Alginate as a Promising Biopolymer in Drug Delivery and Wound Healing: A Review of the State-of-the-Art

Abstract

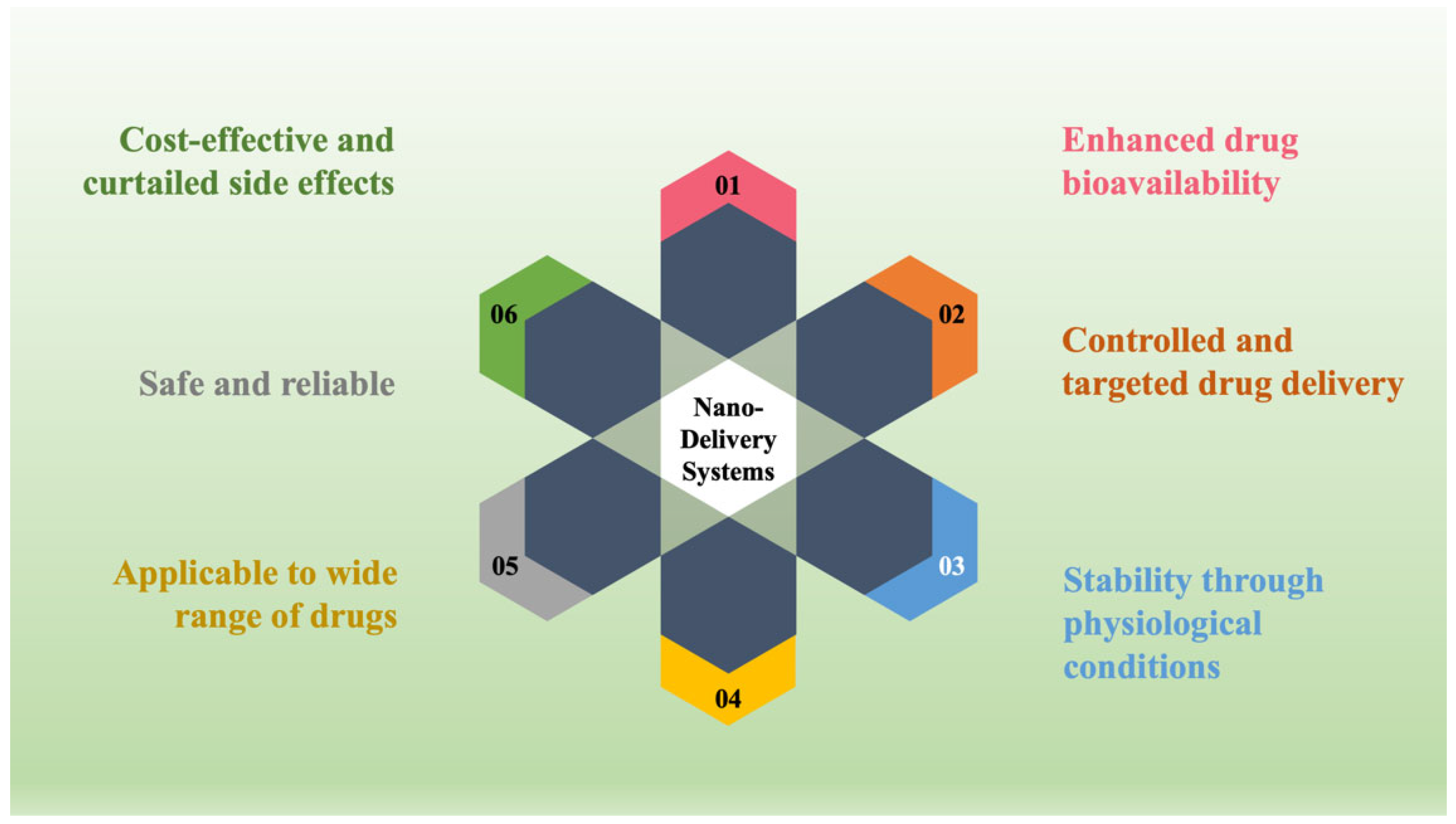

:1. Introduction

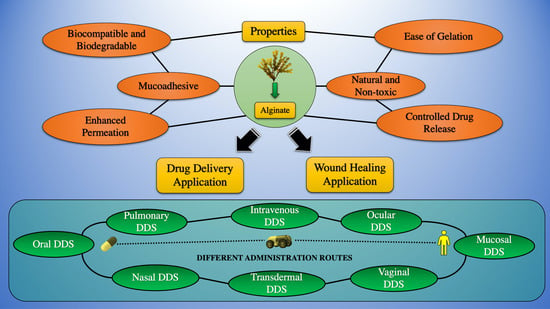

2. The Purview of the Present Review

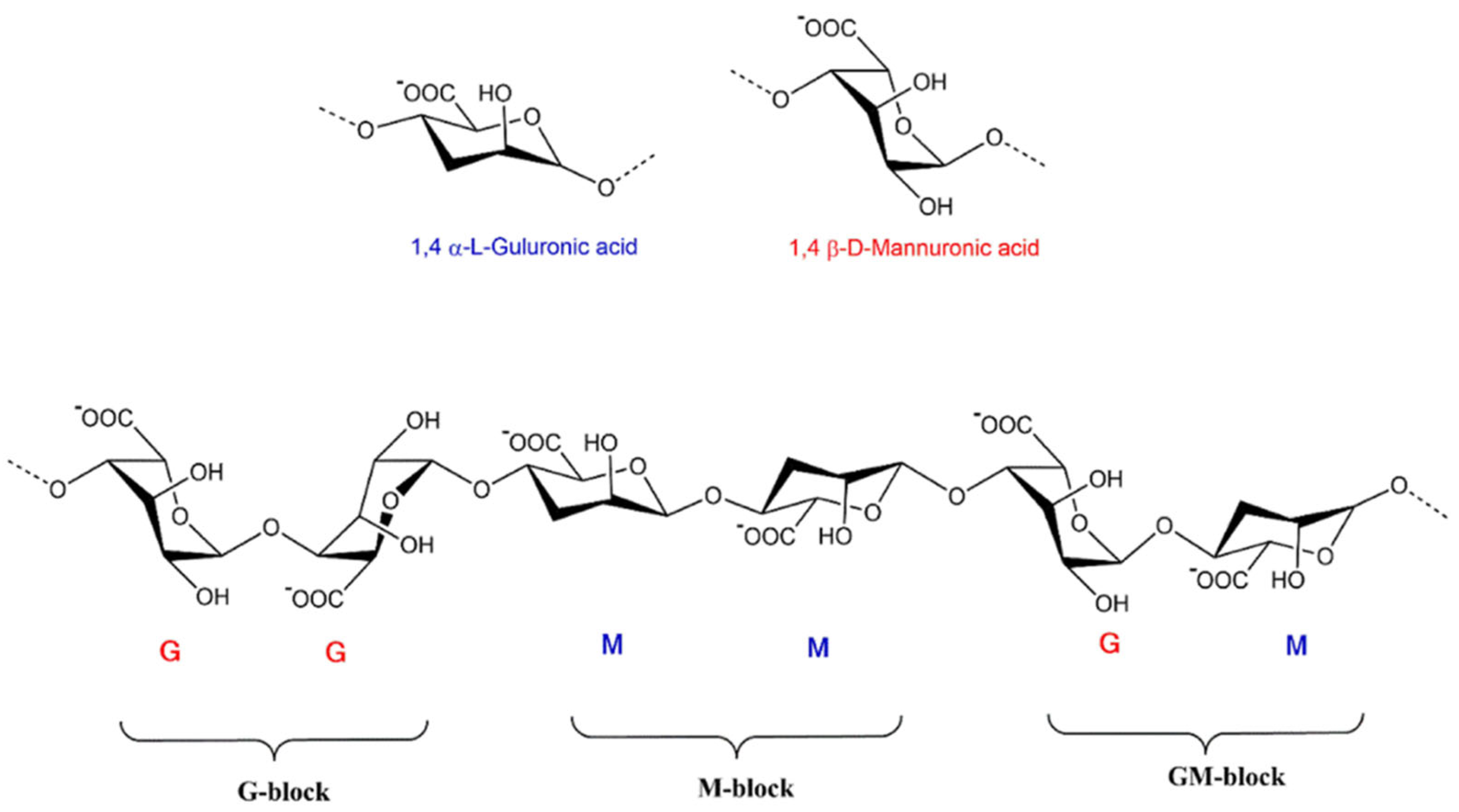

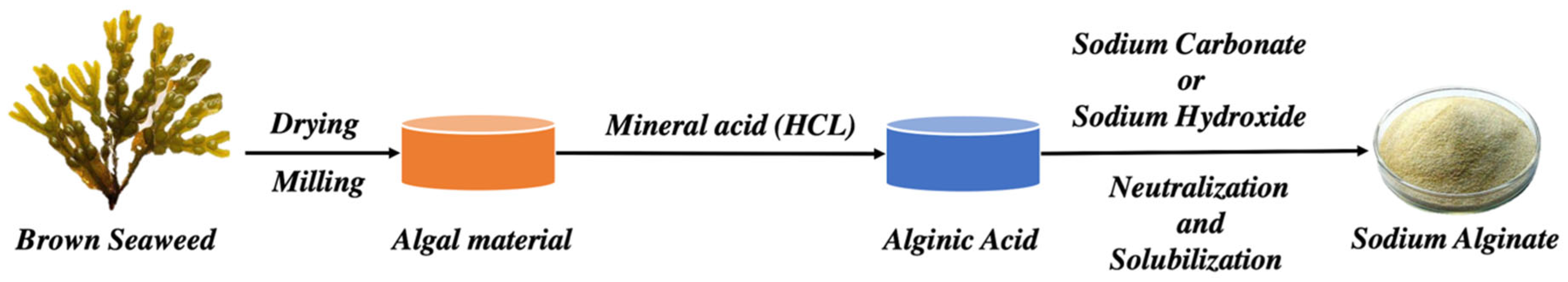

3. Sources of Extraction and Properties of Alginate

4. Hydrogel Formation Methods

4.1. Ionic Cross-Linking

4.2. Covalent Cross-Linking

4.3. Photo Crosslinking

4.4. Click Chemistry Reactions

4.5. Thermal Gelling

4.6. Cell Cross-Linking

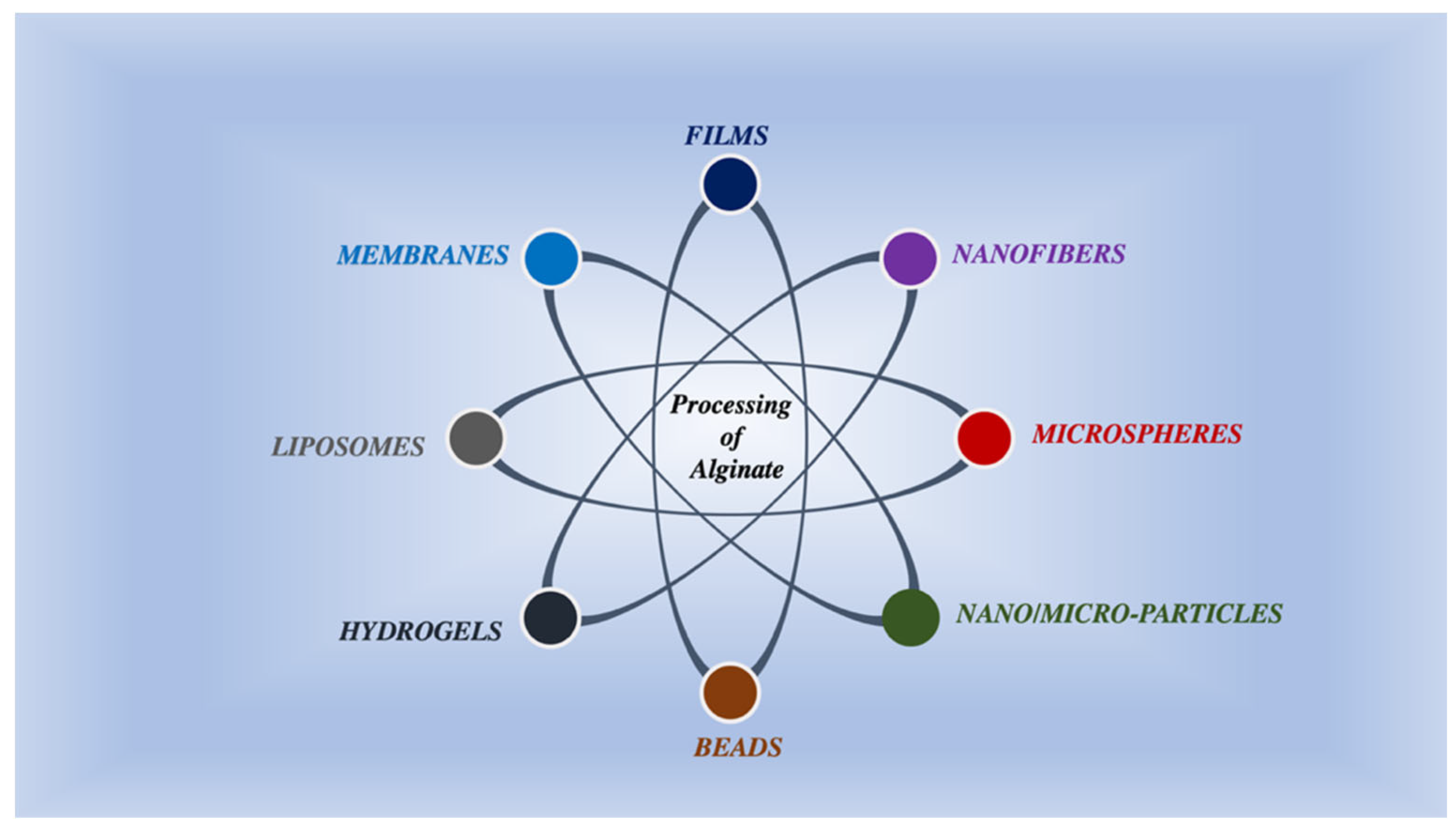

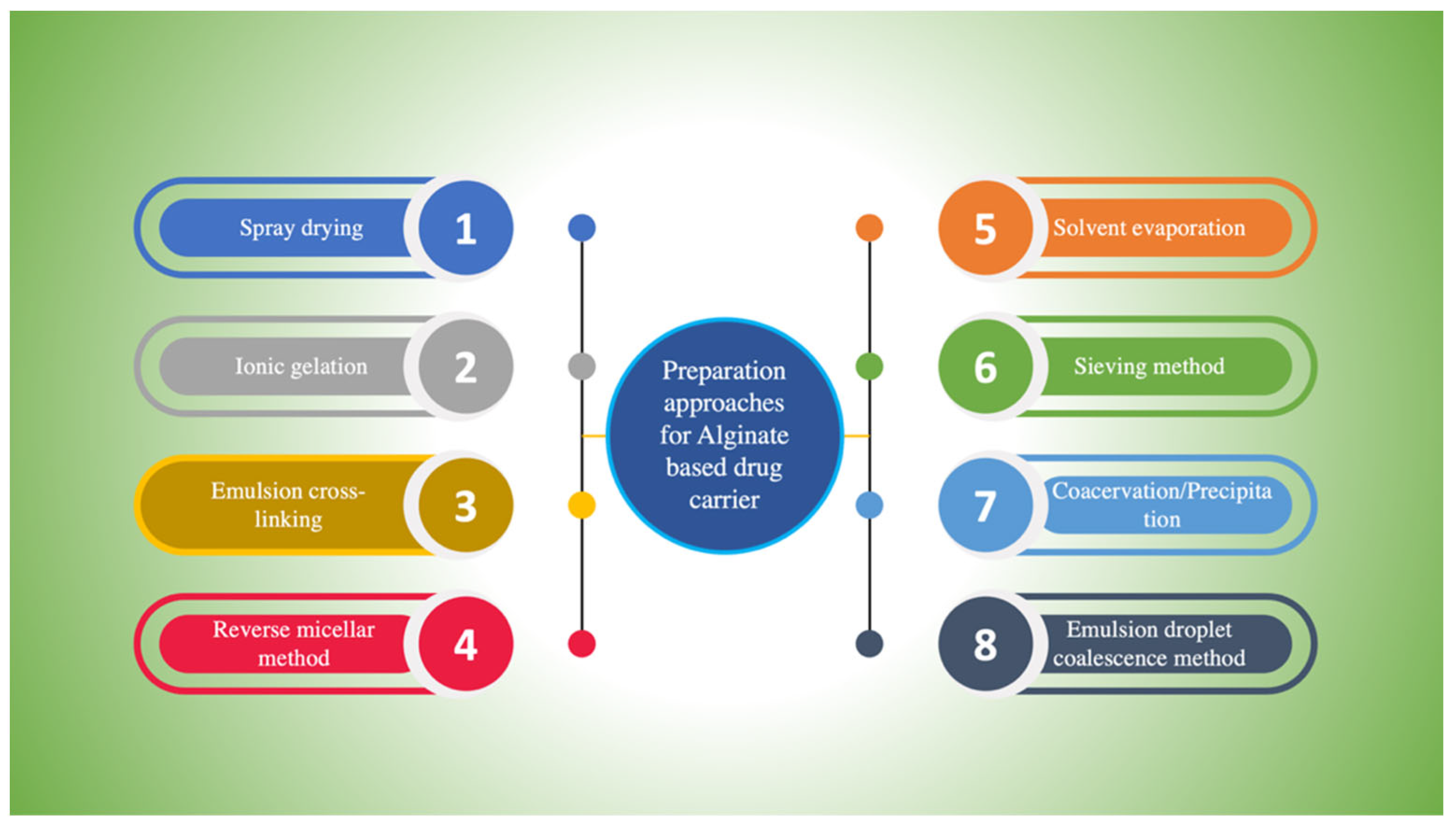

5. ALG Particles Formation Methods

6. Current Advancements in ALG Formulations in Drug Delivery

6.1. Oral Drug Delivery

6.2. Ocular Drug Delivery

6.3. Pulmonary Drug Delivery

6.4. Vaginal Drug Delivery

6.5. Nasal Drug Delivery

6.6. Transdermal Drug Delivery

6.7. Mucosal Drug Delivery

6.8. Intravenous Drug Delivery

6.9. Others

7. Recent Advances in ALG Formulations in Wound Healing

| Type of Wound Dressing Materials | ALG-Based Composite Materials | Applications | References |

|---|---|---|---|

| Nanocomposite hydrogel | ALG/Eudragit | Chronic cutaneous wound healing in diabetic mice | [367] |

| Hydrogel | ALG/collagen | Drug delivery for skin wounds in trauma patients | [368] |

| Hydrogel | ALG/Pluronic F127 | Drug release-based bleeding wound healing | [369] |

| Films | ALG | Chronic wound healing | [370] |

| Hydrogel | ALG/gelatin methacrylate | Wound healing | [371] |

| Hydrogel | Oxidized ALG | Chronic wound healing in diabetic mice | [372] |

| Thermoreversible hydrogel | SA/chondroitin sulfate | Drug delivery and diabetic wound healing | [373] |

| Ion exchange responsive film | ALG/hyaluronate | Drug delivery and skin wound healing | [374] |

| Films | ALG/pectin | Wound healing for moderate exudates | [375] |

| Hydrogel | SA/poly(N-isopropyl acrylamide) | Drug delivery and wound healing | [376] |

| Xerogel | ALG/g-polyethylene glycol methacrylate | Wound healing | [377] |

| Film | SA/K-carrageenan | Sustained drug release-based topical wound dressing | [378] |

| Electrospun mat | ALG/polyvinyl alcohol | Wound dressing and real-time evaluation of healing | [379] |

| Sponges | ALG/CS/HA | Wound healing in full-thickness wounds in rats | [380] |

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 5-FU | 5-Fluorouracil |

| AAC | antioxidant activity coefficient |

| Aah | Androctonus australis hector |

| AGM | agomelatine |

| AGMPs | sodium alginate(AG)based microparticles |

| ALG | Alginate |

| Alg-APBA | 3-aminophenylboronic acid-modified alginate |

| ALG-CNC NPs | Alginate cellulose nanocrystals nanoparticles |

| AmpB | Amphotericin B |

| ARPE-18 | Human retinal pigmented epithelium cells |

| ATO | Arsenic trioxide |

| BALB/c | Bagg Albino mouse strain |

| BBSA | Bifurcaria bifurcata |

| BCG | Bacille Calmette–Guérin |

| BET | Brunauer–Emmett–Teller |

| BSA | Bovine serum albumin |

| CA | Calcium alginate |

| CAC | composite alginate collagen |

| CaG | calcium gluconate |

| CANPs | chitosan/alginate nanoparticles |

| CBSA | C. barbata sodium alginate |

| CD | Crohn’s disease |

| CDD | Curcumin diethyl disuccinate |

| CFX | Cefixime |

| CMC | carboxymethyl cellulose |

| CNCs | Cellulose nanocrystals |

| COPD | Chronic obstructive pulmonary disease |

| CpG ODN | CpG oligodeoxynucleotides |

| CS | Chitosan |

| CTFR | cystic fibrosis transmembrane conductance regulator |

| DDS | Drug delivery system |

| DLS | Dynamic light scattering |

| Dox | Doxorubicin |

| DPPH | 1,1-Diphenyl-2 picrylhydrazyl |

| DTZ | diltiazem |

| ECT | Encapsulated-cell therapy |

| EE | Entrapment efficiency |

| ERG | electroretinogram |

| F–ERG | Flash electroretinogram |

| Fe3O4-SA-DOX | Fe3O4-sodium alginate–doxorubicin |

| FITC | fluorescein isothiocyanate |

| FSSA | Fucus spiralis L. |

| G | 4-α-L-guluronic acid |

| GA | gallic acid |

| GDNF | glial-derived neurotropic factor |

| GL | glycyrrhizin |

| GO | graphene oxide |

| GSM | glyceryl monostearate |

| HA | Hyaluronic acid |

| HaCat | Cultured Human Keratinocyte |

| HAI | Haemagglutinin inhibition |

| HAp | hydroxyapatite |

| HB-CNPs | HbsAg-loaded chitosan nanoparticles |

| HbsAg | Hepatitis B surface antigen |

| HEK293 | Human Embryonic Kidney cells |

| HEMA | (Hydroxyethyl)methacrylate |

| HPBCD | Hydroxypropyl beta cyclodextrin |

| HPMC | Hydroxypropyl methylcellulose |

| HP-β-CD | hydroxypropyl-beta-cyclodextrin |

| i.m. | intramuscular |

| IL | Interleukins |

| KF | ketotifen fumarate |

| KGM | Konjac glucomannan |

| M | 1,4-linked-β-D-mannuronic acid |

| MA | Methyl acrylate |

| MAPTAC | Methacryolyl aminopropyl trimethyl ammonium chloride |

| m-CNC | magnetic cellulose nanocrystal |

| MFS | Miltefosine |

| MIC | Minimum inhibitory concentration |

| MMP-2 | Matrix metalloproteinase-2 |

| M-MSNs | magnetic mesoporous silica nanoparticles |

| MNs | Microneedles |

| MPs | Microparticles |

| MTT | 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyl tetrazolium bromide |

| NLC | nanostructured lipid carriers |

| nMBA | N, N′-methylenebisacrylamide |

| OA | Oxidized alginate |

| PAH | poly(allylamine hydrochloride) |

| PBMC | Peripheral blood mononuclear cell |

| PCL | Polycaprolactone |

| PECs | polyelectrolyte complexes |

| PEG | Polyethylene glycol |

| PEG-co-PCL | poly (ethylene glycol)-co-poly(-caprolactone) |

| PEG@VTMSg-CS | Polyethylene glycol coated vinyl trimethoxy silane-g-chitosan |

| PEM | polyelectrolyte multilayers |

| PF | Pluronic |

| PFD | pirfenidone |

| P-gp shRNA | P-glycoprotein short hairpin RNA |

| PGX | Pressurized gas expanded liquid |

| PLC/PEG | poly(caprolactone)/polyethylene glycol |

| PLGA | poly (lactic-co-glycolic acid) |

| PLL | Polylysine |

| PMX | Polymyxin B |

| PR8-ALG | PR8 influenza virus sodium alginate |

| PR8-CHT | PR8 influenza virus chitosan |

| PR8-TMC-ALG | PR8 influenza virus sodium alginate-coated chitosan and trimethyl chitosan |

| PSSCMA | poly(4-styrenesulfonic acid-co-maleic acid) sodium salt |

| RBA | Relative Bioavailability |

| RCS | Royal College of Surgeons |

| RPA | Relative Pharmacologic Availability |

| s.c. | subcutaneous |

| SA | sodium alginate |

| SA-ATO-NPs | make ATO-loaded sodium alginate nanoparticles |

| SCC | squamous cell carcinoma |

| SD rat | Sprague Dawley rat |

| SGF | simulated gastric fluid |

| SH | sulfhydryl |

| SpBMP-9 | Small peptide Bone Morphogenetic Protein 9 |

| SRG | Sargassum sp |

| SS | salbutamol sulfate |

| SWCNT-GI | single-walled carbon nanotube modified by glucose |

| TA | Tannic acid |

| TCS | thiolated-chitosan coated sodium alginate |

| TEM | Transmission electron microscopy |

| THSG | 2,3,5,40 -tetrahydroxystilbene 2-O-β-D-glucoside |

| TRB | Turbinaria sp |

| TSA | thiolated sodium alginate |

| UTI | Urinary tract infection |

| VEP | visual evoked potential |

| VLF-AG-NPs | venlafaxine alginate nanoparticles |

| XRD | X-ray Diffraction |

References

- Jain, K.K. Drug Delivery Systems—An Overview. Methods Mol. Biol. 2008, 437, 1–50. [Google Scholar]

- Ansari, M.J.; Ahmed, M.M.; Anwer, M.K.; Jamil, S.; Alshetaili, A.S.; Ali, R.; Shakeel, F. Formulation and Characterization of Fluconazole Loaded Olive Oil Nanoemulsions. Indo Am. J. Pharm. Sci. 2017, 4, 852–860. [Google Scholar]

- Agrawal, P. Significance of Polymers in Drug Delivery System. J. Pharmacovigil. 2015, 3, 10–12. [Google Scholar] [CrossRef]

- Bhowmik, D.; Gopinath, H.; Kumar, B.P.; Duraivel, S.; Kumar, K.P.S. Controlled Release Drug Delivery Systems. Pharma Innov. J. 2012, 1, 24–32. [Google Scholar]

- Abourehab, M.A.S.; Ansari, M.J.; Singh, A.; Hassan, A.; Abdelgawad, M.A.; Shrivastav, P.; Abualsoud, B.M.; Amaral, L.S.; Pramanik, S. Cubosomes as an Emerging Platform for Drug Delivery: A State-of-the-Art Review. J. Mater. Chem. B 2022, 10, 2781–2819. [Google Scholar] [CrossRef]

- Ansari, M.J. An Overview of Techniques for Multifold Enhancement in Solubility of Poorly Soluble Drugs. Curr. Issues Pharm. Med. Sci. 2019, 32, 203–209. [Google Scholar] [CrossRef]

- Ahmed, M.M.; Fatima, F.; Anwer, M.K.; Ansari, M.J.; Das, S.S.; Alshahrani, S.M. Development and Characterization of Ethyl Cellulose Nanosponges for Sustained Release of Brigatinib for the Treatment of Non-Small Cell Lung Cancer. J. Polym. Eng. 2020, 40, 823–832. [Google Scholar] [CrossRef]

- Grund, S.; Bauer, M.; Fischer, D. Polymers in Drug Delivery-State of the Art and Future Trends. Adv. Eng. Mater. 2011, 13, 61–87. [Google Scholar] [CrossRef]

- Zhuo, F.; Abourehab, M.A.S.; Hussain, Z. Hyaluronic Acid Decorated Tacrolimus-Loaded Nanoparticles: Efficient Approach to Maximize Dermal Targeting and Anti-Dermatitis Efficacy. Carbohydr. Polym. 2018, 197, 478–489. [Google Scholar] [CrossRef] [PubMed]

- Langer, R. Polymeric Delivery Systems for Controlled Drug Release. Chem. Eng. Commun. 1980, 6, 1–48. [Google Scholar] [CrossRef]

- Mady, F.M.; Ibrahim, S.; Abourehab, M. Development and Evaluation of Alginate-Gum Blend Mucoadhesive Microspheres for Controlled Release of Metformin Hydrochloride. J. Adv. Biomed. Pharm. Sci. 2021, 4, 111–118. [Google Scholar] [CrossRef]

- Hussain, Z.; Rahim, M.A.; Jan, N.; Shah, H.; Rawas-Qalaji, M.; Khan, S.; Sohail, M.; Thu, H.E.; Ramli, N.A.; Sarfraz, R.M.; et al. Cell Membrane Cloaked Nanomedicines for Bio-Imaging and Immunotherapy of Cancer: Improved Pharmacokinetics, Cell Internalization and Anticancer Efficacy. J. Control. Release 2021, 335, 130–157. [Google Scholar] [CrossRef]

- Pramanik, S.; Sali, V. Connecting the Dots in Drug Delivery: A Tour d’horizon of Chitosan-Based Nanocarriers System. Int. J. Biol. Macromol. 2021, 169, 103–121. [Google Scholar] [CrossRef]

- Abourehab, M.A.; Ahmed, O.A.; Balata, G.F.; Almalki, W.H. Self-Assembled Biodegradable Polymeric Micelles to Improve Dapoxetine Delivery across the Blood-Brain Barrier. Int. J. Nanomed. 2018, 13, 3679–3687. [Google Scholar] [CrossRef]

- Dong, J.; Tao, L.; Abourehab, M.A.S.; Hussain, Z. Design and Development of Novel Hyaluronate-Modified Nanoparticles for Combo-Delivery of Curcumin and Alendronate: Fabrication, Characterization, and Cellular and Molecular Evidences of Enhanced Bone Regeneration. Int. J. Biol. Macromol. 2018, 116, 1268–1281. [Google Scholar] [CrossRef]

- Fatima, I.; Rasul, A.; Shah, S.; Saadullah, M.; Islam, N.; Khames, A.; Salawi, A.; Ahmed, M.M.; Almoshari, Y.; Abbas, G.; et al. Novasomes as Nano-Vesicular Carriers to Enhance Topical Delivery of Fluconazole: A New Approach to Treat Fungal Infections. Molecules 2022, 27, 2936. [Google Scholar] [CrossRef]

- Ashfaq, M.; Shah, S.; Rasul, A.; Hanif, M.; Khan, H.U.; Khames, A.; Abdelgawad, M.A.; Ghoneim, M.M.; Ali, M.Y.; Abourehab, M.A.S.; et al. Enhancement of the Solubility and Bioavailability of Pitavastatin through a Self-Nanoemulsifying Drug Delivery System (SNEDDS). Pharmaceutics 2022, 14, 482. [Google Scholar] [CrossRef]

- Abdel-Kader, M.; Al-Shdefat, R. Evaluation of Antifungal Activity of Olive Oil Based Nanoemulsions. Bull. Env. Pharmacol. Life Sci. 2016, 5, 1–4. [Google Scholar]

- Tiwari, G.; Tiwari, R.; Bannerjee, S.; Bhati, L.; Pandey, S.; Pandey, P.; Sriwastawa, B. Drug Delivery Systems: An Updated Review. Int. J. Pharm. Investig. 2012, 2, 2–11. [Google Scholar] [CrossRef]

- Hamid Akash, M.S.; Rehman, K.; Chen, S. Natural and Synthetic Polymers as Drug Carriers for Delivery of Therapeutic Proteins. Polym. Rev. 2015, 55, 371–406. [Google Scholar] [CrossRef]

- Pramanik, S.; Shrivastav, P.; Pramanik, S.; Vaidya, G.; Abdelgawad, M.A.; Ghoneim, M.M.; Singh, A.; Abualsoud, B.M.; Amaral, L.S.; Abourehab, M.A.S. Bacterial Cellulose as a Potential Biopolymer in Biomedical Applications: A State-of-the-Art Review. J. Mater. Chem. B 2022, 10, 3199–3241. [Google Scholar] [CrossRef]

- Hay, I.D.; Rehman, Z.U.; Moradali, M.F.; Wang, Y.; Rehm, B.H.A. Microbial Alginate Production, Modification and Its Applications. Microb. Biotechnol. 2013, 6, 637–650. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.Y.; Mooney, D.J. Alginate: Properties and Biomedical Applications. Prog. Polym. Sci. 2012, 37, 106–126. [Google Scholar] [CrossRef]

- Remminghorst, U.; Rehm, B.H.A. Bacterial Alginates: From Biosynthesis to Applications. Biotechnol. Lett. 2006, 28, 1701–1712. [Google Scholar] [CrossRef] [PubMed]

- Sachan, N.; Pushkar, S.; Jha, A.; Bhattcharya, A. Sodium Alginate: The Wonder Polymer for Controlled Drug Delivery. J. Pharm. Res. 2009, 2, 1191–1199. [Google Scholar]

- Tavakoli, J.; Laisak, E.; Gao, M.; Tang, Y. AIEgen Quantitatively Monitoring the Release of Ca2+ during Swelling and Degradation Process in Alginate Hydrogels. Mater. Sci. Eng. C 2019, 104, 109951. [Google Scholar] [CrossRef] [PubMed]

- Abasalizadeh, F.; Moghaddam, S.V.; Alizadeh, E.; akbari, E.; Kashani, E.; Fazljou, S.M.B.; Torbati, M.; Akbarzadeh, A. Alginate-Based Hydrogels as Drug Delivery Vehicles in Cancer Treatment and Their Applications in Wound Dressing and 3D Bioprinting. J. Biol. Eng. 2020, 14, 8. [Google Scholar] [CrossRef]

- Mohammed, A.; Bissoon, R.; Bajnath, E.; Mohammed, K.; Lee, T.; Bissram, M.; John, N.; Jalsa, N.K.; Lee, K.Y.; Ward, K. Multistage Extraction and Purification of Waste Sargassum Natans to Produce Sodium Alginate: An Optimization Approach. Carbohydr. Polym. 2018, 198, 109–118. [Google Scholar] [CrossRef] [PubMed]

- Qin, Y. Alginate Fibres: An Overview of the Production Processes and Applications in Wound Management. Polym. Int. 2008, 57, 171–180. [Google Scholar] [CrossRef]

- Satheeshababu, B.K.; Mohamed, I. Synthesis and Characterization of Sodium Alginate Conjugate and Study of Effect of Conjugation on Drug Release from Matrix Tablet. Indian J. Pharm. Sci. 2015, 77, 579–585. [Google Scholar] [CrossRef] [PubMed]

- Zubia, M.; Payri, C.; Deslandes, E. Alginate, Mannitol, Phenolic Compounds and Biological Activities of Two Range-Extending Brown Algae, Sargassum Mangarevense and Turbinaria Ornata (Phaeophyta: Fucales), from Tahiti (French Polynesia). J. Appl. Phycol. 2008, 20, 1033–1043. [Google Scholar] [CrossRef]

- Torres, M.R.; Sousa, A.P.A.; Silva Filho, E.A.T.; Melo, D.F.; Feitosa, J.P.A.; de Paula, R.C.M.; Lima, M.G.S. Extraction and Physicochemical Characterization of Sargassum Vulgare Alginate from Brazil. Carbohydr. Res. 2007, 342, 2067–2074. [Google Scholar] [CrossRef]

- Fenoradosoa, T.A.; Ali, G.; Delattre, C.; Laroche, C.; Petit, E.; Wadouachi, A.; Michaud, P. Extraction and Characterization of an Alginate from the Brown Seaweed Sargassum Turbinarioides Grunow. J. Appl. Phycol. 2010, 22, 131–137. [Google Scholar] [CrossRef]

- Blanco-Pascual, N.; Montero, M.P.; Gómez-Guillén, M.C. Antioxidant Film Development from Unrefined Extracts of Brown Seaweeds Laminaria Digitata and Ascophyllum Nodosum. Food Hydrocoll. 2014, 37, 100–110. [Google Scholar] [CrossRef]

- Sellimi, S.; Younes, I.; Ayed, H.B.; Maalej, H.; Montero, V.; Rinaudo, M.; Dahia, M.; Mechichi, T.; Hajji, M.; Nasri, M. Structural, Physicochemical and Antioxidant Properties of Sodium Alginate Isolated from a Tunisian Brown Seaweed. Int. J. Biol. Macromol. 2015, 72, 1358–1367. [Google Scholar] [CrossRef]

- Gomez, C.G.; Pérez Lambrecht, M.V.; Lozano, J.E.; Rinaudo, M.; Villar, M.A. Influence of the Extraction-Purification Conditions on Final Properties of Alginates Obtained from Brown Algae (Macrocystis Pyrifera). Int. J. Biol. Macromol. 2009, 44, 365–371. [Google Scholar] [CrossRef]

- González-lópez, N.; Moure, A.; Domínguez, H. Hydrothermal Fractionation of Sargassum Muticum Biomass. J. Appl. Phycol. 2012, 24, 1569–1578. [Google Scholar] [CrossRef]

- Pascaline, M.; Andriamanantoanina, H.; Heyraud, A.; Rinaudo, M. Food Hydrocolloids Structure and Properties of Three Alginates from Madagascar Seacoast Algae. Food Hydrocoll. 2013, 32, 143–146. [Google Scholar] [CrossRef]

- Mazumder, A.; Holdt, S.L.; De Francisci, D.; Alvarado-Morales, M.; Mishra, H.N.; Angelidaki, I. Extraction of Alginate from Sargassum Muticum: Process Optimization and Study of Its Functional Activities. J. Appl. Phycol. 2016, 28, 3625–3634. [Google Scholar] [CrossRef]

- Vauchel, P.; Arhaliass, A.; Legrand, J.; Kaas, R.; Baron, R. Decrease in Dynamic Viscosity and Average Molecular Weight of Alginate from Laminaria Digitata during Alkaline Extraction1. J. Phycol. 2008, 44, 515–517. [Google Scholar] [CrossRef]

- Vauchel, P.; Kaas, R.; Arhaliass, A.; Baron, R.; Legrand, J. A New Process for Extracting Alginates from Laminaria Digitata: Reactive Extrusion. Food Bioprocess Technol. 2008, 1, 297–300. [Google Scholar] [CrossRef]

- Peteiro, C. Alginate Production from Marine Macroalgae, with Emphasis on Kelp Farming. In Alginates and Their Biomedical Applications; Rehm, B.H.A., Moradali, M.F., Eds.; Springer: Singapore, 2018; pp. 27–66. ISBN 978-981-10-6910-9. [Google Scholar]

- Ching, S.H.; Bansal, N.; Bhandari, B. Alginate Gel Particles–A Review of Production Techniques and Physical Properties. Crit. Rev. Food Sci. Nutr. 2017, 57, 1133–1152. [Google Scholar] [CrossRef]

- Cardoso, M.J.; Costa, R.R.; Mano, J.F. Marine Origin Polysaccharides in Drug Delivery Systems. Mar. Drugs 2016, 14, 34. [Google Scholar] [CrossRef]

- Fertah, M.; Belfkira, A.; montassir Dahmane, E.; Taourirte, M.; Brouillette, F. Extraction and Characterization of Sodium Alginate from Moroccan Laminaria Digitata Brown Seaweed. Arab. J. Chem. 2017, 10, S3707–S3714. [Google Scholar] [CrossRef]

- Augst, A.D.; Kong, H.J.; Mooney, D.J. Alginate Hydrogels as Biomaterials. Macromol. Biosci. 2006, 6, 623–633. [Google Scholar] [CrossRef]

- Jain, D.; Bar-Shalom, D. Alginate Drug Delivery Systems: Application in Context of Pharmaceutical and Biomedical Research. Drug Dev. Ind. Pharm. 2014, 40, 1576–1584. [Google Scholar] [CrossRef]

- Tønnesen, H.H.; Karlsen, J. Alginate in Drug Delivery Systems. Drug Dev. Ind. Pharm. 2002, 28, 621–630. [Google Scholar] [CrossRef]

- Haugstad, K.E.; Håti, A.G.; Nordgård, C.T.; Adl, P.S.; Maurstad, G.; Sletmoen, M.; Draget, K.I.; Dias, R.S.; Stokke, B.T. Direct Determination of Chitosan–Mucin Interactions Using a Single-Molecule Strategy: Comparison to Alginate–Mucin Interactions. Polymers 2015, 7, 161–185. [Google Scholar] [CrossRef]

- Taylor, C.; Pearson, J.P.; Draget, K.I.; Dettmar, P.W.; Smidsrød, O. Rheological Characterisation of Mixed Gels of Mucin and Alginate. Carbohydr. Polym. 2005, 59, 189–195. [Google Scholar] [CrossRef]

- Aderibigbe, B.A.; Buyana, B. Alginate in Wound Dressings. Pharmaceutics 2018, 10, 42. [Google Scholar] [CrossRef]

- Wang, B.; Wan, Y.; Zheng, Y.; Lee, X.; Liu, T.; Yu, Z.; Huang, J.; Ok, Y.S.; Chen, J.; Gao, B.; et al. Technology Alginate-Based Composites for Environmental Applications: A Critical Review. Crit. Rev. Environ. Sci. Technol. 2019, 49, 318–356. [Google Scholar] [CrossRef]

- Pawar, S.N.; Edgar, K.J. Biomaterials Alginate Derivatization: A Review of Chemistry, Properties and Applications. Biomaterials 2012, 33, 3279–3305. [Google Scholar] [CrossRef]

- Spasojevic, M.; Bhujbal, S.; Paredes, G.; de Haan, B.J.; Schouten, A.J.; de Vos, P. Considerations in Binding Diblock Copolymers on Hydrophilic Alginate Beads for Providing an Immunoprotective Membrane. J. Biomed. Mater. Res. Part. A 2014, 102, 1887–1896. [Google Scholar] [CrossRef]

- Zhou, R.; Shi, X.; Gao, Y.; Cai, N.; Jiang, Z.; Xu, X. Anti-Inflammatory Activity of Guluronate Oligosaccharides Obtained by Oxidative Degradation from Alginate in Lipopolysaccharide-Activated Murine Macrophage RAW 264.7 Cells. J. Agric. Food Chem. 2015, 63, 160–168. [Google Scholar] [CrossRef]

- Rocha de Souza, M.C.; Marques, C.T.; Guerra Dore, C.M.; Ferreira da Silva, F.R.; Oliveira Rocha, H.A.; Leite, E.L. Antioxidant Activities of Sulfated Polysaccharides from Brown and Red Seaweeds. J. Appl. Phycol. 2007, 19, 153–160. [Google Scholar] [CrossRef]

- Maciel, D.; Figueira, P.; Xiao, S.; Hu, D.; Shi, X.; Rodrigues, J.; Tomás, H.; Li, Y. Redox-Responsive Alginate Nanogels with Enhanced Anticancer Cytotoxicity. Biomacromolecules 2013, 14, 3140–3146. [Google Scholar] [CrossRef] [PubMed]

- Ansari, M.J.; Rajendran, R.R.; Mohanto, S.; Agarwal, U.; Panda, K.; Dhotre, K.; Manne, R.; Deepak, A.; Zafar, A.; Yasir, M.; et al. Poly(N-Isopropylacrylamide)-Based Hydrogels for Biomedical Applications: A Review of the State-of-the-Art. Gels 2022, 8, 454. [Google Scholar] [CrossRef]

- Grant, G.T.; Morris, E.R.; Rees, D.A.; Smith, P.J.C.; Thom, D. Biological Interactions between Polysaccharides and Divalent Cations: The Egg-Box Model. FEBS Lett. 1973, 32, 195–198. [Google Scholar] [CrossRef]

- Crow, B.B.; Nelson, K.D. Release of Bovine Serum Albumin from a Hydrogel-Cored Biodegradable Polymer Fiber. Biopolymers 2006, 81, 419–427. [Google Scholar] [CrossRef] [PubMed]

- Kuo, C.K.; Ma, P.X. Ionically Crosslinked Alginate Hydrogels as Scaffolds for Tissue Engineering: Part 1. Structure, Gelation Rate and Mechanical Properties. Biomaterials 2001, 22, 511–521. [Google Scholar] [CrossRef]

- Drury, J.L.; Dennis, R.G.; Mooney, D.J. The Tensile Properties of Alginate Hydrogels. Biomaterials 2004, 25, 3187–3199. [Google Scholar] [CrossRef] [PubMed]

- Urzedo, A.L.; Gonçalves, M.C.; Nascimento, M.H.M.; Lombello, C.B.; Nakazato, G.; Seabra, A.B. Cytotoxicity and Antibacterial Activity of Alginate Hydrogel Containing Nitric Oxide Donor and Silver Nanoparticles for Topical Applications. ACS Biomater. Sci. Eng. 2020, 6, 2117–2134. [Google Scholar] [CrossRef]

- Bruchet, M.; Melman, A. Fabrication of Patterned Calcium Cross-Linked Alginate Hydrogel Films and Coatings through Reductive Cation Exchange. Carbohydr. Polym. 2015, 131, 57–64. [Google Scholar] [CrossRef] [PubMed]

- Gattás-Asfura, K.M.; Fraker, C.A.; Stabler, C.L. Covalent Stabilization of Alginate Hydrogel Beads via Staudinger Ligation: Assessment of Poly(Ethylene Glycol) and Alginate Cross-Linkers. J. Biomed. Mater. Res. A 2011, 99, 47–57. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, R.; Kulkarni, G.T.; Ramana, M.V.; de Jesus Andreoli Pinto, T.; Kikuchi, I.S.; Molim Ghisleni, D.D.; de Souza Braga, M.; De Bank, P.; Dua, K. Dual Crosslinked Pectin–Alginate Network as Sustained Release Hydrophilic Matrix for Repaglinide. Int. J. Biol. Macromol. 2017, 97, 721–732. [Google Scholar] [CrossRef]

- Eiselt, P.; Lee, K.Y.; Mooney, D.J. Rigidity of Two-Component Hydrogels Prepared from Alginate and Poly(Ethylene Glycol)-Diamines. Macromolecules 1999, 32, 5561–5566. [Google Scholar] [CrossRef]

- Lee, K.Y.; Rowley, J.A.; Eiselt, P.; Moy, E.M.; Bouhadir, K.H.; Mooney, D.J. Controlling Mechanical and Swelling Properties of Alginate Hydrogels Independently by Cross-Linker Type and Cross-Linking Density. Macromolecules 2000, 33, 4291–4294. [Google Scholar] [CrossRef]

- Gao, Y.; Jin, X. Dual Crosslinked Methacrylated Alginate Hydrogel Micron Fibers and Tissue Constructs for Cell Biology. Mar. Drugs 2019, 17, 557. [Google Scholar] [CrossRef] [PubMed]

- Basu, S.; Pacelli, S.; Paul, A. Self-Healing DNA-Based Injectable Hydrogels with Reversible Covalent Linkages for Controlled Drug Delivery. Acta Biomater. 2020, 105, 159–169. [Google Scholar] [CrossRef] [PubMed]

- Xing, L.; Sun, J.; Tan, H.; Yuan, G.; Li, J.; Jia, Y.; Xiong, D.; Chen, G.; Lai, J.; Ling, Z.; et al. Covalently Polysaccharide-Based Alginate/Chitosan Hydrogel Embedded Alginate Microspheres for BSA Encapsulation and Soft Tissue Engineering. Int. J. Biol. Macromol. 2019, 127, 340–348. [Google Scholar] [CrossRef] [PubMed]

- Smeds, K.A.; Pfister-Serres, A.; Miki, D.; Dastgheib, K.; Inoue, M.; Hatchell, D.L.; Grinstaff, M.W. Photocrosslinkable Polysaccharides for in Situ Hydrogel Formation. J. Biomed. Mater. Res. 2001, 54, 115–121. [Google Scholar] [CrossRef]

- Rouillard, A.D.; Berglund, C.M.; Lee, J.Y.; Polacheck, W.J.; Tsui, Y.; Bonassar, L.J.; Kirby, B.J. Methods for Photocrosslinking Alginate Hydrogel Scaffolds with High Cell Viability. Tissue Eng.-Part C Methods 2011, 17, 173–179. [Google Scholar] [CrossRef]

- Bonino, C.A.; Samorezov, J.E.; Jeon, O.; Alsberg, E.; Khan, S.A. Real-Time in Situ Rheology of Alginate Hydrogel Photocrosslinking. Soft Matter 2011, 7, 11510–11517. [Google Scholar] [CrossRef]

- Jeon, O.; Samorezov, J.E.; Alsberg, E. Single and Dual Crosslinked Oxidized Methacrylated Alginate/PEG Hydrogels for Bioadhesive Applications. Acta Biomater. 2014, 10, 47–55. [Google Scholar] [CrossRef] [PubMed]

- Jeon, O.; Bouhadir, K.H.; Mansour, J.M.; Alsberg, E. Photocrosslinked Alginate Hydrogels with Tunable Biodegradation Rates and Mechanical Properties. Biomaterials 2009, 30, 2724–2734. [Google Scholar] [CrossRef] [PubMed]

- Buono, P.; Duval, A.; Averous, L.; Habibi, Y. Lignin-Based Materials Through Thiol–Maleimide “Click” Polymerization. ChemSusChem 2017, 10, 984–992. [Google Scholar] [CrossRef]

- Jain, E.; Neal, S.; Graf, H.; Tan, X.; Balasubramaniam, R.; Huebsch, N. Copper-Free Azide–Alkyne Cycloaddition for Peptide Modification of Alginate Hydrogels. ACS Appl. Bio Mater. 2021, 4, 1229–1237. [Google Scholar] [CrossRef]

- Anugrah, D.S.B.; Ramesh, K.; Kim, M.; Hyun, K.; Lim, K.T. Near-Infrared Light-Responsive Alginate Hydrogels Based on Diselenide-Containing Cross-Linkage for on Demand Degradation and Drug Release. Carbohydr. Polym. 2019, 223, 115070. [Google Scholar] [CrossRef]

- García-Astrain, C.; Avérous, L. Synthesis and Evaluation of Functional Alginate Hydrogels Based on Click Chemistry for Drug Delivery Applications. Carbohydr. Polym. 2018, 190, 271–280. [Google Scholar] [CrossRef]

- Wang, G.; Zhu, J.; Chen, X.; Dong, H.; Li, Q.; Zeng, L.; Cao, X. Alginate Based Antimicrobial Hydrogels Formed by Integrating Diels-Alder “Click Chemistry” and the Thiol-Ene Reaction. RSC Adv. 2018, 8, 11036–11042. [Google Scholar] [CrossRef]

- Lueckgen, A.; Garske, D.S.; Ellinghaus, A.; Desai, R.M.; Stafford, A.G.; Mooney, D.J.; Duda, G.N.; Cipitria, A. Hydrolytically-Degradable Click-Crosslinked Alginate Hydrogels. Biomaterials 2018, 181, 189–198. [Google Scholar] [CrossRef]

- Pérez-Madrigal, M.M.; Shaw, J.E.; Arno, M.C.; Hoyland, J.A.; Richardson, S.M.; Dove, A.P. Robust Alginate/Hyaluronic Acid Thiol-Yne Click-Hydrogel Scaffolds with Superior Mechanical Performance and Stability for Load-Bearing Soft Tissue Engineering. Biomater. Sci. 2020, 8, 405–412. [Google Scholar] [CrossRef]

- Roy, D.; Cambre, J.N.; Sumerlin, B.S. Future Perspectives and Recent Advances in Stimuli-Responsive Materials. Prog. Polym. Sci. 2010, 35, 278–301. [Google Scholar] [CrossRef]

- Zhao, S.; Cao, M.; Li, H.; Li, L.; Xu, W. Synthesis and Characterization of Thermo-Sensitive Semi-IPN Hydrogels Based on Poly(Ethylene Glycol)-Co-Poly($ε$-Caprolactone) Macromer, N-Isopropylacrylamide, and Sodium Alginate. Carbohydr. Res. 2010, 345, 425–431. [Google Scholar] [CrossRef]

- Bezerra, I.C.S.; de Freitas, E.D.; da Silva, M.G.C.; Vieira, M.G.A. Synthesis and Characterization of Furosemide-Loaded Sericin/Alginate Beads Subjected to Thermal or Chemical Cross-Linking for Delayed and Sustained Release. Polym. Adv. Technol. 2021, 32, 461–473. [Google Scholar] [CrossRef]

- Yu, J.; Du, K.T.; Fang, Q.; Gu, Y.; Mihardja, S.S.; Sievers, R.E.; Wu, J.C.; Lee, R.J. The Use of Human Mesenchymal Stem Cells Encapsulated in RGD Modified Alginate Microspheres in the Repair of Myocardial Infarction in the Rat. Biomaterials 2010, 31, 7012–7020. [Google Scholar] [CrossRef]

- Fonseca, K.B.; Bidarra, S.J.; Oliveira, M.J.; Granja, P.L.; Barrias, C.C. Molecularly Designed Alginate Hydrogels Susceptible to Local Proteolysis as Three-Dimensional Cellular Microenvironments. Acta Biomater. 2011, 7, 1674–1682. [Google Scholar] [CrossRef]

- Hua, S.; Ma, H.; Li, X.; Yang, H.; Wang, A. PH-Sensitive Sodium Alginate/Poly(Vinyl Alcohol) Hydrogel Beads Prepared by Combined Ca2+ Crosslinking and Freeze-Thawing Cycles for Controlled Release of Diclofenac Sodium. Int. J. Biol. Macromol. 2010, 46, 517–523. [Google Scholar] [CrossRef]

- Tkalec, G.; Kranvogl, R.; Perva Uzunalić, A.; Knez, Ž.; Novak, Z. Optimisation of Critical Parameters during Alginate Aerogels’ Production. J. Non-Cryst. Solids 2016, 443, 112–117. [Google Scholar] [CrossRef]

- Mattiasson, B.; Kumar, A.; Galeaev, I.Y. Macroporous Polymers: Production Properties and Biotechnological/Biomedical Applications; CRC Press: Boca Raton, FL, USA, 2009; ISBN 1420084623. [Google Scholar]

- Subrahmanyam, R.; Gurikov, P.; Meissner, I.; Smirnova, I. Preparation of Biopolymer Aerogels Using Green Solvents. J. Vis. Exp. 2016, 113, e54116. [Google Scholar] [CrossRef]

- Gurikov, P.; Smirnova, I. Non-Conventional Methods for Gelation of Alginate. Gels 2018, 4, 14. [Google Scholar] [CrossRef]

- Pérez-Madrigal, M.M.; Torras, J.; Casanovas, J.; Häring, M.; Alemán, C.; Díaz, D.D. Paradigm Shift for Preparing Versatile M2+-Free Gels from Unmodified Sodium Alginate. Biomacromolecules 2017, 18, 2967–2979. [Google Scholar] [CrossRef] [PubMed]

- Király, G.; Egu, J.C.; Hargitai, Z.; Kovács, I.; Fábián, I.; Kalmár, J.; Szemán-Nagy, G. Mesoporous Aerogel Microparticles Injected into the Abdominal Cavity of Mice Accumulate in Parathymic Lymph Nodes. Int. J. Mol. Sci. 2021, 22, 9756. [Google Scholar] [CrossRef] [PubMed]

- Vasvári, G.; Kalmár, J.; Veres, P.; Vecsernyés, M.; Bácskay, I.; Fehér, P.; Ujhelyi, Z.; Haimhoffer, Á.; Rusznyák, Á.; Fenyvesi, F.; et al. Matrix Systems for Oral Drug Delivery: Formulations and Drug Release. Drug Discov. Today Technol. 2018, 27, 71–80. [Google Scholar] [CrossRef] [PubMed]

- Veres, P.; Sebők, D.; Dékány, I.; Gurikov, P.; Smirnova, I.; Fábián, I.; Kalmár, J. A Redox Strategy to Tailor the Release Properties of Fe(III)-Alginate Aerogels for Oral Drug Delivery. Carbohydr. Polym. 2018, 188, 159–167. [Google Scholar] [CrossRef] [PubMed]

- Lovskaya, D.; Menshutina, N. Alginate-Based Aerogel Particles as Drug Delivery Systems: Investigation of the Supercritical Adsorption and In Vitro Evaluations. Materials 2020, 13, 329. [Google Scholar] [CrossRef]

- Athamneh, T.; Amin, A.; Benke, E.; Ambrus, R.; Gurikov, P.; Smirnova, I.; Leopold, C.S. Pulmonary Drug Delivery with Aerogels: Engineering of Alginate and Alginate–Hyaluronic Acid Microspheres. Pharm. Dev. Technol. 2021, 26, 509–521. [Google Scholar] [CrossRef]

- Athamneh, T.; Amin, A.; Benke, E.; Ambrus, R.; Leopold, C.S.; Gurikov, P.; Smirnova, I. Alginate and Hybrid Alginate-Hyaluronic Acid Aerogel Microspheres as Potential Carrier for Pulmonary Drug Delivery. J. Supercrit. Fluids 2019, 150, 49–55. [Google Scholar] [CrossRef]

- Sugiura, S.; Oda, T.; Izumida, Y.; Aoyagi, Y. Size Control of Calcium Alginate Beads Containing Living Cells Using Micro-Nozzle Array. Biomaterials 2005, 26, 3327–3331. [Google Scholar] [CrossRef]

- Silva, C.M.; Ribeiro, J.; Vit, I. Alginate Microspheres Prepared by Internal Gelation: Development and Effect on Insulin Stability. Int. J. Pharm. 2006, 311, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Ouerghi, O.; Geesi, M.H.; Ibnouf, E.O.; Ansari, M.J.; Alam, P.; Elsanousi, A.; Kaiba, A.; Riadi, Y. Sol-Gel Synthesized Rutile TiO2 Nanoparticles Loaded with Cardamom Essential Oil: Enhanced Antibacterial Activity. J. Drug Deliv. Sci. Technol. 2021, 64, 102581. [Google Scholar] [CrossRef]

- Ansari, M.J. Factors Affecting Preparation and Properties of Nanoparticles by Nanoprecipitation Method. Indo Am. J. Pharm. Sci. 2017, 4, 4854–4858. [Google Scholar]

- Fundueanu, G.; Nastruzzi, C.; Carpov, A.; Desbrieres, J.; Rinaudo, M. Physico-Chemical Characterization of Ca-Alginate Microparticles Produced with Different Methods. Biomaterials 1999, 20, 1427–1435. [Google Scholar] [CrossRef]

- Seifert, D.B.; Phillips, J.A. Production of Small, Monodispersed Alginate Beads for Cell Immobilization. Biotechnol. Prog. 2008, 13, 562–568. [Google Scholar] [CrossRef]

- Andriola, A.K.; Brun-graeppi, S.; Richard, C.; Bessodes, M.; Scherman, D.; Merten, O. Cell Microcarriers and Microcapsules of Stimuli-Responsive Polymers. J. Control. Release 2011, 149, 209–224. [Google Scholar] [CrossRef]

- Zimmermann, H.; Shirley, S.G.; Zimmermann, U. Alginate-Based Encapsulation of Cells: Past, Present, and Future. Curr. Diab. Rep. 2007, 7, 314–320. [Google Scholar] [CrossRef]

- Reis, C.P.; Neufeld, R.J.; Vilela, S.; Ribeiro, A.J.; Veiga, F. Review and Current Status of Emulsion/Dispersion Technology Using an Internal Gelation Process for the Design of Alginate Particles. J. Microencapsul. 2006, 23, 245–257. [Google Scholar] [CrossRef] [PubMed]

- Shilpa, A.; Agrawal, S.S.; Ray, A.R. Controlled Delivery of Drugs from Alginate Matrix. J. Macromol. Sci.-Polym. Rev. 2003, 43, 187–221. [Google Scholar] [CrossRef]

- Patel, M.A.; AbouGhaly, M.H.H.; Schryer-Praga, J.V.; Chadwick, K. The Effect of Ionotropic Gelation Residence Time on Alginate Cross-Linking and Properties. Carbohydr. Polym. 2017, 155, 362–371. [Google Scholar] [CrossRef]

- Poncelet, D.; Lencki, R.; Beaulieu, C.; Halle, J.P.; Neufeld, R.J.; Fournier, A. Production of Alginate Beads by Emulsification/Internal Gelation. I. Methodology. Appl. Microbiol. Biotechnol. 1992, 38, 39–45. [Google Scholar] [CrossRef]

- Poncelet, D. Production of Alginate Beads by Emulsification/Internal Gelation. Ann. N. Y. Acad. Sci. 2001, 944, 74–82. [Google Scholar] [CrossRef] [PubMed]

- Sæther, H.V.; Holme, H.K.; Maurstad, G.; Smidsrød, O.; Stokke, B.T. Polyelectrolyte Complex Formation Using Alginate and Chitosan. Carbohydr. Polym. 2008, 74, 813–821. [Google Scholar] [CrossRef]

- Rajaonarivony, M.; Vauthier, C.; Couarraze, G.; Puisieux, F.; Couvreur, P. Development of a New Drug Carrier Made from Alginate. J. Pharm. Sci. 1993, 82, 912–917. [Google Scholar] [CrossRef]

- Severino, P.; da Silva, C.F.; Andrade, L.N.; de Lima Oliveira, D.; Campos, J.; Souto, E.B. Alginate Nanoparticles for Drug Delivery and Targeting. Curr. Pharm. Des. 2019, 25, 1312–1334. [Google Scholar] [CrossRef]

- Ansari, M.; Ahmed, M.M.; Fatima; Anwer, M.K.; Jamil, S.; Al-Shdefat, R.; Ali, B. Solubility and Stability Enhancement of Curcumin through Cyclodextrin Complexation. Int. J. Biol. Pharm. Allied Sci. 2014, 3, 2668–2675. [Google Scholar]

- Dawoud, M.; Abourehab, M.A.S.; Abdou, R. Monoolein Cubic Nanoparticles as Novel Carriers for Docetaxel. J. Drug Deliv. Sci. Technol. 2020, 56, 101501. [Google Scholar] [CrossRef]

- El-aziz, E.A.; Elgayar, S.F.; Mady, F.M.; Abourehab, M.A.S.; Hasan, O.A.; Reda, L.M.; Alaaeldin, E. The Potential of Optimized Liposomes in Enhancement of Cytotoxicity and Apoptosis of Encapsulated Egyptian Propolis on Hep-2 Cell Line. Pharmaceutics 2021, 13, 2184. [Google Scholar] [CrossRef]

- Ansari, M.J.; Alshetaili, A.; Aldayel, I.A.; Alablan, F.M.; Alsulays, B.; Alshahrani, S.; Alalaiwe, A.; Ansari, M.N.; Ur Rehman, N.; Shakeel, F. Formulation, Characterization, in Vitro and in Vivo Evaluations of Self-Nanoemulsifying Drug Delivery System of Luteolin. J. Taibah Univ. Sci. 2020, 14, 1386–1401. [Google Scholar] [CrossRef]

- Choi, H.J.; Kim, M.C.; Kang, S.M.; Montemagno, C.D. The Osmotic Stress Response of Split Influenza Vaccine Particles in an Acidic Environment. Arch. Pharm. Res. 2014, 37, 1607–1616. [Google Scholar] [CrossRef]

- Araújo, F.; das Neves, J.; Martins, J.P.; Granja, P.L.; Santos, H.A.; Sarmento, B. Functionalized Materials for Multistage Platforms in the Oral Delivery of Biopharmaceuticals. Prog. Mater. Sci. 2017, 89, 306–344. [Google Scholar] [CrossRef]

- Ansari, M.J. Oral Delivery of Insulin for Treatment of Diabetes: Classical Challenges and Current Opportunities. J. Med. Sci. 2015, 15, 209–220. [Google Scholar] [CrossRef]

- Bowman, K.; Leong, K.W. Chitosan Nanoparticles for Oral Drug and Gene Delivery. Int. J. Nanomed. 2006, 1, 117–128. [Google Scholar] [CrossRef]

- Ilgin, P.; Ozay, H.; Ozay, O. Synthesis and Characterization of PH Responsive Alginate Based-Hydrogels as Oral Drug Delivery Carrier. J. Polym. Res. 2020, 27, 251. [Google Scholar]

- Ayub, A.D.; Chiu, H.I.; Yusuf, S.N.A.M.; Kadir, E.A.; Ngalim, S.H.; Lim, V. Biocompatible Disulphide Cross-Linked Sodium Alginate Derivative Nanoparticles for Oral Colon-Targeted Drug Delivery. Artif. Cells Nanomed. Biotechnol. 2019, 47, 353–369. [Google Scholar] [CrossRef] [PubMed]

- Cong, A.Z.; Shi, Y.; Wang, Y. A Novel Controlled Drug Delivery System Based on Alginate Hydrogel / Chitosan Micelle Composites. Int. J. Biol. Macromol. 2017, 107, 855–864. [Google Scholar] [CrossRef] [PubMed]

- Van De Ven, H.; Paulussen, C.; Feijens, P.B.; Matheeussen, A.; Rombaut, P.; Kayaert, P.; Mooter, G. Van Den PLGA Nanoparticles and Nanosuspensions with Amphotericin B: Potent in Vitro and in Vivo Alternatives to Fungizone and AmBisome. J. Control. Release 2012, 161, 795–803. [Google Scholar] [CrossRef]

- Abourehab, M.A.S.; Khames, A.; Genedy, S.; Mostafa, S.; Khaleel, M.A.; Omar, M.M.; El Sisi, A.M. Sesame Oil-Based Nanostructured Lipid Carriers of Nicergoline, Intranasal Delivery System for Brain Targeting of Synergistic Cerebrovascular Protection. Pharmaceutics 2021, 13, 581. [Google Scholar] [CrossRef] [PubMed]

- Barradas, N.; Cardoso, S.; Castiglione, T.C.; Michael, J.; Gyselle, K.; Holanda, D.; Regina, C.; Mansur, E. Dual Alginate-Lipid Nanocarriers as Oral Delivery Systems for Amphotericin B. Colloids Surf. B Biointerfaces 2018, 166, 187–194. [Google Scholar] [CrossRef]

- Panyam, J.; Labhasetwar, V. Biodegradable Nanoparticles for Drug and Gene Delivery to Cells and Tissue. Adv. Drug Deliv. Rev. 2003, 55, 329–347. [Google Scholar] [CrossRef]

- Ooi, S.Y.; Ahmad, I.; Cairul, M.; Mohd, I. Cellulose Nanocrystals Extracted from Rice Husks as a Reinforcing Material in Gelatin Hydrogels for Use in Controlled Drug Delivery Systems. Ind. Crop. Prod. 2015, 93, 227–234. [Google Scholar] [CrossRef]

- Lin, N.; Huang, J.; Chang, P.R.; Feng, L.; Yu, J. Colloids and Surfaces B: Biointerfaces Effect of Polysaccharide Nanocrystals on Structure, Properties, and Drug Release Kinetics of Alginate-Based Microspheres. Colloids Surf. B Biointerfaces 2011, 85, 270–279. [Google Scholar] [CrossRef]

- Thomas, D.; Latha, M.S.; Thomas, K.K. Journal of Drug Delivery Science and Technology Synthesis and in Vitro Evaluation of Alginate-Cellulose Nanocrystal Hybrid Nanoparticles for the Controlled Oral Delivery of Rifampicin. J. Drug Deliv. Sci. Technol. 2018, 46, 392–399. [Google Scholar] [CrossRef]

- Lakkakula, J.R.; Matshaya, T.; Werner, R.; Krause, M. Cationic Cyclodextrin/Alginate Chitosan Nano Fl Owers as 5- Fl Uorouracil Drug Delivery System. Mater. Sci. Eng. C 2017, 70, 169–177. [Google Scholar] [CrossRef] [PubMed]

- Pitchaya Treenate, P.M. In Vitro Drug Release Profiles of PH-Sensitive Hydroxyethylacryl Chitosan/Sodium Alginate Hydrogels Using Paracetamol as a Soluble Model Drug. Int J Biol Macromol 2017, 99, 71–78. [Google Scholar] [CrossRef]

- Agili, F.A.; Aly, S.F.M. Physicochemical Characterization and Release Properties of Oral Drug Delivery: A PH-Sensitive Nanocomposite Based on Sodium Alginate–Pectin–Tannic Acid–Silver. Polym. Polym. Compos. 2019, 28, 598–608. [Google Scholar] [CrossRef]

- Olayemi, O.J.; Apeji, Y.E.; Isimi, C.Y. Formulation and Evaluation of Cyperus Esculentus (Tiger Nut) Starch-Alginate Microbeads in the Oral Delivery of Ibuprofen. J. Pharm. Innov. 2020, 17, 366–375. [Google Scholar] [CrossRef]

- Chegeni, M.; Rozbahani, Z.S.; Ghasemian, M.; Mehri, M. International Journal of Biological Macromolecules Synthesis and Application of the Calcium Alginate / SWCNT-Gl as a Bio-Nanocomposite for the Curcumin Delivery. Int. J. Biol. Macromol. 2020, 156, 504–513. [Google Scholar] [CrossRef]

- Mao, X.; Li, X.; Zhang, W.; Yuan, L.; Deng, L.; Ge, L.; Mu, C.; Li, D. Development of Microspheres Based on Thiol-Modi Fi Ed Sodium Alginate for Intestinal-Targeted Drug Delivery. ACS Appl. Bio Mater. 2019, 2, 5810–5818. [Google Scholar] [CrossRef]

- Long, L.; Lai, M.; Ke, Z.; Yang, L. Investigation Of Vitamin B 12 -Modi Fi Ed Amphiphilic Sodium Alginate Derivatives For Enhancing The Oral Delivery Ef Fi Cacy Of Peptide Drugs. Int. J. Nanomed. 2019, 14, 7743–7758. [Google Scholar] [CrossRef]

- Chiu, H.I.; Ayub, A.D.; Nur, S.; Mat, A.; Yahaya, N. Docetaxel-Loaded Disulfide Cross-Linked Nanoparticles Derived from Thiolated Sodium Alginate for Colon Cancer Drug Delivery. Pharmaceutics 2020, 12, 38. [Google Scholar] [CrossRef]

- Abdellatif, A.A.H.; Ibrahim, M.A.; Amin, M.A. Cetuximab Conjugated with Octreotide and Entrapped Calcium Alginate-Beads for Targeting Somatostatin Receptors. Sci. Rep. 2020, 10, 4736. [Google Scholar] [CrossRef]

- Kahya, N.; Gölcü, A.; Erim, F.B. Barium Ion Cross-Linked Alginate-Carboxymethyl Cellulose Composites for Controlled Release of Anticancer Drug Methotrexate. J. Drug Deliv. Sci. Technol. 2019, 54, 101324. [Google Scholar] [CrossRef]

- Shamekhi, F.; Tamjid, E.; Khajeh, K. Development of Chitosan Coated Calcium-Alginate Nanocapsules for Oral Delivery of Liraglutide to Diabetic Patients. Int. J. Biol. Macromol. 2018, 120, 460–467. [Google Scholar] [CrossRef] [PubMed]

- Karzar Jeddi, M.; Mahkam, M. Magnetic Nano Carboxymethyl Cellulose-Alginate/Chitosan Hydrogel Beads as Biodegradable Devices for Controlled Drug Delivery. Int. J. Biol. Macromol. 2019, 135, 829–838. [Google Scholar] [CrossRef] [PubMed]

- Urtti, A. Challenges and Obstacles of Ocular Pharmacokinetics and Drug Delivery. Adv. Drug Deliv. Rev. 2006, 58, 1131–1135. [Google Scholar] [CrossRef]

- De, M.; Raviña, M.; Paolicelli, P.; Sanchez, A.; Seijo, B.; Jose, M. Chitosan-Based Nanostructures: A Delivery Platform for Ocular Therapeutics . Adv. Drug Deliv. Rev. 2010, 62, 100–117. [Google Scholar] [CrossRef]

- Rupenthal, I.D.; O’Rourke, M. Ocular Drug Delivery—Eye on Innovation. Drug Deliv. Transl. Res. 2016, 6, 631–633. [Google Scholar] [CrossRef]

- Pedraz, L.; Wahlberg, L.U.; De Vos, P.; Emerich, D. Cell Encapsulation: Technical and Clinical Advances. Trends Pharmacol. Sci. 2015, 36, 537–546. [Google Scholar] [CrossRef]

- Siu, F.; Wong, Y.; Kin, K.; Man, A.; Chu, W.; Pui, B.; Ming, K.; Cheuk, A.; Lo, Y. Biomaterials Injectable Cell-Encapsulating Composite Alginate-Collagen Platform with Inducible Termination Switch for Safer Ocular Drug Delivery. Biomaterials 2019, 201, 53–67. [Google Scholar] [CrossRef]

- Patel, A. Ocular Drug Delivery Systems: An Overview. World J. Pharmacol. 2013, 2, 47–64. [Google Scholar] [CrossRef]

- Shelley, H.; Rodriguez-Galarza, R.M.; Duran, S.H.; Abarca, E.M.; Babu, R.J. In Situ Gel Formulation for Enhanced Ocular Delivery of Nepafenac. J. Pharm. Sci. 2018, 107, 3089–3097. [Google Scholar] [CrossRef] [PubMed]

- Nagarwal, R.C.; Kumar, R.; Pandit, J.K. Chitosan Coated Sodium Alginate-Chitosan Nanoparticles Loaded with 5-FU for Ocular Delivery: In Vitro Characterization and in Vivo Study in Rabbit Eye. Eur. J. Pharm. Sci. 2012, 47, 678–685. [Google Scholar] [CrossRef] [PubMed]

- Noreen, S.; Ghumman, S.A.; Batool, F.; Ijaz, B.; Basharat, M.; Noureen, S.; Kausar, T.; Iqbal, S. Terminalia Arjuna Gum/Alginate in Situ Gel System with Prolonged Retention Time for Ophthalmic Drug Delivery. Int. J. Biol. Macromol. 2020, 152, 1056–1067. [Google Scholar] [CrossRef]

- Polat, H.K.; Pehlivan, S.B.; Özkul, C.; Çalamak, S.; Aytekin, E.; Fırat, A.; Ulubayram, K.; Kocabeyoğlu, S. Development of Besifloxacin HCl Loaded Nanofibrous Ocular Inserts for the Treatment of Bacterial Keratitis: In Vitro, Ex Vivo and in Vivo Evaluation. Int. J. Pharm. 2020, 585, 119552. [Google Scholar] [CrossRef] [PubMed]

- Silva, D.; Pinto, L.F.V.; Bozukova, D.; Santos, L.F.; Serro, A.P.; Saramago, B. Chitosan/Alginate Based Multilayers to Control Drug Release from Ophthalmic Lens. Colloids Surf. B Biointerfaces 2016, 147, 81–89. [Google Scholar] [CrossRef] [PubMed]

- Costa, J.R.; Silva, N.C.; Sarmento, B.; Pintado, M. Potential Chitosan-Coated Alginate Nanoparticles for Ocular Delivery of Daptomycin. Eur. J. Clin. Microbiol. 2015, 34, 1255–1262. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Chauhan, N.; Gopal, M.; Kumar, R. International Journal of Biological Macromolecules Development and Evaluation of Alginate—Chitosan Nanocapsules for Controlled Release of Acetamiprid. Int. J. Biol. Macromol. 2015, 81, 631–637. [Google Scholar] [CrossRef]

- Gupta, H.; Aqil, M.; Khar, R.K.; Ali, A.; Bhatnagar, A. An Alternative in Situ Gel-Formulation of Levofloxacin Eye Drops for Prolong Ocular Retention. J. Pharm. Bioallied Sci. 2015, 7, 9–14. [Google Scholar] [CrossRef]

- Gökçe, E.H.; Okur, N.Ü. Novel Nanostructured Lipid Carrier Based Flurbiprofen Loaded Sodium Alginate Inserts for Ocular Drug Delivery. Lat. Am. J. Pharm. 2016, 35, 972–979. [Google Scholar]

- Mokhtari, S.; Jafari, S.M.; Assadpour, E. Development of a Nutraceutical Nano-Delivery System through Emulsification/Internal Gelation of Alginate. Food Chem. 2017, 229, 286–295. [Google Scholar] [CrossRef]

- Khan, N.; Aqil, M.; Ameeduzzafar; Imam, S.S.; Ali, A. Development and Evaluation of a Novel in Situ Gel of Sparfloxacin for Sustained Ocular Drug Delivery: In Vitro and Ex Vivo Characterization. Pharm. Dev. Technol. 2015, 20, 662–669. [Google Scholar] [CrossRef]

- Reed, K.; Lankford, M. Calcium Gluconatee Mediated In-Situ Gelling of Alginates for Ocular Drug Delivery. J. Am. Pharm. Assoc. 2018, 58, e49. [Google Scholar]

- Xu, W.; Liu, K.; Li, T.; Zhang, W.; Dong, Y.; Lv, J.; Wang, W.; Sun, J.; Li, M.; Wang, M.; et al. An in Situ Hydrogel Based on Carboxymethyl Chitosan and Sodium Alginate Dialdehyde for Corneal Wound Healing after Alkali Burn. J. Biomed. Mater. Res. Part A 2019, 107, 742–754. [Google Scholar] [CrossRef]

- Wafa, H.G.; Essa, E.A.; El-Sisi, A.E.; El Maghraby, G.M. Ocular Films versus Film-Forming Liquid Systems for Enhanced Ocular Drug Delivery. Drug Deliv. Transl. Res. 2021, 11, 1084–1095. [Google Scholar] [CrossRef]

- Shinde, U.A.; Shete, J.N.; Nair, H.A.; Singh, K.H. Design and Characterization of Chitosan-Alginate Microspheres for Ocular Delivery of Azelastine. Pharm. Dev. Technol. 2014, 19, 813–823. [Google Scholar] [CrossRef]

- Sadeghi, A.M.; Farjadian, F.; Alipour, S. Sustained Release of Linezolid in Ocular Insert Based on Lipophilic Modified Structure of Sodium Alginate. Iran. J. Basic Med. Sci. 2021, 24, 331–340. [Google Scholar] [CrossRef]

- Jaafar-Maalej, C.; Elaissari, A.; Fessi, H. Lipid-Based Carriers: Manufacturing and Applications for Pulmonary Route. Expert Opin. Drug Deliv. 2012, 9, 1111–1127. [Google Scholar] [CrossRef] [PubMed]

- Pramanik, S.; Mohanto, S.; Manne, R.; Rajendran, R.R.; Deepak, A.; Edapully, S.J.; Patil, T.; Katari, O. Nanoparticle-Based Drug Delivery System: The Magic Bullet for the Treatment of Chronic Pulmonary Diseases. Mol. Pharm. 2021, 18, 3671–3718. [Google Scholar] [CrossRef]

- Sung, J.C.; Pulliam, B.L.; Edwards, D.A. Nanoparticles for Drug Delivery to the Lungs. Trends Biotechnol. 2007, 25, 563–570. [Google Scholar] [CrossRef] [PubMed]

- Rajendran, R.R.; Kumaran, S.; Banerjee, A.; Berlinski, A. A Hybrid in Vitro in Silico Framework for Albuterol Delivery through an Adult Ventilator Circuit to a Patient-Specific Lung Airway Model. J. Aerosol Sci. 2021, 158, 105844. [Google Scholar] [CrossRef]

- Rajendran, R.R.; Banerjee, A. Mucus Transport and Distribution by Steady Expiration in an Idealized Airway Geometry. Med. Eng. Phys. 2019, 66, 26–39. [Google Scholar] [CrossRef]

- Rajendran, R.R.; Banerjee, A. Effect of Non-Newtonian Dynamics on the Clearance of Mucus From Bifurcating Lung Airway Models. J. Biomech. Eng. 2020, 143, 021011. [Google Scholar] [CrossRef]

- Dolovich, M.B.; Dhand, R. Aerosol Drug Delivery: Developments in Device Design and Clinical Use. Lancet 2011, 377, 19–25. [Google Scholar] [CrossRef]

- Yhee, J.; Im, J.; Nho, R. Advanced Therapeutic Strategies for Chronic Lung Disease Using Nanoparticle-Based Drug Delivery. J. Clin. Med. 2016, 5, 82. [Google Scholar] [CrossRef]

- Mahmoud, A.A.; Elkasabgy, N.A.; Abdelkhalek, A.A. Design and Characterization of Emulsified Spray Dried Alginate Microparticles as a Carrier for the Dually Acting Drug Roflumilast. Eur. J. Pharm. Sci. 2018, 122, 64–76. [Google Scholar] [CrossRef]

- Alsmadi, M.M.; Obaidat, R.M.; Alnaief, M.; Albiss, B.A.; Hailat, N. Development, In Vitro Characterization, and In Vivo Toxicity Evaluation of Chitosan-Alginate Nanoporous Carriers Loaded with Cisplatin for Lung Cancer Treatment. AAPS PharmSciTech 2020, 21, 191. [Google Scholar] [CrossRef]

- López-Iglesias, C.; Casielles, A.M.; Altay, A.; Bettini, R.; Alvarez-Lorenzo, C.; García-González, C.A. From the Printer to the Lungs: Inkjet-Printed Aerogel Particles for Pulmonary Delivery. Chem. Eng. J. 2019, 357, 559–566. [Google Scholar] [CrossRef]

- Alnaief, M.; Obaidat, R.M.; Alsmadi, M.M. Preparation of Hybrid Alginate-Chitosan Aerogel as Potential Carriers for Pulmonary Drug Delivery. Polymers 2020, 12, 2223. [Google Scholar] [CrossRef]

- Dulhanty, A.M.; Riordan, J.R. Mutation of Potential Phosphorylation Sites in the Recombinant R Domain of the Cystic Fibrosis Transmembrane Conductance Regulator Has Significant Effects on Domain Conformation. Biochem. Biophys. Res. Commun. 1995, 206, 207–214. [Google Scholar] [CrossRef]

- Haley, C.L.; Colmer-Hamood, J.A.; Hamood, A.N. Characterization of Biofilm-like Structures Formed by Pseudomonas Aeruginosa in a Synthetic Mucus Medium. BMC Microbiol. 2012, 12, 181. [Google Scholar] [CrossRef] [PubMed]

- May, T.B.; Shinabarger, D.; Maharaj, R.; Kato, J.; Chu, L.; Devault, J.D.; Roychoudhury, S.; Zielinski, N.A.; Berry, A.; Rothmel, R.K.; et al. Alginate Synthesis by Pseudomonas Aeruginosa: A Key Pathogenic Factor in Chronic Pulmonary Infections of Cystic Fibrosis Patients. Clin. Microbiol. Rev. 1991, 4, 191–206. [Google Scholar] [CrossRef]

- Selimoglu, E. Aminoglycoside-Induced Ototoxicity. Curr. Pharm. Des. 2007, 13, 119–126. [Google Scholar] [CrossRef] [PubMed]

- Kumin, G.D. Clinical Nephrotoxicity of Tobramycin and Gentamicin: A Prospective Study. JAMA 1980, 244, 1808–1810. [Google Scholar] [CrossRef] [PubMed]

- Hill, M.; Twigg, M.; Sheridan, E.A.; Hardy, J.G.; Elborn, J.S.; Taggart, C.C.; Scott, C.J.; Migaud, M.E. Alginate/Chitosan Particle-Based Drug Delivery Systems for Pulmonary Applications. Pharmaceutics 2019, 11, 379. [Google Scholar] [CrossRef]

- Scolari, I.R.; Páez, P.L.; Musri, M.M.; Petiti, J.P.; Torres, A.; Granero, G.E. Rifampicin Loaded in Alginate/Chitosan Nanoparticles as a Promising Pulmonary Carrier against Staphylococcus Aureus. Drug Deliv. Transl. Res. 2020, 10, 1403–1417. [Google Scholar] [CrossRef] [PubMed]

- Cheaburu-Yilmaz, C.N.; Lupuşoru, C.E.; Vasile, C. New Alginate/PNIPAAm Matrices for Drug Delivery. Polymers 2019, 11, 366. [Google Scholar] [CrossRef] [PubMed]

- Hariyadi, D.M.; Hendradi, E.; Kurniawan, T.D. Alginate Microspheres Encapsulating Ciprofloxacin HCl: Characteristics, Release and Antibacterial Activity. Int. J. Pharma Res. Health Sci. 2019, 7, 3020–3027. [Google Scholar] [CrossRef]

- Longuinho, M.M.; Leitão, S.G.; Silva, R.S.F.; Silva, P.E.A.; Rossi, A.L.; Finotelli, P. V Lapazine Loaded Alginate/Chitosan Microparticles: Enhancement of Anti-Mycobacterium Activity. J. Drug Deliv. Sci. Technol. 2019, 54, 101292. [Google Scholar] [CrossRef]

- Islan, G.A.; Ruiz, M.E.; Morales, J.F.; Sbaraglini, M.L.; Enrique, A.V.; Burton, G.; Talevi, A.; Bruno-Blanch, L.E.; Castro, G.R. Hybrid Inhalable Microparticles for Dual Controlled Release of Levofloxacin and DNase: Physicochemical Characterization and in Vivo Targeted Delivery to the Lungs. J. Mater. Chem. B 2017, 5, 3132–3144. [Google Scholar] [CrossRef]

- Tao, L.; Jiang, J.; Gao, Y.; Wu, C.; Liu, Y. Biodegradable Alginate-Chitosan Hollow Nanospheres for Codelivery of Doxorubicin and Paclitaxel for the Effect of Human Lung Cancer A549 Cells. Biomed. Res. Int. 2018, 2018, 4607945. [Google Scholar] [CrossRef] [PubMed]

- Abdelghany, S.; Parumasivam, T.; Pang, A.; Roediger, B.; Tang, P.; Jahn, K.; Britton, W.J.; Chan, H.K. Alginate Modified-PLGA Nanoparticles Entrapping Amikacin and Moxifloxacin as a Novel Host-Directed Therapy for Multidrug-Resistant Tuberculosis. J. Drug Deliv. Sci. Technol. 2019, 52, 642–651. [Google Scholar] [CrossRef]

- Nagpal, P.S.; Kesarwani, A.; Sahu, P.; Upadhyay, P. Aerosol Immunization by Alginate Coated Mycobacterium (BCG/MIP) Particles Provide Enhanced Immune Response and Protective Efficacy than Aerosol of Plain Mycobacterium against M.Tb. H37Rv Infection in Mice. BMC Infect. Dis. 2019, 19, 568. [Google Scholar] [CrossRef] [PubMed]

- Shen, H.; Li, F.; Wang, D.; Yang, Z.; Yao, C.; Ye, Y.; Wang, X. Chitosan-Alginate BSA-Gel-Capsules for Local Chemotherapy against Drug-Resistant Breast Cancer. Drug Des. Devel. Ther. 2018, 12, 921–934. [Google Scholar] [CrossRef] [PubMed]

- Srikrishna, S.; Cardozo, L. The Vagina as a Route for Drug Delivery: A Review. Int. Urogynecol. J. Pelvic Floor Dysfunct. 2013, 24, 537–543. [Google Scholar] [CrossRef] [PubMed]

- Vermani, K.; Garg, S. The Scope and Potential of Vaginal Drug Delivery. Pharm. Sci. Technol. Today 2000, 3, 359–364. [Google Scholar] [CrossRef]

- Deshpande, A.A.; Rhodes, C.T.; Danish, M. Intravaginal Drug Delivery. Drug Dev. Ind. Pharm. 1992, 18, 1225–1279. [Google Scholar] [CrossRef]

- Meng, J.; Agrahari, V.; Ezoulin, M.J.; Purohit, S.S.; Zhang, T.; Molteni, A.; Dim, D.; Oyler, N.A.; Youan, B.B.C. Spray-Dried Thiolated Chitosan-Coated Sodium Alginate Multilayer Microparticles for Vaginal HIV Microbicide Delivery. AAPS J. 2017, 19, 692–702. [Google Scholar] [CrossRef]

- Maestrelli, F.; Jug, M.; Cirri, M.; Kosalec, I.; Mura, P. Characterization and Microbiological Evaluation of Chitosan-Alginate Microspheres for Cefixime Vaginal Administration. Carbohydr. Polym. 2018, 192, 176–183. [Google Scholar] [CrossRef]

- Ferreira, N.N.; Perez, T.A.; Pedreiro, L.N.; Prezotti, F.G.; Boni, F.I.; Cardoso, V.M.d.O.; Venâncio, T.; Gremião, M.P.D. A Novel PH-Responsive Hydrogel-Based on Calcium Alginate Engineered by the Previous Formation of Polyelectrolyte Complexes (PECs) Intended to Vaginal Administration. Drug Dev. Ind. Pharm. 2017, 43, 1656–1668. [Google Scholar] [CrossRef]

- Jadhav, K.R.; Kadam, V.J.; Pisal, S.S. Formulation and Evaluation of Lecithin Organogel for Topical Delivery of Fluconazole. Curr. Drug. Deliv. 2009, 6, 174–183. [Google Scholar] [CrossRef]

- Bayomi, M.A. Role of Chitosan on Controlling the Characteristics and Antifungal Activity of Bioadhesive Fluconazole Vaginal Tablets. Saudi. Pharm. J. 2017, 26, 151–161. [Google Scholar] [CrossRef]

- Darwesh, B.; Aldawsari, H.M.; Badr-Eldin, S.M. Optimized Chitosan/Anion Polyelectrolyte Complex Based Inserts for Vaginal Delivery of Fluconazole: In Vitro/in Vivo Evaluation. Pharmaceutics 2018, 10, 227. [Google Scholar] [CrossRef]

- Soliman, G.M.; Fetih, G.; Abbas, A.M. Thermosensitive Bioadhesive Gels for the Vaginal Delivery of Sildenafil Citrate: In Vitro Characterization and Clinical Evaluation in Women Using Clomiphene Citrate for Induction of Ovulation. Drug. Dev. Ind. Pharm. 2017, 43, 399–408. [Google Scholar] [CrossRef]

- Hassan, A.; Soliman, G.; Ali, M.; El-Gindy, G. Mucoadhesive Tablets for the Vaginal Delivery of Progesterone: In Vitro Evaluation and Pharmacokinetics/Pharmacodynamics in Female Rabbits. Drug. Dev. Ind. Pharm. 2017, 44, 224–232. [Google Scholar] [CrossRef]

- Kamel, R.; Abbas, H. A Multi-Microcarrier of Metronidazole-Biopolymers Complexes as a Potential Vaginal Delivery System. Int. J. Polym. Mater. Polym. Biomater. 2018, 67, 239–246. [Google Scholar] [CrossRef]

- Yang, T.-T.; Cheng, Y.-Z.; Qin, M.; Wang, Y.-H.; Yu, H.-L.; Wang, A.-L.; Zhang, W.-F. Thermosensitive Chitosan Hydrogels Containing Polymeric Microspheres for Vaginal Drug Delivery. Biomed. Res. Int. 2017, 2017, 3564060. [Google Scholar] [CrossRef]

- Gafitanu, C.A.; Filip, D.; Cernatescu, C.; Rusu, D.; Tuchilus, C.G.; Macocinschi, D.; Zaltariov, M. Design, Preparation and Evaluation of HPMC-Based PAA or SA Freeze-Dried Scaffolds for Vaginal Delivery of Fluconazole. Pharm. Res. 2017, 34, 2185–2196. [Google Scholar] [CrossRef]

- Cirri, M.; Maestrelli, F.; Scuota, S.; Bazzucchi, V.; Mura, P. Development and Microbiological Evaluation of Chitosan and Chitosan-Alginate Microspheres for Vaginal Administration of Metronidazole. Int. J. Pharm. 2021, 598, 120375. [Google Scholar] [CrossRef]

- Ghosal, K.; Ranjan, A.; Brata, B. A Novel Vaginal Drug Delivery System: Anti-HIV Bioadhesive Film Containing Abacavir. J. Mater. Sci. Mater. Med. 2014, 25, 1679–1689. [Google Scholar] [CrossRef]

- Nematpour, N.; Moradipour, P.; Mahdi, M.; Arkan, E. Materials Science & Engineering C The Application of Nanomaterial Science in the Formulation a Novel Antibiotic: Assessment of the Antifungal Properties of Mucoadhesive Clotrimazole Loaded Nano Fi Ber versus Vaginal Fi Lms. Mater. Sci. Eng. C 2020, 110, 110635. [Google Scholar] [CrossRef]

- Gnaman, K.C.N.G.; Bouttier, S.; Yeo, A.; Any-grah, A.A.S.A.; Geiger, S. Characterization and in Vitro Evaluation of a Vaginal Gel Containing Lactobacillus Crispatus for the Prevention of Gonorrhea. Int. J. Pharm. 2020, 588, 119733. [Google Scholar] [CrossRef]

- da Silva Campelo, M.; Melo, E.O.; Arrais, S.P.; do Nascimento, F.B.S.A.; Gramosa, N.V.; de Aguiar Soares, S.; Ribeiro, M.E.N.P.; da Silva, C.R.; Júnior, H.V.N.; Ricardo, N.M.P.S. Clove Essential Oil Encapsulated on Nanocarrier Based on Polysaccharide: A Strategy for the Treatment of Vaginal Candidiasis. Colloids Surf. A Physicochem. Eng. Asp. 2021, 610, 125732. [Google Scholar] [CrossRef]

- Tentor, F.; Siccardi, G.; Sacco, P.; Demarchi, D.; Marsich, E.; Almdal, K. Long Lasting Mucoadhesive Membrane Based on Alginate and Chitosan for Intravaginal Drug Delivery. J. Mater. Sci. Mater. Med. 2020, 31, 25. [Google Scholar] [CrossRef]

- Kissel, T.; Werner, U. Nasal Delivery of Peptides: An in Vitro Cell Culture Model for the Investigation of Transport and Metabolism in Human Nasal Epithelium. J. Control. Release 1998, 53, 195–203. [Google Scholar] [CrossRef]

- Illum, L. Nasal Drug Delivery-Recent Developments and Future Prospects. J. Control. Release 2012, 161, 254–263. [Google Scholar] [CrossRef]

- Fortuna, A.; Alves, G.; Serralheiro, A.; Sousa, J.; Falcão, A. Intranasal Delivery of Systemic-Acting Drugs: Small-Molecules and Biomacromolecules. Eur. J. Pharm. Biopharm. 2014, 88, 8–27. [Google Scholar] [CrossRef] [PubMed]

- Dukovski, B.J.; Plantić, I.; Čunčić, I.; Krtalić, I.; Juretić, M.; Pepić, I.; Lovrić, J.; Hafner, A. Lipid/Alginate Nanoparticle-Loaded in Situ Gelling System Tailored for Dexamethasone Nasal Delivery. Int. J. Pharm. 2017, 533, 480–487. [Google Scholar] [CrossRef] [PubMed]

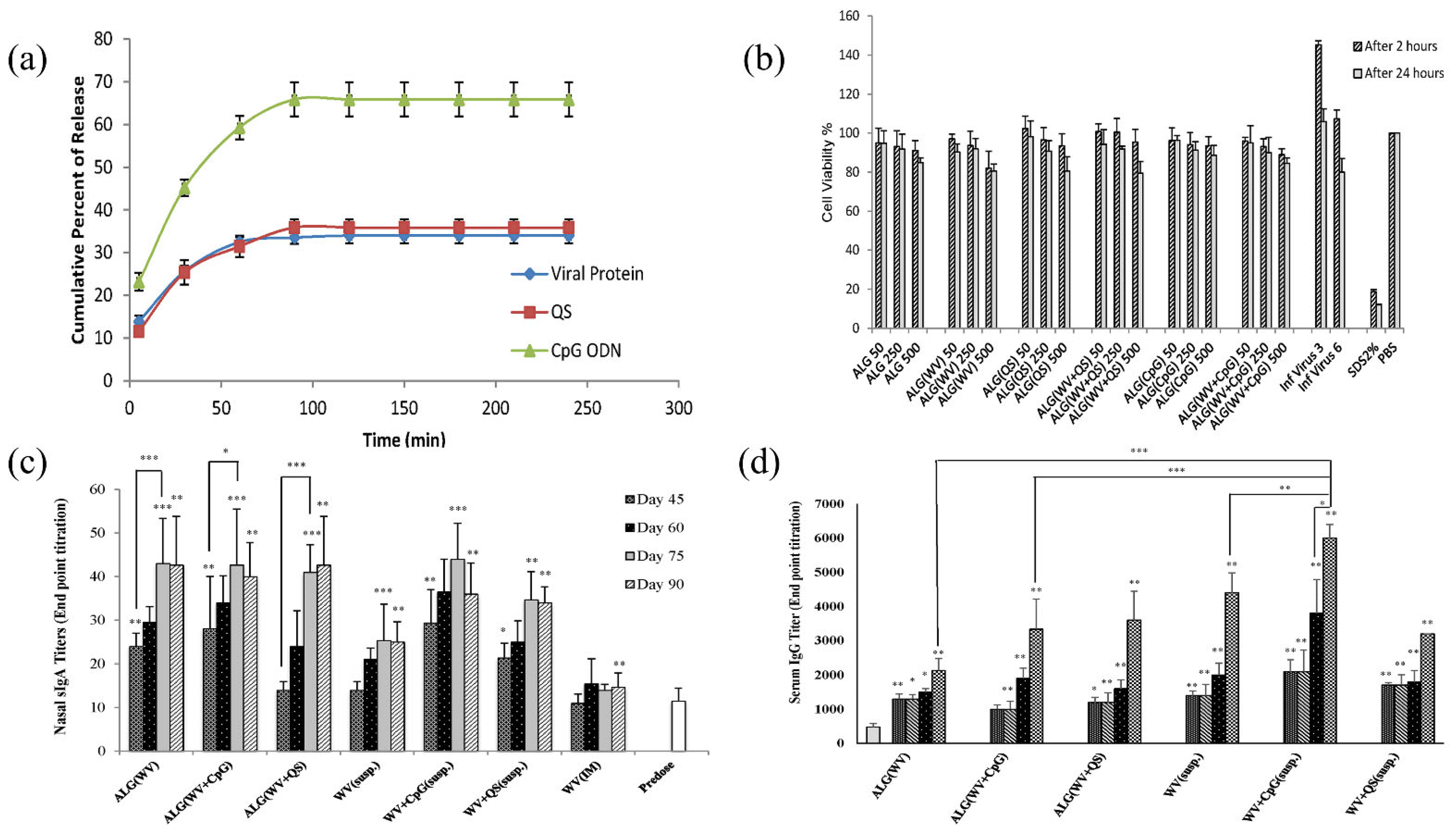

- Dehghan, S.; Kheiri, M.T.; Abnous, K.; Eskandari, M.; Tafaghodi, M. Preparation, Characterization and Immunological Evaluation of Alginate Nanoparticles Loaded with Whole Inactivated Influenza Virus: Dry Powder Formulation for Nasal Immunization in Rabbits. Microb. Pathog. 2017, 115, 74–85. [Google Scholar] [CrossRef]

- Rao, M.; Agrawal, D.K.; Shirsath, C. Thermoreversible Mucoadhesive in Situ Nasal Gel for Treatment of Parkinson’s Disease. Drug Dev. Ind. Pharm. 2017, 43, 142–150. [Google Scholar] [CrossRef]

- Youssef, N.A.H.A.; Kassem, A.A.; Farid, R.M.; Ismail, F.A.; EL-Massik, M.A.E.; Boraie, N.A. A Novel Nasal Almotriptan Loaded Solid Lipid Nanoparticles in Mucoadhesive in Situ Gel Formulation for Brain Targeting: Preparation, Characterization and in Vivo Evaluation. Int. J. Pharm. 2018, 548, 609–624. [Google Scholar] [CrossRef]

- Amorij, J.P.; Hinrichs, W.L.J.; Frijlink, H.W.; Wilschut, J.C.; Huckriede, A. Needle-Free Influenza Vaccination. Lancet Infect. Dis. 2010, 10, 699–711. [Google Scholar] [CrossRef]

- Saluja, V.; Amorij, J.P.; Van Roosmalen, M.L.; Leenhouts, K.; Huckriede, A.; Hinrichs, W.L.J.; Frijlink, H.W. Intranasal Delivery of Influenza Subunit Vaccine Formulated with GEM Particles as an Adjuvant. AAPS J. 2010, 12, 109–116. [Google Scholar] [CrossRef]

- Amin, M.; Jaafari, M.R.; Tafaghodi, M. Impact of Chitosan Coating of Anionic Liposomes on Clearance Rate, Mucosal and Systemic Immune Responses Following Nasal Administration in Rabbits. Colloids Surf. B Biointerfaces 2009, 74, 225–229. [Google Scholar] [CrossRef]

- Tafaghodi, M.; Jaafari, M.; Sajadi Tabassi, S. Nasal Immunization Studies by Cationic, Fusogenic and Cationic-Fusogenic Liposomes Encapsulated with Tetanus Toxoid. Curr. Drug Deliv. 2008, 5, 108–113. [Google Scholar] [CrossRef]

- Slütter, B.; Hagenaars, N.; Jiskoot, W. Rational Design of Nasal Vaccines. J. Drug Target. 2008, 16, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Köping-Höggård, M.; Sánchez, A.; Alonso, M.J. Nanoparticles as Carriers for Nasal Vaccine Delivery. Expert Rev. Vaccines 2005, 4, 185–196. [Google Scholar] [CrossRef]

- Brayden, D.J.; Baird, A.W. Microparticle Vaccine Approaches to Stimulate Mucosal Immunisation. Microbes Infect. 2001, 3, 867–876. [Google Scholar] [CrossRef]

- Mosafer, J.; Sabbaghi, A.H.; Badiee, A.; Dehghan, S.; Tafaghodi, M. Preparation, Characterization and in Vivo Evaluation of Alginate-Coated Chitosan and Trimethylchitosan Nanoparticles Loaded with PR8 Influenza Virus for Nasal Immunization. Asian J. Pharm. Sci. 2019, 14, 216–221. [Google Scholar] [CrossRef]

- Chen, W.; Li, R.; Zhu, S.; Ma, J.; Pang, L.; Ma, B.; Du, L.; Jin, Y. Nasal Timosaponin BII Dually Sensitive in Situ Hydrogels for the Prevention of Alzheimer’s Disease Induced by Lipopolysaccharides. Int. J. Pharm. 2020, 578, 119115. [Google Scholar] [CrossRef]

- Fatouh, A.M.; Elshafeey, A.H.; Abdelbary, A. Agomelatine-Based in Situ Gels for Brain Targeting via the Nasal Route: Statistical Optimization, in Vitro, and in Vivo Evaluation. Drug Deliv. 2017, 24, 1077–1085. [Google Scholar] [CrossRef]

- Karimi, S.; Bagher, Z.; Najmoddin, N.; Simorgh, S.; Pezeshki-Modaress, M. Alginate-Magnetic Short Nanofibers 3D Composite Hydrogel Enhances the Encapsulated Human Olfactory Mucosa Stem Cells Bioactivity for Potential Nerve Regeneration Application. Int. J. Biol. Macromol. 2021, 167, 796–806. [Google Scholar] [CrossRef] [PubMed]

- Trapani, A.; Corbo, F.; Agrimi, G.; Ditaranto, N.; Cioffi, N.; Perna, F.; Quivelli, A.; Stefàno, E.; Lunetti, P.; Muscella, A.; et al. Oxidized Alginate Dopamine Conjugate: In Vitro Characterization for Nose-to-Brain Delivery Application. Materials 2021, 14, 3495. [Google Scholar] [CrossRef]

- Haque, S.; Md, S.; Sahni, J.K.; Ali, J.; Baboota, S. Development and Evaluation of Brain Targeted Intranasal Alginate Nanoparticles for Treatment of Depression. J. Psychiatr. Res. 2014, 48, 1–12. [Google Scholar] [CrossRef]

- Caetano, L.A.; Almeida, A.J.; Gonçalves, L.M.D. Effect of Experimental Parameters on Alginate/Chitosan Microparticles for BCG Encapsulation. Mar. Drugs 2016, 14, 90. [Google Scholar] [CrossRef] [PubMed]

- Amokrane, F.; Mohamed, N.; Laraba-djebari, F. Development and Characterization of a New Carrier for Vaccine Delivery Based on Calcium-Alginate Nanoparticles: Safe Immunoprotective Approach against Scorpion Envenoming. Vaccine 2016, 34, 2692–2699. [Google Scholar] [CrossRef]

- Lauzon, M.-A.; Marcos, B.; Faucheux, N. Characterization of Alginate/Chitosan-Based Nanoparticles and Mathematical Modeling of Their SpBMP-9 Release Inducing Neuronal Differentiation of Human SH-SY5Y Cells. Carbohydr. Polym. 2018, 181, 801–811. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Jin, W.; Cruz, J.G.; Marasini, N.; Khalil, Z.G.; Capon, R.J.; Hussein, W.M.; Skwarczynski, M.; Toth, I. Development of Polyelectrolyte Complexes for the Delivery of Peptide-Based Subunit Vaccines Against Group A Streptococcus. Bioorg. Med. Chem. 2020, 10, 823. [Google Scholar] [CrossRef]

- Rodrigues, F.J.; Omura, M.H.; Cedran, M.F.; Dekker, R.F.H.; Barbosa-dekker, A.M.; Garcia, S. Effect of natural polymers on the survival ofLac tobace Pt Ed illus caseiencapsulated in alginate micr Tospheres. J. Microencapsul. 2017, 34, 431–439. [Google Scholar] [CrossRef]

- Ahmed, M.M.; Fatima, F.; Anwer, M.K.; Ibnouf, E.O.; Kalam, M.A.; Alshamsan, A.; Aldawsari, M.F.; Alalaiwe, A.; Ansari, M.J. Formulation and in Vitro Evaluation of Topical Nanosponge-Based Gel Containing Butenafine for the Treatment of Fungal Skin Infection. Saudi Pharm. J. 2021, 29, 467–477. [Google Scholar] [CrossRef]

- Badri, W.; Eddabra, R.; Fessi, H.; Elaissari, A. Biodegradable Polymer Based Nanoparticles: Dermal and Transdermal Drug Delivery. J. Colloid Sci. Biotechnol. 2015, 3, 141–149. [Google Scholar] [CrossRef]

- Tewes, F.; Gobbo, O.L.; Ehrhardt, C.; Healy, A.M. Amorphous Calcium Carbonate Based-Microparticles for Peptide Pulmonary Delivery. ACS Appl. Mater. Interfaces 2016, 8, 1164–1175. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.B.; Du, Z.; Tang, C.; Guan, Y.X.; Yao, S.J. Formulation of Insulin-Loaded N-Trimethyl Chitosan Microparticles with Improved Efficacy for Inhalation by Supercritical Fluid Assisted Atomization. Int. J. Pharm. 2016, 505, 223–233. [Google Scholar] [CrossRef] [PubMed]

- Shi, K.; Fang, Y.; Kan, Q.; Zhao, J.; Gan, Y.; Liu, Z. Surface Functional Modification of Self-Assembled Insulin Nanospheres for Improving Intestinal Absorption. Int. J. Biol. Macromol. 2015, 74, 49–60. [Google Scholar] [CrossRef] [PubMed]

- Yan, G.; Warner, K.S.; Zhang, J.; Sharma, S.; Gale, B.K. Evaluation Needle Length and Density of Microneedle Arrays in the Pretreatment of Skin for Transdermal Drug Delivery. Int. J. Pharm. 2010, 391, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Vrdoljak, A.; McGrath, M.G.; Carey, J.B.; Draper, S.J.; Hill, A.V.S.; O’Mahony, C.; Crean, A.M.; Moore, A.C. Coated Microneedle Arrays for Transcutaneous Delivery of Live Virus Vaccines. J. Control. Release 2012, 159, 34–42. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.; Jiang, G.; Zhang, Y.; Liu, D.; Xu, B.; Zhou, J. Polymer Microneedles Fabricated from Alginate and Hyaluronate for Transdermal Delivery of Insulin. Mater. Sci. Eng. C 2017, 80, 187–196. [Google Scholar] [CrossRef]

- Lefnaoui, S.; Moulai-Mostefa, N.; Yahoum, M.M.; Gasmi, S.N. Design of Antihistaminic Transdermal Films Based on Alginate–Chitosan Polyelectrolyte Complexes: Characterization and Permeation Studies. Drug Dev. Ind. Pharm. 2018, 44, 432–443. [Google Scholar] [CrossRef]

- Abebe, M.W.; Appiah-Ntiamoah, R.; Kim, H. Gallic Acid Modified Alginate Self-Adhesive Hydrogel for Strain Responsive Transdermal Delivery. Int. J. Biol. Macromol. 2020, 163, 147–155. [Google Scholar] [CrossRef]

- Sgalla, G.; Biffi, A.; Richeldi, L. Idiopathic Pulmonary Fibrosis: Diagnosis, Epidemiology and Natural History. Respirology 2016, 21, 427–437. [Google Scholar] [CrossRef]

- McLean-Tooke, A.; Moore, I.; Lake, F. Idiopathic and Immune-Related Pulmonary Fibrosis: Diagnostic and Therapeutic Challenges. Clin. Transl. Immunol. 2019, 8, e1086. [Google Scholar] [CrossRef]

- Abnoos, M.; Mohseni, M.; Mousavi, S.A.J.; Ashtari, K.; Ilka, R.; Mehravi, B. Chitosan-Alginate Nano-Carrier for Transdermal Delivery of Pirfenidone in Idiopathic Pulmonary Fibrosis. Int. J. Biol. Macromol. 2018, 118, 1319–1325. [Google Scholar] [CrossRef]

- Anirudhan, T.S.; Nair, A.S.; Ss, G. The Role of Biopolymer Matrix Films Derived from Carboxymethyl Cellulose, Sodium Alginate and Polyvinyl Alcohol on the Sustained Transdermal Release of Diltiazem. Int. J. Biol. Macromol. 2017, 107, 779–789. [Google Scholar] [CrossRef] [PubMed]

- Kataria, K.; Gupta, A.; Rath, G.; Mathur, R.B.; Dhakate, S.R. In Vivo Wound Healing Performance of Drug Loaded Electrospun Composite Nanofibers Transdermal Patch. Int. J. Pharm. 2014, 469, 102–110. [Google Scholar] [CrossRef] [PubMed]

- Aktar, B.; Erdal, M.S.; Sagirli, O.; Güngör, S.; Özsoy, Y. Optimization of Biopolymer Based Transdermal Films of Metoclopramide as an Alternative Delivery Approach. Polymers 2014, 6, 1350–1365. [Google Scholar] [CrossRef]

- El-Houssiny, A.S.; Ward, A.A.; Mostafa, D.M.; Abd-El-Messieh, S.L.; Abdel-Nour, K.N.; Darwish, M.M.; Khalil, W.A. Sodium Alginate Nanoparticles as a New Transdermal Vehicle of Glucosamine Sulfate for Treatment of Osteoarthritis. Eur. J. Nanomedicine 2017, 9, 105–114. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, G.; Yu, W.; Liu, D.; Xu, B. Microneedles Fabricated from Alginate and Maltose for Transdermal Delivery of Insulin on Diabetic Rats. Mater. Sci. Eng. C 2018, 85, 18–26. [Google Scholar] [CrossRef]

- Ahmed, T.A.; El-Say, K.M. Development of Alginate-Reinforced Chitosan Nanoparticles Utilizing W/O Nanoemulsification/Internal Crosslinking Technique for Transdermal Delivery of Rabeprazole. Life Sci. 2014, 110, 35–43. [Google Scholar] [CrossRef]

- Lai, W.; Tang, R.; Wong, W. Ionically Crosslinked Complex Gels Loaded with Oleic Acid-Containing Vesicles for Transdermal Drug Delivery. Pharmaceutics 2020, 12, 725. [Google Scholar] [CrossRef]

- Giacone, D.V.; Dartora, V.F.M.C.; De Matos, J.K.R.; Passos, J.S.; Miranda, D.A.G.; De Oliveira, E.A.; Silveira, E.R.; Costa-lotufo, L.V.; Maria-engler, S.S.; Lopes, L.B. International Journal of Biological Macromolecules Effect of Nanoemulsion Modi Fi Cation with Chitosan and Sodium Alginate on the Topical Delivery and Ef Fi Cacy of the Cytotoxic Agent Piplartine in 2D and 3D Skin Cancer Models. Int. J. Biol. Macromol. 2020, 165, 1055–1065. [Google Scholar] [CrossRef]

- Esposito, L.; Barbosa, A.I.; Moniz, T.; Lima, S.C.; Costa, P.; Celia, C.; Reis, S. Design and Characterization of Sodium Alginate and Poly ( Vinyl ) Alcohol Hydrogels for Enhanced Skin Delivery of Quercetin. Pharmaceutics 2020, 12, 1149. [Google Scholar] [CrossRef]

- Ng, S.F.; Tan, L.S.; Buang, F. Transdermal Anti-Inflammatory Activity of Bilayer Film Containing Olive Compound Hydroxytyrosol: Physical Assessment, in Vivo Dermal Safety and Efficacy Study in Freund’s Adjuvant-Induced Arthritic Rat Model. Drug Dev. Ind. Pharm. 2017, 43, 108–119. [Google Scholar] [CrossRef] [PubMed]

- Sadashivaiah, R.; Babu, B.K.S. Role of Sodium L-Cysteine Alginate Conjugate and Isopropyl Myristate to Enhance the Permeation Enhancing Activity of BCS Class III Drug from TDDS.; Optimization by Central Composite Design and in Vivo Pharmacokinetics Study. Drug Dev. Ind. Pharm. 2020, 46, 1427–1442. [Google Scholar] [CrossRef]

- Anirudhan, T.S.; Nair, A.S.; Bino, S.J. Nanoparticle Assisted Solvent Selective Transdermal Combination Therapy of Curcumin and 5-Flurouracil for Efficient Cancer Treatment. Carbohydr. Polym. 2017, 173, 131–142. [Google Scholar] [CrossRef]

- George, M.; Abraham, T.E. Polyionic Hydrocolloids for the Intestinal Delivery of Protein Drugs: Alginate and Chitosan-a Review. J. Control. Release 2006, 114, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Khutoryanskiy, V.V. Advances in Mucoadhesion and Mucoadhesive Polymers. Macromol. Biosci. 2011, 11, 748–764. [Google Scholar] [CrossRef]

- Shah, J.P.; Gil, Z. Current Concepts in Management of Oral Cancer-Surgery. Oral Oncol. 2009, 45, 394–401. [Google Scholar] [CrossRef] [PubMed]

- Shtenberg, Y.; Goldfeder, M.; Prinz, H.; Shainsky, J.; Ghantous, Y.; Abu El-Naaj, I.; Schroeder, A.; Bianco-Peled, H. Mucoadhesive Alginate Pastes with Embedded Liposomes for Local Oral Drug Delivery. Int. J. Biol. Macromol. 2018, 111, 62–69. [Google Scholar] [CrossRef]

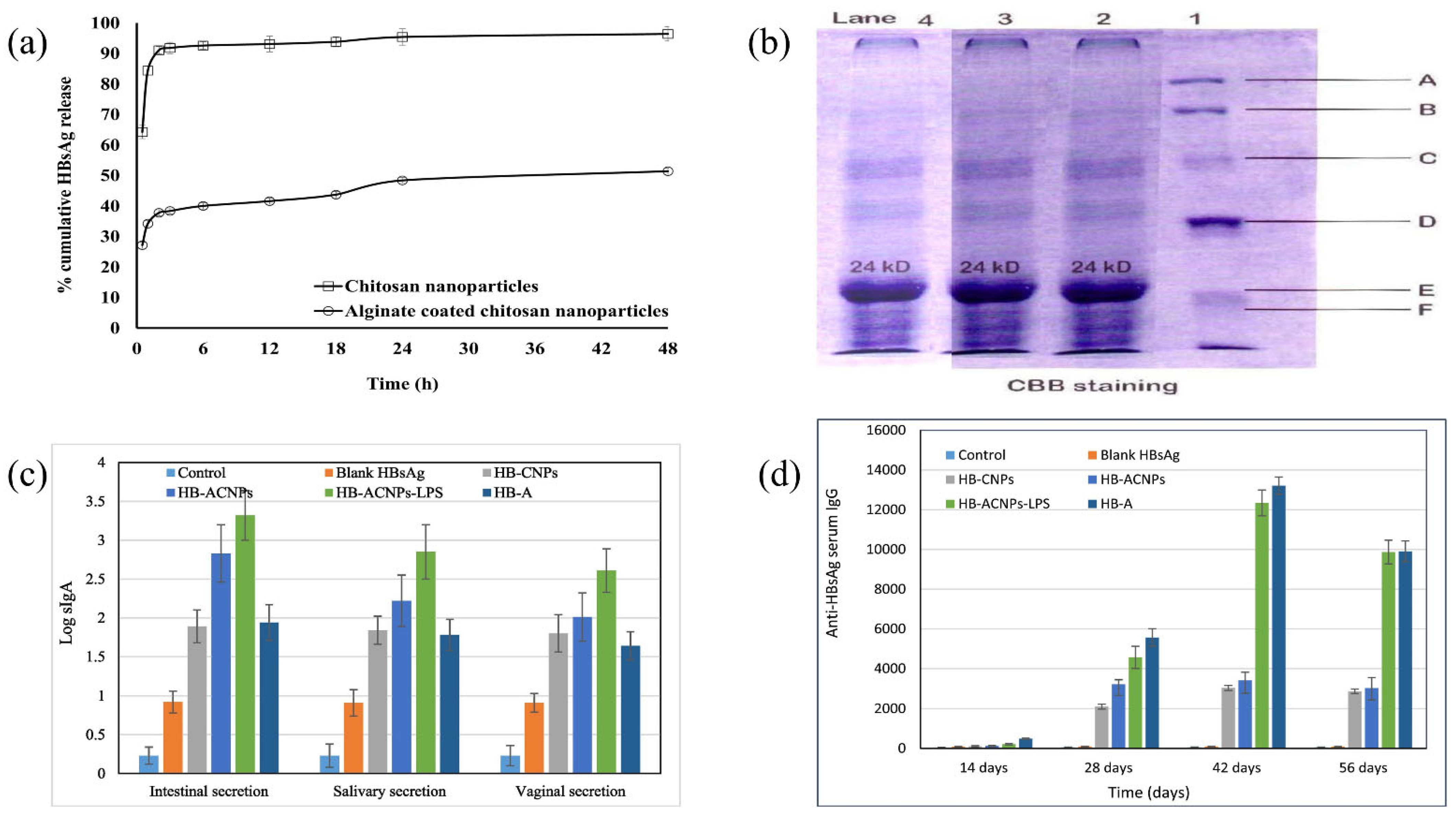

- Saraf, S.; Jain, S.; Sahoo, R.N.; Mallick, S. Lipopolysaccharide Derived Alginate Coated Hepatitis B Antigen Loaded Chitosan Nanoparticles for Oral Mucosal Immunization. Int. J. Biol. Macromol. 2020, 154, 466–476. [Google Scholar] [CrossRef] [PubMed]

- Akram, S.; Noreen, S. International Journal of Biological Macromolecules Linum Usitatissimum Seed Mucilage-Alginate Mucoadhesive Microspheres of Metformin HCl: Fabrication, Characterization and Evaluation. Int. J. Biol. Macromol. 2020, 155, 358–368. [Google Scholar] [CrossRef]

- Kilicarslan, M.; Ilhan, M.; Inal, O.; Orhan, K. European Journal of Pharmaceutical Sciences Preparation and Evaluation of Clindamycin Phosphate Loaded Chitosan / Alginate Polyelectrolyte Complex Fi Lm as Mucoadhesive Drug Delivery System for Periodontal Therapy. Eur. J. Pharm. Sci. 2018, 123, 441–451. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, V.S.S.; Gurikov, P.; Poejo, J.; Matias, A.A.; Heinrich, S.; Duarte, C.M.M.; Smirnova, I. Alginate-Based Hybrid Aerogel Microparticles for Mucosal Drug Delivery. Eur. J. Pharm. Biopharm. 2016, 107, 160–170. [Google Scholar] [CrossRef]

- Kaur, I.P.; Kakkar, S. Topical Delivery of Antifungal Agents. Expert Opin. Drug Deliv. 2010, 7, 1303–1327. [Google Scholar] [CrossRef]

- Pemán, J.; Salavert, M. Epidemiología General de La Enfermedad Fúngica Invasora. Enferm. Infecc. Y Microbiol. Clínica 2012, 30, 90–98. [Google Scholar] [CrossRef]

- Croy, S.R.; Kwon, G.S. The Effects of Pluronic Block Copolymers on the Aggregation State of Nystatin. J. Control. Release 2004, 95, 161–171. [Google Scholar] [CrossRef]

- Martín-Villena, M.J.; Fernández-Campos, F.; Calpena-Campmany, A.C.; Bozal-De Febrer, N.; Ruiz-Martínez, M.A.; Clares-Naveros, B. Novel Microparticulate Systems for the Vaginal Delivery of Nystatin: Development and Characterization. Carbohydr. Polym. 2013, 94, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Martín, M.J.; Calpena, A.C.; Fernández, F.; Mallandrich, M.; Gálvez, P.; Clares, B. Development of Alginate Microspheres as Nystatin Carriers for Oral Mucosa Drug Delivery. Carbohydr. Polym. 2015, 117, 140–149. [Google Scholar] [CrossRef]

- Gennari, C.G.M.; Sperandeo, P.; Polissi, A.; Minghetti, P.; Cilurzo, F. Lysozyme Mucoadhesive Tablets Obtained by Freeze-Drying. J. Pharm. Sci. 2019, 108, 3667–3674. [Google Scholar] [CrossRef]

- Wang, Y.; Li, H.; Wang, L.; Han, J.; Yang, Y.; Fu, T.; Qiao, H.; Wang, Z.; Li, J. Colloids and Surfaces B: Biointerfaces Mucoadhesive Nanocrystal-in-Microspheres with High Drug Loading Capacity for Bioavailability Enhancement of Silybin. Colloids Surf. B Biointerfaces 2020, 198, 111461. [Google Scholar] [CrossRef]

- El-feky, G.S.; Abdulmaguid, R.F.; Zayed, G.M.; Kamel, R.; Abdulmaguid, R.F.; Zayed, G.M.; Kamel, R. Mucosal Co-Delivery of Ketorolac and Lidocaine Using Polymeric Wafers for Dental Application. Drug Deliv. 2018, 25, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Okeke, O.C.; Boateng, J.S. Composite HPMC and Sodium Alginate Based Buccal Formulations for Nicotine Replacement Therapy. Int. J. Biol. Macromol. 2016, 91, 31–44. [Google Scholar] [CrossRef]

- Shtenberg, Y.; Goldfeder, M.; Schroeder, A.; Bianco-Peled, H. Alginate Modified with Maleimide-Terminated PEG as Drug Carriers with Enhanced Mucoadhesion; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; Volume 175, ISBN 0014350580. [Google Scholar]

- Jang, C.H.; Ahn, S.H.; Kim, G.H. Antifibrotic Effect of Dexamethasone/Alginate-Coated Silicone Sheet in the Abraded Middle Ear Mucosa. Int. J. Biol. Macromol. 2016, 93, 1612–1619. [Google Scholar] [CrossRef] [PubMed]

- Singh, B.; Kumar, A. Rohit Synthesis and Characterization of Alginate and Sterculia Gum Based Hydrogel for Brain Drug Delivery Applications. Int. J. Biol. Macromol. 2020, 148, 248–257. [Google Scholar] [CrossRef]

- Bera, H.; Ippagunta, S.R.; Kumar, S.; Vangala, P. Core-Shell Alginate-Ghatti Gum Modified Montmorillonite Composite Matrices for Stomach-Specific Flurbiprofen Delivery. Mater. Sci. Eng. C 2017, 76, 715–726. [Google Scholar] [CrossRef]

- Boppana, R.; Yadaorao Raut, S.; Krishna Mohan, G.; Sa, B.; Mutalik, S.; Reddy, K.R.; Das, K.K.; Biradar, M.S.; Kulkarni, R.V. Novel PH-Sensitive Interpenetrated Network Polyspheres of Polyacrylamide-g-Locust Bean Gum and Sodium Alginate for Intestinal Targeting of Ketoprofen: In Vitro and in Vivo Evaluation. Colloids Surf. B Biointerfaces 2019, 180, 362–370. [Google Scholar] [CrossRef]

- Ivanovska, T.P.; Mladenovska, K.; Zhivikj, Z.; Pavlova, M.J.; Gjurovski, I.; Ristoski, T.; Petrushevska-Tozi, L. Synbiotic Loaded Chitosan-Ca-Alginate Microparticles Reduces Inflammation in the TNBS Model of Rat Colitis. Int. J. Pharm. 2017, 527, 126–134. [Google Scholar] [CrossRef]

- Saralkar, P.; Dash, A.K. Alginate Nanoparticles Containing Curcumin and Resveratrol: Preparation, Characterization, and In Vitro Evaluation Against DU145 Prostate Cancer Cell Line. AAPS Pharmscitech 2017, 18, 2814–2823. [Google Scholar] [CrossRef]

- Yang, H.; Chen, Y.; Chen, Z.; Geng, Y.; Xie, X.; Shen, X.; Li, T.; Li, S.; Wu, C.; Liu, Y. Chemo-Photodynamic Combined Gene Therapy and Dual-Modal Cancer Imaging Achieved by PH-Responsive Alginate/Chitosan Multilayer-Modified Magnetic Mesoporous Silica Nanocomposites. Biomater. Sci. 2017, 5, 1001–1013. [Google Scholar] [CrossRef]

- Wang, Q.S.; Gao, L.N.; Zhu, X.N.; Zhang, Y.; Zhang, C.N.; Xu, D.; Cui, Y.L. Co-Delivery of Glycyrrhizin and Doxorubicin by Alginate Nanogel Particles Attenuates the Activation of Macrophage and Enhances the Therapeutic Efficacy for Hepatocellular Carcinoma. Theranostics 2019, 9, 6239–6255. [Google Scholar] [CrossRef]

- Lian, Y.; Wang, X.; Guo, P.; Li, Y.; Raza, F.; Su, J.; Qiu, M. Erythrocyte Membrane-Coated Arsenic Trioxide-Loaded Sodium Alginate Nanoparticles for Tumor Therapy. Pharmaceutics 2020, 12, 21. [Google Scholar] [CrossRef]

- Karabasz, A.; Lachowicz, D.; Karewicz, A.; Mezyk-Kopec, R.; Stalińska, K.; Werner, E.; Cierniak, A.; Dyduch, G.; Bereta, J.; Bzowska, M. Analysis of Toxicity and Anticancer Activity of Micelles of Sodium Alginate-Curcumin. Int. J. Nanomed. 2019, 14, 7249–7262. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.; Guo, X.; Zhong, R.; Wang, C.; Liu, H.; Li, H.; Ma, L.; Guan, J.; You, C.; Tian, M. Interactions of Alginate-Deferoxamine Conjugates With Blood Components and Their Antioxidation in the Hemoglobin Oxidation Model. Front. Bioeng. Biotechnol. 2020, 8, 53. [Google Scholar] [CrossRef] [PubMed]