Two-Dimensional Transition Metal Dichalcogenide: Synthesis, Characterization, and Application in Candlelight OLED

Abstract

:1. Introduction

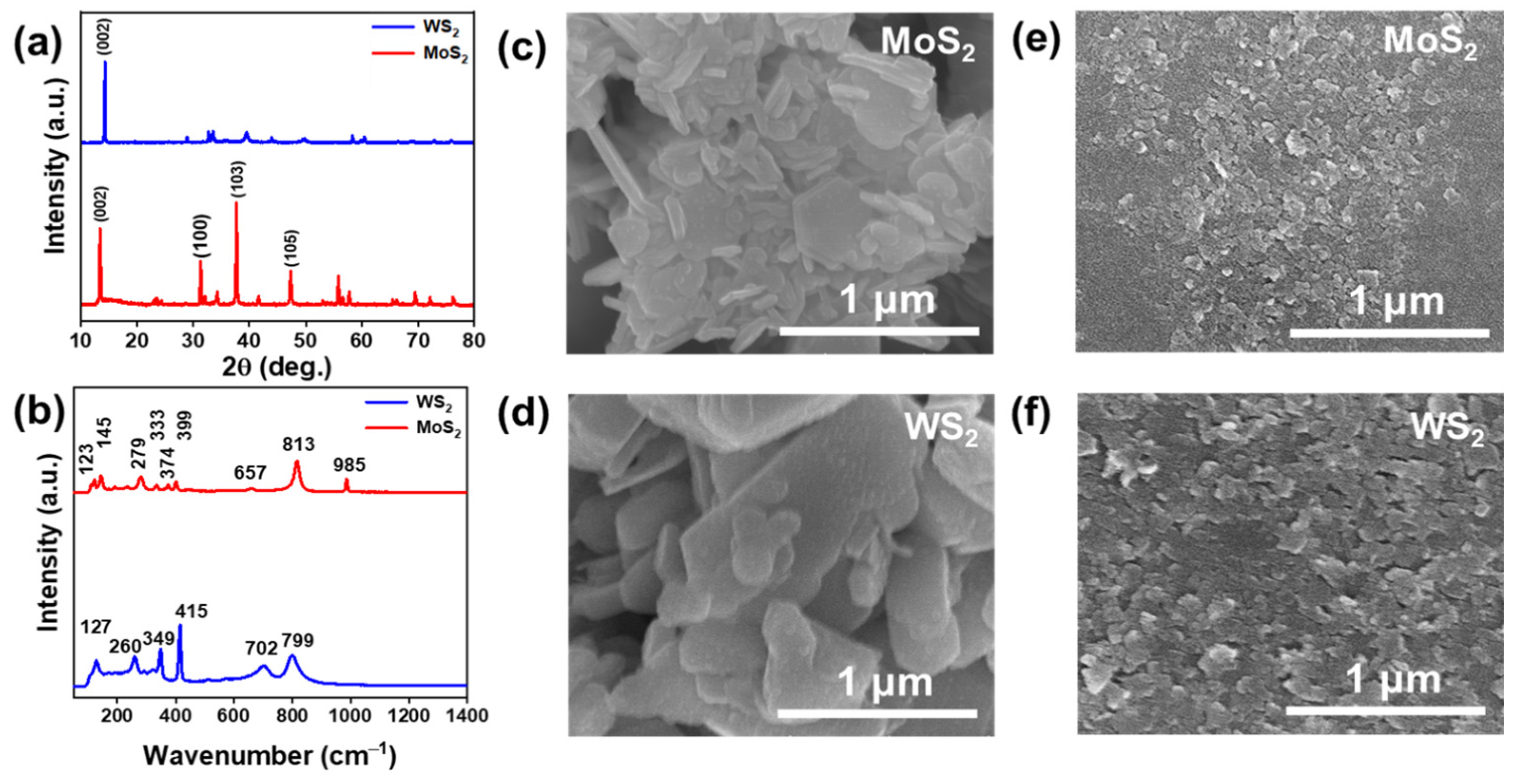

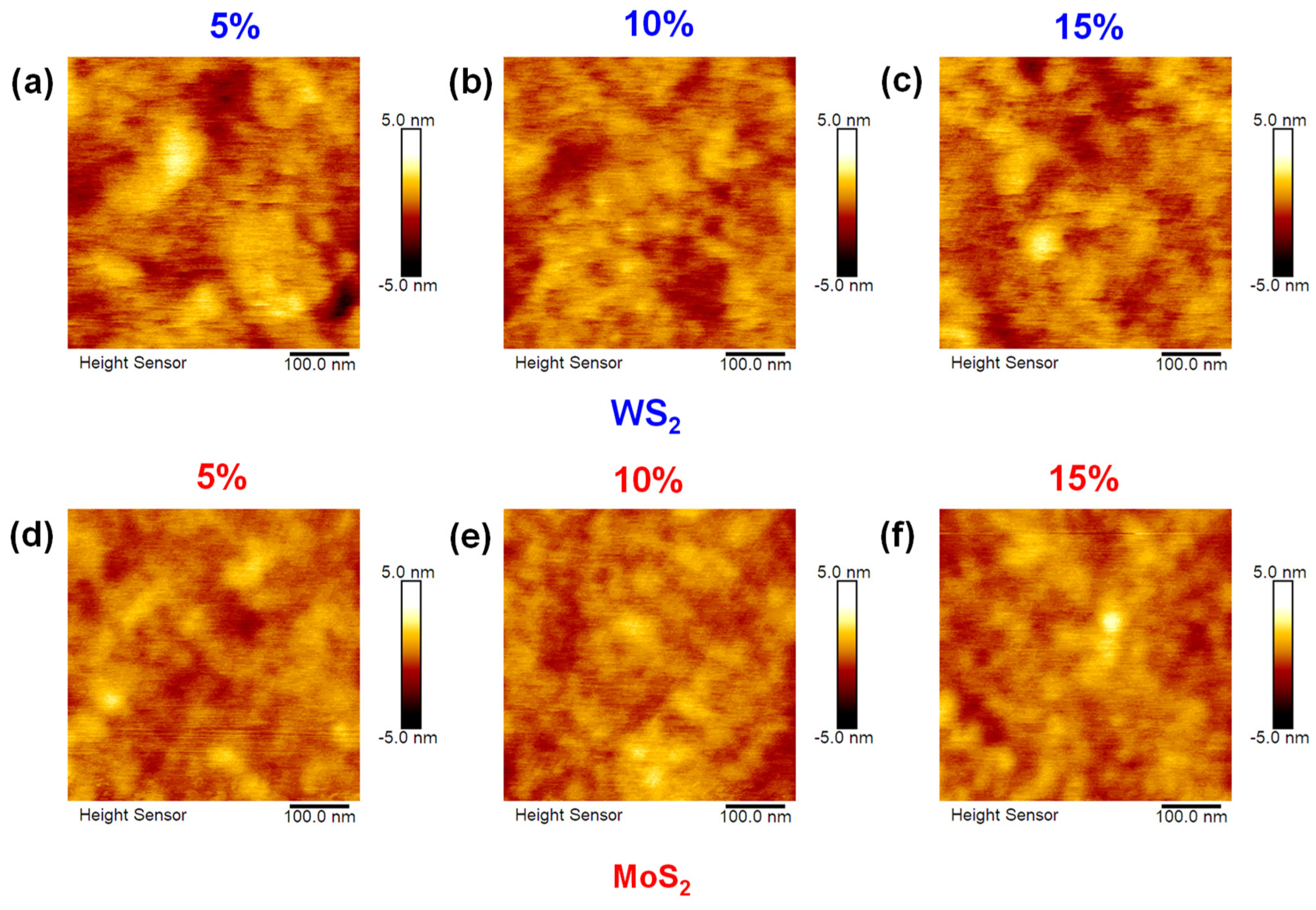

2. Results and Discussion

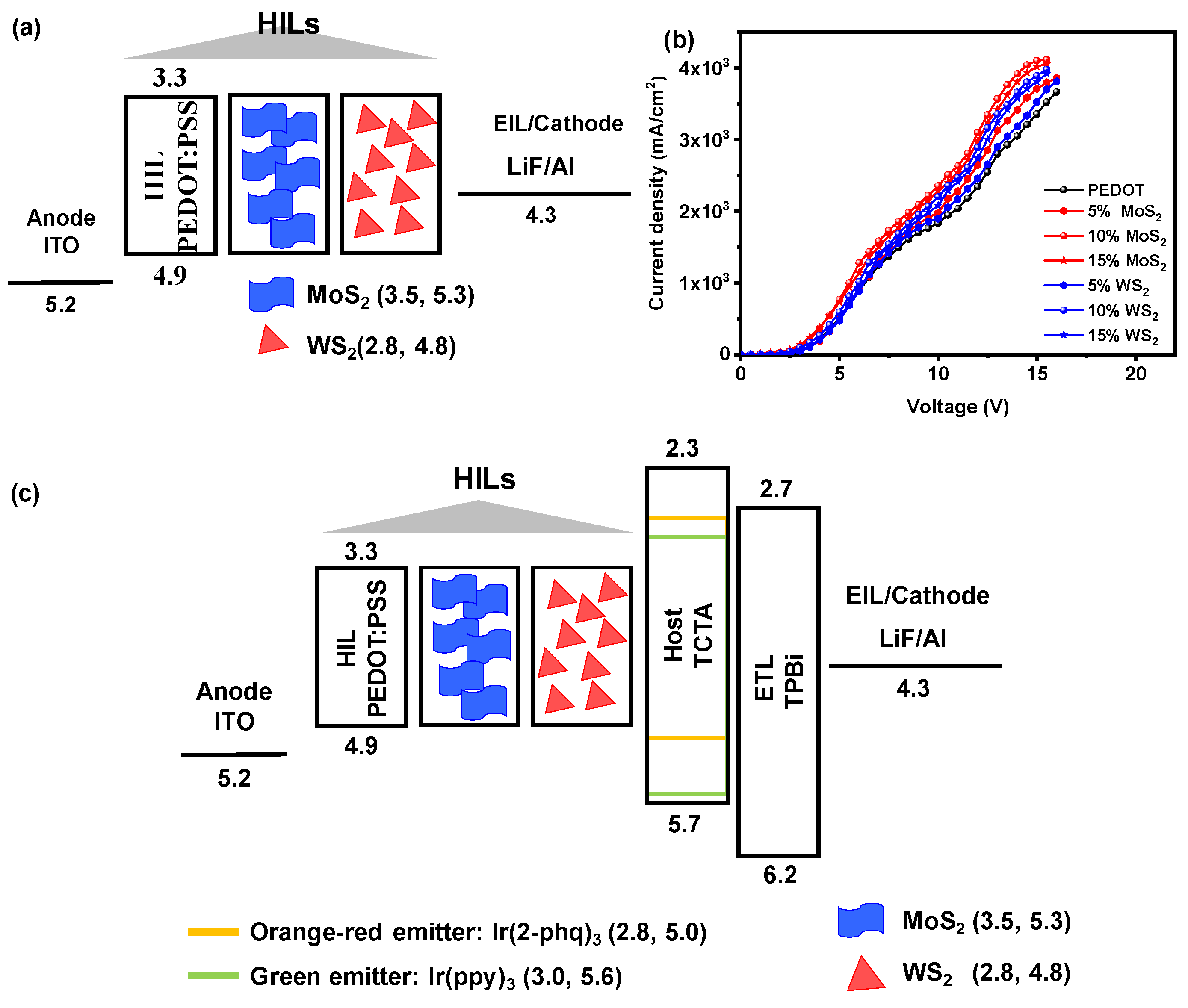

2.1. Hole-Only Device (HOD)

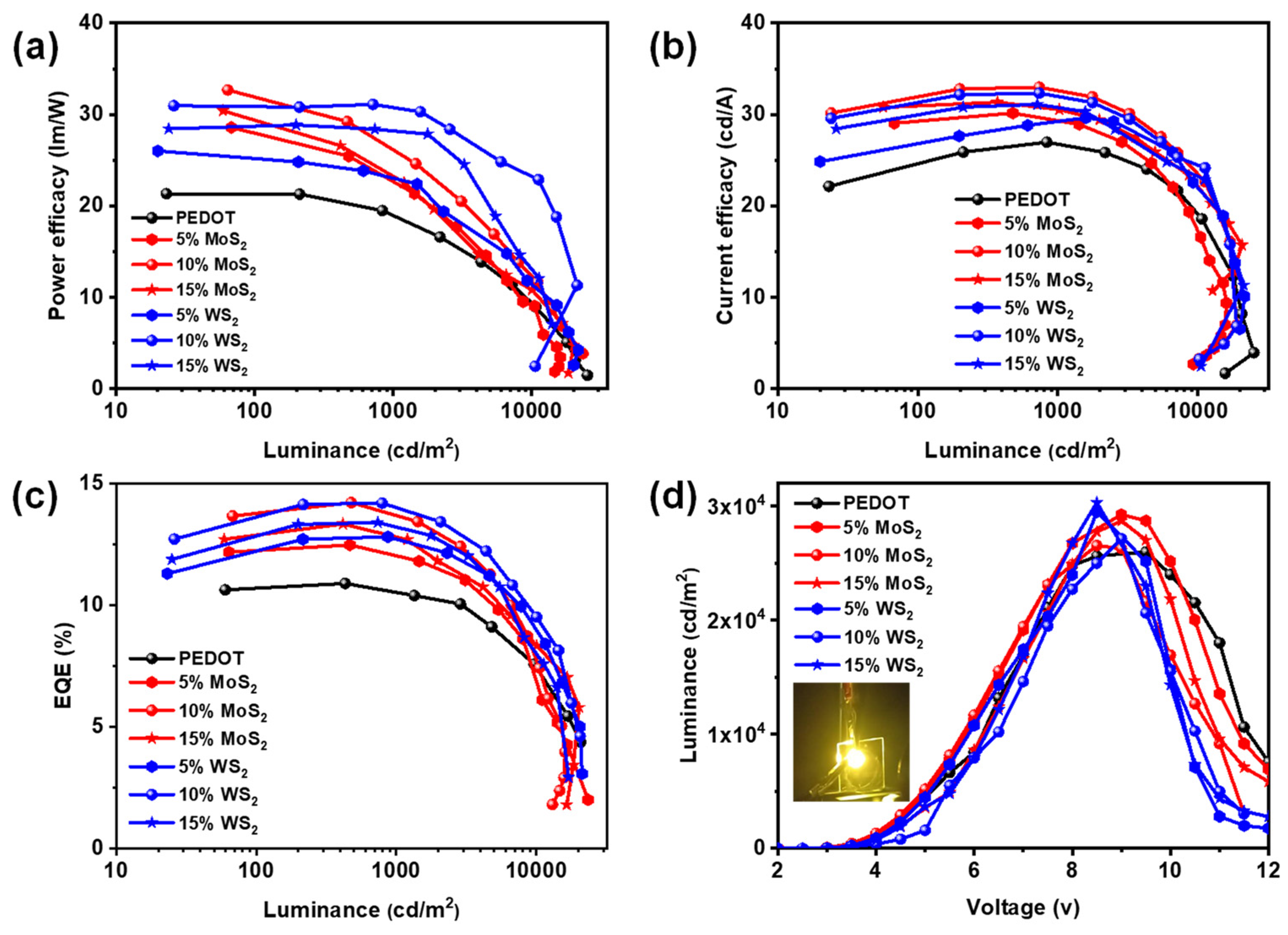

2.2. Device Performance and Characterization of Solution-Processed Phosphorescent OLEDs

2.3. Health and Environmental Considerations

3. Experimental Section

3.1. Instruments

3.2. Synthesis of TMDs (MoS2 and WS2)

3.3. Device Fabrication

Test Conditions After Device Fabrication

3.4. Characterizations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gooley, J.J.; Rajaratnam, S.M.; Brainard, G.C.; Kronauer, R.E.; Czeisler, C.A.; Lockley, S.W. Spectral responses of the human circadian system depend on the irradiance and duration of exposure to light. Sci. Transl. Med. 2010, 2, 31ra33. [Google Scholar] [CrossRef]

- West, K.E.; Jablonski, M.R.; Warfield, B.; Cecil, K.S.; James, M.; Ayers, M.A.; Maida, J.; Bowen, C.; Sliney, D.H.; Rollag, M.D.; et al. Blue light from light-emitting diodes elicits a dose-dependent suppression of melatonin in humans. J. Appl. Physiol. 2011, 110, 619–626. [Google Scholar] [CrossRef]

- Dauchy, R.T.; Hoffman, A.E.; Wren-Dail, M.A.; Hanifin, J.P.; Warfield, B.; Brainard, G.C.; Xiang, S.; Yuan, L.; Hill, S.M.; Belancio, V.P.; et al. Daytime blue light enhances the nighttime circadian melatonin inhibition of human prostate cancer growth. Comp. Med. 2015, 65, 473–485. [Google Scholar] [CrossRef] [PubMed]

- Cougnard-Gregoire, A.; Merle, B.M.J.; Aslam, T.; Seddon, J.M.; Aknin, I.; Klaver, C.C.W.; Garhöfer, G.; Layana, A.G.; Minnella, A.M.; Silva, R.; et al. Blue Light Exposure: Ocular Hazards and Prevention—A Narrative Review. Ophthalmol. Ther. 2023, 12, 755–788. [Google Scholar] [CrossRef]

- Mak, K.F.; Lee, C.; Hone, J.; Shan, J.; Heinz, T.F. Atomically thin MoS2: A new direct-gap semiconductor. Phys. Rev. Lett. 2010, 105, 136805. [Google Scholar] [CrossRef] [PubMed]

- AMA Adopts Guidance to Reduce Harm from High Intensity Street Lights. American Medical Association. Available online: https://www.ama-assn.org/press-center/press-releases/ama-adopts-guidance-reduce-harm-high-intensity-street-lights (accessed on 10 September 2024).

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, A.; Iqbal, M.Z.; Dahshan, A.; Aftab, S.; Hegazy, H.H. Recent advances in 2D transition metal dichalcogenide-based photodetectors: A review. Nanoscale 2024, 16, 2097–2120. [Google Scholar] [CrossRef]

- Mak, K.F.; Shan, J. Photonics and optoelectronics of 2D semiconductor transition metal dichalcogenides. Nat. Photonics 2016, 10, 216–226. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Katsnelson, M.I.; Grigorieva, I.V.; Dubonos, S.V.; Firsov, A.A. Two-dimensional gas of massless Dirac fermions in graphene. Nature 2005, 438, 197–200. [Google Scholar] [CrossRef]

- Miro, P.; Audiffred, M.; Heine, T. An atlas of two-dimensional materials. Chem. Soc. Rev. 2014, 43, 6537–6554. [Google Scholar] [CrossRef]

- Wang, F.; Wang, Z.; Yin, L.; Cheng, R.; Wang, J.; Wen, Y.; Shifa, T.A.; Wang, F.; Zhang, Y.; Zhan, X.; et al. 2D library beyond graphene and transition metal dichalcogenides: A focus on photodetection. Chem. Soc. Rev. 2018, 47, 6296–6341. [Google Scholar] [CrossRef] [PubMed]

- Retamal, J.R.D.; Periyanagounder, D.; Ke, J.J.; Tsai, M.L.; He, J.H.H. Charge carrier injection and transport engineering in two-dimensional transition metal dichalcogenides. Chem. Sci. 2018, 9, 7727–7745. [Google Scholar] [CrossRef]

- Kuc, A.; Heine, T.; Kis, A. Electronic properties of transition-metal dichalcogenides. MRS Bull. 2015, 40, 577–584. [Google Scholar] [CrossRef]

- Zhou, K.G.; Mao, N.N.; Wang, H.X.; Peng, Y.; Zhang, H.L. A mixed-solvent strategy for efficient exfoliation of inorganic graphene analogues. Angew. Chem. Int. Ed. 2011, 46, 10839–10842. [Google Scholar] [CrossRef]

- Splendiani, A.; Sun, L.; Zhang, Y.; Li, T.; Kim, J.; Chim, C.Y.; Galli, G.; Wang, F. Emerging photoluminescence in monolayer MoS2. Nano Lett. 2010, 10, 1271–1275. [Google Scholar] [CrossRef] [PubMed]

- Munshi, M.N.; Loganathan, N.; Chakaroun, M.; Racine, B.; Maret, L.; Fischer, A.P. High-speed OLED bandwidth optimization method based on Relative Intensity Noise measurements. Org. Electron. 2023, 123, 106935. [Google Scholar] [CrossRef]

- Lee, S.T.; Wang, Y.M.; Hou, X.Y.; Tang, C.W. Interfacial Electronic Structures in an Organic Light-Emitting Diode. Appl. Phys. Lett. 1999, 74, 670–672. [Google Scholar] [CrossRef]

- Wang, H.; Klubek, K.P.; Tang, C.W. Current Efficiency in Organic Light-Emitting Diodes with a Hole-Injection Layer. Appl. Phys. Lett. 2008, 93, 325. [Google Scholar] [CrossRef]

- Song, C.; Hu, Z.; Luo, Y.; Cun, Y.; Wang, L.; Ying, L.; Huang, F.; Peng, J.; Wang, J.; Cao, Y. Organic/Inorganic Hybrid EIL for All-Solution-Processed OLEDs. Phys. Rev. Appl. 2023, 19, 054067. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, J.; Wu, Y.; Wei, F.; Wang, H.; Chen, X.; Xiong, Z. Evolution Between Exciton and Exciplex Emission in Planar Heterojunction OLEDs with Different Hole-Injection Characteristics. Phys. Rev. Appl. 2023, 19, 054067. [Google Scholar] [CrossRef]

- Xie, M.; Pang, H.; Wang, J.; Cui, Z.; Ding, H.; Zheng, R.; Kwong, R.; Xia, S. Charge Balance in OLEDs: Optimization of Hole Injection Layer Using Novel P-Dopants. J. Soc. Inf. Disp. 2024, 32, 59–69. [Google Scholar] [CrossRef]

- Zhu, W.; Ding, K.; Yi, C.; Chen, R.; Wei, B.; Huang, L.; Li, J. Use of hybrid PEDOT/metal sulfide quantum dots for a hole injection layer in highly efficient green phosphorescent organic light-emitting diodes. Front. Chem. 2021, 9, 657557. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Li, D.; Yuan, Y.; Chi, F.; Liu, L.; Wang, L.; Lu, Z.; Lin, Z.; Zhang, X. Solution-processed WS2 and its doping in PEDOT for tailoring hole injection in near ultraviolet organic light-emitting diodes. Appl. Opt. 2021, 60, 2610–2615. [Google Scholar] [CrossRef]

- Sathiyan, S.; Ahmad, H.; Chong, W.Y.; Lee, S.H.; Sivabalan, S. Evolution of the Polarizing Effect of MoS2. IEEE Photonics J. 2015, 7, 6100610. [Google Scholar] [CrossRef]

- Huang, F.; Jian, J.; Wu, R. Few-layer thick WS2 nanosheets produced by intercalation/exfoliation route. J. Mater. Sci. 2016, 51, 10160–10165. [Google Scholar] [CrossRef]

- Berkdemir, A.; Gutiérrez, H.R.; Botello-Méndez, A.R.; Perea-López, N.; Elías, A.L.; Chia, C.-I.; Wang, B.; Crespi, V.H.; López-Urías, F.; Charlier, J.-C. Probing the optical phonons in few-layer graphene by Raman spectroscopy. Sci. Rep. 2013, 3, 1755. [Google Scholar] [CrossRef]

- Zheng, W.; Zhu, Y.; Li, F.; Huang, F. Raman spectroscopy regulation in van der Waals crystals. Photon. Res. 2018, 6, 991–995. [Google Scholar] [CrossRef]

- Gautam, P.; Gupta, S.; Siddiqui, I.; Lin, W.Z.; Sharma, D.; Ranjan, A.; Tai, N.H.; Lu, M.Y.; Jou, J.H. 0, 1, 2, and 3-Dimensional zinc oxides enabling high-efficiency OLEDs. Chem. Eng. J. 2024, 495, 153220. [Google Scholar] [CrossRef]

- Kumar, K.; Sharma, D.; Thakur, D.; Lin, W.Z.; Nagar, M.R.; Banik, S.; Jou, J.H.; Ghosh, S. Exploring Acceptor-Functionalized Perylenes as Hole Transport Materials for Solution Process Organic Light-Emitting Diodes. ACS Appl. Electron. Mater. 2024, 6, 3874–3883. [Google Scholar] [CrossRef]

- Kumar, K.; Kumar, S.; Karmakar, A.; Sharma, D.; Chen, F.R.; Nagar, M.R.; Jou, J.H.; Banik, S.; Ghosh, S. Design strategy and molecular level understanding: Hole transport materials with suitable transition dipole orientation for OLEDs. Mol. Syst. Des. Eng. 2024, 9, 1116–1129. [Google Scholar] [CrossRef]

- Nagar, M.R.; Yadav, R.A.K.; Dubey, D.K.; Jou, J.H. Solution process feasible highly efficient organic light emitting diode with hybrid metal oxide-based hole injection/transport layer. MRS Adv. 2019, 4, 1801–1809. [Google Scholar] [CrossRef]

| Material Name | Doping Concentration (%) | Ra (nm) | Rq (nm) |

|---|---|---|---|

| PEDOT:PSS | 0.695 | 1.030 | |

| MoS2 | 5% | 0.438 | 0.558 |

| 10% | 0.410 | 0.523 | |

| 15% | 0.427 | 0.552 | |

| WS2 | 5% | 0.619 | 0.801 |

| 10% | 0.483 | 0.606 | |

| 15% | 0.532 | 0.669 |

| Dopant | Doping Concentration % | Driving Voltage (V) | Operation Voltage (V) | Power Efficacy (lm/W) | Current Efficacy (cd/A) | EQE (%) | CIE | Maximum Luminance (cd/m2) |

|---|---|---|---|---|---|---|---|---|

| @ 100/1000/10,000 cd/m2 | ||||||||

| PEDOT/PSS | 0 | 2.8 | 3.5/4.3/6.1 | 23.6/17.5/9.8 | 25.7/26.8/19.2 | 9.7/9.8/6.6 | (0.55, 0.44)/(0.55, 0.44)/(0.54, 0.45) | 25,990 |

| MoS2 | 5 | 2.6 | 3/3.8/6.4 | 28.6/23.4/9 | 29.1/29.3/18.2 | 12.9/12.1/8.8 | (0.56, 0.44)/(0.55, 0.44)/(0.54, 0.45) | 29,270 |

| 10 | 2.6 | 3/3.8/5.8 | 32.7/25.6/11.6 | 31/31.4/21.5 | 13.6/13/9.3 | (0.56, 0.44)/(0.55, 0.44)/(0.55, 0.45) | 26,550 | |

| 15 | 2.6 | 3.1/3.9/6 | 30.4/23.6/10.8 | 30.1/28.9/20.7 | 13.1/12.8/9 | (0.56, 0.44)/(0.55, 0.44)/(0.55, 0.45) | 28,730 | |

| WS2 | 5 | 2.7 | 3.2/4.1/5.9 | 25.2/21.5/11.5 | 27.6/29.7/22.1 | 11.5/12.3/9.1 | (0.55, 0.44)/(0.55, 0.44)/(0.54, 0.45) | 26,330 |

| 10 | 2.7 | 3.2/4.1/6.3 | 30.1/24.5/12.3 | 30.7/32.1/24.8 | 13.1/13.9/9.5 | (0.55, 0.44)/(0.54, 0.44)/(0.53, 0.45) | 27,150 | |

| 15 | 2.7 | 3.2/4.2/5.9 | 28.9/23.3/13 | 1.4/30.8/24.4 | 12.2/12.9/9.3 | (0.55, 0.44)/(0.54, 0.44)/(0.54, 0.45) | 30,320 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharma, D.; Gull, S.; Ramakrishnan, A.; Lenka, S.; Kumar, A.; Kumar, K.; Lin, P.-K.; Wang, C.-W.; Chen, S.-W.; Grigalevicius, S.; et al. Two-Dimensional Transition Metal Dichalcogenide: Synthesis, Characterization, and Application in Candlelight OLED. Molecules 2025, 30, 27. https://doi.org/10.3390/molecules30010027

Sharma D, Gull S, Ramakrishnan A, Lenka S, Kumar A, Kumar K, Lin P-K, Wang C-W, Chen S-W, Grigalevicius S, et al. Two-Dimensional Transition Metal Dichalcogenide: Synthesis, Characterization, and Application in Candlelight OLED. Molecules. 2025; 30(1):27. https://doi.org/10.3390/molecules30010027

Chicago/Turabian StyleSharma, Dipanshu, Sanna Gull, Anbalagan Ramakrishnan, Sushanta Lenka, Anil Kumar, Krishan Kumar, Pin-Kuan Lin, Ching-Wu Wang, Sinn-Wen Chen, Saulius Grigalevicius, and et al. 2025. "Two-Dimensional Transition Metal Dichalcogenide: Synthesis, Characterization, and Application in Candlelight OLED" Molecules 30, no. 1: 27. https://doi.org/10.3390/molecules30010027

APA StyleSharma, D., Gull, S., Ramakrishnan, A., Lenka, S., Kumar, A., Kumar, K., Lin, P.-K., Wang, C.-W., Chen, S.-W., Grigalevicius, S., & Jou, J.-H. (2025). Two-Dimensional Transition Metal Dichalcogenide: Synthesis, Characterization, and Application in Candlelight OLED. Molecules, 30(1), 27. https://doi.org/10.3390/molecules30010027