Design and Practical Considerations for Active Polymeric Films in Food Packaging

Abstract

:1. Introduction

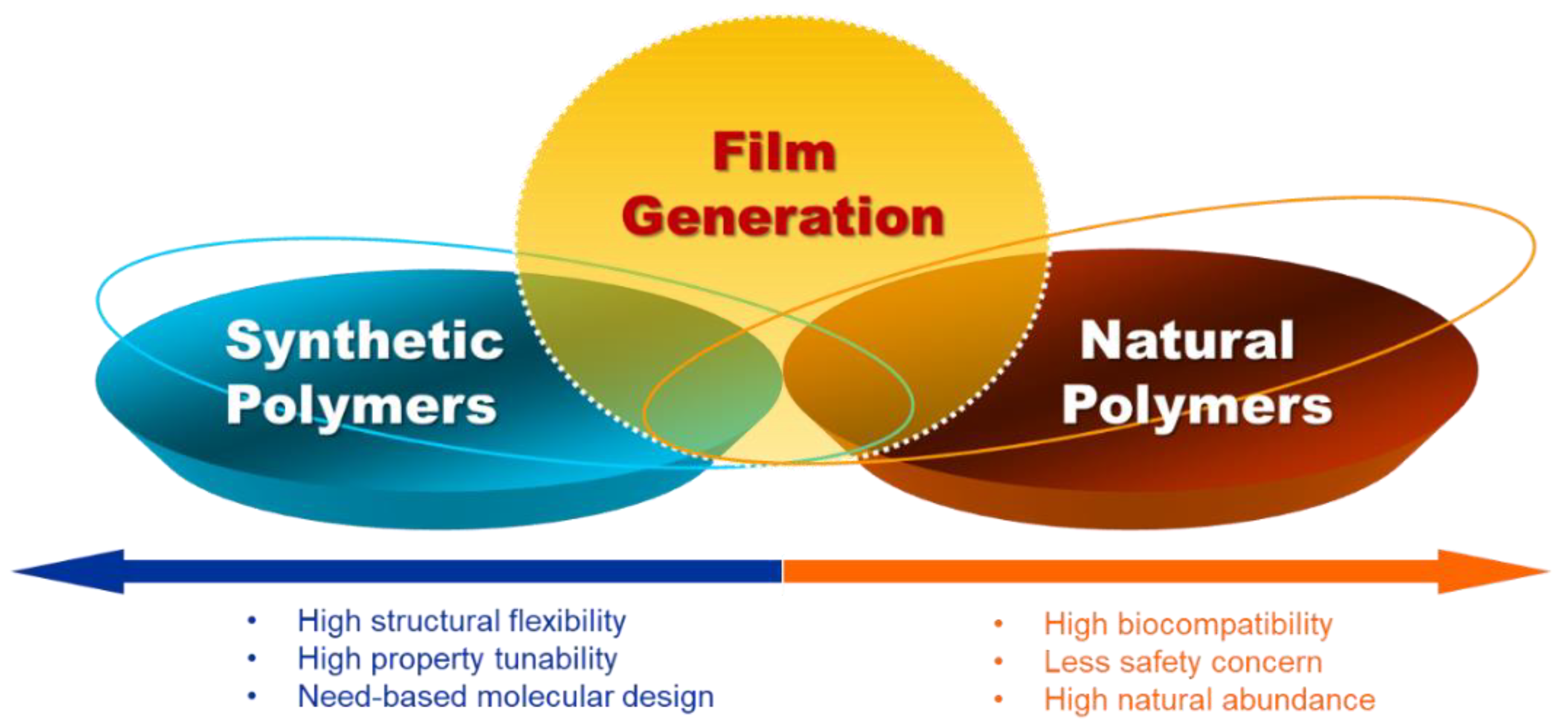

2. Design of Film Compositions for Food Packaging

3. Strategies for the Production of Polymeric Films

3.1. Solution Casting

3.2. Melt Extrusion

3.3. Electrospinning

4. Optimization of Film Properties for Food Packaging

4.1. Concentrations of an Active Ingredient

4.2. Nature and Loading of an Active Ingredient

5. Practical Considerations for Applications in Active Food Packaging

6. Environmental Sustainability of Active Food Packaging

7. Concluding Remarks and Outlooks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Parhi, A.; Tang, J.M.; Sablani, S.S. Functionality of ultra-high barrier metal oxide-coated polymer films for in-package, thermally sterilized food products. Food Packag. Shelf Life 2020, 25, 100514. [Google Scholar] [CrossRef]

- de Carvalho, A.P.A.; Conte, C.A. Green strategies for active food packagings: A systematic review on active properties of graphene-based nanomaterials and biodegradable polymers. Trends Food Sci. Technol. 2020, 103, 130–143. [Google Scholar] [CrossRef]

- Hu, K.Q.; Huyan, Z.Y.; Ding, S.X.; Dong, Y.Y.; Yu, X.Z. Investigation on food packaging polymers: Effects on vegetable oil oxidation. Food Chem. 2020, 315, 126299. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, S.S.; Romani, V.P.; Filipini, G.D.; Martins, V.G. Chia seeds to develop new biodegradable polymers for food packaging: Properties and biodegradability. Polym. Eng. Sci. 2020, 60, 2214–2223. [Google Scholar] [CrossRef]

- Diez-Pascual, A.M. Antimicrobial polymer-based materials for food packaging applications. Polymers 2020, 12, 731. [Google Scholar] [CrossRef] [Green Version]

- Lai, W.F.; Huang, E.M.; Wong, W.T. A gel-forming clusteroluminogenic polymer with tunable emission behavior as a sustained-release carrier enabling real-time tracking during bioactive agent delivery. Appl. Mater. Today 2020, 21, 100876. [Google Scholar] [CrossRef]

- Lai, W.F. Non-conjugated polymers with intrinsic luminescence for drug delivery. J. Drug Deliv. Sci. Technol. 2020, 59, 101916. [Google Scholar] [CrossRef]

- Li, T.; Shang, D.; Gao, S.; Wang, B.; Kong, H.; Yang, G.; Shu, W.; Xu, P.; Wei, G. Two-dimensional material-based electrochemical sensors/biosensors for food safety and biomolecular detection. Biosensors 2022, 12, 314. [Google Scholar] [CrossRef]

- Li, X.; Yue, X.; Huang, Q.; Zhang, B. Effects of wet-media milling on multi-scale structures and in vitro digestion of tapioca starch and the structure-digestion relationship. Carbohydr. Polym. 2022, 284, 119176. [Google Scholar] [CrossRef]

- Tran, T.N.; Mai, B.T.; Setti, C.; Athanassiou, A. Transparent bioplastic derived from CO2-based polymer functionalized with oregano waste extract toward active food packaging. ACS Appl. Mater. Int. 2020, 12, 46667–46677. [Google Scholar] [CrossRef]

- Makvandi, P.; Iftekhar, S.; Pizzetti, F.; Zarepour, A.; Zare, E.N.; Ashrafizadeh, M.; Agarwal, T.; Padil, V.V.T.; Mohammadinejad, R.; Sillanpaa, M.; et al. Functionalization of polymers and nanomaterials for water treatment, food packaging, textile and biomedical applications: A review. Environ. Chem. Lett. 2021, 19, 583–611. [Google Scholar] [CrossRef]

- Topuz, F.; Uyar, T. Antioxidant, antibacterial and antifungal electrospun nanofibers for food packaging applications. Food Res. Int. 2020, 130, 108927. [Google Scholar] [CrossRef] [PubMed]

- Nesic, A.; Cabrera-Barjas, G.; Dimitrijevic-Brankovic, S.; Davidovic, S.; Radovanovic, N.; Delattre, C. Prospect of polysaccharide-based materials as advanced food packaging. Molecules 2019, 25, 135. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, T.; Qian, Y.; Wei, J.; Zhou, C. Polymeric antimicrobial food packaging and its applications. Polymers 2019, 11, 560. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Chen, M.; Xu, C.; Yam, K.L. Critical review of controlled release packaging to improve food safety and quality. Crit. Rev. Food Sci. Nutr. 2019, 59, 2386–2399. [Google Scholar] [CrossRef]

- Lai, W.F.; Zhao, S.; Chiou, J. Antibacterial and clusteroluminogenic hypromellose-graft-chitosan-based polyelectrolyte complex films with high functional flexibility for food packaging. Carbohydr. Polym. 2021, 271, 118447. [Google Scholar] [CrossRef]

- Lai, W.F.; Wong, W.T. Edible clusteroluminogenic films obtained from starch of different botanical origins for food packaging and quality management of frozen foods. Membranes 2022, 12, 437. [Google Scholar] [CrossRef]

- Lai, W.F. Design of polymeric films for antioxidant active food packaging. Int. J. Mol. Sci. 2021, 23, 12. [Google Scholar] [CrossRef]

- Velazquez-Contreras, F.; Zamora-Ledezma, C.; Lopez-Gonzalez, I.; Meseguer-Olmo, L.; Nunez-Delicado, E.; Gabaldon, J.A. Cyclodextrins in polymer-based active food packaging: A fresh look at nontoxic, biodegradable, and sustainable technology trends. Polymers 2021, 14, 104. [Google Scholar] [CrossRef]

- Roy, S.; Priyadarshi, R.; Ezati, P.; Rhim, J.W. Curcumin and its uses in active and smart food packaging applications—A comprehensive review. Food Chem. 2022, 375, 131885. [Google Scholar] [CrossRef]

- Ozdemir, M.; Floros, J.D. Active food packaging technologies. Crit. Rev. Food Sci. Nutr. 2004, 44, 185–193. [Google Scholar] [CrossRef] [PubMed]

- Basavegowda, N.; Baek, K.H. Advances in Functional Biopolymer-Based Nanocomposites for Active Food Packaging Applications. Polymers 2021, 13, 4198. [Google Scholar] [CrossRef] [PubMed]

- Zaitoon, A.; Luo, X.; Lim, L.T. Triggered and controlled release of active gaseous/volatile compounds for active packaging applications of agri-food products: A review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 541–579. [Google Scholar] [CrossRef] [PubMed]

- Sultana, A.; Kathuria, A.; Gaikwad, K.K. Metal-organic frameworks for active food packaging. A review. Environ. Chem. Lett. 2022, 20, 1479–1495. [Google Scholar] [CrossRef]

- Raul, P.K.; Thakuria, A.; Das, B.; Devi, R.R.; Tiwari, G.; Yellappa, C.; Kamboj, D.V. Carbon nanostructures as antibacterials and active food-packaging materials: A review. ACS Omega 2022, 7, 11555–11559. [Google Scholar] [CrossRef]

- Ludwicka, K.; Kaczmarek, M.; Bialkowska, A. Bacterial nanocellulose—A biobased polymer for active and intelligent food packaging applications: Recent advances and developments. Polymers 2020, 12, 2209. [Google Scholar] [CrossRef]

- Krasniewska, K.; Galus, S.; Gniewosz, M. Biopolymers-based materials containing silver nanoparticles as active packaging for food applications—A review. Int. J. Mol. Sci. 2020, 21, 698. [Google Scholar] [CrossRef] [Green Version]

- Mahmud, J.; Sarmast, E.; Shankar, S.; Lacroix, M. Advantages of nanotechnology developments in active food packaging. Food Res. Int. 2022, 154, 111023. [Google Scholar] [CrossRef]

- Hamed, I.; Jakobsen, A.N.; Lerfall, J. Sustainable edible packaging systems based on active compounds from food processing byproducts: A review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 198–226. [Google Scholar] [CrossRef]

- Casalini, S.; Giacinti Baschetti, M. The use of essential oils in chitosan or cellulose-based materials for the production of active food packaging solutions: A review. J. Sci. Food Agric. 2022. [Google Scholar] [CrossRef]

- Vianna, T.C.; Marinho, C.O.; Marangoni Junior, L.; Ibrahim, S.A.; Vieira, R.P. Essential oils as additives in active starch-based food packaging films: A review. Int. J. Biol. Macromol. 2021, 182, 1803–1819. [Google Scholar] [CrossRef] [PubMed]

- Soltani Firouz, M.; Mohi-Alden, K.; Omid, M. A critical review on intelligent and active packaging in the food industry: Research and development. Food Res. Int. 2021, 141, 110113. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Barkauskaite, S.; Jaiswal, A.K.; Jaiswal, S. Essential oils as additives in active food packaging. Food Chem. 2021, 343, 128403. [Google Scholar] [CrossRef] [PubMed]

- Kadam, A.A.; Singh, S.; Gaikwad, K.K. Chitosan based antioxidant films incorporated with pine needles (Cedrus deodara) extract for active food packaging applications. Food Control. 2021, 124, 107877. [Google Scholar] [CrossRef]

- Rambabu, K.; Bharath, G.; Banat, F.; Show, P.L.; Cocoletzi, H.H. Mango leaf extract incorporated chitosan antioxidant film for active food packaging. Int. J. Biol. Macromol. 2019, 126, 1234–1243. [Google Scholar]

- Ju, A.; Baek, S.K.; Kim, S.; Song, K.B. Development of an antioxidative packaging film based on khorasan wheat starch containing moringa leaf extract. Food Sci. Biotechnol. 2019, 28, 1057–1063. [Google Scholar] [CrossRef]

- Bastante, C.C.; Silva, N.H.C.S.; Cardoso, L.C.; Serrano, C.M.; Martínez de la Ossa, E.J.; Freire, C.S.R.; Vilela, C. Biobased films of nanocellulose and mango leaf extract for active food packaging: Supercritical impregnation versus solvent casting. Food Hydrocoll. 2021, 117, 106709. [Google Scholar] [CrossRef]

- Otoni, C.G.; Moura, M.R.D.; Aouada, F.A.; Camilloto, G.P.; Cruz, R.S.; Lorevice, M.V.; Soares, N.d.F.F.; Mattoso, L.H.C. Antimicrobial and physical-mechanical properties of pectin/papaya puree/cinnamaldehyde nanoemulsion edible composite films. Food Hydrocoll. 2014, 41, 188–194. [Google Scholar] [CrossRef]

- Tulamandi, S.; Rangarajan, V.; Rizvi, S.S.H.; Singhal, R.S.; Chattopadhyay, S.K.; Saha, N.C. A biodegradable and edible packaging film based on papaya puree, gelatin, and defatted soy protein. Food Packag. Shelf Life 2016, 10, 60–71. [Google Scholar] [CrossRef]

- Lai, W.F. Non-aromatic clusteroluminogenic polymers: Structural design and applications in bioactive agent delivery. Mater. Today Chem. 2022, 23, 100712. [Google Scholar] [CrossRef]

- Lai, W.F.; Deng, R.; He, T.C.; Wong, W.T. A bioinspired, sustained-release material in response to internal signals for biphasic chemical sensing in wound therapy. Adv. Healthc. Mater. 2021, 10, 2001267. [Google Scholar] [CrossRef] [PubMed]

- Lai, W.F.; Hu, C.S.; Deng, G.X.; Lui, K.H.; Wang, X.; Tsoi, T.H.; Wang, S.X.; Wong, W.T. A biocompatible and easy-to-make polyelectrolyte dressing with tunable drug delivery properties for wound care. Int. J. Pharmaceut. 2019, 566, 101–110. [Google Scholar] [CrossRef] [PubMed]

- Lai, W.F.; Wong, W.T. Design of polymeric gene carriers for effective intracellular delivery. Trends Biotechnol. 2018, 36, 713–728. [Google Scholar] [CrossRef] [PubMed]

- Lai, W.F.; Rogach, A.L. Hydrogel-based materials for delivery of herbal medicines. ACS Appl. Mater. Int. 2017, 9, 11309–11320. [Google Scholar] [CrossRef] [PubMed]

- Risch, S.J. Food packaging history and innovations. J. Agric. Food Chem. 2009, 57, 8089–8092. [Google Scholar] [CrossRef]

- Bos, H.L.; Meesters, K.P.H.; Conijn, S.G.; Corre, W.J.; Patel, M.K. Accounting for the constrained availability of land: A comparison of bio-based ethanol, polyethylene, and PLA with regard to non-renewable energy use and land use. Biofuels Bioprod. Biorefin. 2012, 6, 146–158. [Google Scholar] [CrossRef]

- Siracusa, V.; Blanco, I. Bio-polyethylene (Bio-PE), bio-polypropylene (Bio-PP) and bio-poly(ethylene terephthalate) (Bio-PET): Recent developments in bio-based polymers analogous to petroleum-derived ones for packaging and engineering applications. Polymers 2020, 12, 1641. [Google Scholar] [CrossRef]

- Zia, J.; Paul, U.C.; Heredia-Guerrero, J.A.; Athanassiou, A.; Fragouli, D. Low-density polyethylene/curcumin melt extruded composites with enhanced water vapor barrier and antioxidant properties for active food packaging. Polymer 2019, 175, 137–145. [Google Scholar] [CrossRef]

- Lukic, I.; Vulic, J.; Ivanovic, J. Antioxidant activity of PLA/PCL films loaded with thymol and/or carvacrol using scCO2 for active food packaging. Food Packag. Shelf Life 2020, 26, 100578. [Google Scholar] [CrossRef]

- Janani, N.; Zare, E.N.; Salimi, F.; Makvandi, P. Antibacterial tragacanth gum-based nanocomposite films carrying ascorbic acid antioxidant for bioactive food packaging. Carbohyd. Polym. 2020, 247, 116678. [Google Scholar] [CrossRef]

- Li, F.; Ye, Q.; Gao, Q.; Chen, H.; Shi, S.Q.; Zhou, W.; Li, X.; Xia, C.; Li, J. Facile fabrication of self-healable and antibacterial soy protein-based films with high mechanical strength. ACS Appl. Mater. Interfaces 2019, 11, 16107–16116. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Wang, X.; Yang, F.; Wang, L.; Wu, D. Highly elastic and ultratough hybrid ionic-covalent hydrogels with tunable structures and mechanics. Adv. Mater. 2018, 30, e1707071. [Google Scholar] [CrossRef] [PubMed]

- Fasihnia, S.H.; Peighambardoust, S.H.; Peighambardoust, S.J.; Oromiehie, A.; Soltanzadeh, M.; Peressini, D. Migration analysis, antioxidant, and mechanical characterization of polypropylene-based active food packaging films loaded with BHA, BHT, and TBHQ. J. Food Sci. 2020, 85, 2317–2328. [Google Scholar] [CrossRef] [PubMed]

- Aydogdu, A.; Yildiz, E.; Aydogdu, Y.; Sumnu, G.; Sahin, S.; Ayhan, Z. Enhancing oxidative stability of walnuts by using gallic acid loaded lentil flour based electrospun nanofibers as active packaging material. Food Hydrocoll. 2019, 95, 245–255. [Google Scholar] [CrossRef]

- Li, M.; Yu, H.; Xie, Y.; Guo, Y.; Cheng, Y.; Qian, H.; Yao, W. Fabrication of eugenol loaded gelatin nanofibers by electrospinning technique as active packaging material. LWT 2021, 139, 110800. [Google Scholar] [CrossRef]

- Hosseini, S.F.; Nahvi, Z.; Zandi, M. Antioxidant peptide-loaded electrospun chitosan/poly(vinyl alcohol) nanofibrous mat intended for food biopackaging purposes. Food Hydrocoll. 2019, 89, 637–648. [Google Scholar] [CrossRef]

- Rodríguez, G.M.; Sibaja, J.C.; Espitia, P.J.P.; Otoni, C.G. Antioxidant active packaging based on papaya edible films incorporated with Moringa oleifera and ascorbic acid for food preservation. Food Hydrocoll. 2020, 103, 105630. [Google Scholar] [CrossRef]

- Gao, B.J.; An, F.Q.; Liu, K.K. Studies on chelating adsorption properties of novel composite material polyethyleneimine/silica gel for heavy-metal ions. Appl. Surf. Sci. 2006, 253, 1946–1952. [Google Scholar] [CrossRef]

- Srinivasa, P.C.; Ramesh, M.N.; Kumar, K.R.; Tharanathan, R.N. Properties and sorption studies of chitosan-polyvinyl alcohol blend films. Carbohyd. Polym. 2003, 53, 431–438. [Google Scholar] [CrossRef]

- Iqbal, S.; Bhanger, M.I. Effect of season and production location on antioxidant activity of Moringa oleifera leaves grown in Pakistan. J. Food Compos. Anal. 2006, 19, 544–551. [Google Scholar] [CrossRef]

- Potrc, S.; Krasevac Glaser, T.; Vesel, A.; Poklar Ulrih, N.; Fras Zemljic, L. Two-layer functional coatings of chitosan particles with embedded catechin and pomegranate extracts for potential active packaging. Polymers 2020, 12, 1855. [Google Scholar] [CrossRef] [PubMed]

- Muriel-Galet, V.; Talbert, J.N.; Hernandez-Munoz, P.; Gavara, R.; Goddard, J.M. Covalent immobilization of lysozyme on ethylene vinyl alcohol films for nonmigrating antimicrobial packaging applications. J. Agric. Food Chem. 2013, 61, 6720–6727. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chung, D.; Papadakis, S.E.; Yam, K.L. Simple models for assessing migration from food-packaging films. Food Addit. Contam. 2002, 19, 611–617. [Google Scholar] [CrossRef] [PubMed]

- Stoffers, N.H.; Dekker, M.; Linssen, J.P.H.; Stormer, A.; Franz, R.; van Boekel, M.A.J.S. Modelling of simultaneous two-sided migration into water and olive oil from nylon food packaging. Eur. Food Res. Technol. 2005, 220, 156–162. [Google Scholar] [CrossRef]

- Pocas, M.F.; Oliveira, J.C.; Brandsch, R.; Hogg, T. Analysis of mathematical models to describe the migration of additives from packaging plastics to foods. J. Food Process. Eng. 2012, 35, 657–676. [Google Scholar] [CrossRef]

- Gavriil, G.; Kanavouras, A.; Coutelieris, F.A. Food-packaging migration models: A critical discussion. Crit. Rev. Food Sci. 2018, 58, 2262–2272. [Google Scholar] [CrossRef]

- Douziech, M.; Benitez-Lopez, A.; Ernstoff, A.; Askham, C.; Hendriks, A.J.; King, H.; Huijbregts, M.A.J. A regression-based model to predict chemical migration from packaging to food. J. Expo. Sci. Environ. Epidemiol. 2020, 30, 469–477. [Google Scholar] [CrossRef]

- Arvanitoyannis, I.S.; Bosnea, L.A. Recycling of polymeric materials used for food packaging: Current status and perspectives. Food Rev. Int. 2001, 17, 291–346. [Google Scholar] [CrossRef]

- Bohlmann, G.M. Biodegradable packaging life-cycle assessment. Environ. Prog. 2004, 23, 342–346. [Google Scholar] [CrossRef]

- Islamipour, Z.; Zare, E.N.; Salimi, F.; Ghomi, M.; Makvandi, P. Biodegradable antibacterial and antioxidant nanocomposite films based on dextrin for bioactive food packaging. J. Nano Struct. Chem. 2022, 1–16. [Google Scholar] [CrossRef]

- Cvek, M.; Paul, U.C.; Zia, J.; Mancini, G.; Sedlarik, V.; Athanassiou, A. Biodegradable films of PLA/PPC and curcumin as packaging materials and smart indicators of food spoilage. ACS Appl. Mater. Int. 2022, 14, 14654–14667. [Google Scholar] [CrossRef] [PubMed]

- Akshaykranth, A.; Jayarambabu, N.; Rao, T.V.; Kumar, R.R.; Rao, L.S. Antibacterial activity study of ZnO incorporated biodegradable poly (lactic acid) films for food packaging applications. Polym. Bull. 2022, 1–16. [Google Scholar] [CrossRef]

- Ahmed, M.; Verma, A.K.; Patel, R. Physiochemical, antioxidant, and food simulant release properties of collagen-carboxymethyl cellulose films enriched with Berberis lyceum root extract for biodegradable active food packaging. J. Food Process. Preserv. 2022, 46, e16485. [Google Scholar] [CrossRef]

- Lopez-Rubio, A.; Almenar, E.; Hernandez-Munoz, P.; Lagaron, J.M.; Catala, R.; Gavara, R. Overview of active polymer-based packaging technologies for food applications. Food Rev. Int. 2004, 20, 357–387. [Google Scholar] [CrossRef]

- Ahvenainen, R.; Hurme, E. Active and smart packaging for meeting consumer demands for quality and safety. Food Addit. Contam. 1997, 14, 753–763. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, W.-F.; Wong, W.-T. Design and Practical Considerations for Active Polymeric Films in Food Packaging. Int. J. Mol. Sci. 2022, 23, 6295. https://doi.org/10.3390/ijms23116295

Lai W-F, Wong W-T. Design and Practical Considerations for Active Polymeric Films in Food Packaging. International Journal of Molecular Sciences. 2022; 23(11):6295. https://doi.org/10.3390/ijms23116295

Chicago/Turabian StyleLai, Wing-Fu, and Wing-Tak Wong. 2022. "Design and Practical Considerations for Active Polymeric Films in Food Packaging" International Journal of Molecular Sciences 23, no. 11: 6295. https://doi.org/10.3390/ijms23116295

APA StyleLai, W.-F., & Wong, W.-T. (2022). Design and Practical Considerations for Active Polymeric Films in Food Packaging. International Journal of Molecular Sciences, 23(11), 6295. https://doi.org/10.3390/ijms23116295