Biocomposites of Epoxidized Natural Rubber/Poly(lactic acid) Modified with Natural Fillers (Part I)

Abstract

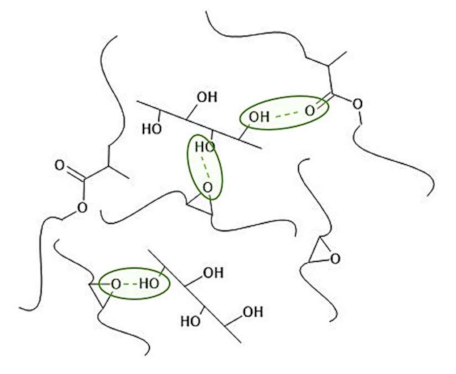

1. Introduction

2. Results and Discussion

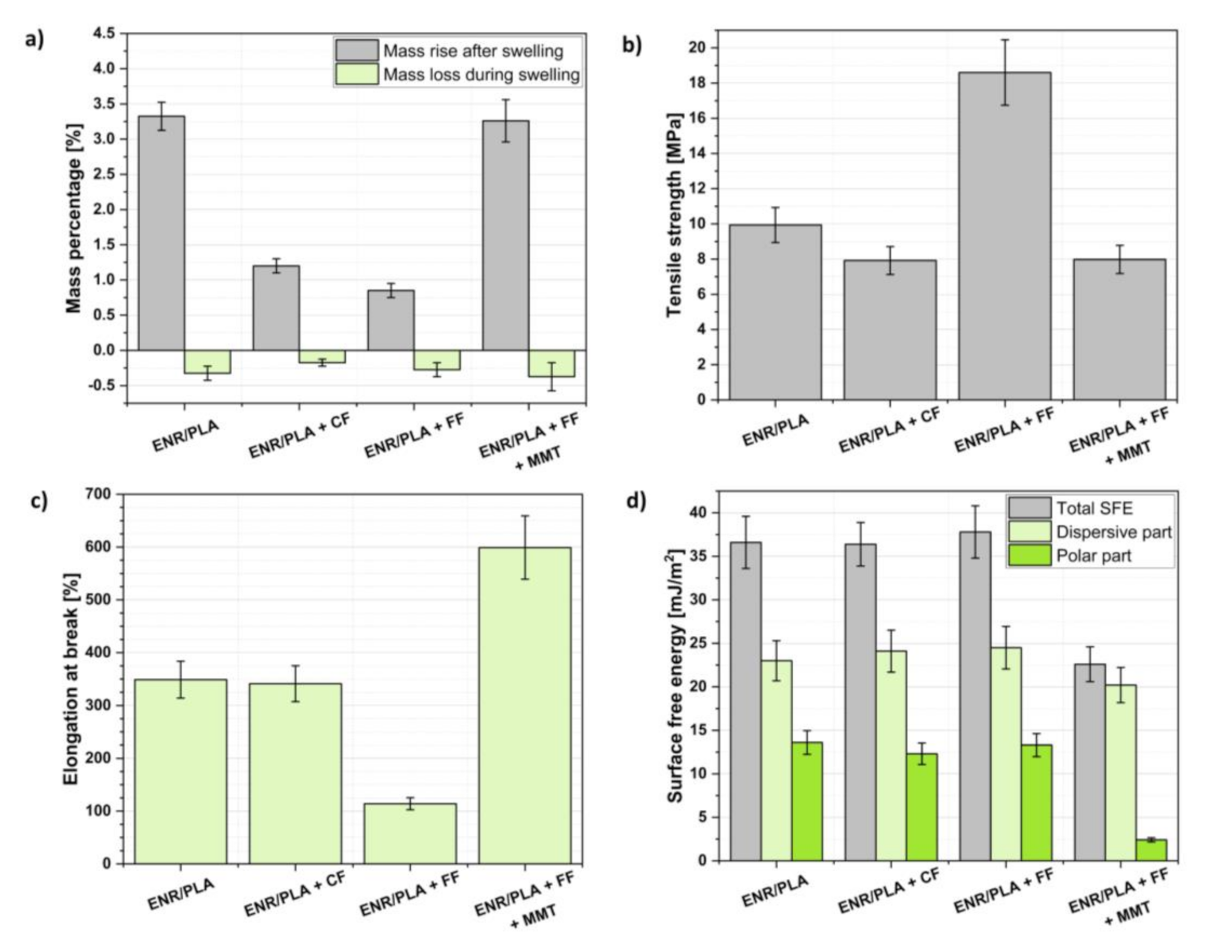

2.1. Characterization of Specimens Before the Accelerated Ageing Process

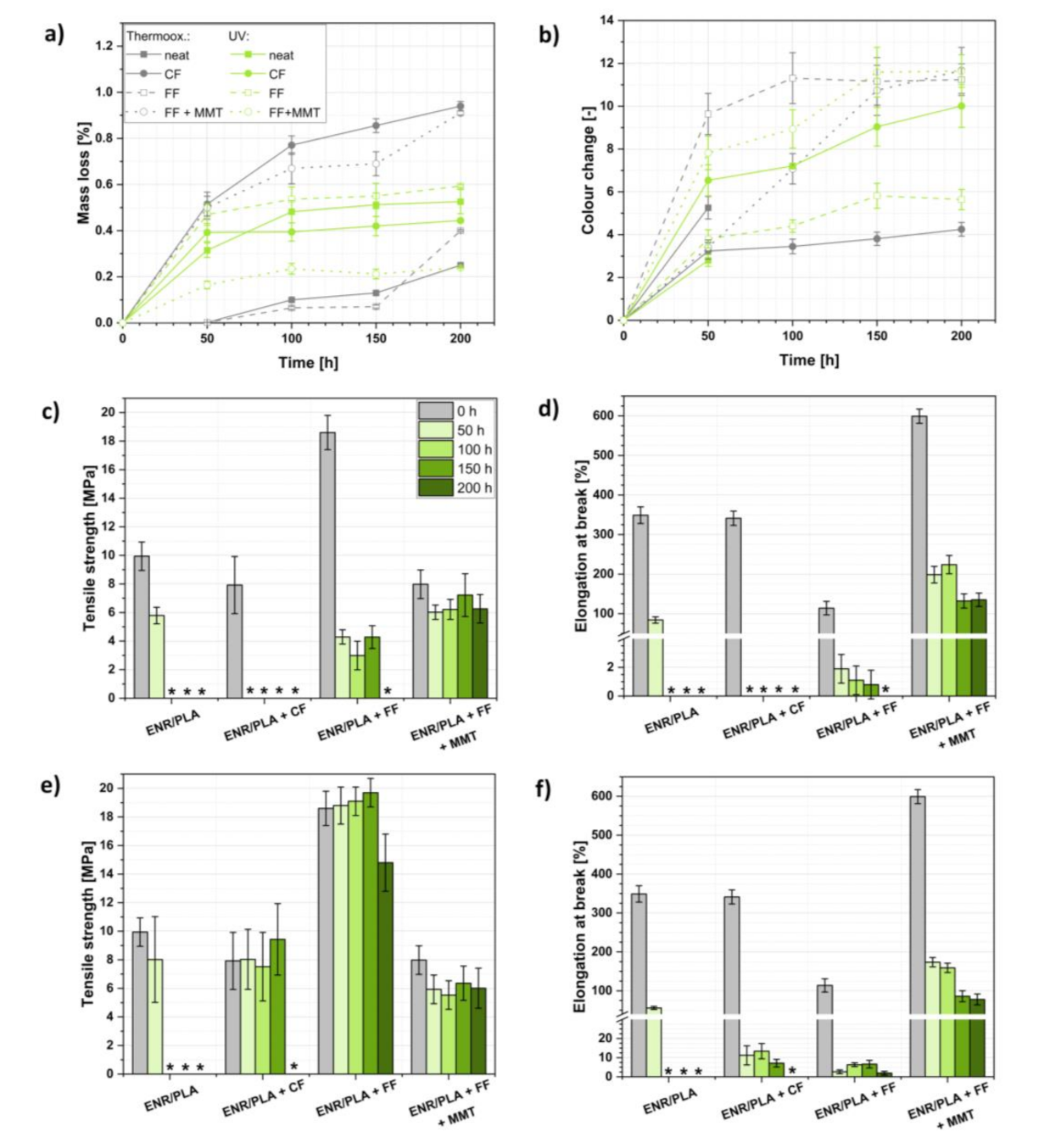

2.2. Characterization of the Aging Impact

2.3. Microorganism Growth Tests

3. Materials and Methods

3.1. Materials

3.2. Preparation of ENR/PLA Blend Samples

3.3. Accelerated Ageing of the Materials

3.3.1. Thermo-Oxidative Ageing

3.3.2. UV irradiation

3.4. Methods of Polymer Blend Sample Characterization

3.4.1. Swelling in Toluene

3.4.2. Contact Angle Measurement

3.4.3. Tensile Tests

3.4.4. Color Change

3.4.5. Mass Loss during the Degradation Process

3.5. Microorganism Growth Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Rayung, M.; Ibrahim, N.A.; Zainuddin, N.; Saad, W.Z.; Razak, N.I.A.; Chieng, B.W. The Effect of Fiber Bleaching Treatment on the Properties of Poly(lactic acid)/Oil Palm Empty Fruit Bunch Fiber Composites. Int. J. Mol. Sci. 2014, 15, 14728–14742. [Google Scholar] [CrossRef] [PubMed]

- Aliotta, L.; Gigante, V.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A. Evaluation of Mechanical and Interfacial Properties of Bio-Composites Based on Poly(Lactic Acid) with Natural Cellulose Fibers. Int. J. Mol. Sci. 2019, 20, 960. [Google Scholar] [CrossRef] [PubMed]

- Hamad, K.; Kaseem, M.; Ayyoob, M.; Joo, J.; Deri, F. Polylactic acid blends: The future of green, light and tough. Prog. Polym. Sci. 2018, 85, 83–127. [Google Scholar] [CrossRef]

- Müller, P.; Bere, J.; Fekete, E.; Móczó, J.; Nagy, B.; Kállay, M.; Gyarmati, B.; Pukánszky, B. Interactions, structure and properties in PLA/plasticized starch blends. Polymer 2016, 103, 9–18. [Google Scholar] [CrossRef]

- Bijarimi, M.; Ahmad, S.; Rasid, R. Mechanical, thermal and morphological properties of poly(lactic acid)/epoxidized natural rubber blends. J. Elastomers Plast. 2012, 46, 338–354. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Skórczewska, K.; Kloziński, A. Improving the toughness and thermal resistance of polyoxymeth-ylene/poly(lactic acid) blends: Evaluation of structure-properties correlation for reactive processing. Polymers 2020, 12, 307. [Google Scholar] [CrossRef] [PubMed]

- Formela, K.; Zedler, Ł.; Hejna, A.; Tercjak, A. Reactive extrusion of bio-based polymer blends and composites–current trends and future developments. Express Polym. Lett. 2018, 12, 24–57. [Google Scholar] [CrossRef]

- Yao, Q.; Cosme, J.G.; Xu, T.; Miszuk, J.M.; Picciani, P.H.; Fong, H.; Sun, H. Three dimensional electrospun PCL/PLA blend nanofibrous scaffolds with significantly improved stem cells osteogenic differentiation and cranial bone formation. Biomaterials 2017, 115, 115–127. [Google Scholar] [CrossRef]

- Ahmed, M.F.; Li, Y.; Yao, Z.; Cao, K.; Zeng, C. TPU/PLA blend foams: Enhanced foamability, structural stability, and implications for shape memory foams. J. Appl. Polym. Sci. 2019, 136, 1–12. [Google Scholar] [CrossRef]

- Siracusa, V.; Karpova, S.; Olkhov, A.; Zhulkina, A.; Kosenko, R.; Iordanskii, A. Gas Transport Phenomena and Polymer Dynamics in PHB/PLA Blend Films as Potential Packaging Materials. Polymers 2020, 12, 647. [Google Scholar] [CrossRef] [PubMed]

- Kwiecien, I.; Adamus, G.; Jiang, G.; Radecka, I.; Baldwin, T.C.; Khan, H.R.; Johnston, B.; Pennetta, V.; Hill, D.; Bretz, I.; et al. Biodegradable PBAT/PLA Blend with Bioactive MCPA-PHBV Conjugate Suppresses Weed Growth. Biomacromolecules 2018, 19, 511–520. [Google Scholar] [CrossRef]

- Sookprasert, P.; Hinchiranan, N. Morphology, mechanical and thermal properties of poly(lactic acid) (PLA)/natural rubber (NR) blends compatibilized by NR-graft-PLA. J. Mater. Res. 2017, 32, 788–800. [Google Scholar] [CrossRef]

- Ishida, S.; Nagasaki, R.; Chino, K.; Dong, T.; Inoue, Y. Toughening of poly(L-lactide) by melt blending with rubbers. J. Appl. Polym. Sci. 2009, 113, 558–566. [Google Scholar] [CrossRef]

- Bitinis, N.; Verdejo, R.; Cassagnau, P.; Lopez-Manchado, M. Structure and properties of polylactide/natural rubber blends. Mater. Chem. Phys. 2011, 129, 823–831. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, W.; Huang, Y.; Pan, Y.; Jiang, L.; Dan, Y.; Luo, Y.; Peng, Z. Thermal, mechanical and rheological properties of polylactide toughened by expoxidized natural rubber. Mater. Des. 2013, 45, 198–205. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A. Rigid Polyurethane Foams Based on BioPolyol and Additionally Reinforced with Silanized and Acetylated Walnut Shells for the Synthesis of Environmentally Friendly Insulating Materials. Materials 2020, 13, 3245. [Google Scholar] [CrossRef]

- Członka, S.; Kairyte, A.; Miedzinska, K.; Strakowska, A. Polyurethane Hybrid Composites Reinforced with Lavender Residue Functionalized with Kaolinite and Hydroxyapatite. Materials 2021, 14, 415. [Google Scholar] [CrossRef] [PubMed]

- Kairyte, A.; Kremensas, A.; Vaitkus, S.; Członka, S.; Strakowska, A. Fire suppression and thermal behavior of biobased rigid polyurethane foam filled with biomass incinerationwaste ash. Polymers 2020, 12, 683. [Google Scholar] [CrossRef]

- Bartos, A.; Anggono, J.; Farkas, Á.E.; Kun, D.; Soetaredjo, F.E.; Móczó, J.; Purwaningsih, H.; Pukánszky, B. Alkali treatment of lignocellulosic fibers extracted from sugarcane bagasse: Composition, structure, properties. Polym. Test. 2020, 88, 106549. [Google Scholar] [CrossRef]

- Szadkowski, B.; Kuśmierek, M.; Rybiński, P.; Zukowski, W.; Marzec, A. Application of earth pigments in cycloolefin co-polymer: Protection against combustion and accelerated aging in the full sunlight spectrum. Materials 2020, 13, 3381. [Google Scholar] [CrossRef]

- Blessing, B.; Trout, C.; Morales, A.; Rybacki, K.; Love, S.A.; Lamoureux, G.; O’Malley, S.M.; Hu, X.; la Cruz, D.S.-D. The Impact of Composition and Morphology on Ionic Conductivity of Silk/Cellulose Bio-Composites Fabricated from Ionic Liquid and Varying Percentages of Coagulation Agents. Int. J. Mol. Sci. 2020, 21, 4695. [Google Scholar] [CrossRef]

- Porras, A.; Maranon, A. Development and characterization of a laminate composite material from polylactic acid (PLA) and woven bamboo fabric. Compos. Part B Eng. 2012, 43, 2782–2788. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I.; Madaan, J. Development and characterization of PLA-based green composites: A review. J. Thermo-Plast. Compos. Mater. 2014, 27, 52–81. [Google Scholar] [CrossRef]

- Dong, Y.; Ghataura, A.; Takagi, H.; Haroosh, H.J.; Nakagaito, A.N.; Lau, K.-T. Polylactic acid (PLA) biocomposites reinforced with coir fibres: Evaluation of mechanical performance and multifunctional properties. Compos. Part A Appl. Sci. Manuf. 2014, 63, 76–84. [Google Scholar] [CrossRef]

- Shumao, L.; Jie, R.; Hua, Y.; Tao, Y.; Weizhong, Y. Influence of ammonium polyphosphate on the flame retardancy andmechanical properties of ramie fiber-reinforced poly(lactic acid) biocomposites. Polym. Int. 2010, 59, 242–248. [Google Scholar] [CrossRef]

- Plackett, D.; Andersen, T.L.; Pedersen, W.B.; Nielsen, L. Biodegradable composites based on l-polylactide and jute fibres. Compos. Sci. Technol. 2003, 63, 1287–1296. [Google Scholar] [CrossRef]

- Csikós, Á.; Faludi, G.; Domján, A.; Renner, K.; Móczó, J.; Pukánszky, B. Modification of interfacial adhesion with a functionalized polymer in PLA/wood composites. Eur. Polym. J. 2015, 68, 592–600. [Google Scholar] [CrossRef]

- Hegyesi, N.; Zhang, Y.; Kohári, A.; Polyák, P.; Sui, X.; Pukánszky, B. Enzymatic degradation of PLA/cellulose nanocrystal composites. Ind. Crop. Prod. 2019, 141, 111799. [Google Scholar] [CrossRef]

- Csizmadia, R.; Faludi, G.; Renner, K.; Moczo, J.; Pukanszky, B. PLA/wood biocomposites: Improving composite strength by chemical treatment of the fibers. Compos. Part A Appl. Sci. Manuf. 2013, 53, 46–53. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Szostak, M.; Barczewski, M.; Łuczak, P. Cork-wood hybrid filler system for polypropylene and poly(lactic acid) based injection molded composites. Structure evaluation and mechanical performance. Compos. Part B Eng. 2019, 163, 655–668. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O.; Matykiewicz, D.; Skórczewska, K.; Lewandowski, K.; Andrzejewski, J.; Piasecki, A. Development of polylactide composites with improved thermomechanical properties by simultaneous use of basalt powder and a nucleating agent. Polym. Compos. 2020, 41, 2947–2957. [Google Scholar] [CrossRef]

- Barczewski, M.; Sałasińska, K.; Szulc, J. Application of sunflower husk, hazelnut shell and walnut shell as waste agricultural fillers for epoxy-based composites: A study into mechanical behavior related to structural and rheological properties. Polym. Test. 2019, 75, 1–11. [Google Scholar] [CrossRef]

- Trifol, J.; Plackett, D.; Sillard, C.; Szabo, P.; Bras, J.; Daugaard, A.E. Hybrid poly(lactic acid)/nanocellulose/nanoclay composites with synergistically enhanced barrier properties and improved thermomechanical resistance. Polym. Int. 2016, 65, 988–995. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M.; Skórczewska, K.; Szulc, J.; Kloziński, A. Accelerated Weathering of Polylactide-Based Composites Filled with Linseed Cake: The Influence of Time and Oil Content within the Filler. Polymers 2019, 11, 1495. [Google Scholar] [CrossRef]

- Boubekeur, B.; Belhaneche-Bensemra, N.; Massardier, V. Valorization of waste jute fibers in developing low-density polyethylene /poly lactic acid bio-based composites. J. Reinf. Plast. Compos. 2015, 34, 649–661. [Google Scholar] [CrossRef]

- Bocz, K.; Szolnoki, B.; Marosi, A.; Tábi, T.; Wladyka-Przybylak, M.; Marosi, G. Flax fibre reinforced PLA/TPS biocomposites flame retarded with multifunctional additive system. Polym. Degrad. Stab. 2014, 106, 63–73. [Google Scholar] [CrossRef]

- Xu, C.; Zheng, Z.; Wu, W.; Fu, L.; Lin, B. Design of healable epoxy composite based on β-hydroxyl esters crosslinked networks by using carboxylated cellulose nanocrystals as crosslinker. Compos. Sci. Technol. 2019, 181, 107677. [Google Scholar] [CrossRef]

- Harani, H.; Fellahi, S.; Bakar, M. Toughening of epoxy resin using hydroxyl-terminated polyesters. J. Appl. Polym. Sci. 1999, 71, 29–38. [Google Scholar] [CrossRef]

- Liu, H.; Fang, Z.; Peng, M.; Shen, L.; Wang, Y. The effects of irradiation cross-linking on the thermal degradation and flame-retardant properties of the HDPE/EVA/magnesium hydroxide composites. Radiat. Phys. Chem. 2009, 78, 922–926. [Google Scholar] [CrossRef]

- Żołek-Tryznowska, Z.; Prica, M.; Pavlović, Ž.; Cveticanin, L.; Annusik, T. The influence of aging on surface free energy of corona treated packaging films. Polym. Test. 2020, 89, 106629. [Google Scholar] [CrossRef]

- Homma, H.; Kuroyagi, T.; Mirley, C.L.; Ronzello, J.; Boggs, S.A. Diffusion of low molecular weight siloxane from bulk to surface [outdoor insulators]. In Proceedings of the 1996 IEEE International Symposium on Electrical Insulation, Montreal, QC, Canada, 16–19 June 1996; pp. 279–282. [Google Scholar]

- Bismarck, A.; Aranberri-Askargorta, I.; Lampke, T.; Wielage, B.; Stamboulis, A.; Shenderovich, I.; Limbach, H.-H. Surface characterization of flax, hemp and cellulose fibers; Surface properties and the water uptake behavior. Polym. Compos. 2002, 23, 872–894. [Google Scholar] [CrossRef]

- Awal, A.; Rana, M.; Sain, M. Thermorheological and mechanical properties of cellulose reinforced PLA bio-composites. Mech. Mater. 2015, 80, 87–95. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Pongwisuthiruchte, A.; Potiyaraj, P. Natural Rubber/Microcrystalline Cellulose Composites with Epoxidized Natural Rubber as Compatibilizer. Rubber Chem. Technol. 2019, 92, 378–387. [Google Scholar] [CrossRef]

- Selvakumar, V.; Palanikumar, K.; Palanivelu, K. Studies on Mechanical Characterization of Polypropylene/Na-MMT Nanocomposites. J. Miner. Mater. Charact. Eng. 2010, 9, 671–681. [Google Scholar] [CrossRef]

- Bee, S.-T.; Abdullah, M.; Sin, L.T.; Rahmat, A. Polymer nanocomposites based on silylated-montmorillonite: A review. Prog. Polym. Sci. 2018, 85, 57–82. [Google Scholar] [CrossRef]

- Keawkumay, C.; Jarukumjorn, K.; Wittayakun, J.; Suppakarn, N. Influences of surfactant content and type on physical properties of natural rubber/organoclay nanocomposites. J. Polym. Res. 2012, 19, 19. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, J.; Ma, Y.; Agarwal, U.S. Study on mechanical properties, thermal stability and crystallization behavior of PET/MMT nanocomposites. Compos. Part B Eng. 2006, 37, 399–407. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, J.; Wolcott, M.P. Comparison of polylactide/nano-sized calcium carbonate and polylactide/montmorillonite composites: Reinforcing effects and toughening mechanisms. Polymers 2007, 48, 7632–7644. [Google Scholar] [CrossRef]

- Papageorgiou, G.; Achilias, D.; Nanaki, S.; Beslikas, T.; Bikiaris, D. PLA nanocomposites: Effect of filler type on non-isothermal crystallization. Thermochim. Acta 2010, 511, 129–139. [Google Scholar] [CrossRef]

- Mathew, A.P.; Oksman, K.; Sain, M. The effect of morphology and chemical characteristics of cellulose reinforcements on the crystallinity of polylactic acid. J. Appl. Polym. Sci. 2006, 101, 300–310. [Google Scholar] [CrossRef]

- Seguchi, T.; Tamura, K.; Shimada, A.; Sugimoto, M.; Kudoh, H. Mechanism of antioxidant interaction on polymer oxidation by thermal and radiation ageing. Radiat. Phys. Chem. 2012, 81, 1747–1751. [Google Scholar] [CrossRef]

- Sun, C.C. Mechanism of moisture induced variations in true density and compaction properties of microcrystalline cellulose. Int. J. Pharm. 2008, 346, 93–101. [Google Scholar] [CrossRef] [PubMed]

- Oleyaei, S.A.; Almasi, H.; Ghanbarzadeh, B.; Moayedi, A.A. Synergistic reinforcing effect of TiO 2 and montmorillonite on potato starch nanocomposite films: Thermal, mechanical and barrier properties. Carbohydr. Polym. 2016, 152, 253–262. [Google Scholar] [CrossRef]

- Ramesh, P.; Prasad, B.D.; Narayana, K.L. Effect of MMT Clay on Mechanical, Thermal and Barrier Properties of Treated Aloevera Fiber/ PLA-Hybrid Biocomposites. Silicon 2020, 12, 1751–1760. [Google Scholar] [CrossRef]

- Othman, S.H.; Ling, H.N.; Talib, R.A.; Naim, M.N.; Risyon, N.P. Saifullah PLA/MMT and PLA/Halloysite Bio-Nanocomposite Films: Mechanical, Barrier, and Transparency. J. Nano Res. 2019, 59, 77–93. [Google Scholar] [CrossRef]

- Marzec, A.; Szadkowski, B.; Kuśmierek, M.; Rogowski, J.; Maniukiewicz, W.; Rybiński, P.; Zaborski, M. Impact of organic-inorganic color additive on the properties of ethylene-norbornene copolymer. Polym. Test. 2020, 82, 106290. [Google Scholar] [CrossRef]

- Intharapat, P.; Kongnoo, A.; Kateungngan, K. The Potential of Chicken Eggshell Waste as a Bio-filler Filled Epoxidized Natural Rubber (ENR) Composite and its Properties. J. Polym. Environ. 2013, 21, 245–258. [Google Scholar] [CrossRef]

- Pongdong, W.; Nakason, C.; Kummerlöwe, C.; Vennemann, N. Influence of filler from a renewable resource and silane coupling agent on the properties of epoxidized natural rubber vulcanizates. J. Chem. 2015, 2015. [Google Scholar] [CrossRef]

| Sample | Tensile Tension [MPa] at Elongation of: | ||

|---|---|---|---|

| 100% | 200% | 300% | |

| ENR/PLA | 4.5 ± 0.2 | 6.7 ± 0.3 | 8.8 ± 0.2 |

| ENR/PLA + CF | 5.9 ± 0.2 | 6.6 ± 0.4 | 7.7 ± 0.5 |

| ENR/PLA + FF | 16.2 ± 0.4 | ----- | ----- |

| ENR/PLA + FF + MMT | 5.0 ± 0.5 | 6.1 ± 0.2 | 6.6 ± 0.3 |

| Sample | Contact Angle [°] | |

|---|---|---|

| Water | Diiodomethane | |

| ENR/PLA | 70 ± 3 | 57 ± 2 |

| ENR/PLA + CF | 71 ± 3 | 56 ± 2 |

| ENR/PLA + FF | 69 ± 1 | 55 ± 3 |

| ENR/PLA + FF + MMT | 97 ± 2 | 71 ± 2 |

| Sample | Whiteness index Wi [-] – thermooxidation | ||||

| 0 h | 50 h | 100 h | 150 h | 200 h | |

| ENR/PLA | 40 ± 4 | 37 ± 1 | * | * | * |

| ENR/PLA + CF | 41 ± 3 | 38 ± 5 | 39 ± 2 | 38 ± 3 | 38 ± 2 |

| ENR/PLA + FF | 41 ± 2 | 37 ± 3 | 36 ± 2 | 35 ± 4 | 39 ± 2 |

| ENR/PLA + FF + MMT | 46 ± 2 | 48 ± 2 | 41 ± 4 | 40 ± 1 | 40 ± 3 |

| Sample | Whiteness index Wi [-] – UV irradiation | ||||

| 0 h | 50 h | 100 h | 150 h | 200 h | |

| ENR/PLA | 40 ± 4 | 42 ± 2 | * | * | * |

| ENR/PLA + CF | 41 ± 3 | 40 ± 3 | 42 ± 1 | 41 ± 2 | 48 ± 4 |

| ENR/PLA + FF | 41 ± 2 | 41 ± 2 | 42 ± 2 | 40 ± 2 | 42 ± 2 |

| ENR/PLA + FF + MMT | 46 ± 2 | 42 ± 3 | 41 ± 2 | 40 ± 3 | 45 ± 2 |

| Sample | Chroma Cab [-] – thermooxidation | ||||

| 0 h | 50 h | 100 h | 150 h | 200 h | |

| ENR/PLA | 45 ± 2 | 50 ± 4 | * | * | * |

| ENR/PLA + CF | 44 ± 2 | 46 ± 2 | 44 ± 1 | 47 ± 2 | 48 ± 4 |

| ENR/PLA + FF | 47 ± 3 | 45 ± 3 | 45 ± 3 | 47 ± 2 | 46 ± 3 |

| ENR/PLA + FF + MMT | 43 ± 2 | 44 ± 1 | 47 ± 3 | 42 ± 2 | 46 ± 2 |

| Sample | Chroma Cab [-] – UV irradiation | ||||

| 0 h | 50 h | 100 h | 150 h | 200 h | |

| ENR/PLA | 45 ± 2 | 46 ± 2 | * | * | * |

| ENR/PLA + CF | 44 ± 2 | 39 ± 3 | 43 ± 2 | 36 ± 2 | 36 ± 2 |

| ENR/PLA + FF | 47 ± 3 | 42 ± 2 | 43 ± 3 | 40 ± 1 | 41 ± 2 |

| ENR/PLA + FF + MMT | 43 ± 2 | 43 ± 3 | 43 ± 2 | 40 ± 3 | 40 ± 1 |

| Sample | Hue angle hab [°] – thermooxidation | ||||

| 0 h | 50 h | 100 h | 150 h | 200 h | |

| ENR/PLA | 83 ± 4 | 76 ± 2 | * | * | * |

| ENR/PLA + CF | 75 ± 3 | 73 ± 4 | 73 ± 3 | 74 ± 4 | 73 ± 3 |

| ENR/PLA + FF | 81 ± 3 | 76 ± 3 | 75 ± 2 | 74 ± 2 | 77 ± 2 |

| ENR/PLA + FF + MMT | 82 ± 2 | 81 ± 2 | 77 ± 3 | 73 ± 3 | 74 ± 2 |

| Sample | Hue angle hab [°] – thermooxidation | ||||

| 0 h | 50 h | 100 h | 150 h | 200 h | |

| ENR/PLA | 83 ± 4 | 78 ± 3 | * | * | * |

| ENR/PLA + CF | 75 ± 3 | 74 ± 3 | 75 ± 2 | 74 ± 3 | 71 ± 2 |

| ENR/PLA + FF | 81 ± 3 | 78 ± 3 | 79 ± 2 | 79 ± 1 | 79 ± 2 |

| ENR/PLA + FF + MMT | 82 ± 2 | 77 ± 2 | 75 ± 2 | 74 ± 3 | 77 ± 2 |

| Sample | Aging coefficient K [-]—thermo-oxidation | |||

| 50 h | 100 h | 150 h | 200 h | |

| ENR/PLA | 0.14 ± 0.06 | * | * | * |

| ENR/PLA + CF | * | * | * | * |

| ENR/PLA + FF | 0.004 ± 0.002 | 0.002 ± 0.001 | 0.002 ± 0.001 | * |

| ENR/PLA + FF + MMT | 0.3 ± 0.1 | 0.3 ± 0.1 | 0.20 ± 0,08 | 0.20 ± 0,07 |

| Sample | Ageing coefficient K [-]—UV irradiation | |||

| 50 h | 100 h | 150 h | 200 h | |

| ENR/PLA | 0.13 ± 0.05 | * | * | * |

| ENR/PLA + CF | 0.03 ± 0.01 | 0.06 ± 0.03 | 0.02 ± 0.01 | * |

| ENR/PLA + FF | 0.02 ± 0.01 | 0.06 ± 0.02 | 0.06 ± 0.02 | 0.01 ± 0.01 |

| ENR/PLA + FF + MMT | 0.2 ± 0.1 | 0.18 ± 0.07 | 0.15 ± 0.05 | 0.21 ± 0.08 |

| Sample | Resistance to Moulds | Fungistatic Effect | |||||

|---|---|---|---|---|---|---|---|

| Method A | Method B | Method B’ | |||||

| MGE [-] | Picture | MGE [-] | Picture | MGE [-] | Picture | ||

| ENR/PLA | 2 |  | 4 |  | 3 |  | |

| ENR/PLA + CF | 3 |  | 5 |  | 5 |  | |

| ENR/PLA + FF | 5 |  | 4 |  | 3 |  | |

| ENR/PLA + FF + MMT | 5 |  | 4 |  | 3 |  | |

| Sample | Polymer Mixture Composition [phr] | |||||||

|---|---|---|---|---|---|---|---|---|

| ENR | PLA | LA | DMI | EH | CF | FF | MMT | |

| ENR/PLA | 100 | 75 | 3 | 0.6 | 0.6 | ---- | ---- | ---- |

| ENR/PLA + CF | 100 | 75 | 3 | 0.6 | 0.6 | 25 | ---- | ---- |

| ENR/PLA + FF | 100 | 75 | 3 | 0.6 | 0.6 | ---- | 25 | ---- |

| ENR/PLA + FF + MMT | 100 | 75 | 3 | 0.6 | 0.6 | ---- | 12.5 | 12.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masek, A.; Cichosz, S.; Piotrowska, M. Biocomposites of Epoxidized Natural Rubber/Poly(lactic acid) Modified with Natural Fillers (Part I). Int. J. Mol. Sci. 2021, 22, 3150. https://doi.org/10.3390/ijms22063150

Masek A, Cichosz S, Piotrowska M. Biocomposites of Epoxidized Natural Rubber/Poly(lactic acid) Modified with Natural Fillers (Part I). International Journal of Molecular Sciences. 2021; 22(6):3150. https://doi.org/10.3390/ijms22063150

Chicago/Turabian StyleMasek, Anna, Stefan Cichosz, and Małgorzata Piotrowska. 2021. "Biocomposites of Epoxidized Natural Rubber/Poly(lactic acid) Modified with Natural Fillers (Part I)" International Journal of Molecular Sciences 22, no. 6: 3150. https://doi.org/10.3390/ijms22063150

APA StyleMasek, A., Cichosz, S., & Piotrowska, M. (2021). Biocomposites of Epoxidized Natural Rubber/Poly(lactic acid) Modified with Natural Fillers (Part I). International Journal of Molecular Sciences, 22(6), 3150. https://doi.org/10.3390/ijms22063150