A Wooden Carbon-Based Photocatalyst for Water Treatment

Abstract

1. Introduction

2. Basic Characteristics of Biochar

2.1. Definition of Biochar

2.2. Physical and Chemical Properties of Biochar

2.3. Source of Biochar

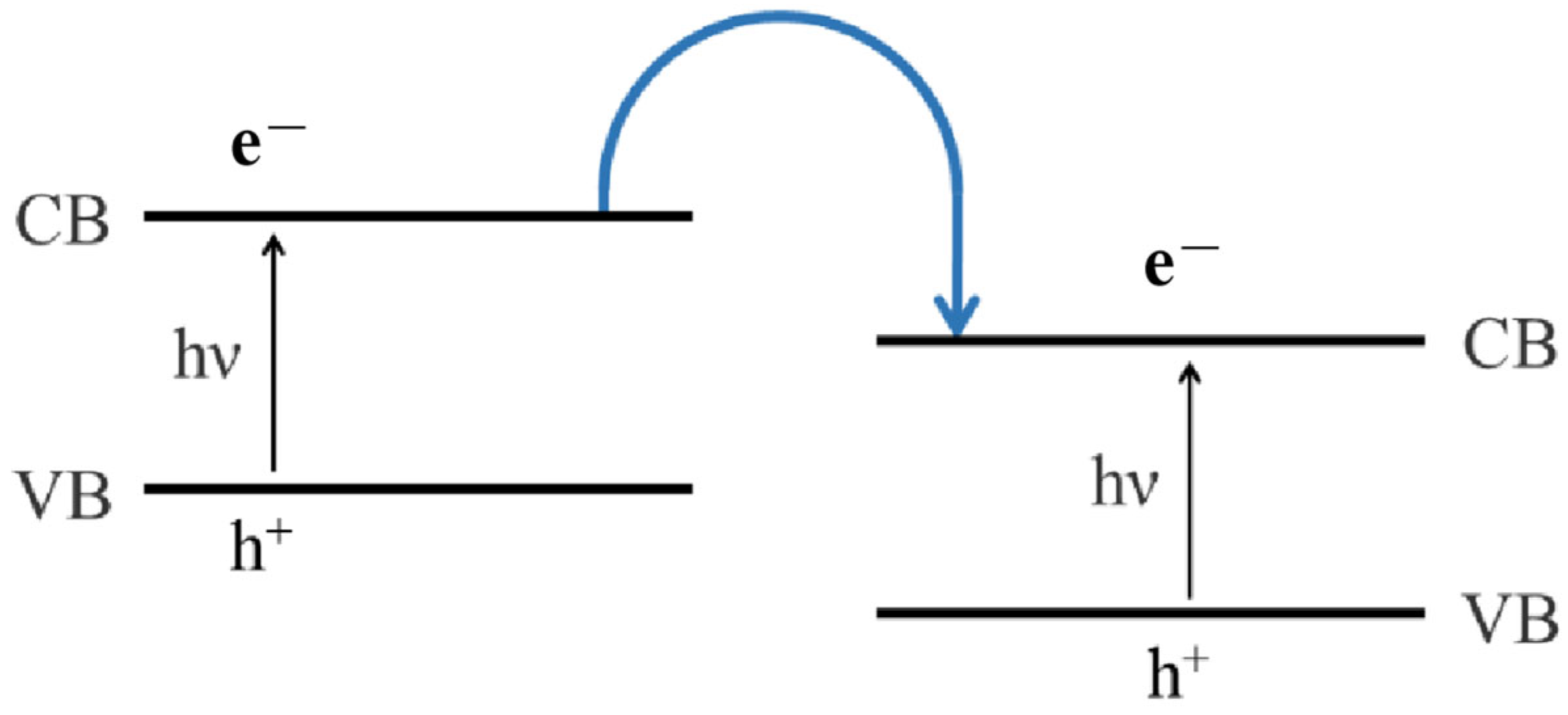

3. Woody Biochar-Based Photocatalyst

4. Preparation Process

4.1. Preparation of Woody Biochar

4.2. Carbonization Methods

4.3. Synthesis of Photocatalysts Supported by Woody Biochar

5. Limitation of Woody Biochar-Based Photocatalysts in Water Treatment

6. Summary and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Ahamad, A.; Madhav, S.; Singh, A.K.; Kumar, A.; Singh, P. Types of Water Pollutants: Conventional and Emerging. In Sensors in Water Pollutants Monitoring: Role of Material, Advanced Functional Materials and Sensors; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Ukaogo, P.O.; Ewuzie, U.; Onwuka, C.V. 21—Environmental pollution: Causes, effects, and the remedies. In Microorganisms for Sustainable Environment and Health; Chowdhary, P., Raj, A., Verma, D., Akhter, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 419–429. [Google Scholar] [CrossRef]

- Ge-Zhang, S.; Cai, T.; Hu, Z.; Zhu, H.; Mu, P.; Cui, J. Investigation and Suggestions regarding Residents’ Understanding of Waste Classification in Chinese Prefecture-Level Cities—A Case Study of Maanshan City, Anhui Province, China. Sustainability 2023, 15, 11124. [Google Scholar] [CrossRef]

- Ramesh, B.; Saravanan, A.; Senthil Kumar, P.; Yaashikaa, P.R.; Thamarai, P.; Shaji, A.; Rangasamy, G. A review on algae biosorption for the removal of hazardous pollutants from wastewater: Limiting factors, prospects and recommendations. Environ. Pollut. 2023, 327, 121572. [Google Scholar] [CrossRef]

- Qiao, J.; Xiong, Y. Electrochemical oxidation technology: A review of its application in high-efficiency treatment of wastewater containing persistent organic pollutants. J. Water Process Eng. 2021, 44, 102308. [Google Scholar] [CrossRef]

- Mashuri, S.I.S.; Rashid, U.; Taufiq-Yap, Y.H.; Ibrahim, M.L.; Mijan, N.A.J.C. Photocatalysis for Organic Wastewater Treatment: From the Basis to Current Challenges for Society. Catalysts 2020, 10, 1260. [Google Scholar] [CrossRef]

- Oblak, R.; Kete, M.; Štangar, U.L.; Tasbihi, M. Alternative support materials for titania photocatalyst towards degradation of organic pollutants. J. Water Process Eng. 2018, 23, 142–150. [Google Scholar] [CrossRef]

- Serpone, N.; Borgarello, E.; Harris, R.; Cahill, P.; Borgarello, M.; Pelizzetti, E. Photocatalysis over TiO2 supported on a glass substrate. Sol. Energy Mater. 1986, 14, 121–127. [Google Scholar] [CrossRef]

- Inagaki, M.; Hirose, Y.; Matsunaga, T.; Tsumura, T.; Toyoda, M. Carbon coating of anatase-type TiO2 through their precipitation in PVA aqueous solution. Carbon 2003, 41, 2619–2624. [Google Scholar] [CrossRef]

- Rodrigues, S.; Ranjit, K.T.; Uma, S.; Martyanov, I.N.; Klabunde, K.J. Single-Step Synthesis of a Highly Active Visible-Light Photocatalyst for Oxidation of a Common Indoor Air Pollutant: Acetaldehyde. Adv. Mater. 2005, 17, 2467–2471. [Google Scholar] [CrossRef]

- Mills, A.; Elliott, N.; Hill, G.; Fallis, D.; Durrant, J.R.; Willis, R.L.J.P.; Sciences, P. Preparation and characterisation of novel thick sol–gel titania film photocatalysts. Photochem. Photobiol. Sci. 2003, 2, 591–596. [Google Scholar] [CrossRef]

- Yu, C.; Yang, K.; Shu, Q.; Yu, J.C.; Cao, F.; Li, X. Preparation of WO3/ZnO Composite Photocatalyst and Its Photocatalytic Performance. Chin. J. Catal. 2011, 32, 555–565. [Google Scholar] [CrossRef]

- Yan, S.C.; Lv, S.B.; Li, Z.S.; Zou, Z.G. Organic-inorganic composite photocatalyst of g-C3N4 and TaON with improved visible light photocatalytic activities. Dalton Trans. 2010, 39, 1488–1491. [Google Scholar] [CrossRef] [PubMed]

- Chun, W.J.; Ishikawa, A.; Fujisawa, H.; Takata, T.; Domen, K.J.C. Conduction and Valence Band Positions of Ta2O5, TaON, and Ta3N5 by UPS and Electrochemical Methods. J. Phys. Chem. B 2003, 34, 1798–1803. [Google Scholar] [CrossRef]

- Li, T.; Zhao, L.; He, Y.; Cai, J.; Luo, M.; Lin, J. Synthesis of g-C3N4/SmVO4 composite photocatalyst with improved visible light photocatalytic activities in RhB degradation. Appl. Catal. B Environ. 2013, 129, 255–263. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Zhao, D.; Ge-Zhang, S.; Zhang, Z.; Tang, H.; Xu, Y.; Gao, F.; Xu, X.; Liu, S.; Zhou, J.; Wang, Z.; et al. Three-Dimensional Honeycomb-Like Carbon as Sulfur Host for Sodium–Sulfur Batteries without the Shuttle Effect. ACS Appl. Mater. Interfaces 2022, 14, 54662–54669. [Google Scholar] [CrossRef] [PubMed]

- Ge-Zhang, S.; Yang, H.; Mu, H. Interfacial solar steam generator by MWCNTs/carbon black nanoparticles coated wood. Alex. Eng. J. 2023, 63, 1–10. [Google Scholar] [CrossRef]

- Chen, X.; Ge-Zhang, S.; Han, Y.; Yang, H.; Ou-Yang, W.; Zhu, H.; Hao, J.; Wang, J. Ultraviolet-Assisted Modified Delignified Wood with High Transparency. Appl. Sci. 2022, 12, 7406. [Google Scholar] [CrossRef]

- Cai, T.; Ge-Zhang, S.; Song, M. Anthocyanins in metabolites of purple corn. Front. Plant Sci. 2023, 14, 1154535. [Google Scholar] [CrossRef] [PubMed]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Sakhiya, A.K.; Anand, A.; Kaushal, P. Production, activation, and applications of biochar in recent times. Biochar 2020, 2, 253–285. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, R.; Sun, M.; Zhang, S.; He, M.; Tsang, D.C.W.; Luo, G. Wood waste biochar promoted anaerobic digestion of food waste: Focusing on the characteristics of biochar and microbial community analysis. Biochar 2022, 4, 62. [Google Scholar] [CrossRef]

- Demirbas, A.; Pehlivan, E.; Altun, T. Potential evolution of Turkish agricultural residues as bio-gas, bio-char and bio-oil sources. Int. J. Hydrogen Energy 2006, 31, 613–620. [Google Scholar] [CrossRef]

- Kumar, A.; Schreiter, I.J.; Wefer-Roehl, A.; Tsechansky, L.; Schüth, C.; Graber, E.R. Chapter 5—Production and Utilization of Biochar from Organic Wastes for Pollutant Control on Contaminated Sites. In Environmental Materials and Waste; Prasad, M.N.V., Shih, K., Eds.; Academic Press: Cambridge, MA, USA, 2016; pp. 91–116. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, L.; Zhao, M.; Rong, H.; Xu, Y. The environmental characteristics and applications of biochar. Environ. Sci. Pollut. Res. 2018, 25, 21525–21534. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Meng, J.; Han, X.; Lan, Y.; Zhang, W. Past, present, and future of biochar. Biochar 2019, 1, 75–87. [Google Scholar] [CrossRef]

- Leng, L.; Xiong, Q.; Yang, L.; Li, H.; Zhou, Y.; Zhang, W.; Jiang, S.; Li, H.; Huang, H. An overview on engineering the surface area and porosity of biochar. Sci. Total Environ. 2021, 763, 144204. [Google Scholar] [CrossRef] [PubMed]

- Scapin, E.; Maciel GD, S.; Polidoro, A.S.; Lazzari, E.; Benvenutti, E.V.; Falcade, T.; Jacques, R.A. Activated carbon from rice husk biochar with high surface area. Biointerface Res. Appl. Chem. 2021, 11, 10265–10277. [Google Scholar]

- Dai, L.; Lu, Q.; Zhou, H.; Shen, F.; Liu, Z.; Zhu, W.; Huang, H. Tuning oxygenated functional groups on biochar for water pollution control: A critical review. J. Hazard. Mater. 2021, 420, 126547. [Google Scholar] [CrossRef] [PubMed]

- Bartoli, M.; Troiano, M.; Giudicianni, P.; Amato, D.; Giorcelli, M.; Solimene, R.; Tagliaferro, A. Effect of heating rate and feedstock nature on electrical conductivity of biochar and biochar-based composites. Appl. Energy Combust. Sci. 2022, 12, 100089. [Google Scholar] [CrossRef]

- He, P.; Liu, Y.; Shao, L.; Zhang, H.; Lü, F. Particle size dependence of the physicochemical properties of biochar. Chemosphere 2018, 212, 385–392. [Google Scholar] [CrossRef]

- Lim, T.J.; Spokas, K.A.; Feyereisen, G.W.; Weis, R.; Koskinen, W.C. Influence of biochar particle size and shape on soil hydraulic properties. J. Environ. Sci. Eng. Technol. 2017, 5, 8–15. [Google Scholar] [CrossRef]

- Saffari, N.; Hajabbasi, M.; Shirani, H.; Mosaddeghi, M.; Mamedov, A. Biochar type and pyrolysis temperature effects on soil quality indicators and structural stability. J. Environ. Manag. 2020, 261, 110190. [Google Scholar] [CrossRef] [PubMed]

- Lou, Z.; Li, Y.; Han, H.; Ma, H.; Wang, L.; Cai, J.; Yang, L.; Yuan, C.; Zou, J. Synthesis of Porous 3D Fe/C Composites from Waste Wood with Tunable and Excellent Electromagnetic Wave Absorption Performance. ACS Sustain. Chem. Eng. 2018, 6, 15598–15607. [Google Scholar] [CrossRef]

- Liberati, D.; Ahmed, S.W.; Samad, N.; Mugnaioni, R.; Shaukat, S.; Muddasir, M.; Marinari, S.; De Angelis, P. Biochar amendment for reducing the environmental impacts of reclaimed polluted sediments. J. Environ. Manag. 2023, 344, 118623. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Fang, G.; Qian, X.; Tian, Q. Z-scheme heterojunction of low conduction band potential MnO2 and biochar-based g-C3N4 for efficient formaldehyde degradation. Chem. Eng. J. 2022, 428, 131052. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Chen, J.; Wang, Y.; Cheng, Z.; Chen, X.; Gao, X.; Guo, M. Porous spherical Cu2O supported by wood-based biochar skeleton for the adsorption-photocatalytic degradation of methyl orange. Appl. Surf. Sci. 2023, 611, 155744. [Google Scholar] [CrossRef]

- Saletnik, B.; Saletnik, A.; Zaguła, G.; Bajcar, M.; Puchalski, C. Oak Biomass in the Form of Wood, Bark, Brushwood, Leaves and Acorns in the Production Process of Multifunctional Biochar. Molecules 2022, 27, 7191. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Wang, Y.; Ding, N.; Liang, L.; Zhao, S.; Yin, D.; Cheng, Y.; Wang, C.; Wang, L. Preparation and hydrogen storage performance of poplar sawdust biochar with high specific surface area. Ind. Crops Prod. 2023, 200, 116788. [Google Scholar] [CrossRef]

- Shan, R.; Lu, L.; Gu, J.; Zhang, Y.; Yuan, H.; Chen, Y.; Luo, B. Photocatalytic degradation of methyl orange by Ag/TiO2/biochar composite catalysts in aqueous solutions. Mater. Sci. Semicond. Process. 2020, 114, 105088. [Google Scholar] [CrossRef]

- He, M.; Xu, Z.; Sun, Y.; Chan, P.S.; Lui, I.; Tsang, D.C.W. Critical impacts of pyrolysis conditions and activation methods on application-oriented production of wood waste-derived biochar. Bioresour. Technol. 2021, 341, 125811. [Google Scholar] [CrossRef]

- Qiu, Y.; Zheng, Z.; Zhou, Z.; Sheng, G.D. Effectiveness and mechanisms of dye adsorption on a straw-based biochar. Bioresour. Technol. 2009, 100, 5348–5351. [Google Scholar] [CrossRef]

- Liu, X.; Yang, L.; Zhao, H.; Wang, W. Pyrolytic production of zerovalent iron nanoparticles supported on rice husk-derived biochar: Simple, in situ synthesis and use for remediation of Cr(VI)-polluted soils. Sci. Total Environ. 2020, 708, 134479. [Google Scholar] [CrossRef]

- Kwapinski, W.; Byrne, C.M.P.; Kryachko, E.; Wolfram, P.; Adley, C.; Leahy, J.J.; Novotny, E.H.; Hayes, M.H.B. Biochar from Biomass and Waste. Waste Biomass Valorization 2010, 1, 177–189. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, X.; Xiao, L.; Huang, Q.; Wang, S.; Jiang, Y. In-situ fibrillated sugarcane cell wall decorated with WO3-Ag nanocatalyst for efficient adsorption-photocatalytic removal of antibiotics from water. Sep. Purif. Technol. 2024, 343, 127181. [Google Scholar] [CrossRef]

- Huang, H.-B.; Wang, Y.; Jiao, W.-B.; Cai, F.-Y.; Shen, M.; Zhou, S.-G.; Cao, H.-L.; Lü, J.; Cao, R. Lotus-Leaf-Derived Activated-Carbon-Supported Nano-CdS as Energy-Efficient Photocatalysts under Visible Irradiation. ACS Sustain. Chem. Eng. 2018, 6, 7871–7879. [Google Scholar] [CrossRef]

- Liu, C.; You, J.; Li, Y.; Zhu, H.; Xia, L.; Zhuang, X. NaBiS2 decorated polysaccharide sponges for adsorption–photocatalytic degradation of dye under visible light illumination. Carbohydr. Polym. 2023, 316, 121072. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Yang, M.; Feng, Q.; McGrouther, K.; Wang, H.; Lu, H.; Chen, Y. Chemical characterization of rice straw-derived biochar for soil amendment. Biomass Bioenergy 2012, 47, 268–276. [Google Scholar] [CrossRef]

- Li, X.; Wu, M.; Xue, Y. Nickel-loaded shrimp shell biochar enhances batch anaerobic digestion of food waste. Bioresour. Technol. 2022, 352, 127092. [Google Scholar] [CrossRef]

- Li, R.; Wang, J.J.; Zhou, B.; Awasthi, M.K.; Ali, A.; Zhang, Z.; Gaston, L.A.; Lahori, A.H.; Mahar, A. Enhancing phosphate adsorption by Mg/Al layered double hydroxide functionalized biochar with different Mg/Al ratios. Sci. Total Environ. 2016, 559, 121–129. [Google Scholar] [CrossRef] [PubMed]

- Brown, T.R.; Wright, M.M.; Brown, R.C. Estimating profitability of two biochar production scenarios: Slow pyrolysis vs. fast pyrolysis. Biofuels Bioprod. Biorefining 2011, 5, 54–68. [Google Scholar] [CrossRef]

- Matthews, R.W. An adsorption water purifier with in situ photocatalytic regeneration. J. Catal. 1988, 113, 549–555. [Google Scholar] [CrossRef]

- Vaiano, V.; Sacco, O.; Sannino, D.; Ciambelli, P. Nanostructured N-doped TiO2 coated on glass spheres for the photocatalytic removal of organic dyes under UV or visible light irradiation. Appl. Catal. B Environ. 2015, 170–171, 153–161. [Google Scholar] [CrossRef]

- Dougna, A.A.; Gombert, B.; Kodom, T.; Djaneye-Boundjou, G.; Boukari, S.O.B.; Leitner, N.K.V.; Bawa, L.M. Photocatalytic removal of phenol using titanium dioxide deposited on different substrates: Effect of inorganic oxidants. J. Photochem. Photobiol. A Chem. 2015, 305, 67–77. [Google Scholar] [CrossRef]

- Dumitriu, D.; Bally, A.R.; Ballif, C.; Hones, P.; Schmid, P.E.; Sanjinés, R.; Lévy, F.; Pârvulescu, V.I. Photocatalytic degradation of phenol by TiO2 thin films prepared by sputtering. Appl. Catal. B Environ. 2000, 25, 83–92. [Google Scholar] [CrossRef]

- Du, X.; Shi, L.; Pang, J.; Zheng, H.; Shi, J.; Zhang, M. Fabrication of superwetting and antimicrobial wood-based mesoporous composite decorated with silver nanoparticles for purifying the polluted-water with oils, dyes and bacteria. J. Environ. Chem. Eng. 2022, 10, 107152. [Google Scholar] [CrossRef]

- Luo, S.; Li, S.; Zhang, S.; Cheng, Z.; Nguyen, T.T.; Guo, M. Visible-light-driven Z-scheme protonated g-C3N4/wood flour biochar/BiVO4 photocatalyst with biochar as charge-transfer channel for enhanced RhB degradation and Cr(VI) reduction. Sci. Total Environ. 2022, 806, 150662. [Google Scholar] [CrossRef] [PubMed]

- Aizat, M.A.; Aziz, F. 12—Chitosan Nanocomposite Application in Wastewater Treatments. In Nanotechnology in Water and Wastewater Treatment; Ahsan, A., Ismail, A.F., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 243–265. [Google Scholar] [CrossRef]

- Zhu, H.; Tan, X.; Tan, L.; Chen, C.; Alharbi, N.S.; Hayat, T.; Fang, M.; Wang, X. Biochar Derived from Sawdust Embedded with Molybdenum Disulfide for Highly Selective Removal of Pb2+. ACS Appl. Nano Mater. 2018, 1, 2689–2698. [Google Scholar] [CrossRef]

- Ye, L.; Liu, J.; Jiang, Z.; Peng, T.; Zan, L. Facets coupling of BiOBr-g-C3N4 composite photocatalyst for enhanced visible-light-driven photocatalytic activity. Appl. Catal. B Environ. 2013, 142–143, 1–7. [Google Scholar] [CrossRef]

- Ma, X.; Zhou, W.; Chen, Y. Structure and photocatalytic properties of Mn-doped TiO2 loaded on wood-based activated carbon fiber composites. Materials 2017, 10, 631. [Google Scholar] [CrossRef] [PubMed]

- Vinodgopal, K.; Kamat, P.V. Enhanced Rates of Photocatalytic Degradation of an Azo Dye Using SnO2/TiO2 Coupled Semiconductor Thin Films. Environ. Sci. Technol. 1995, 29, 841–845. [Google Scholar] [CrossRef]

- Ranjit, K.T.; Viswanathan, B. Synthesis, characterization and photocatalytic properties of iron-doped TiO2 catalysts. J. Photochem. Photobiol. A Chem. 1997, 108, 79–84. [Google Scholar] [CrossRef]

- Low, J.; Yu, J.; Jaroniec, M.; Wageh, S.; Al-Ghamdi, A.A. Heterojunction Photocatalysts. Adv. Mater. 2017, 29, 1601694. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Salvador, P.A.; Rohrer, G.S. Photocatalysts with internal electric fields. Nanoscale 2014, 6, 24–42. [Google Scholar] [CrossRef] [PubMed]

- Jiang, D.; Li, X. Advanced Photocatalysts with Nanoheterostructures. Mater. Focus 2015, 4, 14–19. [Google Scholar] [CrossRef]

- Yuan, Y.-P.; Ruan, L.-W.; Barber, J.; Loo, S.C.J.; Xue, C. Hetero-nanostructured suspended photocatalysts for solar-to-fuel conversion. Energy Environ. Sci. 2014, 7, 3934–3951. [Google Scholar] [CrossRef]

- Bard, A.J. Photoelectrochemistry and heterogeneous photo-catalysis at semiconductors. J. Photochem. 1979, 10, 59–75. [Google Scholar] [CrossRef]

- Tada, H.; Mitsui, T.; Kiyonaga, T.; Akita, T.; Tanaka, K. All-solid-state Z-scheme in CdS–Au–TiO2 three-component nanojunction system. Nat. Mater. 2006, 5, 782–786. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Wang, S.; Low, J.; Xiao, W. Enhanced photocatalytic performance of direct Z-scheme g-C3N4–TiO2 photocatalysts for the decomposition of formaldehyde in air. Phys. Chem. Chem. Phys. 2013, 15, 16883–16890. [Google Scholar] [CrossRef]

- Yeh, T.F.; Teng, C.Y.; Chen, L.C.; Chen, S.J.; Teng, H. Graphene oxide-based nanomaterials for efficient photoenergy conversion. J. Mater. Chem. A 2016, 4, 2014–2048. [Google Scholar] [CrossRef]

- Low, J.; Yu, J.; Ho, W. Graphene-Based Photocatalysts for CO2 Reduction to Solar Fuel. J. Phys. Chem. Lett. 2015, 6, 4244–4251. [Google Scholar] [CrossRef]

- Li, Q.; Guo, B.; Yu, J.; Ran, J.; Zhang, B.; Yan, H.; Gong, J.R. Highly efficient visible-light-driven photocatalytic hydrogen production of CdS-cluster-decorated graphene nanosheets. J. Am. Chem. Soc. 2011, 133, 10878–10884. [Google Scholar] [CrossRef]

- Xu, P.; Yang, J.; Chen, Y.; Li, Y.; Jia, X.; Song, H. Wood-derived fiber/BiOBr/AgBr sponges by in situ synthesis for separation of emulsions and degradation of dyes. Mater. Des. 2019, 183, 108179. [Google Scholar] [CrossRef]

- Qi, X.; Cai, H.; Zhang, X.; Ouyang, J.; Lu, D.; Guo, X.; Jia, S. CdS quantum dots/nano-TiO2 incorporated wood as a long-term stable and easily separable photocatalytic adsorbent for efficient Cr(VI) removal. Chem. Eng. J. 2023, 475, 146320. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, M.; Wang, Q.; Li, L. Efficient and sustainable photocatalytic degradation of dye in wastewater with porous and recyclable wood foam@V2O5 photocatalysts. J. Clean. Prod. 2022, 332, 130054. [Google Scholar] [CrossRef]

- Liang, Z.; Hao, L.; Yu, Y.; Hou, H.; Qian, G.; Min, D. AgI/UiO-66-NH2@carbonized wood fabricated as self-floating heterojunction for enhancing visible light-driving photocatalytic degradation of Rhodamine B. Ind. Crops Prod. 2024, 210, 118125. [Google Scholar] [CrossRef]

- Wang, M.; Wang, P.; Zhang, J.; Li, C.; Jin, Y. A Ternary Pt/Au/TiO2-Decorated Plasmonic Wood Carbon for High-Efficiency Interfacial Solar Steam Generation and Photodegradation of Tetracycline. ChemSusChem 2019, 12, 467–472. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Zhao, X.; Luo, X.; Pang, Y.; Tian, B.; Liu, S.; Li, S.; Li, J.; Strehmel, B.; Chen, Z. A Sustainable Wood-Based Iron Photocatalyst for Multiple Uses with Sunlight: Water Treatment and Radical Photopolymerization. Angew. Chem. Int. Ed. Engl. 2023, 62, e202301242. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Su, X.; Wu, W.; Chen, S.; Zhang, X.; Wu, Y.; Xie, H.; Li, K. Superhydrophobic PDMS@TiO2 wood for photocatalytic degradation and rapid oil-water separation. Surf. Coat. Technol. 2022, 434, 128182. [Google Scholar] [CrossRef]

- Zhang, H.; Gong, X.; Song, Z.; Zhang, S.; Du, W.; Nguyen, T.T.; Guo, M.; Gao, X. Wood-based carbon quantum dots for enhanced photocatalysis of MIL-88B(Fe). Opt. Mater. 2021, 113, 110865. [Google Scholar] [CrossRef]

- Shi, L.; Zou, X.; Wang, T.; Wang, D.; Fan, M.; Gong, Z. Sunlight photocatalytic degradation of ofloxacin using UiO-66/wood composite photocatalysts. Chin. Chem. Lett. 2022, 33, 442–446. [Google Scholar] [CrossRef]

- Luo, L.; Yang, Y.; Xiao, M.; Bian, L.; Yuan, B.; Liu, Y.; Jiang, F.; Pan, X. A novel biotemplated synthesis of TiO2/wood charcoal composites for synergistic removal of bisphenol A by adsorption and photocatalytic degradation. Chem. Eng. J. 2015, 262, 1275–1283. [Google Scholar] [CrossRef]

- Xi, Y.; Du, C.; Li, P.; Zhou, X.; Zhou, C.; Yang, S. Combination of Photothermal Conversion and Photocatalysis toward Water Purification. Ind. Eng. Chem. Res. 2022, 61, 4579–4587. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, X.; Wang, Y.; Gu, Z.; Chen, L. Bi-functional water-purification materials derived from natural wood modified TiO2 by photothermal effect and photocatalysis. RSC Adv. 2022, 12, 26245–26250. [Google Scholar] [CrossRef] [PubMed]

- Loke, J.Y.; Mohd Zaki, R.S.; Setiabudi, H.D. Photocatalytic degradation of methylene blue using ZnO supported on wood waste-derived activated carbon (ZnO/AC). Mater. Today Proc. 2022, 57, 1315–1321. [Google Scholar] [CrossRef]

- Geng, A.; Xu, L.; Gan, L.; Mei, C.; Wang, L.; Fang, X.; Li, M.; Pan, M.; Han, S.; Cui, J. Using wood flour waste to produce biochar as the support to enhance the visible-light photocatalytic performance of BiOBr for organic and inorganic contaminants removal. Chemosphere 2020, 250, 126291. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Tang, M.; Jiang, H.; Dai, J.; Cheng, R.; Luo, B.; Yang, L.; Du, G.; Gao, W. Sustainable, efficient, and synergistic photocatalytic degradation toward organic dyes and formaldehyde gas via Cu2O NPs@wood. J. Environ. Manag. 2024, 351, 119676. [Google Scholar] [CrossRef] [PubMed]

- Pereira, H.J.W.; Science, F. Variability in the chemical composition of plantation eucalypts (Eucalyptus globulus Labill.). Wood Fiber Sci. 1988, 20, 82–90. [Google Scholar]

- Kambo, H.S.; Dutta, A. A comparative review of biochar and hydrochar in terms of production, physico-chemical properties and applications. Renew. Sustain. Energy Rev. 2015, 45, 359–378. [Google Scholar] [CrossRef]

- Knezevic, D.; van Swaaij, W.; Kersten, S. Hydrothermal conversion of biomass. II. Conversion of wood, pyrolysis oil, and glucose in hot compressed water. Ind. Eng. Chem. Res. 2010, 49, 104–112. [Google Scholar] [CrossRef]

- Mani, S.; Sokhansanj, S.; Bi, X.; Turhollow, A. Economics of producing fuel pellets from biomass. Appl. Eng. Agric. 2006, 22, 421–426. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Fenton, J.J. Cost Benefit of Biomass Supply and Pre-Processing; Citeseer: Princeton, NJ, USA, 2006. [Google Scholar]

- Libra, J.A.; Ro, K.S.; Kammann, C.; Funke, A.; Berge, N.D.; Neubauer, Y.; Titirici, M.-M.; Fühner, C.; Bens, O.; Kern, J.; et al. Hydrothermal carbonization of biomass residuals: A comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2011, 2, 71–106. [Google Scholar] [CrossRef]

- Mumme, J.; Eckervogt, L.; Pielert, J.; Diakité, M.; Rupp, F.; Kern, J. Hydrothermal carbonization of anaerobically digested maize silage. Bioresour. Technol. 2011, 102, 9255–9260. [Google Scholar] [CrossRef] [PubMed]

- Khan, T.A.; Saud, A.S.; Jamari, S.S.; Rahim, M.H.A.; Park, J.-W.; Kim, H.-J. Hydrothermal carbonization of lignocellulosic biomass for carbon rich material preparation: A review. Biomass Bioenergy 2019, 130, 105384. [Google Scholar] [CrossRef]

- Xiao, L.-P.; Shi, Z.-J.; Xu, F.; Sun, R.-C. Hydrothermal carbonization of lignocellulosic biomass. Bioresour. Technol. 2012, 118, 619–623. [Google Scholar] [CrossRef] [PubMed]

- Hu, B.; Wang, K.; Wu, L.; Yu, S.-H.; Antonietti, M.; Titirici, M.-M. Engineering carbon materials from the hydrothermal carbonization process of biomass. Adv. Mater. 2010, 22, 813–828. [Google Scholar] [CrossRef] [PubMed]

- Rousset, P.; Macedo, L.; Commandré, J.M.; Moreira, A. Biomass torrefaction under different oxygen concentrations and its effect on the composition of the solid by-product. J. Anal. Appl. Pyrolysis 2012, 96, 86–91. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. Torrefaction of wood: Part 1. Weight loss kinetics. J. Anal. Appl. Pyrolysis 2006, 77, 28–34. [Google Scholar] [CrossRef]

- van der Stelt, M.J.C.; Gerhauser, H.; Kiel, J.H.A.; Ptasinski, K.J. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass Bioenergy 2011, 35, 3748–3762. [Google Scholar] [CrossRef]

- Hakkou, M.; Pétrissans, M.; Gérardin, P.; Zoulalian, A. Investigations of the reasons for fungal durability of heat-treated beech wood. Polym. Degrad. Stab. 2006, 91, 393–397. [Google Scholar] [CrossRef]

- Dastyar, W.; Raheem, A.; Zhao, M.; Yuan, W.; Li, H.; Ting, Z.J. Effects of Ionic Liquid-Assisted Pretreatment of Heavy Metal-Contaminated Biomass on the Yield and Composition of Syngas Production Using Noncatalytic and Catalytic Pyrolysis and Gasification Processes. ACS Sustain. Chem. Eng. 2019, 7, 18303–18312. [Google Scholar] [CrossRef]

- Nargotra, P.; Sharma, V.; Bajaj, B.K. Consolidated bioprocessing of surfactant-assisted ionic liquid-pretreated Parthenium hysterophorus L. biomass for bioethanol production. Bioresour. Technol. 2019, 289, 121611. [Google Scholar] [CrossRef]

- Sharma, V.; Nargotra, P.; Bajaj, B.K. Ultrasound and surfactant assisted ionic liquid pretreatment of sugarcane bagasse for enhancing saccharification using enzymes from an ionic liquid tolerant Aspergillus assiutensis VS34. Bioresour. Technol. 2019, 285, 121319. [Google Scholar] [CrossRef]

- Sarvaramini, A.; Assima, G.P.; Larachi, F. Dry torrefaction of biomass—Torrefied products and torrefaction kinetics using the distributed activation energy model. Chem. Eng. J. 2013, 229, 498–507. [Google Scholar] [CrossRef]

- Brewer, C.E.; Schmidt-Rohr, K.; Satrio, J.A.; Brown, R.C. Characterization of biochar from fast pyrolysis and gasification systems. Environ. Prog. Sustain. Energy 2009, 28, 386–396. [Google Scholar] [CrossRef]

- Meyer, S.; Glaser, B.; Quicker, P. Technical, Economical, and Climate-Related Aspects of Biochar Production Technologies: A Literature Review. Environ. Sci. Technol. 2011, 45, 9473–9483. [Google Scholar] [CrossRef] [PubMed]

- Qian, K.; Kumar, A.; Patil, K.; Bellmer, D.; Wang, D.; Yuan, W.; Huhnke, R.L. Effects of Biomass Feedstocks and Gasification Conditions on the Physiochemical Properties of Char. Energies 2013, 6, 3972–3986. [Google Scholar] [CrossRef]

- Hao, X.; Guo, L.; Zhang, X.; Guan, Y. Hydrogen production from catalytic gasification of cellulose in supercritical water. Chem. Eng. J. 2005, 110, 57–65. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M.; Clough, P.; Yao, J.; Zhong, X.; Memon, M.Z.; Shah, N.; Anthony, E.J.; Fennell, P.S. An overview of advances in biomass gasification. Energy Environ. Sci. 2016, 9, 2939–2977. [Google Scholar] [CrossRef]

- Eluk, T.; Levy, A.; Korytnyi, E.; Bar-Kohany, T. Transition Mechanism Between Combustion Regions in Swirling Entrained Flow Downer Reactors. Energy Fuels 2017, 31, 1927–1934. [Google Scholar] [CrossRef]

- Qian, K.; Kumar, A.; Zhang, H.; Bellmer, D.; Huhnke, R. Recent advances in utilization of biochar. Renew. Sustain. Energy Rev. 2015, 42, 1055–1064. [Google Scholar] [CrossRef]

- Liu, W.-J.; Jiang, H.; Yu, H.-Q. Development of Biochar-Based Functional Materials: Toward a Sustainable Platform Carbon Material. Chem. Rev. 2015, 115, 12251–12285. [Google Scholar] [CrossRef]

- Nachenius, R.W.; Ronsse, F.; Venderbosch, R.H.; Prins, W. Chapter Two—Biomass Pyrolysis. In Advances in Chemical Engineering; Murzin, D.Y., Ed.; Academic Press: Cambridge, MA, USA, 2013; Volume 42, pp. 75–139. [Google Scholar]

- Roets, L.; Bunt, J.R.; Neomagus, H.W.; van Niekerk, D. An evaluation of a new automated duplicate-sample Fischer Assay setup according to ISO/ASTM standards and analysis of the tar fraction. J. Anal. Appl. Pyrolysis 2014, 106, 190–196. [Google Scholar] [CrossRef]

- Marais, C.; Bunt, J.R.; Leokaoke, N.T.; Coetzer, R.L.J.; Neomagus, H.W.J.P. Slow Pyrolysis Products Derived from Extrudates Produced from Discard Coal Fines and Recycled Plastics as Binders. ACS Omega 2024, 9, 6627–6641. [Google Scholar] [CrossRef] [PubMed]

- Bridgwater, A.V.; Peacocke, G.V.C. Fast pyrolysis processes for biomass. Renew. Sustain. Energy Rev. 2000, 4, 1–73. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, R.; Liu, R. Characterization of biochar from fast pyrolysis and its effect on chemical properties of the tea garden soil. J. Anal. Appl. Pyrolysis 2014, 110, 375–381. [Google Scholar] [CrossRef]

- Sun, J.; Norouzi, O.; Mašek, O. A state-of-the-art review on algae pyrolysis for bioenergy and biochar production. Bioresour. Technol. 2022, 346, 126258. [Google Scholar] [CrossRef]

- Wang, K.; Brown, R.C.; Homsy, S.; Martinez, L.; Sidhu, S.S. Fast pyrolysis of microalgae remnants in a fluidized bed reactor for bio-oil and biochar production. Bioresour. Technol. 2013, 127, 494–499. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wan, C.; Li, X.; Wei, S.; Zhang, L.; Tian, W.; Yong, K.-T.; Wu, Y.; Li, J. Sustainable wood-based nanotechnologies for photocatalytic degradation of organic contaminants in aquatic environment. Front. Environ. Sci. Eng. 2020, 15, 1–22. [Google Scholar] [CrossRef]

- Wang, Y.; Ge-Zhang, S.; Mu, P.; Wang, X.; Li, S.; Qiao, L.; Mu, H. Advances in Sol-Gel-Based Superhydrophobic Coatings for Wood: A Review. Int. J. Mol. Sci. 2023, 24, 9675. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, S.; Yu, Q.; Yin, W. The effects of activated carbon supports on the structure and properties of TiO2 nanoparticles prepared by a sol–gel method. Appl. Surf. Sci. 2007, 253, 9254–9258. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Z.; Li, R.; Guo, J.; Li, Y.; Zhu, J.; Xie, X. TiO2 supported on reed straw biochar as an adsorptive and photocatalytic composite for the efficient degradation of sulfamethoxazole in aqueous matrices. Chemosphere 2017, 185, 351–360. [Google Scholar] [CrossRef]

- Li, J.; Ren, D.; Wu, Z.; Xu, J.; Bao, Y.; He, S.; Chen, Y. Flame retardant and visible light-activated Fe-doped TiO2 thin films anchored to wood surfaces for the photocatalytic degradation of gaseous formaldehyde. J. Colloid Interface Sci. 2018, 530, 78–87. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Chang, T.; Gao, H.; Gao, X.; Ge, L. Morphology-controlled WO3−x homojunction: Hydrothermal synthesis, adsorption properties, and visible-light-driven photocatalytic and chromic properties. Nanotechnology 2019, 30, 415601. [Google Scholar] [CrossRef] [PubMed]

- Costa, S.V.; Gonçalves, A.S.; Zaguete, M.A.; Mazon, T.; Nogueira, A.F. ZnO nanostructures directly grown on paper and bacterial cellulose substrates without any surface modification layer. Chem. Commun. 2013, 49, 8096–8098. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Yao, K.; Wang, B.; Ma, M.-G. Microwave-assisted hydrothermal synthesis of cellulose/ZnO composites and its thermal transformation to ZnO/carbon composites. Iran. Polym. J. 2017, 26, 681–691. [Google Scholar] [CrossRef]

- Sheng, C.; Wang, C.; Wang, H.; Jin, C.; Sun, Q.; Li, S. Self-photodegradation of formaldehyde under visible-light by solid wood modified via nanostructured Fe-doped WO3 accompanied with superior dimensional stability. J. Hazard. Mater. 2017, 328, 127–139. [Google Scholar] [CrossRef] [PubMed]

- Koli, V.B.; Dhodamani, A.G.; Delekar, S.D.; Pawar, S.H. In situ sol-gel synthesis of anatase TiO2-MWCNTs nanocomposites and their photocatalytic applications. J. Photochem. Photobiol. A Chem. 2017, 333, 40–48. [Google Scholar] [CrossRef]

- Addamo, M.; Augugliaro, V.; Di Paola, A.; García-López, E.; Loddo, V.; Marcì, G.; Palmisano, L. Photocatalytic thin films of TiO2 formed by a sol–gel process using titanium tetraisopropoxide as the precursor. Thin Solid Film. 2008, 516, 3802–3807. [Google Scholar] [CrossRef]

- Zhao, B.; Chen, Y.-W. Ag/TiO2 sol prepared by a sol–gel method and its photocatalytic activity. J. Phys. Chem. Solids 2011, 72, 1312–1318. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Q.; Lin, Y.; Antonova, E.; Bensch, W.; Patzke, G.R. One-step hydrothermal synthesis of hierarchical Ag/Bi2WO6 composites: In situ growth monitoring and photocatalytic activity studies. Sci. China Chem. 2013, 56, 435–442. [Google Scholar] [CrossRef]

- Kar, P.; Maji, T.K.; Nandi, R.; Lemmens, P.; Pal, S.K. In-Situ Hydrothermal Synthesis of Bi–Bi2O2CO3 Heterojunction Photocatalyst with Enhanced Visible Light Photocatalytic Activity. Nano-Micro Lett. 2016, 9, 18. [Google Scholar] [CrossRef]

- Guo, C.; Wu, B.; Ye, S.; Liu, J.; Deng, X.; Luo, L.; Li, Q.; Xiao, X.; Wang, J.; Liu, J.; et al. Enhancing the heterojunction component-interaction by in-situ hydrothermal growth toward photocatalytic hydrogen evolution. J. Colloid Interface Sci. 2022, 614, 367–377. [Google Scholar] [CrossRef]

- Jin, Z.; Hu, R.; Wang, H.; Hu, J.; Ren, T. One-step impregnation method to prepare direct Z-scheme LaCoO3/g-C3N4 heterojunction photocatalysts for phenol degradation under visible light. Appl. Surf. Sci. 2019, 491, 432–442. [Google Scholar] [CrossRef]

- Zou, J.-J.; Liu, C.-J.; Yu, K.-L.; Cheng, D.-G.; Zhang, Y.-P.; He, F.; Du, H.-Y.; Cui, L. Highly efficient Pt/TiO2 photocatalyst prepared by plasma-enhanced impregnation method. Chem. Phys. Lett. 2004, 400, 520–523. [Google Scholar] [CrossRef]

- Huang, Q.; Song, S.; Chen, Z.; Hu, B.; Chen, J.; Wang, X. Biochar-based materials and their applications in removal of organic contaminants from wastewater: State-of-the-art review. Biochar 2019, 1, 45–73. [Google Scholar] [CrossRef]

- Zhang, M.; Gao, B.; Varnoosfaderani, S.; Hebard, A.; Yao, Y.; Inyang, M. Preparation and characterization of a novel magnetic biochar for arsenic removal. Bioresour. Technol. 2013, 130, 457–462. [Google Scholar] [CrossRef]

- Chen, B.; Chen, Z.; Lv, S. A novel magnetic biochar efficiently sorbs organic pollutants and phosphate. Bioresour. Technol. 2011, 102, 716–723. [Google Scholar] [CrossRef] [PubMed]

- Mohan, D.; Kumar, H.; Sarswat, A.; Alexandre-Franco, M.; Pittman, C.U. Cadmium and lead remediation using magnetic oak wood and oak bark fast pyrolysis bio-chars. Chem. Eng. J. 2014, 236, 513–528. [Google Scholar] [CrossRef]

- Mohan, D.; Kumar, S.; Srivastava, A. Fluoride removal from ground water using magnetic and nonmagnetic corn stover biochars. Ecol. Eng. 2014, 73, 798–808. [Google Scholar] [CrossRef]

- Reguyal, F.; Sarmah, A.K.; Gao, W. Synthesis of magnetic biochar from pine sawdust via oxidative hydrolysis of FeCl2 for the removal sulfamethoxazole from aqueous solution. J. Hazard. Mater. 2017, 321, 868–878. [Google Scholar] [CrossRef]

- Chen, C.; Song, J.; Zhu, S.; Li, Y.; Kuang, Y.; Wan, J.; Kirsch, D.; Xu, L.; Wang, Y.; Gao, T.; et al. Scalable and Sustainable Approach toward Highly Compressible, Anisotropic, Lamellar Carbon Sponge. Chem 2018, 4, 544–554. [Google Scholar] [CrossRef]

- Berglund, L.A.; Burgert, I. Bioinspired Wood Nanotechnology for Functional Materials. Adv. Mater. 2018, 30, 1704285. [Google Scholar] [CrossRef]

- Athanasekou, C.P.; Morales-Torres, S.; Likodimos, V.; Romanos, G.E.; Pastrana-Martinez, L.M.; Falaras, P.; Dionysiou, D.D.; Faria, J.L.; Figueiredo, J.L.; Silva, A.M.T. Prototype composite membranes of partially reduced graphene oxide/TiO2 for photocatalytic ultrafiltration water treatment under visible light. Appl. Catal. B Environ. 2014, 158–159, 361–372. [Google Scholar] [CrossRef]

- Fu, R.; Shi, Q.; Yong, Z.; Griffith, J.C.; Yap, L.W.; Cheng, W. Self-assembled Janus plasmene nanosheets as flexible 2D photocatalysts. Mater. Horiz. 2021, 8, 259–266. [Google Scholar] [CrossRef] [PubMed]

- Xue, B.; Du, L.; Jin, J.; Meng, H.; Mi, J. In situ growth of MIL-88A into polyacrylate and its application in highly efficient photocatalytic degradation of organic pollutants in water. Appl. Surf. Sci. 2021, 564, 150404. [Google Scholar] [CrossRef]

- Song, H.; Wang, Y.; Ling, Z.; Zu, D.; Li, Z.; Shen, Y.; Li, C. Enhanced photocatalytic degradation of perfluorooctanoic acid by Ti3C2 MXene-derived heterojunction photocatalyst: Application of intercalation strategy in DESs. Sci. Total Environ. 2020, 746, 141009. [Google Scholar] [CrossRef] [PubMed]

- Iwu, K.O.; Strano, V.; Di Mauro, A.; Impellizzeri, G.; Mirabella, S. Enhanced Quality, Growth Kinetics, and Photocatalysis of ZnO Nanowalls Prepared by Chemical Bath Deposition. Cryst. Growth Des. 2015, 15, 4206–4212. [Google Scholar] [CrossRef]

- Miranda, C.; Mansilla, H.; Yáñez, J.; Obregón, S.; Colón, G. Improved photocatalytic activity of g-C3N4/TiO2 composites prepared by a simple impregnation method. J. Photochem. Photobiol. A Chem. 2013, 253, 16–21. [Google Scholar] [CrossRef]

- Jin, X.; Ma, K.; Chakkamalayath, J.; Morsby, J.; Gao, H. In Situ Photocatalyzed Polymerization to Stabilize Perovskite Nanocrystals in Protic Solvents. ACS Energy Lett. 2022, 7, 610–616. [Google Scholar] [CrossRef]

- Deng, X.; Zheng, X.; Jia, F.; Cao, C.; Song, H.; Jiang, Y.; Liu, Y.; Liu, G.; Li, S.; Wang, L. Unspecific peroxygenases immobilized on Pd-loaded three-dimensional ordered macroporous (3DOM) titania photocatalyst for photo-enzyme integrated catalysis. Appl. Catal. B Environ. 2023, 330, 122622. [Google Scholar] [CrossRef]

- Chen, D.; Cheng, Y.; Zhou, N.; Chen, P.; Wang, Y.; Li, K.; Huo, S.; Cheng, P.; Peng, P.; Zhang, R.; et al. Photocatalytic degradation of organic pollutants using TiO2-based photocatalysts: A review. J. Clean. Prod. 2020, 268, 121725. [Google Scholar] [CrossRef]

- Hu, B.; Ai, Y.; Jin, J.; Hayat, T.; Alsaedi, A.; Zhuang, L.; Wang, X. Efficient elimination of organic and inorganic pollutants by biochar and biochar-based materials. Biochar 2020, 2, 47–64. [Google Scholar] [CrossRef]

- Lu, Y.; Cai, Y.; Zhang, S.; Zhuang, L.; Hu, B.; Wang, S.; Chen, J.; Wang, X. Application of biochar-based photocatalysts for adsorption-(photo)degradation/reduction of environmental contaminants: Mechanism, challenges and perspective. Biochar 2022, 4, 45. [Google Scholar] [CrossRef]

- Fister, W.; Goldman, N.; Mayer, M.; Suter, M.; Kuhn, N.J. Testing of photogrammetry for differentiation of soil organic carbon and biochar in sandy substrates. Geogr. Helv. 2019, 74, 81–91. [Google Scholar] [CrossRef][Green Version]

- Archanjo, B.S.; Mendoza, M.E.; Albu, M.; Mitchell, D.; Hagemann, N.; Mayrhofer, C.; Anh, M.; Weng, H.; Kappler, A.; Behrens, S.; et al. Nanoscale analyses of the surface structure and composition of biochars extracted from field trials or after co-composting using advanced analytical electron microscopy. Geoderma 2017, 294, 70–79. [Google Scholar] [CrossRef]

- Liao, W.; Sifton, M.A.; Thomas, S.C. Biochar granulation reduces substrate erosion on green roofs. Biochar 2022, 4, 61. [Google Scholar] [CrossRef] [PubMed]

- Kühn, K.P.; Chaberny, I.F.; Massholder, K.; Stickler, M.; Benz, V.W.; Sonntag, H.-G.; Erdinger, L. Disinfection of surfaces by photocatalytic oxidation with titanium dioxide and UVA light. Chemosphere 2003, 53, 71–77. [Google Scholar] [CrossRef] [PubMed]

- Han, H.; Bai, R. Effect of Thickness of Photocatalyst Film Immobilized on a Buoyant Substrate on the Degradation of Methyl Orange Dye in Aqueous Solutions under Different Light Irradiations. Ind. Eng. Chem. Res. 2011, 50, 11922–11929. [Google Scholar] [CrossRef]

- Guan, G.; Kida, T.; Yoshida, A. Reduction of carbon dioxide with water under concentrated sunlight using photocatalyst combined with Fe-based catalyst. Appl. Catal. B Environ. 2003, 41, 387–396. [Google Scholar] [CrossRef]

- Bharadwaj, R.; Madhushree, R.; Sunaja Devi, K.R.; Pinheiro, D.; Manickam, S. Enhancing photocatalytic performance through surfactant-assisted electrochemical synthesis: Surface modification of hierarchical ZnO morphologies with Ag/ZnWO4 nanoparticles. J. Mol. Struct. 2024, 1306, 137835. [Google Scholar] [CrossRef]

- Charles, C.; Martin, N.; Devel, M.; Ollitrault, J.; Billard, A. Correlation between structural and optical properties of WO3 thin films sputter deposited by glancing angle deposition. Thin Solid Film. 2013, 534, 275–281. [Google Scholar] [CrossRef]

| Wood Species | Photocatalyst | Pollutant | PH | Light Source | Efficiency | Cycles of Reuse | Ref |

|---|---|---|---|---|---|---|---|

| Balsa wood | BiOBr/AgB | Rhodamine B (5 mg L−1) | 4 | 500-W xenon lamp | 99% | 5 | [75] |

| Fir wood | CdS quantum dots/nano-TiO2 | Co (20 mg L−1) | 2 | High-pressure mercury lamp | Almost 100% in 80 min | 83.4% after 5 cycles | [76] |

| Balsa wood | V2O5 nanowires | Methylene Blue (100 mg L−1) | 4.6 | 500-W xenon lamp | 51.6% | 10 | [77] |

| Carbonized wood | AgI/UiO-66-NH2 | Rhodamine B (10 mg L−1) | Not reported | 300-W xenon lamp | 96% | Above 85% after 6 cycles | [78] |

| Basswood | Pt/Au/TiO2 | Co (40 mg L−1) | Not reported | 300-W xenon lamp | 94% in 80 min | Not reported | [79] |

| Beech wood | Fe3O4 | TOC (19.4 mg L−1) | 1–9 | 100-W mimetic solar irradiation | 51% in 40 min | 4 | [80] |

| Balsa wood | TiO2 | Methylene Blue (0.1 mmol L−1) | Not reported | Sunlight | 97.7% in 12 h | Not reported | [81] |

| Poplar wood | CQDs@ MIL-88B | Methylene Blue (10 mg L−1) | 2 | 450-W xenon lamp | 98% in 60 min | 92% after 5 cycles | [82] |

| Natural wood | UiO-66 | OFX (4 ppm) | 2–8 | Simulated sunlight | 80.96% | 4 | [83] |

| Honeylocust spine wood | TiO2 | BPA (20 mg L−1) | 7 | 20-W UV lamp | 80.08% | Not reported | [84] |

| Walnut shell | Ag/TiO2 | MO (20 mg L−1) | Not reported | 500-W mercury-vapor lamp | 97.48% in 60 min | 96.10% after 5 cycles | [41] |

| Carbonized wood | Ag3PO4 | Methylene Blue (5 ppm) | 4.6 | Sunlight | About 65% in 90 min | Not reported | [85] |

| Balsa wood | Cu2O | Methyl orange (20 mg L−1) | 4 | Simulated visible light | 94.5% in 140 min | Above 80% after 5 cycles | [38] |

| White oak | TiO2 | Rhodamine B (1 × 10−5 M) | Not reported | 1 kW cm−2 irradiation | 92% in 60 min | 85% after 6 cycles | [86] |

| Wood waste | ZnO/AC | Methylene Blue (100 mg L−1) | 8 | Visible light | 89.73% in 180 min | Not reported | [87] |

| Wood flour | BiOBr | Rhodamine B (20 mg L−1) | Not reported | 200-W LED | Almost 100% in 30 min | Not reported | [88] |

| Poplar wood | pCN/BiVO4 | Rhodamine B (10 mg L−1) | 3 | 400-W mercury lamp | 97.3% in 30 min | Above 90% after 4 cycles | [58] |

| Wood-based activated carbon fiber | Mn/TiO2 | Methylene Blue (33 mg L−1) | Not reported | Visible light | 96% in 4 h | Not reported | [62] |

| Balsa wood | Ag | MB/NaBH4 (100 mg L−1) | 2–12 | Simulated visible light | 94.45% in 10 h | 10 | [57] |

| Fir wood | Cu2O | Methylene Blue (6 mg L−1) | 5 | Visible light | 92.82% in 12 h | Above 80% after 60 cycles | [89] |

| Synthetic Method | Operational Approach | Advantages | Limitations | Ref |

|---|---|---|---|---|

| Sol-gel method | (1) Solvation; (2) Hydrolysis; (3) Polycondensation. | High purity; Low processing temperature; Good adhesion; Low equipment requirements; Simple process; The reaction is easy to control; Product forms are diverse; Homogeneous coating. | Longer time requirements; The manufacturing cost is higher; High water content; The drying stage is easy to crack due to weightlessness; There may be pores; Potential agglomeration; Limited scalability. | [132,133,134] |

| Hydrothermal method | (1) Selecting a reaction precursor and determining the ratio of the precursors; (2) Determining the adding sequence of precursors and stirring wet materials; (3) Load and seal the autoclave, and then put it into the oven; (4) Select the reaction temperature, time and state. | Enhanced crystallinity; The grain linearity is moderately adjustable; No complicated post-treatment; Low reaction energy consumption; High yield; The crystal form and morphology are related to hydrothermal conditions. | Limited precursor options; Limited scalability; Precise control of reaction parameters; By-product formation; Limited application range. | [135,136,137] |

| Immersion method | (1) Preparation of semiconductor support; (2) Impregnation of precursor; (3) Drying; (4) Thermal treatment. | Suitable for substrates of various shapes and sizes; The forming steps are quick and simple; High utilization rate; Relatively low cost. | Limited Penetration; Potential agglomeration; Difficulties in controlling nanoscale features; Precursor solubility; Drying and other conditions may be required. | [138,139] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Ge-Zhang, S.; Wang, Y.; Mu, H. A Wooden Carbon-Based Photocatalyst for Water Treatment. Int. J. Mol. Sci. 2024, 25, 4743. https://doi.org/10.3390/ijms25094743

Zhang C, Ge-Zhang S, Wang Y, Mu H. A Wooden Carbon-Based Photocatalyst for Water Treatment. International Journal of Molecular Sciences. 2024; 25(9):4743. https://doi.org/10.3390/ijms25094743

Chicago/Turabian StyleZhang, Chang, Shangjie Ge-Zhang, Yudong Wang, and Hongbo Mu. 2024. "A Wooden Carbon-Based Photocatalyst for Water Treatment" International Journal of Molecular Sciences 25, no. 9: 4743. https://doi.org/10.3390/ijms25094743

APA StyleZhang, C., Ge-Zhang, S., Wang, Y., & Mu, H. (2024). A Wooden Carbon-Based Photocatalyst for Water Treatment. International Journal of Molecular Sciences, 25(9), 4743. https://doi.org/10.3390/ijms25094743