An Active Bio-Based Food Packaging Material of ZnO@Plant Polyphenols/Cellulose/Polyvinyl Alcohol: DESIGN, Characterization and Application

Abstract

:1. Introduction

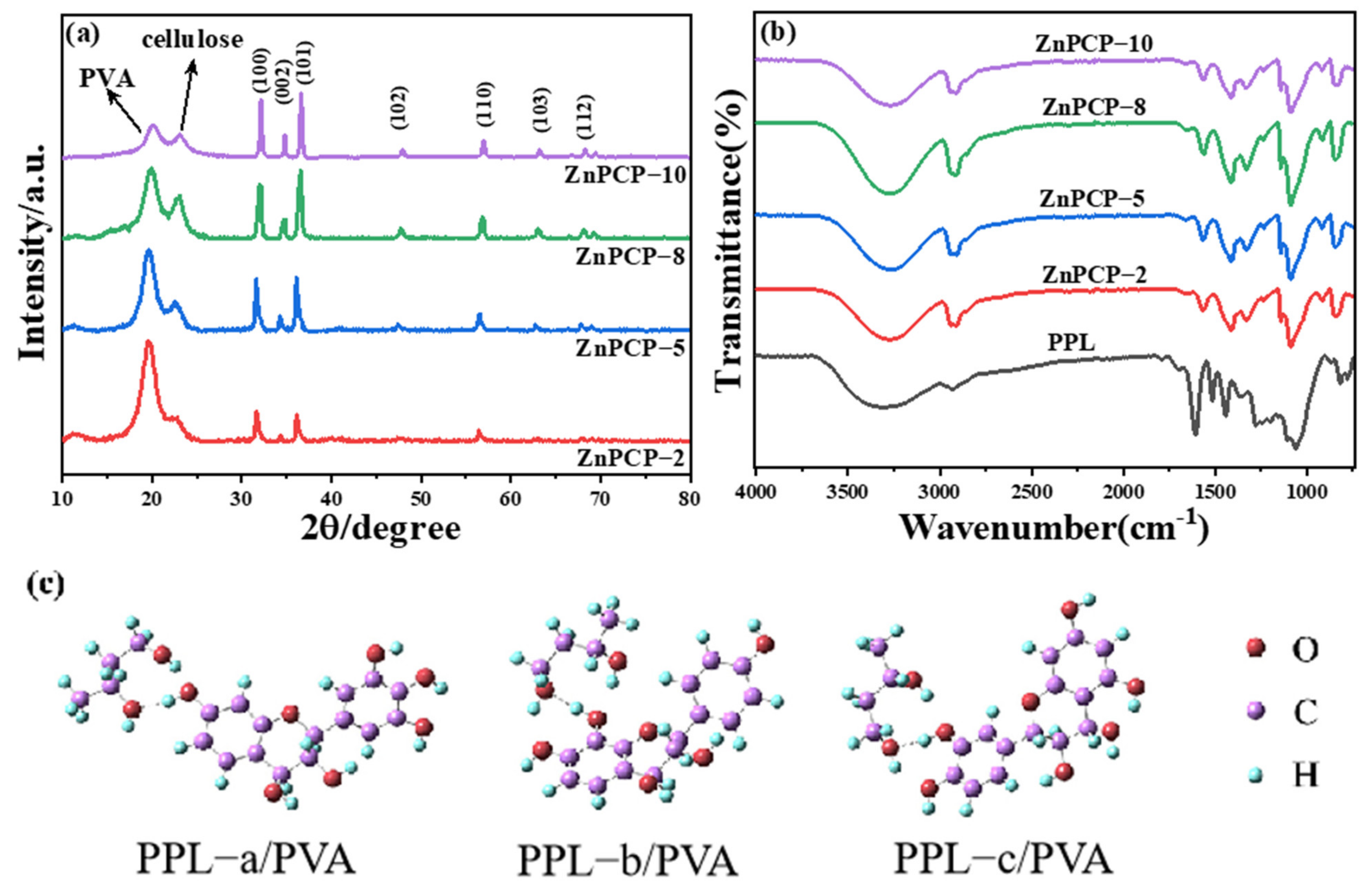

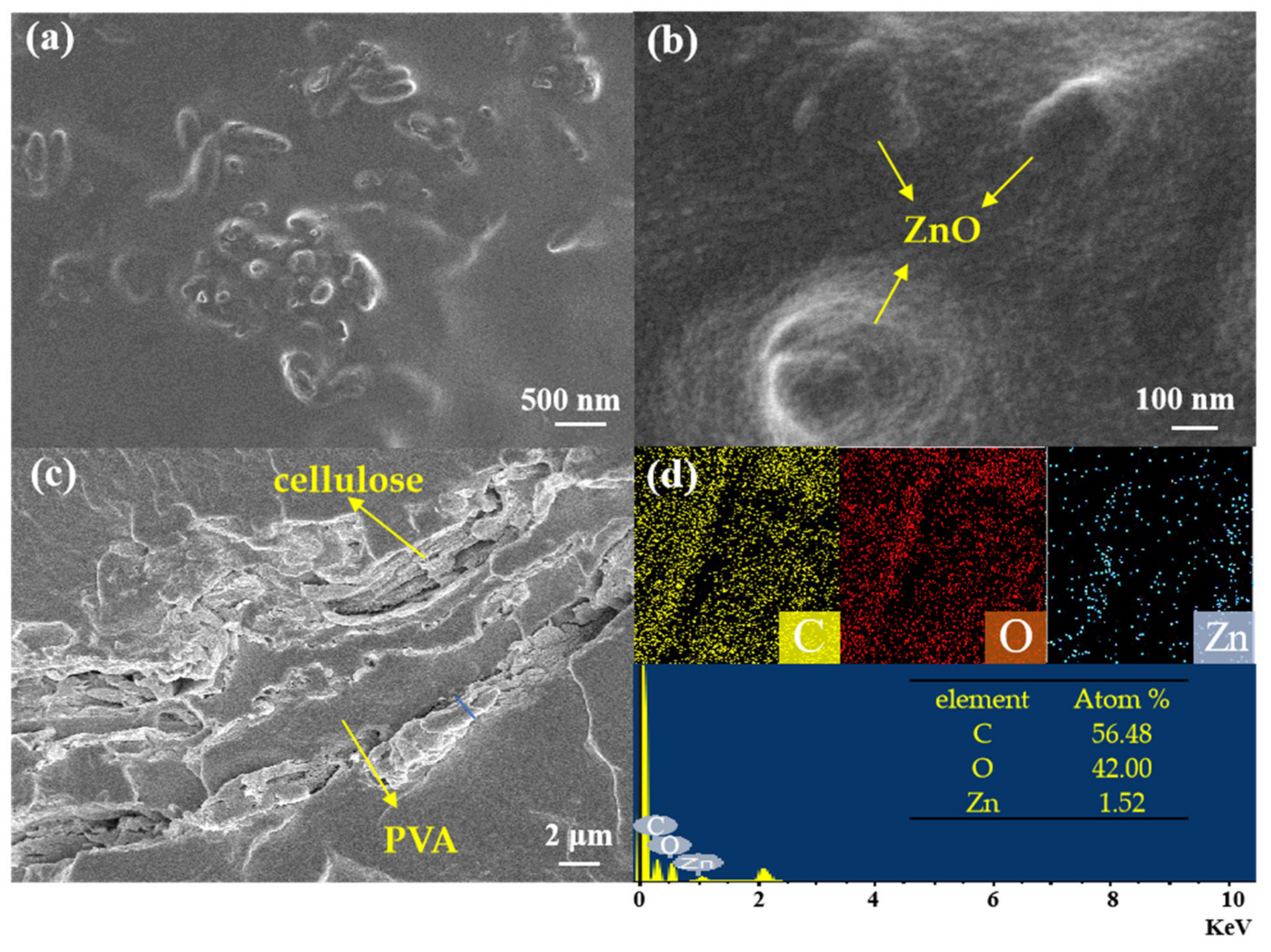

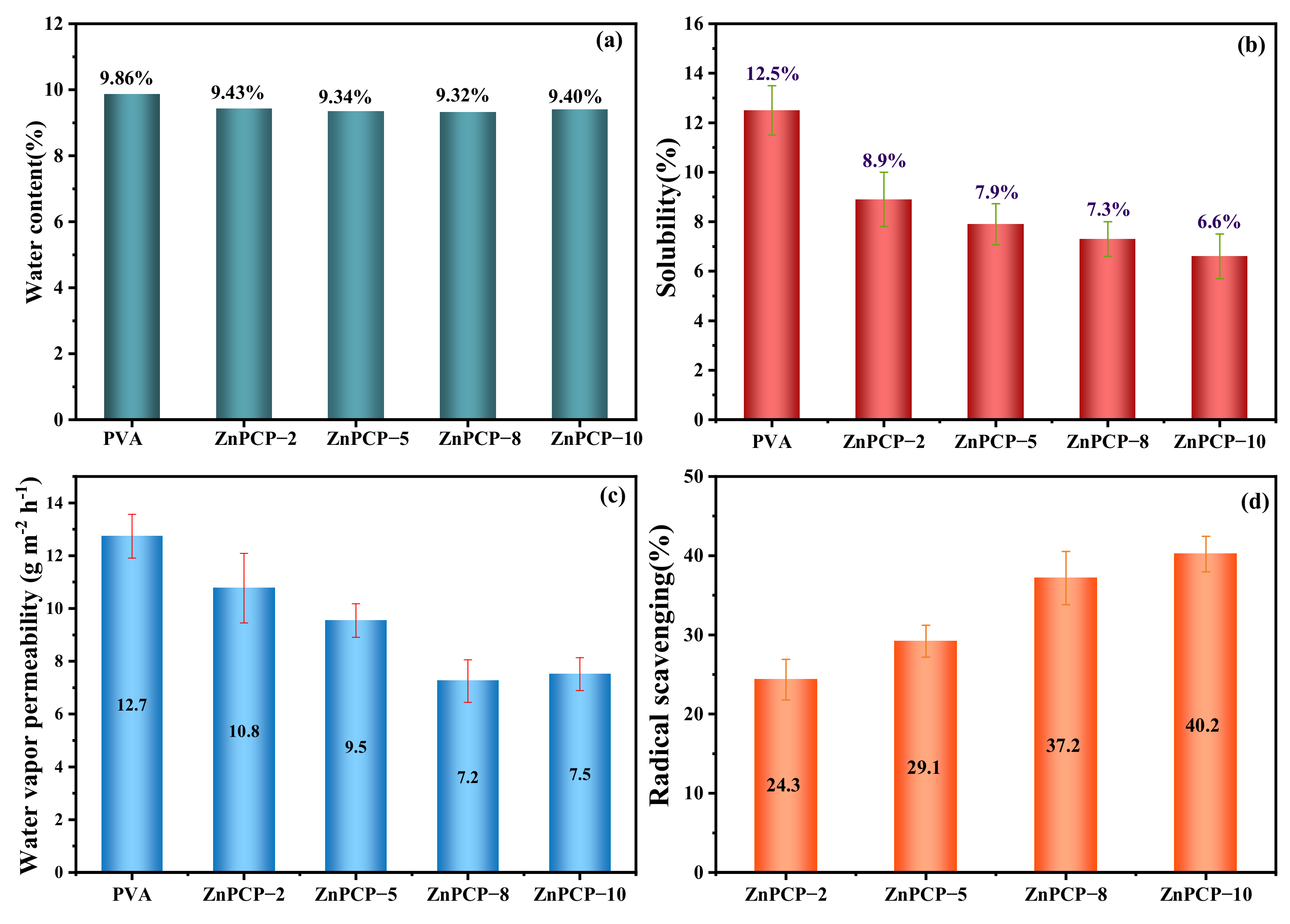

2. Results and Discussion

3. Materials and Methods

3.1. Chemical Reagents

3.2. Extraction of PPL

3.3. Preparation of the ZnO@PPL/Cellulose Composites

3.4. Preparation of the ZnPCP Films

3.5. Characterizations

3.6. Water Content Test

3.7. Water Solubility Test

3.8. Water Vapor Permeability (WVP)

3.9. Antioxidant Activity

3.10. Antibacterial Experiment and Inhibition Zone Method

3.11. Computational Details

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Akhter, R.; Masoodi, F.A.; Wani, T.A.; Rather, S.A. Functional characterization of biopolymer based composite film: Incorporation of natural essential oils and antimicrobial agents. Int. J. Biol. Macromol. 2019, 137, 1245–1255. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, F.V.; Dufresne, A.; Pinheiro, I.F.; Souza, D.H.S.; Gouveia, R.F.; Mei, L.H.I.; Lona, L.M.F. How do cellulose nanocrystals affect the overall properties of biodegradable polymer nanocomposites: A comprehensive review. Eur. Polym. J. 2018, 108, 274–285. [Google Scholar] [CrossRef]

- Elsabee, M.Z.; Abdou, E.S. Chitosan based edible films and coatings: A review. Mater. Sci. Eng. C Mater. Biol. Appl. 2013, 33, 1819–1841. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Rhim, J.W. Preparation of antimicrobial and antioxidant gelatin/curcumin composite films for active food packaging application. Colloids Surf. B Biointerfaces 2020, 188, 110761. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Chi, C. Development of pullulan/carboxylated cellulose nanocrystal/tea polyphenol bionanocomposite films for active food packaging. Int. J. Biol. Macromol. 2021, 186, 405–413. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.B.; Wang, J.J.; Cheng, Y.H.; Wang, C.S.; Liu, H.C.; Bian, H.G.; Pan, Y.R.; Sun, J.Y.; Han, W.W. Application of protein-based films and coatings for food packaging: A review. Polymers 2019, 11, 2039. [Google Scholar] [CrossRef] [Green Version]

- Nie, Y.; Luo, F.J.; Wang, L.; Yang, T.; Shi, L.M.; Li, X.H.; Shen, J.J.; Xu, W.; Guo, T.; Lin, Q.L. Anti-hyperlipidemic effect of rice bran polysaccharide and its potential mechanism in high-fat diet mice. Food Funct. 2017, 8, 4028–4041. [Google Scholar] [CrossRef]

- Myszka, K.; Leja, K.; Majcher, M. A current opinion on the antimicrobial importance of popular pepper essential oil and its application in food industry. J. Essent. Oil Res. 2019, 31, 1–18. [Google Scholar] [CrossRef]

- Quintavalla, S.; Vicini, L. Antimicrobial food packaging in meat industry. Meat Sci. 2002, 62, 373–380. [Google Scholar] [CrossRef]

- Han, J.H. Antimicrobial food packaging. Food Technol. 2000, 54, 56–65. [Google Scholar]

- Dominguez, R.; Barba, F.J.; Gomez, B.; Putnik, P.; Bursac Kovacevic, D.; Pateiro, M.; Santos, E.M.; Lorenzo, J.M. Active packaging films with natural antioxidants to be used in meat industry: A review. Food Res. Int. 2018, 113, 93–101. [Google Scholar] [CrossRef] [PubMed]

- Gaglio, R.; Botta, L.; Garofalo, G.; Miceli, A.; Settanni, L.; Lopresti, F. Carvacrol activated biopolymeric foam: An effective packaging system to control the development of spoilage and pathogenic bacteria on sliced pumpkin and melon. Food Packag. Shelf Life 2021, 28, 100633. [Google Scholar] [CrossRef]

- Ardjoum, N.; Chibani, N.; Shankar, S.; Fadhel, Y.B.; Djidjelli, H.; Lacroix, M. Development of antimicrobial films based on poly(lactic acid) incorporated with Thymus vulgaris essential oil and ethanolic extract of Mediterranean propolis. Int. J. Biol. Macromol. 2021, 185, 535–542. [Google Scholar] [CrossRef]

- Khanjanzadeh, H.; Park, B.D.; Pirayesh, H. Intelligent pH- and ammonia-sensitive indicator films using neutral red immobilized onto cellulose nanofibrils. Carbohydr. Polym. 2022, 296, 119910. [Google Scholar] [CrossRef]

- Masruchin, N.; Park, B.-D.; Lee, J.M. Surface modification of TEMPO-oxidized cellulose nanofibrils for composites to give color change in response to pH level. Cellulose 2018, 25, 7079–7090. [Google Scholar] [CrossRef]

- Khanjanzadeh, H.; Park, B.D. Covalent immobilization of bromocresol purple on cellulose nanocrystals for use in pH-responsive indicator films. Carbohydr. Polym. 2021, 273, 118550. [Google Scholar] [CrossRef] [PubMed]

- Elsheikh, A.H.; Panchal, H.; Shanmugan, S.; Muthuramalingam, T.; El-Kassas, A.M.; Ramesh, B. Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Clean. Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- El-Kassas, A.M.; Elsheikh, A.H. A new eco-friendly mechanical technique for production of rice straw fibers for medium density fiberboards manufacturing. Int. J. Environ. Sci. Technol. 2020, 18, 979–988. [Google Scholar] [CrossRef]

- Cushnie, T.P.; Lamb, A.J. Antimicrobial activity of flavonoids. Int. J. Antimicrob. Agents 2005, 26, 343–356. [Google Scholar] [CrossRef]

- Vilela, C.; Kurek, M.; Hayouka, Z.; Röcker, B.; Yildirim, S.; Antunes, M.D.C.; Nilsen-Nygaard, J.; Pettersen, M.K.; Freire, C.S.R. A concise guide to active agents for active food packaging. Trends Food Sci. Technol. 2018, 80, 212–222. [Google Scholar] [CrossRef]

- Pimentel-Moral, S.; Teixeira, M.C.; Fernandes, A.R.; Arraez-Roman, D.; Martinez-Ferez, A.; Segura-Carretero, A.; Souto, E.B. Lipid nanocarriers for the loading of polyphenols-A comprehensive review. Adv. Colloid Interface Sci. 2018, 260, 85–94. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Jian, Y.; Liu, Y.; Jiang, S.; Muhammad, D.; Wang, W. Flavanols from nature: A phytochemistry and biological activity review. Molecules 2022, 27, 719. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.M.; Chathuranga, K.; Lee, J.S.; Park, W.H. Effects of polyphenols on the thermal decomposition, antioxidative, and antimicrobial properties of poly(vinyl alcohol) and poly(vinyl pyrrolidone). Polym. Test. 2022, 116, 107786. [Google Scholar] [CrossRef]

- Bravo, L. Polyphenols: Chemistry, dietary sources, metabolism, and nutritional significance. Nutr. Rev. 1998, 56, 317–333. [Google Scholar] [CrossRef]

- Daglia, M. Polyphenols as antimicrobial agents. Curr. Opin. Biotechnol. 2012, 23, 174–181. [Google Scholar] [CrossRef]

- Wang, T.; Zhao, J.; Yang, Z.; Xiong, L.; Li, L.; Gu, Z.; Li, Y. Polyphenolic sunscreens for photoprotection. Green Chem. 2022, 24, 3605–3622. [Google Scholar] [CrossRef]

- Wu, X.; Li, M.; Xiao, Z.; Daglia, M.; Dragan, S.; Delmas, D.; Vong, C.T.; Wang, Y.; Zhao, Y.; Shen, J.; et al. Dietary polyphenols for managing cancers: What have we ignored? Trends Food Sci. Technol. 2020, 101, 150–164. [Google Scholar] [CrossRef]

- Minnelli, C.; Cianfruglia, L.; Laudadio, E.; Mobbili, G.; Galeazzi, R.; Armeni, T. Effect of epigallocatechin-3-gallate on EGFR signaling and migration in non-small cell lung cancer. Int. J. Mol. Sci. 2021, 22, 11833. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, L.; Xu, M.; Wang, H.; Gao, X.; Niu, B.; Li, W. Gallic acid functionalized chitosan immobilized nanosilver for modified chitosan/Poly (vinyl alcohol) composite film. Int. J. Biol. Macromol. 2022, 222, 2987–3000. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Z.; Shi, J.; Wang, C.; Ding, L.; Ding, X.; Teng, G.; Wu, J.; Zhang, J. Preparation and antibacterial properties of chitosan/polyvinyl alcohol nanofibrous mats using different organic acids as solvents. Process. Biochem. 2022, 122, 13–28. [Google Scholar] [CrossRef]

- Muiz, L.J.; Juwono, A.L.; Krisnandi, Y.K. A review: Silver–zinc oxide nanoparticles – organoclay-reinforced chitosan bionanocomposites for food packaging. Open Chem. 2022, 20, 1155–1170. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, C.; Pu, Y.; Chen, S.; Li, H.; Zhong, Y. Novel colorimetric films based on polyvinyl alcohol/sodium carboxymethyl cellulose doped with anthocyanins and betacyanins to monitor pork freshness. Food Chem. 2022, 404, 134426. [Google Scholar] [CrossRef]

- Lin, X.; Li, N.; Xiao, Q.; Guo, Y.; Wei, J.; Jiao, T.; Chen, Q.; Chen, Q.; Chen, X. Polyvinyl alcohol/starch-based film incorporated with grape skin anthocyanins and metal-organic framework crystals for colorimetric monitoring of pork freshness. Food Chem. 2022, 395, 133613. [Google Scholar] [CrossRef] [PubMed]

- Dai, H.; Huang, Y.; Huang, H. Enhanced performances of polyvinyl alcohol films by introducing tannic acid and pineapple peel-derived cellulose nanocrystals. Cellulose 2018, 25, 4623–4637. [Google Scholar] [CrossRef]

- Ge, W.; Cao, S.; Shen, F.; Wang, Y.; Ren, J.; Wang, X. Rapid self-healing, stretchable, moldable, antioxidant and antibacterial tannic acid-cellulose nanofibril composite hydrogels. Carbohydr. Polym. 2019, 224, 115147. [Google Scholar] [CrossRef]

- Zhao, S.W.; Guo, C.R.; Hu, Y.Z.; Guo, Y.R.; Pan, Q.J. The preparation and antibacterial activity of cellulose/ZnO composite: A review. Open Chem. 2018, 16, 9–20. [Google Scholar] [CrossRef]

- Prabu, A.S.; Chithambaram, V.; Shanmugan, S.; Cavaliere, P.; Gorjian, S.; Aissa, A.; Mourad, A.; Pardhasaradhi, P.; Muthucumaraswamy, R.; Essa, F.A.E.; et al. The performance enhancement of solar cooker integrated with photovoltaic module and evacuated tubes using ZnO/Acalypha Indica leaf extract: Response surface study analysis. Environ. Sci. Pollut. Res. Int. 2022. [Google Scholar] [CrossRef]

- Suresh, S.; Subash, B.; Karthikeyan, S. Electrical, optical and photocatalytic properties of Ti-loaded ZnO/ZnO and Ti-loaded ZnO nanospheres. J. Iran. Chem. Soc. 2017, 14, 1591–1600. [Google Scholar] [CrossRef]

- Petkova, P.; Francesko, A.; Fernandes, M.M.; Mendoza, E.; Perelshtein, I.; Gedanken, A.; Tzanov, T. Sonochemical coating of textiles with hybrid ZnO/chitosan antimicrobial nanoparticles. ACS Appl. Mater. Interfaces 2014, 6, 1164–1172. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Wang, Y.; Ma, J.; Peng, Y.; Wang, A. A review on bidirectional analogies between the photocatalysis and antibacterial properties of ZnO. J. Alloy. Compd. 2019, 783, 898–918. [Google Scholar] [CrossRef]

- Xu, J.; Huang, Y.; Zhu, S.; Abbes, N.; Jing, X.; Zhang, L. A review of the green synthesis of ZnO nanoparticles using plant extracts and their prospects for application in antibacterial textiles. J. Eng. Fibers Fabr. 2021, 16, 15589250211046242. [Google Scholar] [CrossRef]

- Nie, J.; Wu, Z.; Pang, B.; Guo, Y.; Li, S.; Pan, Q. Fabrication of ZnO@plant polyphenols/cellulose as active food packaging and its enhanced antibacterial activity. Int. J. Mol. Sci. 2022, 23, 5218. [Google Scholar] [CrossRef] [PubMed]

- Pang, B.; Wu, Z.Y.; Wang, Z.B.; You, B.Q.; Guo, Y.R.; Li, S.j.; Pan, Q.J. Design of a ZnO@plant polyphenol/poly(vinyl alcohol) film via plant polyphenol-induced cross-linking and its enhanced UV shielding and antibacterial performance. ACS Sustain. Chem. Eng. 2022, 10, 9369–9380. [Google Scholar] [CrossRef]

- Zhao, N.-D.; Wang, Y.; Zou, X.-H.; Yin, W.-M.; Wang, X.-Y.; Guo, Y.-R.; Pan, Q.-J. Fabrication of cellulose@Mg(OH)2 composite filter via interfacial bonding and its trapping effect for heavy metal ions. Chem. Eng. J. 2021, 426, 130812. [Google Scholar] [CrossRef]

- Wang, X.Y.; Wang, Y.; Zhao, N.D.; Zheng, M.; Guo, Y.R.; Pan, Q.J. Van der Waals enhanced interfacial interaction in cellulose/zinc oxide nanocomposite coupled by graphitic carbon nitride. Carbohydr. Polym. 2021, 268, 118235. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.; Hou, Y.C.; Song, D.; Yin, W.M.; Chen, X.Y.; Wang, C.; Guo, Y.R.; Li, L.; Pan, Q.J. Interfacial coupling enhanced photocatalytic activity: An experimental/DFT combined study of porous graphitic carbon nitride/carbon composite material. Cellulose 2022, 29, 3759–3772. [Google Scholar] [CrossRef]

- Sun, Y.; Yin, W.-M.; Wang, Y.; Zhao, N.-D.; Wang, X.-Y.; Zhang, J.-G.; Guo, Y.-R.; Li, S.; Pan, Q.-J. Fabrication of ultra-thin MgAl layered double oxide by cellulose templating and its immobilization effect toward heavy metal ions: Cation-exchange and deposition mechanism. Chem. Eng. J. 2022, 427, 132017. [Google Scholar] [CrossRef]

- Yu, B.; Zhang, Z.; Liu, W.; Liu, F.; Huang, J.; Na, H.; Zhu, J. Hydroxyl-enriched core/shell carbon nanotubes for catalytic hydrolysis of regenerated cellulose to glucose. ACS Appl. Nano Mater. 2022, 5, 5364–5372. [Google Scholar] [CrossRef]

- Eleutério, T.; Sério, S.; Teodoro, O.M.N.D.; Bundaleski, N.; Vasconcelos, H.C. XPS and FTIR studies of DC reactive magnetron sputtered TiO2 thin films on naturalbased-cellulose fibers. Coatings 2020, 10, 287. [Google Scholar] [CrossRef] [Green Version]

- Pereira, P.H.F.; Voorwald, H.J.C.; Cioffi, M.O.H.; Da Silva, M.L.C.P.; Rego, A.M.B.; Ferraria, A.M.; De Pinho, M.N. Sugarcane bagasse cellulose fibres and their hydrous niobium phosphate composites: Synthesis and characterization by XPS, XRD and SEM. Cellulose 2013, 21, 641–652. [Google Scholar] [CrossRef]

- Yang, S.Y.; Liu, Y.; Mao, J.; Wu, Y.B.; Deng, Y.L.; Qi, S.C.; Zhou, Y.C.; Gong, S.Q. The antibiofilm and collagen-stabilizing effects of proanthocyanidin as an auxiliary endodontic irrigant. Int. Endod. J. 2020, 53, 824–833. [Google Scholar] [CrossRef]

- Elsheikh, A. Bistable morphing composites for energy-harvesting applications. Polymers 2022, 14, 1893. [Google Scholar] [CrossRef]

- Jablonska, J.; Onyszko, M.; Konopacki, M.; Augustyniak, A.; Rakoczy, R.; Mijowska, E. Fabrication of paper sheets coatings based on chitosan/bacterial nanocellulose/ZnO with enhanced antibacterial and mechanical properties. Int. J. Mol. Sci. 2021, 22, 7383. [Google Scholar] [CrossRef]

- Supramaniam, J.; Low, D.Y.S.; Wong, S.K.; Tan, L.T.H.; Leo, B.F.; Goh, B.H.; Darji, D.; Mohd Rasdi, F.R.; Chan, K.G.; Lee, L.H.; et al. Facile synthesis and characterization of palm CNF-ZnO nanocomposites with antibacterial and reinforcing properties. Int. J. Mol. Sci. 2021, 22, 5781. [Google Scholar] [CrossRef]

- Hosseini, S.F.; Rezaei, M.; Zandi, M.; Farahmandghavi, F. Development of bioactive fish gelatin/chitosan nanoparticles composite films with antimicrobial properties. Food Chem. 2016, 194, 1266–1274. [Google Scholar] [CrossRef]

- Zheng, M.; Chen, J.; Tan, K.B.; Chen, M.; Zhu, Y. Development of hydroxypropyl methylcellulose film with xanthan gum and its application as an excellent food packaging bio-material in enhancing the shelf life of banana. Food Chem. 2022, 374, 131794. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, X.; Huang, Y.; Li, H.; Chen, L.; Liu, X. Two colorimetric films based on chitin whiskers and sodium alginate/gelatin incorporated with anthocyanins for monitoring food freshness. Food Hydrocoll. 2022, 127, 107517. [Google Scholar] [CrossRef]

- Miglioranza, B.M.G.; Spinelli, F.R.; Stoffel, F.; Piemolini-Barreto, L.T. Biodegradable film for raisins packaging application: Evaluation of physico-chemical characteristics and antioxidant potential. Food Chem. 2021, 365, 130538. [Google Scholar] [CrossRef]

- Klamt, A.; Schüürmann, G. COSMO: A new approach to dielectric screening in solvents with explicit expressions for the screening energy and its gradient. J. Chem. Soc. Perkin Trans. 2 1993, 799–805. [Google Scholar] [CrossRef]

- Tanwar, R.; Gupta, V.; Kumar, P.; Kumar, A.; Singh, S.; Gaikwad, K.K. Development and characterization of PVA-starch incorporated with coconut shell extract and sepiolite clay as an antioxidant film for active food packaging applications. Int. J. Biol. Macromol. 2021, 185, 451–461. [Google Scholar] [CrossRef] [PubMed]

- Laikov, D.N.; Ustynyuk, Y.A. PRIRODA-04: A quantum-chemical program suite. New possibilities in the study of molecular systems with the application of parallel computing. Russ. Chem. Bull. 2005, 54, 820–826. [Google Scholar] [CrossRef]

- Velde, G.T.; Bickelhaupt, F.M.; Baerends, E.J.; Fonseca Guerra, C.; van Gisbergen, S.J.A.; Snijders, J.G.; Ziegler, T. Chemistry with ADF. J. Comput. Chem. 2001, 22, 931–967. [Google Scholar] [CrossRef]

| Sample | Tensile Strength (Mpa) | Elongation at Break (%) | Young’s Modulus (Mpa) |

|---|---|---|---|

| PVA film | 56.8 ± 4.9 | 104.5 ± 16.3 | 484.3 ± 97.4 |

| ZnPCP−2 film | 30.7 ± 1.5 | 29.5 ± 8.3 | 549.3 ± 75.1 |

| ZnPCP−5 film | 31.3 ± 1.4 | 19.4 ± 4.5 | 649.9 ± 101.1 |

| ZnPCP−8 film | 32.0 ± 1.8 | 13.8 ± 0.1 | 675.9 ± 89.3 |

| ZnPCP−10 film | 32.5 ± 0.9 | 10.7 ± 0.7 | 702.8 ± 45.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, D.; Ma, L.-W.; Pang, B.; An, R.; Nie, J.-H.; Guo, Y.-R.; Li, S. An Active Bio-Based Food Packaging Material of ZnO@Plant Polyphenols/Cellulose/Polyvinyl Alcohol: DESIGN, Characterization and Application. Int. J. Mol. Sci. 2023, 24, 1577. https://doi.org/10.3390/ijms24021577

Song D, Ma L-W, Pang B, An R, Nie J-H, Guo Y-R, Li S. An Active Bio-Based Food Packaging Material of ZnO@Plant Polyphenols/Cellulose/Polyvinyl Alcohol: DESIGN, Characterization and Application. International Journal of Molecular Sciences. 2023; 24(2):1577. https://doi.org/10.3390/ijms24021577

Chicago/Turabian StyleSong, Da, Li-Wei Ma, Bo Pang, Ran An, Jing-Heng Nie, Yuan-Ru Guo, and Shujun Li. 2023. "An Active Bio-Based Food Packaging Material of ZnO@Plant Polyphenols/Cellulose/Polyvinyl Alcohol: DESIGN, Characterization and Application" International Journal of Molecular Sciences 24, no. 2: 1577. https://doi.org/10.3390/ijms24021577