Recovery of Phosphate(V) Ions from Water and Wastewater Using Chitosan-Based Sorbents Modified—A Literature Review

Abstract

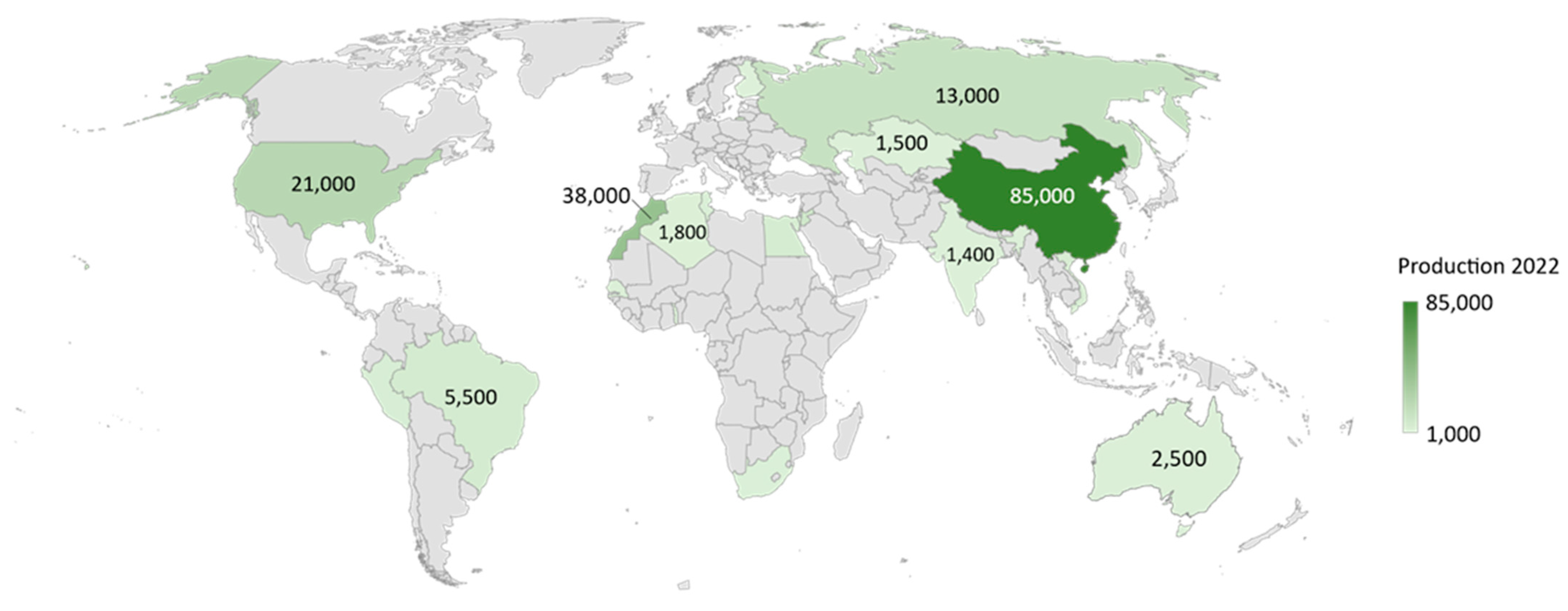

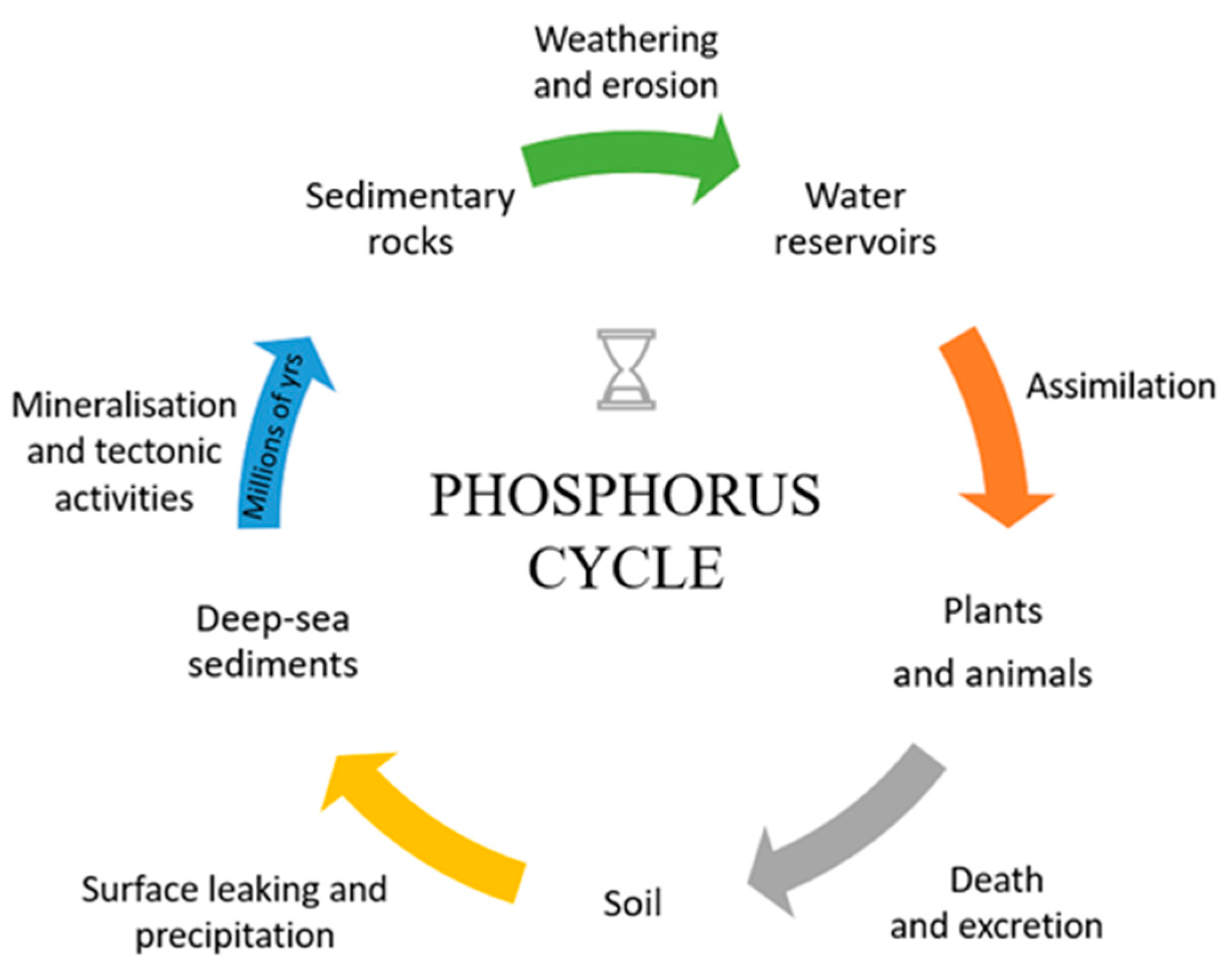

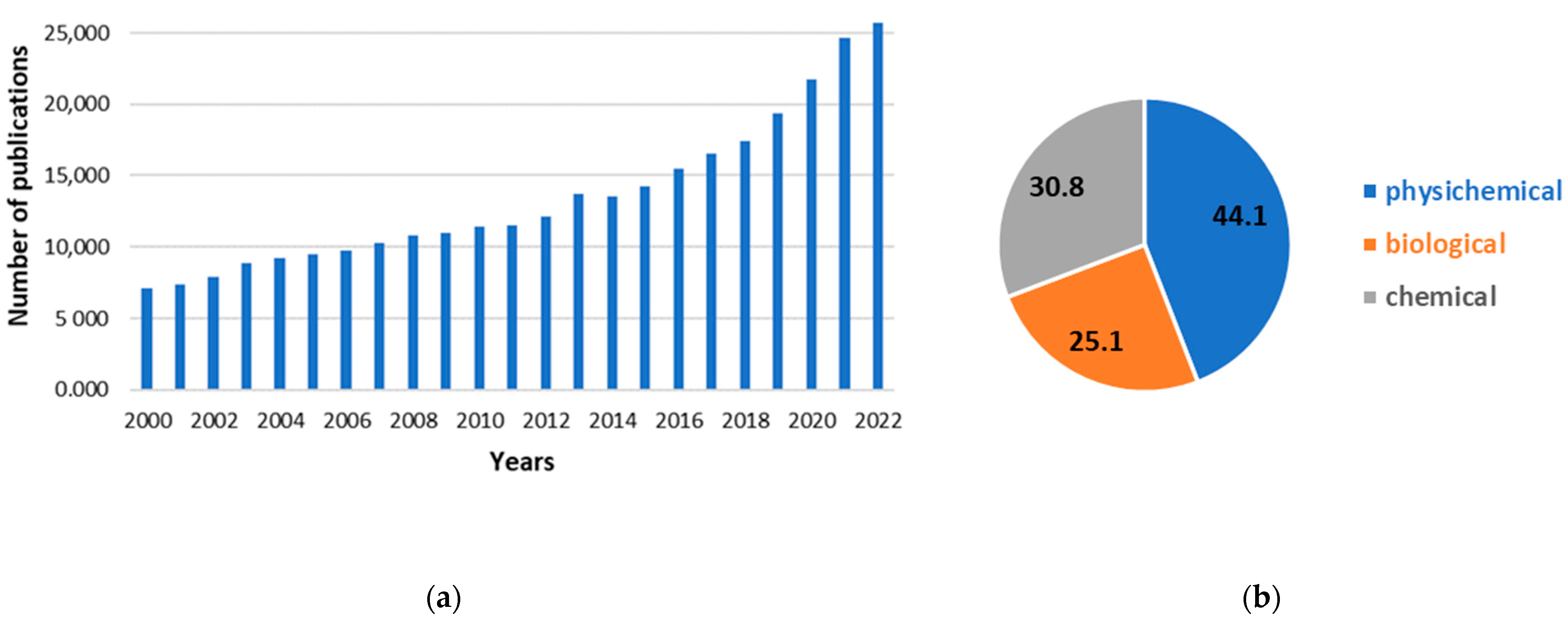

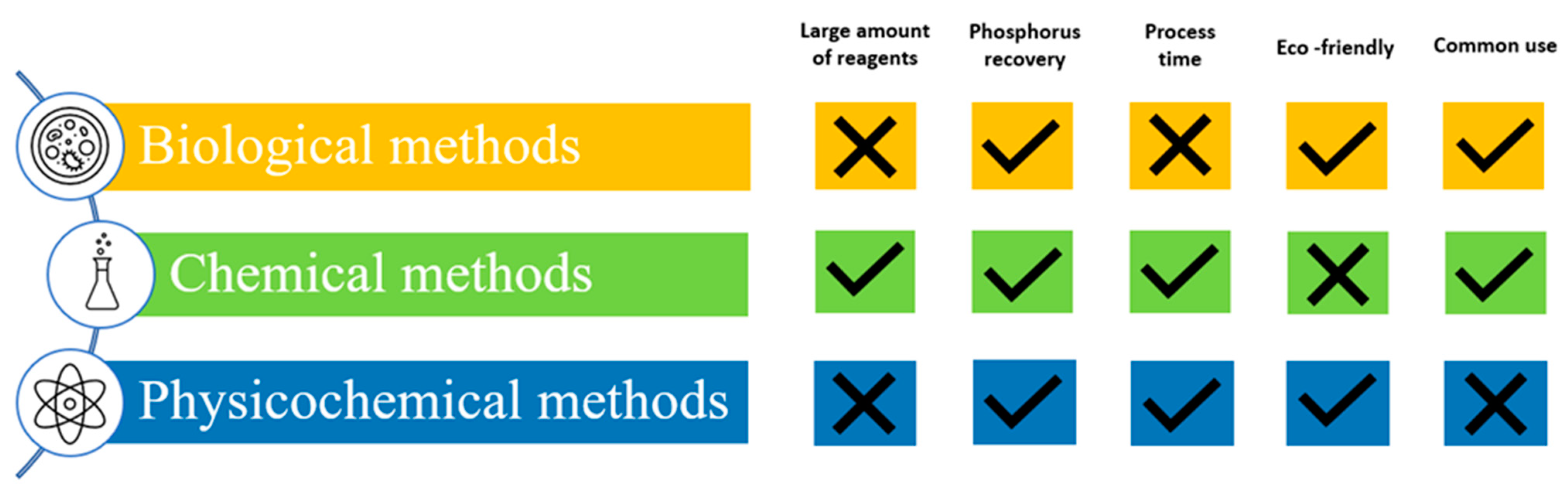

1. Introduction

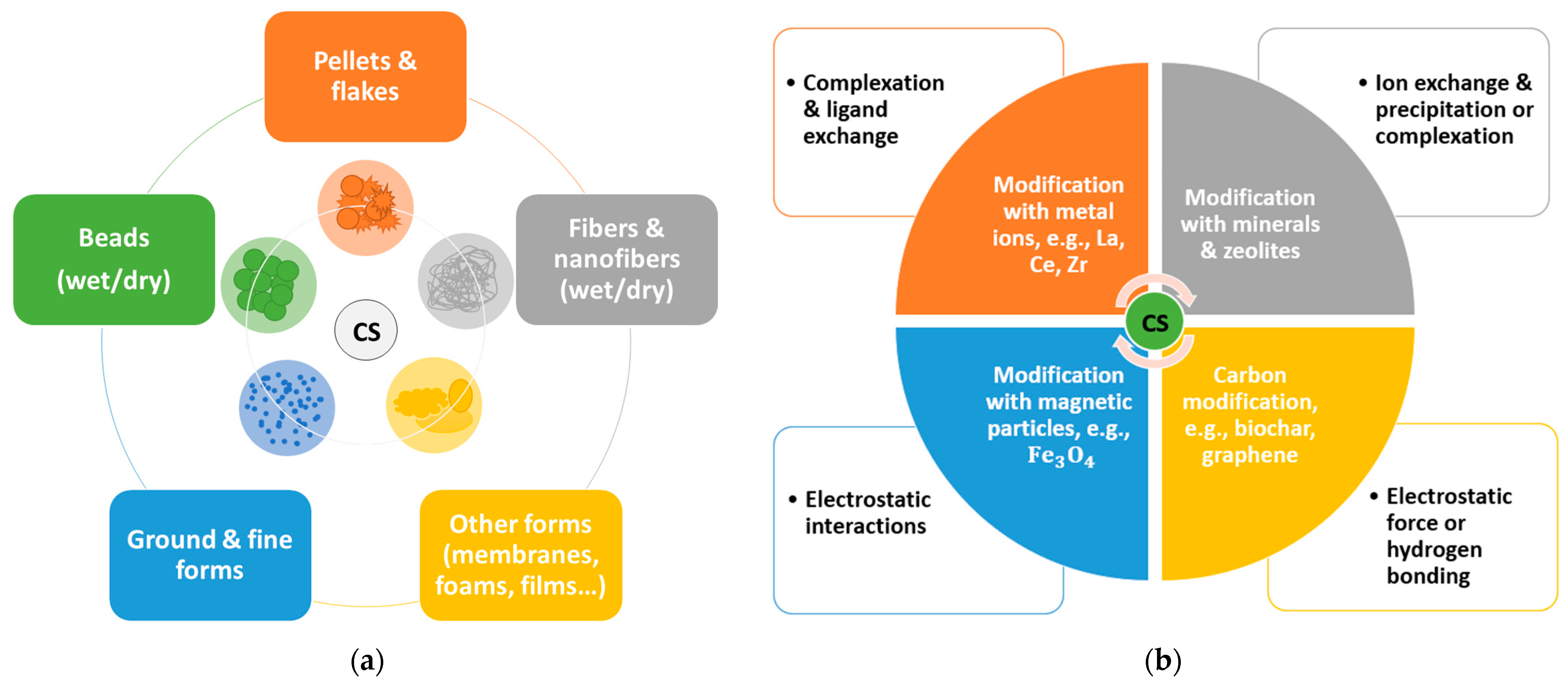

2. The Use of Various Forms of Chitosan for the Removal of Phosphates(V)

2.1. Chitosan Hydrogels in the Final Form of Wet or Dry Beads

2.1.1. Cross-Linked and Non-Cross-Linked Hydrogel Beads

2.1.2. Hydrogel Beads Modified with Metal Ions or Metal Oxides

2.1.3. Hydrogels Beads Filled with Carbon or Biochar

2.1.4. Zeolite and Mineral Composite Hydrogel Beads

2.1.5. Magnetic Chitosan Hydrogel Beads

2.2. Chitosan Nanofibers

2.3. Chitosan Pellets and Flakes

2.4. Ground and Fine Chitosan Forms

2.5. Chitosan Nanoparticles and Chitosan Sponge

2.6. Chitosan as a Direct Bio-Flocculant

2.7. Summary of Chitosan Sorbents for Phosphate Removal

3. Mechanism of Phosphate(V) Adsorption on Chitosan Sorbents

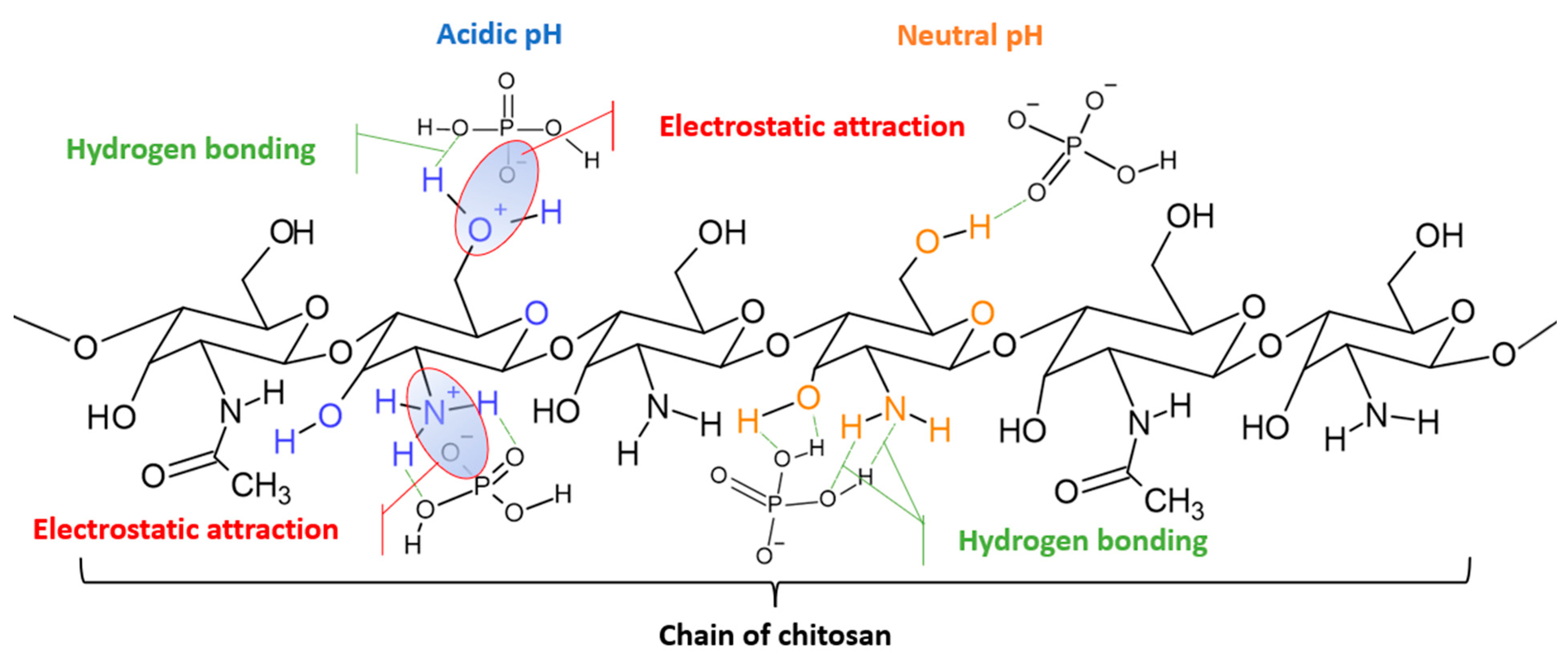

3.1. Non-Modified Chitosan

3.2. Metal-Based Chitosan

3.3. Carbon-Based Chitosan

3.4. Mineral-Based Chitosan

3.5. Magnetic-Based Chitosan

3.6. Polymer-Based Chitosan

4. Desorption of Phosphates(V) from Chitosan Sorbents

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AFMCS | amine-functionalized magnetic chitosan |

| AgNP | silver/silver oxide nanoparticles |

| BC | biochar |

| CCM | chitosan-calcite material |

| Ce–CCS | Ce(III)-impregnated cross-linked chitosan complex |

| Ce–CS–β-CD | chitosan-β-cyclodextrin sorbent with embedded cerium Ce3+ ions |

| CS/Ca–OMMT | chitosan/Ca-organically modified montmorillonite |

| CS/MWCNTs | chitosan modified with multi-walled carbon nanotubes |

| CSB | chitosan bead |

| CSB–Cu | chitosan bead (CSB) modified copper ion (Cu(II)) |

| CSBent | chitosan supported bentonite |

| CSB–G–Cu | chitosan bead (CSB) modified copper ion (Cu(II) glutaraldehyde cross-linked |

| CS–Fe | Fe(III)-doped chitosan composite |

| CS–Fe–CL | cross-linked Fe(III)-chitosan composite |

| CSH | chitosan hydrogel |

| CSHB | chitosan hydrogel beads (non-modified) |

| CSHs | chitosan hydrogel granules (non-modified) |

| CSHs-ECH | chitosan hydrogel granules cross-linked with epichlorohydrin |

| CS–La–N–20% | hydrogel immobilized with La(OH)3 nanoparticles within a quaternary–aminated chitosan |

| CS–Li@Fe3O4 | magnetic Fe3O4 doped lignin-chitosan-based microspheres |

| CS–MgCBC | chitosan modified magnesium impregnated corn straw biochar and glutaraldehyde cross-linked |

| CSNP | chitosan nanoparticles |

| Cu(II) | loaded CS chitosan beads directly after the saturated adsorption of copper(II) ions |

| CZD | chitosan pre-modified diatomite composited with ZIF–8 |

| EP | epichlorohydrin |

| Fe3O4/CS/PEI | polyethylenimine (PEI)-grafted chitosan (CS) core–shell |

| Fe–CS–Alg | Fe3+ loaded chitosan and alginate biopolymeric hybrid beads |

| FTIR | Fourier transform infrared spectroscopy analysis |

| GA | glutaraldehyde |

| GO | graphene oxide |

| HZCSB | hydrogel beads composed of zirconia and chitosan |

| i–PO4 | phosphate(V) ions (PO43−, HPO42−, H2PO4−) |

| La–BCS | lanthanum/chitosan-modified bentonite |

| La–CS@PDA | lanthanum-modified chitosan with a protective coating of polydopamine |

| La–CTS–0X | non-cross-linked lanthanum-chitosan |

| La–CTS–1X/2X | glutaraldehyde cross-linked lanthanum-chitosan composites |

| LaFGO | lanthanum-flocculated graphene oxide |

| La–SBC–CS | lanthanum-modified sludge biochar chitosan |

| LC–CS–Fe | chitosan modified with acid-leached carbon waste and FeCl3 |

| MCS | magnetic chitosan composite |

| MGO | magnetic graphene oxide |

| MGO/CS | magnetic graphene oxide chitosan composite |

| MK-CS | chitosan-encapsulated magnetic kaolin beads |

| MNP | magnetic nanoparticles |

| MNPsCS | chitosan composite of magnetic nanoparticles dispersed |

| nano–ZnO–CS | sorbents developed from CS and zinc compounds |

| NC@GO/Zr | Zr-nanochitosan/graphene oxide composite |

| PDA | polydopamine |

| PEG | polyethylene glycol |

| PEI | polyethylenimine |

| PFC | polyurethane foam impregnated with chitosan nanoparticles |

| PFCA | polyurethane foam impregnated with chitosan nanoparticles and silver/silver oxide nanoparticles |

| PUF | polyurethane foam |

| SEM | scanning electron microscope |

| SF | sponge filter |

| SPE | solid phase extraction |

| TAC | tetra-amine copper(II) |

| TAC@CS | composite chitosan beads by grafting tetra-amine copper(II) (TAC) |

| TETA | triethylene tetramine |

| TETA–MGO/CS | triethylene tetramine-functionalized magnetic graphene oxide chitosan composite |

| T–P | total phosphorous |

| ZCSB | chitosan hydrogel beads modified with Zr4+ ions |

| Zn(II)–CS | sorbents developed from CS and zinc compounds |

| ZnCCSB | chitosan beads carboxylated cross-linked with glutaraldehyde loaded with Zn(II) |

| ZnO–CS | sorbents developed from CS and zinc compounds |

| Zr–CMC/CMCS | Zr(IV)-cross-linked carboxymethyl cellulose/carboxymethyl chitosan hydrogel |

| ZrO2/SiO2 NM | nanofibrous membranes modified with ZrO2 and SiO2 nanoparticles |

References

- Bezak-Mazur, E.; Stoińska, R. The importance of phosphorus in the environment—Review article. Arch. Waste Manag. Environ. Prot. 2013, 15, 33–45. [Google Scholar]

- Ma, C.; Tang, Y.; Ye, C.; Ying, J.; Zhang, H. Mechanisms for phosphorus fluctuation in Phanerozoic volcanic rocks. Lithos 2022, 106764, 424–425. [Google Scholar] [CrossRef]

- U.S. Department of the Interior. Mineral Commodity Summaries; U.S. Geological Survey: Reston VA, USA, 2023. [Google Scholar]

- Korzeniowska, J.; Robaczyk, Z. Czy światu grozi brak fosforu do produkcji nawozów? Nasza Rola Więcej Z Pola 2011, 33, 13–14. [Google Scholar]

- Zhao, D.; Sengupta, A.K. Ultimate removal of phosphate from wastewater using a new class of polymeric ion exchangers. Water Res. 1998, 32, 1613–1625. [Google Scholar] [CrossRef]

- Mekonnen, M.; Hoekstra, Y. Global Anthropogenic Phosphorus Loads to Freshwater and Associated Grey Water Footprints and Water Pollution Levels: A High-Resolution Global Study. Water Resour. Res. 2017, 54, 345–358. [Google Scholar] [CrossRef]

- Young, K.; Morse, G.K.; Scrimshaw, M.D.; Kinniburgh, J.H.; McLeod, C.L.; Lester, J.N. The relation between phosphorus and eutrophication in the Thames catchment. Sci. Total. Environ. 1999, 228, 157–183. [Google Scholar] [CrossRef]

- Sethi, S.; Medha; Kaith, B.S. A review on chitosan-gelatin nanocomposites: Synthesis, characterization and biomedical applications. React. Funct. Polym. 2022, 179, 105362. [Google Scholar] [CrossRef]

- Ghormade, V.; Pathan, E.; Deshpande, M. Can fungi compete with marine sources for chitosan production? Int. J. Biol. Macromol. 2017, 104, 1415–1421. [Google Scholar] [CrossRef]

- Aranaz, I.; Mengibar, M.; Harris, R.; Panos, I.; Miralles, B.; Acosta, N.; Galed, G.; Heras, A. Functional Characterization of Chitin and Chitosan. Curr. Chem. Biol. 2009, 3, 203–230. [Google Scholar]

- Liu, X.; Zhao, X.; Liu, Y.; Zhang, T. Review on preparation and adsorption properties of chitosan and chitosan composites. Polym. Bull. 2021, 79, 2633–2665. [Google Scholar] [CrossRef]

- Liu, B.; Yu, Y.; Han, Q.; Lou, S.; Zhang, L.; Zhang, W. Fast and efficient phosphate removal on lanthanum-chitosan composite synthesized by controlling the amount of cross-linking agent. Int. J. Biol. Macromol. 2020, 157, 247–258. [Google Scholar] [CrossRef] [PubMed]

- Jóźwiak, T.; Filipkowska, U.; Szymczyk, P.; Mielcarek, A. Sorption of nutrients (orthophosphate, nitrate III and V) in an equimolar mixture of P–PO4, N–NO2 and N–NO3 using chitosan. Arab. J. Chem. 2019, 12, 41044117. [Google Scholar] [CrossRef]

- Jóźwiak, T.; Kowalkowska, A.; Filipkowska, U.; Struk-Sokołowska, J.; Bolozan, L.; Gache, L.; Ilie, M. Recovery of phosphorus as soluble phosphates from aqueous solutions using chitosan hydrogel sorbents. Sci. Rep. 2021, 11, 16766. [Google Scholar] [CrossRef] [PubMed]

- Leduc, J.; Leduc, R.; Cabana, H. Phosphate Adsorption onto Chitosan-Based Hydrogel Microspheres. Adsorp. Sci. Technol. 2014, 32, 557–569. [Google Scholar] [CrossRef]

- Mahaninia, M.H.; Wilson, L.D. Cross-linked chitosan beads for phosphate removal from aqueous solution. J. Appl. Polym. Sci. 2016, 133, 42949. [Google Scholar] [CrossRef]

- Karthikeyan, P.; Banu, H.; Meenakshi, S. Synthesis and characterization of metal loaded chitosan-alginate biopolymeric hybrid beads for the efficient removal of phosphate and nitrate ions from aqueous solution. Int. J. Biol. Macromol. 2019, 130, 407–418. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.; Ding, J.; Zhang, Z.; Gao, C.; Halimi, M.; Demey, H.; Yang, Z.; Yang, W. High phosphate removal using La(OH)3 loaded chitosan based composites and mechanistic study. J. Environ. Sci. 2021, 106, 105–115. [Google Scholar] [CrossRef]

- Zhao, Y.; Guo, L.; Shen, W.; An, Q.; Xiao, Z.; Wang, H.; Cai, W.; Zhai, S.; Li, Z. Function integrated chitosan-based beads with throughout sorption sites and inherent diffusion network for efficient phosphate removal. Carbohydr. Polym. 2020, 230, 115639. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, X.; Zhang, Z.; Chen, Z. Removal of phosphate from aqueous solution by chitosan coated and lanthanum loaded biochar derived from urban dewatered sewage sludge: Adsorption mechanism and application to lab-scale columns. Water Sci. Technol. 2021, 84, 3891–3906. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, L. Removal of phosphate anions using the modified chitosan beads: Adsorption kinetic, isotherm and mechanism studies. Powder Technol. 2015, 277, 112–119. [Google Scholar] [CrossRef]

- Chen, Z.; Luo, H.; Rong, H. Development of polyaminated chitosan-zirconium(IV) complex bead adsorbent for highly efficient removal and recovery of phosphorus in aqueous solutions. Int. J. Biol. Macromol. 2020, 164, 1183–1193. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wei, J. Facile synthesis of Zr(IV)-crosslinked carboxymethyl cellulose/carboxymethyl chitosan hydrogel using PEG as pore-forming agent for enhanced phosphate removal. Int. J. Biol. Macromol. 2021, 176, 558–566. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, T.; Wu, D. Facile synthesis of hydrous zirconia-impregnated chitosan beads as a filter medium for efficient removal of phosphate from water. Cellulose 2022, 29, 8749–8768. [Google Scholar] [CrossRef]

- Kluczka, J.; Dudek, G.; Kazek-Kęsik, A.; Gnus, M. Chitosan Hydrogel Beads Supported with Ceria for Boron Removal. Int. J. Mol. Sci. 2019, 20, 1567. [Google Scholar] [CrossRef] [PubMed]

- Hu, P.; Liu, Q.; Wang, J.; Huang, R. Phosphate removal by Ce(III)-impregnated crosslinked chitosan complex from aqueous solutions. Polym. Eng. Sci. 2017, 57, 44–51. [Google Scholar] [CrossRef]

- Karthikeyan, P.; Meenakshi, S. In-situ fabrication of cerium incorporated chitosan-β-cyclodextrin microspheres as an effective adsorbent for toxic anions removal. Environ. Nanotechnol. Monit. Manag. 2019, 12, 100272. [Google Scholar] [CrossRef]

- Ma, P.; Ding, W.; Yuan, J.; Yi, L.; Zhang, H. Total recycle strategy of phosphorus recovery from wastewater using granule chitosan inlaid with γ-AlOOH. Envion. Res. 2020, 184, 109309. [Google Scholar] [CrossRef]

- Sowmya, A.; Meenakshi, S. Effective utilization of the functional groups in chitosan by loading Zn(II) for the removal of nitrate and phosphate. Desalination Water Treat. 2015, 54, 1674–1683. [Google Scholar] [CrossRef]

- Yazdani, M.R.; Virolainen, E.; Conley, K.; Vahala, R. Chitosan–Zinc(II) Complexes as a Bio-Sorbent for the Adsorptive Abatement of Phosphate: Mechanism of Complexation and Assessment of Adsorption Performance. Polymers 2018, 10, 25. [Google Scholar] [CrossRef]

- An, B.; Jung, K.Y.; Lee, S.H.; Lee, S.; Choi, J.-W. Effective Phosphate Removal from Synthesized Wastewater Using Copper–Chitosan Bead: Batch and Fixed-Bed Column Studies. Water Air Soil Pollut. 2014, 225, 2050. [Google Scholar] [CrossRef]

- Kumar, I.A.; Viswanathan, N. Preparation and testing of a tetra-amine copper(II) chitosan bead system for enhanced phosphate remediation. Carbohydr. Polym. 2018, 183, 173–182. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Yang, H.; Yan, H.; Shangguan, Y.; Zheng, Q.; Cheng, R. Phosphate adsorption from aqueous solutions by disused adsorbents: Chitosan hydrogel beads after the removal of copper(II). Chem. Eng. J. 2011, 66, 970–977. [Google Scholar] [CrossRef]

- Deng, L.; Guan, Q.; Ning, P.; He, L.; Zhang, D. Synthesis of 3D calcium-modified microspheres for fast purification of simulated phosphate wastewater. J. Water Process. Eng. 2021, 42, 102182. [Google Scholar] [CrossRef]

- Eltaweil, A.S.; Omer, A.M.; El-Aqapa, H.G.; Gaber, N.M.; Attia, N.F.; El-Subruiti, G.M.; Mohy-Eldin, M.S.; Abd El-Monaem, E.M. Chitosan based adsorbents for the removal of phosphate and nitrate: A critical review. Carbohydr. Polym. 2021, 274, 118671. [Google Scholar] [CrossRef]

- Palansooriya, K.; Kim, S.; Igalavithana, A.; Igalavithana, A.D.; Hashimoto, Y.; Choi, Y.-E.; Mukhopadhyay, R.; Sarkar, B.; Ok, Y.S. Fe(III) loaded chitosan-biochar composite fibers for the removal of phosphate from water. J. Hazard. Mater. 2021, 415, 125464. [Google Scholar] [CrossRef]

- El-Naggar, A.; El-Naggar, A.; Shaheen, S.; Sarkar, B.; Chang, S.X.; Tsang, D.C.W.; Rinklebe, J.; Ok, Y.S. Biochar composition-dependent impacts on soil nutrient release, carbon mineralization, and potential environmental risk: A review. J. Environ. Manag. 2019, 241, 458–467. [Google Scholar] [CrossRef]

- Li, L.; Chen, Q.; Zhao, C.; Guo, B.; Xu, X.; Liu, T.; Zhao, L. A novel chitosan modified magnesium impregnated corn straw biochar for ammonium and phosphate removal from simulated livestock wastewater. Environ. Technol. Innov. 2022, 26, 102519. [Google Scholar] [CrossRef]

- Huang, Y.; Lee, X.; Grattieri, M.; Macazo, F.C.; Cai, R.; Minteer, S.D. A sustainable adsorbent for phosphate removal: Modifying multi-walled carbon nanotubes with chitosan. J. Mater. Sci. 2018, 53, 12641–12649. [Google Scholar] [CrossRef]

- Xu, X.; Cheng, Y.; Wu, X.; Fan, P.; Song, R. La(III)-bentonite/chitosan composite: A new type adsorbent for rapid removal of phosphate from water bodies. Appl. Clay Sci. 2020, 190, 105547. [Google Scholar] [CrossRef]

- Jang, J.; Lee, D.S. Effective phosphorus removal using chitosan/Ca-organically modified montmorillonite beads in batch and fixed-bed column studies. J. Hazard. Mater. 2019, 375, 9–18. [Google Scholar] [CrossRef]

- Banu, T.H.; Karthikeyan, P.; Meenakshi, S. Lanthanum (III) encapsulated chitosan-montmorillonite composite for the adsorptive removal of phosphate ions from aqueous solution. Int. J. Biol. Macromol. 2018, 112, 284–293. [Google Scholar] [CrossRef] [PubMed]

- Salehi, S.; Hosseinifard, M. Highly efficient removal of phosphate by lanthanum modified nanochitosan-hierarchical ZSM-5 zeolite nanocomposite: Characteristics and mechanism. Cellulose 2020, 27, 4637–4664. [Google Scholar] [CrossRef]

- Kumar, I.A.; Viswanathan, N. Development of multivalent metal ions imprinted chitosan biocomposites for phosphate sorption. Int. J. Biol. Macromol. 2017, 104, 1539–1547. [Google Scholar] [CrossRef]

- Henglein, A. Small-particle research: Physicochemical properties of extremely small colloidal metal and semiconductor particles. Chem. Rev. 1989, 89, 1861–1873. [Google Scholar] [CrossRef]

- Cheng, F.; Su, C.; Yang, Y.; Yeh, C.S.; Tsai, C.Y.; Wu, C.L.; Wu, M.T.; Shieh, D.B. Characterization of aqueous dispersions of Fe3O4 nanoparticles and their biomedical applications. Biomaterials 2005, 26, 729–738. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, H.; Zhang, L.; Wan, H.; Zheng, S.; Xu, Z. Adsorptive removal of phosphate by magnetic Fe3O4@C@ZrO2. Colloids Surf. Physicochem. Eng. Aspects 2015, 469, 100–106. [Google Scholar] [CrossRef]

- Kumar, I.A.; Viswanathan, N. Development and Reuse of Amine-Grafted Chitosan Hybrid Beads in the Retention of Nitrate and Phosphate. J. Chem. Eng. Data 2018, 63, 147–158. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, S.-B.; Lee, S.-H.; Choi, J.-W. Laboratory and pilot-scale field experiments for application of iron oxide nanoparticle-loaded chitosan composites to phosphate removal from natural water. Environ. Technol. 2018, 39, 770–779. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, N.; Feng, C.; Zhang, Z. Adsorption for phosphate by crosslinked/non-crosslinked-chitosan-Fe(III) complex sorbents: Characteristic and mechanism. Chem. Eng. J. 2018, 353, 361–372. [Google Scholar] [CrossRef]

- Karthikeyan, P.; Meenakshi, S. Fabrication of hybrid chitosan encapsulated magnetic-kaolin beads for adsorption of phosphate and nitrate ions from aqueous solutions. Int. J. Biol. Macromol. 2021, 168, 750–759. [Google Scholar] [CrossRef]

- Cheng, R.; Shen, L.-J.; Zhang, Y.-Y.; Dai, D.-Y.; Zheng, X.; Liao, L.-W.; Wang, L.; Shi, L. Enhanced Phosphate Removal from Water by Honeycomb-Like Microporous Lanthanum-Chitosan Magnetic Spheres. Water 2018, 10, 1659. [Google Scholar] [CrossRef]

- Cui, X.; Li, H.; Yao, Z.; Shen, Y.; He, Z.; Yang, X.; Ng, H.; Wang, C.H. Removal of nitrate and phosphate by chitosan composited beads derived from crude oil refinery waste: Sorption and cost-benefit analysis. J. Clean. Prod. 2019, 207, 846–856. [Google Scholar] [CrossRef]

- Bozorgpour, F.; Ramandi, H.; Jafari, P.; Samadi, S.; Yazd, S.; Aliabadi, M. Removal of nitrate and phosphate using chitosan/Al2O3/Fe3O4 composite nanofibrous adsorbent: Comparison with chitosan/Al2O3/Fe3O4 beads. Int. J. Biol. Macromol. 2016, 93, 557–565. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Dou, L.; Li, Z.; Yang, L.; Yu, J.; Ding, B. Flexible Hierarchical ZrO2 Nanoparticle-Embedded SiO2 Nanofibrous Membrane as a Versatile Tool for Efficient Removal of Phosphate. ACS Appl. Mater. Interfaces 2016, 8, 34668–34676. [Google Scholar] [CrossRef] [PubMed]

- Nthumbi, R.; Catherine Ngila, J.; Moodley, B.; Kindness, A.; Petrik, L. Application of chitosan/polyacrylamide nanofibres for removal of chromate and phosphate in water. Phys. Chem. Earth 2012, 50–52, 243–251. [Google Scholar] [CrossRef]

- Szymczyk, P.; Filipkowska, U.; Jóźwiak, T.; Kuczajowska-Zazdrożna, M. Phosphate removal from aqueous solutions by chitin and chitosan in flakes. Prog. Chem. Appl. Chitin Deriv. 2016, 21, 192–202. [Google Scholar] [CrossRef]

- Thonsamer, T.; Vinitnantharat, S.; Pinisakul, A.; Werner, D. Chitosan impregnation of coconut husk biochar pellets improves their nutrient removal from eutrophic surface water. Sustain. Environ. Res. 2022, 32, 1–19. [Google Scholar]

- Sowmya, A.; Meenakishi, S. A novel quaternized chitosan–melamine–glutaraldehyde resin for the removal of nitrate and phosphate anions. Int. J. Biol. Macromol. 2014, 64, 224–232. [Google Scholar] [CrossRef]

- Pap, S.; Zhang, H.; Bogdan, A.; Elsby, D.T.; Gibb, S.W.; Bremner, B.; Taggart, M.A. Pilot-scale phosphate recovery from wastewater to create a fertiliser product: An integrated assessment of adsorbent performance and quality. Water Res. 2023, 228, 119369. [Google Scholar] [CrossRef]

- Huang, L.; Lee, X.; Grattieri, M.; Yuan, M.; Cai, R.; Macazo, F.C.; Minteer, S.D. Modified biochar for phosphate adsorption in environmentally relevant conditions. Chem. Eng. J. 2020, 380, 122375. [Google Scholar] [CrossRef]

- Fu, C.; Zuo, Y.; Li, B.; Liu, C.; Liu, D.; Fu, Y.; Yin, Y. Fabrication of lanthanum/chitosan co-modified bentonite and phosphorus removal mechanism from low-concentration landscape water. Water Sci. Technol. 2022, 86, 1017. [Google Scholar] [CrossRef]

- Kumar, I.; Viswanathan, N. Hydrothermal Fabrication of Zirconium Oxyhydroxide Capped Chitosan/Kaolin Framework for Highly Selective Nitrate and Phosphate Retention. Ind. Eng. Chem. Res. 2018, 57, 14470–14481. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, H.; Fan, G.; He, X.; He, Z.; Zhang, L. Diatomite Composited with a Zeolitic Imidazolate Framework for Removing Phosphate from Water. ACS Omega 2022, 7, 26154–26164. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhang, P.; Liu, J. Triethylene Tetramine Functionalized Magnetic Graphene Oxide Chitosan Composite with Superior Capacity for the Removal of Phosphate. J. Chem. Eng. Data. 2017, 62, 3341–3352. [Google Scholar] [CrossRef]

- Fu, C.-C.; Tran, H.-N.; Chen, X.-H.; Juang, R.-S. Preparation of polyaminated Fe3O4@chitosan core-shell magnetic nanoparticles for efficient adsorption of phosphate in aqueous solutions. J. Ind. Eng. Chem. 2020, 83, 235–246. [Google Scholar] [CrossRef]

- Han, Y.; Ma, Z.; Cong, H.; Wang, Q.; Wang, X. Surface Chitosan-coated Fe3O4 immobilized lignin for adsorbed phosphate radicals in solution. Biochem. Eng. J. 2022, 187, 108662. [Google Scholar] [CrossRef]

- Naidoo, S.; Nomadolo, N.; Matshe, W.M.R.; Cele, Z.; Balogun, M. Exploring the potential of N-acylated chitosan for the removal of toxic pollutants from wastewater. IOP Conf. Ser. Mater. Sci. Eng. 2019, 655, 012047. [Google Scholar] [CrossRef]

- Sasidharan, A.P.; Meera, V.; Raphael, V.P. Efficacy of nanochitosan impregnated polyurethane foam in removing phosphate from aqueous solutions. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1114, 012083. [Google Scholar]

- Sasidharan, A.P.; Meera, V.; Raphael, V.P. Investigations on characteristics of polyurethane foam impregnated with nanochitosan and nanosilver/silver oxide and its effectiveness in phosphate removal. Environ. Sci. Pollut. Res. 2021, 28, 12980–12992. [Google Scholar] [CrossRef]

- Sasidharan, A.P.; Meera, V.; Raphael, V.P. Nanochitosan impregnated polyurethane foam in the removal of phosphate and coliforms from greywater. Nanotechnol. Environ. Eng. 2023, 8, 131–142. [Google Scholar] [CrossRef]

- Salehi, S.; Hosseinifard, M. Optimized removal of phosphate and nitrate from aqueous media using zirconium functionalized nanochitosan-graphene oxide composite. Cellulose 2020, 27, 8859–8883. [Google Scholar] [CrossRef]

- Yang, S.; Chen, X.; Zhang, Z.; Jin, P.; Zhang, Q.; Wang, X. The removal of phosphate from aqueous solution through chemical filtration using a sponge filter. Chem. Lett. 2018, 47, 89–91. [Google Scholar] [CrossRef]

- Lichtfouse, E.; Morin-Crini, N.; Fourmentin, M.; Zemmouri, H.; do Carmo Nascimento, I.O.; Queiroz, L.M.; Tadza, M.; Yuhyi, M.; Wilson, L.D.; Crini, G. Chitosan for direct bioflocculation of wastewater. Environ. Chem. Lett. 2019, 17, 1603–1621. [Google Scholar] [CrossRef]

- Rojsitthisak, P.; Burut-Archanai, S.; Pothipongsa, A.; Powtongsook, S. Repeated phosphate removal from recirculating aquaculture system using cyanobacterium remediation and chitosan flocculation. Water Environ. J. 2017, 31, 598–602. [Google Scholar] [CrossRef]

- Zhao, J.; Li, M.; Liu, Q.; Zhou, Z.; Ye, C. Addition of chitosan improves the efficiency of total phosphorus removal from wastewater using the D-A2O reactor and metagenomic analysis. Water Policy 2021, 23, 1530–1541. [Google Scholar]

- Mackay, S.; Malherbe, F.; Eldridge, D. Quaternary amine functionalized chitosan for enhanced adsorption of low concentration phosphate to remediate environmental eutrophication. Colloids Surf. Physicochem. Eng. Aspects. 2022, 653, 129984. [Google Scholar] [CrossRef]

- Wan, J.; Zhu, C.; Hu, J.; Zhang, T.C.; Richter Egger, D.; Feng, X.; Zhou, A.; Tao, T. Zirconium-loaded magnetic interpenetrating network chitosan/poly(vinyl alcohol) hydrogels for phosphorus recovery from the aquatic environment. Appl. Surf. Sci. 2017, 423, 484–491. [Google Scholar] [CrossRef]

- Banu, H.; Karthikeyan, P.; Vigneshwaran, S.; Meenakshi, S. Adsorptive performance of lanthanum encapsulated biopolymer chitosan-kaolin clay hybrid composite for the recovery of nitrate and phosphate from water. Int. J. Biol. Macromol. 2020, 154, 188–197. [Google Scholar] [CrossRef]

- Isidoro, R.N.; Pessanha, B.O.; Pessanha, G.M.; Guimaraes, D. Efficient phosphate adsorption by a composite composed of Mg6Al2(CO3)(OH)16·4H2O LDH and Chitosan: Kinetic, thermodynamic, desorption, and characterization studies. Sep. Purif. Technol. 2023, 307, 122717. [Google Scholar] [CrossRef]

- Zavareh, S.; Behrouzi, Z.; Avanes, A. Cu(II) bind.ed chitosan/Fe3O4 nanocomomposite as a new biosorbent for efficient and selective removal of phosphate. Int. J. Biol. Macromol. 2017, 101, 40–50. [Google Scholar] [CrossRef]

| Form of Chitosan | Modification Type | Name of Sorbent | q [mg/g] | teq(s) [min] | pH, T [K] | CP-PO4 [mg/L], Sorbent Dose [g/L] | Ref. |

|---|---|---|---|---|---|---|---|

| Hydrogel beads | without modification | CSH | 15.72 | 60 | 4, 295 | 3–300, 1 | [13] |

| CSHs | 18.85 | 60 | 3, 295 | 1–100, 1 | [14] | ||

| CHMs | 3.76 | 30 | 6.6, 293 | 1–30, 3.34 | [15] | ||

| with metal ions or metal oxides | La–CS@PDA | 195.3 | 300 | 3, 295 | 25–500, 1 | [19] | |

| La–SBC–CS | 81.54 | 660 | 4.3, 298 | 10–70, 2 | [20] | ||

| ZCSB | 60.6 | 50 | 4, 288 | 5–50, 0.2 | [21] | ||

| Zr–CMC/CMCS | 93.5 | 400 | 2, 298 | 10–100, - | [23] | ||

| HZCSB | 42.02 | 2160 | 6.7, 298 | 1–100, 0.75 | [24] | ||

| Ce–CS–β–CD | 88.54 | 40 | 6, 303 | -, 2 | [27] | ||

| Y–AlOOH@CS | 45.82 | 30 | 4–6, 298 | 5–200, 1 | [28] | ||

| ZnCCSB | 67.5 | 90 | 4–7, 295 | 1–1000, 1 | [29] | ||

| CB–G–Cu | 53.6 | 720 | 7, 295 | 1–100, 1.25 | [31] | ||

| TAC@CS | 43.32 | 40 | 303 | 20–140, 2 | [32] | ||

| Ca–CS | 23.7 | 20 | 7, 298 | 5–50, 1 | [34] | ||

| with carbon or biochar | CS–MgCBC | 221.89 * | 180 | 3–6, 298 | 20–350, 2 | [38] | |

| CS/MWCNTs | 36.1 | 30 | 3, 293 | 25–200, 0.2 | [39] | ||

| with zeolite or mineral | La–CS–MMT | 128.5 | 30 | 5.3, 303 | 50–300, 2 | [42] | |

| Zr@CsKN | 40.58 | 30 | 3–7, 303 | 80–140, - | [44] | ||

| NCs@ZSM–5H/La | 151.51 | 30 | 5, - | 30–150, 0.5 | [43] | ||

| with magnetic particles | MNPsCS | 1.079 | 720 | 5, 303 | 1–8, 30 | [49] | |

| AFMCS | 42.95 | 40 | 3–7, 313 | 20–140,2 | [48] | ||

| CS–Fe | 15.7 | - | -, 303 | 10–200, 10 | [50] | ||

| LC–CS–Fe | 62.72 | 900 | 5, - | 5–200, 2 | [53] | ||

| Nanofibers | CS/Al2O3–Fe3O4 | 135.1 | 60 | 293 | 10–500, 0.5 | [54] | |

| ZrO2/SiO2 NM | 57.38 | 60 | 5, 298 | 1–20, - | [55] | ||

| CS–PAA | 392 | 60 | 4.5, 298 | 0.1–10, 2.5 | [56] | ||

| Pellets and flakes | CS/flakes | 6.64 | 40 | 4, - | 0.5–25 | [57] | |

| CS–EG | 4.7 | 960 | 7, | 10–100, 20 | [58] | ||

| CS/QCMGR | 159.48 | - | 3–10, 303 | 1–100, 2 | [59] | ||

| Ground and fine chitosan forms | La–BCS | 16.13 | 40 | 3, 298 | 1–50, 0.8 | [62] | |

| TETA–MGO/CS | 353.36 | 50 | 298 | 1–500, - | [65] | ||

| CS–Li@Fe3O4 | 98 | 60 | 2–10, | 100–600, - | [67] | ||

| Nanoparticles and sponges | PFCA | 7.8 | 360 | 6, 300 | 50, 3 | [70] | |

| NC@GO/Zr | 172.4 | 20 | 5, 313 | 30–150, 0.5 | [72] | ||

| LaFGO | 13.12 | 120 | 3, - | 5–50, 0.2 | [73] | ||

| Solution pH | Ion Order | Molecular Formula of Orthophosphate(V) Form |

|---|---|---|

| <2.14 | - | H3PO4 |

| 2.14–7.20 | I | H2PO4− |

| 7.21–12.37 | II | HPO42− |

| >12.37 | III | PO43− |

| Desorbing Agent | Concentration | Name of Sorbent | qm [mg/g] | T [K], teq(d) [min] | Number of Cycles, Desorption Efficiency [%] | Ref. |

|---|---|---|---|---|---|---|

| NaOH | 0.1 M | Fe–CS–Alg | 84.74 | -, - | 5, - | [17] |

| 3 M | La–SBC–CS | 81.54 | -, - | 8, 94 * | [20] | |

| 0.5 M | ZCSB | 62.6 | -, - | 5, - | [21] | |

| 0.5 M | HZCSB | 25.58 | -, - | 6, 93 * | [24] | |

| 0.1 M | Ce–C–β–CD | 89 | 293, 60 | 7, - | [27] | |

| 0.1 M | CS/MWCNTs | 26.1 | 293, 60 | 5, - | [39] | |

| 0.1 M | CS/Ca–OMMT | 76 | -, - | 5, 94 * | [41] | |

| 0.25 M | AFMCS | 43 | 293, 60 | 8, 98 * (31 **) | [48] | |

| 0.05 M | Fe3O4/CS/PEI | 50.8 | 298, - | 5, 90 * | [66] | |

| NaCl | 0.05 M | EP | 52.1 | 293, 25 | 4, 95 * | [16] |

| 0.025 M | ZnCCSB | 67.50 | -, 30 | 5, - | [29] | |

| 0.025 M | CS/QCMGR | 159.48 | 298, 25 | 10, - | [59] | |

| CuSO4 | 0.06 M | Cu–CS/Fe3O4 | 88.78 | -, 120 | 5, 95 ** | [81] |

| Mixtures | - M NaOH and | CS–La–N–20% | 160 | 333, - | 7, - | [18] |

| - M NaCl | ||||||

| 0.1 M NaOH and | La–CS@PDA | 195.3 | -, 360 | 5, 96 * | [19] | |

| 0.3 M NaCl | ||||||

| 1 M NaOH and | TETA–MGO/CS | 353.36 | -, 480 | 6, 60 ** | [65] | |

| 1 M NaCl |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wujcicki, Ł.; Kluczka, J. Recovery of Phosphate(V) Ions from Water and Wastewater Using Chitosan-Based Sorbents Modified—A Literature Review. Int. J. Mol. Sci. 2023, 24, 12060. https://doi.org/10.3390/ijms241512060

Wujcicki Ł, Kluczka J. Recovery of Phosphate(V) Ions from Water and Wastewater Using Chitosan-Based Sorbents Modified—A Literature Review. International Journal of Molecular Sciences. 2023; 24(15):12060. https://doi.org/10.3390/ijms241512060

Chicago/Turabian StyleWujcicki, Łukasz, and Joanna Kluczka. 2023. "Recovery of Phosphate(V) Ions from Water and Wastewater Using Chitosan-Based Sorbents Modified—A Literature Review" International Journal of Molecular Sciences 24, no. 15: 12060. https://doi.org/10.3390/ijms241512060

APA StyleWujcicki, Ł., & Kluczka, J. (2023). Recovery of Phosphate(V) Ions from Water and Wastewater Using Chitosan-Based Sorbents Modified—A Literature Review. International Journal of Molecular Sciences, 24(15), 12060. https://doi.org/10.3390/ijms241512060