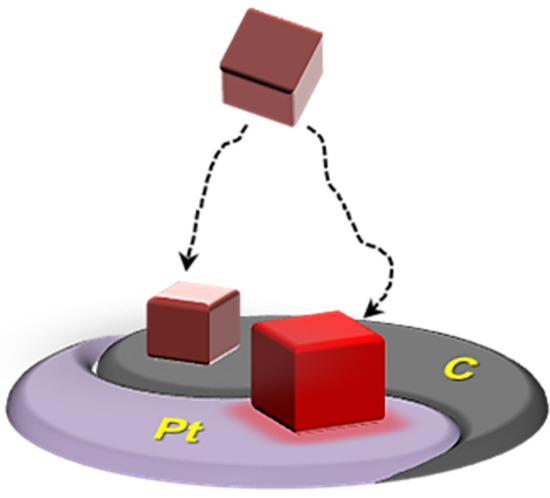

Single Co3O4 Nanocubes Electrocatalyzing the Oxygen Evolution Reaction: Nano-Impact Insights into Intrinsic Activity and Support Effects

Abstract

:1. Introduction

2. Results and Discussion

3. Materials and Methods

3.1. Chemicals

3.2. Preparation of Co3O4 Nanocubes

3.3. Materials Characterization

3.4. Electrochemical Measurements

3.4.1. Ensemble Characterization with Rotating Disc Electrodes (RDEs)

3.4.2. Microelectrode Preparation and Characterization

3.4.3. Ensemble Characterization with Microelectrodes

3.4.4. Nano-Impact Experiments Probing Individual Co3O4 Nanocubes

3.5. Finite Element Simulations for Diffusion-Controlled Currents at Cubic Nanoparticles

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Minguzzi, A.; Fan, F.-R.F.; Vertova, A.; Rondinini, S.; Bard, A.J. Dynamic potential—pH diagrams application to electrocatalysts for water oxidation. Chem. Sci. 2012, 3, 217–229. [Google Scholar] [CrossRef] [Green Version]

- Suen, N.-T.; Hung, S.-F.; Quan, Q.; Zhang, N.; Xu, Y.-J.; Chen, H.M. Electrocatalysis for the oxygen evolution reaction: Recent development and future perspectives. Chem. Soc. Rev. 2017, 46, 337–365. [Google Scholar] [CrossRef]

- Quast, T.; Aiyappa, H.B.; Saddeler, S.; Wilde, P.; Chen, Y.-T.; Schulz, S.; Schuhmann, W. Single-Entity Electrocatalysis of Individual “Picked-and-Dropped” Co3O4 Nanoparticles on the Tip of a Carbon Nanoelectrode. Angew. Chem. Int. Ed. 2021, 60, 3576–3580. [Google Scholar] [CrossRef]

- Quast, T.; Varhade, S.; Saddeler, S.; Chen, Y.-T.; Andronescu, C.; Schulz, S.; Schuhmann, W. Single Particle Nanoelectrochemistry Reveals the Catalytic Oxygen Evolution Reaction Activity of Co3O4 Nanocubes. Angew. Chem. Int. Ed. 2021, 60, 23444–23450. [Google Scholar] [CrossRef]

- Brasiliense, V.; Clausmeyer, J.; Berto, P.; Tessier, G.; Combellas, C.; Schuhmann, W.; Kanoufi, F. Monitoring Cobalt-Oxide Single Particle Electrochemistry with Subdiffraction Accuracy. Anal. Chem. 2018, 90, 7341–7348.6. [Google Scholar] [CrossRef]

- Mefford, J.T.; Akbashev, A.R.; Kang, M.; Bentley, C.L.; Gent, W.E.; Deng, H.D.; Alsem, D.H.; Yu, Y.-S.; Salmon, N.J.; Shapiro, D.A.; et al. Correlative operando microscopy of oxygen evolution electrocatalysts. Nature 2021, 593, 67–73. [Google Scholar] [CrossRef]

- Masa, J.; Andronescu, C.; Schuhmann, W. Electrocatalysis as the Nexus for Sustainable Renewable Energy: The Gordian Knot of Activity, Stability, and Selectivity. Angew. Chem. Int. Ed. 2020, 59, 15298–15312. [Google Scholar] [CrossRef]

- Stevenson, K.J.; Tschulik, K. A materials driven approach for understanding single entity nano impact electrochemistry. Curr. Opin. Electrochem. 2017, 6, 38–45. [Google Scholar] [CrossRef]

- Baker, L.A. Perspective and Prospectus on Single-Entity Electrochemistry. J. Am. Chem. Soc. 2018, 140, 15549–15559. [Google Scholar] [CrossRef]

- Bentley, C.L.; Kang, M.; Unwin, P.R. Nanoscale Surface Structure—Activity in Electrochemistry and Electrocatalysis. J. Am. Chem. Soc. 2019, 141, 2179–2193. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Qiu, G.; Li, X. Shape-controlled synthesis and properties of uniform spinel cobalt oxide nanocubes. Nanotechnology 2005, 16, 3035–3040. [Google Scholar] [CrossRef]

- Hu, L.; Peng, Q.; Li, Y. Selective Synthesis of Co3O4 Nanocrystal with Different Shape and Crystal Plane Effect on Catalytic Property for Methane Combustion. J. Am. Chem. Soc. 2008, 130, 16136–16137. [Google Scholar] [CrossRef]

- Linnemann, J.; Kanokkanchana, K.; Tschulik, K. Design Strategies for Electrocatalysts from an Electrochemist’s Perspective. ACS Catal. 2021, 11, 5318–5346. [Google Scholar] [CrossRef]

- Blanc, N.; Rurainsky, C.; Tschulik, K. Implications of resistance and mass transport limitations on the common Tafel approach at composite catalyst thin-film electrodes. J. Electroanal. Chem. 2020, 872, 114345. [Google Scholar] [CrossRef]

- Siegmund, D.; Blanc, N.; Smialkowski, M.; Tschulik, K.; Apfel, U.-P. Metal-Rich Chalcogenides for Electrocatalytic Hydrogen Evolution: Activity of Electrodes and Bulk Materials. ChemElectroChem 2020, 7, 1514–1527. [Google Scholar] [CrossRef]

- Brummel, O.; Libuda, J. Electrifying Oxide Model Catalysis: Complex Electrodes Based on Atomically-Defined Oxide Films. J. Catal. Lett. 2020, 150, 1546–1560. [Google Scholar] [CrossRef]

- Amin, H.M.A.; Bondue, C.J.; Eswara, S.; Kaiser, U.; Baltruschat, H. A Carbon-Free Ag −Co3O4 Composite as a Bifunctional Catalyst for Oxygen Reduction and Evolution: Spectroscopic, Microscopic and Electrochemical Characterization. Electrocatalysis 2017, 8, 540–553. [Google Scholar] [CrossRef]

- Jayabal, S.; Saranya, G.; Geng, D.; Lin, L.-Y.; Meng, X. Insight into the correlation of Pt—Support interactions with electrocatalytic activity and durability in fuel cells. J. Mater. Chem. A 2020, 8, 9420–9446. [Google Scholar] [CrossRef]

- Yeo, B.S.; Bell, A.T. Enhanced Activity of Gold-Supported Cobalt Oxide for the Electrochemical Evolution of Oxygen. J. Am. Chem. Soc. 2011, 133, 5587–5593. [Google Scholar] [CrossRef]

- Zhou, M.; Bao, S.; Bard, A.J. Probing Size and Substrate Effects on the Hydrogen Evolution Reaction by Single Isolated Pt Atoms, Atomic Clusters, and Nanoparticles. J. Am. Chem. Soc. 2019, 141, 7327–7332. [Google Scholar]

- Guilminot, E.; Corcella, A.; Chatenet, M.; Maillard, F. Comparing the thin-film rotating disk electrode and the ultramicroelectrode with cavity techniques to study carbon-supported platinum for proton exchange membrane fuel cell applications. J. Electroanal. Chem. 2007, 599, 111–120. [Google Scholar] [CrossRef]

- Sokolov, S.V.; Eloul, S.; Kätelhön, E.; Batchelor-McAuley, C.; Compton, R.G. Electrode—Particle impacts: A users guide. Phys. Chem. Chem. Phys. 2017, 19, 28–43. [Google Scholar] [CrossRef]

- Kwon, S.J.; Fan, F.-R.F.; Bard, A.J. Observing Iridium Oxide (IrOx) Single Nanoparticle Collisions at Ultramicroelectrodes. J. Am. Chem. Soc. 2010, 132, 13165–13167. [Google Scholar] [CrossRef] [PubMed]

- El Arrassi, A.; Liu, Z.; Evers, M.V.; Blanc, N.; Bendt, G.; Saddeler, S.; Tetzlaff, D.; Pohl, D.; Damm, C.; Schulz, S.; et al. Intrinsic Activity of Oxygen Evolution Catalysts Probed at Single CoFe2O4 Nanoparticles. J. Am. Chem. Soc. 2019, 141, 9197–9201. [Google Scholar] [CrossRef] [PubMed]

- Kätelhön, E.; Barnes, E.O.; Krause, K.J.; Wolfrum, B.; Compton, R.G. Equality of diffusion-limited chronoamperometric currents to equal area spherical and cubic nanoparticles on a supporting electrode surface. Chem. Phys. Lett. 2014, 595–596, 31–34. [Google Scholar] [CrossRef] [Green Version]

- Batchelor-McAuley, C.; Compton, R.G. Diffusion to a cube: A 3D implicit finite difference method. J. Electroanal. Chem. 2020, 877, 114607. [Google Scholar] [CrossRef]

- Amin, H.M.A.; Königshoven, P.; Hegemann, M.; Baltruschat, H. Role of Lattice Oxygen in the Oxygen Evolution Reaction on Co3O4: Isotope Exchange Determined Using a Small-Volume Differential Electrochemical Mass Spectrometry Cell Design. Anal. Chem. 2019, 91, 12653–12660. [Google Scholar] [CrossRef]

- Oh, H.-S.; Nong, H.N.; Reier, T.; Bergmann, A.; Gliech, M.; de Araújo, J.F.; Willinger, E.; Schlögl, R.; Teschner, D.; Strasser, P. Electrochemical Catalyst—Support Effects and Their Stabilizing Role for IrOx Nanoparticle Catalysts during the Oxygen Evolution Reaction. J. Am. Chem. Soc. 2016, 138, 12552–12563. [Google Scholar] [CrossRef]

- Frydendal, R.; Busch, M.; Halck, N.B.; Paoli, E.A.; Krtil, P.; Chorkendorff, I.; Rossmeisl, J. Enhancing Activity for the Oxygen Evolution Reaction: The Beneficial Interaction of Gold with Manganese and Cobalt Oxides. ChemCatChem 2015, 7, 149–154. [Google Scholar] [CrossRef]

- Fester, J.; Makoveev, A.; Grumelli, D.; Gutzler, R.; Sun, Z.; Rodríguez-Fernández, J.; Kern, K.; Lauritsen, J.V. The Structure of the Cobalt Oxide/Au Catalyst Interface in Electrochemical Water Splitting. Angew. Chem. Int. Ed. 2018, 57, 11893–11897. [Google Scholar] [CrossRef]

- Faisal, F.; Bertram, M.; Stumm, C.; Wähler, T.; Schuster, R.; Lykhach, Y.; Neitzel, A.; Skála, T.; Tsud, N.; Beranová, K.; et al. Electrocatalysis with Atomically Defined Model Systems: Metal—Support Interactions between Pt Nanoparticles and Co3O4(111) under Ultrahigh Vacuum and in Liquid Electrolytes. J. Phys. Chem. C 2018, 122, 20787–20799. [Google Scholar] [CrossRef]

- Reikowski, F.; Maroun, F.; Pacheco, I.; Wiegmann, T.; Allongue, P.; Stettner, J.; Magnussen, O.M. Operando Surface X-ray Diffraction Studies of Structurally Defined Co3O4 and CoOOH Thin Films during Oxygen Evolution. ACS Catal. 2019, 9, 3813821. [Google Scholar] [CrossRef]

- Bergmann, A.; Martinez-Moreno, E.; Teschner, D.; Chernev, P.; Gliech, M.; Ferreira de Araújo, J.; Reier, T.; Dau, H.; Strasser, P. Reversible amorphization and the catalytically active state of crystalline Co3O4 during oxygen evolution. Nat. Commun. 2015, 6, 8625. [Google Scholar]

- Yi, Y.; Weinberg, G.; Prenzel, M.; Greiner, M.; Heumann, S.; Becker, S.; Schlögl, R. Electrochemical corrosion of a glassy carbon electrode. Catal. Today 2017, 295, 32–40. [Google Scholar] [CrossRef]

- Lide, D.R. CRC Handbook of Chemistry and Physics, 87th ed.; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Corva, M.; Amin, H.M.A.; Blanc, N.; Linnemann, J.; Tschulik, K. Single Co3O4 Nanocubes Electrocatalyzing the Oxygen Evolution Reaction: Nano-Impact Insights into Intrinsic Activity and Support Effects. Int. J. Mol. Sci. 2021, 22, 13137. https://doi.org/10.3390/ijms222313137

Liu Z, Corva M, Amin HMA, Blanc N, Linnemann J, Tschulik K. Single Co3O4 Nanocubes Electrocatalyzing the Oxygen Evolution Reaction: Nano-Impact Insights into Intrinsic Activity and Support Effects. International Journal of Molecular Sciences. 2021; 22(23):13137. https://doi.org/10.3390/ijms222313137

Chicago/Turabian StyleLiu, Zhibin, Manuel Corva, Hatem M. A. Amin, Niclas Blanc, Julia Linnemann, and Kristina Tschulik. 2021. "Single Co3O4 Nanocubes Electrocatalyzing the Oxygen Evolution Reaction: Nano-Impact Insights into Intrinsic Activity and Support Effects" International Journal of Molecular Sciences 22, no. 23: 13137. https://doi.org/10.3390/ijms222313137

APA StyleLiu, Z., Corva, M., Amin, H. M. A., Blanc, N., Linnemann, J., & Tschulik, K. (2021). Single Co3O4 Nanocubes Electrocatalyzing the Oxygen Evolution Reaction: Nano-Impact Insights into Intrinsic Activity and Support Effects. International Journal of Molecular Sciences, 22(23), 13137. https://doi.org/10.3390/ijms222313137