Effects of Biochar and Nitrogen Application on Rice Biomass Saccharification, Bioethanol Yield and Cell Wall Polymers Features

Abstract

1. Introduction

2. Results

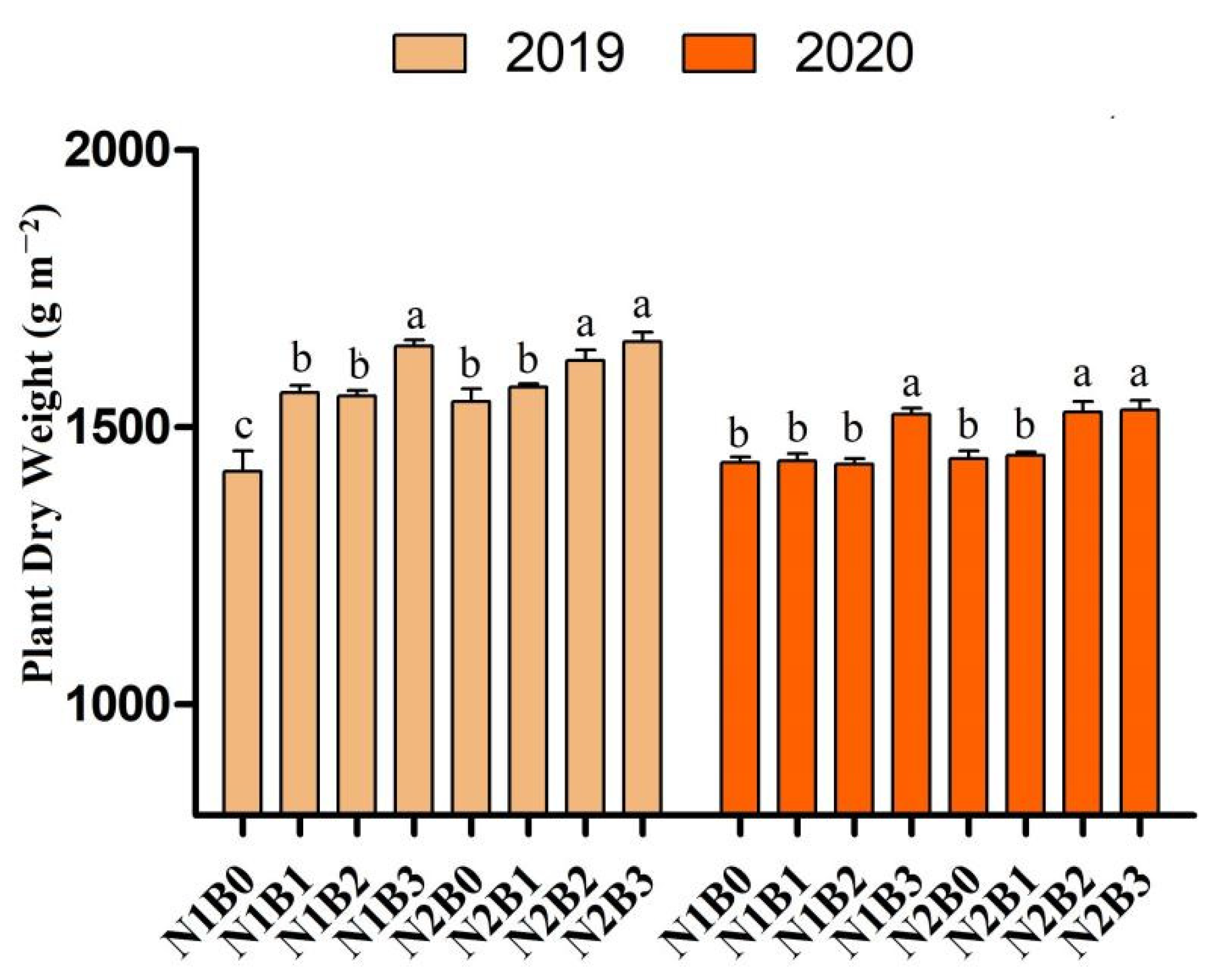

2.1. Biochar and Nitrogen Impact on Rice Plant Dry Matter

2.2. Biochar and Nitrogen Impact on Cell Wall Compositions of Biomass Residues

2.3. Biomass Saccharification under 1% NaOH with and without Tween-80

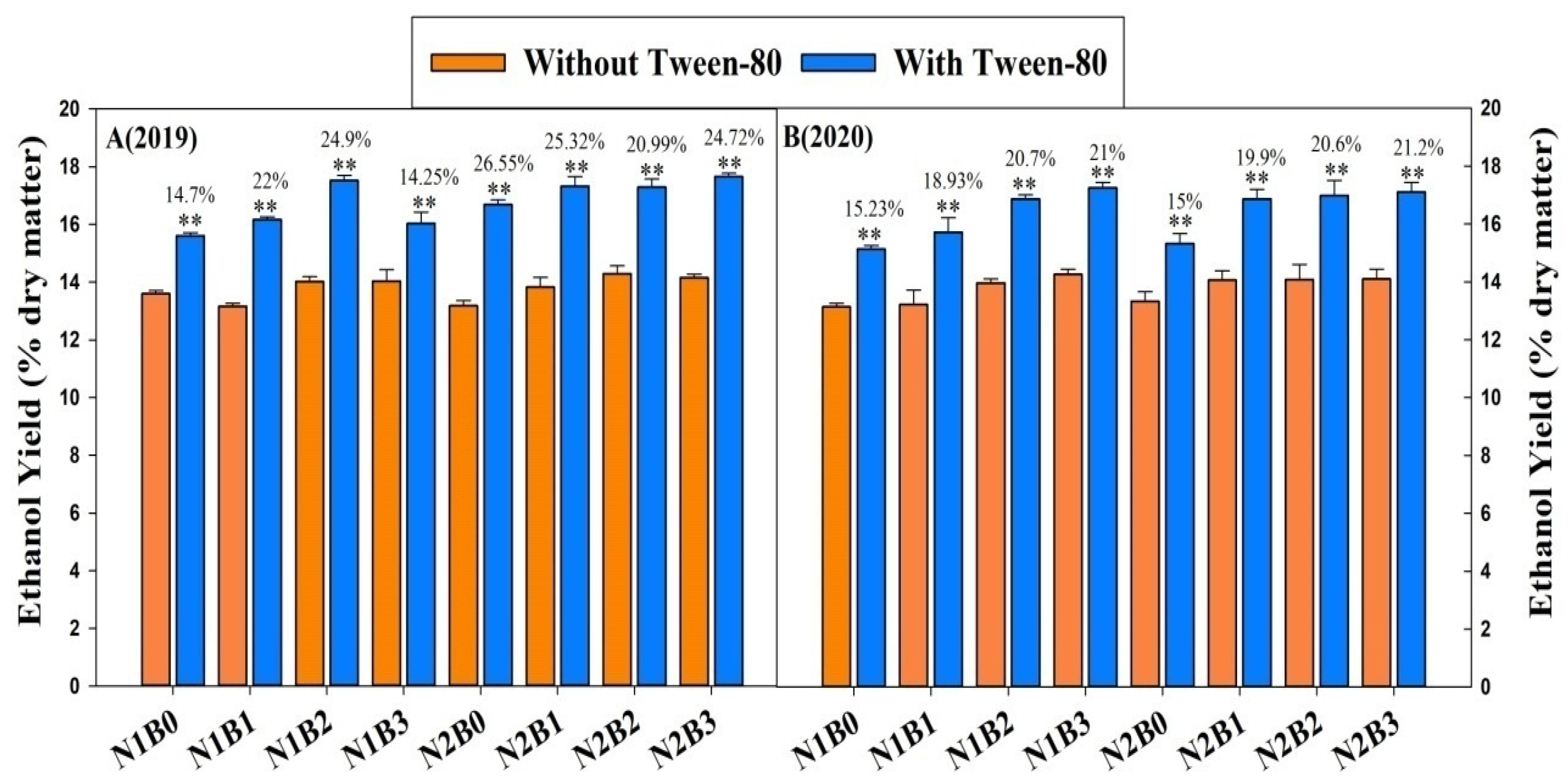

2.4. Bio-Ethanol Yield (% Dry Matter) from Yeast Fermentation

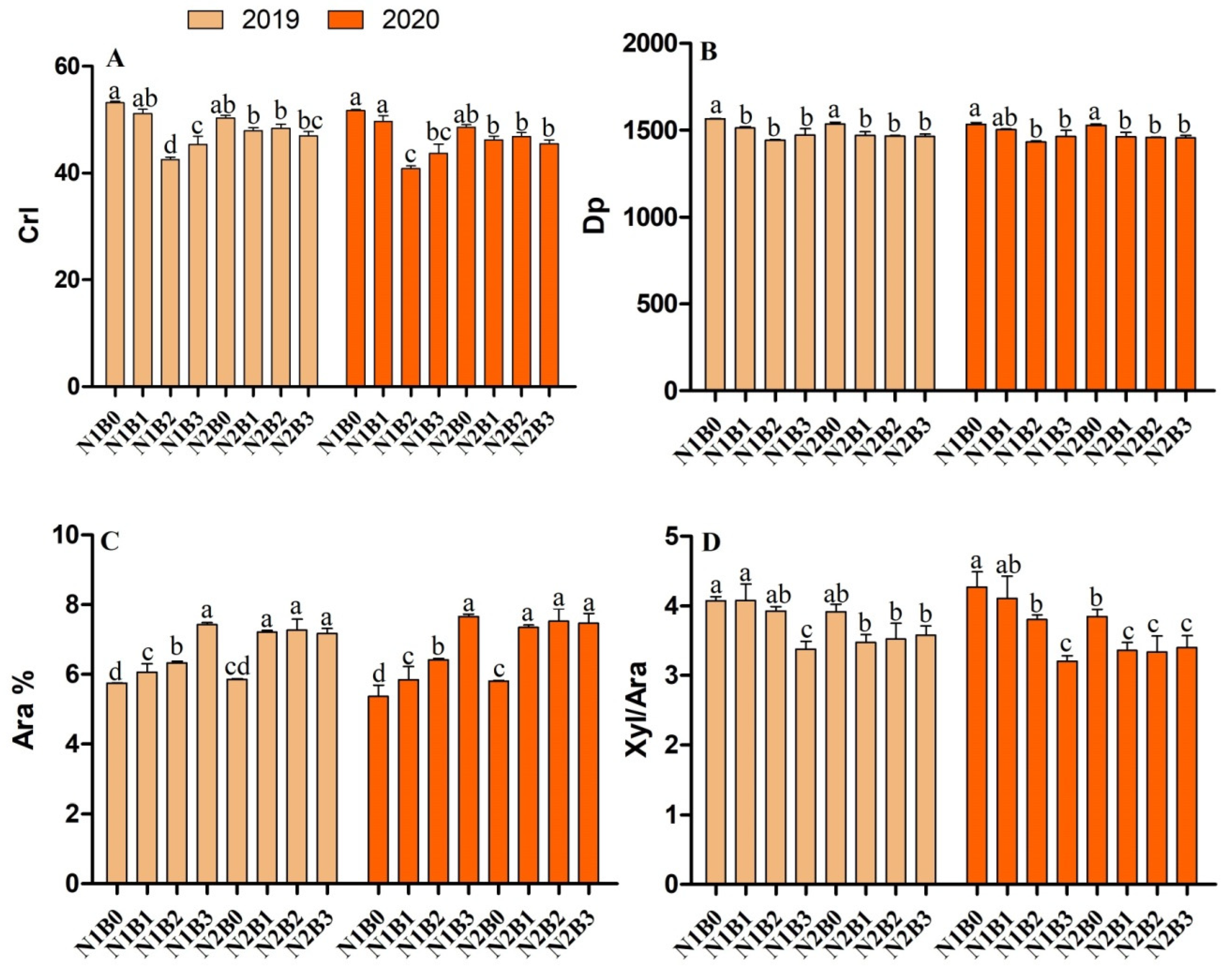

2.5. Changes in Cellulose Features and Hemicelluloses Monomers

2.6. Mechanism of Biochar and Nitrogen Application Improvements on Biomass Digestibility

3. Discussion

4. Material and Methods

4.1. Experimental Location and Design

4.2. Biochar (Production) and Soil Properties

4.3. Measurement and Analysis

4.3.1. Chemical Pretreatments and Biomass Enzymatic Saccharification

4.3.2. Biomass Composition Analysis

4.3.3. Determination of Hexoses and Pentoses

4.4. Hemicelluloses Monosaccharides and Lignin Determination

4.5. Cellulose Crystallinity Detection

4.6. Determination of Cellulose DP

4.7. Determination of Bioethanol

4.8. Statistical Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hosseini, S.E.; Wahid, M.A. Hydrogen production from renewable and sustainable energy resources: Promising green energy carrier for clean development. Renew. Sustain. Energy Rev. 2016, 57, 850–866. [Google Scholar] [CrossRef]

- Gomiero, T.; Paoletti, M.G.; Pimentel, D. Biofuels: Efficiency, Ethics, and Limits to Human Appropriation of Ecosystem Services. J. Agric. Environ. Ethic 2010, 23, 403–434. [Google Scholar] [CrossRef]

- Ali, I.; Adnan, M.; Ullah, S.; Zhao, Q.; Iqbal, A.; He, L.; Cheng, F.; Muhammad, I.; Ahmad, S.; Wei, S.; et al. Biochar combined with nitrogen fertilizer: A practical approach for increasing the biomass digestibility and yield of rice and promoting food and energy security. Biofuels Bioprod. Biorefining 2022, 16, 1304–1318. [Google Scholar] [CrossRef]

- Zahoor; Sun, D.; Li, Y.; Wang, J.; Tu, Y.; Wang, Y.; Hu, Z.; Zhou, S.; Wang, L.; Xie, G.; et al. Biomass saccharification is largely enhanced by altering wall polymer features and reducing silicon accumulation in rice cultivars harvested from nitrogen fertilizer supply. Bioresour. Technol. 2017, 243, 957–965. [Google Scholar] [CrossRef]

- Xin, L. Chemical fertilizer rate, use efficiency and reduction of cereal crops in China, 1998–2018. J. Geogr. Sci. 2022, 32, 65–78. [Google Scholar] [CrossRef]

- Iqbal, A.; He, L.; Ali, I.; Ullah, S.; Khan, A.; Akhtar, K.; Wei, S.; Fahad, S.; Khan, R.; Jiang, L. Co-incorporation of manure and inorganic fertilizer improves leaf physiological traits, rice production and soil functionality in a paddy field. Sci. Rep. 2021, 11, 1–16. [Google Scholar] [CrossRef]

- Iqbal, A.; He, L.; Khan, A.; Wei, S.; Akhtar, K.; Ali, I.; Ullah, S.; Munsif, F.; Zhao, Q.; Jiang, L. Organic Manure Coupled with Inorganic Fertilizer: An Approach for the Sustainable Production of Rice by Improving Soil Properties and Nitrogen Use Efficiency. Agronomy 2019, 9, 651. [Google Scholar] [CrossRef]

- Wu, K.; Ali, I.; Xie, H.; Ullah, S.; Iqbal, A.; Wei, S.; He, L.; Huang, Q.; Wu, X.; Cheng, F.; et al. Impact of fertilization with reducing in nitrogen and phosphorous application on growth, yield and biomass accumulation of rice (Oryza sativa L.) under a dual cropping system. PeerJ 2021, 9, e11668. [Google Scholar] [CrossRef] [PubMed]

- Ullah, S.; Zhao, Q.; Wu, K.; Ali, I.; Liang, H.; Iqbal, A.; Wei, S.; Cheng, F.; Ahmad, S.; Jiang, L.; et al. Biochar application to rice with 15N-labelled fertilizers, enhanced leaf nitrogen concentration and assimilation by improving morpho-physiological traits and soil quality. Saudi J. Biol. Sci. 2021, 28, 3399–3413. [Google Scholar] [CrossRef] [PubMed]

- Ali, I.; He, L.; Ullah, S.; Quan, Z.; Wei, S.; Iqbal, A.; Munsif, F.; Shah, T.; Xuan, Y.; Luo, Y.; et al. Biochar addition coupled with nitrogen fertilization impacts on soil quality, crop productivity, and nitrogen uptake under double-cropping system. Food Energy Secur. 2020, 9, e208. [Google Scholar] [CrossRef]

- Ali, I.; Zhao, Q.; Wu, K.; Ullah, S.; Iqbal, A.; Liang, H.; Zhang, J.; Muhammad, I.; Khan, A.; Khan, A.A.; et al. Bi-ochar in combination with nitrogen fertilizer is a technique: To enhance physiological and morphological traits of Rice (Oryza sativa L.) by improving soil physio-biochemical properties. J. Plant Growth Regul. 2021, 9, e208. [Google Scholar]

- Kamali, M.; Sweygers, N.; Al-Salem, S.; Appels, L.; Aminabhavi, T.M.; Dewil, R. Biochar for soil applica-tions-sustainability aspects, challenges and future prospects. Chem. Eng. J. 2022, 428, 131189. [Google Scholar] [CrossRef]

- Dume, B.; Mosissa, T.; Nebiyu, A. Effect of biochar on soil properties and lead (Pb) availability in a military camp in South West Ethiopia. Afr. J. Environ. Sci. Technol. 2016, 10, 77–85. [Google Scholar] [CrossRef]

- Palanivelu, K.; Ramachandran, A.; Raghavan, V. Biochar from biomass waste as a renewable carbon material for climate change mitigation in reducing greenhouse gas emissions–A review. Biomass- Convers. Biorefinery 2021, 11, 2247–2267. [Google Scholar] [CrossRef]

- Case, S.D.C.; McNamara, N.P.; Reay, D.S.; Whitaker, J. Can biochar reduce soil greenhouse gas emissions from a Miscanthus bioenergy crop? GCB Bioenergy 2014, 6, 76–89. [Google Scholar] [CrossRef]

- Mukherjee, A.; Lal, R. Biochar Impacts on Soil Physical Properties and Greenhouse Gas Emissions. Agronomy 2013, 3, 313. [Google Scholar] [CrossRef]

- Doblin, M.S.; Pettolino, F.; Bacic, A. Plant cell walls: The skeleton of the plant world. Funct. Plant Biol. 2010, 37, 357–381. [Google Scholar] [CrossRef]

- Janke, L.; McCabe, B.K.; Harris, P.; Hill, A.; Lee, S.; Weinrich, S.; Marchuk, S.; Baillie, C. Ensiling fermentation reveals pre-treatment effects for anaerobic digestion of sugarcane biomass: An assessment of ensiling additives on methane potential. Bioresour. Technol. 2019, 279, 398–403. [Google Scholar] [CrossRef]

- Li, F.; Zhang, M.; Guo, K.; Hu, Z.; Zhang, R.; Feng, Y.; Yi, X.; Zou, W.; Wang, L.; Wu, C.; et al. High-level hemicellulosic arabinose predominately affects lignocellulose crystallinity for genetically enhancing both plant lodging resistance and biomass enzymatic digestibility in rice mutants. Plant Biotechnol. J. 2015, 13, 514–525. [Google Scholar] [CrossRef]

- Zhang, W.; Yi, Z.; Huang, J.; Li, F.; Hao, B.; Li, M.; Hong, S.; Lv, Y.; Sun, W.; Ragauskas, A.; et al. Three lignocellulose features that distinctively affect biomass enzymatic digestibility under NaOH and H2SO4 pretreatments in Miscanthus. Bioresour. Technol. 2013, 130, 30–37. [Google Scholar] [CrossRef]

- Chundawat, S.P.; Beckham, G.T.; Himmel, M.E.; Dale, B.E. Deconstruction of Lignocellulosic Biomass to Fuels and Chemicals. Annu. Rev. Chem. Biomol. Eng. 2011, 2, 121–145. [Google Scholar] [CrossRef] [PubMed]

- Himmel, M.E.; Picataggio, S.K. Our Challenge is to Acquire Deeper Understanding of Biomass Recalcitrance and Conversion. In Biomass Recalcitrance; Blackwell Publishing Ltd.: Oxford, UK, 2009; p. 1. [Google Scholar] [CrossRef]

- Harholt, J.; Suttangkakul, A.; Scheller, H.V. Biosynthesis of Pectin. Plant Physiol. 2010, 153, 384–395. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.-H.; Qin, L.; Pang, F.; Jin, M.-J.; Li, B.-Z.; Kang, Y.; Dale, B.E.; Yuan, Y.-J. Effects of biomass particle size on steam explosion pretreatment performance for improving the enzyme digestibility of corn stover. Ind. Crop. Prod. 2013, 44, 176–184. [Google Scholar] [CrossRef]

- Fan, L.T.; Lee, Y.-H.; Beardmore, D.H. Mechanism of the enzymatic hydrolysis of cellulose: Effects of major structural features of cellulose on enzymatic hydrolysis. Biotechnol. Bioeng. 1980, 22, 177–199. [Google Scholar] [CrossRef]

- Fan, L.T.; Lee, Y.-H.; Beardmore, D.R. The influence of major structural features of cellulose on rate of enzymatic hydrolysis. Biotechnol. Bioeng. 1981, 23, 419–424. [Google Scholar] [CrossRef]

- Hendriks, A.; Zeeman, G. Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour. Technol. 2009, 100, 10–18. [Google Scholar] [CrossRef]

- Ioelovich, M.; Morag, E. Effect of cellulose structure on enzymatic hydrolysis. BioResources 2011, 6, 2818–2835. [Google Scholar] [CrossRef]

- Jeoh, T.; Ishizawa, C.I.; Davis, M.F.; Himmel, M.E.; Adney, W.S.; Johnson, D.K. Cellulase digestibility of pretreated biomass is limited by cellulose accessibility. Biotechnol. Bioeng. 2007, 98, 112–122. [Google Scholar] [CrossRef]

- Park, S.; Baker, J.O.; Himmel, M.E.; Parilla, P.A.; Johnson, D.K. Cellulose crystallinity index: Measurement techniques and their impact on interpreting cellulase performance. Biotechnol. Biofuels 2010, 3, 1–10. [Google Scholar] [CrossRef]

- Wada, M.; Ike, M.; Tokuyasu, K. Enzymatic hydrolysis of cellulose I is greatly accelerated via its conversion to the cellulose II hydrate form. Polym. Degrad. Stab. 2010, 95, 543–548. [Google Scholar] [CrossRef]

- Spokas, K.A.; Novak, J.M.; Stewart, C.E.; Cantrell, K.B.; Uchimiya, M.; DuSaire, M.G.; Ro, K.S. Qualitative analysis of volatile organic compounds on biochar. Chemosphere 2011, 85, 869–882. [Google Scholar] [CrossRef] [PubMed]

- Bruun, S.; El-Zehery, T. Biochar effect on the mineralization of soil organic matter. Pesqui. Agropecuária Bras. 2012, 47, 665–671. [Google Scholar] [CrossRef]

- Ahmad, R.; Gao, J.; Gao, Z.; Khan, A.; Ali, I.; Fahad, S. Influence of Biochar on Soil Nutrients and Associated Rhizobacterial Communities of Mountainous Apple Trees in Northern Loess Plateau China. Microorganisms 2022, 10, 2078. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Ullah, F.; Ahmad, R.; Ali Shah, S.U.; Khan, A.; Adnan, M. Response of Soil Proteobacteria to Biochar Amendment inSustainable Agriculture—A Mini Review. J. Soil Plant Environ. 2022, 1, 16–30. [Google Scholar] [CrossRef]

- Xu, C.-Y.; Hosseini-Bai, S.; Hao, Y.; Rachaputi, R.C.N.; Wang, H.; Xu, Z.; Wallace, H. Effect of biochar amendment on yield and photosynthesis of peanut on two types of soils. Environ. Sci. Pollut. Res. 2015, 22, 6112–6125. [Google Scholar] [CrossRef]

- Khan, Z.; Zhang, K.; Khan, M.N.; Fahad, S.; Xu, Z.; Hu, L. Coupling of Biochar with Nitrogen Supplements Improve Soil Fertility, Nitrogen Utilization Efficiency and Rapeseed Growth. Agronomy 2020, 10, 1661. [Google Scholar] [CrossRef]

- Xia, H.; Riaz, M.; Zhang, M.; Liu, B.; Li, Y.; El-Desouki, Z.; Jiang, C. Biochar-N fertilizer interaction increases N utilization efficiency by modifying soil C/N component under N fertilizer deep placement modes. Chemosphere 2021, 286, 131594. [Google Scholar] [CrossRef]

- Decker, S.R.; Harman-Ware, A.E.; Happs, R.M.; Wolfrum, E.J.; Tuskan, G.A.; Kainer, D.; Oguntimein, G.B.; Rodriguez, M.; Weighill, D.; Jones, P.; et al. High Throughput Screening Technologies in Biomass Characterization. Front. Energy Res. 2018, 6, 120. [Google Scholar] [CrossRef]

- Alam, A.; Zhang, R.; Liu, P.; Huang, J.; Wang, Y.; Hu, Z.; Madadi, M.; Sun, D.; Hu, R.; Ragauskas, A.J.; et al. A finalized determinant for complete lignocellulose enzymatic saccharification potential to maximize bioethanol production in bioenergy Miscanthus. Biotechnol. Biofuels 2019, 12, 1–22. [Google Scholar] [CrossRef]

- Jin, W.; Chen, L.; Hu, M.; Sun, D.; Li, A.; Li, Y.; Hu, Z.; Zhou, S.; Tu, Y.; Xia, T.; et al. Tween-80 is effective for enhancing steam-exploded biomass enzymatic saccharification and ethanol production by specifically lessening cellulase absorption with lignin in common reed. Appl. Energy 2016, 175, 82–90. [Google Scholar] [CrossRef]

- Huang, M.; Fan, L.; Jiang, L.-G.; Yang, S.-Y.; Zou, Y.-B.; Uphoff, N. Continuous applications of biochar to rice: Effects on grain yield and yield attributes. J. Integr. Agric. 2019, 18, 563–570. [Google Scholar] [CrossRef]

- Sun, D.; Yang, Q.; Wang, Y.; Gao, H.; He, M.; Lin, X.; Lu, J.; Wang, Y.; Kang, H.; Alam, A.; et al. Distinct mechanisms of enzymatic saccharification and bioethanol conversion enhancement by three surfactants under steam explosion and mild chemical pretreatments in bioenergy Miscanthus. Ind. Crop. Prod. 2020, 153, 112559. [Google Scholar] [CrossRef]

- Zhang, J.; Zou, W.; Li, Y.; Feng, Y.; Zhang, H.; Wu, Z.; Tu, Y.; Wang, Y.; Cai, X.; Peng, L. Silica distinctively affects cell wall features and lignocellulosic saccharification with large enhancement on biomass production in rice. Plant Sci. 2015, 239, 84–91. [Google Scholar] [CrossRef]

- Hu, M.; Yu, H.; Li, Y.; Li, A.; Cai, Q.; Liu, P.; Tu, Y.; Wang, Y.; Hu, R.; Hao, B.; et al. Distinct polymer extraction and cellulose DP reduction for complete cellulose hydrolysis under mild chemical pretreatments in sugarcane. Carbohydr. Polym. 2018, 202, 434–443. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Zhang, M.; Wang, L.; Tu, Y.; Zhang, J.; Xie, G.; Zou, W.; Li, F.; Guo, K.; Li, Q.; et al. Biomass digestibility is predominantly affected by three factors of wall polymer features distinctive in wheat accessions and rice mutants. Biotechnol. Biofuels 2013, 6, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Hocart, C.H.; Redmond, J.W.; Williamson, R.E. Fractionation of carbohydrates in Arabidopsis root cell walls shows that three radial swelling loci are specifically involved in cellulose production. Planta 2000, 211, 406–414. [Google Scholar] [CrossRef]

- Aftab, M.N.; Iqbal, I.; Riaz, F.; Karadag, A.; Tabatabaei, M. Different Pretreatment Methods of Lignocellulosic Biomass for Use in Biofuel Production. In Biomass for Bioenergy-Recent Trends and Future Challenges; IntechOpen: London, UK, 2019. [Google Scholar]

- Li, F.; Ren, S.; Zhang, W.; Xu, Z.; Xie, G.; Chen, Y.; Tu, Y.; Li, Q.; Zhou, S.; Li, Y.; et al. Arabinose substitution degree in xylan positively affects lignocellulose enzymatic digestibility after various NaOH/H2SO4 pretreatments in Miscanthus. Bioresour. Technol. 2013, 130, 629–637. [Google Scholar] [CrossRef]

| Treatments 2019 | Cellulose | Hemicelluloses | Lignin | Pictin | Starch |

|---|---|---|---|---|---|

| N1B0 | 31.22 ± 1.22 b | 19.022 ± 1.5 b | 16.603 ± 1.0 ab | 2.218 ± 0.09 c | 14.120 ± 2.3 b |

| N1B1 | 32.72 ± 1.73 ab | 20.387 ± 1.7 ab | 16.166 ± 0.9 b | 2.267 ± 0.89 c | 14.960 ± 1.6 b |

| N1B2 | 33.71 ± 2.58 a | 21.640 ± 2.3 a | 17.023 ± 1.8 a | 2.275 ± 0.26 c | 15.277 ± 2.3 a |

| N1B3 | 33.30 ± 2.32 a | 21.967 ± 2.4 a | 17.036 ± 1.8 a | 2.440 ± 0.17 b | 15.413 ± 1.5 a |

| N2B0 | 31.57 ± 3.34 b | 19.567 ± 1.3 b | 16.182 ± 1.2 ab | 2.033 ± 0.88 c | 14.362 ± 1.2 b |

| N2B1 | 32.43 ± 2.29 ab | 20.433 ± 2.2 ab | 16.823 ± 2.7 ab | 2.433 ± 0.29 b | 14.853 ± 1.5 b |

| N2B2 | 33.30 ± 2.52 a | 21.300 ± 2.7 a | 17.290 ± 1.9 a | 2.600 ± 0.05 ab | 15.241 ± 1.7 a |

| N2B3 | 33.27 ± 3.26 a | 21.267 ± 2.4 a | 17.156 ± 2.8 a | 2.733 ± 0.23 a | 15.246 ± 1.9 a |

| 2020 | |||||

| N1B0 | 30.80 ± 2.2 b | 18.119 ± 1.6 b | 16.129 ± 2.5 b | 2.267 ± 0.2 c | 14.776 ± 0.9 c |

| N1B1 | 32.31 ± 2.3 a | 19.517 ± 1.8 ab | 16.210 ± 1.8 b | 2.237 ± 0.3 c | 15.650 ± 1.2 ab |

| N1B2 | 33.38 ± 2.5 a | 20.640 ± 2.3 a | 16.956 ± 1.9 ab | 2.277 ± 0.28 c | 15.847 ± 1.9 a |

| N1B3 | 32.93 ± 1.3 a | 20.967 ± 2.6 a | 17.254 ± 1.8 a | 2.477 ± 0.19 b | 15.983 ± 1.6 a |

| N2B0 | 31.18 ± 1.2 b | 18.567 ± 1.9 b | 16.323 ± 1.7 b | 2.133 ± 0.35 c | 14.932 ± 1.2 c |

| N2B1 | 32.11 ± 2.2 a | 19.433 ± 1.8 ab | 17.056 ± 2.1 a | 2.533 ± 0.58 b | 15.423 ± 17 b |

| N2B2 | 32.95 ± 2.5 a | 20.523 ± 2.2 a | 17.077 ± 1.9 a | 2.700 ± 0.29 ab | 15.811 ± 1.5 a |

| N2B3 | 32.90 ± 3.6 a | 20.933 ± 2.7 a | 17.098 ± 1.6 a | 2.833 ± 049 a | 15.816 ± 1.8 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, I.; Adnan, M.; Iqbal, A.; Ullah, S.; Khan, M.R.; Yuan, P.; Zhang, H.; Nasar, J.; Gu, M.; Jiang, L. Effects of Biochar and Nitrogen Application on Rice Biomass Saccharification, Bioethanol Yield and Cell Wall Polymers Features. Int. J. Mol. Sci. 2022, 23, 13635. https://doi.org/10.3390/ijms232113635

Ali I, Adnan M, Iqbal A, Ullah S, Khan MR, Yuan P, Zhang H, Nasar J, Gu M, Jiang L. Effects of Biochar and Nitrogen Application on Rice Biomass Saccharification, Bioethanol Yield and Cell Wall Polymers Features. International Journal of Molecular Sciences. 2022; 23(21):13635. https://doi.org/10.3390/ijms232113635

Chicago/Turabian StyleAli, Izhar, Muhammad Adnan, Anas Iqbal, Saif Ullah, Muhammad Rafiullah Khan, Pengli Yuan, Hua Zhang, Jamal Nasar, Minghua Gu, and Ligeng Jiang. 2022. "Effects of Biochar and Nitrogen Application on Rice Biomass Saccharification, Bioethanol Yield and Cell Wall Polymers Features" International Journal of Molecular Sciences 23, no. 21: 13635. https://doi.org/10.3390/ijms232113635

APA StyleAli, I., Adnan, M., Iqbal, A., Ullah, S., Khan, M. R., Yuan, P., Zhang, H., Nasar, J., Gu, M., & Jiang, L. (2022). Effects of Biochar and Nitrogen Application on Rice Biomass Saccharification, Bioethanol Yield and Cell Wall Polymers Features. International Journal of Molecular Sciences, 23(21), 13635. https://doi.org/10.3390/ijms232113635