Use of a Novel Extremophilic Xylanase for an Environmentally Friendly Industrial Bleaching of Kraft Pulps

Abstract

:1. Introduction

2. Results and Discussion

2.1. Effect of Xyn11 Pretreatment Duration (EXP 1)

2.2. Potential ClO2 Savings with Xyn11 Pretreatment (EXP 2)

2.3. Comparison between Different Xylanases (EXP3)

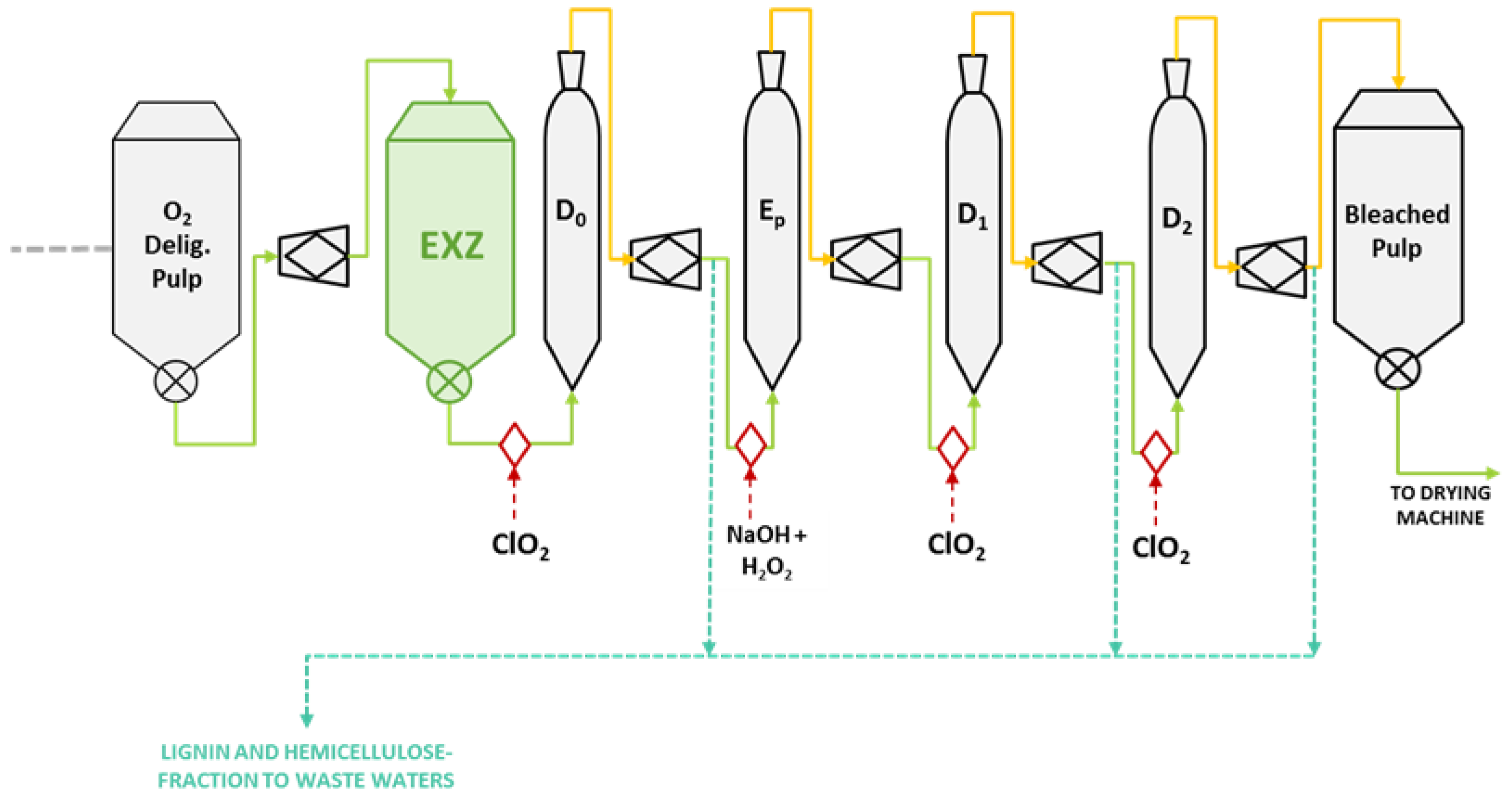

2.4. Pilot Validation of the Xyn11-Assisted Bleaching of Eucalyptus Kraft Pulp

2.5. Evaluation of the EXZ-Assisted Bleaching Sequence on Other Hardwood Kraft Pulps

3. Materials and Methods

3.1. Raw Material

3.2. Enzyme Production

3.3. Enzymatic Pretreatment

3.4. Optimisation of the Extremozyme-Bleaching Sequence

- EXP 1. The enzymatic treatment was carried out at Xyn11 optimal conditions (90 °C, pH 10.5) during 18 h, 5 h or 3 h at 10% consistency.

- EXP 2. This set of experiments were carried out at the best time tested in EXP 1 (5 h) and same conditions, but reducing the amount of ClO2 by 15%, 20% or 25% in each D stage. The objective was to find the highest savings in ClO2 that allowed reaching the reference pulp brightness obtained with the control test (88.1% ISO).

- EXP 3. In this set of experiments Xyn11, Com-X2 (a commercial MetZyme® xylanase provided by MetGen, Kaarina, Finland), and a mixture of both enzymes in a ratio 1:1 v/v named XMIX were used in the previously optimised conditions: 5 h, 90 °C and pH 10.5 for EXZ stage, and 15% less ClO2.

3.5. X-ray Diffraction

3.6. Pilot Scale Trial

3.7. Evaluation of Pulp Properties

3.8. Analysis of the Effluents

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Herpoël, I.; Jeller, H.; Fang, G.; Petit-Conil, M.; Bourbonnais, R.; Robert, J.L. Efficient enzymatic delignification of wheat straw pulp by a sequential xylanase-laccase mediator treatment. J. Pulp Pap. Sci. 2002, 28, 67–71. [Google Scholar]

- Roncero, M.; Torres, A.L.; Colom, J.; Vidal, T. Effects of xylanase treatment on fibre morphology in totally chlorine free bleaching (TCF) of Eucalyptus pulp. Process Biochem. 2000, 36, 45–50. [Google Scholar] [CrossRef]

- Roncero, M.B.; Torres, A.L.; Vidal, T. Effect of xylanase on ozone bleaching kinetics and properties of Eucalyptus kraft pulp. J. Chem. Technol. Biotechnol. 2003, 78, 1023–1031. [Google Scholar] [CrossRef]

- Roncero, M.B.; Torres, A.L.; Colom, J.F.; Vidal, T. The effect of xylanase on lignocellulosic components during the bleaching of wood pulps. Bioresour. Technol. 2005, 96, 21–30. [Google Scholar] [CrossRef]

- Bajpai, P. Application of Enzymes in the Pulp and Paper Industry. Biotechnol. Prog. 1999, 15, 147–157. [Google Scholar] [CrossRef]

- Campioni, T.S.; de Jesus Moreira, L.; Moretto, E.; Nunes, N.S.S.; de Oliva Neto, P. Biobleaching of Kraft pulp using fungal xylanases produced from sugarcane straw and the subsequent decrease of chlorine consumption. Biomass Bioenergy 2019, 121, 22–27. [Google Scholar] [CrossRef]

- Sharma, D.; Chaudhary, R.; Kaur, J.; Arya, S.K. Greener approach for pulp and paper industry by Xylanase and Laccase. Biocatal. Agric. Biotechnol. 2020, 25, 101604. [Google Scholar] [CrossRef]

- Valls, C.; Roncero, M.B. Using both xylanase and laccase enzymes for pulp bleaching. Bioresour. Technol. 2009, 100, 2032–2039. [Google Scholar] [CrossRef]

- Kantelinen, A.; Hortling, B.; Sundquist, J.; Linko, M.; Viikari, L. Proposed Mechanism of the Enzymatic Bleaching of Kraft Pulp with Xylanases. Holzforschung 1993, 47, 318–324. [Google Scholar] [CrossRef]

- Dukare, A.; Saxena, S.; Sharma, K.; Vigneshwaran, N.; Kautkar, S. Microbial Xylanase: An Eco-friendly Tool for Bleaching of Lignocellulosic Paper Pulp. Vigyan Varta 2021, 2, 62–65. [Google Scholar]

- Talens-Perales, D.; Jiménez-Ortega, E.; Sánchez-Torres, P.; Sanz-Aparicio, J.; Polaina, J. Phylogenetic, functional and structural characterization of a GH10 xylanase active at extreme conditions of temperature and alkalinity. Comput. Struct. Biotechnol. J. 2021, 19, 2676–2686. [Google Scholar] [CrossRef] [PubMed]

- Krüger, A.; Schäfers, C.; Schröder, C.; Antranikian, G. Towards a sustainable biobased industry–Highlighting the impact of extremophiles. New Biotechnol. 2018, 40, 144–153. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, S.N.; Flores, A.; Talamantes, D.; Dar, F.; Valdez, A.; Schwans, J.; Berlemont, R. GeneHunt for rapid domain-specific annotation of glycoside hydrolases. Sci. Rep. 2019, 9, 10137. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Talens-Perales, D.; Sánchez-Torres, P.; Marín-Navarro, J.; Polaina, J. In silico screening and experimental analysis of family GH11 xylanases for applications under conditions of alkaline pH and high temperature. Biotechnol. Biofuels 2020, 13, 198. [Google Scholar] [CrossRef] [PubMed]

- Sierra-Alvarez, R.; Kortekaas, S.; Van Eekert, M.; Lettinga, G. The Anaerobic Biodegradability and Methanogenic Toxicity of Pulping Wastewaters. Water Sci. Technol. 1991, 24, 113–125. [Google Scholar] [CrossRef]

- Mehmood, K.; Rehman, S.K.U.; Wang, J.; Farooq, F.; Mahmood, Q.; Jadoon, A.M.; Javed, M.F.; Ahmad, I. Treatment of Pulp and Paper Industrial Effluent Using Physicochemical Process for Recycling. Water 2019, 11, 2393. [Google Scholar] [CrossRef] [Green Version]

- Kaur, A.; Mahajan, R.; Singh, A.; Garg, G.; Sharma, J. Application of cellulase-free xylano-pectinolytic enzymes from the same bacterial isolate in biobleaching of kraft pulp. Bioresour. Technol. 2010, 101, 9150–9155. [Google Scholar] [CrossRef]

- Dwivedi, P.; Vivekanand, V.; Pareek, N.; Sharma, A.; Singh, R.P. Bleach Enhancement of Mixed Wood Pulp by Xylanase–Laccase Concoction Derived Through Co-culture Strategy. Appl. Biochem. Biotechnol. 2009, 160, 255–268. [Google Scholar] [CrossRef]

- Sharma, A.; Thakur, V.V.; Shrivastava, A.; Jain, R.K.; Mathur, R.M.; Gupta, R.; Kuhad, R.C. Xylanase and laccase based enzymatic kraft pulp bleaching reduces adsorbable organic halogen (AOX) in bleach effluents: A pilot scale study. Bioresour. Technol. 2014, 169, 96–102. [Google Scholar] [CrossRef]

- Parab, P.; Khandeparker, R. Xylanolytic enzyme consortia from Bacillus sp. NIORKP76 for improved biobleaching of kraft pulp. Bioprocess Biosyst. Eng. 2021, 44, 2513–2524. [Google Scholar] [CrossRef]

- Beg, Q.K.; Bhushan, B.; Kapoor, M.; Hoondal, G. Enhanced production of a thermostable xylanase from Streptomyces sp. QG-11-3 and its application in biobleaching of eucalyptus kraft pulp. Enzym. Microb. Technol. 2000, 27, 459–466. [Google Scholar] [CrossRef]

- Damiano, V.; Bocchini, D.A.; Gomes, E.; Da Silva, R. Application of crude xylanase from Bacillus licheniformis 77-2 to the bleaching of eucalyptus Kraft pulp. World J. Microbiol. Biotechnol. 2003, 19, 139–144. [Google Scholar] [CrossRef]

- Dhillon, A.; Gupta, J.K.; Jauhari, B.M.; Khanna, S. A cellulase-poor, thermostable, alkalitolerant xylanase produced by _Bacillus_ _circulans_ AB 16 grown on rice straw and its application in biobleaching of eucalyptus pulp. Bioresour. Technol. 2000, 73, 273–277. [Google Scholar] [CrossRef]

- Jiang, Z.Q.; Li, X.T.; Yang, S.Q.; Li, L.T.; Li, Y.; Feng, W.Y. Biobleach boosting effect of recombinant xylanase B from the hyperthermophilic Thermotoga maritima on wheat straw pulp. Appl. Microbiol. Biotechnol. 2005, 70, 65–71. [Google Scholar] [CrossRef] [PubMed]

- Satyanarayana, D.V.T. Improvement in thermostability of metagenomic GH11 endoxylanase (Mxyl) by site-directed mutagenesis and its applicability in paper pulp bleaching process. J. Ind. Microbiol. Biotechnol. 2013, 40, 1373–1381. [Google Scholar] [CrossRef]

- Birikh, K.R.; Heikkila, M.W.; Michine, A.; Mialon, A.; Grönroos, T.; Ihalainen, P.; Varho, A.; Hämäläinen, V.; Suonpää, A.; Rantanen, S.-P. CHAPTER 11 MetGen: Value from Wood–Enzymatic Solutions. In Biocatal: An Ind Perspect; The Royal Society of Chemistry: Cambridge, UK, 2018; pp. 298–322. [Google Scholar] [CrossRef]

- Ahvenainen, P.; Kontro, I.; Svedström, K. Comparison of sample crystallinity determination methods by X-ray diffraction for challenging cellulose I materials. Cellulose 2016, 23, 1073–1086. [Google Scholar] [CrossRef]

| BLEACHING SEQUENCE | EXZD0EpD1D2 | D0EpD1D2 |

|---|---|---|

| Kappa Number (after Ep) | 2.8 | 3.4 |

| Pulp Brightness (% ISO) | 91.1 | 89.0 |

| Cellulose DPv | 1240 | 1120 |

| Drainage Index (°SR) | 23 | 19 |

| ClO2 Consumption (%) | 91 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almeida, N.; Meyer, V.; Burnet, A.; Boucher, J.; Talens-Perales, D.; Pereira, S.; Ihalainen, P.; Levée, T.; Polaina, J.; Petit-Conil, M.; et al. Use of a Novel Extremophilic Xylanase for an Environmentally Friendly Industrial Bleaching of Kraft Pulps. Int. J. Mol. Sci. 2022, 23, 13423. https://doi.org/10.3390/ijms232113423

Almeida N, Meyer V, Burnet A, Boucher J, Talens-Perales D, Pereira S, Ihalainen P, Levée T, Polaina J, Petit-Conil M, et al. Use of a Novel Extremophilic Xylanase for an Environmentally Friendly Industrial Bleaching of Kraft Pulps. International Journal of Molecular Sciences. 2022; 23(21):13423. https://doi.org/10.3390/ijms232113423

Chicago/Turabian StyleAlmeida, Nazaré, Valérie Meyer, Auphélia Burnet, Jeremy Boucher, David Talens-Perales, Susana Pereira, Petri Ihalainen, Thomas Levée, Julio Polaina, Michel Petit-Conil, and et al. 2022. "Use of a Novel Extremophilic Xylanase for an Environmentally Friendly Industrial Bleaching of Kraft Pulps" International Journal of Molecular Sciences 23, no. 21: 13423. https://doi.org/10.3390/ijms232113423

APA StyleAlmeida, N., Meyer, V., Burnet, A., Boucher, J., Talens-Perales, D., Pereira, S., Ihalainen, P., Levée, T., Polaina, J., Petit-Conil, M., Camarero, S., & Pinto, P. (2022). Use of a Novel Extremophilic Xylanase for an Environmentally Friendly Industrial Bleaching of Kraft Pulps. International Journal of Molecular Sciences, 23(21), 13423. https://doi.org/10.3390/ijms232113423