Abstract

Foodborne infections are an important global health problem due to their high prevalence and potential for severe complications. Bacterial contamination of meat during processing at the enterprise can be a source of foodborne infections. Polymeric coatings with antibacterial properties can be applied to prevent bacterial contamination. A composite coating based on fluoroplast and Ag2O NPs can serve as such a coating. In present study, we, for the first time, created a composite coating based on fluoroplast and Ag2O NPs. Using laser ablation in water, we obtained spherical Ag2O NPs with an average size of 45 nm and a ζ-potential of −32 mV. The resulting Ag2O NPs at concentrations of 0.001–0.1% were transferred into acetone and mixed with a fluoroplast-based varnish. The developed coating made it possible to completely eliminate damage to a Teflon cutting board. The fluoroplast/Ag2O NP coating was free of defects and inhomogeneities at the nano level. The fluoroplast/Ag2O NP composite increased the production of ROS (H2O2, OH radical), 8-oxogualnine in DNA in vitro, and long-lived active forms of proteins. The effect depended on the mass fraction of the added Ag2O NPs. The 0.01–0.1% fluoroplast/NP Ag2O coating exhibited excellent bacteriostatic and bactericidal properties against both Gram-positive and Gram-negative bacteria but did not affect the viability of eukaryotic cells. The developed PTFE/NP Ag2O 0.01–0.1% coating can be used to protect cutting boards from bacterial contamination in the meat processing industry.

1. Introduction

Bacterial contamination of meat products can occur at any stage of its journey to the consumer: from slaughter and carcass-cutting to storage at points of sale [1,2]. At the same time, bacteria can form biofilms on work surfaces that are resistant to classical disinfection methods [3,4]. Contamination of meat processing products with bacteria of epidemiological significance (Listeria monocytogenes, Clostridium perfringens) is a serious global health problem. In total, in worldwide in 1990–2012, approximately 2 billion cases of foodborne infections were registered and caused over 1,000,000 deaths [5]. In the European Union, the number of cases of foodborne infections registered in 2005 exceeded 197,000 cases per year. In 2016, this figure increased to 240,000 cases per year [6,7]. In Canada, the incidence of foodborne infections is comparable [8]. In the United States, the number of cases of foodborne illness (foodborne illness) of a bacterial nature exceeds 48 million cases per year, of which there are 128,000 hospitalizations and over 3000 deaths [9]. In Africa and Asia, foodborne infections are of particular danger, as they are so common among children [10]. Danger to the life and health of consumers is not only due to the microorganisms themselves but also due to the produced or bacterial toxins with various natures [11]. In this regard, it is very important to prevent bacterial contamination during the initial stages of meat preparation in order to minimize the possible accumulation of bacterial toxins. In some cases, foodborne infections can lead to serious complications, as well as death.

Among the complications of bacterial infections were reported lesions of the gastrointestinal tract (gastritis, stomach ulcers, severe forms of diarrhea), CNS (meningitis, encephalitis), kidneys, liver, spleen, musculoskeletal system (reactive arthritis), cardiovascular system (endocarditis), and reproductive system (premature birth, stillbirth) [12,13,14,15,16,17,18].

According to the NCBI, the first studies on bacterial food contamination date back to the first half of the twentieth century. Over the past 60 years, the rate of publications on this subject has grown from a few dozen papers per year to hundreds and even thousands of papers per year. This indicates not only the high significance of the problem but also the lack of a solution and the continuation of active research in this direction.

One of the promising methods for combating the bacterial contamination of work surfaces at food industry enterprises is the use of polymer coatings designed to reduce the adhesion of bacteria to treated surfaces [19,20,21].

One of the most promising polymers for this application is fluoroplasts (Teflon, fluoroplast, polytetrafluoroethylene, PTFE). It has been shown that the adhesion of bacteria to working surfaces coated with fluoroplasts is lower than to other surfaces, in particular, ceramic ones [22]. Fluoroplasts are a polymer consisting of 1,1,2,2-tetrafluoroethylene monomers and can be described by the formula -(CF2-CF2)n-.It is an opaque and smooth milky white material. Fluoroplastics are widely used in various fields: mechanical engineering, chemical production, space and marine industries, biomedicine in the manufacture of implants, and in the food industry [23,24,25,26,27,28,29,30,31]. The breadth of applications of fluoroplastics is due to its unique properties: high mechanical and chemical resistance, thermal and electrical stability, low coefficient of friction, self-lubrication, and self-healing ability [32,33,34,35]. An additional advantage of fluoroplasts is its very low toxicity to mammals in vivo [36]. Due to pronounced hydrophobic properties and mechanical resistance, fluoroplasts can be used to reduce adhesion to working surfaces in food production [32,33,34].

In a number of studies, the antibacterial activity of polymeric materials was enhanced by adding metal NPs and their oxides, for example, Ag, Cu, ZnO, or Ag2O [37,38,39,40]. The antimicrobial properties of metal NPs and their oxides are well described in numerous works [41,42,43,44]. Among the general pool of works, since 2005, a significant part (over 30% of publications) are publications devoted to the antibacterial activity of silver NPs, including those in the form of silver oxide. Ag2O NPs are able to realize their antibacterial action through several mechanisms: enzyme inactivation, genotoxic action, disruption of cell wall integrity, and photocatalytic action (Table 1).

Table 1.

Mechanisms of antimicrobial action of Ag2O/Ag NPs.

Based on the foregoing, one of the promising materials in this case is a composite based on fluoroplasts and Ag/Ag2O NPs. In particular, such a composite was developed for medical applications [55]. However, we believe that this composite can be used in the protection of work surfaces in the food industry, in particular, the processing of cutting boards in the processing of meat. Unfortunately, new data on the development of bacterial resistance against NPs of metals and metal oxides have recently appeared. Bacterial defense mechanisms include the increased expression of extracellular matrix molecules (flagellin) to inactivate NPs, the release of pigments to inactivate metal ions, and the activation of antioxidant defense to combat oxidative stress [56,57]. It should be noted that these mechanisms are most likely implemented after a certain amount of time after the introduction of single NPs [58]. We assume that the constant dosed release of new portions of NPs from a material during their using can be a way to reduce bacterial resistance against NPs. Composite materials based on polymers and NPs are capable of the controlled release of NPs.

Previously, we showed that Ag2O NPs, when added to our previously created composite materials based on PLGA and borosiloxane, showed a good bacteriostatic effect and low cytotoxicity against eukaryotic cells [59,60]. In this work, we, for the first time, attempted to create a nanocomposite coating based on fluoroplasts and Ag2O NPs, to study its physicochemical properties, the effect on the generation of ROS and markers of DCH and protein oxidation, bacteriostatic and bactericidal actions, and cytotoxicity against eukaryotic cells.

2. Results and Discussion

2.1. Physicochemical Properties

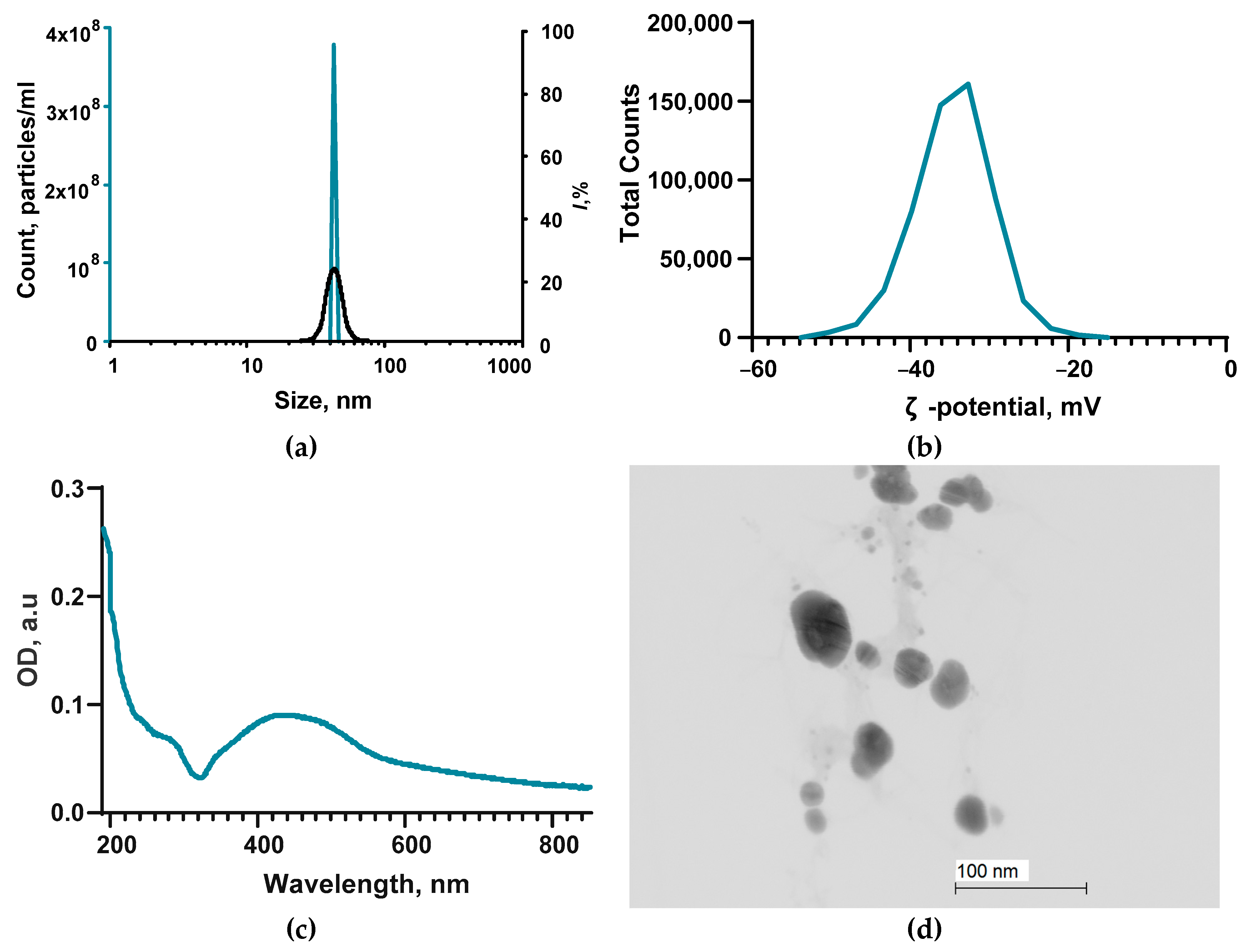

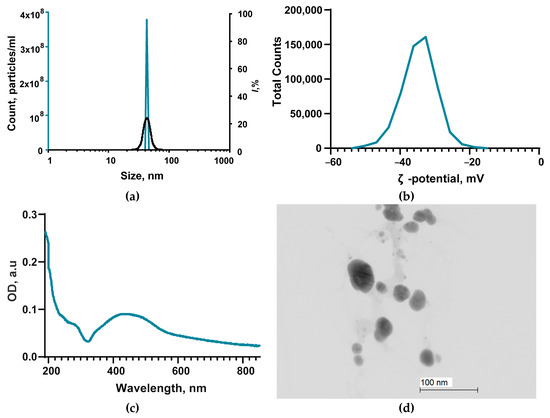

At the initial stage of the study, we characterized the main parameters of the obtained NPs: size, ζ-potential, absorption spectrum, and shape (Figure 1). The resulting NPs have a monomodal size distribution with an average hydrodynamic diameter of ~45 nm and a half-width of no more than 35–55 nm (Figure 1a). The resulting size distribution coincides with the literature data [50,75,76,77]. The average value of the ζ-potential of the obtained NPs was ~32 mV, and the half-width was from −42 to 28 mV (Figure 1b). The data obtained agree with the literature data and indicate the stability of the aqueous colloid of the synthesized NPs [78,79]. In the absorption spectrum of colloidal NPs, a clear peak was observed in the region of ~420 nm, which is characteristic of Ag2O NPs [80]. According to TEM data, the obtained NPs have a round shape (Figure 1d), which is consistent with the literature data [50]. Thus, by laser ablation in water, we obtained rounded Ag2O NPs with a unimodal size distribution that are stable in aqueous colloids.

Figure 1.

Main characteristics of Ag2O NPs: (a) Size distribution of NPs obtained by DLS (blue line) and CPS (black line). (b) NP distribution over the ζ-potential obtained by the ELS method. (c) Absorption spectrum from the UV–vis region of the NP colloid. (d) TEM photograph of the obtained NPs. Scale bar: 100 nm.

The resulting Ag2O NPs were mixed with a fluoroplast-based varnish (see Section 3).

2.2. Composite Material Preparation and Characterization

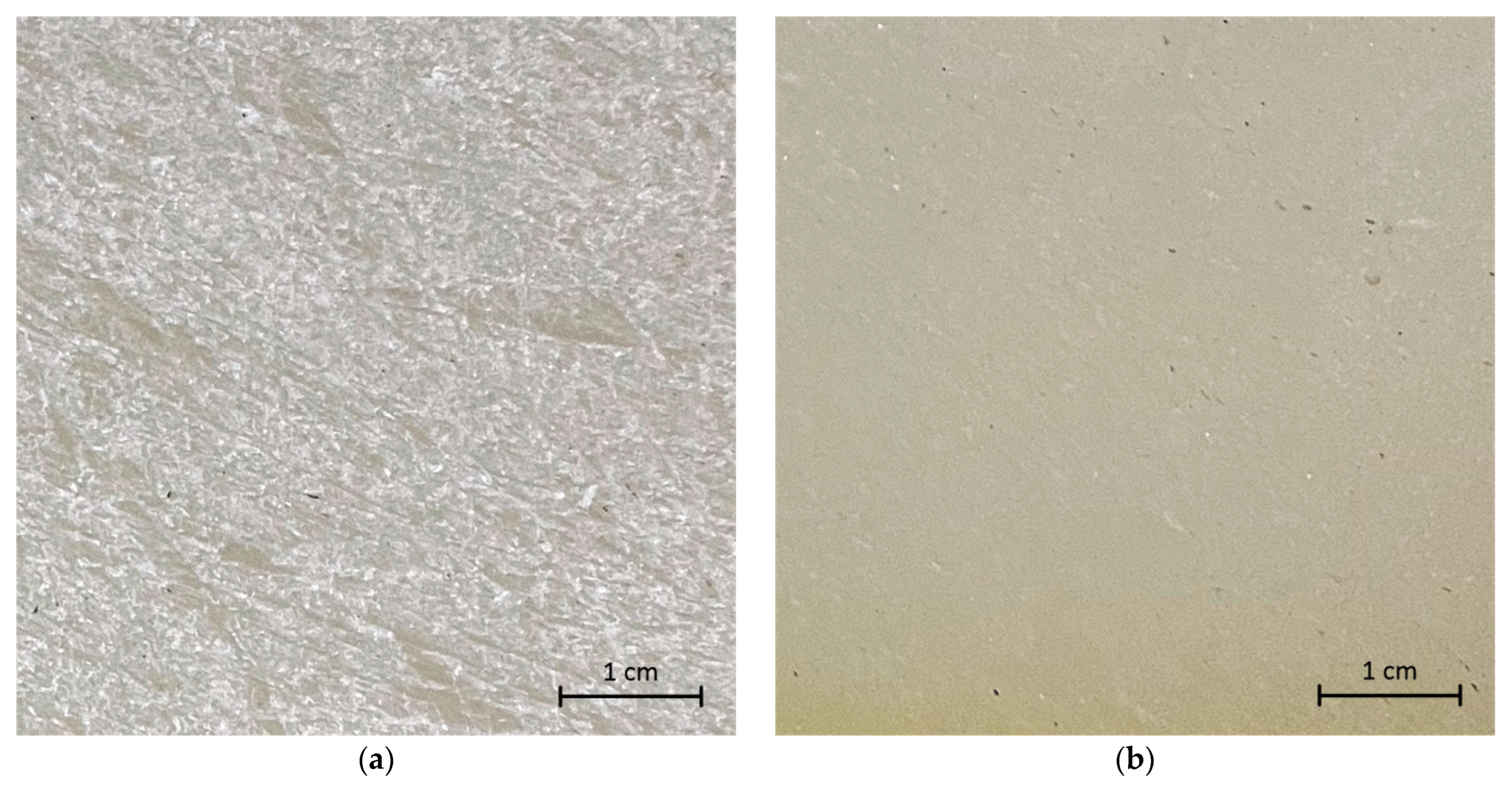

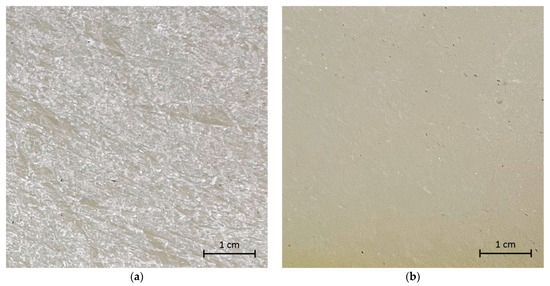

At the next stage of the study, we tested the ability of the developed coating based on fluoroplastic varnish and Ag2O NPs to fill visible damage on a fragment of a used Teflon cutting board (Figure 2a). After drying, the composite coating remained evenly distributed over the treated surface, and no visible damage was observed (Figure 2b). When trying to mechanically damage the surface of the coating, no scratches, chips, or other traces of mechanical impact were observed.

Figure 2.

Photographs of a section of a Teflon (PTFE) cutting board with damage before coating (a) and after the application and drying of the PTFE/Ag2O-NPs 0.1% composite coating (b).

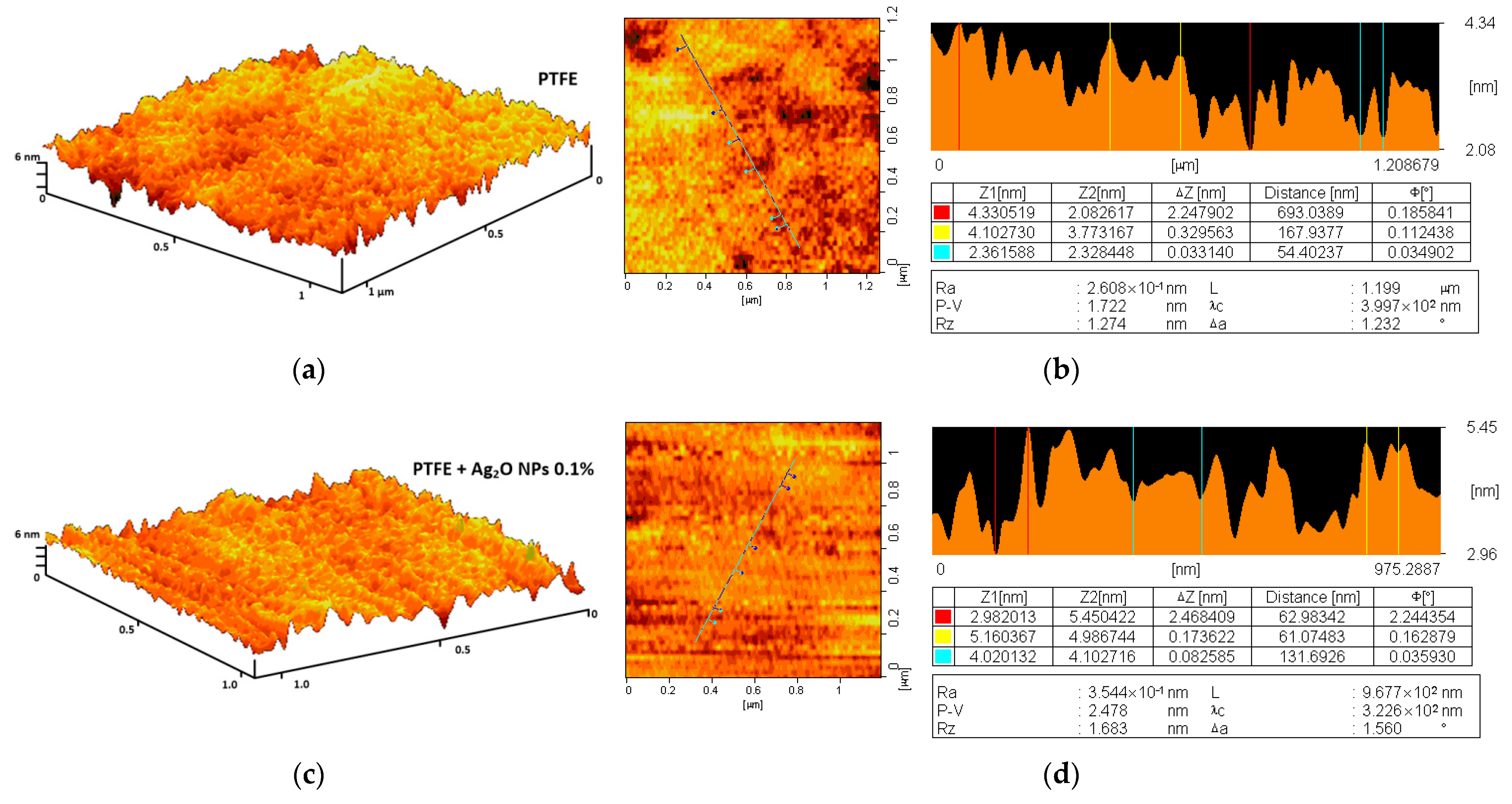

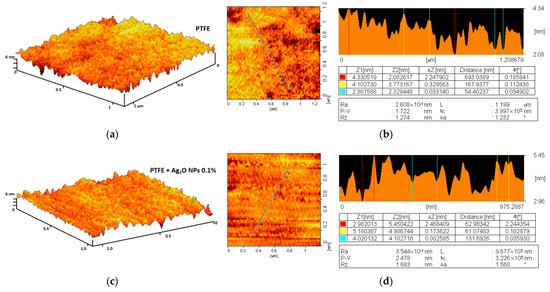

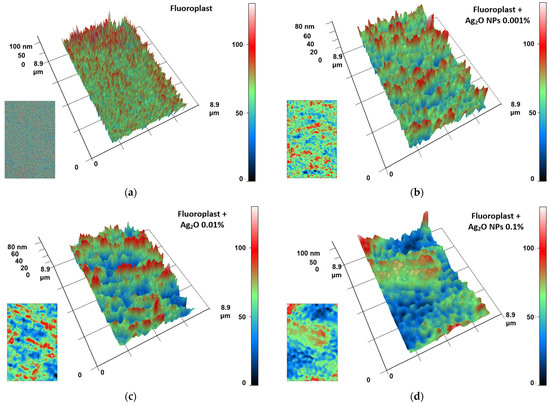

To assess the microrelief of the treated surface, the samples were analyzed using the AFM method. Fluoroplastic without the addition of NPs after drying forms a smooth surface without cracks, protrusions, or other inhomogeneities (Figure 3a). The difference in the height of the sample section with an area of ~1 μm2 did not exceed 2–3 nm (Figure 3c).

Figure 3.

Investigation of the microrelief of a composite material using the AFM method: 3D reconstruction of the surface of a PTFE coating without NPs (a) and with the addition of 0.1% Ag2O NPs (c); examples of the results of a quantitative assessment of the surface inhomogeneity of a PTFE coating without NPs (b) and with the addition of 0.1% Ag2O NPs (d).

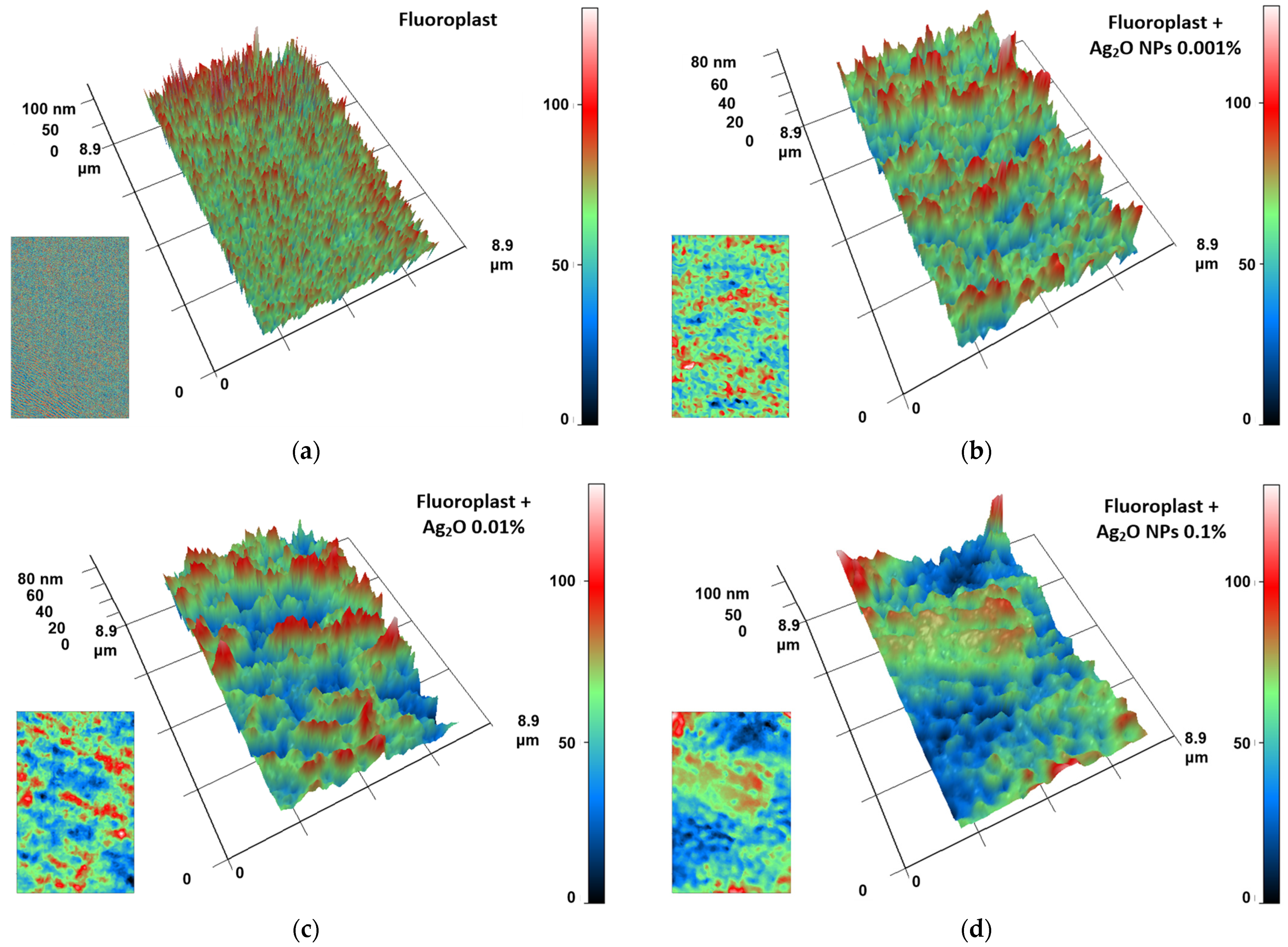

The addition of Ag2O NPs at a concentration of 0.1% did not affect the coating morphology (Figure 3b). The difference in the height of the sample area with an area of ~1 µm2 also did not exceed 2–3 nm (Figure 3d). Using the AFM method, we did not detect NPs on the surface of the samples; therefore, most of the Ag2O NPs are contained in the bulk of the polymer matrix. The obtained data on the high degree of homogeneity of the microrelief of the fluoroplastic coating are consistent with the literature data obtained for the fluoroplastic [81,82]. To estimate the distribution of Ag2O NPs inside the polymer coating, we used the MIM method based on the difference between the refractive indices of the NPs and the polymer matrix [83]. In the PTFE without the addition of NPs, we did not find large inhomogeneities (Figure 4a).

Figure 4.

The results of the analysis of the fluoroplast/Ag2O NPs composite coating by MIM method: (a) PTFE without the addition of nanoparticles; (b) PTFE with the addition of 0.001% Fe2O3 nanoparticles; (c) PTFE with the addition of 0.01% Fe2O3 nanoparticles; (d) PTFE with the addition of 0.1% Fe2O3 nanoparticles. The images are presented as 3D reconstructions, where the abscissa and ordinate axes correspond to the real distance in μm. The Oz axis displays the phase difference in nm (the larger the phase difference, the higher the value on the Oz axis). Coloring is a pseudo color. The initial data on the spatial distribution of the phase difference in the analyzed sample, used to construct 3D reconstructions, are shown in the lower left corners of each panel.

After the addition of 0.001% Ag2O NPs, structures were observed in the polymer matrix, presumably being aggregates of NPs. The aggregates had an average length of 1–2 µm and a width of 0.5–1 µm. The phase difference between the NP aggregates and the polymer matrix was no more than 80 nm (Figure 4b). With an increase in the mass fraction of Ag2O NPs to 0.01%, an increase in the length of aggregates up to 3–5 µm was observed. The phase difference values remained comparable (Figure 4c). At an Ag2O NP concentration of 0.1%, the aggregate width increased to 2–3 μm. The aggregate lenght exceeded 8 μm. The phase difference increased to 100 nm and above (Figure 4d). Thus, we can assume that the size of NP aggregates depends on the concentration in the polymer matrix. Our data agree with the literature data on the ability of metal oxide nanoparticles to aggregate in a polymer matrix [84]. Similar data were obtained by us for other nanocomposites using polymer matrices of PLGA and borosiloxane [85,86,87].

2.3. Effect of Nanocomposite on ROS Generation

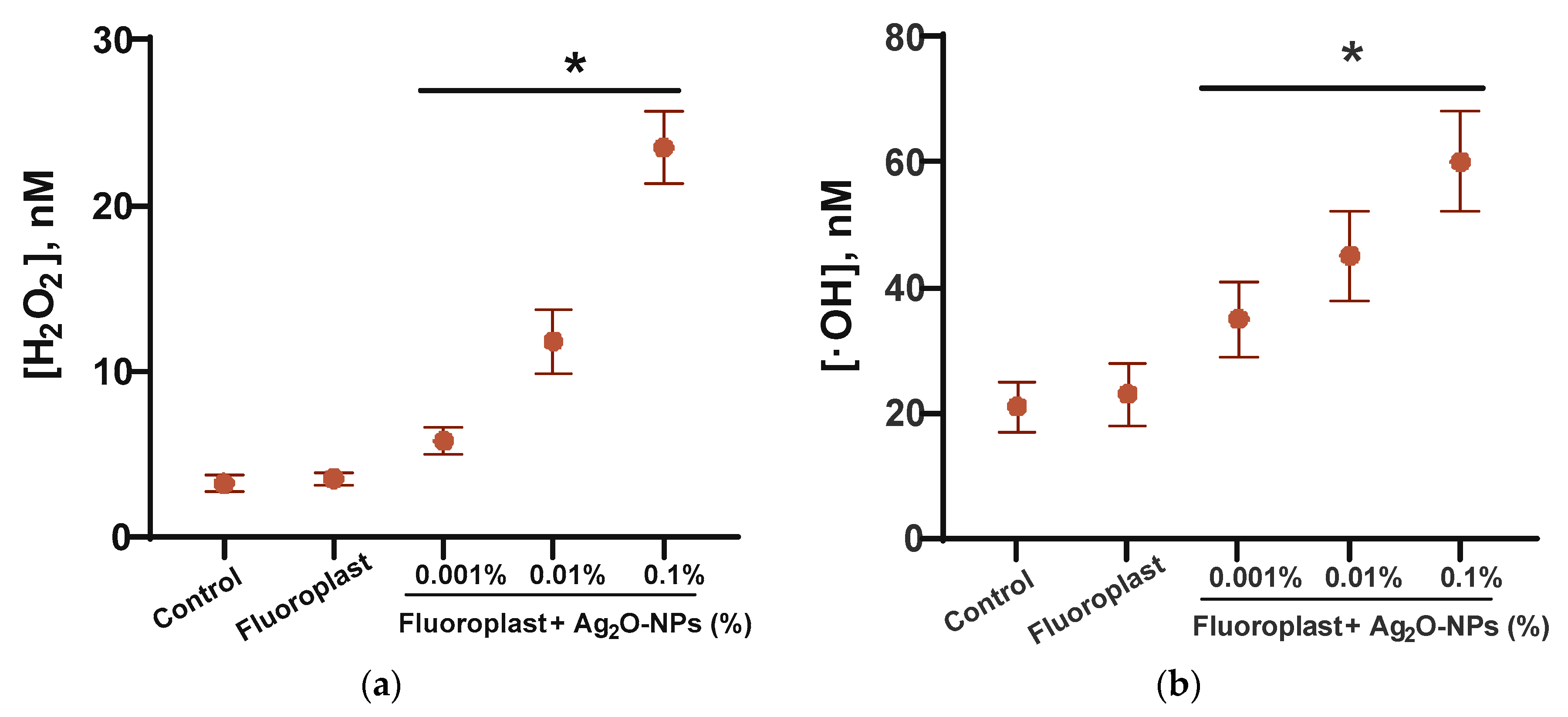

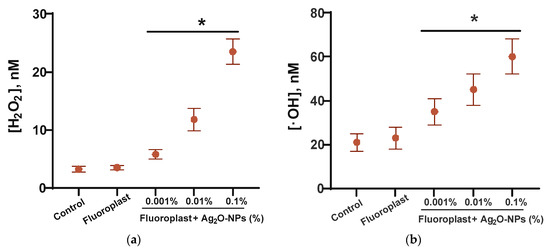

At the next stage, the ability of composite coatings based on PTFE and NPs Ag2O to influence the formation of ROS in aqueous solutions was studied (Figure 5). It was found that fluoroplasts without the addition of NPs (“Fluoroplast” group) did not affect the formation of hydroxyl radicals or hydrogen peroxide ([H2O2] = 3.5 ± 0.4 nM, [•OH] = 23 ± 5 nM). At the same time, the addition of NPs Ag2O to the fluoroplast matrix increased the concentration of the formed hydroxyl radicals, even at the minimum concentration of NPs (0.001%). The concentration of H2O2 in solutions aged with fluoroplast/NPs Ag2O composite materials was 5.8 ± 0.8, 11.8 ± 1.9, and 23.5 ± 2.2 nM for composite coatings containing 0.001, 0.01, and 0.1% NPs Ag2O, respectively. The concentration of hydroxyl radicals in the fluoroplast functionalized with NPs Ag2O was 35 ± 6, 45 ± 7, and 60 ± 8 nM for composite coatings containing 0.001, 0.01, and 0.1% NPs Ag2O, respectively.

Figure 5.

ROS generation in the presence of fluoroplast/Ag2O NPs composite coating: (a) generation of hydrogen peroxide (2 h, 40 °C); (b) generation of hydroxyl radicals (2 h, 80 °C). Data are presented as Mean ± SE. * p < 0.05, Mann–Whitney test (n = 3).

ROS generation (intracellular and extracellular) is one of the most important and key mechanisms of the antibacterial action of metal NPs and metal oxides, including NPs Ag2O. An increase in the formation of ROS, such as superoxide (O2−), hydroxyl radicals (•OH), and hydrogen peroxide (H2O2) outside cells under the influence of Ag NPs, including those mediated by Ag+, has been reported [88,89,90]. Hydrogen peroxide is one of the most stable ROS that can be transported across the membrane. Hydroxyl radicals are highly reactive but unable to pass through cell membranes. However, they can be sources of secondary radicals [91,92,93]. The generation of moderate amounts of ROS is an important part of the functioning of normal eukaryotic cells: ROS are involved in the regulation of cell division, differentiation, and migration [94]. In the case of the excessive production of ROS and/or the disruption of the functioning of antioxidant systems, the development of “oxidative stress” is possible, leading to DNA modification, protein inactivation, lipid peroxidation, etc. [95,96,97]. “Oxidative stress” of cells may be associated with carcinogenesis, mutagenesis, and accelerated aging processes [98]. The amounts of ROS, both hydrogen peroxide and hydroxyl radical, generated in the presence of composite coatings, do not exceed 25 and 60 nM, respectively (Figure 5). It is known that ROS concentrations below 1 μM are characteristic of normal cell functioning [99]; therefore, ROS generation in the presence of a nanocomposite coating cannot be considered a major mechanism of antimicrobial action.

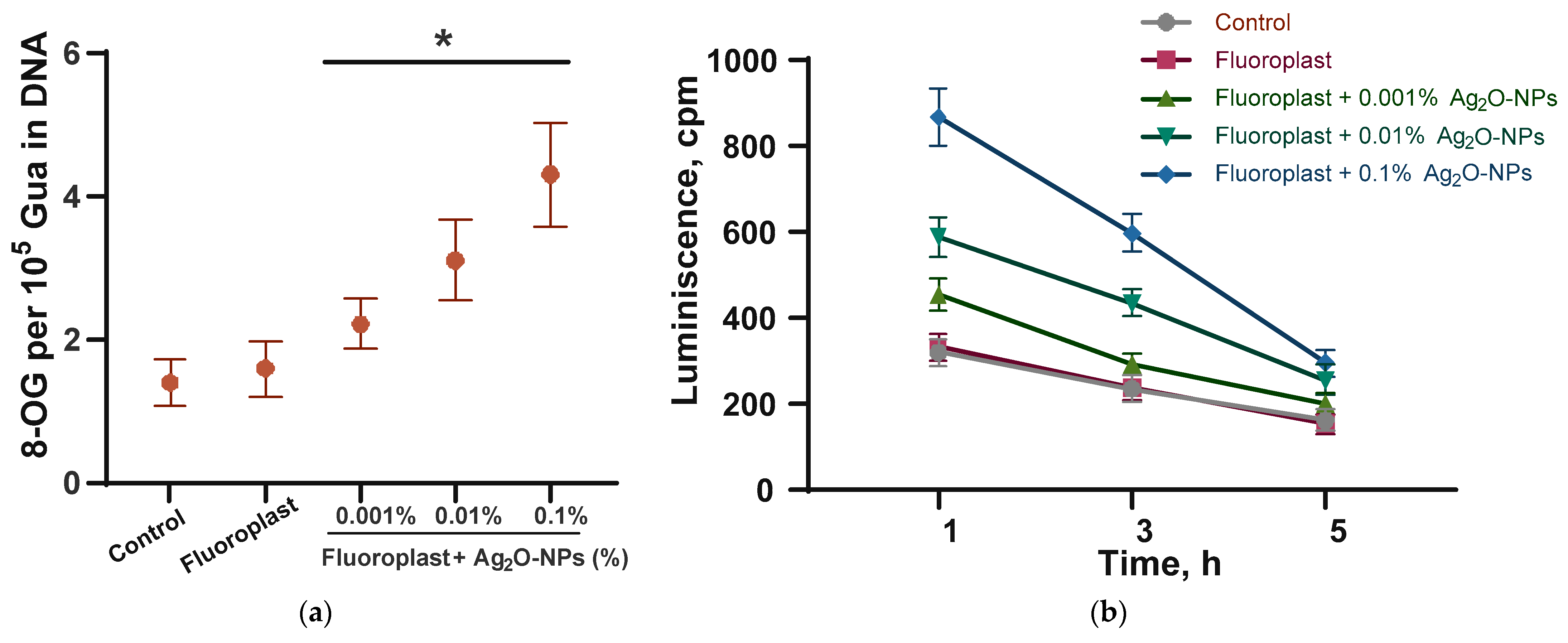

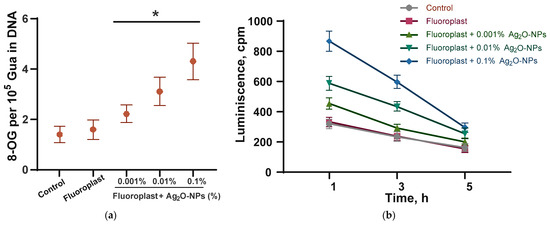

2.4. 8-Oxoguanine and LRPS Generation Study

We have studied the effect of the developed composite coating on the generation of markers of “oxidative stress” and damage to DNA and proteins: 8-oxoguanine and LRPS. The first is formed during the oxidative modification of DNA guanine. LRPS are formed during protein modification, while LRPS can be sources of new secondary free radicals [62,97,100,101]. The PTFE coating without the addition of NPs did not affect the generation of either 8-oxoguanine (Figure 6a) or LRPS (Figure 6b). The addition of Ag2O NPs to the fluoroplastic matrix increased the generation of 8-oxoguanine in a dose-dependent manner (Figure 6a).

Figure 6.

Generation of DNA and protein oxidative damage markers in the presence of fluoroplast/Ag2O NPs composite coating: (a) generation of 8-oxoguanine in DNA in vitro (2 h, 45 °C); (b) LRPS generation (2 h, 40 °C). Data are presented as mean ± SE. * p < 0.05, Mann–Whitney test (n = 3). 8-OG-8-oxoguanine.

The addition of 0.001% Ag2O NPs increased the generation of 8-oxoguanine by ~50% compared to the control. The addition of 0.01 and 0.1% Ag2O NPs increased the generation of 8-oxoguanine by ~100 and ~180% compared to the control. The enhancement of 8-oxoguanine generation in the presence of Ag2O NPs agrees with the literature data [51,52]. The addition of Ag2O NPs at concentrations of 0.001, 0.01, and 0.1% increased LRPS generation by 20, 90, and 200% compared to control (Figure 6b). It is noteworthy that the half-life rate of LRPS did not depend on the presence of Ag2O NPs and their concentration and was 5 h in all variants of the experiment. We have found the potential ability of a composite coating of fluoroplast/Ag2O NPs to enhance the oxidative modification of biopolymers using DNA and proteins as an example. The effect is due solely to the properties of NPs Ag2O.

2.5. Evaluation of Antibacterial Activity and Antibiofilm Activity

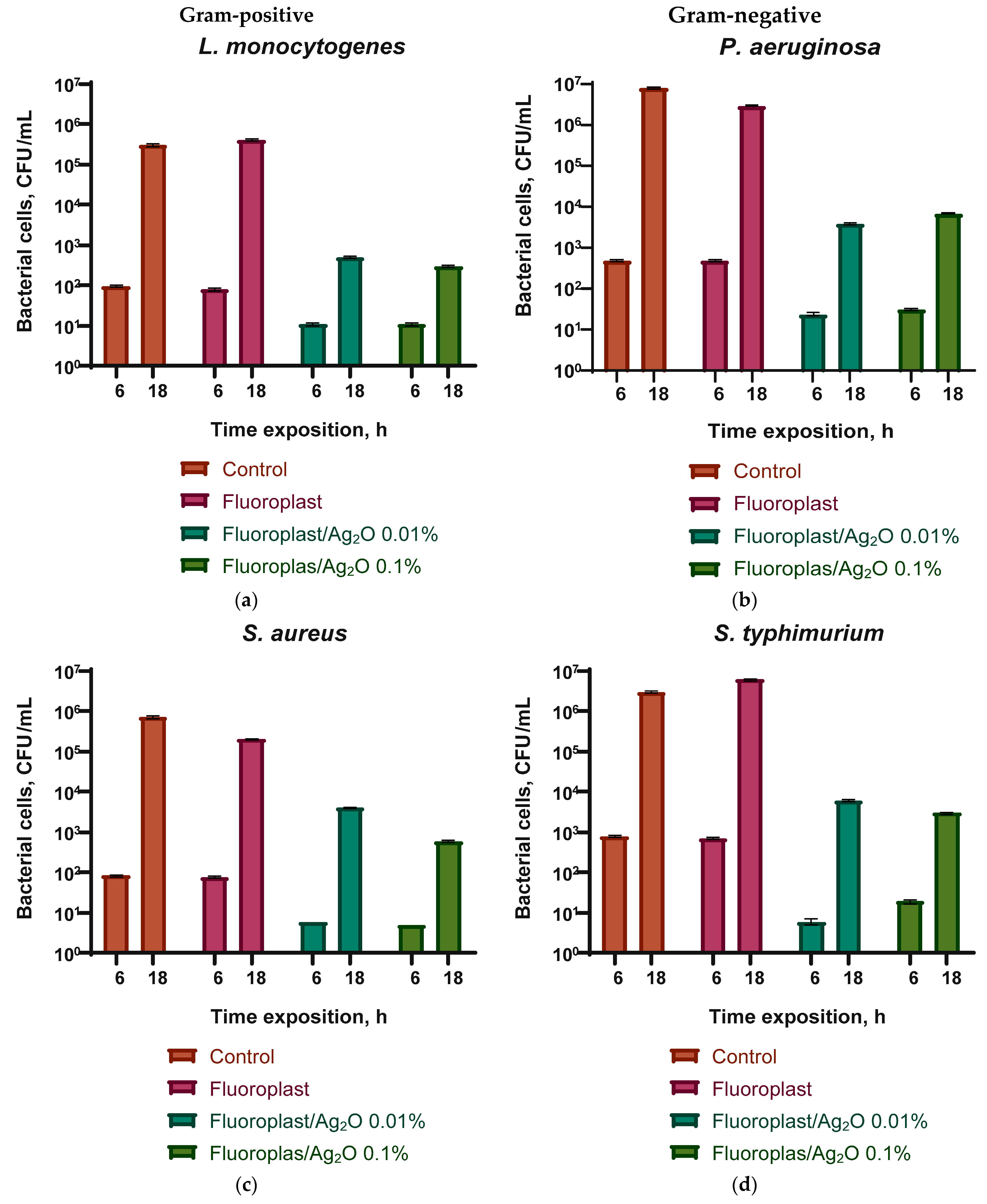

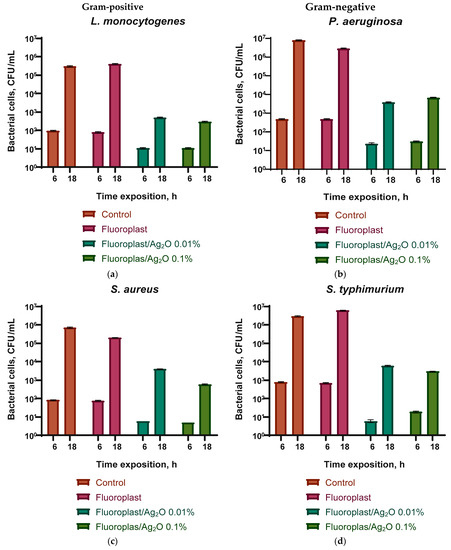

We have evaluated the bacteriostatic effect of the developed composite material PTFE/Ag2O NPs, as well as the fluoroplastic coating without the addition of Ag2O NPs (Figure 7). Fluoroplast without the addition of NPs had no effect on the growth of all studied bacteria.

Figure 7.

Evaluation of the bacteriostatic effect of a composite material based on fluoroplasts and Ag2O NPs against Gram-positive bacteria Listeria monocytogenes (a) and Staphylococcus aureus (c) and Gram-negative Pseudomonas aeruginosa (b) and Salmonella typhimurium (d) after 6 and 18 h of cultivation. Results are presented as mean ± SE (n = 3).

The addition of 0.01 or 0.1% Ag2O NPs significantly inhibited the growth of all studied bacteria after 6 and 18 h of cultivation. In the case of L. monocytogenes on the fluoroplastic/NP Ag2O 0.01% composite, the growth rate was reduced by an order of magnitude compared with the control after 6 h and by three orders of magnitude compared with the control after 18 h of cultivation (Figure 7a). The fluoroplast/NP Ag2O 0.1% composite had a comparable bacteriostatic effect against L. monocytogenes. In the case of S. aureus, the addition of 0.01% Ag2O NPs showed a more pronounced growth inhibition after 6 h (by 1.5 orders of magnitude compared to the control) and a less pronounced inhibitory effect after 18 h (by 2.5 orders of magnitude compared to the control). Increasing the dopant concentration to 0.1% increased the bacteriostatic effect of the composite. The number of S. aureus was reduced by three orders of magnitude compared to the control (Figure 7c). In the case of P. aeruginosa, the addition of Ag2O at concentrations of 0.01 and 0.1% caused a comparable bacteriostatic effect. There was a decrease in the number of bacteria by 1.5–2 orders of magnitude compared with the control after 6 h and a decrease by 3–3.5 orders of magnitude compared with the control after 18 h (Figure 7b). Composite coating with the addition of Ag2O at concentrations of 0.01 and 0.1% also inhibited the growth of S. typhimurium by 2.5 orders of magnitude after 6 h and 3.6–4 orders of magnitude (Figure 7d). In this case, the effect was practically independent of the concentration of Ag2O NPs.

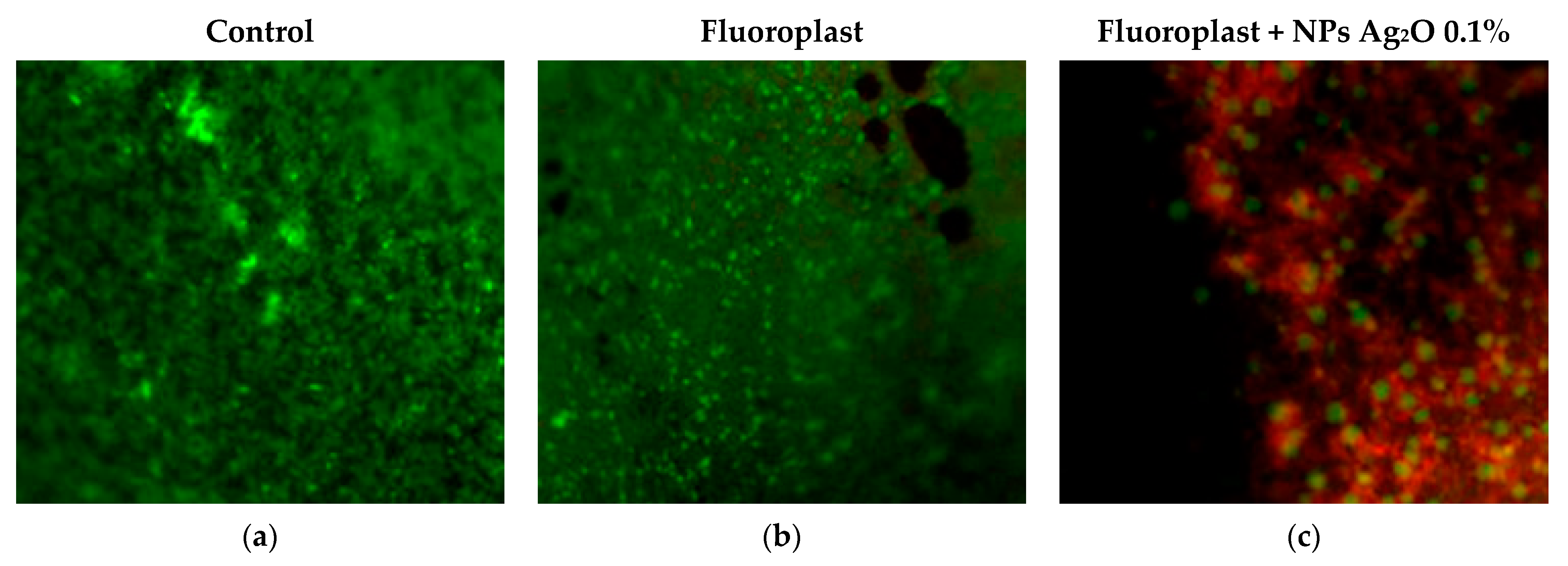

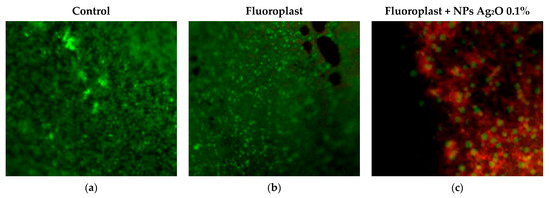

The data obtained indicate a significant bactericidal effect of the developed composite coating, which inhibited the growth of biofilms of all considered microorganisms. Composite coatings based on fluoroplast containing 0.01 and 0.1 wt % of Ag2O NPs reduced the number of CFU by ~three orders of magnitude for all considered bacterial species. It is noteworthy that the bacteriostatic effect depended to a greater extent on the species of bacteria and not on Gram staining. However, similar data were also obtained by other authors [102,103]. The results of the assessment of bacterial viability are shown in Figure 8. We found that there are practically no dead bacterial cells on the surface of the control sample and that the PTFE coating without NPs, the morphology is without disturbances (Figure 8a,b). On a sample of the composite coating with the addition of 0.1% Ag2O NPs, the bacterial cell morphology was preserved, but, at the same time, a significant increase in the number of dead cells was observed (Figure 8c). A small number of living cells were found in this sample, but their number relative to the dead is extremely small. In addition, a significant violation of bacterial cell morphology and destruction of the biofilm were found (Figure 8c).

Figure 8.

Evaluation of the survival of P. aeruginosa on uncoated samples (a), on PTFE without NPs (b), and on the composite coating of fluoroplast/NP Ag2O 0.1% (c). Living cells are colored green, dead cells red. Magnification ×400.

We have shown a significant bacteriostatic and bactericidal effect of the composite coating against both Gram-negative and Gram-positive bacteria. To date, a large number of studies have been accumulated, demonstrating not only the antibacterial (bacteriostatic and bactericidal) but also the antimycotic effect of silver oxide nanoparticles, as well as composite materials containing Ag2O NPs. At least five key mechanisms for the realization of the antibacterial effect of silver nanooxide have been reported [104]: (1) the formation of silver cations that have a destructive effect on the bacterial cell wall [105]; (2) binding to SH-groups of proteins, leading to the disruption of their functional activity [106]; (3) ROS-mediated toxicity [107]; (4) binding to the N7 atom of guanine in DNA, leading to the disruption of the replication process and the suppression of cell division [52]; and (5) photocatalytic activity of Ag2O-NPs, which enhances the photocatalytic properties of the NPs of other metals and metal oxides [108]. Of particular interest is the use of Ag2O NPs in combination with polymer matrices in the form of composite materials, which makes it possible to improve both the antibacterial properties and the biocompatibility of the material. Table 1 lists studies demonstrating the antibacterial activity of both Ag2O NPs in pure form and as part of polymer–NP composite materials.

Notably, 0.1% by weight can be roughly considered as 10 μg/mL. In this case, the antibacterial properties of the fluoroplast/NPs Ag2O 0.1% nanocomposite significantly exceed the results of most studies (Table 2) [109,110,111,112].

Table 2.

Literature data on the antibacterial activity of Ag2O NPs and nanocomposites based on them.

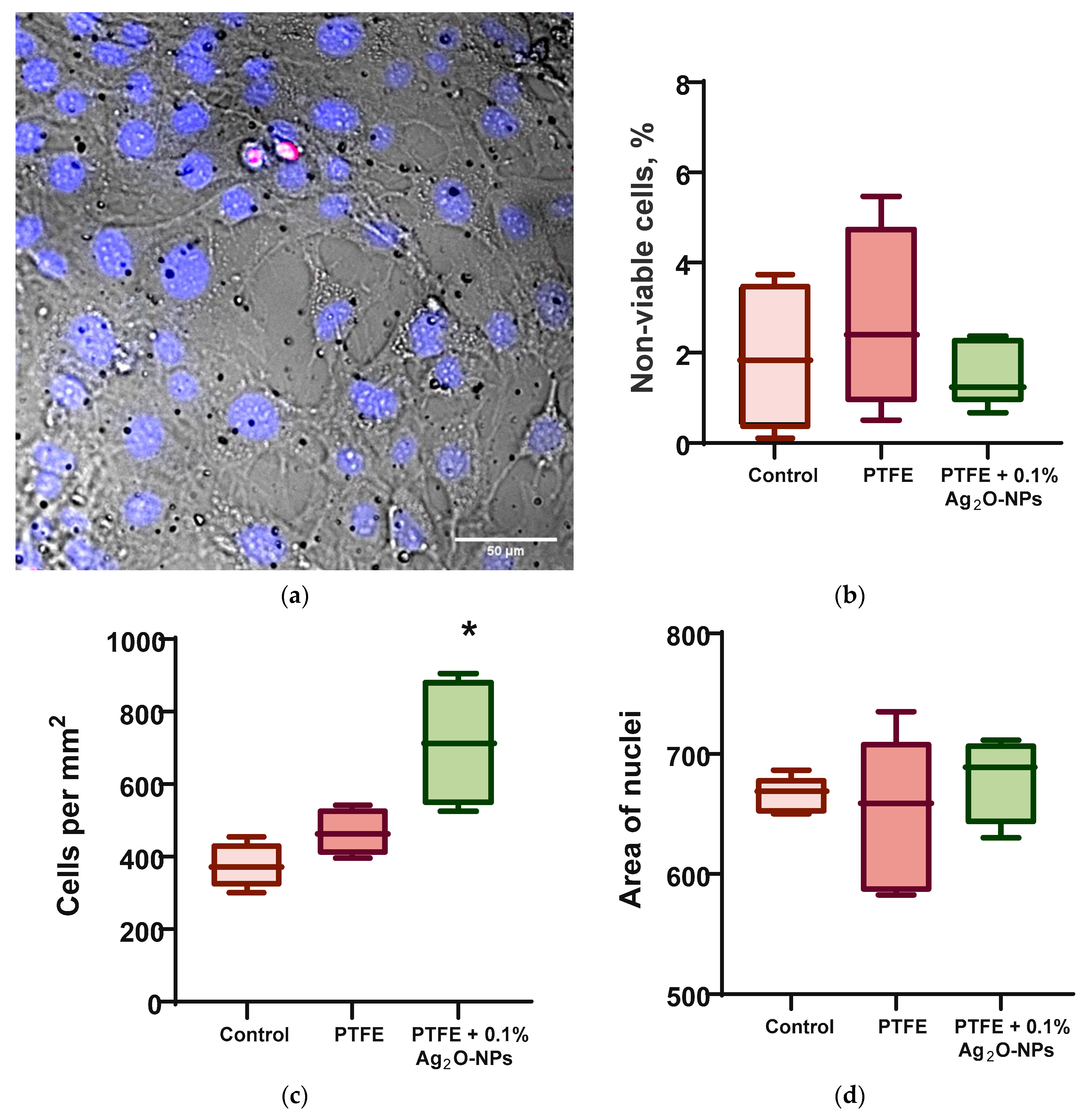

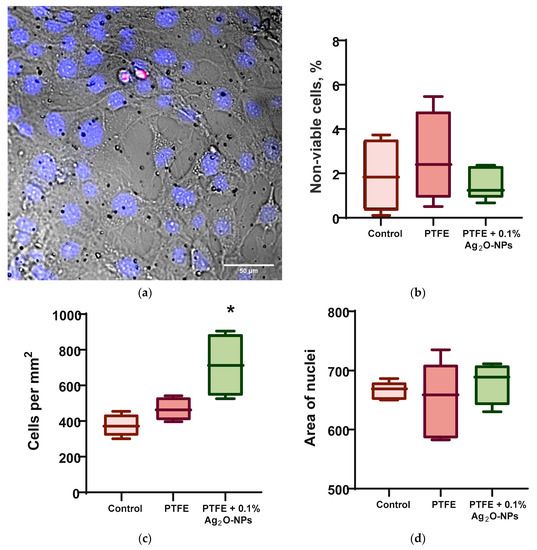

2.6. In Vitro Cytotoxic Study

We evaluated the acute cytotoxicity of the developed composite coating (Figure 9). When cultivating mouse fibroblasts on a fluoroplast/Ag2O NP coating, they showed normal morphology, high density, and, in some areas, almost complete confluence (Figure 9a). Neither the PTFE coating nor the PTFE/NP Ag2O 0.1% composite had any effect on cell viability (Figure 9b). The number of non-viable cells in all variants of the experiment did not exceed 5%. Cultivation of fibroblasts on a PTFE substrate without Ag2O NPs did not affect the culture density (Figure 9c). An almost twofold increase in cell culture density from ~380 cells/mm2 to ~700 cells/mm2 was observed on the fluoroplastic/NP Ag2O 0.1% composite coating. Neither the PTFE nor the PTFE composite with cell/mm2 NPs affected the nuclear area of cultured cells (Figure 9d). Consequently, the composite coating based on fluoroplasts and Ag2O NPs had almost no effect on cell survival and nucleus size and therefore did not exhibit cytotoxicity against mouse fibroblasts. We have discovered an interesting fact in the increase in the density of a cell culture on a composite material with Ag2O NPs. The ability of Ag NPs to accelerate cell proliferation is described in the literature [118]. Probably, the increase in cell culture density on the fluoroplast/NP Ag2O composite is due to the presence of NP Ag2O at a concentration higher than 2 μg/mL [118].

Figure 9.

Influence of composite coating fluoroplast/Ag2O NPs on the growth of mouse fibroblasts in vitro after 72 h of cultivation. (a) An example of a photomicrograph of cells growing on the surface of a composite coating of fluoroplast/NP Ag2O 0.1% (merge: blue-Hoechst, red-PI, transmitted light-gray). (b) proportion of non-viable cells. (c) Density of cell cultures. (d) Mean nuclear area. *: statistically significant difference compared to the “Control” group (p < 0.05). Data are presented as mean ± standard error of the mean.

It should be noted that the data on the cytotoxicity of NPs Ag2O and their composites with polymers are rather contradictory. In a number of works, it was noted that the introduction of nanoparticles into the culture medium reduced the viability of HepG2 [110] and A549 [76] cells. One of the ways to reduce the cytotoxicity of Ag2O NPs is the use of Ag2O-NPs in the composition of polymer matrices and conjugated with polymers (for example, silk fibroin), which significantly reduced cytotoxicity against the 3T3 fibroblast line [112] and the SH-SY5Y cell line [60]. Examples of the successful functionalization of synthetic [115] and natural [112] fibers with NPs Ag2O, which have pronounced antibacterial properties, are described, which can be useful in creating tissues and other materials resistant to bacterial growth. Furthermore, the efficient construction of polyethersulfone/cellulose acetate/Ag2O-Cu NPs membranes, nanocomposite membranes with antibiofilm activity and capable of removing nitrophenol from aqueous media was noted [115]. Thus, the use of composite materials based on polymers with the addition of NPs Ag2O is of interest for the creation of new biosafe antibacterial materials.

3. Materials and Methods

3.1. Synthesis and Characterization of Ag2O-NPs

For the synthesis of silver oxide nanoparticles, the method of laser ablation in deionized water was used. A setup based on a P-Mark TT 100 ytterbium-doped pulsed fiber laser (Pokkels, Moscow Russia) was used. Laser radiation parameters: λ = 1064 nm, τ = 4–200 ns; v = 20 kHz; average power up to 20 W; E = 1 mJ. The layer of liquid (0.05 M NaNO3 aqueous solution) above the target (silver plate of high chemical purity) was about 1 mm. Irradiation time varied within 5–20 min. Using the Zetasizer Ultra Red Label (Malvern Panalytical Ltd., Malvern, UK), the hydrodynamic diameter (DLS) and zeta potential (ELS) of the obtained NPs were determined. The woofer diameter was confirmed using a CPS 24,000 (CPS Instruments, Prairieville, LA, USA). Morphological features (shape, topology) of nanoparticles were assessed using a Libra 200 FE HR transmission electron microscope (TEM) (Carl Zeiss, Jena, Germany), and the elemental composition of NPs was determined using energy-dispersive X-ray spectrometry (EDS) using a JED-2300 system. (Carl Zeiss, Jena, Germany). The composition of the obtained colloidal solutions of NPs was confirmed using Cintra 4040 (GBC Scientific Equipment, Braeside, Australia). Samples were prepared for TEM according to the protocol, according to which droplets of colloidal solutions of Ag2O NPs were deposited on the surface of a gold mesh (Ø4), dried at room temperature, and evacuated. The sample grid was placed in a titanium holder. More detailed details of the methods are described in previous works [61,62,63].

3.2. Composite Material Preparation and Characterization

After the synthesis of nanoparticles, water was replaced with acetone by centrifugation. The colloidal solution of nanoparticles was centrifuged in a Sigma 3-16KL centrifuge (Sigma Laborzentrifugen GmbH, Osterode am Harz, Germany) with a 12,158 rotor for 40 min at 7000× g.; the supernatant (water) was replaced with acetone. These manipulations were carried out at least three times. The resulting colloidal solution was mixed with fluoroplastic varnish (Plast Polymer-Prom, Saint-Petersburg, Russia) to a final concentration of nanoparticles of 0.1, 0.01, and 0.001%. The varnish is a fluoroplastic dissolved in a mixture of acetone, butyl acetate, cyclohexanone, and toluene in a ratio of 25:40:10:25 mass parts. To assess the ability of the obtained composite coating to cover visible damage, the section of the Teflon cutting board with damage as a result of the operation was treated with a composite coating and dried for 24 h at room temperature. For experiments on the evaluation of the generation of ROS, 8-oxoguanine, and long-lived active forms of proteins, drops of a solution of nanoparticles in lacquer with a volume of 500 μL were applied to round degreased glasses 25 mm in diameter. Before the start of the experiments, the coatings were dried for 48 h in a fume hood. For cytotoxic and microbiological studies, samples with a composite coating were preliminarily disinfected by soaking in 70% ethanol for 2–3 h. For microbiological studies, varnish was applied to bulk samples of fluoroplasts (4 × 4 × 6 mm). The surface of the composite coatings was evaluated by atomic force microscopy (AFM) using NPX200 (Seiko Instruments, Tokyo, Japan). The distribution of nanoparticles in the composite polymer–polymer NP coating was assessed using a modulation interference microscope (MIM) using a MIM-321 (Amphora Lab, Moscow, Russia) [64].

3.3. Quantification of ROS Concentration

The concentration of hydrogen peroxide formed in aqueous solutions was estimated from the intensity of chemiluminescence of the luminol-p-iodophenol-horseradish peroxidase system. Chemiluminescence was measured on a highly sensitive Biotoks-7A-UZE chemiluminometer (Engineering Center-Ecology, Moscow, Russia). Samples of the studied composite material were placed in polypropylene vials (Beckman, Brea, CA, USA) with the addition of 1 mL of “counting solution” prepared immediately before measurement, containing 1 mM Tris-HCl buffer pH 8.5, 50 μM p-iodophenol, 50 µM luminol, and nM horseradish peroxidase 10. The sensitivity of this method is <1 nM. Samples of composite materials containing various concentrations of NPs in the composition (0.001–0.1 wt %) in the form of films 10 mm × 10 mm in size and 200 μm thick were placed in polypropylene vials (Beckman, CA, USA). After incubation in 20 mL of water, 1 mL of a previously prepared “counting solution” was added to the sample.

To quantify the content of hydroxyl radicals in aqueous solutions, the reaction with coumarin-3-carboxylic acid (CCA) was used. A total of 0.2 M PBS (pH 7.4) was added to a solution of CCA in water (0.5 mM, pH 3.6). Coating samples containing various concentrations of NPs in the composition (0.001–0.1 wt %) were added to vials in the form of films 10 × 10 mm in size and 200 μm thick. In the “Control” group, the experiment was carried out without a sample. Next, polypropylene vials with samples and reagents were heated in a thermostat at a temperature of 80.0 ± 0.1 °C for 2 h. As a result of the hydroxylation reaction, a fluorescent product, 7-hydroxycoumarin-3-carboxylic acid (7-OH-CCA), is formed. 7-OH-CCA fluorescence was detected using a JASCO 8300 spectrofluorimeter (JASCO, Tokyo, Japan) at λex = 400 nm, λem = 450 nm [63,65].

3.4. Measurement of the Concentration of the Formed Active Long-Lived Forms of Proteins

The number of long-lived reactive proteins (LRPS) was estimated from the chemiluminescence of protein solutions after heating to 40 °C for 2 h. All samples were stored in the dark at room temperature for 30 min after exposure. The measurements were carried out in 20 mL polypropylene vials (Beckman, Brea, CA, USA) in the dark at room temperature on a highly sensitive Biotox-7A chemiluminometer (Engineering Center—Ecology, Moscow, Russia). Protein solutions (BSA) not subjected to heating were used as controls [66].

3.5. Quantitative Determination of 8-Oxoguanine in DNA In Vitro by ELISA Method

To quantify 8-oxoguanine in DNA, a non-competitive enzyme-linked immunosorbent assay (ELISA) was used, using monoclonal antibodies specific for 8-oxoguanine (anti-8-OG antibodies). DNA samples (350 μg/mL) were denatured by boiling in a water bath for 5 min and cooled on ice for 3–4 min. Aliquots (42 μL) were applied to the bottom of the wells of the ELISA plates. The DNA was immobilized using a simple adsorption procedure with incubation for 3 h at 80 °C until the solution became completely dry. Non-specific adsorption sites were blocked with 300 μL of a solution containing 1% skimmed milk powder in 0.15 M Tris-HCl buffer, pH 8.7 and 0.15 M NaCl. Next, the plates were incubated at room temperature overnight (14–18 h). The formation of an antigen–antibody complex with antibodies against anti-8-OG (at a dilution of 1:2000) was carried out in a blocking solution (100 µL/well) by incubation for 3 h at 37 °C. Then, it was washed twice (300 µL/well) with 50 mM Tris-HCl buffer (pH 8.7) and 0.15 M NaCl with 0.1% Triton X-100 after 20 min incubation. Next, a complex with a conjugate (anti-mouse immunoglobulin labeled with horseradish peroxidase (1:1000) was formed by incubation for 1.5 h at 37 °C in a blocking solution (80 µL/well). Then the wells were washed 3 times as described above. Next, a chromogenic substrate containing 18.2 mM ABTS and hydrogen peroxide (2.6 mM) in 75 mM citrate buffer, pH 4.2 (100 µL/well), was added to each well. Reactions were stopped by adding an equal volume of 1.5 mM NaN3 in 0.1 M citrate buffer (pH 4.3) upon reaching the color. The optical density of the samples was measured on a plate photometer Titertek Multiscan, (Titretek, Helsinki, Finland) at λ = 405 nm [67].

3.6. Evaluation of Antibacterial Activity and Antibiofilm Activity of Samples

The antibacterial properties of PTFE/Ag2O-NPs coatings containing various concentrations of Ag2O-NPs were tested against two Gram-positive L. monocytogenes (azithromycin-, erythromycin-, and sulfamethoxazole-resistant), S. aureus and two Gram-negative bacterial species, P. aeruginosa, S. enterica serotype Typhimurium (azithromycin-resistant). Bacterial cultures were obtained from the working collection of the Laboratory of Microbiology of the Research Institute of Food Systems named after V.I. Gorbatov. These strains have previously been isolated from samples of meat products and from work surfaces at meat processing plants. There strains have high epidemiological significance [68,69,70,71]. Luria–Bertani (LB) medium (BD Difco, Franklin Lakes, NJ, USA) and tryptone soy broth (TSB) (Panreac AppliChem, Barcelona, Spain) were used as culture media. As test surfaces for cultivating bacterial cells, we used Teflon cubes with sides of 4 mm × 4 mm × 6 mm, coated with a composite material with different concentrations of Ag2O NPs (0.001–0.1%) in the composition, as well as uncoated and with a fluoroplastic coating not containing Ag2O NPs. For the study, daily broth cultures of the studied microorganisms with initial concentration 109 CFU/mL were diluted 100 times to a final concentration of 107 CFU/mL in sterile LB broth and poured into sterile test tubes (V = 2 mL). Next, pre-sterilized Teflon cubes (one sample each) were added to each tube and incubated for 6 and 18 h in a thermostat at 37 °C. After incubation, the cubes were washed once with distilled water (to remove planktonic cells), transferred into test tubes with sterile saline (0.9% NaCl solution), and vigorously shaken for 15 min at least 3 times. Further, the obtained washings were titrated (ten-fold dilutions were carried out), transferred to Petri dishes with a = LB agar, and evenly distributed over the surface with a sterile spatula. The results were recorded by counting the number of colony-forming units (CFU) 24 h after incubation at 37 °C.

To study the antibiofilm activity of fluoroplast/Ag2O-NP coatings, a broth culture of bacterial cells (V = 30 μL) was applied to the surface of Teflon cubes and left to dry at room temperature for 30 min. Next, to visualize live and dead cells, the samples were stained with a set of fluorescent dyes Filmtracer Live/Dead Biofilm Viability Kit (Invitrogen, Waltham, MA, USA) and analyzed under a microscope with appropriate filters. The kit used contains SYTO®9 fluorescent dyes and propidium iodide (PI). Both of them stain the DNA of microorganisms; however, SYTO®9 can quickly penetrate the membrane of living bacteria, while propidium iodide (PI) has more difficulty penetrating the walls of living bacteria. After 20 min of staining, living cells are stained green, and dead cells are stained red. Microscopy was performed using the Eclipse Ni (Nikon, Tokyo, Japan) imaging system.

3.7. Isolation and Cultivation of Fibroblasts from Mouse Lungs

All manipulations with animal tissues and cells were performed in clean rooms using a Laminar-S class II biological safety cabinet (Lamsystems, Miass, Russia). Primary cell cultures of isolated mouse lung fibroblasts were obtained according to the standard protocol with minor modifications. Male BALC/b 2–3-month-old mice were used in a cytotoxicity assay. Euthanasia of mice was performed by displacing the cervical vertebrae. Using surgical scissors, the lungs were removed from the animal’s thorax. The lungs were placed in a sterile Ø60 Petri dish (TPP, Trasadingen, Switzerland) containing a small volume of PBS solution. The organs were chopped with sterile scissors into pieces with a volume of ~1 mm3. Pieces of lung tissue were incubated for 1 h in 25 mL of DMEM medium containing 0.2% type II collagenase at 37 °C on an MR-1 rocking shaker (Biosan, Riga, Latvia). Collagenase was inhibited by 20% FBS. Tissue pieces incubated in collagenase solution were resuspended by pipetting and then passed through a 70 μm EASTstrainer™ sieve (Greiner bio-one, Kremsmunster, Austria). Cells were washed by centrifugation twice at 350× g for 5 min in DMEM. The isolated cells were further cultivated in TC T-25 culture mats (TPP, Trasadingen, Switzerland) in DMEM/F12 medium supplemented with 10% FBS, 2 mM L-glutamine, 100 U/mL penicillin, 100 μg/mL streptomycin obtained from PanEco (PanEco, Moscow, Russia). Upon reaching 80–90% confluence, the cells were attached with 0.05% trypsin-EDTA solution (PanEco, Moscow, Russia) for 5 min at 37 °C. Trypsin was inactivated with 10% FBS. Cells were passaged at least 3 times before starting cytotoxic studies [72].

3.8. In Vitro Cytotoxic Studies Using Mouse Lung Fibroblast Cultures

Round glasses for microscopy Ø25 Menzel Glaser (Thermo Fisher Scientific, Waltham, MA, USA) coated with PTFE/Ag2O-NPs and without (control group) composite coating (V = 500 µL) were sterilized in 70% ethanol for 2–3 h and then placed in the wells of a 6-well plate (TPP, Trasadingen, Switzerland). A cell suspension (50 μL) was applied to each coating sample, then incubated for 45 min for cell adhesion, after which it was brought to a final volume of 1 mL with warm nutrient medium. The total time from the moment the cells were planted on the surface to microscopic measurements was at least 72 h. Cultivation was carried out in an S-Bt Smart Biotherm CO2 incubator (Biosan, Riga, Latvia) at 37 °C and 5% CO2. The medium for cell culture was DMEM/F12 medium with additives, the preparation of which was described in detail earlier. The initial number of cells in the suspension placed on the surface of the material was ~50,000 cells per sample. Cytotoxicity was assessed using Hoechst 33342 dyes and propidium iodide (PI) (Thermo Fisher Scientific, Waltham, MA, USA). Immediately after incubation, a sample of the composite coating with cultured cells was placed in a quick-change imaging chamber (RC-40LP, Warner Instruments, Holliston, MA, USA), washed thoroughly with PBS, stained with Hoechst 33342 at a concentration of 5 µg/mL, and incubated for 30 min at 37 °C. The sample was then washed with PBS and stained with 2 μM PI (Thermo Fisher, Waltham, MA, USA) for 1 min. Samples were analyzed using a DMI4000 B fluorescence microscope (Leica Microsystems, Wetzlar, Germany) equipped with an SDU-285 digital camera (SpetsTeleTekhnika, Moscow, Russia). Fluorescence spectra were recorded at excitation/emission wavelengths: 350/470 for Hoechst 33342 (D-filter, Leica Microsystems, Wetzlar, Germany) and 540/590 for PI (TRITC filter cube, Leica Microsystems, Wetzlar, Germany). Light-emitting diodes (LED) M375D2m, M490D3 (Thorlabs, Newton, NJ, USA) and white LED (Cree Inc., Durham, NC, USA) were used as light sources for the excitation of Hoechst 33342 and fluorescence of PI. All images were taken at the following LED currents: 100 mA for the M375D2m LED (Hoechst 33342) and 250 mA for the white LED (PI). The exposure time in all experiments was the same: 500 ms for Hoechst 33342 and 700 ms for PI. The detector gain was ×423 and was the same for all fluorophores and experimental conditions [73,74].

Data acquisition and microscope adjustment control were performed using the Win-FluorXE software version 3.8.7. 8-12-16 (J. Dempster, Strathclyde Electrophysiology Software, University of Strathclyde, Glasgow, UK). The data was collected as 12-bit grayscale images. Subsequent analysis was performed using ImageJ2 (Fiji) software version 2.3.1 (NIH, Bethesda, MD, USA). For each variant of the experiment, at least five samples were analyzed. At least 200 cells were analyzed in each sample. ROIs were determined using ImageJ’s “Threshold” and “Particle Analysis” automated procedures. For an image of 1392 × 1024 pixels obtained at a value of ×20, the following parameters were used: “size” = 100–750 and “circularity” = 0.10–1.00. The nuclei had different fluorescence intensities from Hoechst 33342 and PI. To ensure that all nuclei are included in the analysis, we performed a series of thresholding and particle analysis procedures for each image. The images were converted to 8-bit prior to determining the ROI. Threshold levels ranged from 5 to 255 a.u. with a step of 5 c.u. ROIs were saved as binary masks, and then all were combined, with the removal of duplicates. All procedures were combined in automated macros.

4. Conclusions

We have successfully developed a new composite coating based on fluoroplasts and silver oxide NPs. The developed coating effectively covers visible damage on the surface of Teflon, which was in operation. At the micro- and nanolevels, the surface of the composite is smooth, without cracks and defects. The resulting material enhances the generation of ROS (hydrogen peroxide and hydroxyl radical), as well as 8-oxoguanine and LRPS. The intensity of the effect depends on the concentration of added Ag2O NPs. The resulting fluoroplast/Ag2O NP composite demonstrates a strong bacteriostatic and bactericidal effect. Fluoroplast/NP Ag2O 0.01–0.1% inhibits the growth of both Gram-positive and Gram-negative bacteria. At the same time, the developed composite did not show cytotoxicity against the primary culture of mouse fibroblasts. The nanocomposite material fluoroplast/NP Ag2O can be used to create protective coatings with antimicrobial properties for cutting boards at meat processing plants.

Author Contributions

Conceptualization, S.V.G., A.A.S. and A.B.L.; methodology, E.R.T. and V.N.L.; software, M.E.A.; validation, E.R.T. and A.V.S.; investigation, D.E.B., I.V.B., A.S.B.; N.B.N., S.Y.S., A.V.O., A.G.K., O.V.U., M.A.K., M.A.S., A.D. and S.Y.S.; resources, S.V.G., A.A.S. and A.B.L.; data curation, V.N.L.; writing—original draft preparation, D.E.B., D.A.S.; I.V.B. and E.R.T.; writing—review and editing, S.V.G., R.L. and V.N.L.; visualization, D.A.S., D.E.B., M.E.A. and E.R.T.; supervision, S.V.G. and A.A.S.; project administration, S.V.G.; funding acquisition, A.B.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Ministry of Science and Education of the Russian Federation (Grant Agreement 075-15-2020-775).

Institutional Review Board Statement

The animal study protocol was approved by the Institutional Ethics Committee of Institute of Cell Biophysics of Russian Academy of Sciences (12306, 2006).

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Conflicts of Interest

The authors declare no conflict of interests.

References

- Losito, P.; Visciano, P.; Genualdo, M.; Satalino, R.; Migailo, M.; Ostuni, A.; Luisi, A.; Cardone, G. Evaluation of hygienic conditions of food contact surfaces in retail outlets: Six years of monitoring. LWT 2017, 77, 67–71. [Google Scholar] [CrossRef]

- Yibar, A.; Cetin, E.; Ata, Z.; Erkose, E.; Tayar, M. Clostridium perfringens Contamination in Retail Meat and Meat-Based Products in Bursa, Turkey. Foodborne Pathog. Dis. 2018, 15, 239–245. [Google Scholar] [CrossRef] [PubMed]

- Srey, S.; Jahid, I.K.; Ha, S.-D. Biofilm formation in food industries: A food safety concern. Food Control 2013, 31, 572–585. [Google Scholar] [CrossRef]

- Bai, X.; Nakatsu, C.H.; Bhunia, A.K. Bacterial Biofilms and Their Implications in Pathogenesis and Food Safety. Foods 2021, 10, 2117. [Google Scholar] [CrossRef]

- Kirk, M.D.; Pires, S.M.; Black, R.E.; Caipo, M.; Crump, J.A.; Devleesschauwer, B.; Döpfer, D.; Fazil, A.; Fischer-Walker, C.L.; Hald, T.; et al. World Health Organization Estimates of the Global and Regional Disease Burden of 22 Foodborne Bacterial, Protozoal, and Viral Diseases, 2010: A Data Synthesis. PLoS Med. 2015, 12, e1001921. [Google Scholar] [CrossRef]

- Inatsu, Y.; Bari, M.L.; Kawasaki, S.; Isshiki, K. Survival of Escherichia coli O157:H7, Salmonella enteritidis, Staphylococcus aureus, and Listeria monocytogenes in Kimchi. J. Food Prot. 2004, 67, 1497–1500. [Google Scholar] [CrossRef]

- White, D.G.; Zhao, S.; Sudler, R.; Ayers, S.; Friedman, S.; Chen, S.; Mcdermott, P.F.; Mcdermott, S.; Wagner, D.D.; Meng, J. The isolation of antibiotic-resistant salmonella from retail ground meats. N. Engl. J. Med. 2001, 345, 1147–1154. [Google Scholar] [CrossRef]

- Cheesbrough, J.S.; Green, J.; Gallimore, C.I.; Wright, P.A.; Brown, D.W. Widespread environmental contamination with Norwalk-like viruses (NLV) detected in a prolonged hotel outbreak of gastroenteritis. Epidemiol. Infect. 2000, 125, 93–98. [Google Scholar] [CrossRef]

- Scallan, E.; Hoekstra, R.M.; Angulo, F.J.; Tauxe, R.V.; Widdowson, M.A.; Roy, S.L.; Jones, J.L.; Griffin, P.M. Foodborne illness acquired in the United States—Major pathogens. Emerg. Infect. Dis. 2011, 17, 7–15. [Google Scholar] [CrossRef]

- Besser, R.E.; Lett, S.M.; Weber, J.T.; Doyle, M.P.; Barrett, T.J.; Wells, J.G.; Griffin, P.M. An outbreak of diarrhea and hemolytic uremic syndrome from Escherichia coli O157:H7 in fresh-pressed apple cider. JAMA 1993, 269, 2217–2220. [Google Scholar] [CrossRef]

- Mora, Z.V.; Macías-Rodríguez, M.E.; Arratia-Quijada, J.; Gonzalez-Torres, Y.S.; Nuño, K.; Villarruel-López, A. Clostridium perfringens as Foodborne Pathogen in Broiler Production: Pathophysiology and Potential Strategies for Controlling Necrotic Enteritis. Animal 2020, 10, 1718. [Google Scholar] [CrossRef] [PubMed]

- Rowe, S.Y.; Rocourt, J.R.; Shiferaw, B.; Kassenborg, H.D.; Segler, S.D.; Marcus, R.; Daily, P.J.; Hardnett, F.P.; Slutsker, L. Breast-feeding decreases the risk of sporadic salmonellosis among infants in FoodNet sites. Clin. Infect. Dis. 2004, 38 (Suppl. 3), S262–S270. [Google Scholar] [CrossRef] [PubMed]

- Batz, M.B.; Henke, E.; Kowalcyk, B. Long-term consequences of foodborne infections. Infect. Dis. Clin. N. Am. 2013, 27, 599–616. [Google Scholar] [CrossRef] [PubMed]

- Kalyoussef, S.; Feja, K.N. Foodborne Illnesses. Adv. Pediatr. 2014, 61, 287–312. [Google Scholar] [CrossRef]

- Quaglia, N.C.; Dambrosio, A. Helicobacter pylori: A foodborne pathogen? World J. Gastroenterol. 2018, 24, 3472–3487. [Google Scholar] [CrossRef] [PubMed]

- Posfay-Barbe, K.M.; Wald, E.R. Listeriosis. Semin. Fetal Neonatal. Med. 2009, 14, 228–233. [Google Scholar] [CrossRef]

- Kelesidis, T.; Salhotra, A.; Fleisher, J.; Uslan, D.Z. Listeria endocarditis in a patient with psoriatic arthritis on infliximab: Are biologic agents as treatment for inflammatory arthritis increasing the incidence of Listeria infections? J. Infect. 2010, 60, 386–396. [Google Scholar] [CrossRef]

- Chlebicz, A.; Śliżewska, K. Campylobacteriosis, Salmonellosis, Yersiniosis, and Listeriosis as Zoonotic Foodborne Diseases: A Review. Int. J. Environ. Res. Public Health 2018, 15, 863. [Google Scholar] [CrossRef]

- Moerman, F. Antimicrobial Materials, Coatings, and Biomimetic Surfaces with Modified Microtography to Control Microbial Fouling of Product Contact Surfaces Within Food Processing Equipment: Legislation, Requirements, Effectiveness, and Challenges. J. Hyg. Eng. Des. 2014, 7, 8–29. [Google Scholar]

- Pinho, A.C.; Piedade, A.P. Polymeric Coatings with Antimicrobial Activity: A Short Review. Polymers 2020, 12, 2469. [Google Scholar] [CrossRef]

- Deflorio, W.; Liu, S.; White, A.R.; Taylor, T.M.; Cisneros-Zevallos, L.; Min, Y.; Scholar, E.M.A. Recent developments in antimicrobial and antifouling coatings to reduce or prevent contamination and cross-contamination of food contact surfaces by bacteria. Compr. Rev. Food Sci. Food Saf. 2021, 20, 3093–3134. [Google Scholar] [CrossRef] [PubMed]

- Zore, A.; Bezek, K.; Jevšnik, M.; Abram, A.; Runko, V.; Slišković, I.; Raspor, P.; Kovačević, D.; Bohinc, K. Bacterial adhesion rate on food grade ceramics and Teflon as kitchen worktop surfaces. Int. J. Food Microbiol. 2020, 332, 108764. [Google Scholar] [CrossRef] [PubMed]

- O’brien, M.; Baxendale, I.R.; Ley, S.V. Flow Ozonolysis Using a Semipermeable Teflon AF-2400 Membrane To Effect Gas−Liquid Contact. Org. Lett. 2010, 12, 1596–1598. [Google Scholar] [CrossRef] [PubMed]

- Dearn, K.D.; Hoskins, T.J.; Petrov, D.G.; Reynolds, S.C.; Banks, R. Applications of dry film lubricants for polymer gears. Wear 2013, 298–299, 99–108. [Google Scholar] [CrossRef]

- Barish, J.A.; Goddard, J.M. Anti-fouling surface modified stainless steel for food processing. Food Bioprod. Process. 2013, 91, 352–361. [Google Scholar] [CrossRef]

- Greene, J.F.; Preger, Y.; Stahl, S.S.; Root, T.W. PTFE-Membrane Flow Reactor for Aerobic Oxidation Reactions and Its Application to Alcohol Oxidation. Org. Process Res. Dev. 2015, 19, 858–864. [Google Scholar] [CrossRef]

- Rodriguez-Lopez, J.; Alpuche-Aviles, M.A.; Bard, A.J. Selective Insulation with Poly(tetrafluoroethylene) of Substrate Electrodes for Electrochemical Background Reduction in Scanning Electrochemical Microscopy. Anal. Chem. 2008, 80, 1813–1818. [Google Scholar] [CrossRef]

- Feng, S.; Zhong, Z.; Zhang, F.; Wang, Y.; Xing, W. Amphiphobic Polytetrafluoroethylene Membranes for Efficient Organic Aerosol Removal. ACS Appl. Mater. Interfaces 2016, 8, 8773–8781. [Google Scholar] [CrossRef]

- Rondinella, A.; Andreatta, F.; Turrin, D.; Fedrizzi, L. Degradation Mechanisms Occurring in PTFE-Based Coatings Employed in Food-Processing Applications. Coatings 2021, 11, 1419. [Google Scholar] [CrossRef]

- Mccook, N.L.; Burris, D.L.; Dickrell, P.L.; Sawyer, W.G. Cryogenic Friction Behavior of PTFE based Solid Lubricant Composites. Tribol. Lett. 2005, 20, 109–113. [Google Scholar] [CrossRef]

- Teo, A.J.T.; Mishra, A.; Park, I.; Kim, Y.-J.; Park, W.-T.; Yoon, Y.-J. Polymeric Biomaterials for Medical Implants and Devices. ACS Biomater. Sci. Eng. 2016, 2, 454–472. [Google Scholar] [CrossRef]

- Chao, Q.; Meng, L.; Shuxian, C. Anti-icing characteristics of PTFE super hydrophobic coating on titanium alloy surface. J. Alloy. Compd. 2021, 860, 157907. [Google Scholar] [CrossRef]

- Song, W.; Wang, S.; Lu, Y.; Zhang, X.; Xia, Z. Friction behavior of PTFE-coated Si3N4/TiC ceramics fabricated by spray technique under dry friction. Ceram. Int. 2021, 47, 7487–7496. [Google Scholar] [CrossRef]

- Wu, X.; Yang, F.; Gan, J.; Zhao, W.; Wu, Y. A flower-like waterborne coating with self-cleaning, self-repairing properties for superhydrophobic applications. J. Mater. Res. Technol. 2021, 14, 1820–1829. [Google Scholar] [CrossRef]

- Sajid, M.; Ilyas, M. PTFE-coated non-stick cookware and toxicity concerns: A perspective. Environ. Sci. Pollut. Res. 2017, 24, 23436–23440. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Kang, K.K.; Sung, S.E.; Choi, J.H.; Sung, M.; Seong, K.Y.; Lee, J.; Kang, S.; Yang, S.Y.; Lee, S.; et al. In Vivo Toxicity and Pharmacokinetics of Polytetrafluoroethylene Microplastics in ICR Mice. Polymer 2022, 14, 2220. [Google Scholar] [CrossRef]

- Kumar, V.; Jolivalt, C.; Pulpytel, J.; Jafari, R.; Arefi-Khonsari, F. Development of silver nanoparticle loaded antibacterial polymer mesh using plasma polymerization process. J. Biomed. Mater. Res. Part A 2013, 101, 1121–1132. [Google Scholar] [CrossRef]

- Petkova, P.; Francesko, A.; Fernandes, M.M.; Mendoza, E.; Perelshtein, I.; Gedanken, A.; Tzanov, T. Sonochemical Coating of Textiles with Hybrid ZnO/Chitosan Antimicrobial Nanoparticles. ACS Appl. Mater. Interfaces 2014, 6, 1164–1172. [Google Scholar] [CrossRef]

- Rtimi, S.; Sanjines, R.; Pulgarin, C.; Kiwi, J. Effect of light and oxygen on repetitive bacterial inactivation on uniform, adhesive, robust and stable Cu-polyester surfaces. J. Adv. Oxid. Technol. 2017, 20. [Google Scholar] [CrossRef]

- Dubas, S.T.; Kumlangdudsana, P.; Potiyaraj, P. Layer-by-layer deposition of antimicrobial silver nanoparticles on textile fibers. Colloids Surf. A Physicochem. Eng. Asp. 2006, 289, 105–109. [Google Scholar] [CrossRef]

- Gudkov, S.V.; Burmistrov, D.E.; Serov, D.A.; Rebezov, M.B.; Semenova, A.A.; Lisitsyn, A.B. Do Iron Oxide Nanoparticles Have Significant Antibacterial Properties? Antibiotics 2021, 10, 884. [Google Scholar] [CrossRef]

- Gudkov, S.V.; Burmistrov, D.E.; Serov, D.A.; Rebezov, M.B.; Semenova, A.A.; Lisitsyn, A.B. A Mini Review of Antibacterial Properties of ZnO Nanoparticles. Front. Phys. 2021, 9, 641481. [Google Scholar] [CrossRef]

- Gudkov, S.V.; Burmistrov, D.E.; Smirnova, V.V.; Semenova, A.A.; Lisitsyn, A.B. A Mini Review of Antibacterial Properties of Al2O3 Nanoparticles. Nanomaterials 2022, 12, 2635. [Google Scholar] [CrossRef] [PubMed]

- Giedraitienė, A.; Ruzauskas, M.; Šiugždinienė, R.; Tučkutė, S.; Milcius, D. Antimicrobial Properties of CuO Particles Deposited on a Medical Mask. Materials 2022, 15, 7896. [Google Scholar] [CrossRef] [PubMed]

- Gomaa, E.Z. Silver nanoparticles as an antimicrobial agent: A case study on Staphylococcus aureus and Escherichia coli as models for Gram-positive and Gram-negative bacteria. J. Gen. Appl. Microbiol. 2017, 63, 36–43. [Google Scholar] [CrossRef]

- Xia, T.; Kovochich, M.; Brant, J.; Hotze, M.; Sempf, J.; Oberley, T.; Sioutas, C.; Yeh, J.I.; Wiesner, M.R.; Nel, A.E. Comparison of the abilities of ambient and manufactured nanoparticles to induce cellular toxicity according to an oxidative stress paradigm. Nano Lett. 2006, 6, 1794–1807. [Google Scholar] [CrossRef]

- Raffi, M.; Hussain, F.; Bhatti, T.; Akhter, J.; Hameed, A.; Hasan, M. Antibacterial characterization of silver nanoparticles against E. coli ATCC-15224. J. Mater. Sci. Technol. 2008, 24, 192–196. [Google Scholar]

- Sondi, I.; Salopek-Sondi, B. Silver nanoparticles as antimicrobial agent: A case study on E. coli as a model for Gram-negative bacteria. J. Colloid Interface Sci. 2004, 275, 177–182. [Google Scholar] [CrossRef]

- Bruskov, V.I.; Karp, O.E.; Garmash, S.A.; Shtarkman, I.N.; Chernikov, A.V. Prolongation of oxidative stress by long-lived reactive protein species induced by X-ray radiation and their genotoxic action. Free Radic. Res. 2012, 46, 1280–1290. [Google Scholar] [CrossRef]

- Li, D.; Chen, S.; Zhang, K.; Gao, N.; Zhang, M.; Albasher, G.; Shi, J.; Wang, C. The interaction of Ag2O nanoparticles with Escherichia coli: Inhibition–sterilization process. Sci. Rep. 2021, 11, 1703. [Google Scholar] [CrossRef]

- Panáček, A.; Kvítek, L.; Prucek, R.; Kolář, M.; Večeřová, R.; Pizúrová, N.; Sharma, V.K.; Nevěčná, T.j.; Zbořil, R. Silver Colloid Nanoparticles: Synthesis, Characterization, and Their Antibacterial Activity. J. Phys. Chem. B 2006, 110, 16248–16253. [Google Scholar] [CrossRef]

- Ocsoy, I.; Paret, M.L.; Ocsoy, M.A.; Kunwar, S.; Chen, T.; You, M.; Tan, W. Nanotechnology in Plant Disease Management: DNA-Directed Silver Nanoparticles on Graphene Oxide as an Antibacterial against Xanthomonas perforans. ACS Nano 2013, 7, 8972–8980. [Google Scholar] [CrossRef]

- Haq, S.; Rehman, W.; Waseem, M.; Meynen, V.; Awan, S.U.; Saeed, S.; Iqbal, N. Fabrication of pure and moxifloxacin functionalized silver oxide nanoparticles for photocatalytic and antimicrobial activity. J. Photochem. Photobiol. B 2018, 186, 116–124. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.; Lu, Y.; Huang, J. A hierarchical Ag2O-nanoparticle/TiO2-nanotube composite derived from natural cellulose substance with enhanced photocatalytic performance. Cellulose 2019, 26, 6683–6700. [Google Scholar] [CrossRef]

- Carvalho, D.; Sousa, T.; Morais, P.V.; Piedade, A.P. Polymer/metal nanocomposite coating with antimicrobial activity against hospital isolated pathogen. Appl. Surf. Sci. 2016, 379, 489–496. [Google Scholar] [CrossRef]

- Niño-Martínez, N.; Salas Orozco, M.F.; Martínez-Castañón, G.-A.; Torres Méndez, F.; Ruiz, F. Molecular Mechanisms of Bacterial Resistance to Metal and Metal Oxide Nanoparticles. Int. J. Mol. Sci. 2019, 20, 2808. [Google Scholar] [CrossRef]

- Amaro, F.; Morón, Á.; Díaz, S.; Martín-González, A.; Gutiérrez, J.C. Metallic Nanoparticles-Friends or Foes in the Battle against Antibiotic-Resistant Bacteria? Microorganisms 2021, 9, 364. [Google Scholar] [CrossRef]

- Helmlinger, J.; Sengstock, C.; Groß-Heitfeld, C.; Mayer, C.; Schildhauer, T.; Köller, M.; Epple, M. Silver nanoparticles with different size and shape: Equal cytotoxicity, but different antibacterial effects. RSC Adv. 2016, 6, 18490–18501. [Google Scholar] [CrossRef]

- Chausov, D.N.; Smirnova, V.V.; Burmistrov, D.E.; Sarimov, R.M.; Kurilov, A.D.; Astashev, M.E.; Uvarov, O.V.; Dubinin, M.V.; Kozlov, V.A.; Vedunova, M.V.; et al. Synthesis of a Novel, Biocompatible and Bacteriostatic Borosiloxane Composition with Silver Oxide Nanoparticles. Materials 2022, 15, 527. [Google Scholar] [CrossRef]

- Smirnova, V.V.; Chausov, D.N.; Serov, D.A.; Kozlov, V.A.; Ivashkin, P.I.; Pishchalnikov, R.Y.; Uvarov, O.V.; Vedunova, M.V.; Semenova, A.A.; Lisitsyn, A.B.; et al. A Novel Biodegradable Composite Polymer Material Based on PLGA and Silver Oxide Nanoparticles with Unique Physicochemical Properties and Biocompatibility with Mammalian Cells. Materials 2021, 14, 6915. [Google Scholar] [CrossRef]

- Baimler, I.V.; Lisitsyn, A.B.; Gudkov, S.V. Water decomposition occurring during laser breakdown of aqueous solutions containing individual gold, zirconium, molybdenum, iron or nickel nanoparticles. Front. Phys. 2020, 8, 600. [Google Scholar] [CrossRef]

- Burmistrov, D.E.; Yanykin, D.V.; Paskhin, M.O.; Nagaev, E.V.; Efimov, A.D.; Kaziev, A.V.; Ageychenkov, D.G. Additive Production of a Material Based on an Acrylic Polymer with a Nanoscale Layer of Zno Nanorods Deposited Using a Direct Current Magnetron Discharge: Morphology, Photoconversion Properties, and Biosafety. Materials 2021, 14, 6586. [Google Scholar] [CrossRef] [PubMed]

- Baimler, I.; Simakin, A.; Uvarov, O.; Volkov, M.Y. Generation of hydroxyl radicals during laser breakdown of aqueous solutions in the presence of Fe and Cu nanoparticles of different sizes. Phys. Wave Phenom. 2020, 28, 107–110. [Google Scholar] [CrossRef]

- Carapeto, A.P.; Ferraria, A.M.; Rego, A.M.B.D. Silver nanoparticles on cellulose surfaces: Quantitative measurements. Nanomaterials 2019, 9, 780. [Google Scholar] [CrossRef] [PubMed]

- Chernov, A.S.; Reshetnikov, D.A.; Ristsov, G.K.; Kovalitskaya, Y.A.; Ermakov, A.M.; Manokhin, A.A.; Simakin, A.V.; Vasilov, R.G. Influence of electromagnetic waves, with maxima in the green or red range, on the morphofunctional properties of multipotent stem cells. J. Biol. Phys. 2019, 45, 317–334. [Google Scholar] [CrossRef]

- Gudkov, S.; Shtarkman, I.; Chernikov, A.; Usacheva, A.; Bruskov, V. Guanosine and inosine (riboxin) eliminate the long-lived protein radicals induced X-ray radiation. Dokl. Biochem. Biophys. 2007, 413, 50–53. [Google Scholar] [CrossRef]

- Chernikov, A.; Gudkov, S.; Shtarkman, I.; Bruskov, V. Oxygen effect in heat-mediated damage to DNA. Biofizika 2007, 52, 244–251. [Google Scholar]

- Thakur, M.; Asrani, R.K.; Patial, V. Chapter 6—Listeria monocytogenes: A Food-Borne Pathogen. In Foodborne Diseases: Handbook of Food Bioengineering; Academic Press: Cambridge, MA, USA, 2018; pp. 157–192. [Google Scholar] [CrossRef]

- Fetsch, A.; Johler, S. Staphylococcus aureus as a Foodborne Pathogen. Curr. Clin. Microbiol. Rep. 2018, 5, 88–96. [Google Scholar] [CrossRef]

- Rezaloo, M.; Motalebi, A.; Mashak, Z.; Anvar, A. Prevalence, Antimicrobial Resistance, and Molecular Description of Pseudomonas aeruginosa Isolated from Meat and Meat Products. J. Food Qual. 2022, 2022, 9899338. [Google Scholar] [CrossRef]

- Eng, S.-K.; Pusparajah, P.; Ab Mutalib, N.-S.; Ser, H.-L.; Chan, K.-G.; Lee, L.-H. Salmonella: A review on pathogenesis, epidemiology and antibiotic resistance. Front. Life Sci. 2015, 8, 284–293. [Google Scholar] [CrossRef]

- Seluanov, A.; Vaidya, A.; Gorbunova, V. Establishing primary adult fibroblast cultures from rodents. J. Vis. Exp. 2010. [Google Scholar] [CrossRef] [PubMed]

- Sevostyanov, M.A.; Baikin, A.S.; Kaplan, M.A.; Kolmakov, A.G.; Rebezov, M.B.; Garnov, S.V. A β Ti–20Nb–10Ta–5Zr Alloy with the Surface Structured on the Micro- and Nanoscale. Dokl. Phys. 2021, 66, 14–16. [Google Scholar] [CrossRef]

- Sevostyanov, M.A.; Kolmakov, A.G.; Sergiyenko, K.V.; Kaplan, M.A.; Baikin, A.S. Mechanical, physical–chemical and biological properties of the new Ti–30Nb–13Ta–5Zr alloy. J. Mater. Sci. 2020, 55, 14516–14529. [Google Scholar] [CrossRef]

- Fayyadh, A.A.; Jaduaa Alzubaidy, M.H. Green-synthesis of Ag2O nanoparticles for antimicrobial assays. J. Mech. Behav. Mater. 2021, 30, 228–236. [Google Scholar] [CrossRef]

- Dharmaraj, D.; Krishnamoorthy, M.; Rajendran, K.; Karuppiah, K.; Annamalai, J.; Durairaj, K.R.; Santhiyagu, P.; Ethiraj, K. Antibacterial and cytotoxicity activities of biosynthesized silver oxide (Ag2O) nanoparticles using Bacillus paramycoides. J. Drug Deliv. Sci. Technol. 2021, 61, 102111. [Google Scholar] [CrossRef]

- Roy, A.; Srivastava, S.K.; Shrivastava, S.L.; Mandal, A.K. Hierarchical Assembly of Nanodimensional Silver–Silver Oxide Physical Gels Controlling Nosocomial Infections. ACS Omega 2020, 5, 32617–32631. [Google Scholar] [CrossRef]

- Begum, I.; Shamim, S.; Ameen, F.; Hussain, Z.; Bhat, S.A.; Qadri, T.; Hussain, M. A Combinatorial Approach towards Antibacterial and Antioxidant Activity Using Tartaric Acid Capped Silver Nanoparticles. Processes 2022, 10, 716. [Google Scholar] [CrossRef]

- Pochapski, D.J.; Carvalho Dos Santos, C.; Leite, G.W.; Pulcinelli, S.H.; Santilli, C.V. Zeta Potential and Colloidal Stability Predictions for Inorganic Nanoparticle Dispersions: Effects of Experimental Conditions and Electrokinetic Models on the Interpretation of Results. Langmuir 2021, 37, 13379–13389. [Google Scholar] [CrossRef]

- Tiwari, A.K.; Gupta, M.K.; Pandey, G.; Tilak, R.; Narayan, R.J.; Pandey, P.C. Size and Zeta Potential Clicked Germination Attenuation and Anti-Sporangiospores Activity of PEI-Functionalized Silver Nanoparticles against COVID-19 Associated Mucorales (Rhizopus arrhizus). Nanomaterials 2022, 12, 2235. [Google Scholar] [CrossRef]

- Lin, G.R.; Meng, F.S.; Pai, Y.H.; Lin, Y.H. Enhanced conversion efficiency and surface hydrophobicity of nano-roughened Teflon-like film coated poly-crystalline Si solar cells. Phys. Chem. Chem. Phys. 2012, 14, 3968–3973. [Google Scholar] [CrossRef]

- Kruss, S.; Wolfram, T.; Martin, R.; Neubauer, S.; Kessler, H.; Spatz, J.P. Stimulation of Cell Adhesion at Nanostructured Teflon Interfaces. Adv. Mater. 2010, 22, 5499–5506. [Google Scholar] [CrossRef] [PubMed]

- Gizinger, O.A.; Levkova, E.A.; Savin, S.Z. Use of modulation interference microscopy in applied immunology (in Russ). RUDN J. Med. 2020, 24, 168–175. [Google Scholar] [CrossRef]

- Dimitrakellis, P.; Kaprou, G.D.; Papavieros, G.; Mastellos, D.C.; Constantoudis, V.; Tserepi, A.; Gogolides, E. Enhanced antibacterial activity of ZnO-PMMA nanocomposites by selective plasma etching in atmospheric pressure. Micro Nano Eng. 2021, 13, 100098. [Google Scholar] [CrossRef]

- Chausov, D.N.; Burmistrov, D.E.; Kurilov, A.D.; Bunkin, N.F.; Astashev, M.E.; Simakin, A.V.; Vedunova, M.V. New Organosilicon Composite Based on Borosiloxane and Zinc Oxide Nanoparticles Inhibits Bacterial Growth, but Does Not Have a Toxic Effect on the Development of Animal Eukaryotic Cells. Materials 2021, 14, 6281. [Google Scholar] [CrossRef] [PubMed]

- Mollaeva, M.R.; Yabbarov, N.; Sokol, M.; Chirkina, M.; Mollaev, M.D.; Zabolotskii, A.; Seregina, I.; Bolshov, M.; Kaplun, A.; Nikolskaya, E. Optimization, Characterization and Pharmacokinetic Study of Meso-Tetraphenylporphyrin Metal Complex-Loaded PLGA Nanoparticles. Int. J. Mol. Sci. 2021, 22, 12261. [Google Scholar] [CrossRef] [PubMed]

- Zare, E.N.; Jamaledin, R.; Naserzadeh, P.; Afjeh-Dana, E.; Ashtari, B.; Hosseinzadeh, M.; Vecchione, R.; Wu, A.; Tay, F.R.; Borzacchiello, A.; et al. Metal-Based Nanostructures/PLGA Nanocomposites: Antimicrobial Activity, Cytotoxicity, and Their Biomedical Applications. ACS Appl. Mater. Interfaces 2020, 12, 3279–3300. [Google Scholar] [CrossRef] [PubMed]

- Onodera, A.; Nishiumi, F.; Kakiguchi, K.; Tanaka, A.; Tanabe, N.; Honma, A.; Yayama, K.; Yoshioka, Y.; Nakahira, K.; Yonemura, S.; et al. Short-term changes in intracellular ROS localisation after the silver nanoparticles exposure depending on particle size. Toxicol. Rep. 2015, 2, 574–579. [Google Scholar] [CrossRef]

- He, D.; Jones, A.M.; Garg, S.; Pham, A.N.; Waite, T.D. Silver Nanoparticle−Reactive Oxygen Species Interactions: Application of a Charging−Discharging Model. J. Phys. Chem. C 2011, 115, 5461–5468. [Google Scholar] [CrossRef]

- He, D.; Garg, S.; Waite, T.D. H2O2-Mediated Oxidation of Zero-Valent Silver and Resultant Interactions among Silver Nanoparticles, Silver Ions, and Reactive Oxygen Species. Langmuir 2012, 28, 10266–10275. [Google Scholar] [CrossRef]

- Gudkov, S.V.; Lyakhov, G.A.; Pustovoy, V.I.; Shcherbakov, I.A. Vibration–Vortex Mechanism of Radical-Reaction Activation in an Aqueous Solution: Physical Analogies. Phys. Wave Phenom. 2021, 29, 108–113. [Google Scholar] [CrossRef]

- Sharapov, M.G.; Gordeeva, A.E.; Goncharov, R.G.; Tikhonova, I.V.; Ravin, V.K.; Temnov, A.A.; Fesenko, E.E.; Novoselov, V.I. The Effect of Exogenous Peroxiredoxin 6 on the State of Mesenteric Vessels and the Small Intestine in Ischemia–Reperfusion Injury. Biophysics 2017, 62, 998–1008. [Google Scholar] [CrossRef]

- Winterbourn, C.C. Toxicity of iron and hydrogen peroxide: The Fenton reaction. Toxicol. Lett. 1995, 82–83, 969–974. [Google Scholar] [CrossRef] [PubMed]

- Wegner, A.M.; Haudenschild, D.R. NADPH oxidases in bone and cartilage homeostasis and disease: A promising therapeutic target. J. Orthop. Res. 2020, 38, 2104–2112. [Google Scholar] [CrossRef] [PubMed]

- Shcherbakov, I.A.; Baimler, I.V.; Lyakhov, G.A.; Mikhailova, G.N.; Pustovoy, V.I.; Sarimov, R.M.; Simakin, A.V.; Troitsky, A.V. Influence of a Constant Magnetic Field on Some Properties of Water Solutions. Dokl. Phys. 2020, 65, 273–275. [Google Scholar] [CrossRef]

- Menshchikova, E.B.; Kozhin, P.M.; Chechushkov, A.V.; Khrapova, M.V.; Zenkov, N.K. The Oral Delivery of Water-Soluble Phenol TS-13 Ameliorates Granuloma Formation in an In Vivo Model of Tuberculous Granulomatous Inflammation. Oxidative Med. Cell. Longev. 2021, 2021, 6652775. [Google Scholar] [CrossRef]

- Cadet, J.; Douki, T.; Gasparutto, D.; Ravanat, J.-L. Oxidative damage to DNA: Formation, measurement and biochemical features. Mutat. Res./Fundam. Mol. Mech. Mutagen. 2003, 531, 5–23. [Google Scholar] [CrossRef]

- Klaunig, J.E.; Kamendulis, L.M.; Hocevar, B.A. Oxidative Stress and Oxidative Damage in Carcinogenesis. Toxicol. Pathol. 2009, 38, 96–109. [Google Scholar] [CrossRef]

- Sies, H.; Jones, D.P. Reactive oxygen species (ROS) as pleiotropic physiological signalling agents. Nat. Rev. Mol. Cell Biol. 2020, 21, 363–383. [Google Scholar] [CrossRef]

- Fernández-Bertólez, N.; Costa, C.; Bessa, M.J.; Park, M.; Carriere, M.; Dussert, F.; Teixeira, J.P.; Pásaro, E.; Laffon, B.; Valdiglesias, V. Assessment of oxidative damage induced by iron oxide nanoparticles on different nervous system cells. Mutat. Res./Genet. Toxicol. Environ. Mutagen. 2019, 845, 402989. [Google Scholar] [CrossRef]

- Gudkov, S.V.; Garmash, S.A.; Shtarkman, I.N.; Chernikov, A.V.; Karp, O.E.; Bruskov, V.I. Long-lived protein radicals induced by X-ray irradiation are the source of reactive oxygen species in aqueous medium. Dokl. Biochem. Biophys. 2010, 430, 1–4. [Google Scholar] [CrossRef]

- Akbari, Z.; Rashidi Ranjbar, Z.; Khaleghi, M. Synthesis, characterization, and antibacterial activities of Ag2O nanoparticle and silver (I) nano-rod complex. Nanochem. Res. 2020, 5, 233–240. [Google Scholar]

- Boopathi, S.; Gopinath, S.; Boopathi, T.; Balamurugan, V.; Rajeshkumar, R.; Sundararaman, M. Characterization and Antimicrobial Properties of Silver and Silver Oxide Nanoparticles Synthesized by Cell-Free Extract of a Mangrove-Associated Pseudomonas aeruginosa M6 Using Two Different Thermal Treatments. Ind. Eng. Chem. Res. 2012, 51, 5976–5985. [Google Scholar] [CrossRef]

- Gudkov, S.V.; Serov, D.A.; Astashev, M.E.; Semenova, A.A.; Lisitsyn, A.B. Ag2O Nanoparticles as a Candidate for Antimicrobial Compounds of the New Generation. Pharmaceuticals 2022, 15, 968. [Google Scholar] [CrossRef] [PubMed]

- Sambhy, V.; Macbride, M.M.; Peterson, B.R.; Sen, A. Silver bromide nanoparticle/polymer composites: Dual action tunable antimicrobial materials. J. Am. Chem. Soc. 2006, 128, 9798–9808. [Google Scholar] [CrossRef] [PubMed]

- Russell, A.D.; Hugo, W.B. 7 Antimicrobial Activity and Action of Silver. Prog. Med. Chem. 1994, 31, 351–370. [Google Scholar] [CrossRef] [PubMed]

- Burmistrov, D.E.; Simakin, A.V.; Smirnova, V.V.; Uvarov, O.V.; Ivashkin, P.I.; Kucherov, R.N.; Ivanov, V.E.; Bruskov, V.I.; Sevostyanov, M.A.; Baikin, A.S.; et al. Bacteriostatic and Cytotoxic Properties of Composite Material Based on ZnO Nanoparticles in PLGA Obtained by Low Temperature Method. Polymers 2022, 14, 49. [Google Scholar] [CrossRef]

- Allahverdiyev, A.M.; Abamor, E.S.; Bagirova, M.; Rafailovich, M. Antimicrobial effects of TiO2 and Ag2O nanoparticles against drug-resistant bacteria and leishmania parasites. Future Microbiol. 2011, 6, 933–940. [Google Scholar] [CrossRef]

- Shen, W.; Li, P.; Feng, H.; Ge, Y.; Liu, Z.; Feng, L. The bactericidal mechanism of action against Staphylococcus aureus for AgO nanoparticles. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 75, 610–619. [Google Scholar] [CrossRef]

- Abbasi, B.A.; Iqbal, J.; Nasir, J.A.; Zahra, S.A.; Shahbaz, A.; Uddin, S.; Hameed, S.; Gul, F.; Kanwal, S.; Mahmood, T. Environmentally friendly green approach for the fabrication of silver oxide nanoparticles: Characterization and diverse biomedical applications. Microsc. Res. Tech. 2020, 83, 1308–1320. [Google Scholar] [CrossRef]

- Rokade, A.A.; Patil, M.P.; Yoo, S.I.; Lee, W.K.; Park, S.S. Pure green chemical approach for synthesis of Ag2O nanoparticles. Green Chem. Lett. Rev. 2016, 9, 216–222. [Google Scholar] [CrossRef]

- Babu, P.J.; Doble, M.; Raichur, A.M. Silver oxide nanoparticles embedded silk fibroin spuns: Microwave mediated preparation, characterization and their synergistic wound healing and anti-bacterial activity. J. Colloid Interface Sci. 2018, 513, 62–71. [Google Scholar] [CrossRef] [PubMed]

- Negi, H.; Rathinavelu Saravanan, P.; Agarwal, T.; Ghulam Haider Zaidi, M.; Goel, R. In vitro assessment of Ag2O nanoparticles toxicity against Gram-positive and Gram-negative bacteria. J. Gen. Appl. Microbiol. 2013, 59, 83–88. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Zhang, J.; Chan, W.L.; Szeto, Y.S. Suspension of Silver Oxide Nanoparticles in Chitosan Solution and its Antibacterial Activity in Cotton Fabrics. MRS Online Proc. Libr. 2006, 920, 203. [Google Scholar] [CrossRef]

- Rajabi, A.; Ghazali, M.J.; Mahmoudi, E.; Baghdadi, A.H.; Mohammad, A.W.; Mustafah, N.M.; Ohnmar, H.; Naicker, A.S. Synthesis, Characterization, and Antibacterial Activity of Ag2O-Loaded Polyethylene Terephthalate Fabric via Ultrasonic Method. Nanomaterials 2019, 9, 450. [Google Scholar] [CrossRef] [PubMed]

- Tripathi, S.; Mehrotra, G.K.; Dutta, P.K. Chitosan–silver oxide nanocomposite film: Preparation and antimicrobial activity. Bull. Mater. Sci. 2011, 34, 29–35. [Google Scholar] [CrossRef]

- Gul, S.; Rehan, Z.A.; Khan, S.A.; Akhtar, K.; Khan, M.A.; Khan, M.I.; Rashid, M.I.; Asiri, A.M.; Khan, S.B. Antibacterial PES-CA-Ag2O nanocomposite supported Cu nanoparticles membrane toward ultrafiltration, BSA rejection and reduction of nitrophenol. J. Mol. Liq. 2017, 230, 616–624. [Google Scholar] [CrossRef]

- Arsenopoulou, Z.V.; Taitzoglou, I.A.; Molyvdas, P.A.; Gourgoulianis, K.I.; Hatzoglou, C.; Zarogiannis, S.G. Silver Nanoparticles Alter Cell Adhesion and Proliferation of Sheep Primary Mesothelial Cells. In Vivo 2018, 32, 109–112. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).