The Cracking Behavior of Two Dental Composite Materials Validated through Multifractal Analyzes

Abstract

1. Introduction

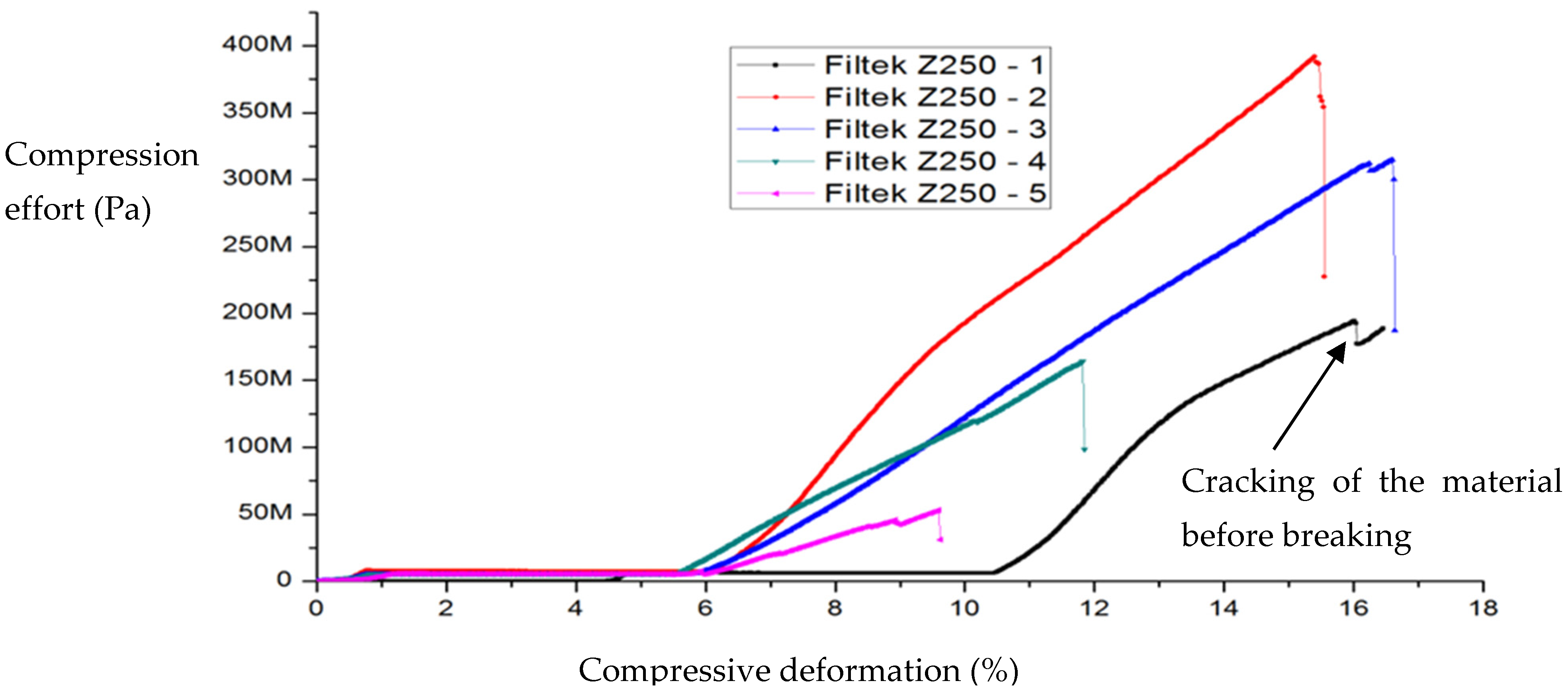

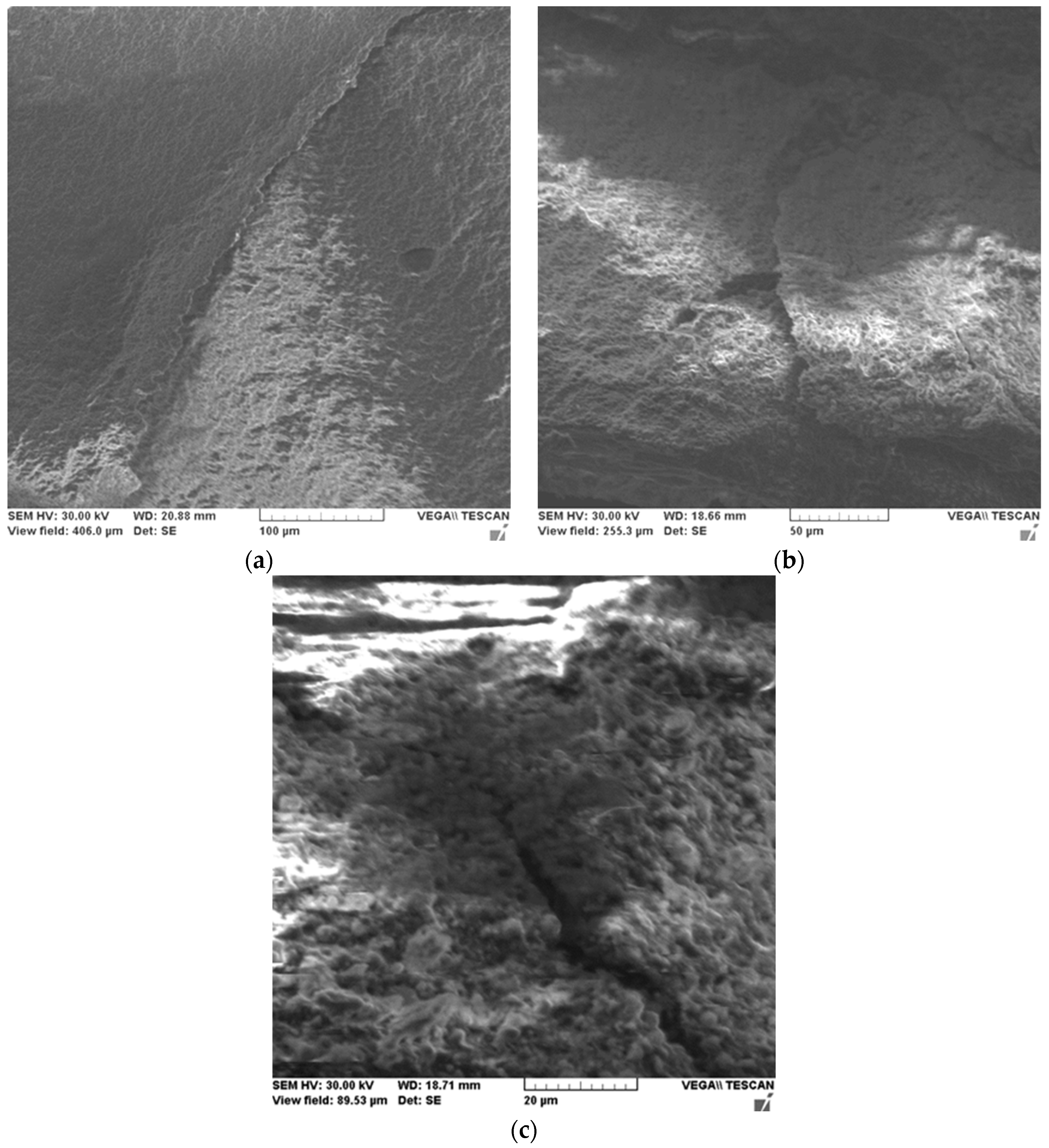

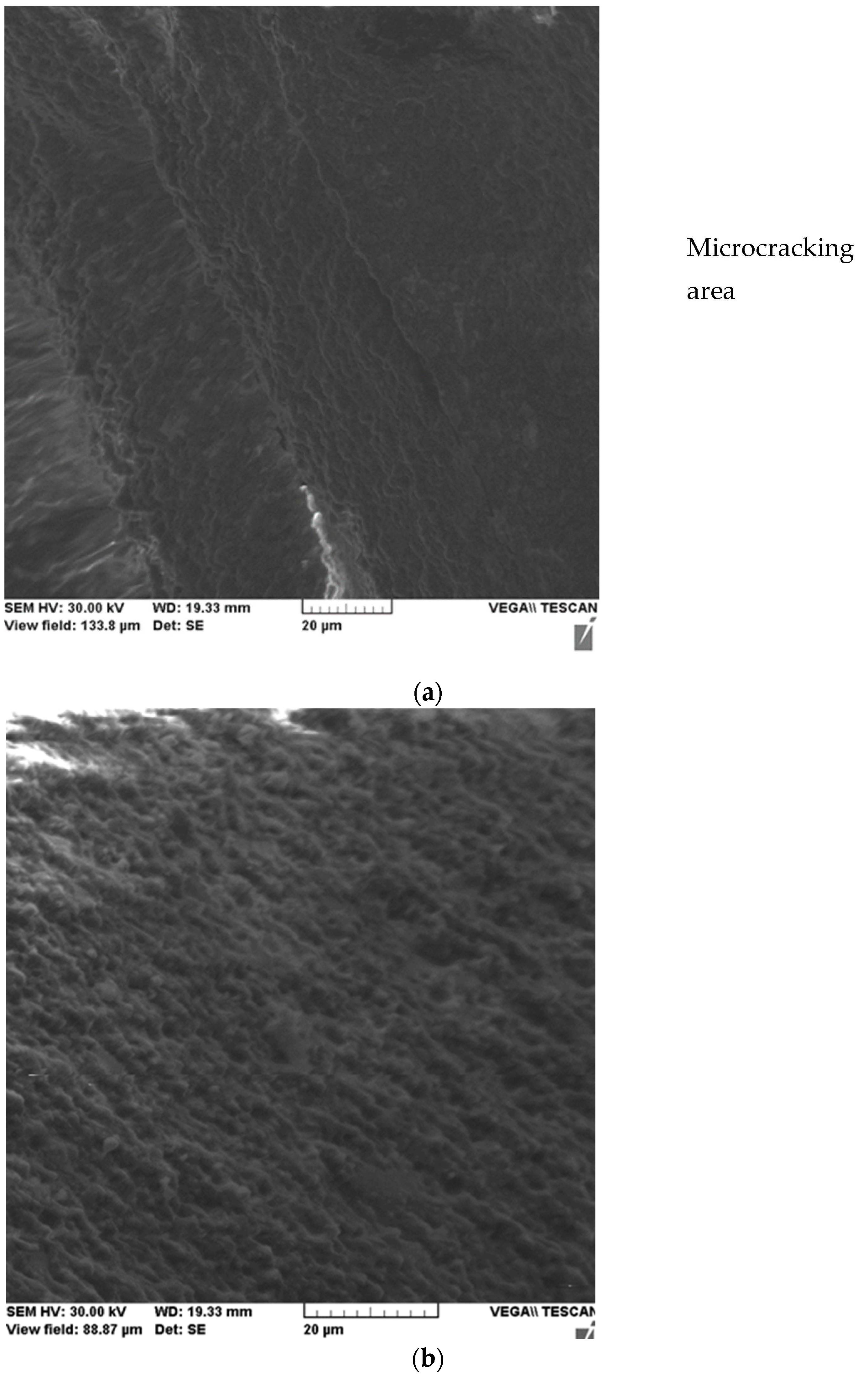

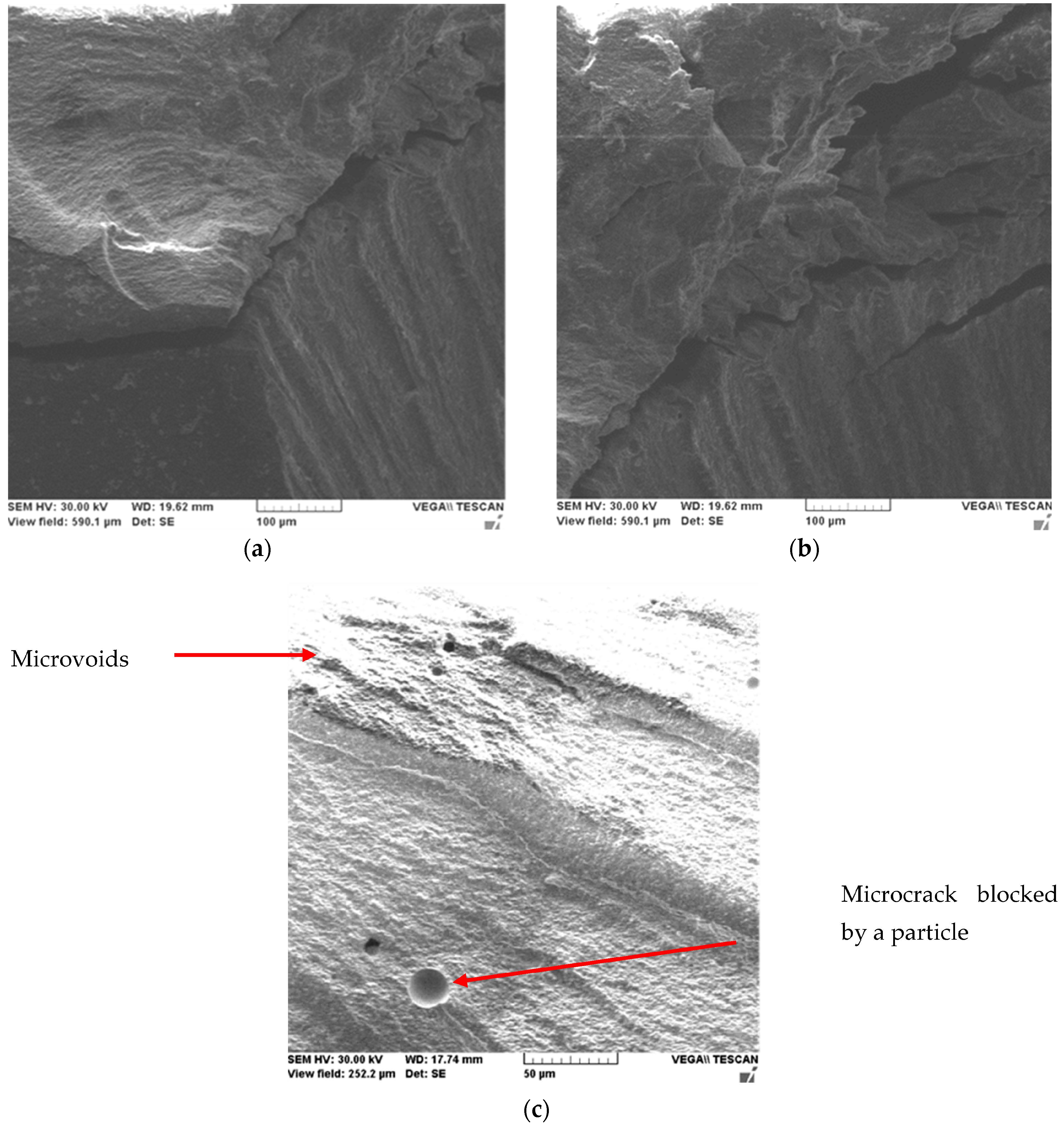

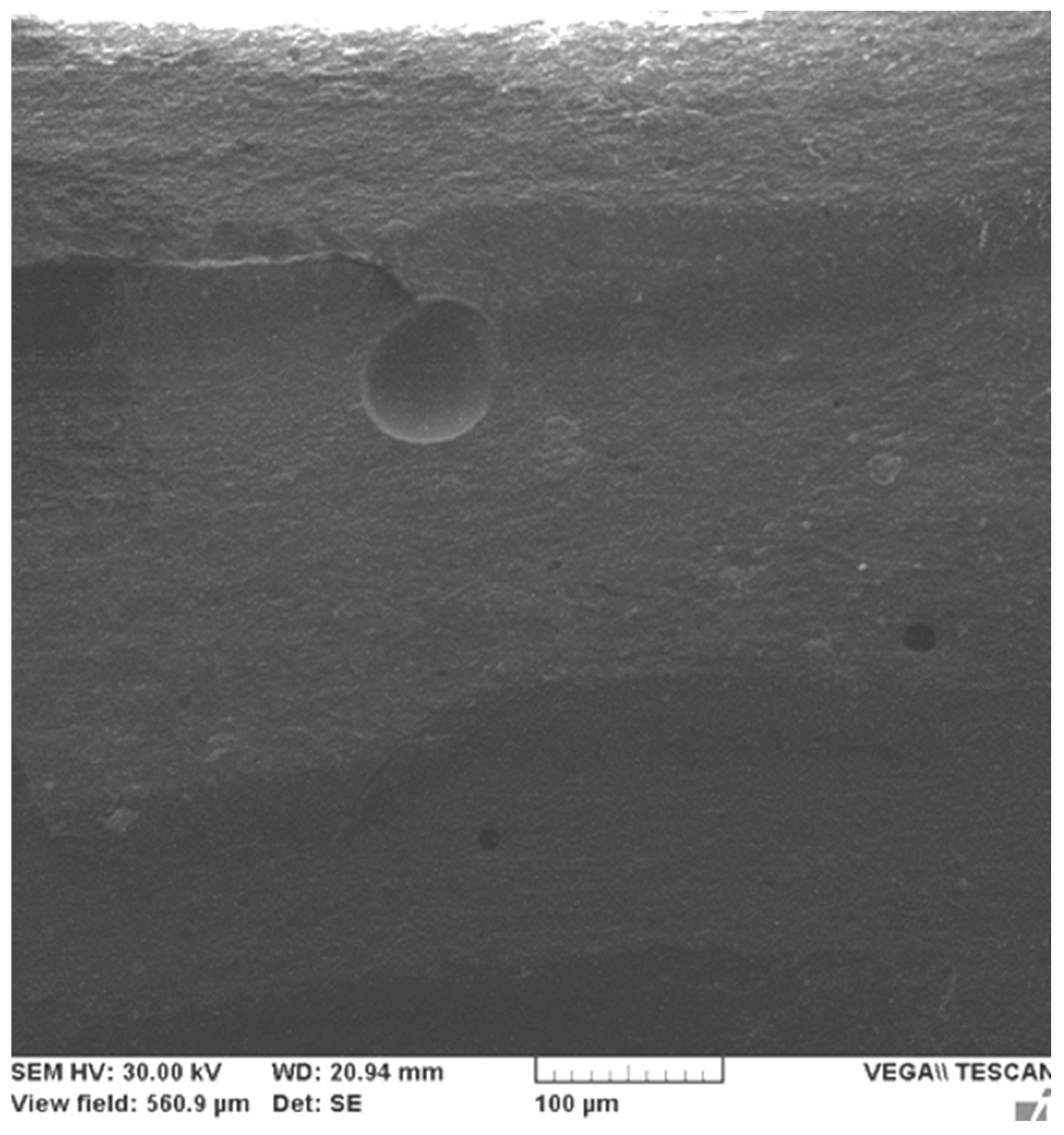

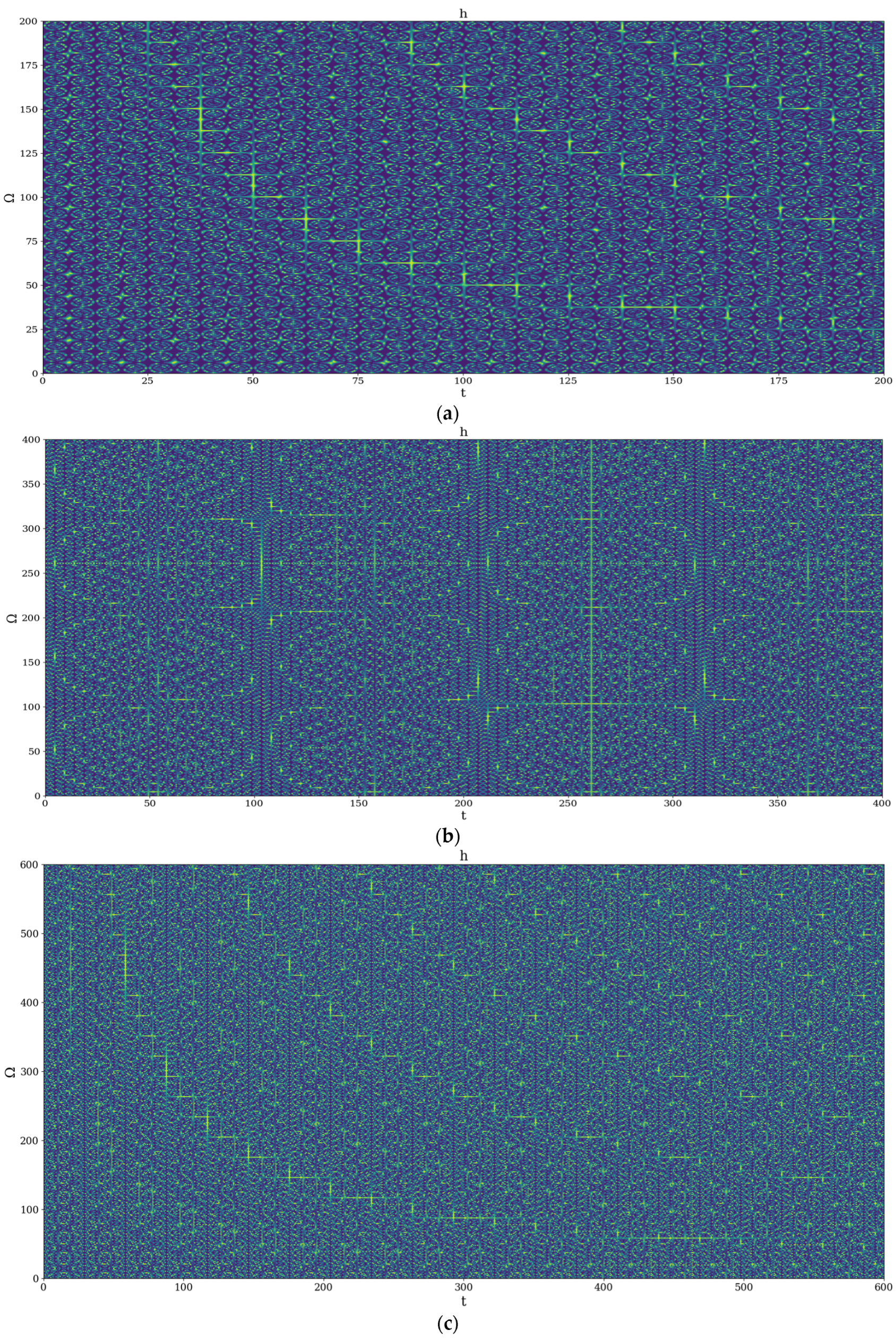

2. Results

3. Discussion

3.1. Analysis of the Experimental Data

3.2. Theoretical Design Considerations

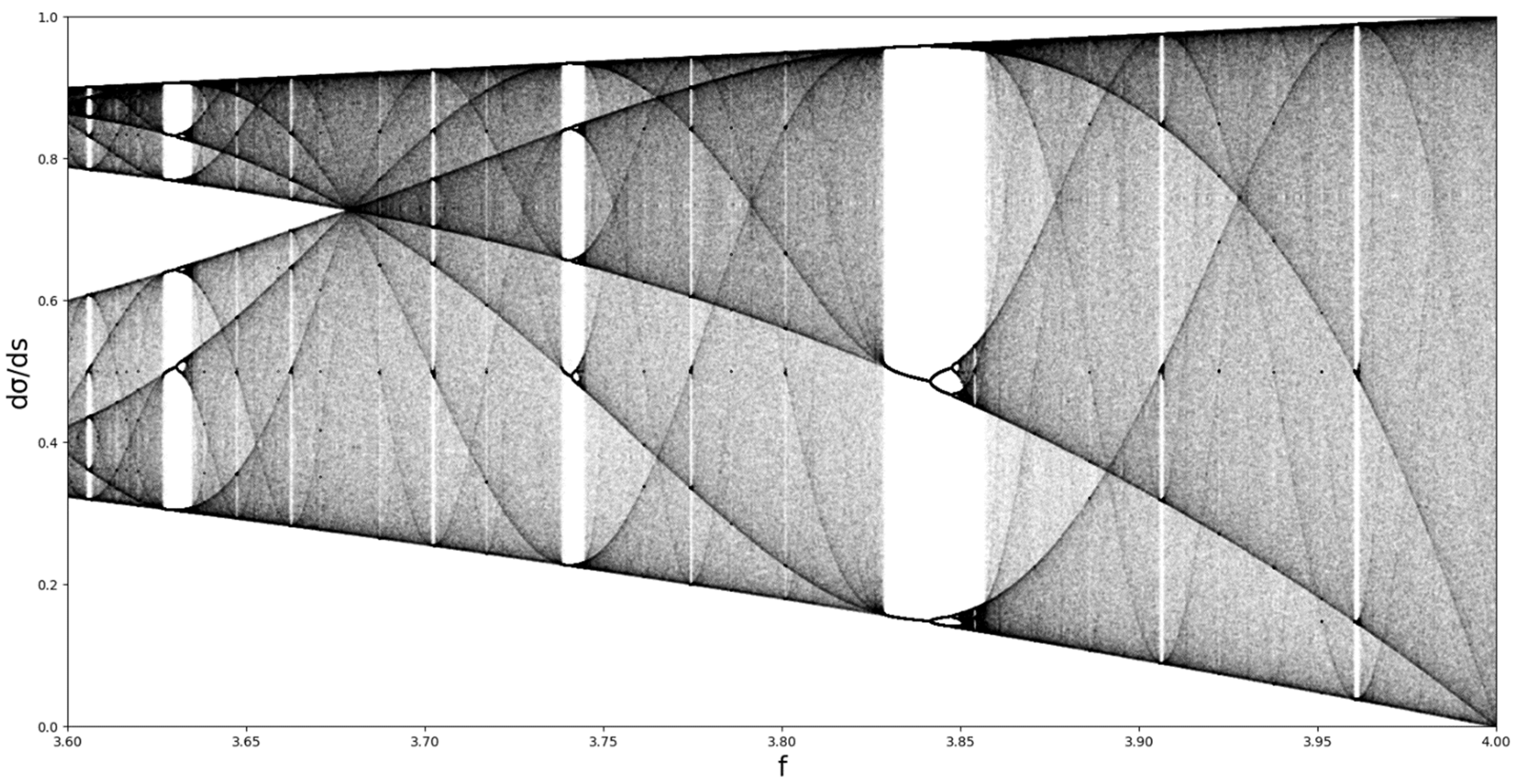

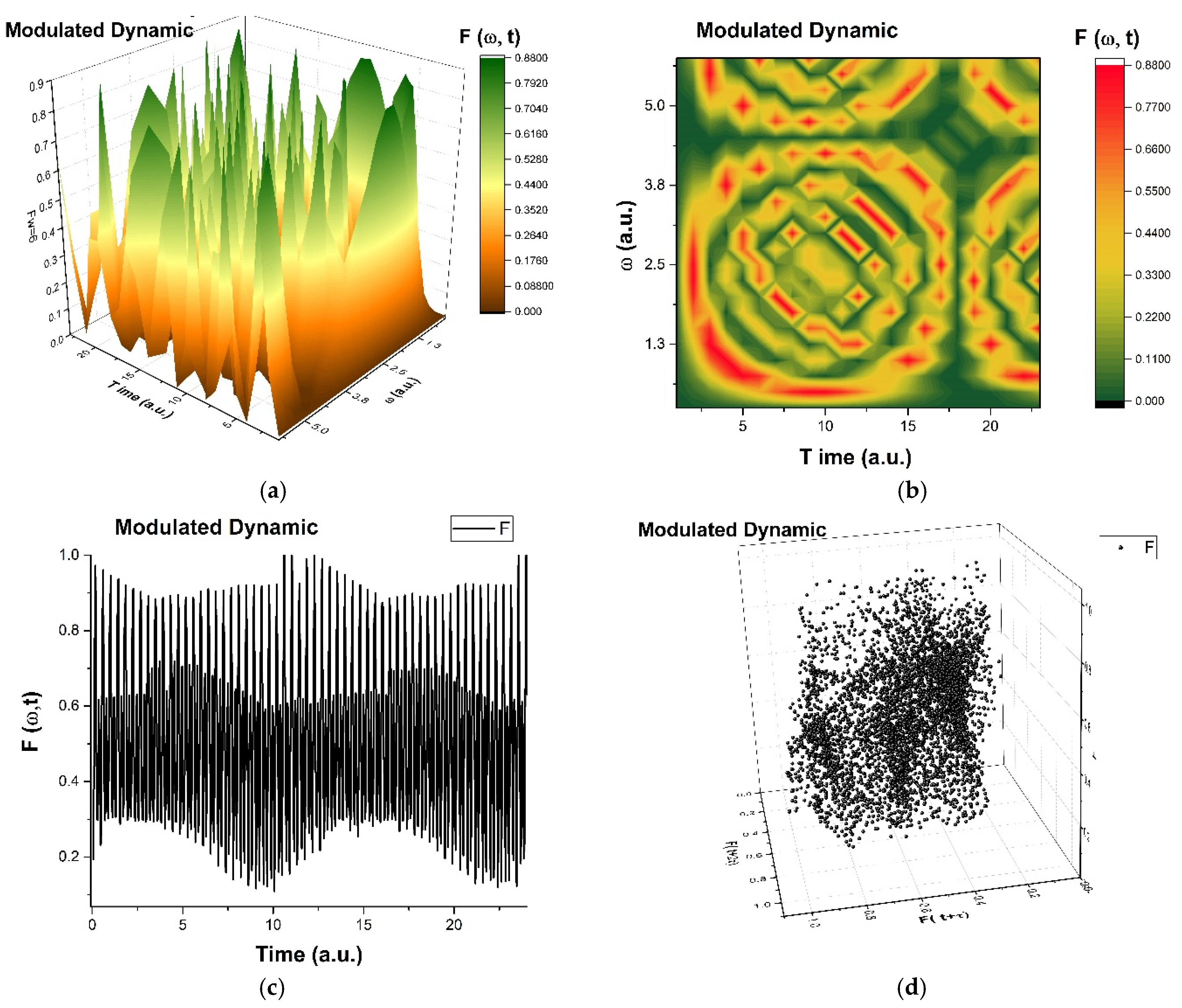

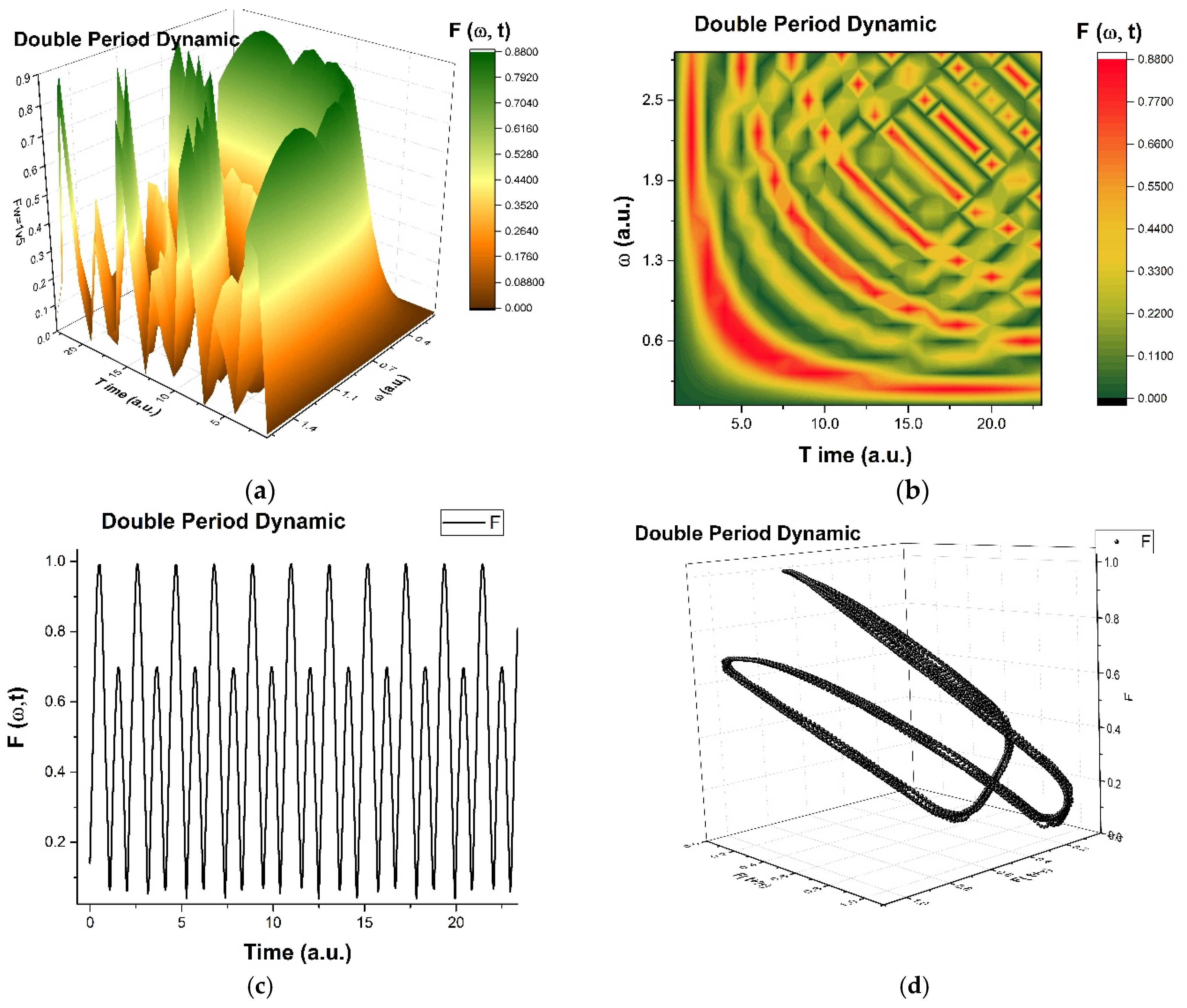

3.2.1. Types of Scenarios in the Description of Dental Composite Materials Dynamics

- Any dental composite materials structural units are in permanent contact with a multifractal medium through the multifractal specific force;

- The multifractal medium can be assimilated with a multifractal fluid whose dynamics are characterized by the multifractal hydrodynamic equation system;

- The velocity field is absent from the multifractal states density conservation laws. In such a context, it induces non-manifest dental composite materials dynamics facilitating the transmission of multifractal specific momentum and multifractal energy of focus;

- In dental composite materials dynamics, the ”self-aspect” of the multifractal specific momentum, transfer the reversibility, and existence of eigenstates are guaranteed by the conservation of multifractal energy and multifractal momentum. Using the tensor:

3.2.2. Material Constitutive Laws

4. Materials and Methods

Experimental Design

- ○

- load capacity of 100 kN with a maximum speed of 500 mm/min, minimum speed of 5 × 10−3 mm/min;

- ○

- maximum force at maximum speed: 50 kN;

- ○

- maximum speed at maximum force: 250 mm/min;

- ○

- return speed: 600 mm/min;

- ○

- Blue hill® Lite software;

- ○

- INSTRON climatic enclosure with a possible temperature range of −70 °C to +350 °C;

- ○

- INSTRON 3-point bending device, 100kN, and a compression device.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SRT | Scale Relativity Theory |

| Bis-GMA | bisphenol A-glycidyl methacrylate |

| bis-EMA | bisphenol A-ethoxylateddimethacrylate |

| TEGDMA | triethyleneglycoldimethacrylate |

| UDMA | urethane dimethacrylate, |

References

- Miletic, V. Dental Composite Materials for Direct Restorations; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Brenna, F. Restorative Dentistry: Treatment Procedures and Future Prospects; Elsevier/Saunders: St. Louis, MO, USA, 2012. [Google Scholar]

- Mitchell, M. Complexity: A Guided Tour; Oxford University Press: Oxford, UK, 2009. [Google Scholar]

- Badii, R. Complexity: Hierarchial Structures and Scaling in Physics; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Bar-Yam, Y. Dynamics of Complex Systems; The Advanced Book Program; Addison-Wesley: Reading, MA, USA, 1997. [Google Scholar]

- Nottale, L. Scale Relativity and Fractal Space-Time: A New Approach to Unifying Relativity and Quantum Mechanics; Imperial College Press: London, UK, 2011. [Google Scholar]

- Merches, I.; Agop, M. Differentiability and Fractality in Dynamics of Physical Systems; World Scientific: Hackensack, NJ, USA, 2016. [Google Scholar]

- Agop, M.; Paun, V.-P. On the New Perspectives of Fractal Theory. Fundaments and Applications; Romanian Academy Publishing House: Bucharest, Romania, 2017. [Google Scholar]

- Moezzyzadeh, M. Evaluation of the compressive strength of hybrid and nanocomposites. J. Dent. Sch. 2012, 1, 24–29. [Google Scholar]

- Mohandesi, J.A.; Rafiee, M.A.; Barzegaran, V. Compressive fatigue behavior of dental restorative composites. Dent. Mater. J. 2007, 26, 827–837. [Google Scholar] [CrossRef] [PubMed]

- Pradeep, K.; Ginjupalli, K.; Kuttappa, M.A.; Kudva, A.; Butula, R. In vitro Comparison of Compressive Strength of Bulk-fill Composites and Nanohybrid Composite. World J. Dent. 2016, 7, 119–122. [Google Scholar] [CrossRef]

- Gamen, A.; Iovan, G.; Stoleriu, S.; Pancu, G.; Nica, I.; Georgescu, A.; Taraboanta, I.; Andrian, S. Evaluation of Mechanical Parameters at Compression Test for Different Restorative Composite Resins. Mater. Plast. 2019, 56, 592–595. [Google Scholar] [CrossRef]

- Rakhee, R.; Jayasree, S.; Ramesh, K.; Prashant, B.; Rajeesh, M.K.; Abdu Semeer, P. Comparative Evaluation of Compressive And Flexural Strength of Newer Nanocomposite Materials with Conventional Hybrid Composites-An Invitro Study. IOSR-JDMS 2017, 16, 65–69. [Google Scholar]

- Meenakumari, C.; Manohar Bhat, K.; Bansal, R.; Singh, N. Evaluation of Mechanical Properties of Newer Nanoposterior Restorative Resin Composites: An In vitro Study. Contemp. Clin. Dent. 2018, 9, 142–146. [Google Scholar] [CrossRef] [PubMed]

- Stoleriu, S.; Andrian, S.; Nica, I.; Sandu, A.V.; Pancu, G.; Murariu, A.; Iovan, G. Evaluation of Adhesive Capacity of Universal Bonding Agents Used in Direct Composite Resins Repair. Mater. Plast. 2017, 54, 574. [Google Scholar] [CrossRef]

- Ghiorghe, C.A.; Iovan, G.; Topoliceanu, C.; Sandu, A.V.; Andrian, S. Comparative Study Regarding the Colorimetric Changes of Two Composite Resins after Immersion in Several Beverages and One Antibacterial Mouthwash. Rev. Chem. 2013, 64, 1436–1440. [Google Scholar]

- Jackson, E.A. Perspectives of Nonlinear Dynamics; Cambridge University Press: New York, NY, USA, 1993; Volume 1–2. [Google Scholar]

- Cristescu, C.P. Nonlinear Dynamics and Chaos. Theoretical Fundaments and Applications; Romanian Academy Publishing House: Bucharest, Romania, 2008. [Google Scholar]

- Mandelbrot, B.B. The Fractal Geometry of Nature; W.H. Freeman and Company: San Francisco, CA, USA, 1982. [Google Scholar]

- Mazilu, N.; Agop, M. At the Crossroads of Theories. Between Newton and Einstein—The Barbilian Universe; ArsLonga Publishing House: Iasi, Romania, 2010. (In Romanian) [Google Scholar]

- Mazilu, N.; Agop, M. Skyrmions: A Great Finishing Touch to Classical Newtonian Philosophy, World Philosophy Series; Nova: New York, NY, USA, 2012. [Google Scholar]

- Plăcintă, C.; Stanciu, S.; Panainte-Lehadus, M.; Mosnegutu, E.; Nedeff, F.; Nedeff, V.; Tomozei, C.; Petrescu, T.-C.; Agop, M. Theoretical and Experimental Designs on Several Mechanical Properties of Cu–Al–Zn Shape Memory Alloys Used in the Processing Industry. Materials 2023, 16, 1441. [Google Scholar] [CrossRef] [PubMed]

- Schauperl, Z.; Ivankovi’c, L.; Bauer, L.; Šolić, S.; Ivankovic, M. Effects of Different Surface Treatments of Woven Glass Fibers on Mechanical Properties of an Acrylic Denture Base Material. Int. J. Mol. Sci. 2023, 24, 909. [Google Scholar] [CrossRef] [PubMed]

- Beketova, A.; Tzanakakis, E.G.C.; Vouvoudi, E.; Anastasiadis, K.; Rigos, A.E.; Pandoleon, P.; Bikiaris, D.; Tzoutzas, I.G.; Kontonasaki, E. Zirconia Nanoparticles as Reinforcing Agents for Contemporary Dental Luting Cements: Physicochemical Properties and Shear Bond Strength to Monolithic Zirconia. Int. J. Mol. Sci. 2023, 24, 2067. [Google Scholar] [CrossRef] [PubMed]

| No. crt. | Sample | Ultimate Compressive Strain (%) | Ultimate Compressive Strength (MPa) |

|---|---|---|---|

| 1 | Filtek Supreme XT-1 | 10.45 | 82 |

| 2 | Filtek Supreme XT-2 | 11.18 | 97.41 |

| 3 | Filtek Supreme XT-3 | 15.79 | 333.12 |

| 4 | Filtek Supreme XT-4 | 13.61 | 205.19 |

| 5 | Filtek Supreme XT-5 | 12.66 | 177.18 |

| 6 | Filtek Supreme XT-6 | 14.35 | 172.83 |

| 7 | Filtek Supreme XT-7 | 10.55 | 213.81 |

| 8 | Filtek Z250-1 | 16.45 | 194.58 |

| 9 | Filtek Z250-2 | 15.54 | 392 |

| 10 | Filtek Z250-3 | 16.63 | 314.72 |

| 11 | Filtek Z250-4 | 11.84 | 164.39 |

| 12 | Filtek Z250-5 | 9.62 | 53.08 |

| Material | Manufacturer | Type/Shade | Matrix | Filler |

|---|---|---|---|---|

| Filtek Supreme XT Universal Restorative | 3MESPE, St. Paul, MN, USA | Nanocomposite/A2 | Bis-GMA, Bis-EMA, TEGDMA UDMA | Non-agglomerated/non-aggregated 20 nm silica particles, Non-agglomerated/non-aggregated 4 to 11 nm zirconia particles, Aggregated zirconia/silica cluster filler (comprised of 20 nm silica and 4 to 11 nm zirconia particles) 78.5 wt % 63.3 vol% |

| Filtek Z250 Universal Restorative | 3MESPE, St. Paul, MN, USA | Microhybrid/A2 | Bis-GMA, Bis-EMA, TEGDMA UDMA | Silica and zirconia particles 0.01–3.5 µm, average size 0.6 µm 84.5 wt% 60 vol% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nica, I.; Nedeff, F.; Nedeff, V.; Popa, C.; Toma, Ș.L.; Agop, M.; Vasincu, D. The Cracking Behavior of Two Dental Composite Materials Validated through Multifractal Analyzes. Int. J. Mol. Sci. 2023, 24, 6493. https://doi.org/10.3390/ijms24076493

Nica I, Nedeff F, Nedeff V, Popa C, Toma ȘL, Agop M, Vasincu D. The Cracking Behavior of Two Dental Composite Materials Validated through Multifractal Analyzes. International Journal of Molecular Sciences. 2023; 24(7):6493. https://doi.org/10.3390/ijms24076493

Chicago/Turabian StyleNica, Irina, Florin Nedeff, Valentin Nedeff, Cristina Popa, Ștefan Lucian Toma, Maricel Agop, and Decebal Vasincu. 2023. "The Cracking Behavior of Two Dental Composite Materials Validated through Multifractal Analyzes" International Journal of Molecular Sciences 24, no. 7: 6493. https://doi.org/10.3390/ijms24076493

APA StyleNica, I., Nedeff, F., Nedeff, V., Popa, C., Toma, Ș. L., Agop, M., & Vasincu, D. (2023). The Cracking Behavior of Two Dental Composite Materials Validated through Multifractal Analyzes. International Journal of Molecular Sciences, 24(7), 6493. https://doi.org/10.3390/ijms24076493