Abstract

Perfluorosulphonic acid-based membranes such as Nafion are widely used in fuel cell applications. However, these membranes have several drawbacks, including high expense, non-eco-friendliness, and low proton conductivity under anhydrous conditions. Biopolymer-based membranes, such as chitosan (CS), cellulose, and carrageenan, are popular. They have been introduced and are being studied as alternative materials for enhancing fuel cell performance, because they are environmentally friendly and economical. Modifications that will enhance the proton conductivity of biopolymer-based membranes have been performed. Ionic liquids, which are good electrolytes, are studied for their potential to improve the ionic conductivity and thermal stability of fuel cell applications. This review summarizes the development and evolution of CS biopolymer-based membranes and ionic liquids in fuel cell applications over the past decade. It also focuses on the improved performances of fuel cell applications using biopolymer-based membranes and ionic liquids as promising clean energy.

1. Introduction

The occurrence of global warming is due to carbon dioxide emissions, which leads to earth’s climate change and consequently affects the environment, health, and economy. In this context, fuel cells are attracting interest. These cells are devices for power generation that operate in a similar manner as conventional batteries and that require a continuous supply of fuel. They are electrochemical devices that function as good alternative nonpolluting power sources. They generate electricity by using fuel sources such as hydrogen through electrochemical reaction. Fuel cells are among the pollution-free clean energy technologies that meet the requirements for energy conservation, environmental sustainability, and economic growth.

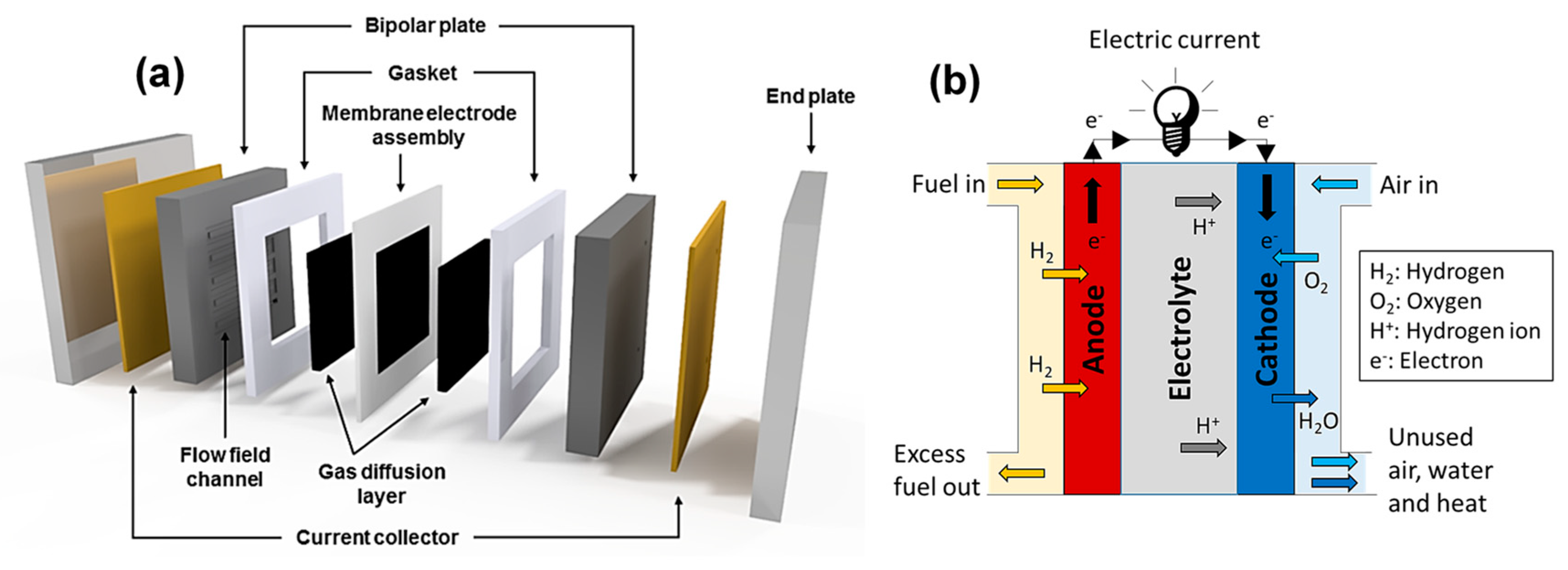

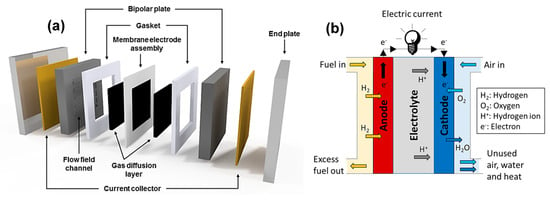

Polymer electrolyte membrane fuel cells (PEMFCs) are highly promising fuel cells for large-scale use; in this technology, an advanced plastic electrolyte in the form of a thin, ion-permeable sheet is used to exchange protons from the anode to the cathode [1]. PEMFCs are light, highly efficient, and compact. They operate at relatively low temperatures (≈80 °C), have high power density, and are suitable for various applications. Figure 1 shows that PEMFC consists of various important elements, namely, bipolar plates, diffusion layers, electrodes (anode and cathode), and an electrolyte. The core of a PEMFC is a membrane electrode assembly (MEA) composed of a proton exchange membrane (PEM) placed between two electrodes.

Figure 1.

(a) Main components of a polymer electrolyte membrane fuel cell (PEMFC) and (b) schematic of a typical membrane electrode assembly (MEA).

Nafion is popularly used as a proton-conducting polymer membrane in fuel cells because of its ability to conduct protons, high thermal and mechanical stability, and selectivity for cations [2]. However, Nafion membranes have limitations, such as high manufacturing costs, not eco-friendly, and hydrogen crossover from anode to cathode that reduces fuel efficiency and fuel cell open circuit voltage (OCV) [3]. Nafion also limits the operation of PEMFC to low temperatures (≈80 °C), because it needs hydration and permanent gas humidification to assure high proton conductivity and as the temperature is increased above 100 °C, the water affinity and mechanical strength of the membrane will also be reduced. These limitations of Nafion membranes have prompted researchers to study and produce new environmentally friendly and economical PEM materials from renewable sources, with improved chemical and thermal stability, water uptake, and mechanical properties, that can potentially replace the synthetic polymers in fuel cell applications.

Numerous studies have been carried out to replace Nafion membranes because of their shortcomings, and biopolymer-based composites are considered for environmental protection. Biopolymers are molecules that have long chains and are created from repeating chemical blocks, have enticing properties, and research on biopolymer membrane materials has focused on the development and productivity of biopolymers and increasing their membrane-processing capacity and operation [4]. However, biopolymers such as polysaccharides have drawbacks such as their hydrophilicity properties that can lead to excessive water uptake and swelling in the membrane, which can affect its durability and as the biopolymer membranes are incorporated with super acid that is highly soluble in water, they tend to leach out from the membrane, which then will restrict the long-term use in fuel cell operations [5,6]. Other than that, aside from excellent thermal stability, another factor that affected the fuel cell performance is the durability of the membranes in oxidative conditions. As the cell test is conducted in a strong oxidizing environment, the oxidative degradation is a crucial factor in membrane degradation mechanisms due to the decomposition of products of HO* and HOO* radicals initiated from the hydrogen peroxide that has strong oxidizing characteristics throughout the fuel cell operation. The oxidative stability of the membranes was evaluated through immersion of membranes in Fenton’s reagent for 1 h at 80 °C, and membranes that can endure the oxidative environment can be further used during fuel cell operation. Despite having these drawbacks, polysaccharides have been widely used and studied due to their distinctive properties, abundance, hydrophilicity, and can be chemically modified and functionalized to be used as PEM in fuel cell applications.

Polysaccharides, such as chitosan (CS) and cellulose, are among the best natural polymer materials because of their abundance in the environment. CS is a linear polysaccharide consisting of randomly distributed β-(1-4)-linked ᴅ-glucosamine (deacetylated unit) and N-acetyl-ᴅ-glucosamine (acetylated unit), which is produced by the deacetylation of chitin. CS has high water affinity properties as there is the presence of three different polar functional groups, which are hydroxyl (–OH), primary amine (–NH2), and C–O–C groups. CS has a structure that is very similar to cellulose, but the difference among them is that CS contains amine groups and its structure is characterized by its molecular weight and degree of deacetylation, where its solubility is depended on [7].

CS has rigid structure and high crystallinity as there are three hydrogen atoms strongly bonded between the amino and hydroxyl groups within the CS monomers, due to the immobilized structure, which leads to its proton conduction limitation. Moreover, CS has attractive physicochemical properties in aqueous solution due to its polycationic nature and this leads to wide range of biological purposes such as antimicrobial activity and disease resistance activities in plants [8]. CS membranes are one of the most preferable and favorable materials to replace Nafion membranes as they have shown improved performance in low temperature fuel cell applications and due to their enticing alcohol barrier properties, proton conductivity, and thermal stability after they undergo the cross-linking process [5,9].

This review paper focuses on the development and recent progress in the modifications of CS-based composite membranes and the utilization of ionic liquids as proton conductors in composite membranes. We discuss the improvements achieved through the addition of inorganic fillers, CS/polymer blends, and chemical modifications to CS composite membranes. Then, we discuss ionic liquids and their roles in enhancing the proton conductivity and hydrophilicity of CS membranes.

2. Biopolymer-Based Membranes

2.1. CS-Based Biopolymer Membranes

CS is a natural polymer that is hydrophilic, biodegradable, and biocompatible. It is the N-deacetylated derivative of chitin and the second most abundant natural biopolymer. It can be obtained by deproteinization or by CS alkaline deacetylation of crustacean shells, molluscan organs, fungi, and insects [10]. The hydrophilicity of CS is a desirable property for environments with high temperature and low relative humidity (RH). CS has a high potential for development into sophisticated functional polymers, because its backbone contains free amine and hydroxyl groups. CS is a preferred biomaterial membrane for ultrafiltration, reverse osmosis, and pervaporation because of its low-cost production. CS has attracted attention in diverse scientific and engineering processes given its excellent nontoxicity, eco-compatibility, chemical and thermal stability, and natural abundance [11].

Given that the membrane is the crucial component of PEMFC, it needs to exhibit desirable properties, such as high hydrophilicity, good chemical and thermal stability, to achieve high efficiency [12]. Despite its advantages, CS has low mechanical strength and proton conductivity; it is also highly brittle due to its high glass transition temperature [13]. These disadvantages can be overcome by blending CS with other polymers, creating CS based organic–inorganic hybrids, doping inorganic fillers in the CS matrix, or chemically modifying the CS [14]. CS modified through various techniques, such as sulphonation, phosphorylation, quaternization, and chemical cross-linking, is a cost-effective biopolymer electrolyte membrane with low methanol permeability and suitable ion conductivity, especially at high temperatures [15].

2.2. CS-Based Composite Membranes

2.2.1. CS/Inorganic Filler Composite Membranes

Nonmodified CS membranes have high hydrophilic properties that cause a high degree of swelling and reduce sturdiness in fuel cell applications by increasing the water uptake excessively and affecting their fragility [10]. Other than that, in contrast to Nafion membranes, which have high mechanical and thermal strengths and high proton conductivity, the pristine, unmodified CS membranes possess low proton conductivity due to the absence of mobile hydrogen ions in their structure and the excess swelling properties of the membranes gives negative impacts in their mechanical properties. These characteristics limit their function and performance, thus, the CS membranes were modified by incorporating the inorganic fillers into them [13].

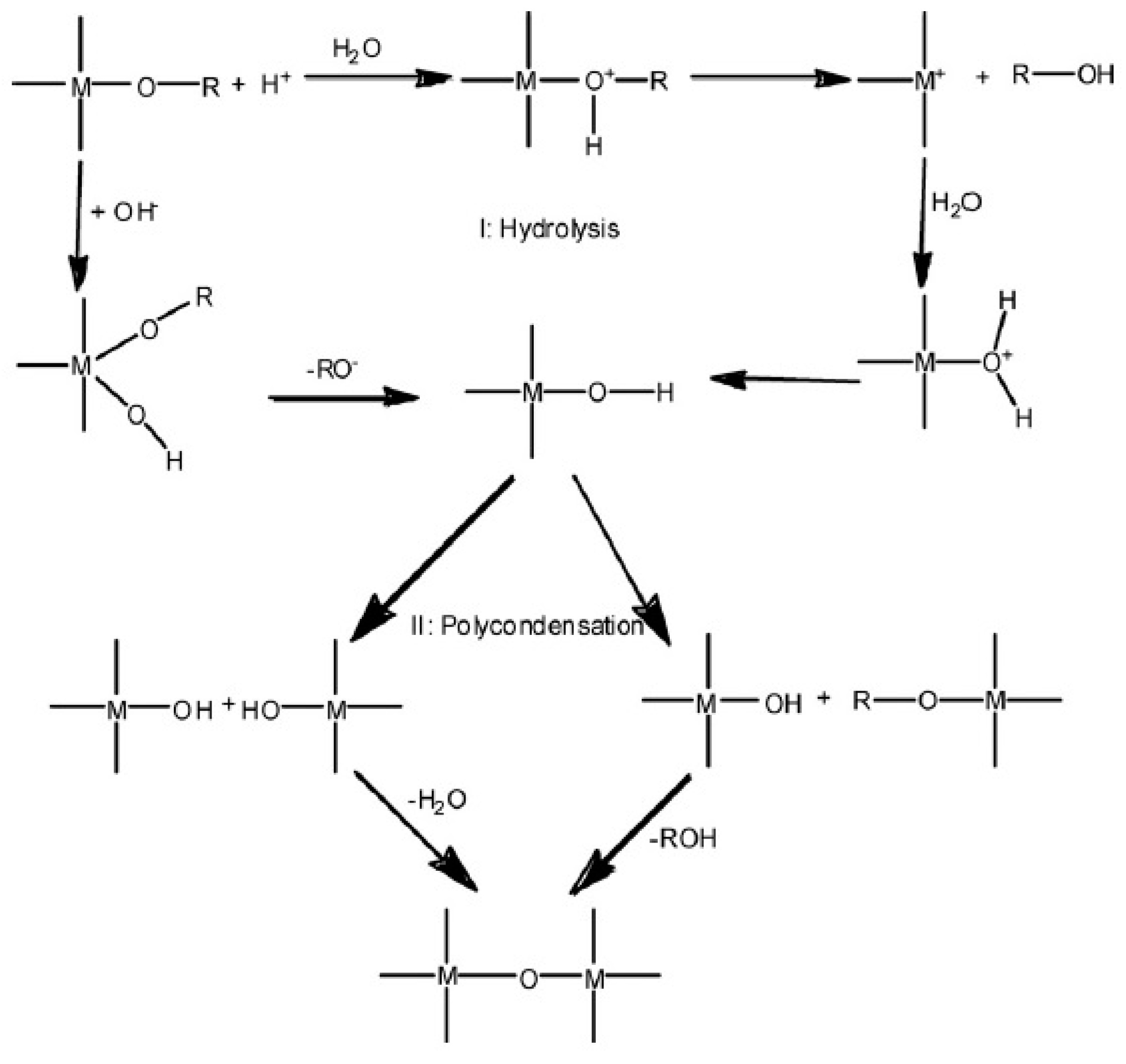

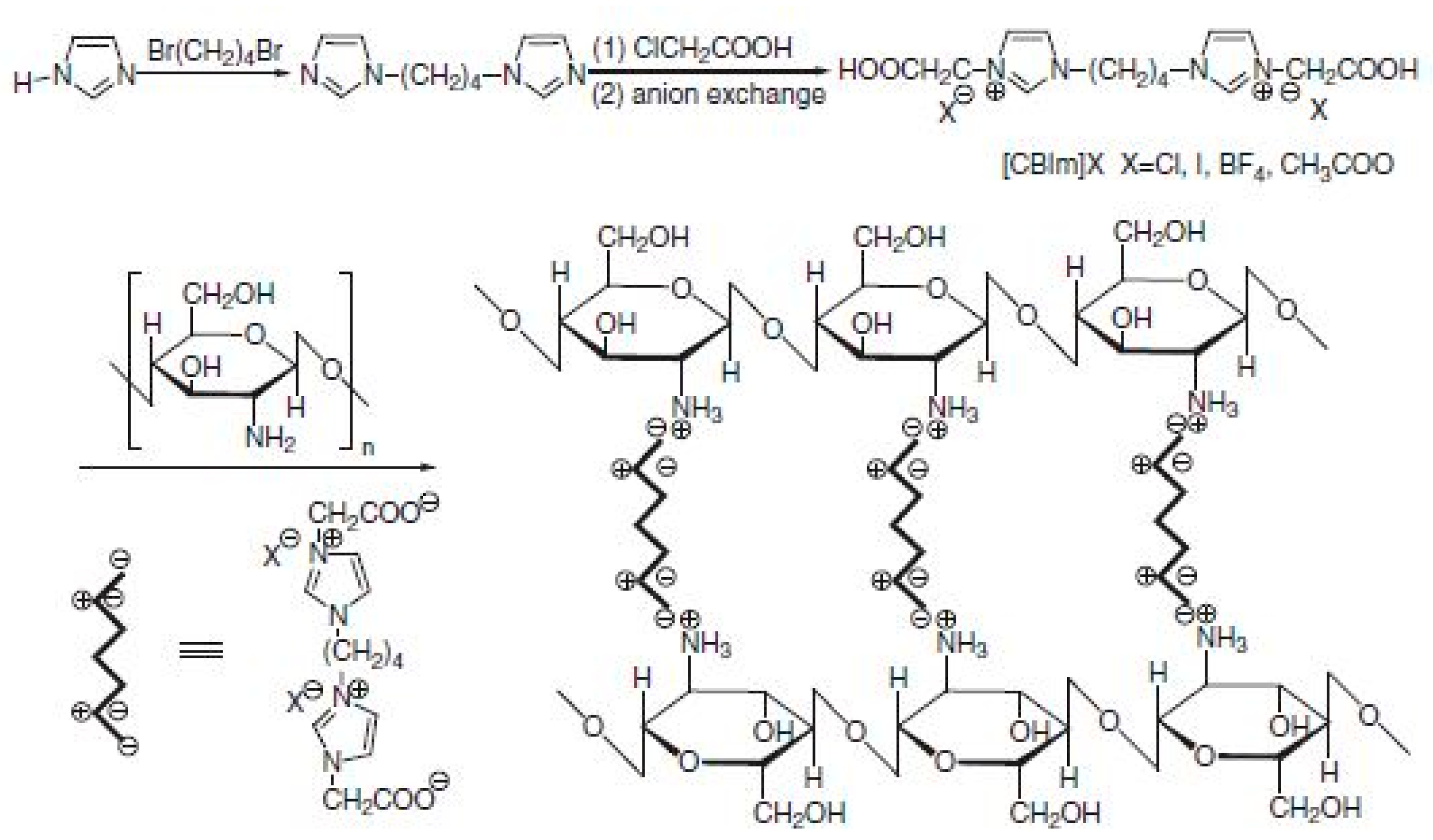

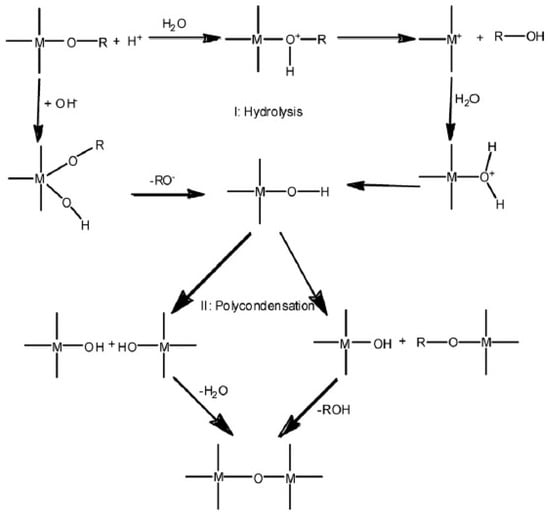

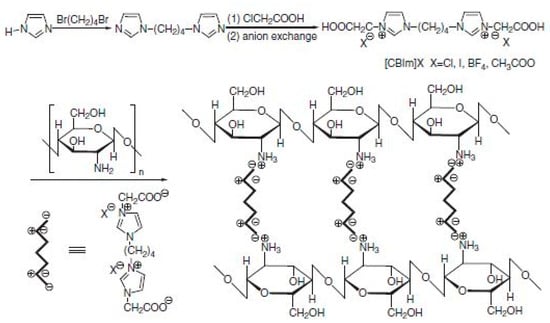

Tripathi and Shahi [16] reported that one of the ways to overcome these problems is to make chitosan-chitosan-inorganic composite membranes, because they balance the hydrophilic and hydrophobic nature of chitosan and reduce fuel crossover occurrence that diminishes the membranes’ methanol permeability, enhances the mechanical and thermal stabilities, and improves the proton conductivity and fuel cell performance by incorporating solid inorganic proton conductors. Two strategies for combining inorganic and polymer substances have been summarized from previous studies, namely, the in situ formation of inorganic particles within the biopolymer matrix through the sol–gel reaction or crystallization and the physical mixing of organic solutions and inorganic fillers succeeded by simple casting. Figure 2 shows that sol–gel reaction involves two consecutive steps, namely, the hydrolysis of metal alkoxides to produce hydroxyl groups and the polycondensation of hydroxyl groups to form a 3D network. Inorganic fillers used in CS-based membranes include hygroscopic oxides, heteropoly acids, carbon nanotubes (CNTs), and graphene oxide (GO) have been studied extensively, as summarized in the following subsections.

Figure 2.

Schematic of the two-step sol–gel reaction routes for metal alkoxides [16]. Copyright 2011, reproduced with permission from Elsevier

(1) Hygroscopic Oxides

Embedding nonporous and porous inorganic hygroscopic fillers, such as silica, titanium dioxide, montmorillonite, zeolites, metal phosphates, and metal oxides [17], that have permissible pore sizes and structures within membranes, enhances mechanical and thermal strengths and overcomes methanol crossover because these materials could obstruct polymer chain packing and generate diffusion paths with high complexity [10]. The addition of hygroscopic oxides, e.g., Al2O3, TiO2, ZrO2, and (SiO2)n, into the CS polymer matrix by functionalizing the inorganic fillers enhances the water retention capacity and ionic conductivity of polymer composites at low RH as new proton pathway is formed [18,19,20]. Other than that, the methanol crossover can be reduced as the swelling behavior of the membrane is suppressed and the mechanical, chemical, and thermal properties can also be improved through the inherent interfacial interactions between the inorganic fillers and the CS polymer matrix. The study regarding polybenzimidazole membranes with functionalized montmorillonite, which is the protonated montmorillonite (MMT-H) has proven that with very high loadings of MMT-H, the proton conductivity of the membranes achieve drastic improvement at 20% RH with the values of 436 mS cm−1 and mechanical strength of 8.4 MPa [21]. Although hydrophilic fillers provide numerous hydrogen bonding sites to increase the water uptake in membranes, conductivity decreases with increasing filler content due to the poor and weak interfacial interaction between the organic polymer and inorganic fillers in hybrid membranes [22,23]. To enhance the morphology, water retention capacity, and proton conductivity of the hybrid membranes and to overcome fuel permeation, inorganic fillers are modified with functional groups, such as sulphonic acid groups and amine or grafted with macromolecules [24,25].

Silicon dioxide (SiO2), also known as silica, is a common hygroscopic inorganic filler that is widely used in fuel cells, particularly in direct methanol fuel cells and proton exchange membrane fuel cells. Silica is hydrophilic and is an enticing material for preparing proton exchange membranes because of the support it provides and its thermal stability [26]. A nanostructured N-p-carboxy benzyl CS–silica–PVA hybrid membrane has been prepared through the sol–gel method in aqueous media and cross-linking with HCHO and H2SO4; afterward, the oxidation of the thiol group into the sulphonic acid group is completed [27]. Proton conductivity increased with increasing content of N-p-carboxy benzyl CS–silica because of high functional group concentration. The –COOH grafted on CS and the –SO3H grafted on silica acted as proton-conducting groups. –SO3H groups are highly acidic. Thus, membrane conductivity improved when the concentration of –SO3H groups was less than the concentration of the acidic –COOH groups. The highest conductivity was obtained when the content of N-p-carboxy benzyl CS-silica was increased to 5.31 × 10−2 S cm−1 because of the increase in –SO3H concentration and the low cross-linking density amongst the fabricated polyelectrolyte membranes. The stability test was performed for 1 h at 80 °C by using Fenton′s reagent (3% H2O2 aqueous solution containing 3 ppm FeSO4) and has shown that in oxidative condition, the weight loss was inhibited due to the highly cross-linked and compact structure, which led to excellent oxidative stability of the membrane [27].

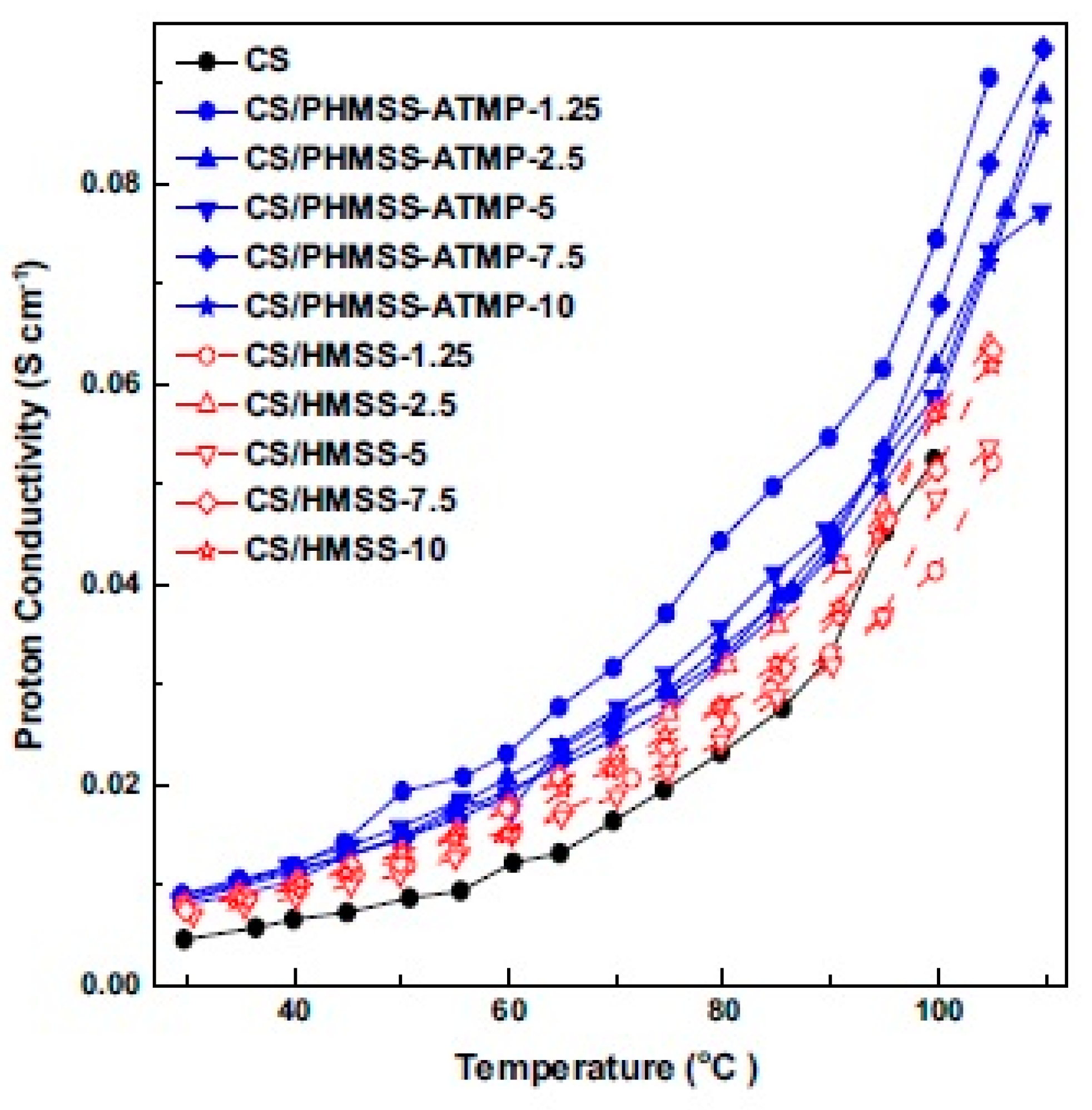

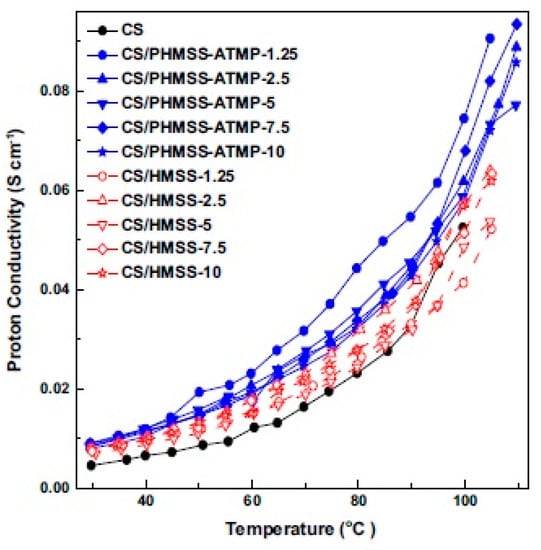

By contrast, the proton conductivity of the composite membrane decreases when unmodified silica particles are incorporated in the biopolymer membrane [21]. Nonetheless, upon functionalization with carboxylic, sulphonic, and quaternary groups on silica, proton conductivity increases due to the increase in water adsorption. The proton conductivity of the carboxylated silica/CS was highest and increased to 0.029 S cm−1 by 40% when compared with those of pure unmodified CS, sulphonated silica/CS (0.024 S cm−1) and quaternary aminated silica/CS (0.018 S cm−1) membranes. Incorporating phosphorylated hollow mesoporous silica sub-microspheres (PHMSS) with amino tris (methylene phosphonic acid) into a CS matrix enhanced water uptake by 47.8%, suppressed swelling properties by approximately 27.1%, and increased the proton conductivity (2.2 × 10−5–1.2 × 10−2 S cm−1 at 80 °C and 41–78% RH) of the hybrid membranes [28]. The mesoporous structure promotes water retention by adsorbing the moisture inside the mesopores [29,30], whilst –PO3H2 groups successfully improve proton conduction. At 110 °C and 100% RH, the CS/PHMSS-ATMP hybrid membrane incorporated with 7.5 wt.% PHMSS-ATMP sub-microsphere fillers showed the highest proton conductivity of 9.40 × 10−2 S cm−1, which was higher than those of pristine CS membrane and CS/HMSS hybrid membranes without modification and inorganic sphere incorporation (Figure 3).

Figure 3.

Proton conductivity of the pristine chitosan (CS), CS/HMSS, and CS/phosphorylated hollow mesoporous silica sub-microspheres (PHMSS)-ATMP hybrid membranes with increasing temperature at 100% relative humidity (RH) [28]. Copyright 2014, reproduced with permission from Elsevier

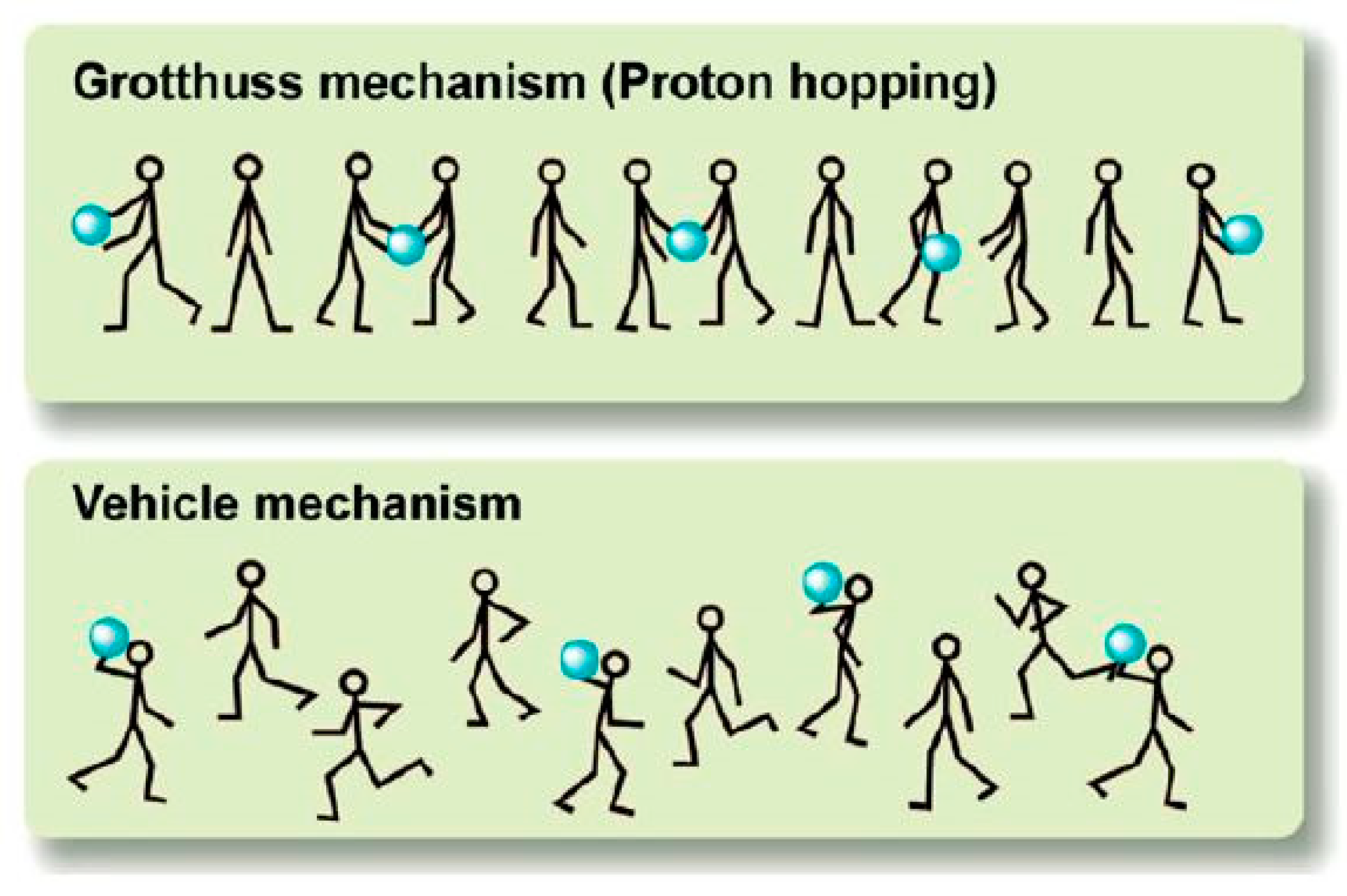

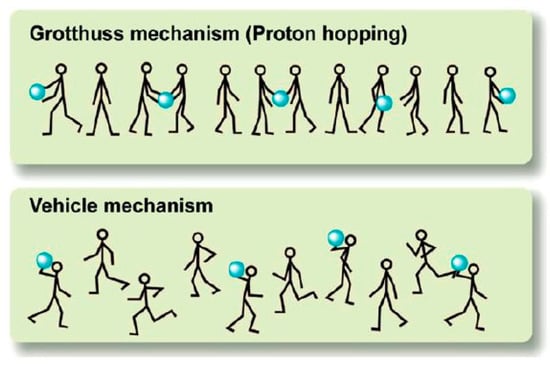

In recent years, numerous studies have been conducted on the use of fillers with zwitterionic groups to enhance the proton conductivity of membranes. Novel hybrid membranes of CS/titania–silica inorganic dopant functionalized with carboxyl and amino groups (TiC–SiN) have been fabricated through a facile in situ sol–gel method [31]. The membranes were cross-linked with H2SO4 solution for 24 h. The inorganic materials from the dopants, titania and silica, which acted as precursors, were functionalized with –COOH and –NH2 groups on TiC–SiN dopants and provided zwitterionic groups that could produce new proton pathways to improve the membranes’ proton conductivity and water uptake. The water uptake and proton conductivity of all the hybrid membranes increased with increasing content of TiC–SiN due to the hygroscopic properties of silica and titania and the hydrophilic groups of –COOH and –NH2 in TiC–SiN that attracted water. The highest proton conductivity of the CS/2TiC–1SiN−7 membrane (0.0408 S cm−1) at 25 °C was four times higher than that of the pristine CS membrane (0.011 S cm−1). Proton conductivity also increased with increasing temperature from 60 to 100 °C. This response was due to the zwitterion-functionalized TiC–SiN dopants. These dopants were homogeneously dispersed in the CS matrix and with the aid of acidic groups as proton donors and basic groups as proton receptors generated new proton transfer pathways, which were linked by hydrogen-bonded water molecules through the migration of protons via the Grotthuss mechanism.

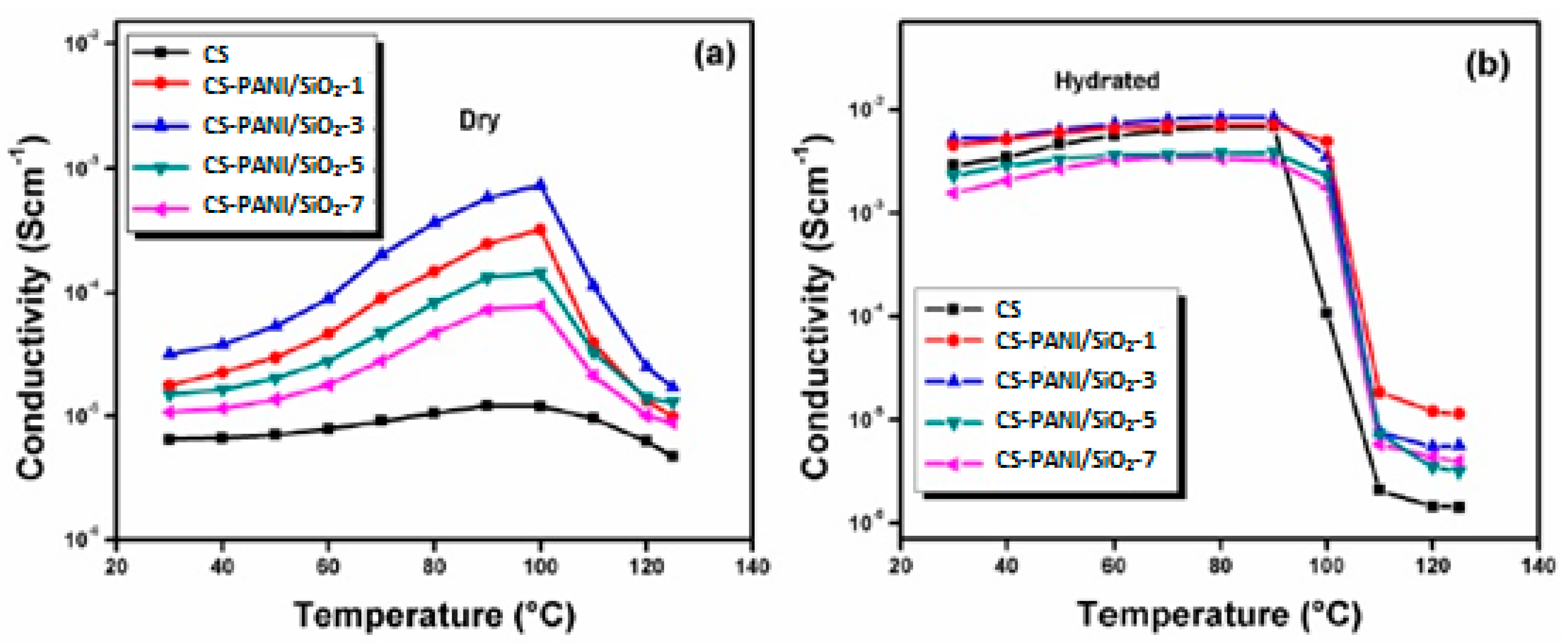

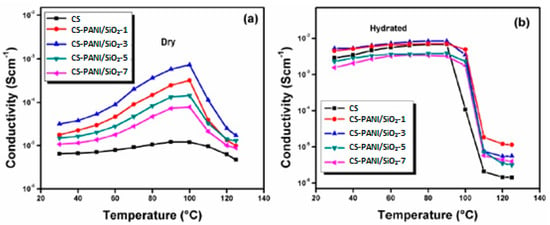

Polyaniline is a highly conducting polymer that is used because of its excellent stability, redox reversibility, and unique electrochemical properties. Polyaniline was modified with hydrophilic silica to enhance the morphology and proton conductivity of a hybrid membrane at low water content [26]. Polyaniline/nanosilica (PANI/SiO2) was produced as a modified inorganic filler through a facile ultrasonication method. Then, it is incorporated into novel ionic cross-linked CS-based hybrid nanocomposites to produce a CS–PANI/SiO2 hybrid membrane that was ionically cross-linked with sulphuric acid [26]. The CS–PANI/SiO2 hybrid membranes exhibited improved mechanical properties, oxidative stabilities, and proton conductivity because of the additional proton pathways contributed by the doped polyaniline. The water uptake and proton conductivity of the hybrid membranes increased with increasing content of the nanofiller PANI/SiO2 up to 3 wt.% loading but decreased with the further addition of PANI/SiO2 fillers because of filler agglomeration, reduced inflexibility, and poor filler dispersion. The proton conductivity of the hybrid membrane decreased when the PANI/SiO2 filler loading content exceeded 3 wt.% because of the block effect that inhibited proton transfer or high tortuosity through the proton-conducting pathway [32,33]. The CS–PANI/SiO2-3 hybrid membrane showed increased water uptake (57.62–72.87%) and possessed the highest conductivity of 8.39 × 10−3 S cm−1 at 80 °C; in its hydrated state, its conductivity decreased when the temperature exceeded 80 °C (Figure 4). The highest conductivity shown by the CS-PANI/SiO2-3 membrane may be due to the existence of sulphate ions in the doped polyaniline, hydroxyl groups on the surface of silica, and protonated amine groups in the matrix polymer of the membrane; moreover, the higher proton conductivity of CS-PANI/SiO2 membranes than that of CS membrane could be due to the incorporated PANI/SiO2 fillers, which acted as connecting bridges that shortened the distance of proton hopping [32,33]. Other than that, the stability test was performed by using Fenton’s reagent (3% H2O2 with 2 ppm FeSO4) for 1 h at 80 °C and has shown that as the concentration of PANI/SiO2 nanofillers was increased, the weight loss was reduced, and this implied that CS-PANI/SiO2 composite membrane has excellent oxidative stability. Consequently, this membrane was tested in single cell for DMFC application and exhibited the peak density of 56.27 mW cm−2, higher than the unmodified CS membrane (41.15 mW cm−2).

Figure 4.

Proton conductivity of (a) dry and (b) hydrated CS-polyaniline/nanosilica (PANI/SiO2) hybrid membranes with increasing temperatures [26]. Copyright 2018, reproduced with permission from Elsevier

Zeolite is another inorganic filler that is commonly used in polymeric membranes; it represents aluminosilicates with framework structures enclosing cavities that could be occupied by water molecules or large ions [19]. The regular pore size, ordered structure, hydrophilic/hydrophobic nature, excellent stability, and tolerable proton conductivity of zeolite have prominent effects on the properties of CS/zeolite membranes [34,35]. The appropriate addition of zeolites enhanced mechanical and thermal strengths because of the presence of hydrogen bonds between CS and zeolites, whereas the excessive addition of zeolites reduced the mechanical strength of the hybrid membranes because of the formation of excessive interfacial voids at the interface of CS and zeolites [35,36]. The diffusion resistance of methanol increased due to the association of hydrophobic zeolites and consequently decreased methanol permeability, whereas hydrophilic zeolites exhibited the opposite trend [36,37]. The homogenous incorporation of sorbitol as a plasticizer and the proper control of membrane formation temperature could improve the interfacial morphology of CS/zeolite membranes [35]. Functionalizing zeolite particles contributed to the inhibition of a methanol crossover [17,34,37]. The methanol permeability of sorbitol-plasticized CS/mordenite hybrid membranes in 12 mol L−1 methanol water solution at 25 °C was 4.9 × 10−7 cm2 s−1, which was 44% lower than that of pristine CS control membrane and four times lower than that of Nafion 117 membrane (2.3 × 10−6 cm2 s−1) under the same test conditions [35].

Surface-modified Y zeolite-filled CS hybrid membranes were fabricated [34] with inorganic fillers modified using the silane coupling agents 3-aminopropyl-triethoxysilane (APTES) and 3-mercaptopropyl-trimethoxysilane (MPTMS). Then, the mercapto group on MPTMS-modified Y zeolite was further oxidized into the sulphonic group (–SO3H). The conductivity of the modified Y zeolite-filled CS hybrid membranes increased to 2.58 × 10−2 S cm−1 with the functionalization of -SO3H groups onto the zeolite surface. Moreover, even though the zeolite content increased and the proton conductivity of the hybrid membranes decreased, the proton conductivity of the membranes remained more acceptable (>1.5 × 10−2 S cm−1) than fully hydrated Nafion 117 (6.91 × 10−2 S cm−1). The incorporation of inorganic fillers and Y zeolites into the CS matrix further reduced methanol permeability because of the dispersion of Y zeolites, which increased the methanol permeation path length and irregularity and the local rigidification of the CS matrix due to the incorporation of rigid zeolite; thus, membrane swelling and methanol uptake decreased [34].

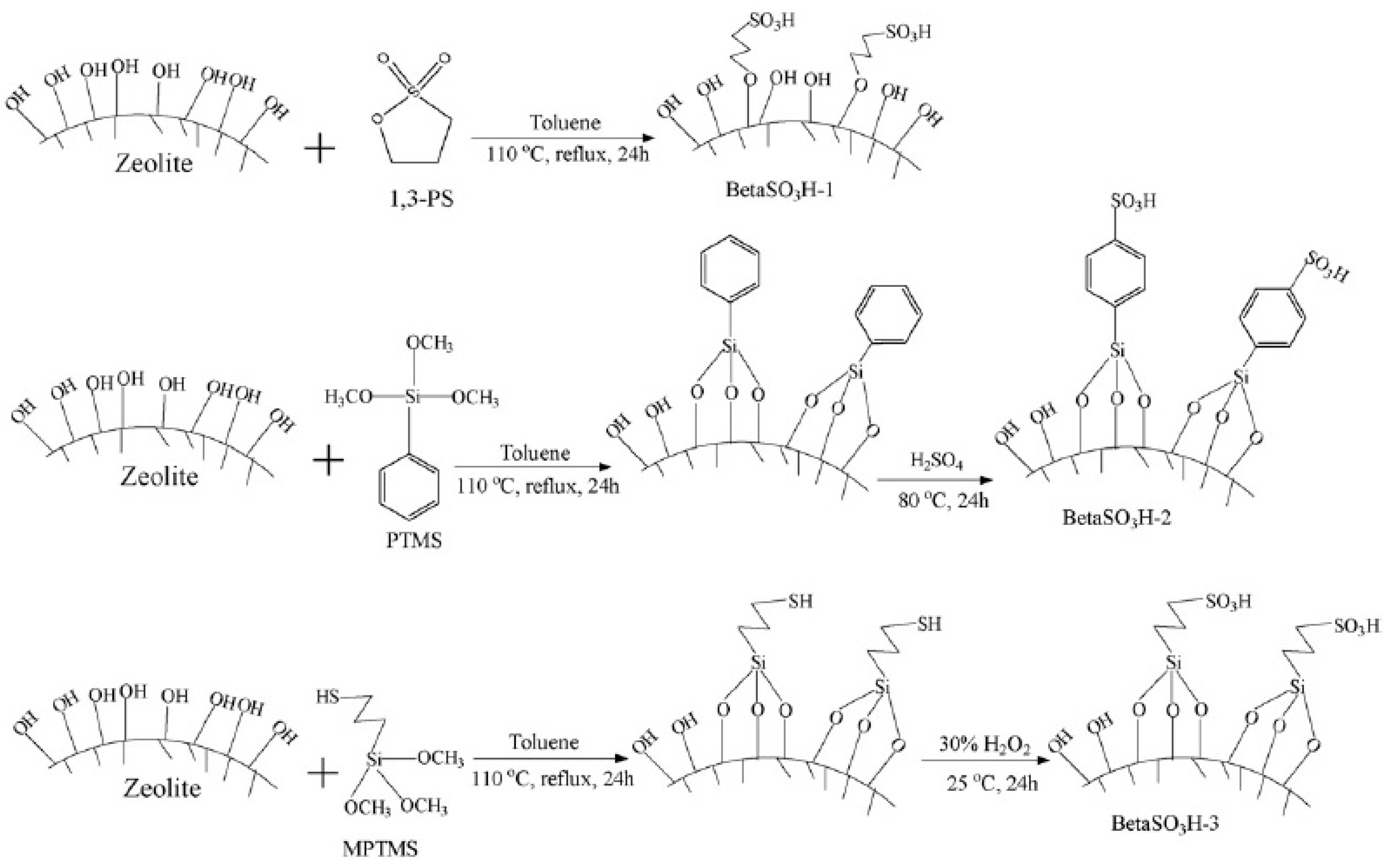

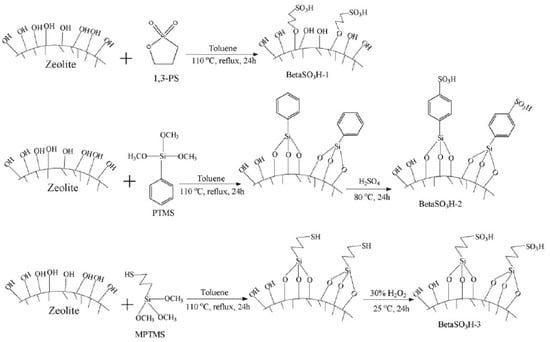

CS/zeolite beta hybrid membranes were prepared and fabricated, and their performances were enhanced by incorporating zeolite beta particles into the CS matrix. As shown in Figure 5, zeolite beta particles were sulphonated through three different pathways. The presence of –SO3H groups on the zeolite surface improved the interaction between the CS and zeolite beta matrix, reduced methanol permeability, and improved the ionic conductivity of CS/zeolite hybrid membranes [17,37]. Zeolite beta was selected as an inorganic filler, because its hydrophobicity could ensure low methanol crossover [36], and its moderate surface acidity could enhance bonding with the CS matrix [38].

Figure 5.

Schematic of three different pathways for the sulphonation of zeolite beta particles [17]. Copyright 2008, reproduced with permission from Elsevier

CS/Beta hybrid membranes have higher thermal stability than pure CS membranes [11] because of the hydrogen bonding interaction between the –OH groups on the surfaces of zeolite beta and the –OH or –NH2 groups of CS [36]. The thermal stability of CS/Beta hybrid membranes increased moderately with increasing zeolite beta contents, because hydrogen bond interactions were enhanced. Moreover, methanol permeability further decreased with the incorporation of zeolite beta particles into the CS matrix. The methanol permeabilities of CS/Beta-2-30% at methanol concentrations of 2 and 12 mol L−1 were 7.04 × 10−6 and 2.46 × 10−6 cm2 s−1, respectively, which were the lowest amongst all fabricated hybrid membranes because of the extension of diffusion path length of methanol in the membrane, the rigidification of CS chains, and the compression of volume amongst CS chains upon the introduction of zeolite beta particles. Thus, the methanol crossover of CS/Beta hybrid membranes decreased. When zeolite beta particles were incorporated into the CS matrix, water and methanol uptake decreased, and proton conductivity decreased to a certain level. CS membranes filled with γ-glycidoxypropyltrimethoxysilane (GPTMS)-modified zeolite beta particles, in which the uniform zeolite beta was synthesized through a hydrothermal method and then functionalized with GPTMS, have been studied and fabricated [31]. These CS/Beta-GPTMS hybrid membranes exhibited low methanol permeability. The lowest methanol permeabilities of 4.4 × 10−7 and 2.2 × 10−7 cm2 s−1 were obtained at the methanol concentrations of 2 and 12 mol L−1, respectively. The decrease in the methanol permeability of CS/Beta-GPTMS hybrid membranes was due to the same reasons for such a decrease in CS/Beta hybrid membranes [17]. The water and methanol uptake of CS/Beta and CS/Beta-GPTMS hybrid membranes further decreased with increasing content of zeolite beta incorporated in the hybrid membranes. The possible reasons for this phenomenon are the higher hydrophobicity of zeolite beta compared with CS and the rigidification of CS chains upon the addition of zeolite beta, thereby reducing their ability to adsorb solvent molecules. Additionally, the proton conductivity of CS/Beta-GPTMS hybrid membranes decreased further as the zeolite beta content of the hybrid membranes was increased. The highest proton conductivity of the CS/Beta-GPTMS-3% hybrid membrane was 1.46 × 10−2 S cm−1, which was slightly lower when than that of the CS/Beta-3% hybrid membrane (1.53 × 10−2 S cm−1). The existence of zeolite beta particles in the hybrid membranes extended the proton transport path. Thus, proton conductivity of the CS/zeolite beta hybrid membranes was lower than that of the pristine CS membrane. In addition, the proton conductivities of CS/Beta-GPTMS hybrid membranes were lower than those of CS/Beta hybrid membranes because of their low water uptake [37].

Previous works by various researchers have proven that the CS composite membrane with unmodified inorganic hygroscopic oxide fillers possess low proton conductivity, water retention capacity, and mechanical stability of the membrane. Thus, these drawbacks can be solved through the presence of modified hygroscopic oxide fillers, such as functionalized silica and zeolite, in CS hybrid membranes, due to hydrogen bonds existing between the CS polymer and the fillers, as well as the presence of the zwitterionic groups in the fillers, which provide an additional proton-conducting pathway in the membrane. These occurrences have suppressed fuel crossover and improved the morphology, proton conductivity, water retention capacity, and mechanical strength and consequently enhanced fuel cell performance of the composite membranes. Table 1 shows a summary of applications of hygroscopic oxide fillers in CS hybrid membranes for fuel cells.

Table 1.

Applications of hygroscopic oxide fillers in CS hybrid membranes.

(2) Heteropoly Acids

Solid superacids have been extensively studied in the last 20 years. Gillespie described superacids as acids with acidity exceeding that of 100% pure sulphuric acid; most superacids are prepared through combination of strong Lewis and Bronsted acids [44]. Solid acids and superacids have been actively used and prepared for studies on dehydration, cracking, hydrocracking, isomerization, alkylation, and acylation [45]. Solid superacids are categorized into three types, namely, metal oxide-supported sulphates (MxOy-SO42−), heteropoly acids (HPAs), and zeolite solid superacids. These acids may enhance the proton conductivity and mechanical properties of CS membranes because of their satisfactory mechanical, hygroscopic, and proton conductive properties [37].

HPAs have been used in fuel cell applications to improve proton conductivity. HPAs are strong Bronsted acids, solid electrolytes, soluble in polar solvents, and solid crystalline materials that are highly conductive and thermally stable; moreover, they exhibit well-defined molecular structures, surface charge densities and chemical and electrochemical properties [46]. HPAs are acids that are made from the combination of hydrogen and oxygen with certain metals and nonmetals; they may adopt the Keggin structure (HnXM12O40) and the Dawson structure (HnX2M18O62) because of the possibilities of different combinations of addenda atoms and different types of hetero atoms. HPAs are highly solubility in water, and their leakage during cell operation may degrade fuel-cell performance [47,48,49]. This obstacle can be solved by mixing HPAs, such as phosphotungstic acid (H3[P(W3O10)4]), phosphomolybdic acid (H3[P(Mo3O10)4]), and silicotungstic acid (H4[Si(W3O10)4]) with the CS matrix to form insoluble complexes that could be immobilized within membranes through strong electrostatic interactions [50,51]. HPAs exhibit strong proton conductivities that could reach as high as 1.9 × 10−1 S cm−1 at room temperature, thereby helping improve the proton conductivity of the CS polymer matrix [52].

The ionic conductivities of CS–phosphotungstic acid (CS/PTA) composite membranes proposed and tested as proton conductors in low-temperature fuel cells fed by methanol, borohydride, and hydrogen are higher than that of CS membranes [53,54]. CS/PTA polyelectrolyte membranes prepared using porous alumina medium for the slow release of H3PW12O40 exhibited good performance when applied as electrolytes in H2 feed fuel cells, and a proton conductivity of ≈14 mS cm−1 was achieved [55,56,57]. The addition of a drying step on a glass support reduced the shrinkage and fabrication of flat homogeneous membranes and improved performance; the measured peak power density of membranes prepared through this approach was 550 mW cm−2 [57]. CS/phosphomolybdic acid (CS/PMA) membranes exhibited a maximum peak power density of 60 mW cm−2 with a proton conductivity of 1.6 mS cm−1. However, free-standing phosphomolybdic acid and mixed phosphotungstic/phosphomolybdic acid CS membranes fabricated and functionalized for 24 h exhibited a higher peak power density of 350 mW cm−2 with a proton conductivity of ≈7 mS cm−1 relative to the CS/PMA membranes when both membranes were tested as proton conductors in a low temperature H2-O2 fuel cell [58].

The mesoporous cesium salt of phosphotungstic acid has been embedded in CS hybrid membranes [59]. The mesoporous properties of the cesium salt of PTA facilitate strong and maximized intermolecular interaction between the organic and inorganic phases in the membranes and enhanced the dispersion degree. At the optimal loading of m-PTA, the maximum peak power density reached 83 mW cm−2 with then proton conductivity of 0.0185 S cm−1 when the membranes were fed with 2 M methanol fuel. The m-PTA also reduced the surface tension originating from the solid substance and increased the mechanical stability of the membrane. Tensile strength increased from 56.43 to 64.30 N mm−2 as the loading of m-PTA was increased from 1 to 10 wt.%. In addition, CS/m-PTA hybrid membranes are attractive alternative membranes for use in direct methanol fuel cells, because they are inexpensive, easy to fabricate, environmentally friendly, and could operate efficiently at high methanol concentrations.

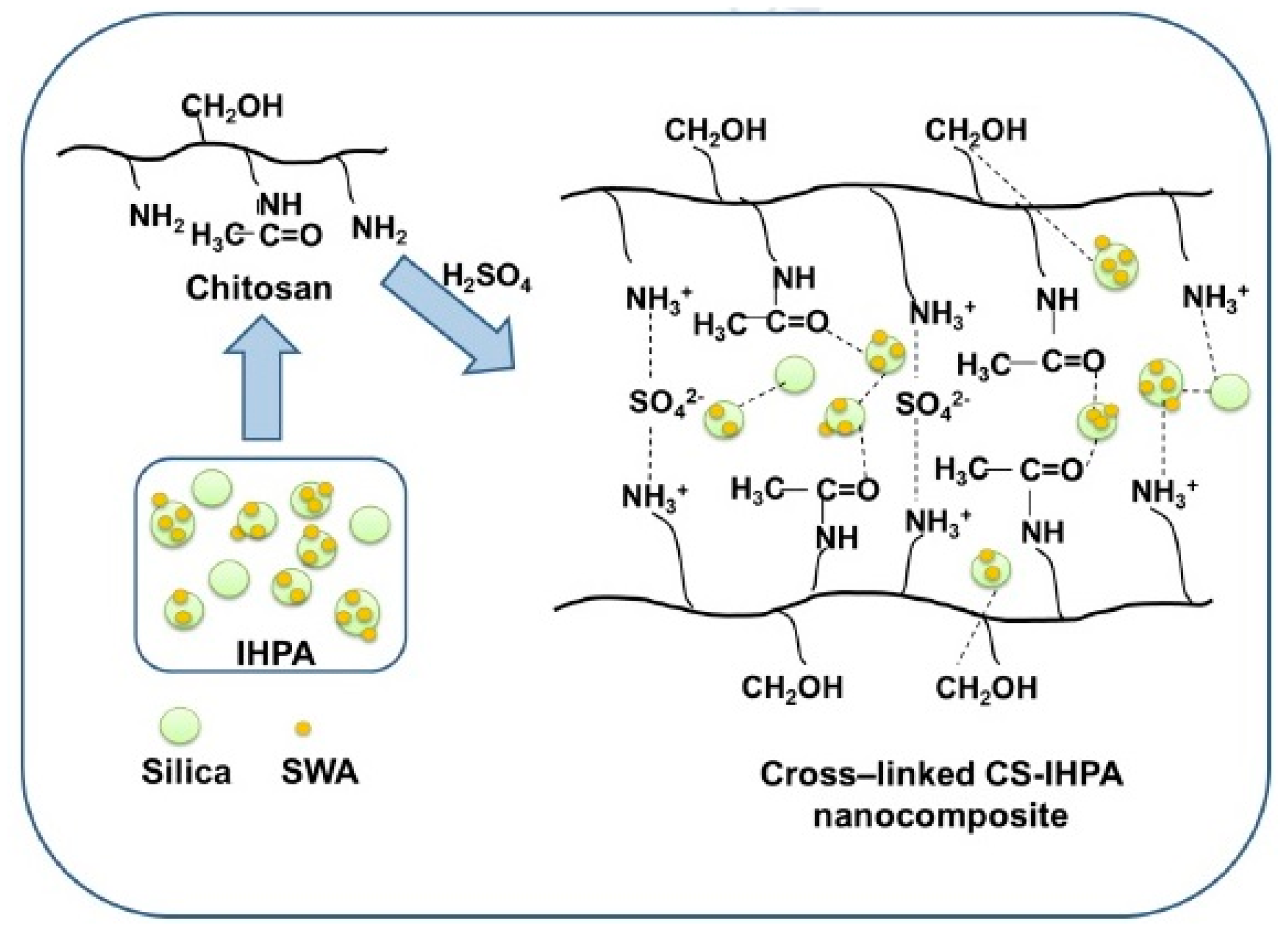

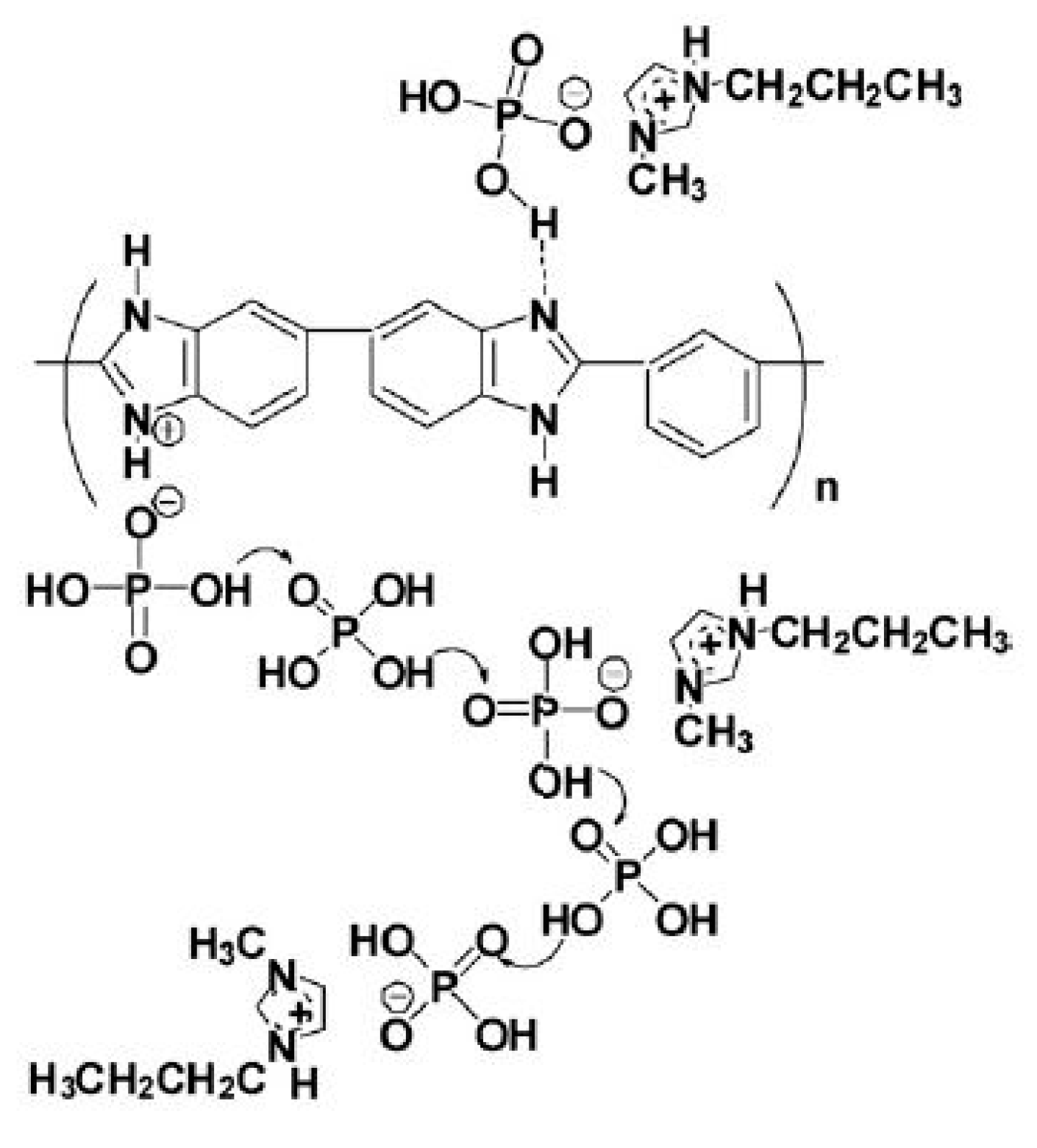

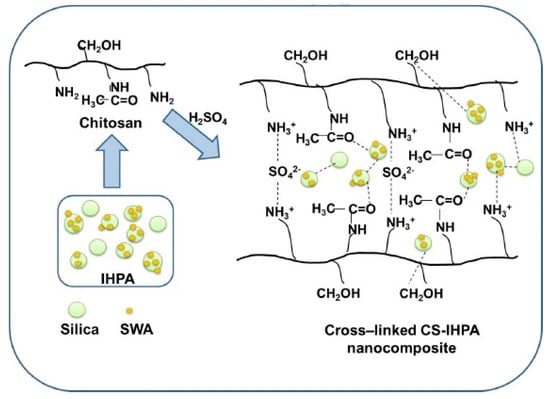

CS and silica-supported silicotungstic acid (IHPA) nanocomposite membranes were produced by using a simple solution casting method [60]. The silica-supported silicotungstic acid-incorporated membranes, also known as inorganic HPA, showed improved thermal, mechanical, and oxidative stabilities and selectivity because of the strong electrostatic interaction and hydrogen bond between the polymer, cross-linking agent (0.5 M H2SO4), and IHPA nanoparticles (Figure 6). The proton conductivities of the CS–IHPA membranes were measured at different temperatures ranging from 30 to 125 °C under dry and hydrated conditions. The proton conductivity of all membranes increased with increasing temperature, because the flexibility of polymer chains and the mobility of water molecules increase at elevated temperatures. The highest proton conductivities of the CS-IHPA-5 membrane in the hydrated state at 30 and 90 °C were 5.8 × 10−3 and 9.0 × 10−3 S cm−1, respectively, which were higher than those of the pristine CS membrane (1.07 × 10−4 S cm−1). The increase in the proton conductivity of the membranes was ascribed to the presence of –OH groups on silica, which yielded additional conduction sites for proton transfer; moreover, the interaction between silicotungstic acid and silica in IHPA resulted in the formation of a continuous hydrophilic channel that permitted the transfer of protons in the form of hydronium ions through diffusion [61,62,63].

Figure 6.

Schematic of the structure of crosslinked CS-silica-supported silicotungstic acid (IHPA) nanocomposite membranes [60]. Copyright 2018, reproduced with permission from Elsevier

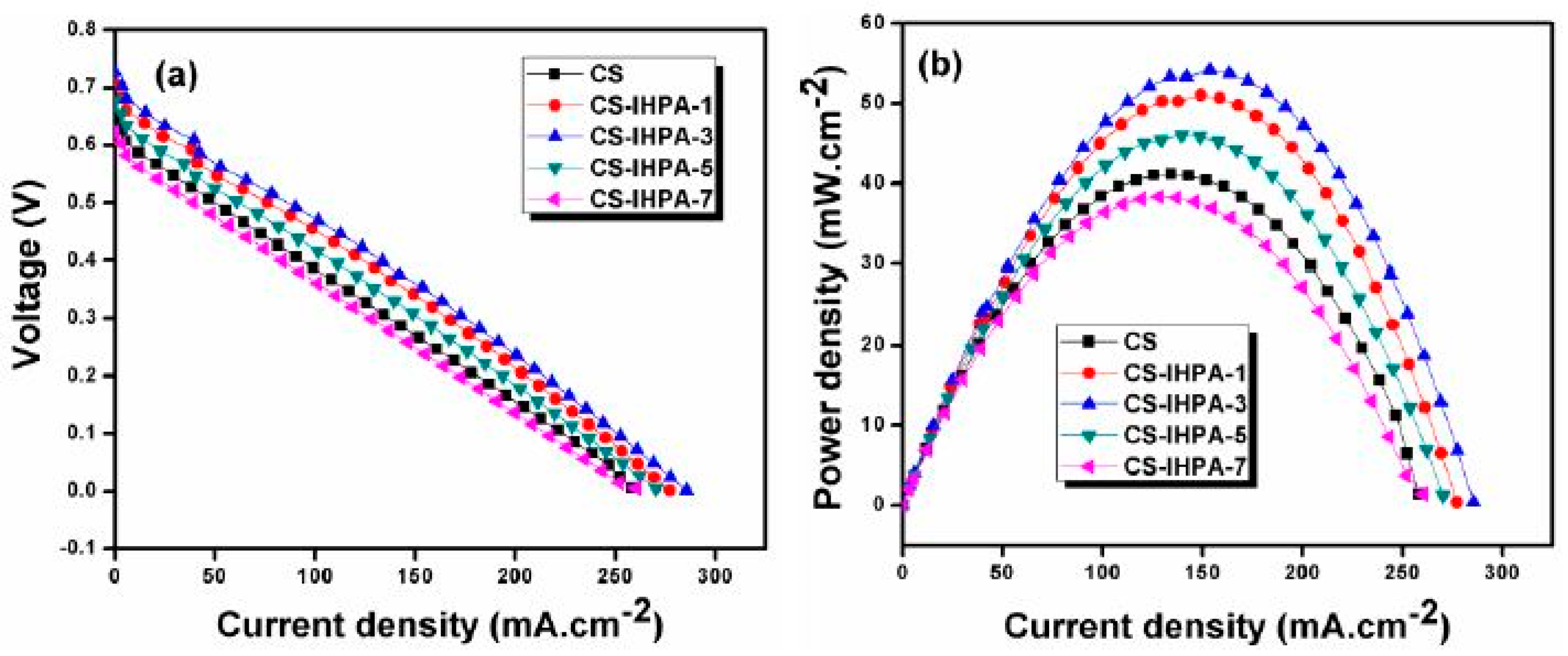

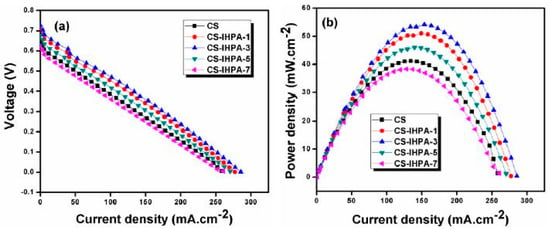

The CS-IHPA-5 membrane exhibited comparatively higher water bonds than other membranes, and its proton conductivity increased gradually with increasing temperature because of its satisfactory water retention capability [64]. Nevertheless, when the filler concentration exceeded 5 wt.%, and the temperature exceeded 90 °C, proton conductivity noticeably decreased. Excess filler loading (>5 wt.%) resulted in agglomeration in the CS-IPHA-7 membrane, thereby reducing the effectiveness for proton conduction by IHPA. The block effect caused by the reduced space between the IHPA filler particles when the IHPA content was excessively high (7 wt.%) inhibited proton transfer or generated proton-conducting pathways with high tortuosity, hence decreasing proton conductivity. The stability test was performed by immersing the membrane in Fenton’s reagent for 1 h at 80 °C, which has shown the composite membrane has better oxidative stability than pure unmodified chitosan, which more than 98% weight of the composite membranes were sustained after conducting the test. This occurrence was due to the shielding effect from the polymer chain and cross-linking agent presented in the composite membrane that prevented the free radicals of hydroxyl and hydro peroxyl from attacking the polymer chains. Moreover, the CS-IHPA-3 membrane exhibited a higher OCV of 0.73 V due to the addition of IHPA and a maximum power density of 54.2 mW cm−2 at a current density of 153.7 mA cm−2 when compared with the pristine CS, which has a maximum power density of 41.2 mW cm−2 and a current density of 134.4 mA cm−2 in a single-cell DMFC under fully hydrated conditions at 80 °C (Figure 7) [60].

Figure 7.

(a) Polarization and (b) power density curves of CS-IHPA nanocomposite membranes operated in DMFC at 80 °C [60]. Copyright 2018, reproduced with permission from Elsevier

The high solubility of HPAs in electrochemically produced water promotes leakage and decreases performance, but mixing the HPAs into a CS matrix can alleviate these issues. Besides that, the fuel cell performance and proton conductivity, as well as the mechanical properties of the CS-HPAs composite membranes can be further improved as the HPAs are functionalized by adding inorganic fillers and mesoporous nature onto them, which have the roles of providing proton conduction sites and the degree of dispersion between the polymer matrix and the modified HPAs that led to the formation of homogeneous hybrid polymer membranes. Table 2 shows the summary of HPA-related CS hybrid membranes in fuel-cell applications.

Table 2.

HPA-related CS hybrid membranes.

(3) Carbon Nanotubes

CNTs, carbon allotropes with cylindrical nanostructures comprising rolled-up graphene sheets that appear similar to an elongated version of C60 were discovered in 1991 [71]. CNTs are composed of carbon atoms linked in hexagonal shapes, with each carbon atom covalently bonded to three other carbon atoms; these materials can be classified as single-walled CNTs (SWCNTs), double-walled carbon nanotubes (DWCNTs), or multiwalled CNTs (MWCNTs) with open or closed ends [71,72]. CNTs can be fabricated through three methods, namely, chemical vapor deposition (CVD) technique [73], laser ablation [74,75], and carbon arc-discharge [76,77,78].

In addition to silica and clay nanoparticles, CNTs have been used as nanofillers for the fabrication of high-performance polymer nanocomposites [79,80], because they have high flexibility, low mass density and extremely high aspect ratio, tensile modulus, and mechanical strength [81,82]. However, polymer/CNT composites are rarely favored, because they exhibit poor dispersion, inert ionic conduction [83], strong π–π interactions, and the ability to form electronic channels in PEMs due to their exquisite electrical conductivity, thereby promoting the risk of short-circuiting in fuel cells. In addition, CNTs must be dispersed uniformly in a polymer matrix considering the strength of the basic Van der Waals interaction amongst tubes. Hence, to overcome these hindrances, the surface of CNTs are functionalized with simple acid groups [84,85] and inorganic materials [33,86], such as carboxylic acid-functionalized CNTs [87], sulphonated CNTs [88], phosphonated CNTs [85] and Naf-, ion-, and polybenzimidazole-functionalized CNTs [89], which are used as inorganic fillers to alter PEMs. Moreover, polyelectrolyte-functionalized CNTs present new proton conducting pathways for rapid proton transport, increased compatibility with polymer matrixes, and additional modification sites [83].

CNTs have been used in composite membranes, and silica-coated CNTs (SCNTs) prepared through a sol–gel method have been applied to the fabrication and preparation of CS/SCNT composite membranes with various SCNT contents [79]. With increasing content of SCNTs from 1 to 10 wt.%, the water uptake of the membranes decreased from 136% to 100% because of the interaction of hydrogen bonds that formed between CSCS and SCNTs [90]. In addition, coating a silica layer containing –SiOH groups on CNTs generated electrostatic and hydrogen bonding interactions between SCNTs and the CS matrix and reduced the moisture absorption capacity of the CS matrix. The proton conductivity of CS/SCNT membranes increased with increasing SCNT content from 0 to 5 wt.% and reached values of 0.015–0.025 S cm−1 but reduced to 0.020 S cm−1 as the SCNT content was further increased to 10 wt.%. Proton conductivity improved when SCNT contents were less than 5 wt.% because of the fine dispersion of SCNTs, which helped improve the formation of continuous proton transport channels and increased proton concentration [86]. Proton conductivity in a PEM is affected by and depends on effective proton mobility and proton concentration [91]. When SCNT contents are excessive (10 wt.%), the agglomeration of SCNTs in the CS matrix increases the tortuosity of the proton-conducting pathway, thereby decreasing proton conductivity. Besides that, a stability test was performed by immersing the membranes in Fenton′s reagent for 1 h at 80°C, which has shown the CS/SCNTs membrane with higher content of SCNTs has better oxidative stability, which was increased by 86% when compared to the pristine CS membrane. This improvement was due to the excellent resistance and restraint effect of the SCNTs on the CS polymer chains.

CNTs functionalized with CS polyelectrolytes through a facile noncovalent surface-deposition and cross-linking method have been studied [76]. CS-coated CNTs (CS@CNTs) were introduced into the CS matrix, and CS/CS@CNT composite membranes were fabricated. The CS coating could improve the compatibility between CNTs and the matrix, enable the homogeneous dispersion of CS@CNTs, enhance the mechanical properties of the composites, and provide supplementary proton-conducting pathways through the membranes. The water uptake of CS/CS@CNT membranes increased from 93.88% to 108.28% with increasing contents of CS@CNTs from 0% to 1% and then decreased to 93.05% when the CS@CNTs content was increased to 3%. As previously reported [79], water uptake decreased, because the incorporation of excessive CS@CNTs reduced ion channel sizes and moisture absorption capacity [92]. The CS/CS@CNTs membrane with 1% CS@CNTs filler had the highest proton conductivity of 3.46 × 10−2 S cm−1 at 80 °C amongst the produced membranes. Other than that, the stability test was performed to observe the degradation of the membranes in Fenton’s reagent at 80 °C, which has shown that the CS/CS@CNTs composite membrane with higher content of CS@CNTs has better oxidative stability, enhanced by 62%, indicated that the filler has excellent oxidation resistance and it was compatible with the polymer matrix, as the degradation of the CS polymer chains was inhibited. Single test results and DMFC performances have shown that the OCV and maximum power density of the CS/CS@CNTs-1 membrane increased to 0.72 V and 47.5 mW cm−2, whereas pure CS membrane had values of 0.63 V and 36.1 mW cm−2, respectively. Considering their simple preparation method and good performance, the fabricated CS/CS@CNT composite membranes are promising PEMs for fuel cell applications [83].

CNTs were coated with superacidic sulphated zirconia (SZr@CNT) through a facile surface-deposition method and incorporated it into the CS matrix [93]. The inorganic proton conductor, superacidic sulphated zirconia (SZr), which has distinguished hydrophilicity, proton conductivity, and stability, was functionalized to CNT to alter PEMs for fuel cell applications. This material successfully improved mechanical strength by 50% and enhanced the proton conductivity (3.4 × 10−2 S cm−1) of the CS/SZr@CNT membrane compared with those of a pristine CS membrane. When the SZr@CNT filler was added to the CS matrix, the Young′s modulus and tensile strength of the CS/SZr@CNT drastically increased and were, respectively, 118% and 50% higher than those of pristine CS membranes. These improvements resulted in the satisfactory mechanical stability of CNT and the fine and homogeneous dispersion of SZr@CNT in the CS matrix. These results could reduce the mobility of the polymer chains under stress and promote mechanical stability. The proton conductivity of all membranes continuously increased with increasing temperature because of the improvement in water uptake at high temperatures. The highest proton conductivity at 80 °C of the CS/SZr@CNT membrane with 0.5 wt.% SZr@CNT content was 3.40 × 10−2 S cm−1, which was greater than that of the pristine, unmodified CS membrane (≈10−4 S cm−1). Moreover, the CS/SZr@CNT membrane with 0.5 wt.% SZr@CNT had a peak power density of 64.6 mW cm−2 at 70 °C when tested in single cell and presented great durability after continuous operation for 100 h at the same temperature. The considerable improvement in the performance of the novel CS/SZr@CNT composite membranes verified that these membranes have potential for use as PEMs for fuel cell applications [93].

The poor dispersion of CNTs in the polymer matrix was caused by strong Van der Waals forces, which can be modified by altering the surfaces of the CNTs. CNTs that are functionalized with inorganic materials have proven their ability in providing additional proton-conducting pathways, which helped in enhancing the proton conductivity of the membrane. Other than that, this modification considerably improved the compatibility of CNT fillers with the polymer matrix, producing homogeneous dispersion of CNT-polymer mixture, and thus enhanced the mechanical stability and fuel cell performance of the composite membranes. Table 3 shows the summary of applications of CNTs used in CS hybrid membranes in fuel cells.

Table 3.

Applications of carbon nanotubes (CNTs) in CS hybrid membranes.

(4) Graphene Oxide

GO is a single-atomic-layered material that consists of oxygen-containing groups, including carbonyl, hydroxyl, carboxyl, and epoxy groups. GO is an enticing active nanofiller for PEM due to its particular properties of facile modification given the presence hydrophilic oxygen-containing groups [101,102,103,104], good mechanical stability and water retention capacity, and potential to improve the proton conductivity of membranes [105,106,107,108]. Moreover, GO exhibits a large surface area, and its proton conduction could be improved through the hopping mechanism, because it contains hydrophilic functional groups. CS membranes were modified by incorporating GO to produce CS hybrid membranes as a promising approach to enhance the interfacial and mechanical properties, proton conductivity, and fuel cell performance of these membranes.

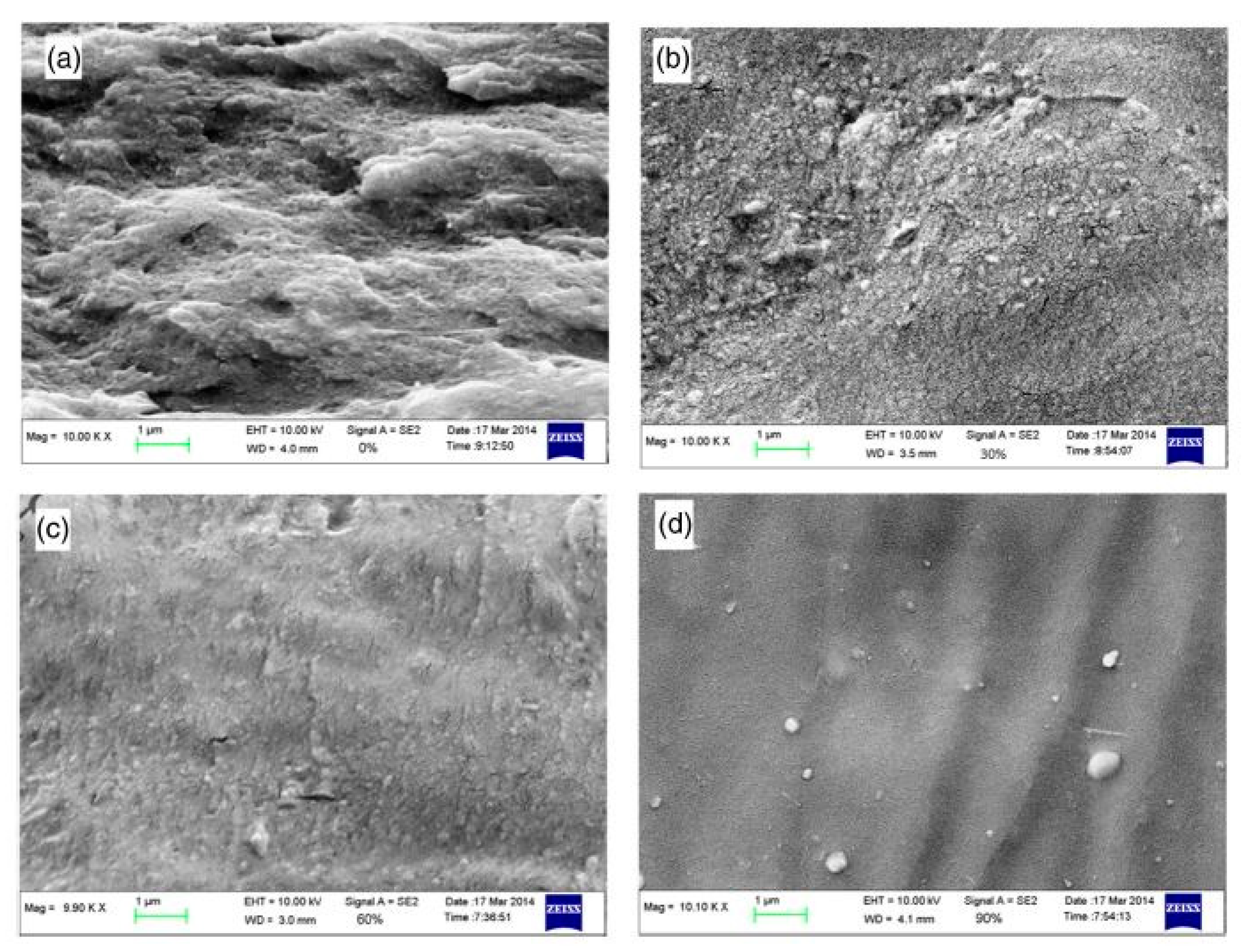

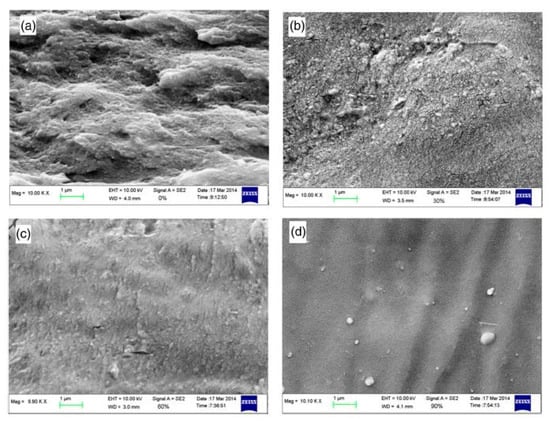

CS and GO have been prepared through a simple self-assembly method given that both materials are in aqueous condition and used to produce CS/GO nanocomposite films [102]. GO cross-linked CS nanocomposite membranes was first reported and prepared by Shao et al. [103]. The incorporation of GO into the CS matrix improved the interfacial and mechanical properties of CS/GO nanocomposite membranes. SEM images showed that GO was well-dispersed in the CS matrix because of the absence of agglomeration, thereby affirming satisfactory adhesion between the GO filler and CS matrix. In addition, these mechanical properties of CS/GO nanocomposite films had improved relative to those of CS films when various contents of GO were added into the CS matrix. The tensile strength and Young’s modulus of the CS/GO nanocomposite film incorporated with 0–1 wt.% GO loadings increased by 122% and 64% to 40.1–89.2 MPa and 1.32–2.17 GPa, respectively [109]. Meanwhile, at elevated temperature, the cross-linking degree of CS/GO strongly increased with increasing GO loading, and the gel content reached almost 100% upon the addition of 2 wt.% GO, thereby indicating that GO can efficiently cross-link with CS [110]. The tensile strength of the GO cross-linked CS membrane was also enhanced by 141% to 104.2 MPa, which was higher than that of pristine CS membrane (43.2 MPa). GO plays an important role in enhancing the mechanical properties of CS-based nanocomposite films, and the uniform dispersion and cross-linking of CS/GO improves interfacial adhesion and electrostatic attraction of nanocomposites [109,110].

The performance of GO nanofillers could be enhanced through the incorporation of acid groups, such as –SO3H. These nanofillers are suitable for mixing with the CS matrix and exhibit homogeneous dispersion, because acid groups could increase the hopping sites for proton migration, thereby increasing the proton conductivity of CS membranes. Similar works have prepared sulphonated GO (SGO) nanosheets with controllable sulphonic acid group loadings [52,111,112] for incorporation into the CS matrix in the production of CS/SGO membranes. The mechanical properties of the CS/SGO membrane improved with increasing SGO filler content from 0 to 4 wt.%, and the tensile strength and Young’s modulus of 44.7–85.3 and 692.3–2697.4 MPa, respectively, were obtained. Moreover, the proton conductivity of CS/SGO membranes was enhanced with increasing content of SGO filler and loading amount of sulphonic acid groups. CS/SGO with 4 wt.% sulphonic acid group and 2 wt.% SGO (CS/S4GO-2) exhibited the highest proton conductivity of 0.0267 S cm−1, which was 222.5% higher than that of pure CS membrane (0.0117 S cm−1) under hydrated conditions at 25 °C. However, as the SGO filler content was further increased to 2.5 wt.%, proton conductivity decreased because of the agglomeration of nanosheets. The CS/S4GO-2 membrane that displayed the highest proton conductivity also showed improvement in H2/O2 cell performance with the highest OCV of 0.99 V, the current density of 459.3 mA cm−2 and the power density of 146.7 mW cm−2 at 120 °C; the OCV value of this membrane was higher than that of Nafion membranes (0.96 V) under similar conditions [52,113].

Another method to improve CS hybrid membranes is by functionalizing CS with –SO3H groups and GO filler with –PO3H acid-grafted group. This functionalization method enhanced water retention capacity, mechanical properties and proton conductivity, and prevented membrane degradation, given that the functionalized GO filler was assimilated into the CS matrix. The proton conductivity of N-o-sulphonic acid benzyl CS (NSBC) and N,N-dimethylenephosphonic acid propylsilane graphene oxide (NMPSGO) composite membrane reached the highest value of 8.87 × 10−2 S cm−1 when 8 wt.% NMPSGO filler was incorporated into the membrane; this value was higher than that of pristine membrane (4.53 × 10−2 S cm−1) [62]. Furthermore, the same membrane that exhibited the highest proton conductivity also showed the highest water uptake (69.98% at 100% RH), and the water retention capacity of the membrane increased by 4-fold of the retention capacity of the Nafion 117 membrane. The mechanical properties of NSBC/NMPSGO membrane at 30 °C increased when the loading of NMPSGO was increased from 0 to 8 wt.% (≈1651 to ≈2462 MPa). When filter loading exceeded 8 wt.%, the membrane performance decreased, and the structure of membrane became brittle because of the agglomeration of NMPSGO filler in the membrane matrix.

Phosphorylated GO (PGO) nanosheets have been introduced into a CS matrix to produce CS/PGO nanohybrid membranes [114]. The phosphonic acid (PA) group, which acted as a proton carrier that was attached to the GO filler, could conduct the proton structure diffusion of protonic defects through a mechanism identical to the mechanism of proton transfer under water-free conditions [115,116]. The mechanical properties of CS/PGO membranes were enhanced with increasing PGO filler loading from 0.5% to 2.5%, and tensile strength values increased from 49.4 to 51.5 MPa. This increment was ascribed to the suppression of the chain motion of the CS matrix and interfacial interactions with the PGO filler. With increasing PGO filler loading from 0.5 to 2.5 wt.%, proton conductivity increased from 19.0 to 31.0 mS cm−1 at 45 °C and 100% RH. The highest conductivity achieved by the CS/PGO membrane with 2.5 wt.% PGO filler was 63.4 mS cm−1 at 95 °C. This trend of conductivity increment was due to the mobility of CS polymer chains and water molecules and enlarged free volume. Moreover, the CS/PGO membrane with 1.5 wt.% PGO filler had an OCV value of 0.99 V, maximum current density of 332.5 mA cm−2, and maximum power density of 107.0 mW cm−2 at 120 °C when tested in a single cell.

In conclusion, previous studies showed that the usage of GO as a filler in CS polymer matrix formed well-dispersed CS-GO composite membranes with good mechanical properties. However, the mechanical properties of the composite membrane can be further improved due to the homogeneous dispersion mixture by adding functionalized GO into the CS polymer matrix. Other than that, this modification included the introduction of acid groups, which acted as proton carriers, providing hopping sites for proton migration in the membranes, enhancing their proton conductivity and fuel cell performance. Table 4 shows the summary of applications of GO in CS hybrid membranes in fuel cells.

Table 4.

Applications of graphene oxide (GO) in CS hybrid membranes.

2.2.2. CS/Polymer Blend Membranes

Polymer blending is the physical mixing of two or more polymers with or without any chemical bonding between them to obtain polymeric materials with unique properties [5]. Polymer blending is performed to improve the properties and performance and overcome the shortcomings of CS membranes. A new improved CS/polymer blend membrane can be formed when synthetic and natural polymer membranes are combined with CS membranes. Two major approaches are used to prepare CS/polymer blends, namely, the dissolution of polymers in solvent followed by evaporation (solution blending) and the mixing of polymers under fusion conditions (melt blending) [120,121,122]. Solution blending is preferable in CS/polymer blends and often performed with the addition of cross-linking agents through casting to improve the mechanical properties of the blended membranes [123].

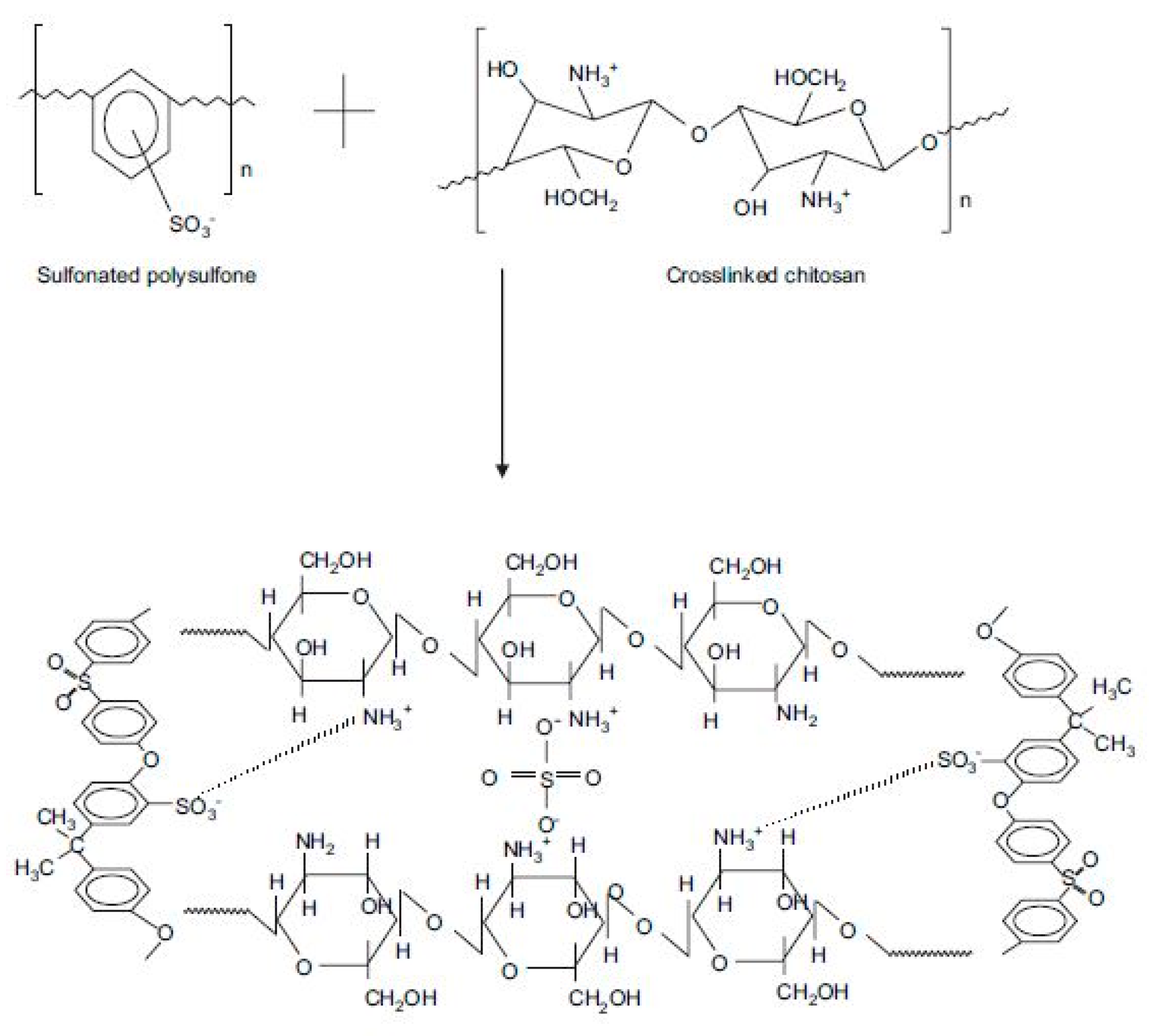

Blending CS with synthetic polymers, such as polysulphone (PSF), poly (vinyl alcohol) (PVA), polyethersulphone (PES), and poly (vinylidene fluoride) (PVDF), has been studied. This method is appealing, because synthetic biodegradable polymers blended with CS matrix could help enhance the water retention capacity and mechanical properties of the blended membranes. The tensile strengths and moduli of these synthetic biodegradable polymers are 16–50 and 400–3000 MPa, respectively [124].

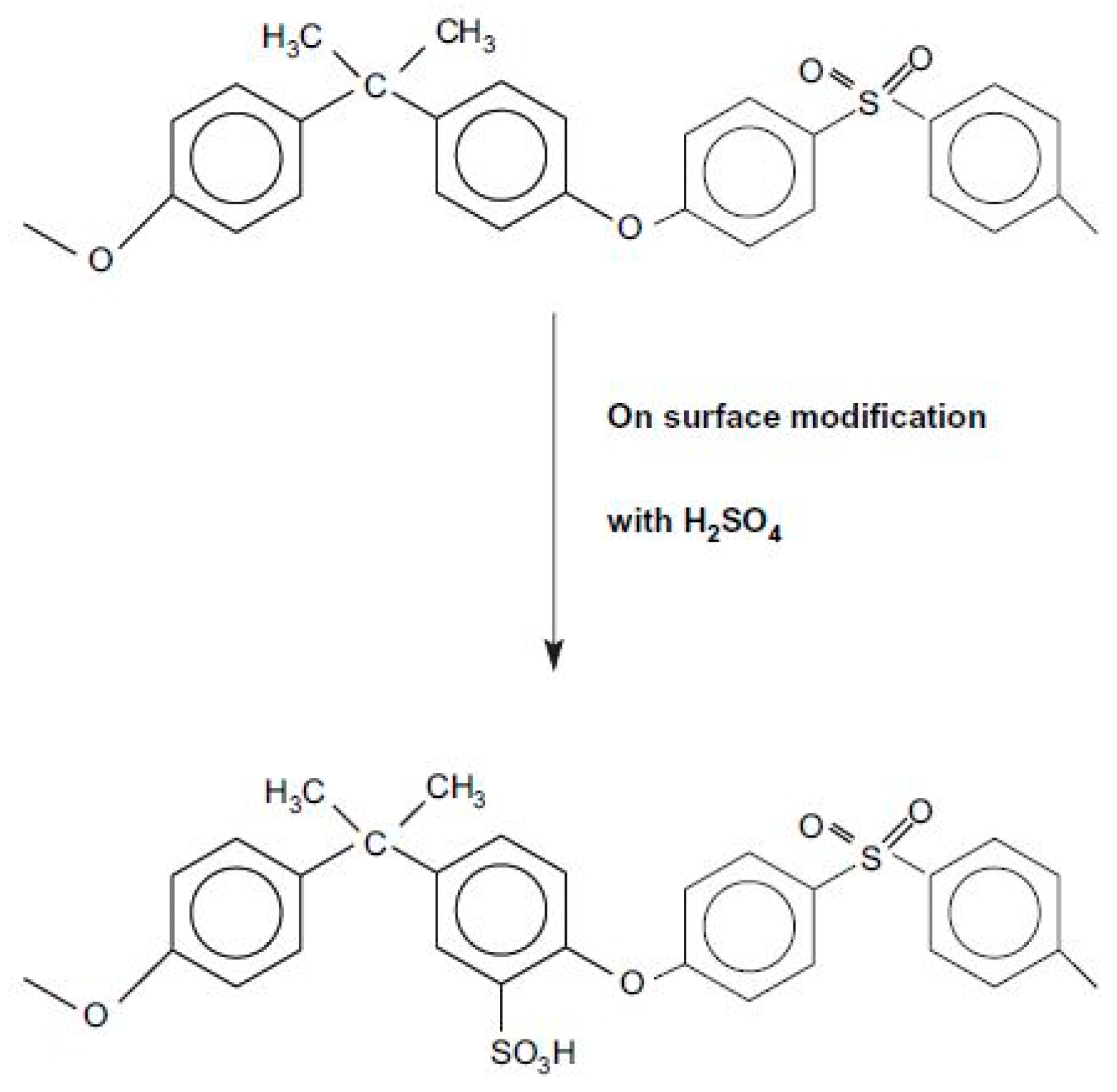

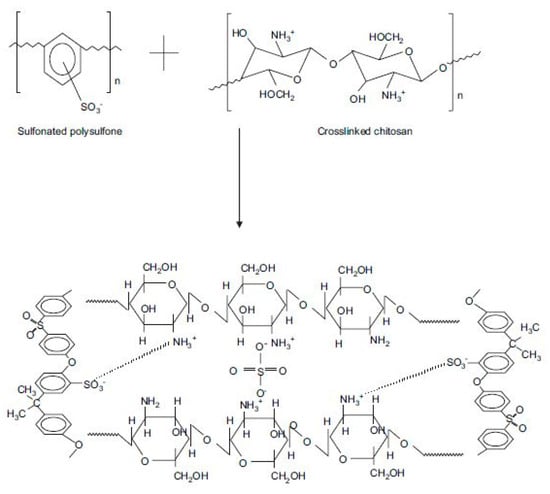

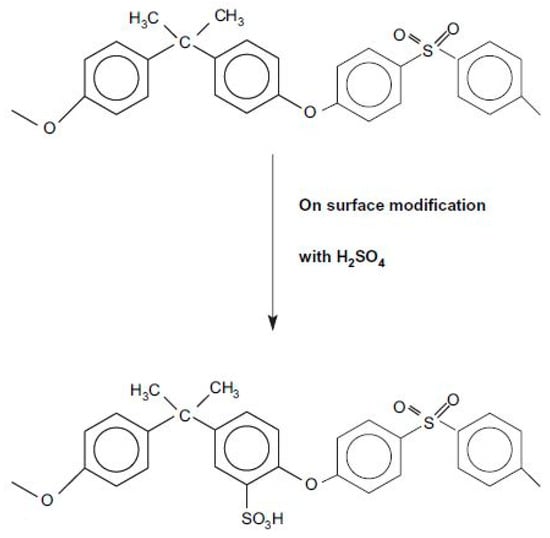

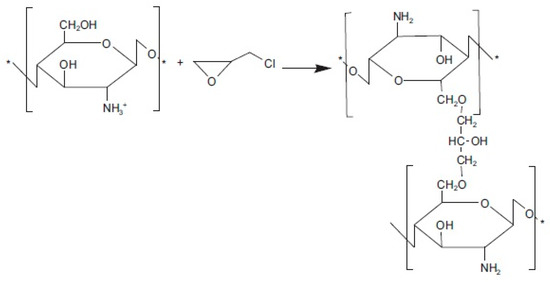

CS and PSF are used to prepare blend membranes despite their distinctive characteristics [125,126,127]. CS could contribute essential conducting properties, and its hydrophilicity could be controlled through cross-linking, whilst PSF could provide structural stability to the membrane [126]. To improve the adhesion of CS and PSF, two methods for modifying the surface of PSF membranes have been proposed. The first method is related to the controlled level of the sulphonation of the chemical structure of PSF [128]. A blended membrane was formed by casting a thin layer of CS and microporous sulphonated PSF (SPFS) as shown in Figure 8. This blend membrane exhibits disadvantages because of the weak interaction and adhesion between the two component polymers. As shown in Figure 9, to overcome this weakness, the surface modification of PSF through sulphonation was conducted to form a SPSF/CS blend membrane, which exhibited higher ionic conductivity than pristine CS membrane [127]. The SPSF/CS blend membrane presented the highest ion exchange capacity, water uptake, and proton conductivity of 2.44 mequiv g−1, 66.67%, and 0.046 S cm−1, respectively. The proton conductivity of this membrane reached 0.180 S cm−1 with increasing temperature up to 120 °C, and this value was higher than that of Nafion 117 membrane (≈0.140 S cm−1). Thus, the improvement shown by the blend membrane indicated that the sulphonated porous substrate modified into CS matrix efficiently played a supporting role. It promoted proton conduction in the membrane.

Figure 8.

Schematic of CS and sulphonated polysulphone (PSF) blend membrane [127]. Copyright 2008, reproduced with permission from Elsevier.

Figure 9.

Schematic of the surface modification of PSF through sulphonation [127]. Copyright 2008, reproduced with permission from Elsevier.

CS and PSF are suitable for blending despite their distinctive features, because modified CS could promote hydrophilicity, whilst PSF could improve the structural stability of the blended membranes [125,129]. CS was modified to produce N-phthloyl CS through reaction with phthalic anhydride in di-methylformamide, and the modified CS was then blended with sulphonated polysulphone (SPSF) to form sulphonated polysulphone/N-phthaloyl CS (SPSF/CS) blended membranes [130]. The ion exchange capacity and water swelling of the blended membranes increased to 0.177 mmol g−1 and ≈280%, respectively, with increasing concentration of the SPSF. The presence of hydrophilic sulphonic acid groups increased, and ion exchange capacity and water swelling were enhanced with increasing concentration of the SPSF.

In addition, PVA polymers are widely used in polymer blended membranes with CS and have been applied in fuel cell applications [131,132,133,134]. PVA/CS (PCS) blended membranes were prepared then cross-linked with glutaraldehyde and applied to a direct methanol alkaline fuel cell (DMAFC) [131]. This blended membrane exhibited enhanced tensile strength and proton conductivity of 46 N mm−2 and 20.0 × 10−3 S cm−1, respectively, and a low methanol permeability of 6.158 × 10−7 cm2 s−1. Upon blending CS with PVA, mechanical strength, proton conductivity, and methanol permeability improved. A CS/PVA blended membrane was initially modified through quaternization with binary quaternizing agents (hexadecyltrimethylammonium bromide (HDT) and 2,3,5-triphenyltetrazolium chloride (TPTZ)) then mixed together to produce a QPVA/QCS blended membrane [134]. The ion exchange capacity and proton conductivity of the CS/PVA membrane quaternized with HDT were 0.60 mmol g−1 and 7.20 × 10−3 S cm−1, respectively, and these values were considerably higher than those of the membrane quaternized with TPTZ. The single-cell test was operated in an alkaline polymer electrolyte fuel cell using the CS/PVA membrane with HDT cross-linker and provided a peak power density of 15 mW cm−2 at 40 °C.

PES is an attractive polymer for blending with CS matrix due to its good mechanical stability, flexibility and low cost [135,136]. However, it has hydrophobic properties, thereby making it insoluble in dipolar solvents. PES has been modified into aryl-substituted sulphonated PES (SPES) to solve this problem. SPES is also blended with N-phthaloyl CS (NPHCs), thereby helping to enhance the hydrophilicity, porosity and water retention of the membrane [129,137]. Muthumeenal et al. [138] reported the increase in proton conductivity and water uptake of SPES/NPHC blended membrane (9.20 × 10−3 to 12.10 × 10−3 S cm−1 and 38.0% to 41.5%, respectively) with increasing temperature from 25 to 80 °C. These increments in proton conductivity and water uptake were due to the presence of sulphonic acid groups in the membrane and polar groups in NPHCs. These findings were supported by Li et al. [137], who also observed increased membrane hydrophilicity with increasing NPHC content.

Vijayalekshmi and Khastgir [139] developed CS/partially sulphonated poly (vinylidene fluoride) (CS/SPVDF) blend membranes and applied them to DMFC. PVDF polymers have been previously used to reduce methanol crossover to a certain limit; however, despite this convenience, PVDF polymers have hydrophobic properties that diminish the ion exchange capacity and proton conductivity of membrane [140,141,142]. This problem can be overcome by modifying PVDF polymers through sulphonation and blending SPVDF with CS, producing a blended membrane with good mechanical strength, water uptake, and retention capacity [143,144]. With increasing content of SPVDF in the blend membrane, water uptake and ion exchange capacity values increased by ≈50% and 0.22 mmol g−1, respectively. Furthermore, the mechanical stability improved with increasing SPVDF content, thereby improving the tensile strength of the CS/SPVDF blend membrane under both dry and hydrated conditions (51.8 and 27.6 MPa). The proton conductivity achieved by the blended membrane also increased to 8.12 × 10−3–2.85 × 10−2 S cm−1 with increasing temperature from 30 to 90 °C, respectively. The lowest methanol permeability obtained was 1.8 × 10−7 cm2 s−1, and the CS/SPVDF blend membrane was highly selective (1.69 × 104 S cm−3 s). These results proved that this blended membrane was suitable and has potential for use as PEM in fuel cell applications.

It can be concluded that as CS polymers are blended with other synthetic polymers, particular properties of the produced blended membranes, such as mechanical stability, proton conductivity, and water uptake can be improved. However, there are certain polymers that possessed hydrophobic properties, which caused reduction in proton conductivity and ion exchange capacity of the blended membranes. These drawbacks can be promoted by functionalizing the polymers with sulfonic acid groups and as the blended membranes undergo a cross-linking process, the mechanical stability, proton conductivity, water retention capacity, and ion exchange capacity of the blended membranes are further improved.

2.3. Chemical Modifications of CS Biopolymer-Based Membrane

Ma and Sahai [10] reported the presence of free hydroxyl and amine functional groups on the backbone of CS, which allowed various chemical modifications of CS, such as sulphonation, phosphorylation, quaternization and chemical cross-linking, to tailor its properties for specific applications. These modifications can make CS a cost-effective biopolymer electrolyte membrane with low methanol permeability and suitable ion conductivity, especially at high temperature [15]. These modifications can also help improve its chemical and mechanical properties and possibly generate ion exchange sites and enhance the ionic conductivity of the membrane [10].

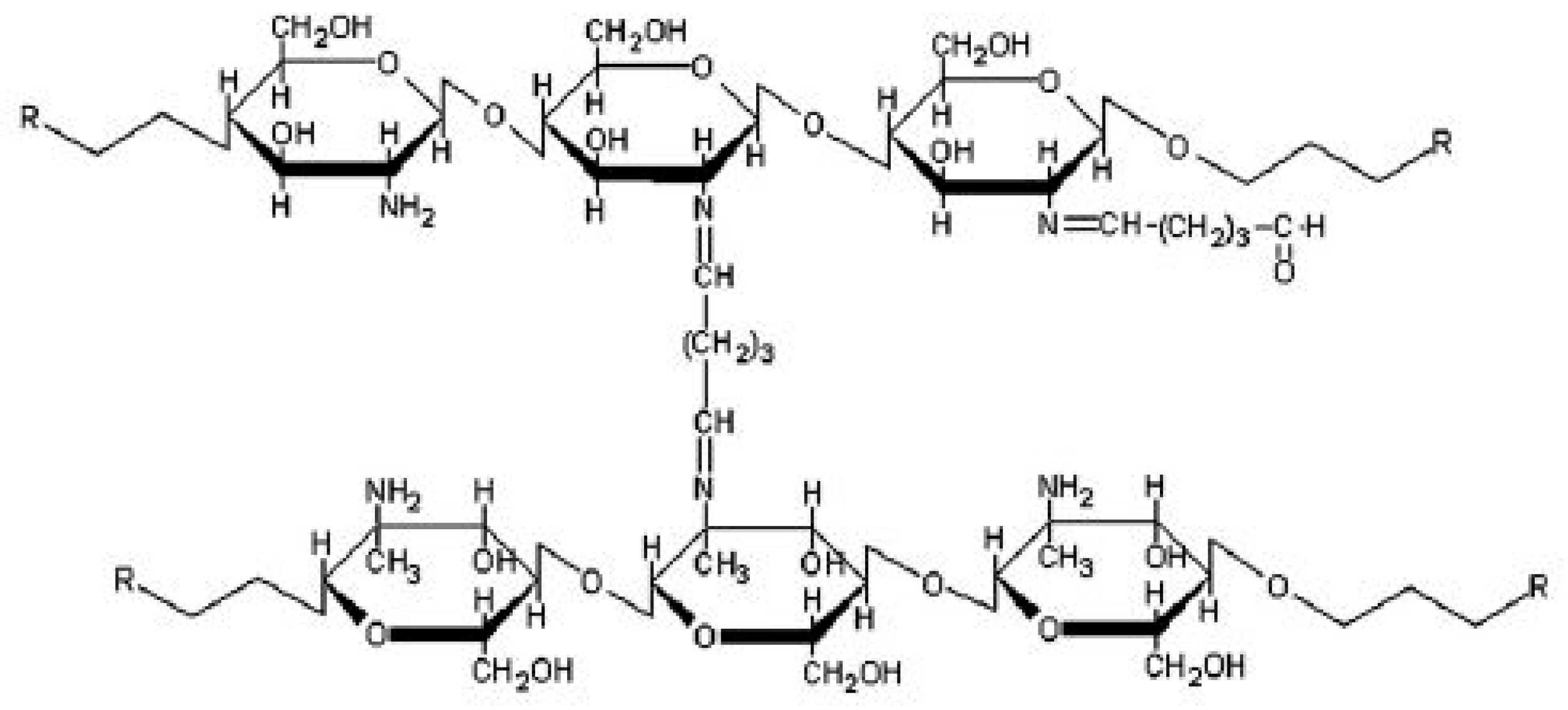

2.3.1. Sulphonation

The modifications of CS through sulphonation have been studied over the years. Sulphonated CS (SCS) was produced through the incorporation of sulphonate groups into CS matrix. Sulphonate groups could be attached to CS matrix in three routes to produce different types of modified CS. The routes included the following: (i) initiation through compounds containing sulphonate groups (R–SO3−) that produce sulphonated products (–NH–R–SO3−); (ii) introduction on hydroxyl groups which produce sulphate products (–O–SO3−); (iii) prompt binding on free amino groups to produce sulphamate products (–NH–SO3−) [145,146,147,148,149]. Given that SCS derivatives have polyampholytic behavior and specific physicochemical properties, they have been widely used in biomedical fields, such as antimicrobial, antioxidant, antiviral, drug delivery, hemocompatible biomaterial, and bone tissue engineering [150].

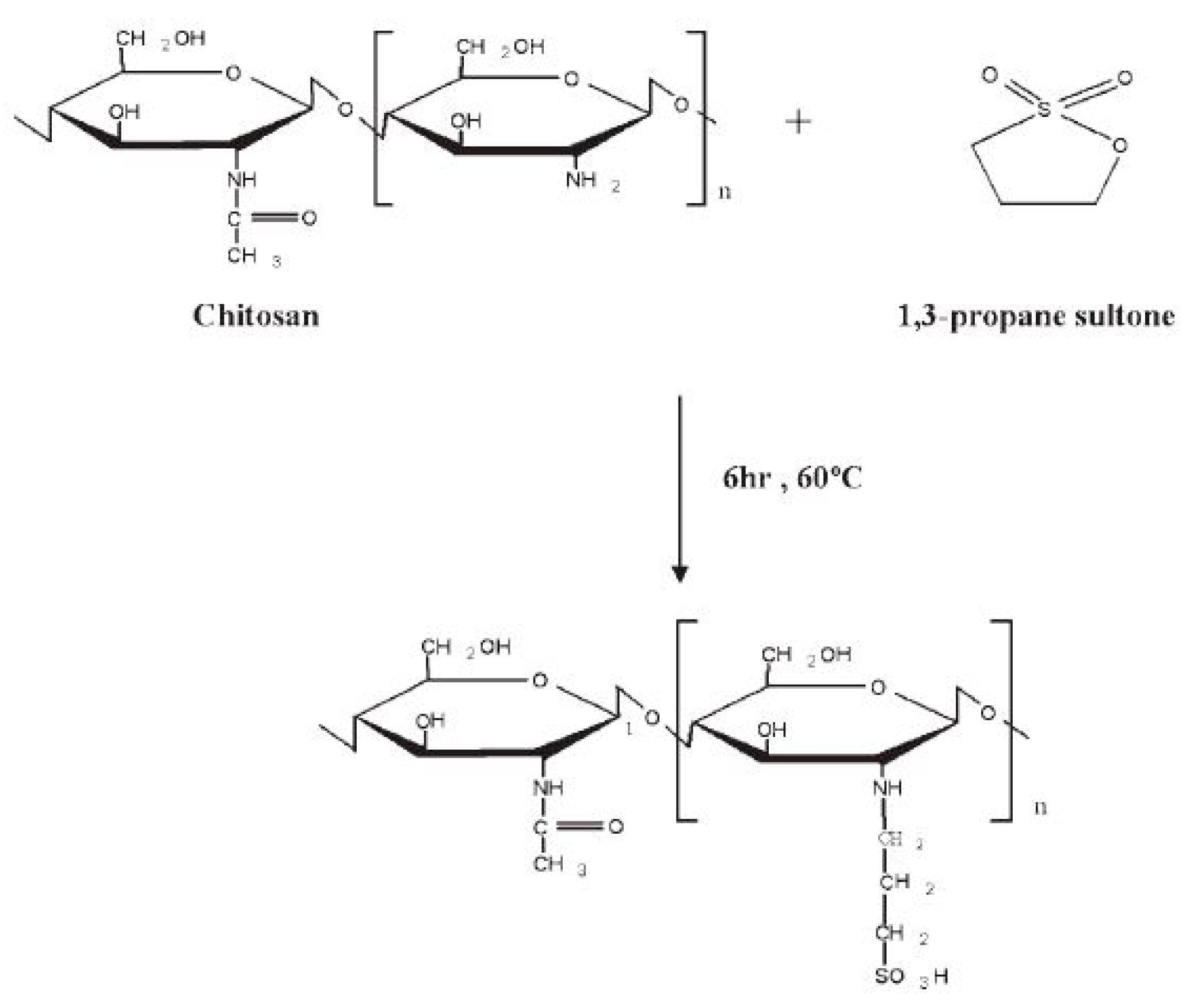

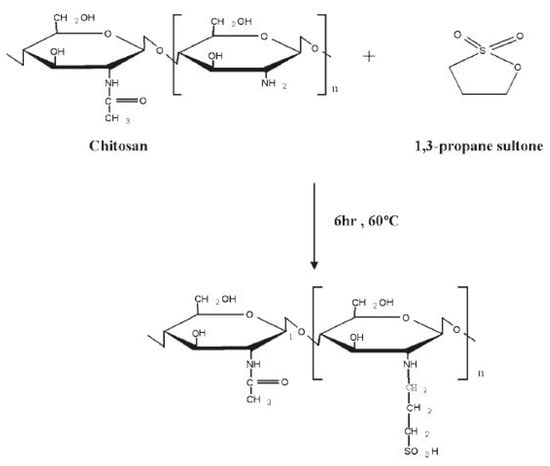

Jayakumar et al. [151] reported that a certain density of sulphonate groups can be chemically attached to CS backbone by using various methods and by altering reaction time, temperature, and reactant concentration. N-sulphonated CS (where the sulphonate group is attached to the –NH2 sites) and O-sulphonated CS (where the sulphonate group is attached to the –OH sites) were prepared by using sulphating reagents under various reaction conditions. N-sulphonated CS with various sulphonation degrees can be prepared using propane sultone (Figure 10) [152]. Sulphonated CS has a pendant alkyl sulphonic group attached to the side chains. Proper pretreatment conditions and solvent systems enable sulphonation to occur selectively on the C3/C6-position (–OH sites). SO3 or chlorosulphonic acid with dimethylformamide complex has been used as a sulphonating reagent [111].

Figure 10.

Schematic of the structure of sulphonated CS [152]. Copyright 2010, reproduced with permission from John Wiley and Sons.

Pure unmodified CS-based biopolymer membranes show low proton conductivity, which can be enhanced via the functionalization of CS with different groups, especially with sulphonic acid, –SO3H groups. Xiang et al. [153] prepared sulphonated CS polymer by grafting CS monomers with sulphonic groups and then preparing CS sulphate blending membrane (CCSM). In order to be used in PEMFC, CCSM was blended with pure chitosan at different weight ratios, and cross-linking occurred when the bonding reaction happened between the sulfonic groups in CCSM and the amide groups in the pure chitosan monomers due to the excessive swelling of CCSM. The mechanical properties of CCSM have improved as the tensile strength value increased from 52.9 to 87.8 MPa, indicating that the CS backbone was stable. The proton conductivity and methanol permeability reduction of the advanced CCSM were improved compared with those of pure nonmodified CS membrane, and the highest values of 3.1× 10−2 S cm−1 at 80 °C and 3.8 × 10−7 cm2 s−1, respectively, were obtained. These improvements exhibited by CCSM showed that CS sulphate successfully functioned as a proton conductor and methanol barrier [153].

Shirdast et al. [111] fabricated a CS/sulphonated CS (CS/SCS) blend membrane by incorporating SCS into the CS matrix. The SCS was prepared using a similar method that was used by Xiang et al. [153], which involves grafting the CS monomers with sulphonic groups. SCS addition to CS matrix caused several enhancements in the performance of the blend membrane. The tensile strength of CS/SCS membrane was improved by 35%, increased from 72.4 to 96.9 MPa. Moreover, the IEC value increased (0.97 mequiv g−1) when compared with that of pristine CS membrane (0.65 mequiv g−1) because of the presence of the sulphonic acid groups in the sulphonated CS matrix. The CS membrane showed a proton conductivity value of 1.30 mS cm−1. However, when blended with 10 wt.% SCS, the CS membrane showed increased proton conductivity that reached 2.20 mS cm−1 due to the presence of proton hopping sites of the CS/SCS membrane. The methanol permeability of CS blended with SCS was reduced to 5.91 × 10−8 cm2 s−1, which ensured the efficient application of polymeric membrane [111].

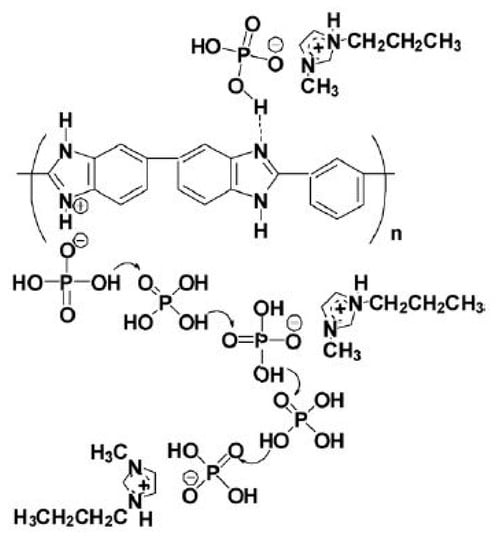

2.3.2. Phosphorylation

Phosphorylated chitin and CS derivatives were applied in several fields, such as biomedical, orthopedics, cosmetics, agricultural, food industrial, and water treatment [154]. Chitin and CS solubility was modified by incorporating phosphonic acid or phosphonate groups through reactions occurring between the phosphorylating agent and the amino groups. Nishi et al. [155] claimed that the solubility of phosphorylated CS can be enhanced even at a low degree of substitution due to the strong interaction between phosphoryl groups and water. This enhancement in solubility indicated that the phosphorylated CS had high hydrophilicity properties and can thus reduce the crystallinity of the CS structure and improve proton conductivity under hydrated conditions.

Various methods have been used to prepare phosphorylated chitin or CS. Jayakumar et al. [156] reported that phosphorylated CS can be prepared by heating CS with orthophosphoric acid and urea in N,N-dimethylformamide, because urea promotes the reaction [157]. The reaction of CS with phosphorous pentoxide (P2O5) in methanesulphonic acid was efficient, because the phosphorylated CS produced was water-soluble due to the high degree of substitution. Phosphorylated CS can also be prepared through the generation of N-methylene phosphonic CS by introducing methylene phosphonic groups into the CS matrix, thereby improving its solubility in water without affecting its filmogenic properties [158]. Jung et al. [159] reported on the preparation of phosphorylated CS through grafting mono (2-methacryloyl oxyethyl) acid phosphate to the CS matrix, thereby improving its zwitterionic and antimicrobial properties. Palma et al. [160] synthesized CS-O-ethyl phosphonate by using KOH/methanol and 2-chloro ethyl phosphonic acid under mild conditions; it was used to increase blueberry yields and soluble solid content. Phosphorylated CS can also be produced by using n-hexane as solvent rather than 2-propanol, because using the latter led to the production of undesired products. CS alkyl phosphate/CS-O-ethyl phosphonate has been synthesized under heterogeneous conditions; alkali CS, NaOH and n-hexane were used with diethyl chlorophosphate as phosphorylating agent. This phosphorylated CS was expected to enhance the reactivity of hydroxyl groups and favor the coupling reaction with diethyl chlorophosphate/2-chloroethyl phosphonic acid [161].

Wan et al. [162] prepared phosphorylated CS membranes through the reaction of orthophosphoric acid and urea in N,N-dimethylformamide; the phosphorylated CS membrane produced showed a decrease in the crystallinity structure due to increased phosphorus content. This phenomenon was due to the presence of bulky phosphate groups, which in turn increased the hydrophilicity and swelling properties of the membrane. Given that the crystallinity of the phosphorylated CS membrane decreased, the tensile strength also decreased. However, polyphosphate cross-linking did not affect the tensile strength and breaking elongation of the membranes. In phosphorylated CS membrane, additional –NH2 groups led to a high proton conductivity of 9.80 × 10−4 S cm−1 under hydrated conditions.

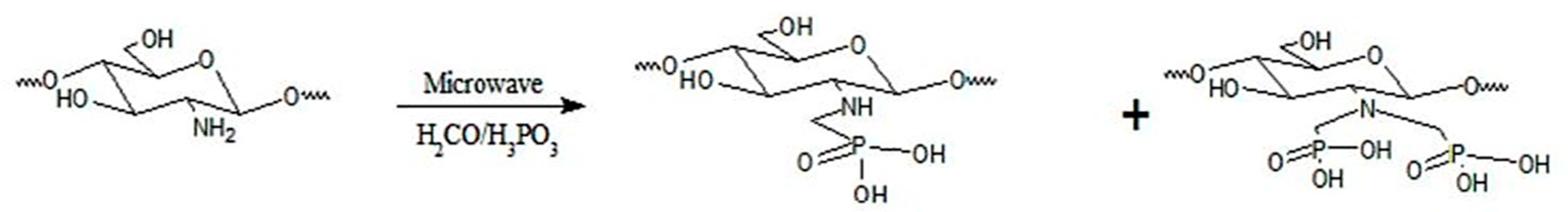

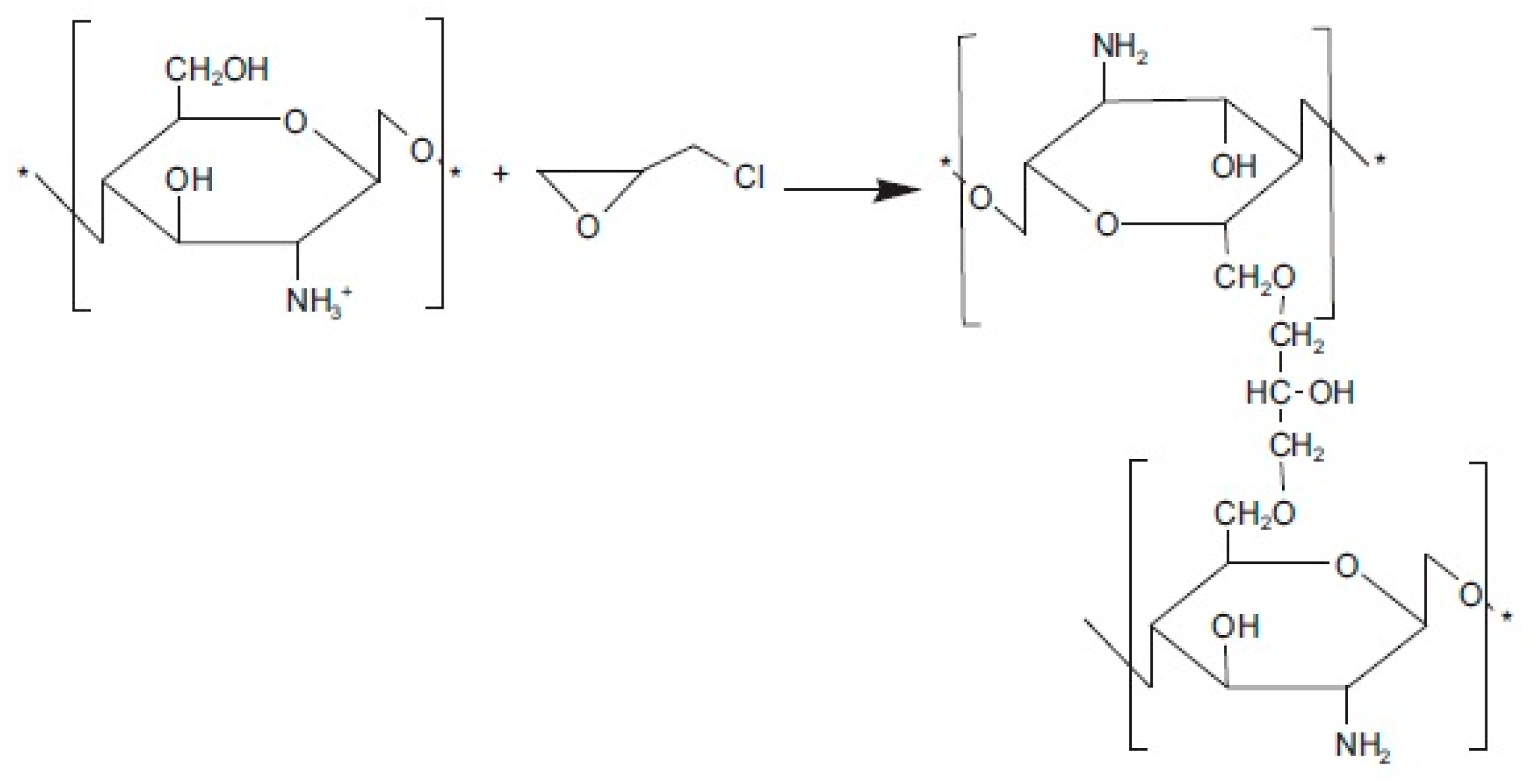

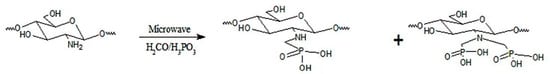

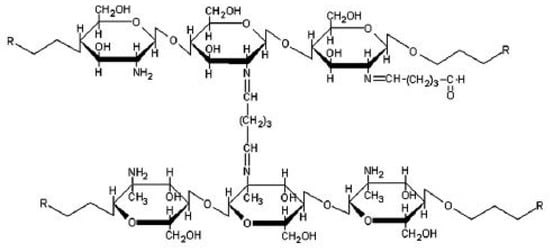

N-methylene phosphonic CS (NMPC) was produced by Dadhich et al. [163] by using microwave-assisted rapid synthesis through Mannich-type reaction (Figure 11). This reaction was developed, because the microwave irradiation can rapidly phosphorylate the CS with high and uniform-yield products without requiring a long reflux time, which is required in the phosphorylation method conducted by Moedritzer and Irani [164]. NMPC improved ionogenic propertyies, and the introduction of phosphonic or phosphonate groups into amino or hydroxyl groups improved biochemical function; thus, NMPC was selected as PEM for fuel cell applications [165,166]. When NMPC was synthesized through microwave irradiation for 10 min, the reaction yielded 55–60% of the products, in contrast with the low percentage of products (40–45%) of the reflux method for 14–24 h. Moreover, NMPC exhibited higher solubility properties than pure CS in aqueous medium. Proton conductivity improved with the increase in aqueous solution content to 5.0%. The highest proton conductivity of 10.15 mS cm−1 was obtained due to the existence of zwitterionic activity and proton transfer [167].

Figure 11.

Synthesis of N-methylene phosphonic CS via microwave irradiation reaction [163]. Copyright 2015, reproduced with permission from Elsevier

The phosphorylation of CS was also studied by Holder et al. [168]. They prepared phosphorylated-CS (CS-P) and phosphorylated-sorbitol-CS (S-CS-P) membranes. They claimed that phosphorylated CS membranes showed improved tensile strength and ion exchange capacity. Moreover, the fabricated PEM in microbial fuel cell (MFC) showed improved performance. The tensile strength of CS-P membrane was 49.9 N mm−2, which was higher compared with that of pure CS membrane (39.3 N mm−2) and S-CS-P membrane (0.4 N mm−2). The presence of sorbitol in S-CS-P membrane increased the flexibility of the CS structure, which promoted the decrement in the elongation and tensile strength of the membrane. Moreover, ion exchange capacity increased due to the introduction of high proton-conducting phosphate groups in the CS-P membrane, with the highest value of 1.43 mequiv g−1. The CS-P membrane reached a maximum power density of 130.03 mW m−2 and maximum current density of 374.73 mA m−2 when tested in the MFC system.

2.3.3. Quaternization

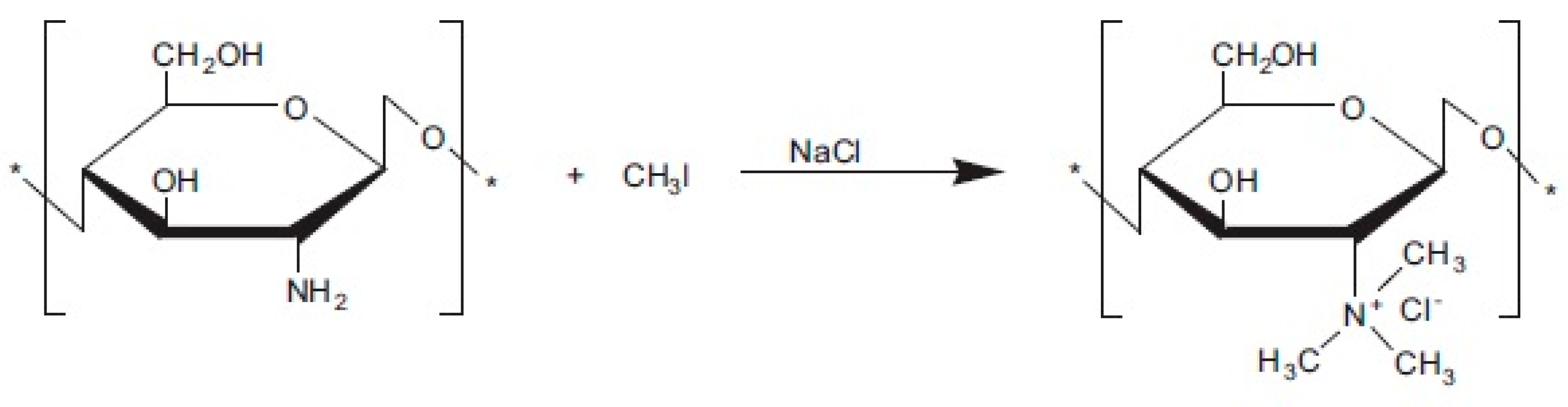

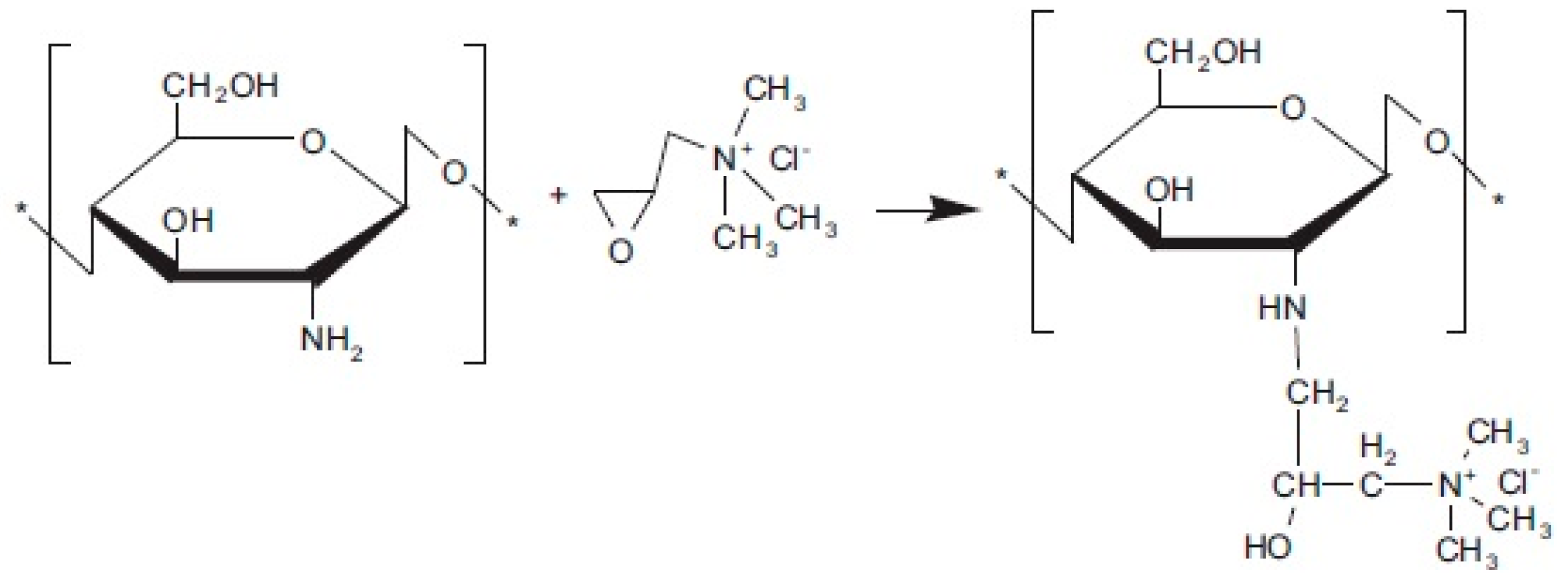

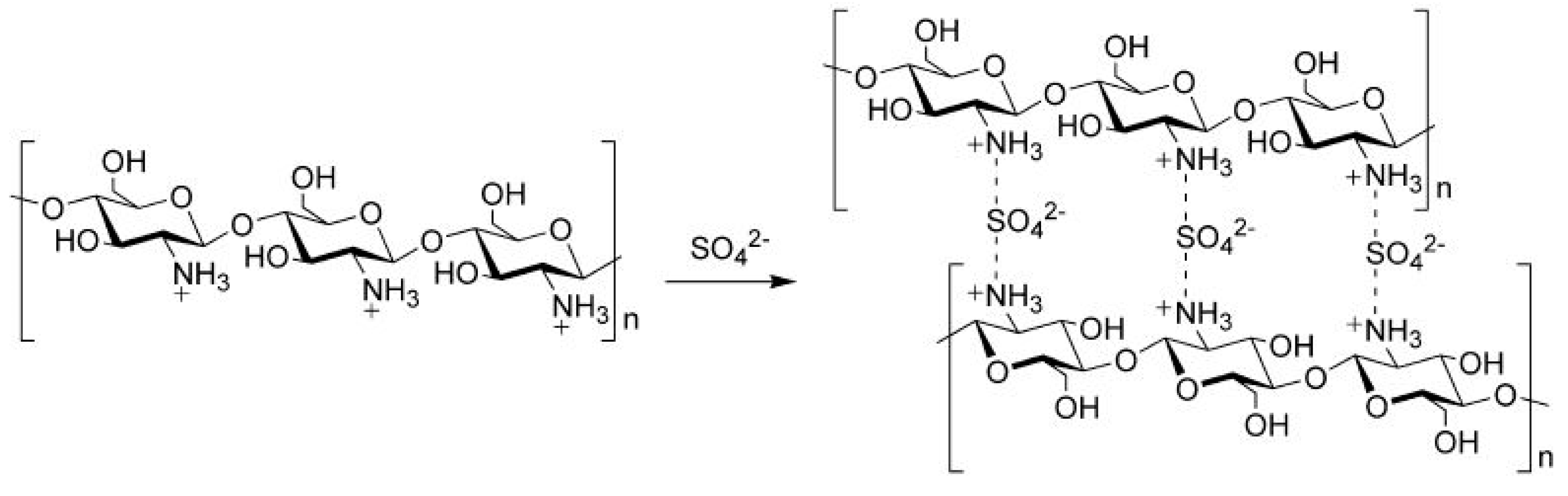

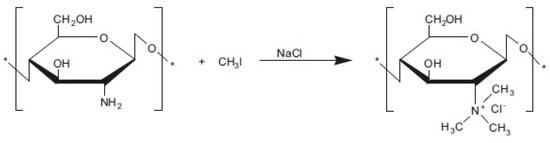

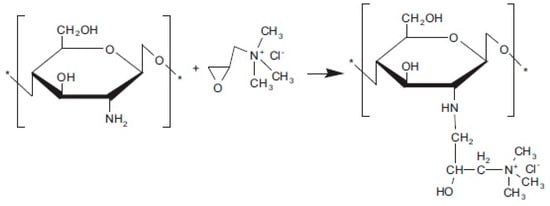

Unmodified CS possessed low conductivity, i.e., 10−9 S cm−1 under anhydrous conditions and 10−4 S cm−1 under hydrated conditions. To improve this drawback, several researchers have modified CS through quaternization. The introduction of quaternary ammonium groups in CS matrix improves the solubility and positive charge density of CS [169,170,171,172], and the groups acted as positive charge-rich gels to be used as antimicrobial and antibacterial reagents [173,174]. Uragami et al. [175] reported that quaternized CS was synthesized using methyl iodide (Figure 12) [176] and by introducing the quaternizing agent glycidyltrimethylammonium chloride (Figure 13) [176], because it also had a quaternary ammonium group. A primary amino group at the C2 position of CS reacted with glycidyltrimethylammonium chloride [177]. The anion exchange conductor of quaternized CS was thus obtained by replacing hydroxide ions with chloride ions.

Figure 12.

Synthesis of quaternized CS [176]. Copyright 2013, reproduced with permission from Elsevier

Figure 13.

Reaction of CS with glycidyltrimethylammonium chloride [176]. Copyright 2013, reproduced with permission from Elsevier

Wan et al. [178] fabricated novel cross-linked quaternized-CS membranes made from N-[(2-hydroxy-3-trimethylammonium) propyl] CS chloride (HTCC). The proton conductivities of these membranes were measured under anhydrous and hydrated conditions. The results showed increased proton conductivity of cross-linked quaternized-CS membranes with increasing degree of quaternization (DQ) of the HTCC. However, no clear trend was observed in the increment that occurred. Thus, the enhancement of cross-linked membrane conductance due to the HTCC with high DQ needs further study. The highest conductivity exhibited by the cross-linked membrane was 7.30 × 10−3 S cm−1 under hydrated conditions, which was near 10−2 S cm−1 and comparable with the conductivity of Nafion N117 membrane [179]. The single cell test was conducted at an H2/O2 pressure ratio of 241/241 kPa at 50 °C with 100% RH by using the cross-linked membrane with the highest proton conductivity due to its high DQ. The OCV achieved was approximately 1.0 V, and the current density was 65 mA cm−2.

Yuan et al. [180] proposed a new type of alkaline anion-exchange membrane by fabricating quaternized CS blended membrane by introducing 2,3-epoxypropyltrimethylammonium chloride (GTMAC) into CS matrix and produced N-[(2-hydroxy−3-trimethyl-ammonium) propyl] CS chloride (HTCC). GTMAC served an important function in the yield of conductive anions (OH−) as charge carriers, thereby avoiding process of quaternisation, which was toxic [178,181]. The quaternised CS blended membranes produced were N-[(2-hydroxy-3-trimethyl-ammonium) propyl] CS chloride (HTCC)/poly (diallyldimethylammonium chloride) (PDDA) (HTCC/PDDA-OH−) composite membranes. These membranes exhibited increased tensile strength with increasing PDDA content due to the function of PDDA as OH− charge carriers and the cyclic structure of PDDA that inhibited the degradation of quaternary ammonium groups under alkaline conditions. The maximum tensile strength achieved by HTCC/PDDA-OH− membrane with mass of 1:0.5 HTCC/PDDA was 25.31 MPa. However, as the ratio increased further, the membrane’s tensile strength decreased to 7.43 MPa. Moreover, the HTCC/PDDA-OH− membrane also exhibited increased IEC and water uptake with maximum values of 3.267 mmol g−1 and 3.708 g g−1, respectively, due to the presence of additional quaternary ammonium groups and further enhancement in hydrophilicity properties when additional PDDA was introduced to the membrane. The proton conductivity of all membranes was measured by increasing the temperature from 30 to 80 °C. The HTCC/PDDA-OH- membrane with a mass of 1:0.5 showed the highest OH− conductivity of 23.7 to 37.9 mS cm−1 from 30 to 80 °C. This enhancement in proton conductivity occurred because of the following: (i) the presence of water molecules that ensured the mobility of OH− ions and ionic transport channel in the membrane; (ii) the activation energy for ion transport was overcome with increasing temperature, diffusion was rapid, and thermal motion of OH− ions improved.

Quaternized CS (Q-CS) nanoparticles incorporated with quaternized poly (vinyl alcohol) (Q-PVA) polymer composite was prepared by Liao et al. [182]. The nanoparticles showed improved proton conductivity and fuel permeation. Lue et al. and Lue et al. [183,184] showed that as Q-CS nanoparticles were incorporated into Q-PVA, which had semicrystalline properties, the composite membrane showed enhanced conductivity and suppressed fuel permeation. The Q-CS nanoparticles acted as fillers in the membrane. Alkaline uptake was further increased from 0.56 g g−1 at 30 °C to 1.16 g g−1 at 30 to 60 °C. Proton conductivity values also increased from 0.020 to 0.022 S cm−1, with the lowest methanol permeability of 2.77 × 10−6 cm2 s−1. The Q-PVA/Q-CS composite membrane was operated in DMAFC and exhibited the highest peak power density of 92 mW cm−2 at 90 °C with 2 M methanol fuel feed.

Ryu et al. [185] showed that as quaternized CS underwent some modifications, producing a novel quaternized anion-exchange membrane, the conductivity and mechanical strength of the composite membrane have been improved relative to that of pristine CS membrane. The quaternized CS was modified with 4-pyridinecarboxaldehyde derivative, producing quaternized poly [O-(2-imidazolyethylene)-N-picolylchitosan (QPIENPC), which was then copolymerized with 1-vinylimidazole. The QPIENPC membrane exhibited increased proton conductivity from 3.48 to 10.15 mS cm−1 as temperature was increased from 30 to 80 °C. This value was higher than that of Q-CS (0.17 mS cm−1). The mechanical strength also improved in QPIENPC membrane, showing a higher tensile strength of 22.39 MPa relative to that of Q-CS (11.74 MPa). The single cell test was operated under alkaline conditions with 3 M methanol fuel feed and 2 M KOH solutions. The maximum peak power density obtained was 10.42 mW cm−2, thereby suggesting that the QPIENPC membrane was potentially suitable to be used as polymer electrolyte in DMAFC applications.

2.3.4. Chemical Cross-Linking

Cross-linking is a common chemical modification method to ensure the good chemical and mechanical stability of CS and make CS insoluble in aqueous medium. CS membrane is cross-linked to reduce its high crystallinity properties and hence improve its water absorption and ionic transport through the membrane [186]. Cross-linking methods include chemical, physical, and oxidative cross-linking [187]. Structure and ionically cross-linked CS were reviewed by Berger et al. [188]. Polymer chains are interconnected by cross-linkers to form 3D networks in cross-linked CS. The main interactions forming the network are covalent or ionic bonds. In terms of their structure, covalently cross-linked CS can be divided into three types, as follows:

- CS cross-linked with itself,

- Hybrid polymer networks, in which cross-linking reaction occurs between a structural unit of a CS chain and a structural unit of a polymeric chain of another type,

- Semi- or full-interpenetrating polymer networks, in which a polymer of another kind is entrapped in self-cross-linked CS network.