A Flexible Proximity Sensor Fully Fabricated by Inkjet Printing

Abstract

:1. Introduction

2. The Sensor Structure

3. Preparation of Inkjet Solutions

4. Fabrication Process

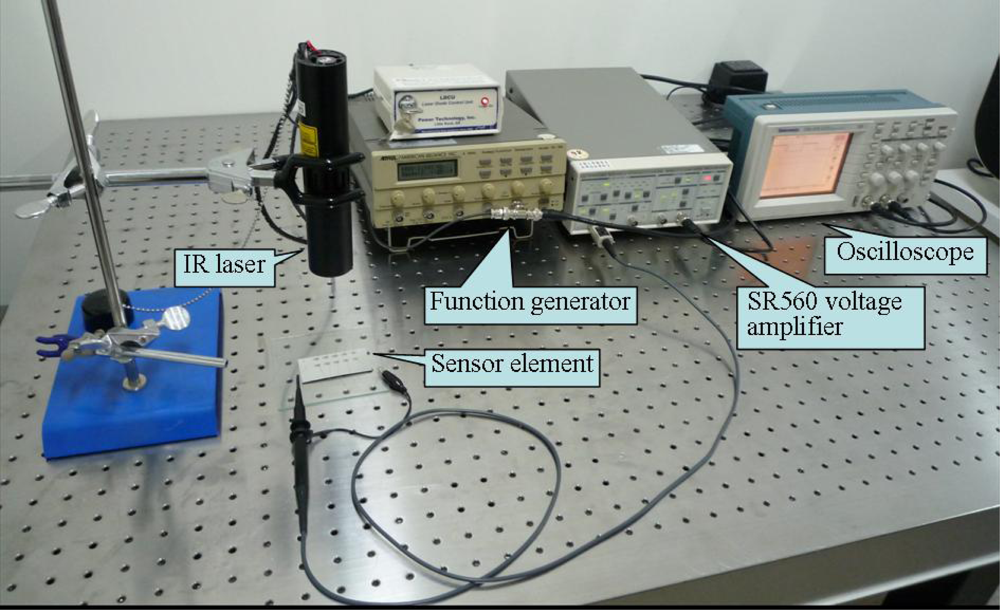

5. Signal Measurement

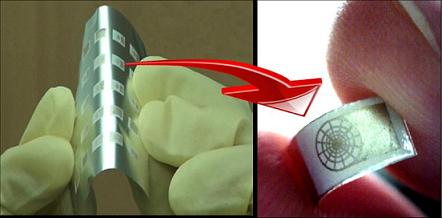

6. Prototype Demonstration

7. Conclusions

Acknowledgments

References

- Cheng, I.C.; Wagner, S. Overview of flexible electronics technology. In Flexible Electronics—Materials and Applications; Wong, W.S., Salleo, A., Eds.; Springer: New York, NY, USA, 2009; pp. 15–16. [Google Scholar]

- Li, L.; Zhang, L.; Yao, X.; Li, B. Computer simulation of temperature field of multilayer pyroelectric thin film IR detector. Ceram. Internat 2004, 30, 1847–1850. [Google Scholar]

- Wei, C.S.; Lin, Y.Y.; Hu, Y.C.; Wu, C.W.; Shih, C.K.; Huang, C.T.; Chang, S.H. Partial-electrode ZnO pyroelectric sensors for responsivity improvement. Sens. Actuat. A–Phys 2006, 128, 18–24. [Google Scholar]

- Özgur, Ü.; Teke, A.; Liu, S.J.; Cho, H.M.; Everitt, H.O. Stimulated emission and time-resolved photoluminescence in RF-sputtered ZnO thin films. Appl. Phys. Lett 2004, 84, 3223–3225. [Google Scholar]

- Li, B.S.; Liu, Y.C.; Chu, Z.S.; Shen, D.Z.; Lu, Y.M.; Zhang, J.Y.; Fan, X.W. High quality ZnO thin films grown by plasma enhanced chemical vapor deposition. J. Appl. Phys 2002, 91, 501–505. [Google Scholar]

- Tan, S.T.; Chen, B.J.; Sun, X.W.; Fan, W.J. Blueshift of optical band gap in ZnO thin films grown by metal-organic chemical-vapor deposition. J. Appl. Phys 2005, 98, 013505. [Google Scholar]

- Pal, B.; Sharon, M. Enhanced photo-catalytic activity of highly porous ZnO thin films prepared by sol-gel process. Mater. Chem. Phys 2002, 76, 82–87. [Google Scholar]

- Ayouchi, R.; Leinen, D.; Martin, F.; Gabas, M.; Dalchiele, E.; Ramos-Barrado, J.R. Preparation and characterization of transparent ZnO thin films obtained by spray pyrolysis. Thin Solid Films 2003, 426, 68–77. [Google Scholar]

- Cheng, I.-C.; Wagner, S. Overview of Flexible Electronics Technology. In Flexible Electronics Materials and Applications; Wong, W.S., Salleo, A., Eds.; Springer: New York, NY, USA, 2009; p. 20. [Google Scholar]

| Plasma | Gas | Compressed dry air |

| Flow rate | 45 slm | |

| Power | 350 W/20 kHz | |

| Stage moving speed | 10 mm/s in x-direction | |

| Stage moving pitch | 2 mm in y-direction | |

| Inkjet printing | Firing voltage | 28 V |

| Drop space | 30 μm | |

| Jetting frequency | 1 kHz | |

| Substrate temperature | 60 °C | |

| Cartridge print height | 1 mm | |

| ZnO anneal |  | |

| Nano-silver curing | Oven Vacuum | 6.7×10−2 Pa |

| Temperature | 200 °C | |

| Time | 30 min. | |

© 2010 by the authors; licensee MDPI, Basel, Switzerland. This article is an Open Access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Wang, C.-T.; Huang, K.-Y.; Lin, D.T.W.; Liao, W.-C.; Lin, H.-W.; Hu, Y.-C. A Flexible Proximity Sensor Fully Fabricated by Inkjet Printing. Sensors 2010, 10, 5054-5062. https://doi.org/10.3390/s100505054

Wang C-T, Huang K-Y, Lin DTW, Liao W-C, Lin H-W, Hu Y-C. A Flexible Proximity Sensor Fully Fabricated by Inkjet Printing. Sensors. 2010; 10(5):5054-5062. https://doi.org/10.3390/s100505054

Chicago/Turabian StyleWang, Chin-Tsan, Kuo-Yi Huang, David T. W. Lin, Wei-Chia Liao, Hua-Wei Lin, and Yuh-Chung Hu. 2010. "A Flexible Proximity Sensor Fully Fabricated by Inkjet Printing" Sensors 10, no. 5: 5054-5062. https://doi.org/10.3390/s100505054

APA StyleWang, C.-T., Huang, K.-Y., Lin, D. T. W., Liao, W.-C., Lin, H.-W., & Hu, Y.-C. (2010). A Flexible Proximity Sensor Fully Fabricated by Inkjet Printing. Sensors, 10(5), 5054-5062. https://doi.org/10.3390/s100505054