Preparation and Physicochemical Properties of 10-Hydroxycamptothecin (HCPT) Nanoparticles by Supercritical Antisolvent (SAS) Process

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

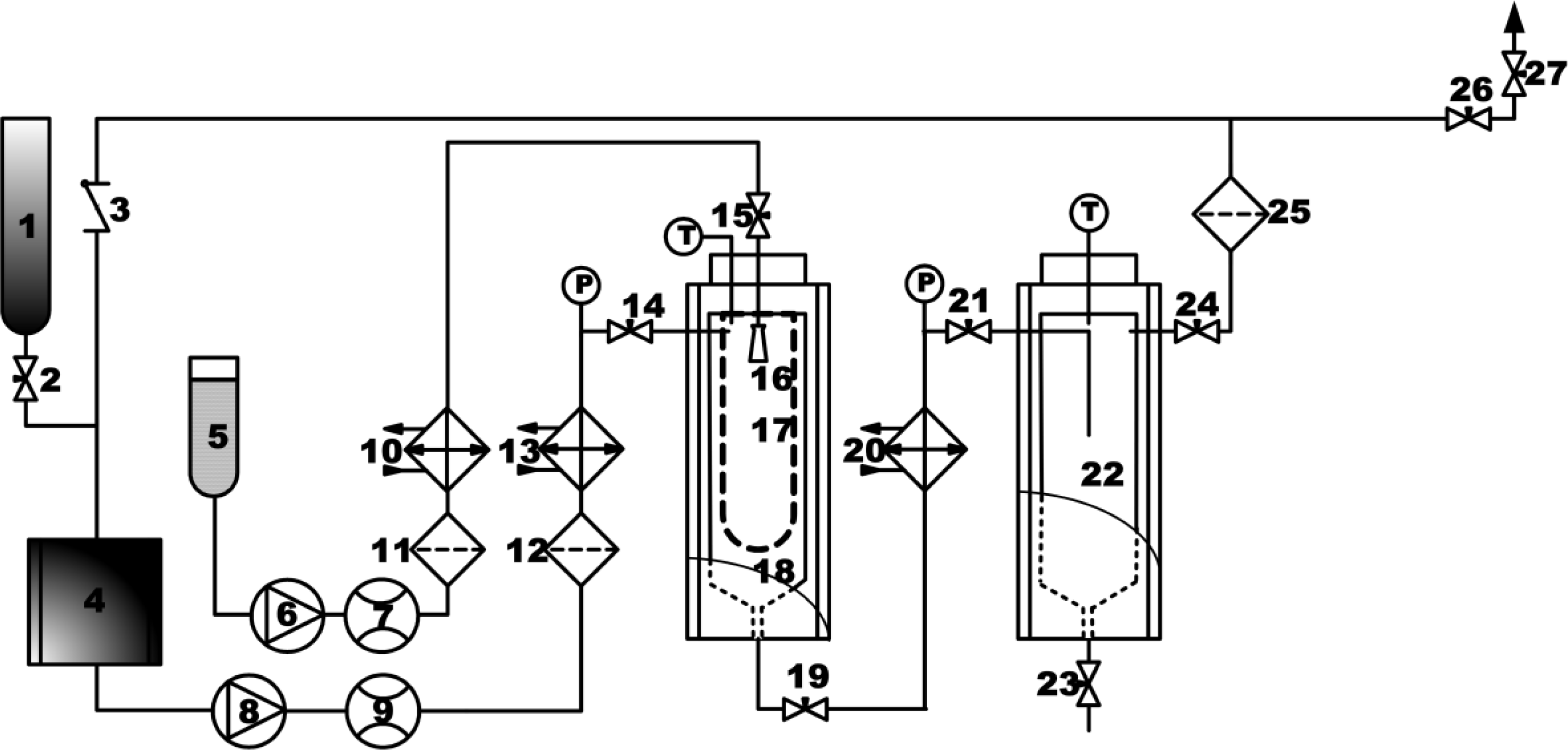

2.2. Apparatus and Supercritical Anti-Solvent (SAS) Process

2.3. Optimization of SAS Process

2.4. Physicochemical Properties of HCPT Nanoparticles

2.4.1. Research of the Morphology

2.4.2. Dynamic Light Scattering (DLS)

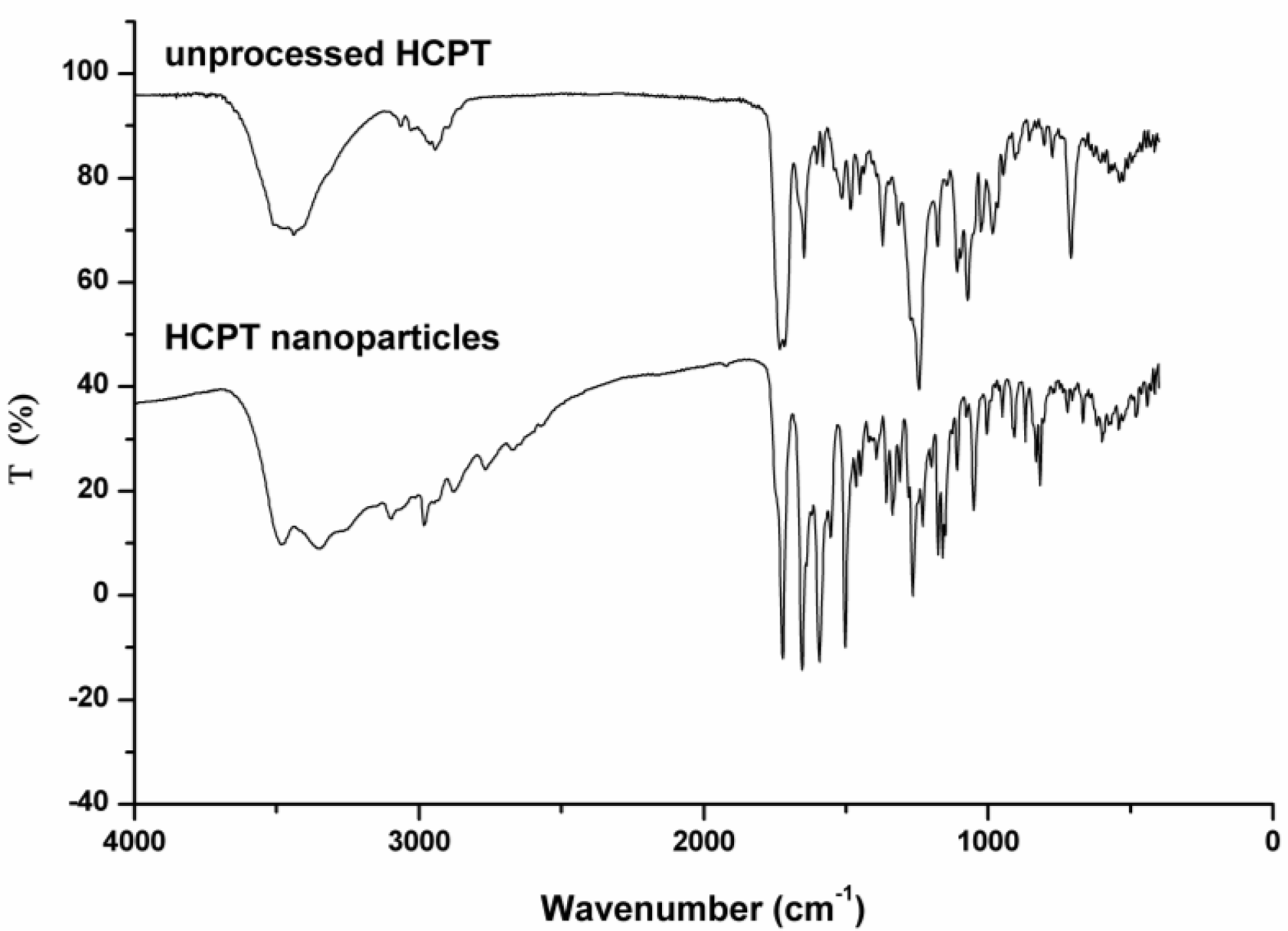

2.4.3. FTIR Analysis

2.4.4. LC-MS Analysis

2.4.5. XRD Analysis

2.4.6. DSC Analysis

2.4.7. Dissolution Studies in Vitro

3. Results and Discussion

3.1. Optimization Study

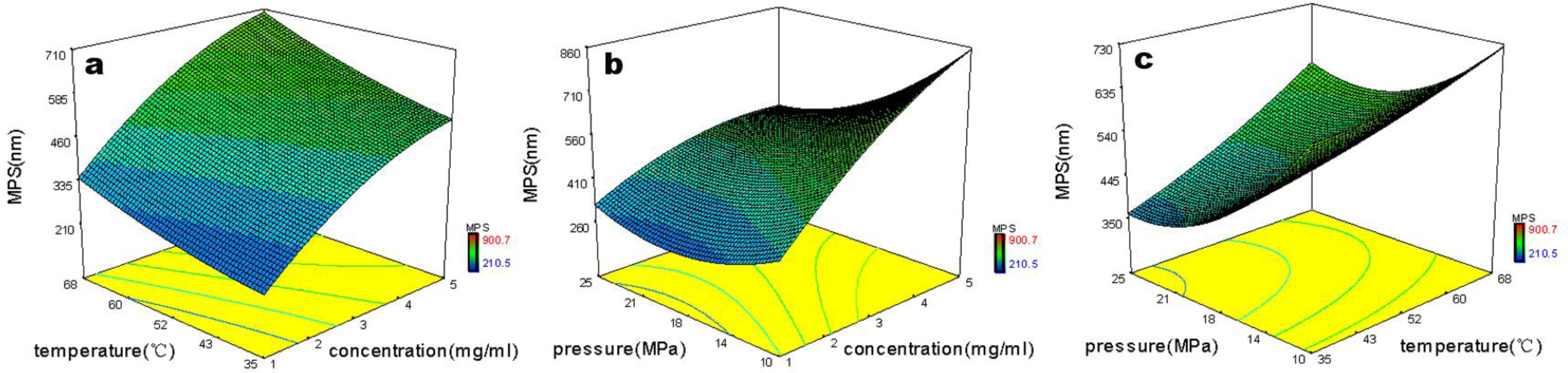

3.2. Effect of Operating Conditions on the MPS of Micronized HCPT

3.3. Morphology of Processed HCPT

3.4. Physicochemical Properties of HCPT Nanoparticles

3.4.1. FTIR Analysis

3.4.2. LC-MS Analysis

3.4.3. X-ray Analysis

3.4.4. DSC Analysis

3.4.5. Dissolution Studies in Vitro

4. Conclusions

Acknowledgments

References

- Yang, L; Cui, F; Cun, D; Tao, A; Shi, K; Lin, W. Preparation, characterization and biodistribution of the lactone form of 10-hydroxycamptothecin (HCPT)-loaded bovine serum albumin (BSA) nanoparticles. Int. J. Pharm 2007, 340, 163–172. [Google Scholar]

- Wang, SL; Lin, SY; Hsieh, TF; Chan, SA. Thermal behavior and thermal decarboxylation of 10-hydroxycamptothecin in the solid state. J. Pharm. Biomed. Anal 2007, 43, 457–463. [Google Scholar]

- Hong, M; Zhu, S; Jiang, Y; Tang, G; Pei, Y. Efficient tumor targeting of hydroxycamptothecin loaded PEGylated niosomes modified with transferrin. J. Control. Release 2009, 133, 96–102. [Google Scholar]

- Ma, J; Liu, CL; Zhu, PL; Jia, ZP; Xu, LT; Wang, R. Simultaneous determination of the carboxylate and lactone forms of 10-hydroxycamptothecin in human serum by restricted-access media high-performance liquid chromatography. J. Chromatogr. B 2002, 772, 197–204. [Google Scholar]

- Zhao, YX; Hua, HY; Chang, M; Liu, WJ; Zhao, Y; Liu, HM. Preparation and cytotoxic activity of hydroxycamptothecin nanosuspensions. Int. J. Pharm 2010, 392, 64–71. [Google Scholar]

- Takayama, H; Watanabe, A; Hosokawa, M; Chiba, K; Satoh, T; Aimi, N. Synthesis of a new class of camptothecin derivatives, the long-chain fatty acid esters of 10-hydroxycamptothecin, as a potent prodrug candidate, and their in vitro metabolic conversion by carboxylesterases. Bioorg. Med. Chem. Lett 1998, 8, 415–418. [Google Scholar]

- Pessah, N; Reznik, M; Shamis, M; Yantiri, F; Xin, H; Bowdish, K; Shomron, N; Ast, G; Shabat, D. Bioactivation of carbamate-based 20(S)-camptothecin prodrugs. Bioorg. Med. Chem 2004, 12, 1859–1866. [Google Scholar]

- Ohwada, J; Ozawa, S; Kohchi, M; Fukuda, H; Murasaki, C; Suda, H; Murata, T; Niizuma, S; Tsukazaki, M; Ori, K; Yoshinari, K; Itezono, Y; Endo, M; Ura, M; Tanimura, H; Miyazaki, Y; Kawashima, A; Nagao, S; Namba, E; Ogawa, K; Kobayashi, K; Okabe, H; Umeda, I; Shimma, N. Synthesis and biological activities of a pH-dependently activated water-soluble prodrug of a novel hexacyclic camptothecin analog. Bioorg. Med. Chem. Lett 2009, 19, 2772–2776. [Google Scholar]

- Angenault, S; Thirot, S; Schmidt, F; Monneret, C; Pfeiffer, B; Renard, P. Cancer chemotherapy: A SN-38 (7-ethyl-10-hydroxycamptothecin) glucuronide prodrug for treatment by a PMT (Prodrug MonoTherapy) strategy. Bioorg. Med. Chem. Lett 2003, 13, 947–950. [Google Scholar]

- Zhang, L; Yang, M; Wang, Q; Li, Y; Guo, R; Jiang, X; Yang, C; Liu, B. 10-Hydroxycamptothecin loaded nanoparticles: Preparation and antitumor activity in mice. J. Control. Release 2007, 119, 153–162. [Google Scholar]

- Wang, A; Li, S. Hydroxycamptothecin-loaded nanoparticles enhance target drug delivery and anticancer effect. BMC Biotechnol 2008, 8, 46. [Google Scholar]

- Shenderova, A; Burke, TG; Schwendeman, SP. Stabilization of 10-hydroxycamptothecin in poly(lactide-co-glycolide) microsphere delivery vehicles. Pharm. Res 1997, 14, 1406–1414. [Google Scholar]

- Mallery, SR; Shenderova, A; Pei, P; Begum, S; Ciminieri, JR; Wilson, RF; Casto, BC; Schuller, DE; Morse, MA. Effects of 10-hydroxycamptothecin, delivered from locally injectable poly(lactide-co-glycolide) microspheres, in a murine human oral squamous cell carcinoma regression model. Anticancer Res 2001, 21, 1713–1722. [Google Scholar]

- Lu, B; Zhang, Z. Novel colon-specific microspheres with highly dispersed hydroxycamptothecin cores: Their preparation, release behavior, and therapeutic efficiency against colonic cancer. J. Pharm. Sci 2006, 95, 2619–2630. [Google Scholar]

- Zhao, Y; Gao, J; Sun, X; Chen, H; Wu, L; Liang, W. Enhanced nuclear delivery and cytotoxic activity of hydroxycamptothecin using o/w emulsions. J. Pharm. Pharm. Sci 2007, 10, 61–70. [Google Scholar]

- Zhang, C; Ding, Y; Yu, LL; Ping, Q. Polymeric micelle systems of hydroxycamptothecin based on amphiphilic N-alkyl-N-trimethyl chitosan derivatives. Colloid. Surface. B 2007, 55, 192–199. [Google Scholar]

- Zhou, YY; Du, YZ; Wang, L; Yuan, H; Zhou, JP; Hu, FQ. Preparation and pharmacodynamics of stearic acid and poly (lactic-co-glycolic acid) grafted chitosan oligosaccharide micelles for 10-hydroxycamptothecin. Int. J. Pharm 2010, 393, 144–152. [Google Scholar]

- Pu, X; Sun, J; Wang, Y; Liu, X; Zhang, P; Tang, X; Pan, W; Han, J; He, Z. Development of a chemically stable 10-hydroxycamptothecin nanosuspensions. Int. J. Pharm 2009, 379, 167–173. [Google Scholar]

- Tavares Cardoso, MA; Geraldes, V; Cabral, JMS; Palavra, AMF. Characterization of minocycline powder micronized by a supercritical antisolvent (SAS) process. J. Supercrit. Fluid 2008, 46, 71–76. [Google Scholar]

- Kim, M-S; Jin, S-J; Kim, J-S; Park, HJ; Song, H-S; Neubert, RHH; Hwang, S-J. Preparation, characterization and in vivo evaluation of amorphous atorvastatin calcium nanoparticles using supercritical antisolvent (SAS) process. Eur. J. Pharm. Biopharm 2008, 69, 454–465. [Google Scholar]

- Reverchon, E; De Marco, I; Torino, E. Nanoparticles production by supercritical antisolvent precipitation: A general interpretation. J. Supercrit. Fluid 2007, 43, 126–138. [Google Scholar]

- Chang, S-C; Lee, M-J; Lin, H-M. Role of phase behavior in micronization of lysozyme via a supercritical anti-solvent process. Chem. Eng. J 2008, 139, 416–425. [Google Scholar]

- Dowy, S; Braeuer, A; Reinhold-López, K; Leipertz, A. In situ optical monitoring of the solution concentration influence on supercritical particle precipitation. J. Supercrit. Fluid 2010, 55, 282–291. [Google Scholar]

- Reverchon, E; Adami, R; Cardea, S; Porta, GD. Supercritical fluids processing of polymers for pharmaceutical and medical applications. J. Supercrit. Fluid 2009, 47, 484–492. [Google Scholar]

- Zhao, X; Zu, Y; Li, Q; Wang, M; Zu, B; Zhang, X; Jiang, R; Zu, C. Preparation and characterization of camptothecin powder micronized by a supercritical antisolvent (SAS) process. J. Supercrit. Fluid 2010, 51, 412–419. [Google Scholar]

- Chattopadhyay, P; Gupta, RB. Production of griseofulvin nanoparticles using supercritical CO(2) antisolvent with enhanced mass transfer. Int. J. Pharm 2001, 228, 19–31. [Google Scholar]

| Trial No. | A | B | C | D | Error | MPS (nm) ± SD (n = 3) |

|---|---|---|---|---|---|---|

| 1 | 1 (0.5) | 1 (35) | 1 (10) | 1 (3.3) | 1 | 381.2 |

| 2 | 1 (0.5) | 2 (46) | 2 (15) | 2 (6.6) | 2 | 210.5 |

| 3 | 1 (0.5) | 3 (57) | 3 (20) | 3 (9.9) | 3 | 350.0 |

| 4 | 1 (0.5) | 4 (68) | 4 (25) | 4 (13.2) | 4 | 424.8 |

| 5 | 2 (1.5) | 1 (35) | 2 (15) | 3 (9.9) | 4 | 409.4 |

| 6 | 2 (1.5) | 2 (46) | 1 (10) | 4 (13.2) | 3 | 458.3 |

| 7 | 2 (1.5) | 3 (57) | 4 (25) | 1 (3.3) | 2 | 437.9 |

| 8 | 2 (1.5) | 4 (68) | 3 (20) | 2 (6.6) | 1 | 446.0 |

| 9 | 3 (3.0) | 1 (35) | 3 (20) | 4 (13.2) | 2 | 350.6 |

| 10 | 3 (3.0) | 2 (46) | 4 (25) | 3 (9.9) | 1 | 428.2 |

| 11 | 3 (3.0) | 3 (57) | 1 (10) | 2 (6.6) | 4 | 752.8 |

| 12 | 3 (3.0) | 4 (68) | 2 (15) | 1 (3.3) | 3 | 641.1 |

| 13 | 4 (5.0) | 1 (35) | 4 (25) | 2 (6.6) | 3 | 402.9 |

| 14 | 4 (5.0) | 2 (46) | 3 (20) | 1 (3.3) | 4 | 474.5 |

| 15 | 4 (5.0) | 3 (57) | 2 (15) | 4 (13.2) | 1 | 720.6 |

| 16 | 4 (5.0) | 4 (68) | 1 (10) | 3 (9.9) | 2 | 900.7 |

| K1a | 341.6 | 386.0 | 623.3 | 483.7 | 494.0 | |

| K2 | 437.9 | 392.9 | 495.4 | 453.1 | 475.0 | |

| K3 | 543.2 | 565.3 | 405.3 | 522.1 | 463.1 | |

| K4 | 624.7 | 603.2 | 423.5 | 488.6 | 515.4 | |

| Rb | 283.1 | 217.1 | 218.0 | 69.0 | 52.3 | |

| Optimal level | A1 | B1 | C3 | D2 |

| Source | Sum of squares (SS) | Degrees of freedom (df) | F-ratio | F0.05 | Type of effect |

|---|---|---|---|---|---|

| (A) Concentration of HCPT solution | 182618.6 | 3 | 29.038 | 9.28 | Significant |

| (B) Precipitation temperature | 154724 | 3 | 24.602 | 9.28 | Significant |

| (C) Precipitation pressure | 117408.4 | 3 | 18.669 | 9.28 | Significant |

| (D) Drug solution flow rate | 9585.187 | 3 | 1.524 | 9.28 | |

| Error | 6289.02 | 3 |

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Zhao, X.; Zu, Y.; Jiang, R.; Wang, Y.; Li, Y.; Li, Q.; Zhao, D.; Zu, B.; Zhang, B.; Sun, Z.; et al. Preparation and Physicochemical Properties of 10-Hydroxycamptothecin (HCPT) Nanoparticles by Supercritical Antisolvent (SAS) Process. Int. J. Mol. Sci. 2011, 12, 2678-2691. https://doi.org/10.3390/ijms12042678

Zhao X, Zu Y, Jiang R, Wang Y, Li Y, Li Q, Zhao D, Zu B, Zhang B, Sun Z, et al. Preparation and Physicochemical Properties of 10-Hydroxycamptothecin (HCPT) Nanoparticles by Supercritical Antisolvent (SAS) Process. International Journal of Molecular Sciences. 2011; 12(4):2678-2691. https://doi.org/10.3390/ijms12042678

Chicago/Turabian StyleZhao, Xiuhua, Yuangang Zu, Ru Jiang, Ying Wang, Yong Li, Qingyong Li, Dongmei Zhao, Baishi Zu, Baoyou Zhang, Zhiqiang Sun, and et al. 2011. "Preparation and Physicochemical Properties of 10-Hydroxycamptothecin (HCPT) Nanoparticles by Supercritical Antisolvent (SAS) Process" International Journal of Molecular Sciences 12, no. 4: 2678-2691. https://doi.org/10.3390/ijms12042678

APA StyleZhao, X., Zu, Y., Jiang, R., Wang, Y., Li, Y., Li, Q., Zhao, D., Zu, B., Zhang, B., Sun, Z., & Zhang, X. (2011). Preparation and Physicochemical Properties of 10-Hydroxycamptothecin (HCPT) Nanoparticles by Supercritical Antisolvent (SAS) Process. International Journal of Molecular Sciences, 12(4), 2678-2691. https://doi.org/10.3390/ijms12042678