Comparison of Properties of Poly(Lactic Acid) Composites Prepared from Different Components of Corn Straw Fiber

Abstract

:1. Introduction

2. Results and Discussion

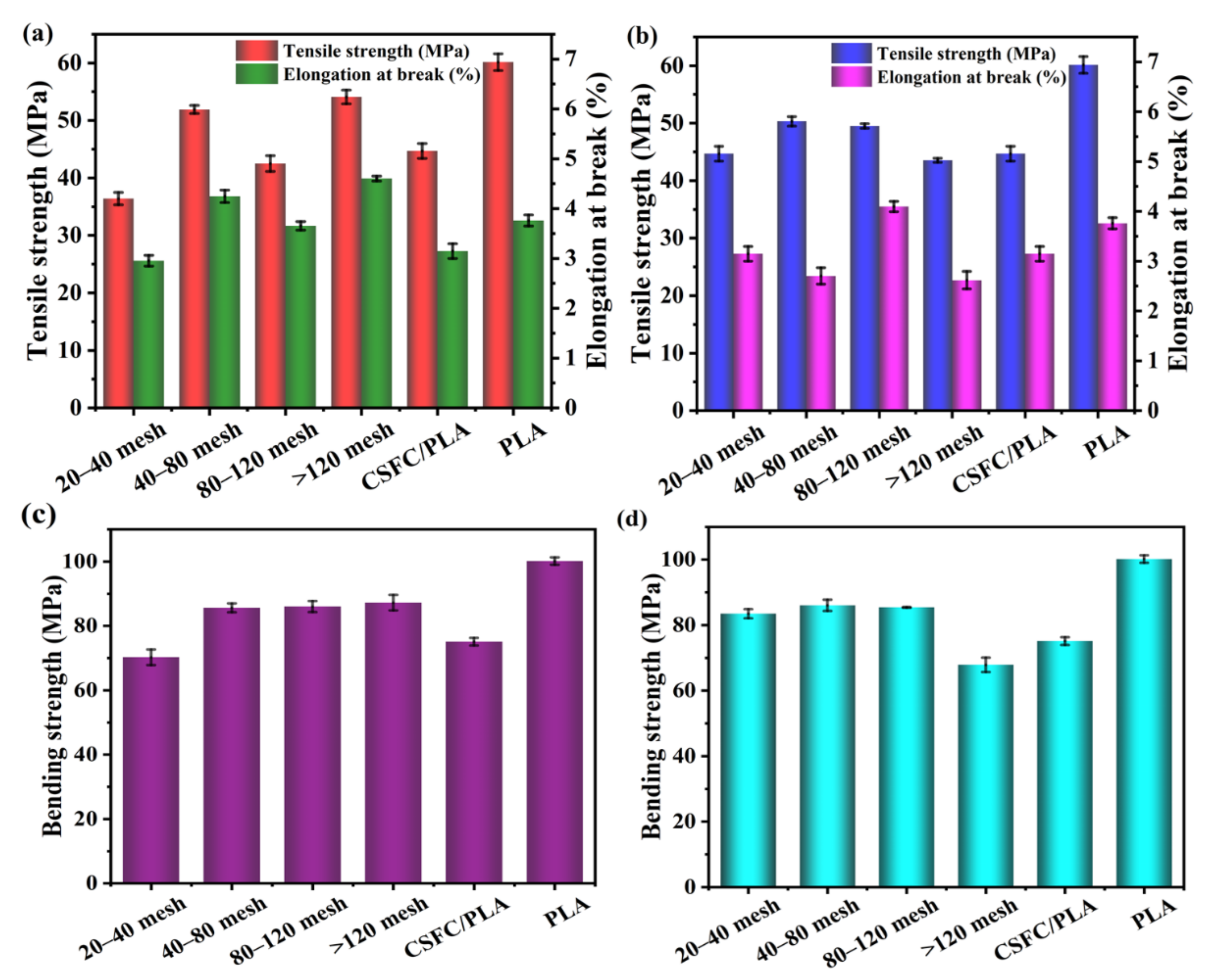

2.1. Mechanical Properties Analysis

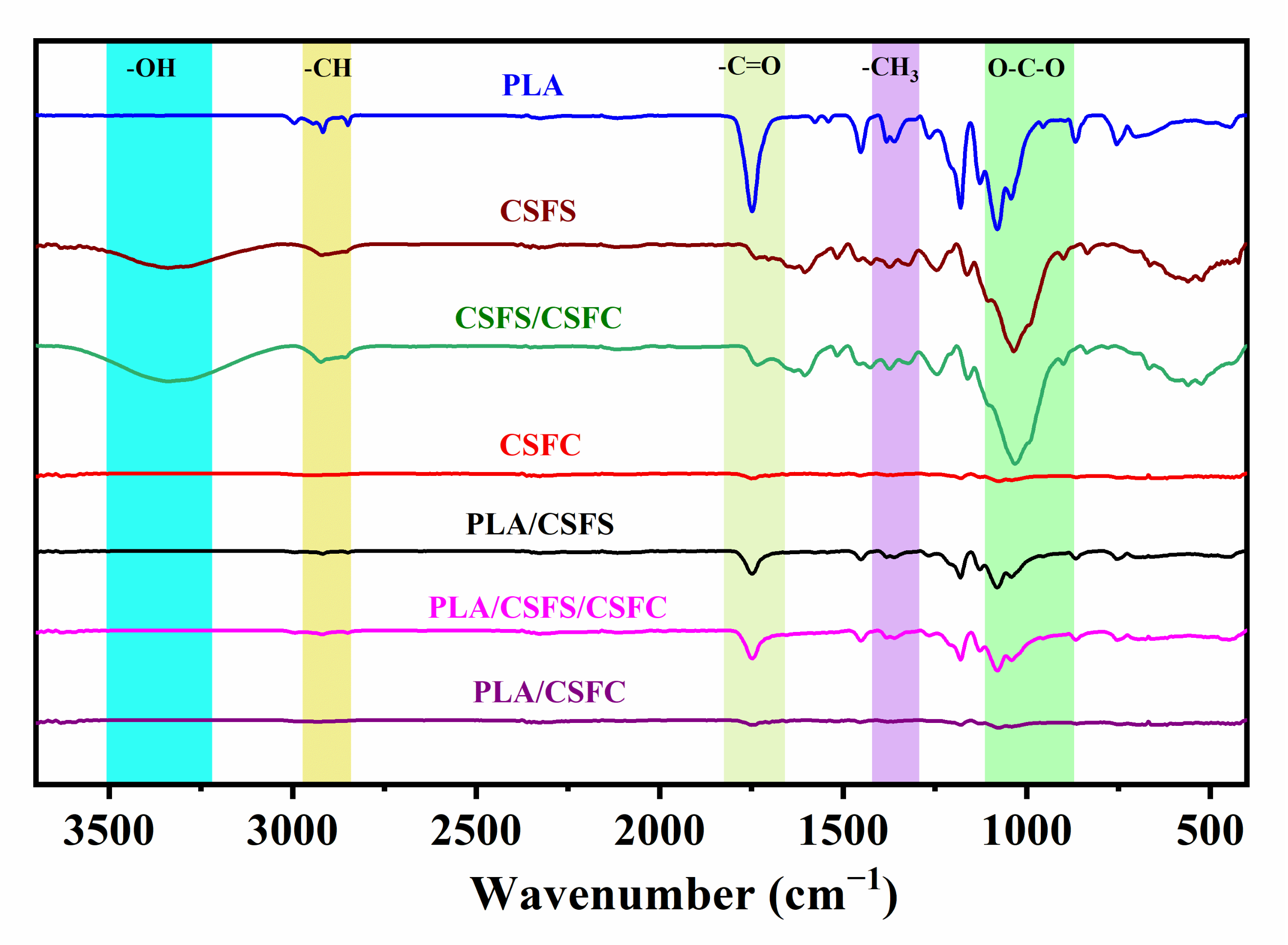

2.2. FT-IR Analysis

2.3. Contact Angle Analysis

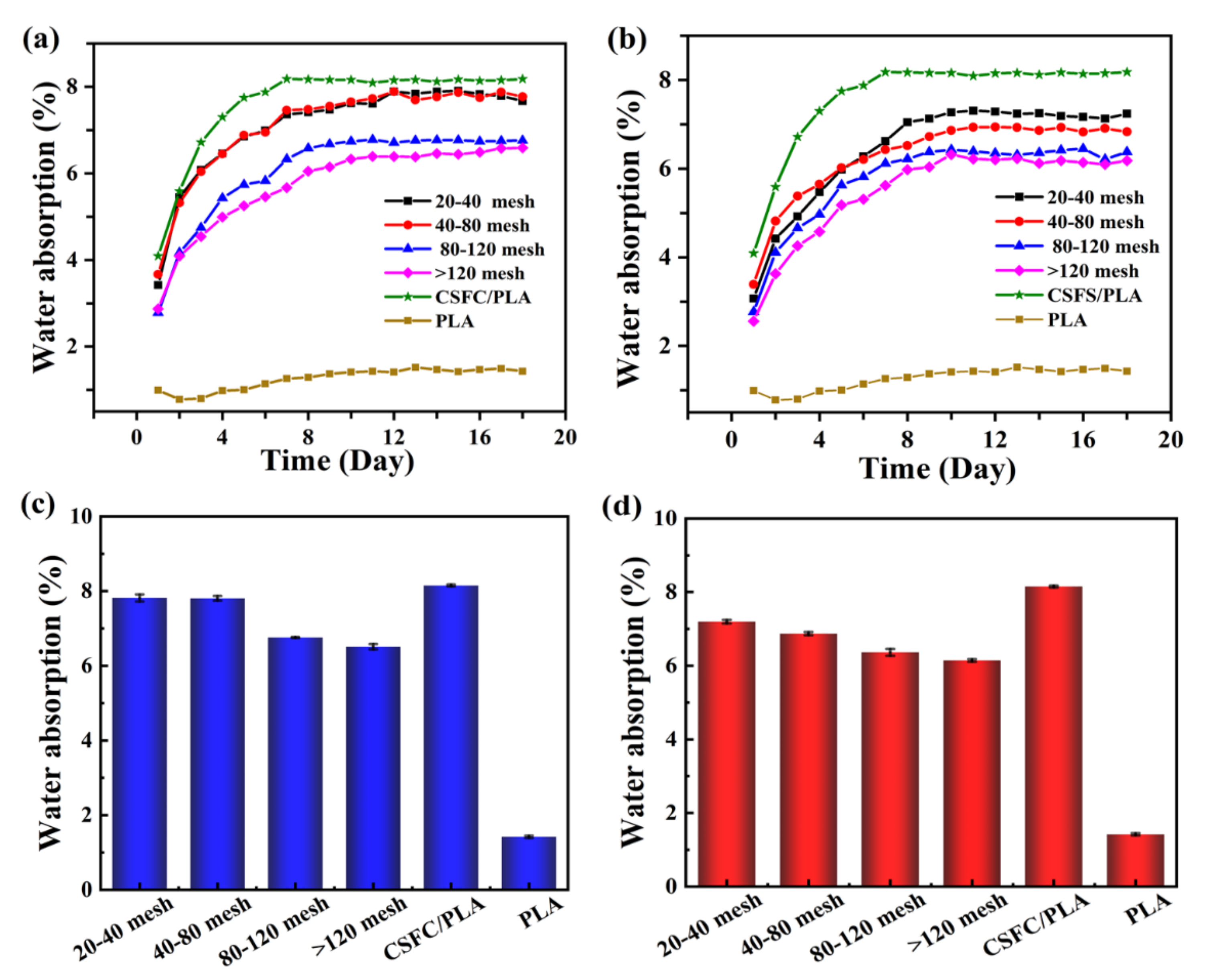

2.4. Water Absorption Analysis

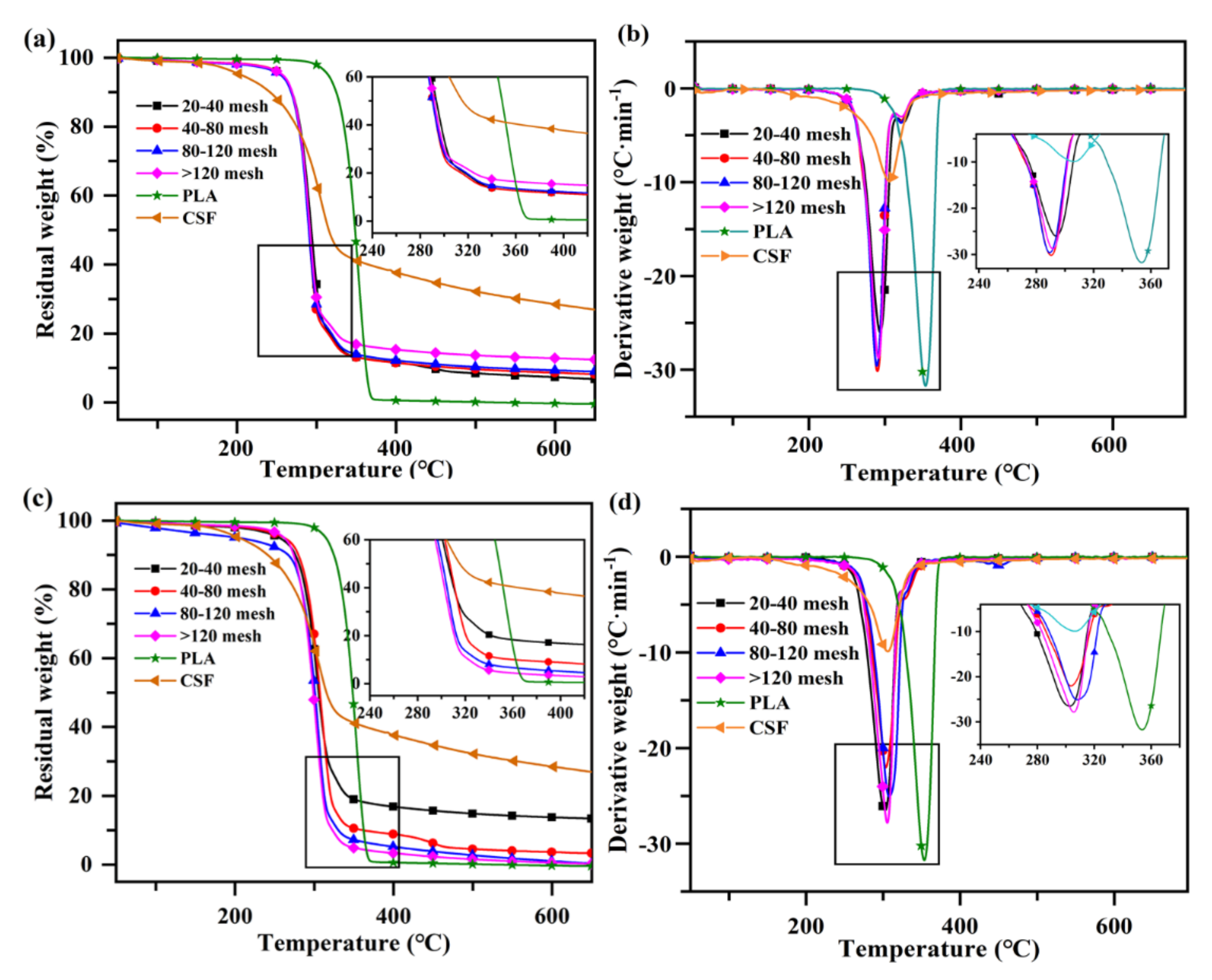

2.5. Thermal Stability of the CSF/PLA Composites

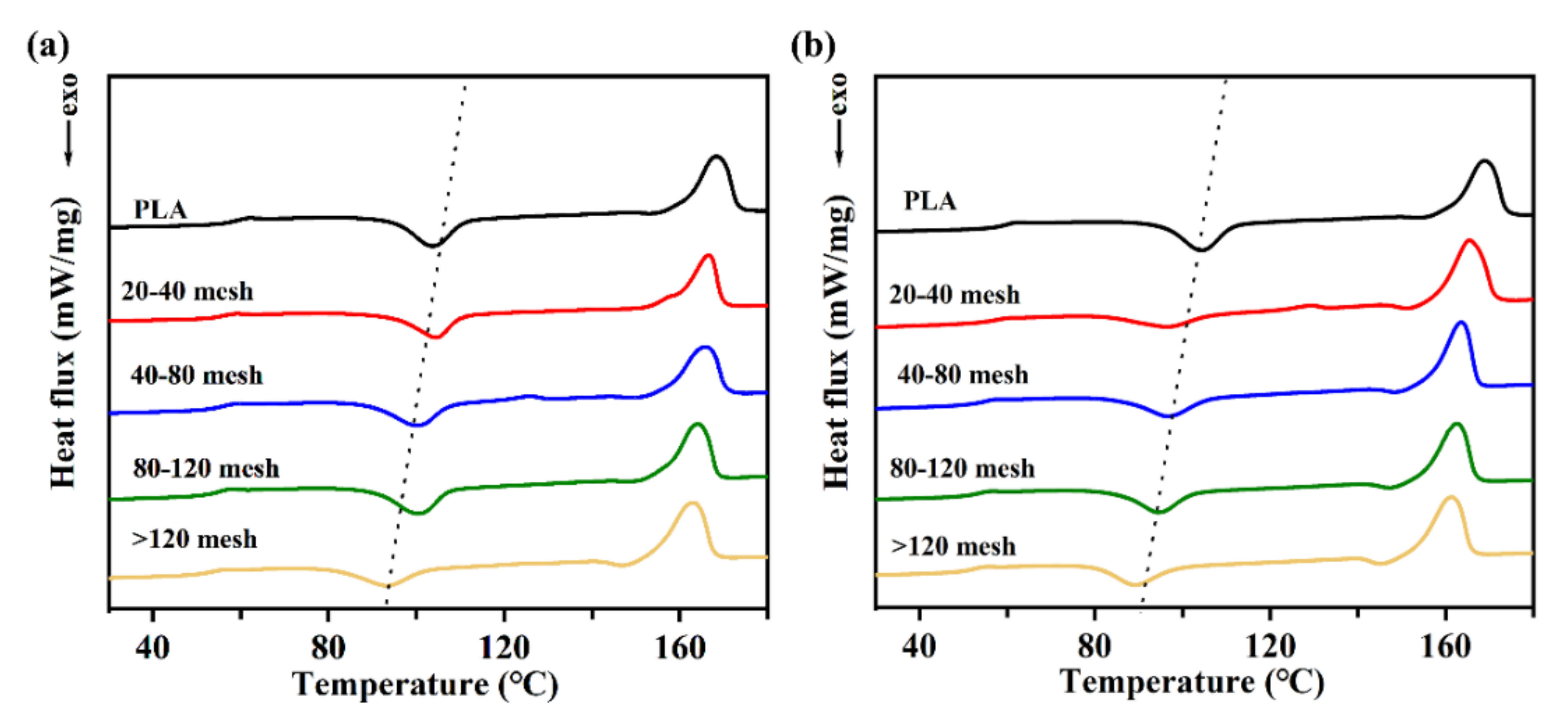

2.6. Analysis of the Differential Scanning Calorimetry

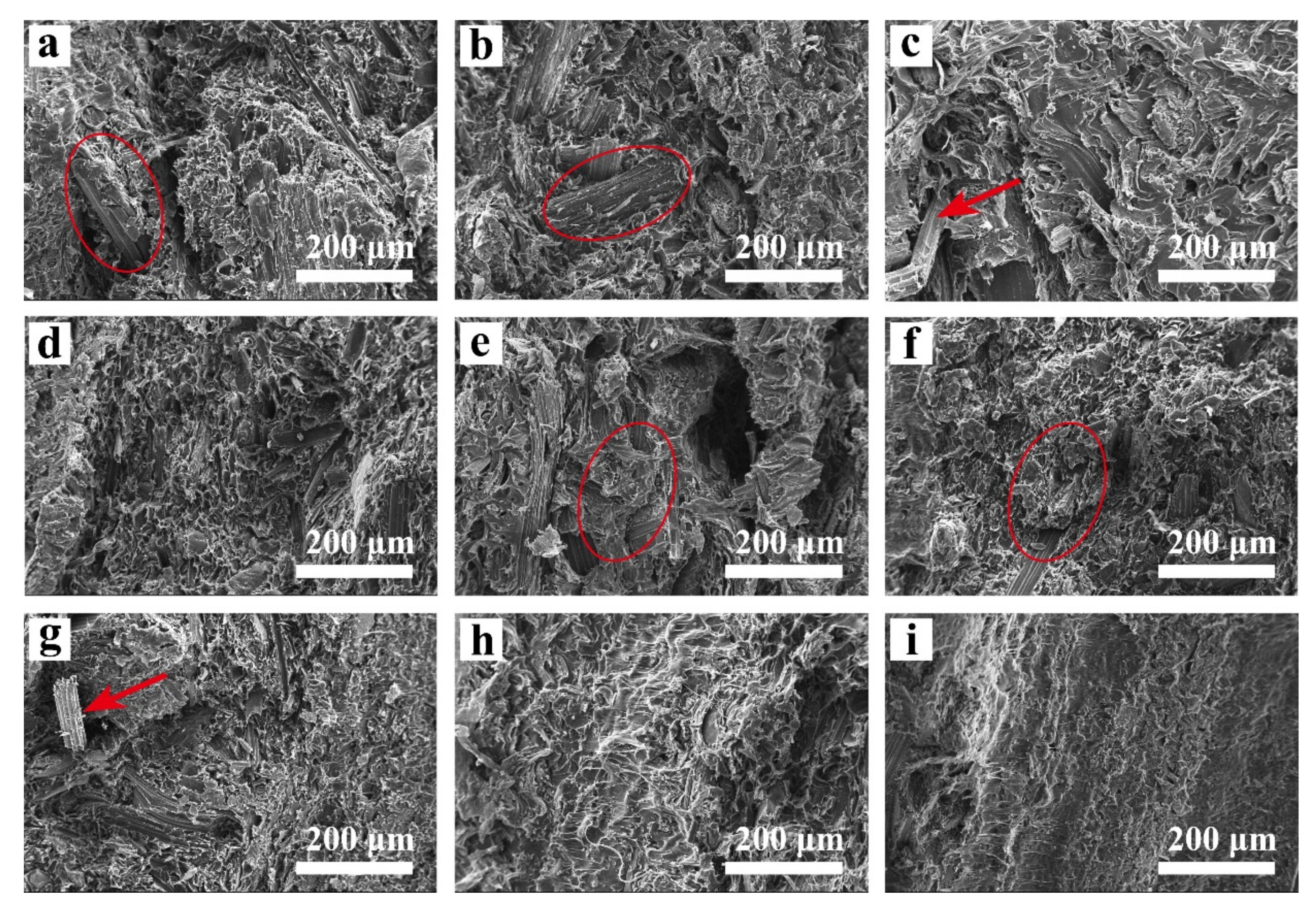

2.7. Fracture Surface of the CSF/PLA Composite

3. Conclusions

4. Materials and Method

4.1. Materials

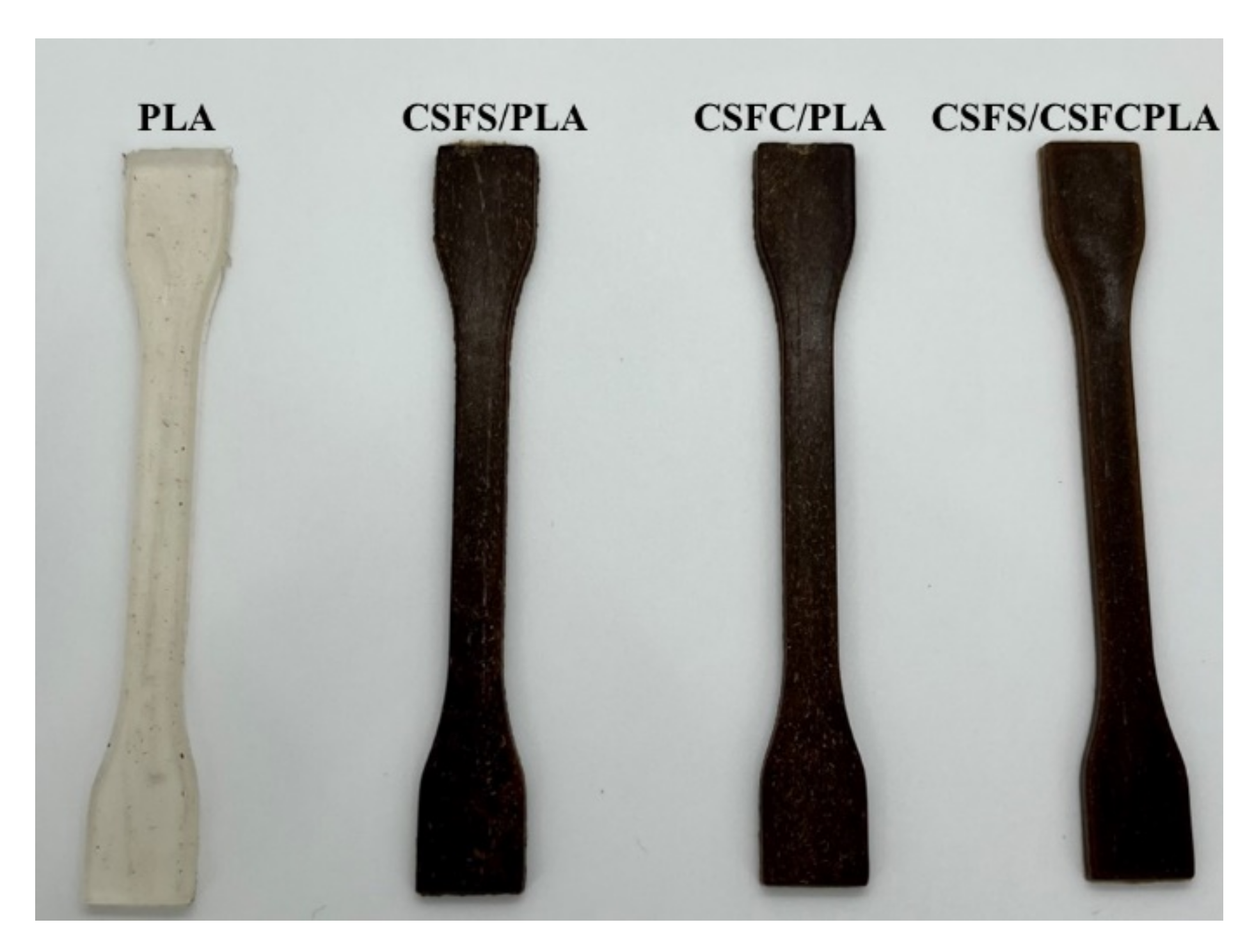

4.2. Preparation of CSF/PLA Composites

4.3. Mechanical Property

4.4. Thermogravimetric Analysis (TGA)

4.5. Differential Scanning Calorimetry (DSC)

4.6. Scanning Electron Microscopy (SEM)

4.7. Fourier Transform Infrared (FTIR)

4.8. Water Absorption Performance

4.9. Hydrophilic Performance

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Jiang, J. Biodegradable Polymer Material. Synth. Technol. Appl. 1996, 11, 32–37. [Google Scholar]

- Gogolewski, S.; Pennings, A.J. Resorbable Materials of Poly(L-lactide). II. Fibers Spun from Solutions of Poly(L-lactide) in Good Solvents. J. Appl. Polym. Sci. 1983, 28, 1045–1061. [Google Scholar] [CrossRef]

- Sun, C.; Li, C.; Tan, H.; Zhang, Y. Synergistic Effects of Wood Fiber and Polylactic Acid during Co-Pyrolysis Using TG-FTIR-MS and Py-GC/MS. Energy Convers. Manag. 2019, 202, 112212. [Google Scholar] [CrossRef]

- Silva-Cavalcanti, J.S.; Silva, J.D.B.; de França, E.J.; de Araújo, M.C.B.; Gusmao, F. Microplastics Ingestion by a Common Tropical Freshwater Fishing Resource. Environ. Pollut. 2017, 221, 218–226. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Romain, C.; Williams, C.K. Sustainable Polymers from Renewable Resources. Nature 2016, 540, 354–362. [Google Scholar] [CrossRef] [PubMed]

- Shimao, M. Biodegradation of Plastics Masayuki Shimao. Curr. Opin. Biotechnol. 2001, 12, 242–247. [Google Scholar] [CrossRef]

- Vink, E.T.H.; Rábago, K.R.; Glassner, D.A.; Springs, B.; O’Connor, R.P.; Kolstad, J.; Gruber, P.R. The Sustainability of Nature WorksTM Polylactide Polymers and IngeoTM Polylactide Fibers: An Update of the Future. Macromol. Biosci. 2004, 4, 551–564. [Google Scholar] [CrossRef]

- Lunt, J. Large-Scale Production, Properties and Commercial Applications of Poly Lactic Acid Polymers. Polym. Degrad. Stab. 1998, 59, 145–152. [Google Scholar] [CrossRef]

- Cong, S. Properties of Polylactic Acid Fiber Based Polymers and Their Correlation with Composition. In Proceedings of the 2007 International Conference on Advanced Fibers and Polymer Materials, ICAFPM 2007, Shanghai, China, 15–17 October 2007; Volume 1, pp. 8–11. [Google Scholar]

- Gupta, B.; Revagade, N.; Hilborn, J. Poly(Lactic Acid) Fiber: An Overview. Prog. Polym. Sci. 2007, 32, 455–482. [Google Scholar] [CrossRef]

- Madhavan Nampoothiri, K.; Nair, N.R.; John, R.P. An Overview of the Recent Developments in Polylactide (PLA) Research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef]

- Suyatma, N.E.; Copinet, A.; Tighzert, L.; Coma, V. Mechanical and Barrier Properties of Biodegradable Films Made from Chitosan and Poly (Lactic Acid) Blends. J. Polym. Environ. 2004, 12, 1–6. [Google Scholar] [CrossRef]

- Gui, Z.Y.; Wang, H.R.; Gao, Y.; Lu, C.; Cheng, S.J. Morphology and Melt Rheology of Biodegradable Poly(Lactic Acid)/Poly(Butylene Succinate Adipate) Blends: Effect of Blend Compositions. Iran. Polym. J. 2012, 21, 81–89. [Google Scholar] [CrossRef]

- Fambri, L.; Pegoretti, A.; Fenner, R.; Incardona, S.D.; Migliaresi, C. Biodegradable Fibres of Poly(L-Lactic Acid) Produced by Melt Spinning. Polymer 1997, 38, 79–85. [Google Scholar] [CrossRef]

- Qin, L.; Qiu, J.; Liu, M.; Ding, S.; Shao, L.; Lü, S.; Zhang, G.; Zhao, Y.; Fu, X. Mechanical and Thermal Properties of Poly(Lactic Acid) Composites with Rice Straw Fiber Modified by Poly(Butyl Acrylate). Chem. Eng. J. 2011, 166, 772–778. [Google Scholar] [CrossRef]

- Friedrich, D. Welfare Effects from Eco-Labeled Crude Oil Preserving Wood-Polymer Composites: A Comprehensive Literature Review and Case Study. J. Clean. Prod. 2018, 188, 625–637. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, T.; Zhong, J.; Zhang, X.; Tan, T. Biorefinery of Sweet Sorghum Stem. Biotechnol. Adv. 2012, 30, 811–816. [Google Scholar] [CrossRef]

- Alismaeel, Z.T.; Abbar, A.H.; Saeed, O.F. Application of Central Composite Design Approach for Optimisation of Zinc Removal from Aqueous Solution Using a Flow-by Fixed Bed Bioelectrochemical Reactor. Sep. Purif. Technol. 2022, 287, 120510. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef]

- Sydow, Z.; Bieńczak, K. The Overview on the Use of Natural Fibers Reinforced Composites for Food Packaging. J. Nat. Fibers 2019, 16, 1189–1200. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, D.-Y.; Haurie, L.; Liu, Z.; Zhang, L. Combination of Corn Pith Fiber and Biobased Flame Retardant: A Novel Method toward Flame Retardancy, Thermal Stability, and Mechanical Properties of Polylactide. Polymers 2021, 13, 1562. [Google Scholar] [CrossRef]

- Liu, S.; Ge, H.; Zou, Y.; Chen, J. Glutaraldehyde/Polyvinyl Alcohol Crosslinked Nanosphere Modified Corn Stalk Reinforced Polypropylene Composite. IOP Conf. Ser. Mater. Sci. Eng. 2019, 472, 012064. [Google Scholar] [CrossRef]

- Huda, S.; Yang, Y. Chemically Extracted Cornhusk Fibers as Reinforcement in Light-Weight Poly(Propylene) Composites. Macromol. Mater. Eng. 2008, 293, 235–243. [Google Scholar] [CrossRef]

- Alvarado, N.; Romero, J.; Torres, A.; López de Dicastillo, C.; Rojas, A.; Galotto, M.J.; Guarda, A. Supercritical Impregnation of Thymol in Poly(Lactic Acid) Filled with Electrospun Poly(Vinyl Alcohol)-Cellulose Nanocrystals Nanofibers: Development an Active Food Packaging Material. J. Food Eng. 2018, 217, 1–10. [Google Scholar] [CrossRef]

- Azeredo, H.M.C.; Rosa, M.F.; Mattoso, L.H.C. Nanocellulose in Bio-Based Food Packaging Applications. Ind. Crops Prod. 2017, 97, 664–671. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, W.; Wang, L.; He, C. Performance Comparison of Four Kinds of Straw/PLA/PBAT Wood Plastic Composites. BioResources 2020, 15, 2596–2604. [Google Scholar] [CrossRef]

- Li, X.; Liu, L.; Yang, P.; Li, P.; Xin, J.; Su, R. Synthesis of Collagen-Modified Polylactide and Its Application in Drug Delivery. J. Appl. Polym. Sci. 2013, 129, 3290–3296. [Google Scholar] [CrossRef]

- Mamun, A.A. The Use of Maize, Oat, Barley and Rye Fibres as Reinforcements in Composites. In Biofiber Reinforcements in Composite Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 454–487. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, Y.; Xia, R.; Li, Y.; Zhao, J.; Lin, L.; Cao, J.; Wang, Q.; Liu, Y.; Guo, H. Graphene-Quantum-Dots-Induced MnO2 with Needle-like Nanostructure Grown on Carbonized Wood as Advanced Electrode for Supercapacitors. Carbon 2020, 162, 114–123. [Google Scholar] [CrossRef]

- Li, C.; Sun, C.; Wang, C.; Tan, H.; Xie, Y.; Zhang, Y. Cellulose Nanocrystal Reinforced Poly(Lactic Acid) Nanocomposites Prepared by a Solution Precipitation Approach. Cellulose 2020, 27, 7489–7502. [Google Scholar] [CrossRef]

- Srikanth, P.; Kim, S.G.; Auer, G.K.; Gong, S. Microcellular Extrusion-Foaming of Polylactide with Chain-Extender. Polym. Eng. Sci. 2009, 49, 1653–1660. [Google Scholar] [CrossRef]

- Huang, H.; Du, H.; Wang, W.; Wang, H. Effects of the Size of Wood Flour on Mechanical Properties of Wood-Plastic Composites. Adv. Mater. Res. 2012, 393–395, 76–79. [Google Scholar] [CrossRef]

- Chotirat, L.; Chaochanchaikul, K.; Sombatsompop, N. On Adhesion Mechanisms and Interfacial Strength in Acrylonitrile-Butadiene-Styrene/Wood Sawdust Composites. Int. J. Adhes. Adhes. 2007, 27, 669–678. [Google Scholar] [CrossRef]

- Albano, C.; Reyes, J.; Ichazo, M.; González, J.; Brito, M.; Moronta, D. Analysis of the Mechanical, Thermal and Morphological Behaviour of Polypropylene Compounds with Sisal Fibre and Wood Flour, Irradiated with Gamma Rays. Polym. Degrad. Stab. 2002, 76, 191–203. [Google Scholar] [CrossRef]

- Li, W.; Zheng, L.; Teng, D.; Ge, D.; Farha, F.I.; Xu, F. Interfacial Modified Unidirectional Wheat Straw/Polylactic Acid Composites. J. Ind. Text. 2020, 152808372091817. [Google Scholar] [CrossRef]

- Robledo-Ortíz, J.R. Valorization of Sugarcane Straw for the Development of Sustainable Biopolymer-Based Composites. Polymers 2021, 13, 3335. [Google Scholar] [CrossRef]

- Aup-Ngoen, K.; Noipitak, M. Effect of Carbon-Rich Biochar on Mechanical Properties of PLA-Biochar Composites. Sustain. Chem. Pharm. 2020, 15, 100204. [Google Scholar] [CrossRef]

- Cuadri, A.A.; Martín-Alfonso, J.E. Thermal, Thermo-Oxidative and Thermomechanical Degradation of PLA: A Comparative Study Based on Rheological, Chemical and Thermal Properties. Polym. Degrad. Stability 2018, 150, 37–45. [Google Scholar] [CrossRef]

- Jadhav, H.; Jadhav, A.; Takkalkar, P.; Hossain, N.; Nizammudin, S.; Zahoor, M.; Jamal, M.; Mubarak, N.M.; Griffin, G.; Kao, N. Potential of Polylactide Based Nanocomposites-Nanopolysaccharide Filler for Reinforcement Purpose: A Comprehensive Review. J. Polym. Res. 2020, 27, 330. [Google Scholar] [CrossRef]

- Chougan, M.; Ghaffar, S.H.; Al-Kheetan, M.J.; Gecevicius, M. Wheat Straw Pre-Treatments Using Eco-Friendly Strategies for Enhancing the Tensile Properties of Bio-Based Polylactic Acid Composites. Ind. Crops Prod. 2020, 155, 112836. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Development and Characterization of Sugar Palm Nanocrystalline Cellulose Reinforced Sugar Palm Starch Bionanocomposites. Carbohydr. Polym. 2018, 202, 186–202. [Google Scholar] [CrossRef]

- Hosseinaei, O.; Wang, S.; Taylor, A.M.; Kim, J.-W. Effect of Hemicellulose Extraction on Water Absorption and Mold Susceptibility of Wood–Plastic Composites. Int. Biodeterior. Biodegrad. 2012, 71, 29–35. [Google Scholar] [CrossRef]

- Li, W.; Sun, C.; Li, C.; Xu, Y.; Tan, H.; Zhang, Y. Preparation of Effective Ultraviolet Shielding Poly (Lactic Acid)/Poly (Butylene Adipate-Co-Terephthalate) Degradable Composite Film Using Co-Precipitation and Hot-Pressing Method. Int. J. Biol. Macromol. 2021, 191, 540–547. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Wei, S.; Tan, H.; Huang, Y.; Zhang, Y. Progress in Upcycling Polylactic Acid Waste as an Alternative Carbon Source: A Review. Chem. Eng. J. 2022, 446, 136881. [Google Scholar] [CrossRef]

- Sun, C.; Chen, X.; Zheng, D.; Yao, W.; Tan, H.; Zhang, Y.; Liu, S. Exploring the Synergetic Effects of the Major Components of Biomass Additives in the Pyrolysis of Polylactic Acid. Green Chem. 2021, 23, 9014–9023. [Google Scholar] [CrossRef]

- Li, Y.; Yin, D.; Liu, W.; Zhou, H.; Zhang, Y.; Wang, X. Fabrication of Biodegradable Poly (Lactic Acid)/Carbon Nanotube Nanocomposite Foams: Significant Improvement on Rheological Property and Foamability. Int. J. Biol. Macromol. 2020, 163, 1175–1186. [Google Scholar] [CrossRef] [PubMed]

- Kuang, T.; Li, K.; Chen, B.; Peng, X. Poly (Propylene Carbonate)-Based in Situ Nanofibrillar Biocomposites with Enhanced Miscibility, Dynamic Mechanical Properties, Rheological Behavior and Extrusion Foaming Ability. Compos. Part B Eng. 2017, 123, 112–123. [Google Scholar] [CrossRef]

- Chen, K.; Li, P.; Li, X.; Liao, C.; Li, X.; Zuo, Y. Effect of Silane Coupling Agent on Compatibility Interface and Properties of Wheat Straw/Polylactic Acid Composites. Int. J. Biol. Macromol. 2021, 182, 2108–2116. [Google Scholar] [CrossRef] [PubMed]

- Turner, J.F.; Riga, A.; O’Connor, A.; Zhang, J.; Collis, J. Characterization of Drawn and Undrawn Poly-L-Lactide Films by Differential Scanning Calorimetry. J. Therm. Anal. Calorim. 2004, 75, 257–268. [Google Scholar] [CrossRef]

- Sucinda, E.F.; Abdul Majid, M.S.; Ridzuan, M.J.M.; Cheng, E.M.; Alshahrani, H.A.; Mamat, N. Development and Characterisation of Packaging Film from Napier Cellulose Nanowhisker Reinforced Polylactic Acid (PLA) Bionanocomposites. Int. J. Biol. Macromol. 2021, 187, 43–53. [Google Scholar] [CrossRef]

| Sample | Tg/°C | Tcc/°C | Tm1/°C | ∆Hcc/(J·g−1) | ∆Hm/(J·g−1) | Xc/% |

|---|---|---|---|---|---|---|

| PLA | 59.08 | 104.04 | 169.01 | 13.60 | 29.80 | 24.70 |

| CSFS/CSFC 40 mesh | 55.26 | 104.34 | 167.10 | 9.20 | 26.90 | 26.99 |

| CSFS/CSFC 40–80 mesh | 54.54 | 100.14 | 166.28 | 10.80 | 27.30 | 25.16 |

| CSFS/CSFC 80–120 mesh | 53.56 | 100.04 | 164.24 | 13.10 | 28.50 | 23.48 |

| CSFS/CSFC >120 mesh | 52.67 | 94.60 | 163.25 | 9.60 | 30.60 | 32.02 |

| CSFS 40 mesh | 56.67 | 99.16 | 165.46 | 5.30 | 28.70 | 35.68 |

| CSFS 40–80 mesh | 53.62 | 97.21 | 163.44 | 9.60 | 26.60 | 25.92 |

| CSFS 80–120 mesh | 52.26 | 94.57 | 162.29 | 9.90 | 27.30 | 26.53 |

| CSFS >120 mesh | 51.49 | 89.97 | 161.73 | 8.60 | 26.80 | 27.75 |

| Sample | CSF (Mesh) | CSFS (Mesh) | CSFC (Mesh) |

|---|---|---|---|

| 1 | 20–40 | - | - |

| 2 | 40–80 | - | - |

| 3 | 80–120 | - | - |

| 4 | >120 | - | - |

| 5 | - | 40 | - |

| 6 | - | 40–80 | - |

| 7 | - | 80–120 | - |

| 8 | - | >120 | - |

| 9 | - | - | 40–120 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, Z.; Wang, B.; Sun, C.; Yang, M.; Chen, X.; Zheng, D.; Yao, W.; Chen, Y.; Cheng, R.; Zhang, Y. Comparison of Properties of Poly(Lactic Acid) Composites Prepared from Different Components of Corn Straw Fiber. Int. J. Mol. Sci. 2022, 23, 6746. https://doi.org/10.3390/ijms23126746

Qi Z, Wang B, Sun C, Yang M, Chen X, Zheng D, Yao W, Chen Y, Cheng R, Zhang Y. Comparison of Properties of Poly(Lactic Acid) Composites Prepared from Different Components of Corn Straw Fiber. International Journal of Molecular Sciences. 2022; 23(12):6746. https://doi.org/10.3390/ijms23126746

Chicago/Turabian StyleQi, Zhongyu, Baiwang Wang, Ce Sun, Minghui Yang, Xiaojian Chen, Dingyuan Zheng, Wenrui Yao, Yang Chen, Ruixiang Cheng, and Yanhua Zhang. 2022. "Comparison of Properties of Poly(Lactic Acid) Composites Prepared from Different Components of Corn Straw Fiber" International Journal of Molecular Sciences 23, no. 12: 6746. https://doi.org/10.3390/ijms23126746

APA StyleQi, Z., Wang, B., Sun, C., Yang, M., Chen, X., Zheng, D., Yao, W., Chen, Y., Cheng, R., & Zhang, Y. (2022). Comparison of Properties of Poly(Lactic Acid) Composites Prepared from Different Components of Corn Straw Fiber. International Journal of Molecular Sciences, 23(12), 6746. https://doi.org/10.3390/ijms23126746