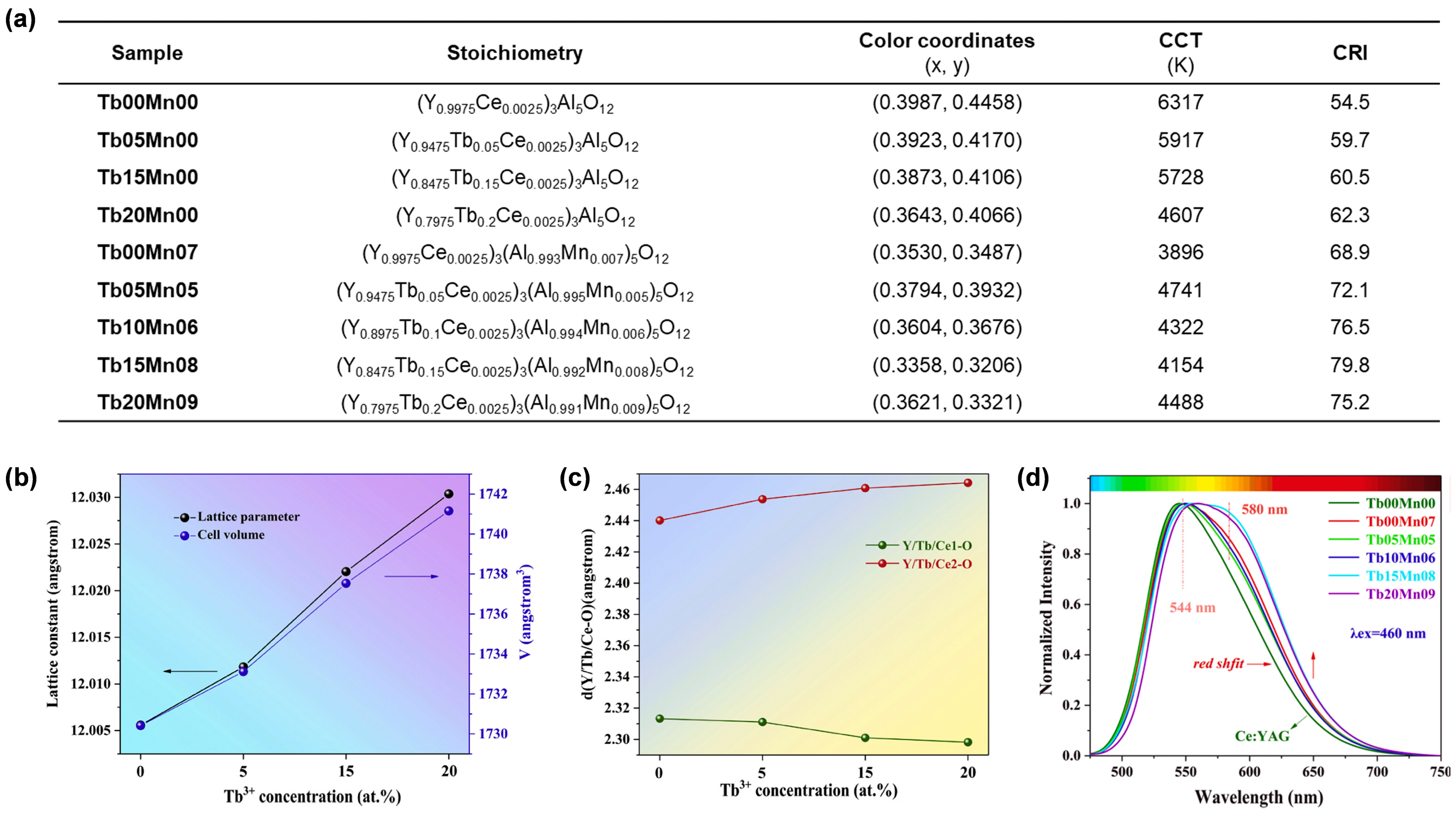

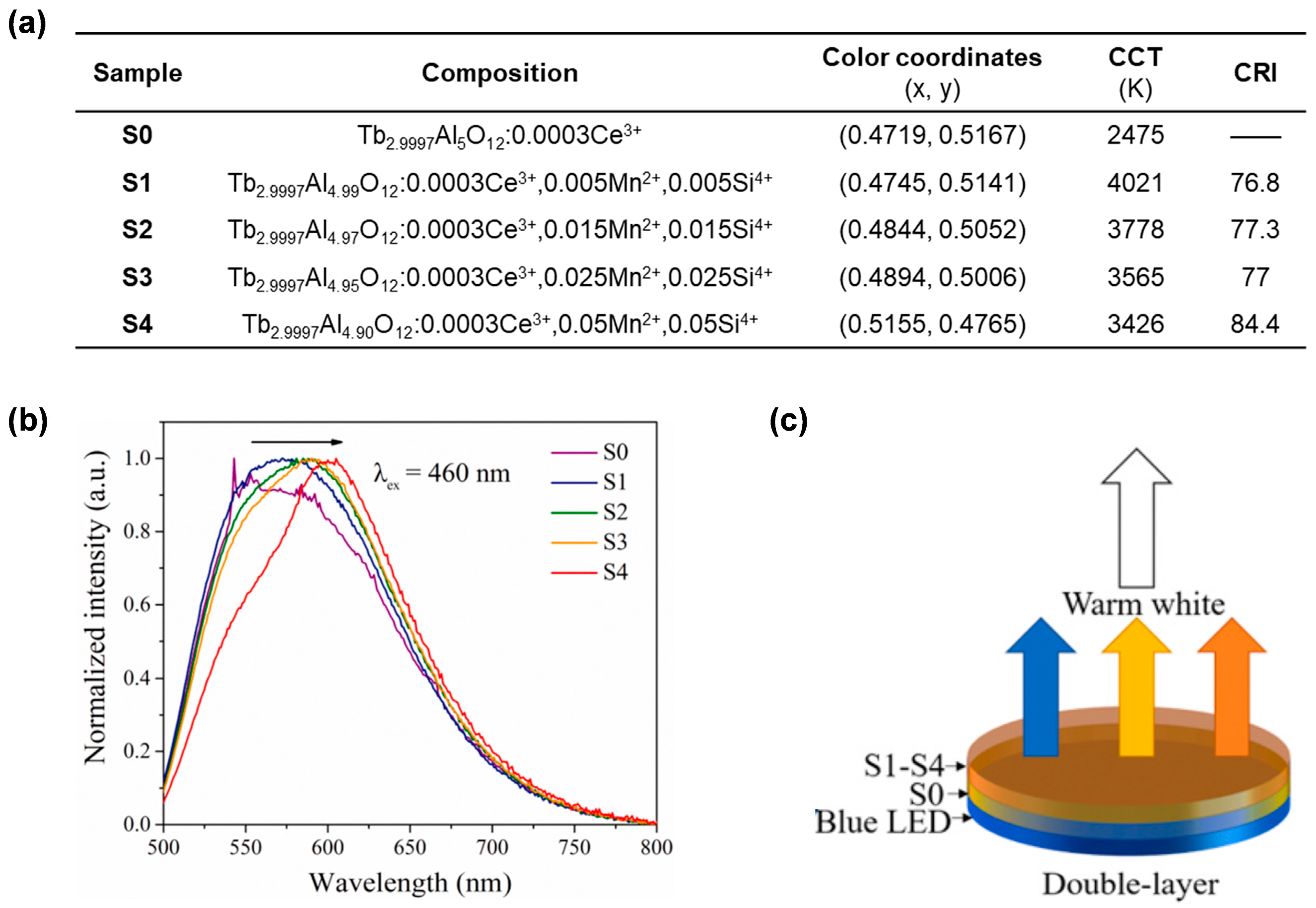

4.1. Co-Doping Mn2+ Ions into TAG:Ce3+

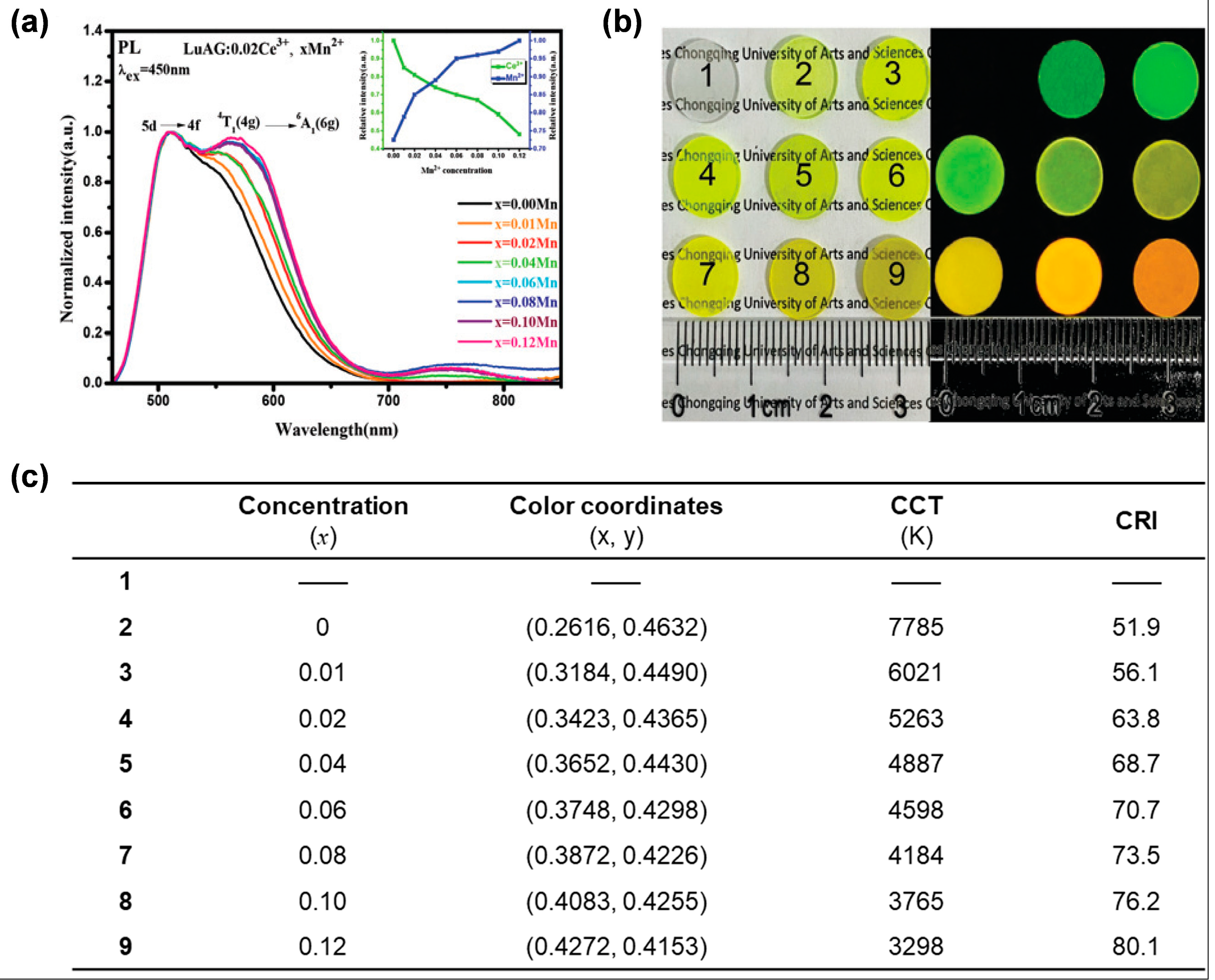

4.2. Co-Doping Mn2+ Ions into LuAG:Ce3+

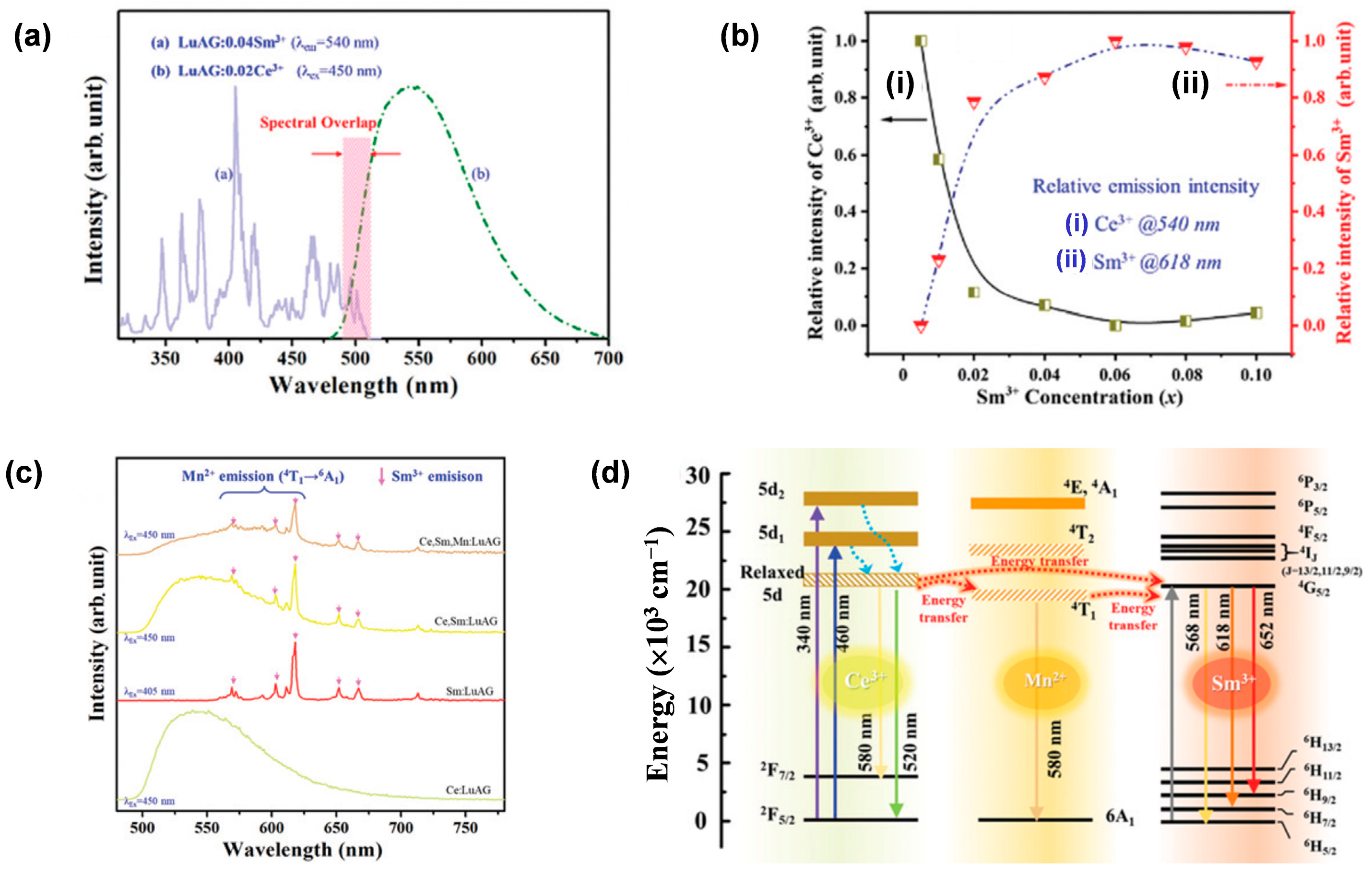

4.3. Co-Doping Sm3+ and Mn2+ Ions into LuAG:Ce3+

5. Designing Composite Structural Ceramics

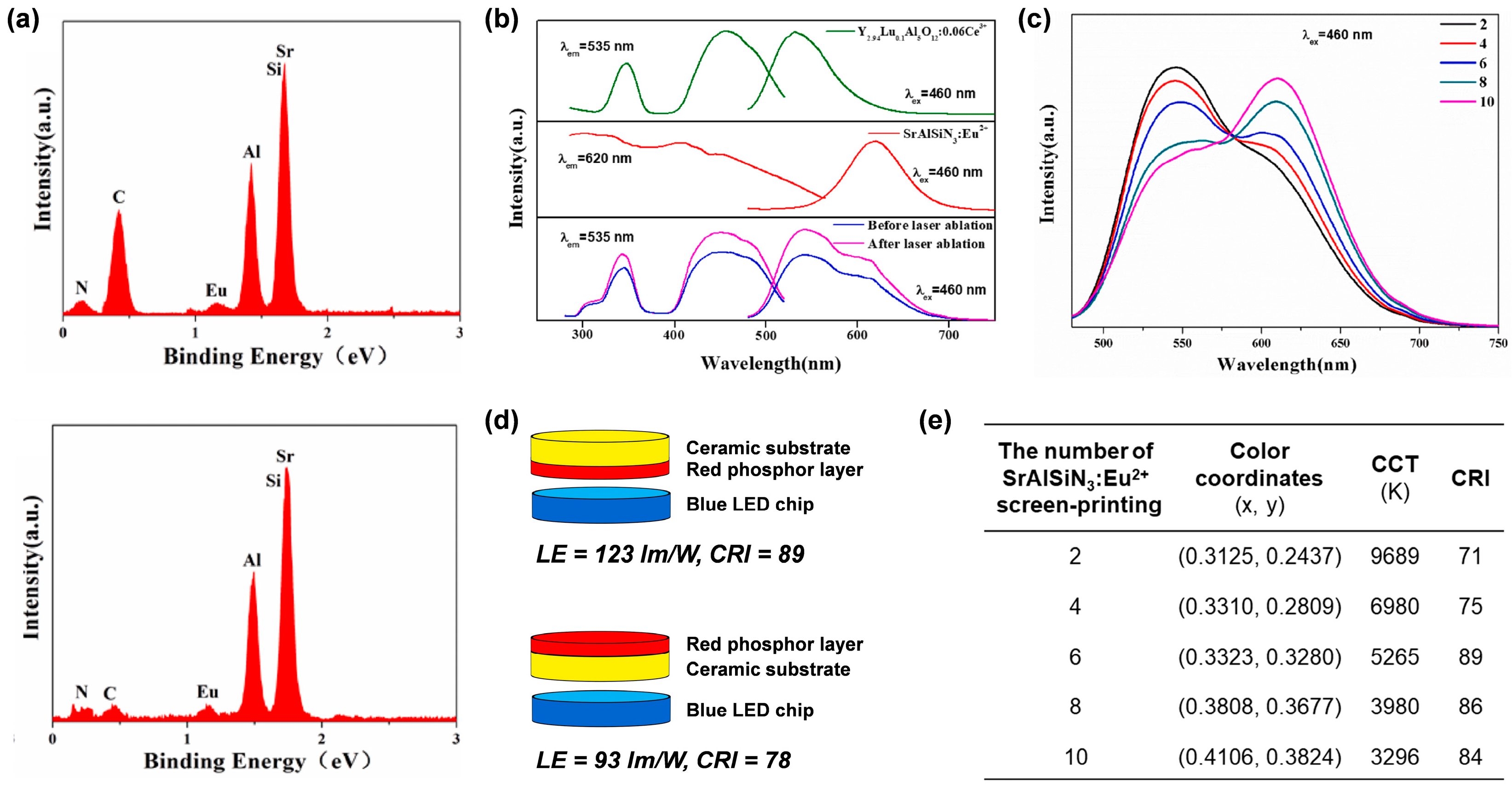

5.1. Combining Two Phosphor Ceramic Layers

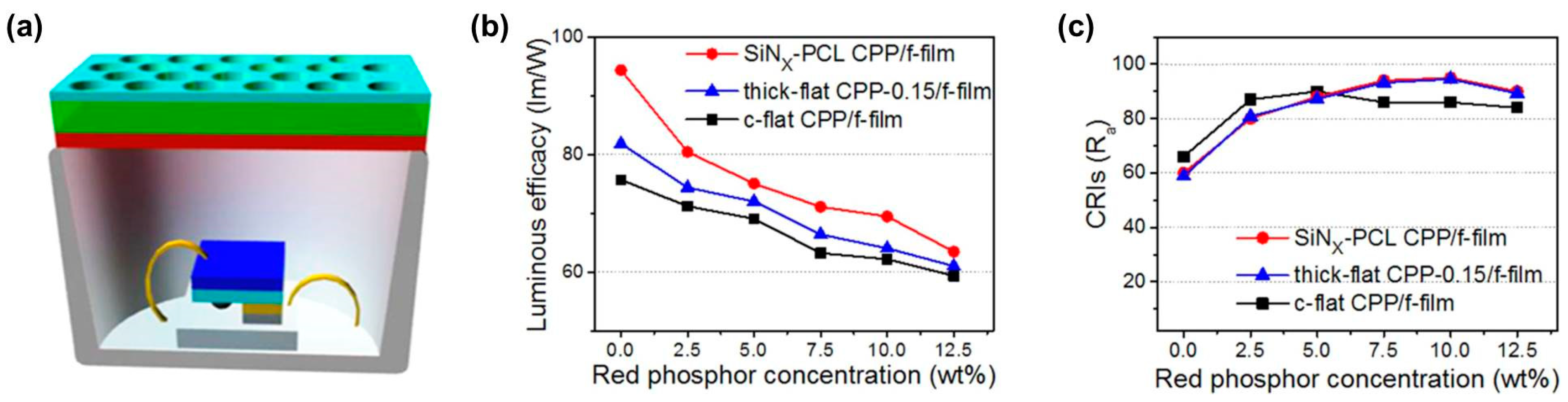

5.2. Combining a Phosphor Ceramic Layer with a Free-Standing Phosphor Film

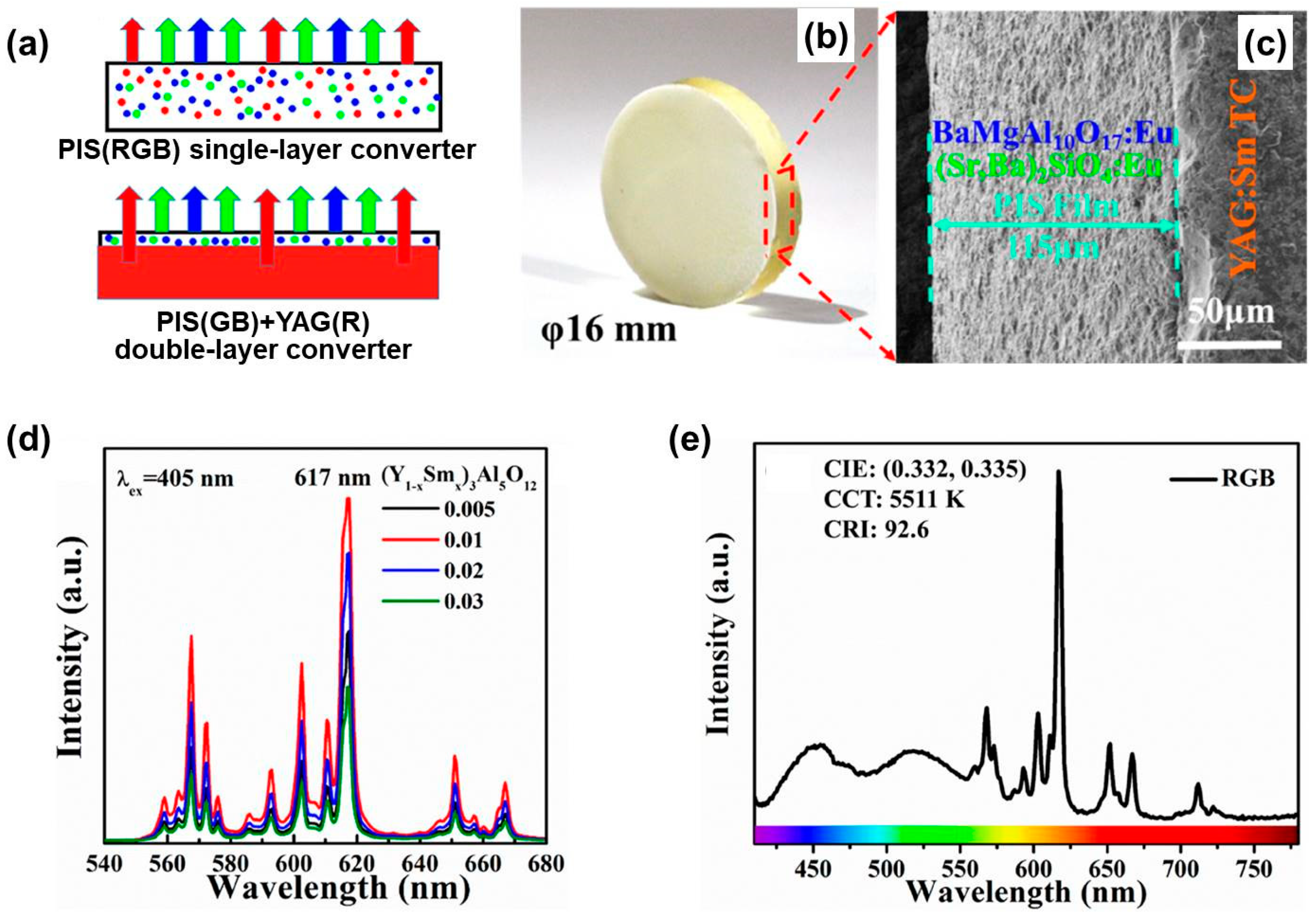

5.3. Coating a Phosphor/QDs Layer onto a Phosphor Ceramic Layer

6. Conclusions and Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Bando, K.; Sakano, K.; Noguchi, Y.; Shimizu, Y. Development of high-bright and pure-white LED lamps. J. Light Vis. Environ. 1998, 22, 2–5. [Google Scholar] [CrossRef]

- Nakamura, S.; Fasol, G. The Blue Laser Diode; Springer: Berlin/Heidelberg, Germany, 1997. [Google Scholar]

- Tsao, J.Y.; Crawford, M.H.; Coltrin, M.E.; Fischer, A.J.; Koleske, D.D.; Subramania, G.S.; Wang, G.T.; Wierer, J.J.; Karlicek, R.F., Jr. Toward smart and ultra-efficient solid-state lighting. Adv. Opt. Mater. 2014, 2, 809–836. [Google Scholar] [CrossRef]

- Pulli, T.; Dönsberg, T.; Poikonen, T.; Manoocheri, F.; Kärhä, P.; Ikonen, E. Advantages of white LED lamps and new detector technology in photometry. Light Sci. Appl. 2015, 4, e332. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, L.; Pan, F.; Wu, M.; Wang, J.; Chen, Y.; Su, Q. Highly thermally stable single-component white-emitting silicate glass for organic-resin-free white-light-emitting diodes. ACS Appl. Mater. Interfaces 2014, 6, 2709–2717. [Google Scholar] [CrossRef]

- Kim, J.-S.; Yang, S.; Bae, B.-S. Thermally stable transparent sol−gel based siloxane hybrid material with high refractive index for light emitting diode (LED) encapsulation. Chem. Mater. 2010, 22, 3549–3555. [Google Scholar] [CrossRef]

- Ishikawa, T.; Sakata, S.-i.; Mitani, A. Durable, ultraluminous structure for incandescent, high-power white-LED. Int. J. Appl. Ceram. Technol. 2006, 3, 144–149. [Google Scholar] [CrossRef]

- Xu, J.; Liu, B.; Liu, Z.; Gong, Y.; Hu, B.; Wang, J.; Li, H.; Wang, X.; Du, B. Design of laser-driven SiO2-YAG:Ce composite thick film: Facile synthesis, robust thermal performance, and application in solid-state laser lighting. Opt. Mater. 2018, 75, 508–512. [Google Scholar] [CrossRef]

- Cozzan, C.; Lheureux, G.; O’Dea, N.; Levin, E.E.; Graser, J.; Sparks, T.D.; Nakamura, S.; DenBaars, S.P.; Weisbuch, C.; Seshadri, R. Stable, heat-conducting phosphor composites for high-power laser lighting. ACS Appl. Mater. Interfaces 2018, 10, 5673–5681. [Google Scholar] [CrossRef] [PubMed]

- Lai, C.-F.; Li, J.-S.; Shen, C.-W. High-efficiency robust free-standing composited phosphor films with 2D and 3D nanostructures for high-power remote white LEDs. ACS Appl. Mater. Interfaces 2017, 9, 4851–4859. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, H.; Zhang, X.; Zhu, G.; Yan, D.; Yu, A. Facile synthesis of YAG:Ce3+ thick films for phosphor converted white light emitting diodes. J. Eur. Ceram. Soc. 2015, 35, 3761–3764. [Google Scholar] [CrossRef]

- Revaux, A.; Dantelle, G.; George, N.; Seshadri, R.; Gacoin, T.; Boilot, J.-P. A protected annealing strategy to enhanced light emission and photostability of YAG:Ce nanoparticle-based films. Nanoscale 2011, 3, 2015–2022. [Google Scholar] [CrossRef]

- Lee, J.S.; Arunkumar, P.; Kim, S.; Lee, I.J.; Lee, H.; Im, W.B. Smart design to resolve spectral overlapping of phosphor-in-glass for high-powered remote-type white light-emitting devices. Opt. Lett. 2014, 39, 762–765. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Xiang, W.; Liang, X.; Zhong, J.; Yu, H.; Ding, M.; Lu, H.; Ji, Z. Advances in transparent glass–ceramic phosphors for white light-emitting diodes—A review. J. Eur. Ceram. Soc. 2015, 35, 859–869. [Google Scholar] [CrossRef]

- Kim, S.; Park, H.-A.; Im, W.B.; Heo, J.; Choi, J.-Y.; Chung, W.J. A low sintering temperature glass based on SiO2–P2O5–ZnO–B2O3–R2O system for white LEDs with high color rendering index. J. Am. Ceram. Soc. 2017, 100, 5186–5192. [Google Scholar] [CrossRef]

- Yu, J.; Si, S.; Liu, Y.; Zhang, X.; Cho, Y.; Tian, Z.; Xie, R.; Zhang, H.; Li, Y.; Wang, J. High-power laser-driven phosphor-in-glass for excellently high conversion efficiency white light generation for special illumination or display backlighting. J. Mater. Chem. C 2018, 6, 8212–8218. [Google Scholar] [CrossRef]

- Kim, Y.H.; Viswanath, N.S.M.; Unithrattil, S.; Kim, H.J.; Im, W.B. Review—Phosphor plates for high-power LED applications: Challenges and opportunities toward perfect lighting. ECS J. Solid State Sci. Technol. 2018, 7, R3134. [Google Scholar] [CrossRef]

- Huang, M.-H.; Zhu, Q.-Q.; Li, S.; Zhai, Y.; Zhang, H.; Wang, L.; Xie, R.-J. Thermally robust Al2O3-La3Si6N11:Ce3+ composite phosphor-in-glass (PiG) films for high-power and brightness laser-driven lighting. J. Mater. Chem. C 2023, 11, 488–496. [Google Scholar] [CrossRef]

- Wang, L.; Wei, R.; Zheng, P.; You, S.; Zhou, T.-L.; Yi, W.; Takeda, T.; Hirosaki, N.; Xie, R.-J. Realizing high-brightness and ultra-wide-color-gamut laser-driven backlighting by using laminated phosphor-in-glass (PiG) films. J. Mater. Chem. C 2020, 8, 1746–1754. [Google Scholar] [CrossRef]

- You, S.; Li, S.; Zheng, P.; Zhou, T.; Wang, L.; Liu, L.; Horisaki, N.; Xu, F.; Xie, R.-J. A thermally robust La3Si6N11:Ce-in-glass film for high-brightness blue-laser-driven solid state lighting. Laser Photonics Rev. 2019, 13, 1800216. [Google Scholar] [CrossRef]

- Wei, R.; Wang, L.; Zheng, P.; Zeng, H.; Pan, G.; Zhang, H.; Liang, P.; Zhou, T.; Xie, R. On the luminance saturation of phosphor-in-glass (PiG) films for blue-laser-driven white lighting: Effects of the phosphor content and the film thickness. J. Eur. Ceram. Soc. 2019, 39, 1909–1917. [Google Scholar] [CrossRef]

- Chung, W.J.; Nam, Y.H. Review—A review on phosphor in glass as a high power LED color converter. ECS J. Solid State Sci. Technol. 2020, 9, 016010. [Google Scholar] [CrossRef]

- Fujita, S.; Yoshihara, S.; Sakamoto, A.; Yamamoto, S.; Tanabe, S. YAG glass-ceramic phosphor for white LED (I): Background and development. In Proceedings of the Fifth International Conference on Solid State Lighting, San Diego, CA, USA, 14 September 2005; SPIE: Bellingham, WA, USA; Volume 5941. [Google Scholar]

- Tanabe, S.; Fujita, S.; Yoshihara, S.; Sakamoto, A.; Yamamoto, S. YAG glass-ceramic phosphor for white LED (II): Luminescence characteristics. In Proceedings of the Fifth International Conference on Solid State Lighting, San Diego, CA, USA, 13 September 2005; SPIE: Bellingham, WA, USA; Volume 5941. [Google Scholar]

- Chen, D.; Xu, W.; Zhou, Y.; Zhong, J.; Li, S. Color tunable dual-phase transparent glass ceramics for warm white light-emitting diodes. J. Mater. Chem. C 2017, 5, 738–746. [Google Scholar] [CrossRef]

- Lin, H.; Hu, T.; Cheng, Y.; Chen, M.; Wang, Y. Glass Ceramic Phosphors: Towards Long-Lifetime High-Power White Light-Emitting-Diode Applications–A Review. Laser Photonics Rev. 2018, 12, 1700344. [Google Scholar] [CrossRef]

- He, M.; Jia, J.; Zhao, J.; Qiao, X.; Du, J.; Fan, X. Glass-ceramic phosphors for solid state lighting: A review. Ceram. Int. 2021, 47, 2963–2980. [Google Scholar] [CrossRef]

- Latynina, A.; Watanabe, M.; Inomata, D.; Aoki, K.; Sugahara, Y.; García Víllora, E.; Shimamura, K. Properties of czochralski grown Ce,Gd:Y3Al5O12 single crystal for white light-emitting diode. J. Alloys Compd. 2013, 553, 89–92. [Google Scholar] [CrossRef]

- Gu, G.; Xiang, W.; Yang, C.; Liang, X. Synthesis and luminescence properties of a H2 annealed Mn-doped Y3Al5O12:Ce3+ single crystal for WLEDs. CrystEngComm 2015, 17, 4554–4561. [Google Scholar] [CrossRef]

- Yang, C.; Gu, G.; Zhao, X.; Liang, X.; Xiang, W. The growth and luminescence properties of Y3Al5O12:Ce3+ single crystal by doping Gd3+ for W-LEDs. Mater. Lett. 2016, 170, 58–61. [Google Scholar] [CrossRef]

- Kang, T.W.; Park, K.W.; Ryu, J.H.; Lim, S.G.; Yu, Y.M.; Kim, J.S. Strong thermal stability of Lu3Al5O12:Ce3+ single crystal phosphor for laser lighting. J. Lumin. 2017, 191, 35–39. [Google Scholar] [CrossRef]

- Balci, M.H.; Chen, F.; Cunbul, A.B.; Svensen, Ø.; Akram, M.N.; Chen, X. Comparative study of blue laser diode driven cerium-doped single crystal phosphors in application of high-power lighting and display technologies. Opt. Rev. 2018, 25, 166–174. [Google Scholar] [CrossRef]

- Xu, J.; Thorseth, A.; Xu, C.; Krasnoshchoka, A.; Rosendal, M.; Dam-Hansen, C.; Du, B.; Gong, Y.; Jensen, O.B. Investigation of laser-induced luminescence saturation in a single-crystal YAG:Ce phosphor: Towards unique architecture, high saturation threshold, and high-brightness laser-driven white lighting. J. Lumin. 2019, 212, 279–285. [Google Scholar] [CrossRef]

- Nishiura, S.; Tanabe, S.; Fujioka, K.; Fujimoto, Y.; Nakatsuka, M. Preparation and optical properties of transparent Ce:YAG ceramics for high power white LED. IOP Conf. Ser. Mater. Sci. Eng. 2009, 1, 012031. [Google Scholar] [CrossRef]

- Nishiura, S.; Tanabe, S.; Fujioka, K.; Fujimoto, Y. Properties of transparent Ce:YAG ceramic phosphors for white LED. Opt. Mater. 2011, 33, 688–691. [Google Scholar] [CrossRef]

- Sun, B.; Zhang, L.; Huang, G.; Li, Y.; Zhou, T.; Kang, J.; Zhang, L.; Ma, Y.; Yao, Q.; A Selim, F.; et al. Fabrication, optical and luminescence properties of low pressure injection molded YAG:Ce tubular ceramics for outdoor lighting. J. Eur. Ceram. Soc. 2021, 41, 1564–1571. [Google Scholar] [CrossRef]

- Peng, X.; Li, S.; Liu, Z.; Zhang, B.; Peng, Y.; Yu, D.; Tian, R.; Yao, X.; Huang, Z.; Liu, X.; et al. Highly thermal conductive red-emitting AlN-CaAlSiN3:Eu2+ composite phosphor ceramics for high-power laser-driven lighting. J. Eur. Ceram. Soc. 2021, 41, 5650–5657. [Google Scholar] [CrossRef]

- Li, S.; Zhu, Q.; Tang, D.; Liu, X.; Ouyang, G.; Cao, L.; Hirosaki, N.; Nishimura, T.; Huang, Z.; Xie, R.-J. Al2O3–YAG:Ce composite phosphor ceramic: A thermally robust and efficient color converter for solid state laser lighting. J. Mater. Chem. C 2016, 4, 8648–8654. [Google Scholar] [CrossRef]

- Wei, N.; Lu, T.; Lu, T.; Li, F.; Zhang, W.; Zhang, W.; Zhang, W.; Ma, B.; Lu, Z.; Qi, J. Transparent Ce:Y3Al5O12 ceramic phosphors for white light-emitting diodes. Appl. Phys. Lett. 2012, 101, 061902. [Google Scholar] [CrossRef]

- Liu, G.H.; Zhou, Z.Z.; Shi, Y.; Liu, Q.; Wan, J.Q.; Pan, Y.B. Ce:YAG transparent ceramics for applications of high power LEDs: Thickness effects and high temperature performance. Mater. Lett. 2015, 139, 480–482. [Google Scholar] [CrossRef]

- Hu, S.; Lu, C.; Zhou, G.; Liu, X.; Qin, X.; Liu, G.; Wang, S.; Xu, Z. Transparent YAG:Ce ceramics for WLEDs with high CRI: Ce3+ concentration and sample thickness effects. Ceram. Int. 2016, 42, 6935–6941. [Google Scholar] [CrossRef]

- Bechtel, H.; Schmidt, P.; Busselt, W.; Schreinemacher, B. Lumiramic: A new phosphor technology for high performance solid state light sources. In Proceedings of the Eighth International Conference on Solid State Lighting, San Diego, CA, USA, 2 September 2008; SPIE: Bellingham, WA, USA, 2008; Volume 7058. [Google Scholar]

- Ma, X.; Li, X.; Li, J.; Genevois, C.; Ma, B.; Etienne, A.; Wan, C.; Véron, E.; Peng, Z.; Allix, M. Pressureless glass crystallization of transparent yttrium aluminum garnet-based nanoceramics. Nat. Commun. 2018, 9, 1175. [Google Scholar] [CrossRef]

- Wierer, J.J., Jr.; Tsao, J.Y.; Sizov, D.S. Comparison between blue lasers and light-emitting diodes for future solid-state lighting. Laser Photonics Rev. 2013, 7, 963–993. [Google Scholar] [CrossRef]

- Sun, B.; Jiang, X.; Yung, K.-C.; Fan, J.; Pecht, M.G. A review of prognostic techniques for high-power white LEDs. IEEE T. Power Electr. 2017, 32, 6338–6362. [Google Scholar] [CrossRef]

- Ma, Y.; Luo, X. Packaging for laser-based white lighting: Status and perspectives. J. Electron. Packag. 2020, 142, 010801. [Google Scholar] [CrossRef]

- Shang, M.; Fan, J.; Lian, H.; Zhang, Y.; Geng, D.; Lin, J. A double substitution of Mg2+–Si4+/Ge4+ for Al(1)3+–Al(2)3+ in Ce3+-doped garnet phosphor for white LEDs. Inorg. Chem. 2014, 53, 7748–7755. [Google Scholar] [CrossRef] [PubMed]

- Robertson, J.M.; van Tol, M.W.; Smits, W.H.; Heynen, J.P.H. Colourshift of the Ce3+ emission in monocrystalline epitaxially grown garnet layers. Philips J. Res. 1981, 36, 15–30. [Google Scholar]

- Du, Q.; Feng, S.; Qin, H.; Hua, H.; Ding, H.; Jia, L.; Zhang, Z.; Jiang, J.; Jiang, H. Massive red-shifting of Ce3+ emission by Mg2+ and Si4+ doping of YAG:Ce transparent ceramic phosphors. J. Mater. Chem. C 2018, 6, 12200–12205. [Google Scholar] [CrossRef]

- Ding, H.; Hu, P.; Liu, Z.; Sun, P.; Liu, Y.; Luo, Z.; Chao, K.; Jiang, H.; Jiang, J. Effect of Ca2+-Si4+ on Y3Al5O12:Ce ceramic phosphors for white laser-diodes lighting. Appl. Phys. Lett. 2021, 118, 211902. [Google Scholar] [CrossRef]

- Kosyanov, D.Y.; Liu, X.; Vornovskikh, A.A.; Kosianova, A.A.; Zakharenko, A.M.; Zavjalov, A.P.; Shichalin, O.O.; Mayorov, V.Y.; Kuryavyi, V.G.; Qian, X.; et al. Al2O3–Ce:YAG and Al2O3–Ce:(Y,Gd)AG composite ceramics for high brightness lighting: Effect of microstructure. Mater. Charact. 2021, 172, 110883. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, L.; Zhou, T.; Sun, B.; Hou, C.; Yang, S.; Huang, J.; Wang, R.; Selim, F.A.; Wang, Z.; et al. Dual effect synergistically triggered Ce:(Y,Tb)3(Al,Mn)5O12 transparent ceramics enabling a high color-rendering index and excellent thermal stability for white LEDs. J. Eur. Ceram. Soc. 2021, 41, 2834–2846. [Google Scholar] [CrossRef]

- Meng, Q.; Zhu, Q.; Li, X.; Sun, X.; Li, J.-G. New Mg2+/Ge4+-stabilized Gd3MgxGexAl5–2xO12:Ce garnet phosphor with orange-yellow emission for warm-white LEDs (x = 2.0–2.5). Inorg. Chem. 2021, 60, 9773–9784. [Google Scholar] [CrossRef]

- Nishiura, S.; Tanabe, S.; Fujioka, K.; Fujimoto, Y. Preparation of transparent Ce3+:GdYAG ceramics phosphors for white LED. IOP Conf. Ser. Mater. Sci. Eng. 2011, 18, 102005. [Google Scholar] [CrossRef]

- Chen, J.; Deng, Z.; Liu, Z.; Lin, Y.; Lan, H.; Chen, D.; Fei, B.; Wang, C.; Wang, F.; Hu, Q.; et al. Optical enhancement brought by doping Gd3+ ions into Ce: YAG ceramics for indoor white light-emitting diodes. Opt. Express 2015, 23, A292–A298. [Google Scholar] [CrossRef]

- Dorenbos, P. Electronic structure and optical properties of the lanthanide activated RE3(Al1−xGax)5O12 (RE=Gd, Y, Lu) garnet compounds. J. Lumin. 2013, 134, 310–318. [Google Scholar] [CrossRef]

- Liu, S.; Sun, P.; Liu, Y.; Zhou, T.; Li, S.; Xie, R.-J.; Xu, X.; Dong, R.; Jiang, J.; Jiang, H. Warm white light with a high color-rendering index from a single Gd3Al4GaO12:Ce3+ transparent ceramic for high-power LEDs and LDs. ACS Appl. Mater. Interfaces 2019, 11, 2130–2139. [Google Scholar] [CrossRef] [PubMed]

- Sun, P.; Hu, P.; Liu, Y.; Liu, S.; Dong, R.; Jiang, J.; Jiang, H. Broadband emissions from Lu2Mg2Al2Si2O12:Ce3+ plate ceramic phosphors enable a high color-rendering index for laser-driven lighting. J. Mater. Chem. C 2020, 8, 1405–1412. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhuang, W.; Hu, Y.; Liu, R.; Jiang, Z.; Liu, Y.; Li, Y.; Zheng, Y.; Chen, L.; Zhong, J. A broad-band orange-yellow-emitting Lu2Mg2Al2Si2O12:Ce3+ phosphor for application in warm white light-emitting diodes. RSC Adv. 2017, 7, 46713–46720. [Google Scholar] [CrossRef]

- Lu, H.; Song, Q.; Xu, X.; Liu, P.; Liu, J.; Xu, J.; Tao, X.; Wang, J.; Bian, K.; Lu, W.; et al. Improving the CRI of Al2O3-YAG:Ce eutectic for high-power white LEDs applications: Energy-transfer and co-luminescence. Opt. Mater. 2021, 121, 111415. [Google Scholar] [CrossRef]

- Liu, Y.; Su, H.; Lu, Z.; Shen, Z.; Guo, Y.; Zhao, D.; Li, S.; Zhang, J.; Liu, L.; Fu, H. Energy transfer and thermal stability enhancement in Ce/Cr co-doped Al2O3/YAG eutectic phosphor ceramics for broadband red-emission. Ceram. Int. 2022, 48, 23598–23608. [Google Scholar] [CrossRef]

- Li, X.; Zhang, C.; Chen, J.; Liu, Q.; Bai, Z.; Liu, X.; Mi, X. Cr3+ ions improving the spectral properties of YAG:Ce3+ luminescent ceramics for white LD lighting. Ceram. Int. 2023, 49, 5489–5495. [Google Scholar] [CrossRef]

- Ao, G.; Tang, Y.; Yi, X.; Tian, Y.; Chen, J.; Hao, D.; Lin, Y.; Zhou, S. Red emission generation in Ce3+/Mn2+ co-doping Y3Al5O12 phosphor ceramics for warm white lighting emitting diodes. J. Alloys Compd. 2019, 798, 695–699. [Google Scholar] [CrossRef]

- Feng, S.; Qin, H.; Wu, G.; Jiang, H.; Zhao, J.; Liu, Y.; Luo, Z.; Qiao, J.; Jiang, J. Spectrum regulation of YAG:Ce transparent ceramics with Pr, Cr doping for white light emitting diodes application. J. Eur. Ceram. Soc. 2017, 37, 3403–3409. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, L.; Zhou, T.; Sun, B.; Wang, Y.; Kang, J.; Gao, P.; Huang, J.; Selim, F.A.; Wong, C.; et al. High recorded color rendering index in single Ce,(Pr,Mn):YAG transparent ceramics for high-power white LEDs/LDs. J. Mater. Chem. C 2020, 8, 4329–4337. [Google Scholar] [CrossRef]

- Duan, Y.; Zhao, C.; Lin, H.; Hong, R.; Tao, C.; Han, Z.; Zhang, D.; Zhou, S. Photoluminescence properties of Tb3Al5O12:Ce3+,Mn2+ phosphor ceramics for high color rendering index warm white LEDs. Opt. Mater. 2021, 111, 110670. [Google Scholar] [CrossRef]

- Xu, Y.; Li, S.; Zheng, P.; Wang, L.; You, S.; Takeda, T.; Hirosaki, N.; Xie, R.-J. A search for extra-high brightness laser-driven color converters by investigating thermally-induced luminance saturation. J. Mater. Chem. C 2019, 7, 11449–11456. [Google Scholar] [CrossRef]

- Li, H.-L.; Liu, X.-J.; Huang, L.-P. Fabrication of transparent cerium-doped lutetium aluminum garnet (LuAG:Ce) ceramics by a solid-state reaction method. J. Am. Ceram. Soc. 2005, 88, 3226–3228. [Google Scholar] [CrossRef]

- Praveena, R.; Shi, L.; Jang, K.H.; Venkatramu, V.; Jayasankar, C.K.; Seo, H.J. Sol–gel synthesis and thermal stability of luminescence of Lu3Al5O12:Ce3+ nano-garnet. J. Alloys Compd. 2011, 509, 859–863. [Google Scholar] [CrossRef]

- Xu, J.; Shi, Y.; Xie, J.; Lei, F. Fabrication, microstructure, and luminescent properties of Ce3+-Doped Lu3Al5O12 (Ce:LuAG) transparent ceramics by low-temperature vacuum sintering. J. Am. Ceram. Soc. 2013, 96, 1930–1936. [Google Scholar] [CrossRef]

- Xu, J.; Fan, L.; Shi, Y.; Li, J.; Xie, J.; Lei, F. Effects of Ce3+ doping concentrations on microstructure and luminescent properties of Ce3+:Lu3Al5O12 (Ce:LuAG) transparent ceramics. Opt. Mater. 2014, 36, 1954–1958. [Google Scholar] [CrossRef]

- Guo, N.; Huang, Y.; You, H.; Yang, M.; Song, Y.; Liu, K.; Zheng, Y. Ca9Lu(PO4)7:Eu2+,Mn2+: A potential single-phased white-light-emitting phosphor suitable for white-light-emitting diodes. Inorg. Chem. 2010, 49, 10907–10913. [Google Scholar] [CrossRef]

- Huang, C.-H.; Chen, T.-M. A novel single-composition trichromatic white-light Ca3Y(GaO)3(BO3)4:Ce3+,Mn2+,Tb3+ phosphor for UV-light emitting diodes. J. Phys. Chem. C 2011, 115, 2349–2355. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, S.; Wang, Z.; Zhou, G.; Wang, S. Pore-existing Lu3Al5O12:Ce ceramic phosphor: An efficient green color converter for laser light source. J. Lumin. 2018, 197, 331–334. [Google Scholar] [CrossRef]

- Yang, J.; Han, T.; Cao, Y.; Lang, T.; Fang, S.; Cao, S.; Peng, L.; Liu, B.; Tian, Z.; Gao, W. Photoluminescent transparent ceramics with an adjustable spectrum for high-color rendering laser lighting. J. Mater. Chem. C 2020, 8, 16483–16488. [Google Scholar] [CrossRef]

- Ling, J.; Zhang, Y.; Yang, J.; Li, Y.; Xu, W.; Zhou, Y.; Hong, M. A single-structured LuAG:Ce,Mn phosphor ceramics with high CRI for high-power white LEDs. J. Am. Ceram. Soc. 2022, 105, 5738–5750. [Google Scholar] [CrossRef]

- Sun, B.; Jiang, B.; Zhang, L. Samarium and manganese incorporation to improve color rendering of LuAG:Ce3+ phosphor ceramics for laser-driven lighting: A Color-tunable and energy transfer study. J. Mater. Chem. C 2021, 9, 16468–16476. [Google Scholar] [CrossRef]

- Huang, J.; Ni, Y.; Ma, Y.; Li, Y.; Sun, Z.; Zhu, X.; Wang, R.; Li, T.; Xi, X.; Huang, G.; et al. Composite structure Cr:YAG/Ce:YAG and (Ce,Cr):YAG/Ce:YAG transparent ceramics with high color rendering index for white LEDs/LDs. Ceram. Int. 2021, 47, 11415–11422. [Google Scholar] [CrossRef]

- Zhou, T.; Hou, C.; Zhang, L.; Ma, Y.; Kang, J.; Li, T.; Wang, R.; Huang, J.; Li, J.; Ren, H.; et al. Efficient spectral regulation in Ce:Lu3(Al,Cr)5O12 and Ce:Lu3(Al,Cr)5O12/Ce:Y3Al5O12 transparent ceramics with high color rendering index for high-power white LEDs/LDs. J. Adv. Ceram. 2021, 10, 1107–1118. [Google Scholar] [CrossRef]

- Park, H.K.; Oh, J.H.; Kang, H.; Zhang, J.; Do, Y.R. Hybrid 2D photonic crystal-assisted Lu3Al5O12:Ce ceramic-plate phosphor and free-standing red film phosphor for white LEDs with high color-rendering index. ACS Appl. Mater. Interfaces 2015, 7, 4549–4559. [Google Scholar] [CrossRef] [PubMed]

- Zhou, T.; Liu, X.; Liu, Q.; Bai, Z.; Zhang, X. Highly thermal stable and color tunable composite fluorescent ceramics for high-power white LEDs. Ceram. Int. 2022, 48, 18716–18722. [Google Scholar] [CrossRef]

- Zheng, R.; Zhang, Q.; Gao, Y.; Ding, J.; Fu, L.; Liu, C.; Wei, W. A double-layer white light converter with high-efficiency heat transfer structure for high-power NUV LEDs/LDs. ACS Appl. Electron. Mater. 2019, 1, 2157–2165. [Google Scholar] [CrossRef]

- Xu, J.; Hu, B.; Xu, C.; Wang, J.; Liu, B.; Li, H.; Wang, X.; Du, B.; Gong, Y. A unique color converter geometry for laser-driven white lighting. Opt. Mater. 2018, 86, 286–290. [Google Scholar] [CrossRef]

- Kosyanov, D.Y.; Vornovskikh, A.A.; Shichalin, O.O.; Papynov, E.K.; Belov, A.A.; Kosianova, A.A.; Fedorets, A.N.; Leonov, A.A.; Zavjalov, A.P.; Tikhonov, S.A.; et al. Reactive SPS of Al2O3–RE:YAG (RE = Ce; Ce+Gd) composite ceramic phosphors. J. Adv. Ceram. 2023, 12, 1015–1032. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, X.; Cheng, Z.; Hu, D.; Zhu, D.; Chen, P.; Tian, F.; Yuan, Q.; Kosyanov, D.Y.; Li, J. Al2O3–Ce:YAG composite phosphor ceramics for white laser lighting: Novel preparation and regulatable properties. J. Am. Ceram. Soc. 2023, 106, 5933–5943. [Google Scholar] [CrossRef]

| Ions | CN = 4 | CN = 6 | CN = 8 |

|---|---|---|---|

| Y3+ | — | — | 1.019 |

| Al3+ | 0.39 | 0.535 | — |

| Ce3+ | — | 1.01 | 1.143 |

| Gd3+ | — | 0.938 | 1.053 |

| Tb3+ | — | 0.923 | 1.04 |

| Lu3+ | — | 0.861 | 0.977 |

| Mg2+ | 0.57 | 0.72 | 0.89 |

| Si4+ | 0.26 | 0.4 | — |

| Cr3+ | — | 0.615 | — |

| Mn2+ | 0.66 | 0.67 | 0.96 |

| Pr3+ | — | 0.99 | 1.126 |

| Sm3+ | — | 0.958 | 1.079 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, B.; Li, W.; Zhang, L.; Chen, P.; Lu, F. Recent Advances in Preparing Transparent Phosphor Ceramics for High-Index Color Rendering and High-Power Lighting. Molecules 2024, 29, 1325. https://doi.org/10.3390/molecules29061325

Du B, Li W, Zhang L, Chen P, Lu F. Recent Advances in Preparing Transparent Phosphor Ceramics for High-Index Color Rendering and High-Power Lighting. Molecules. 2024; 29(6):1325. https://doi.org/10.3390/molecules29061325

Chicago/Turabian StyleDu, Boshen, Wanyuan Li, Lin Zhang, Pei Chen, and Fengniu Lu. 2024. "Recent Advances in Preparing Transparent Phosphor Ceramics for High-Index Color Rendering and High-Power Lighting" Molecules 29, no. 6: 1325. https://doi.org/10.3390/molecules29061325

APA StyleDu, B., Li, W., Zhang, L., Chen, P., & Lu, F. (2024). Recent Advances in Preparing Transparent Phosphor Ceramics for High-Index Color Rendering and High-Power Lighting. Molecules, 29(6), 1325. https://doi.org/10.3390/molecules29061325