Detection of Defects in Reinforced Concrete Structures Using Ultrasonic Nondestructive Evaluation with Piezoceramic Transducers and the Time Reversal Method

Abstract

:1. Introduction

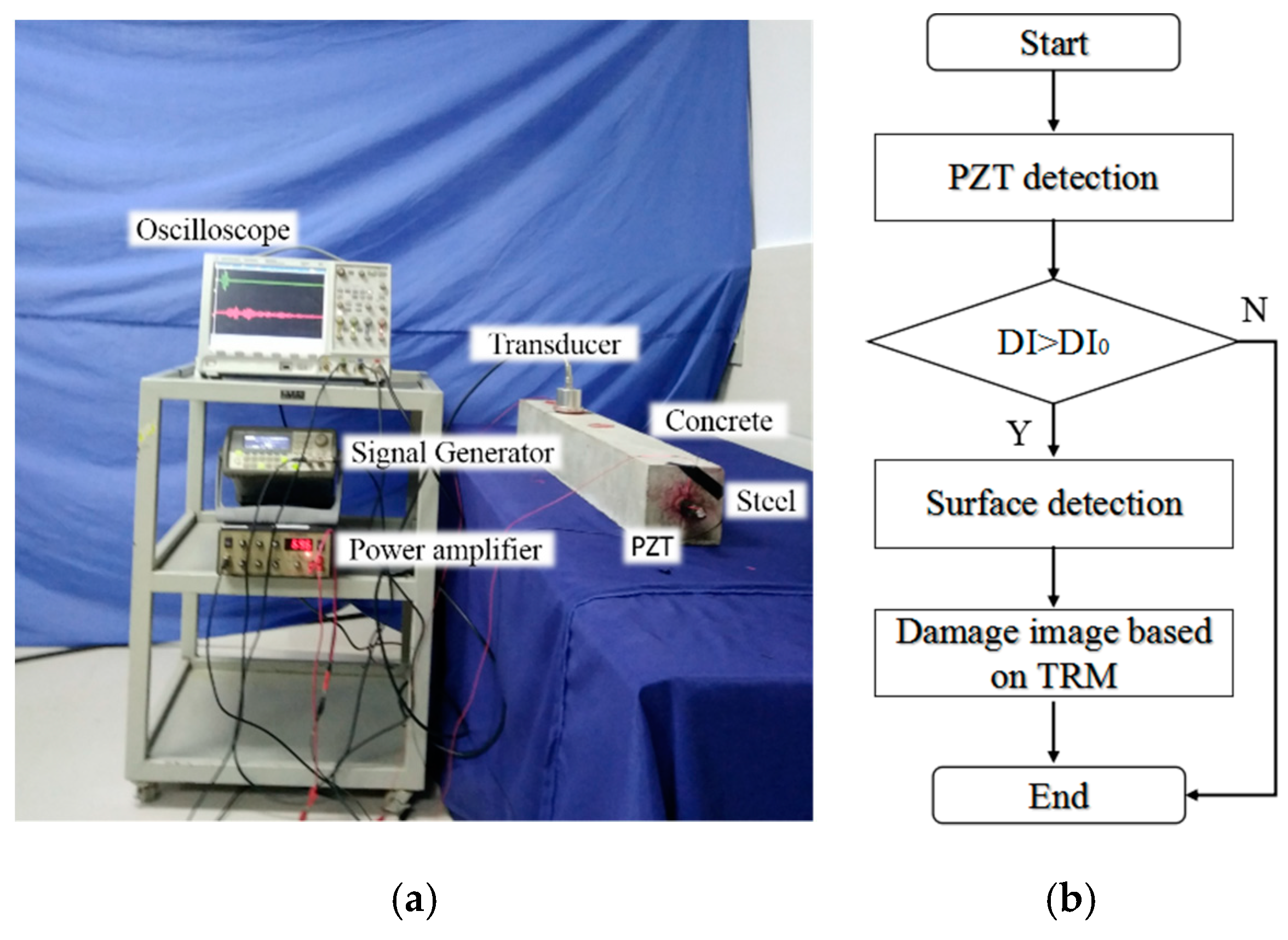

2. Detecting System

2.1. Wave Selection for Time Reversed Method

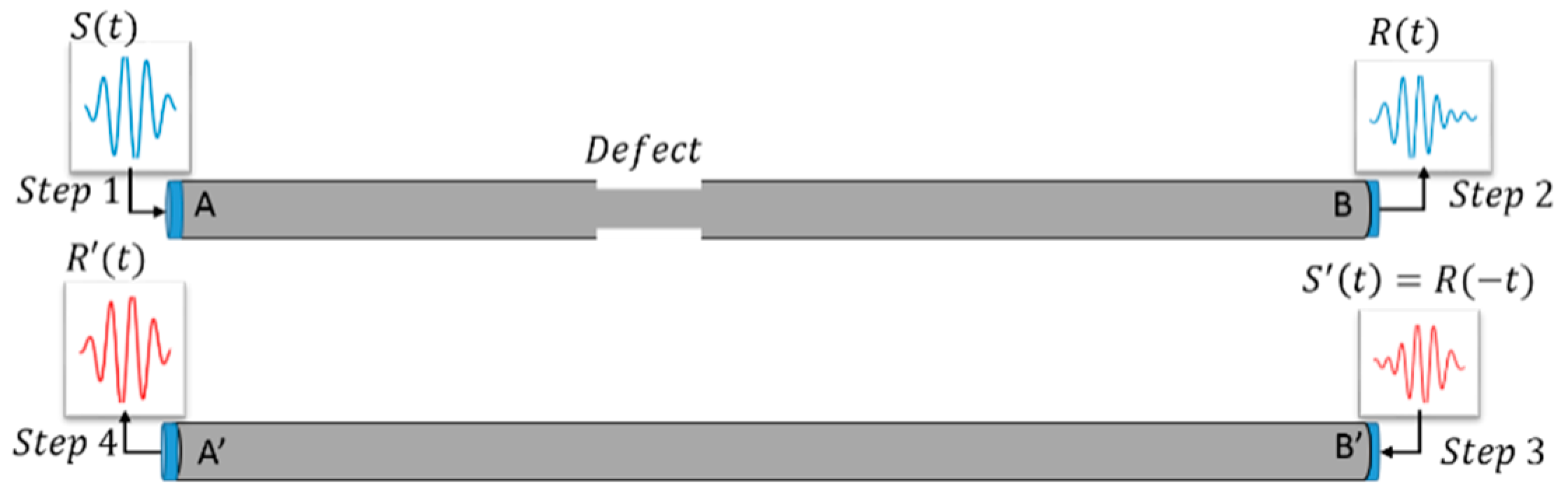

2.2. Steel Reinforced Concrete Corrosion Detecting System Based on Time Reversed Method

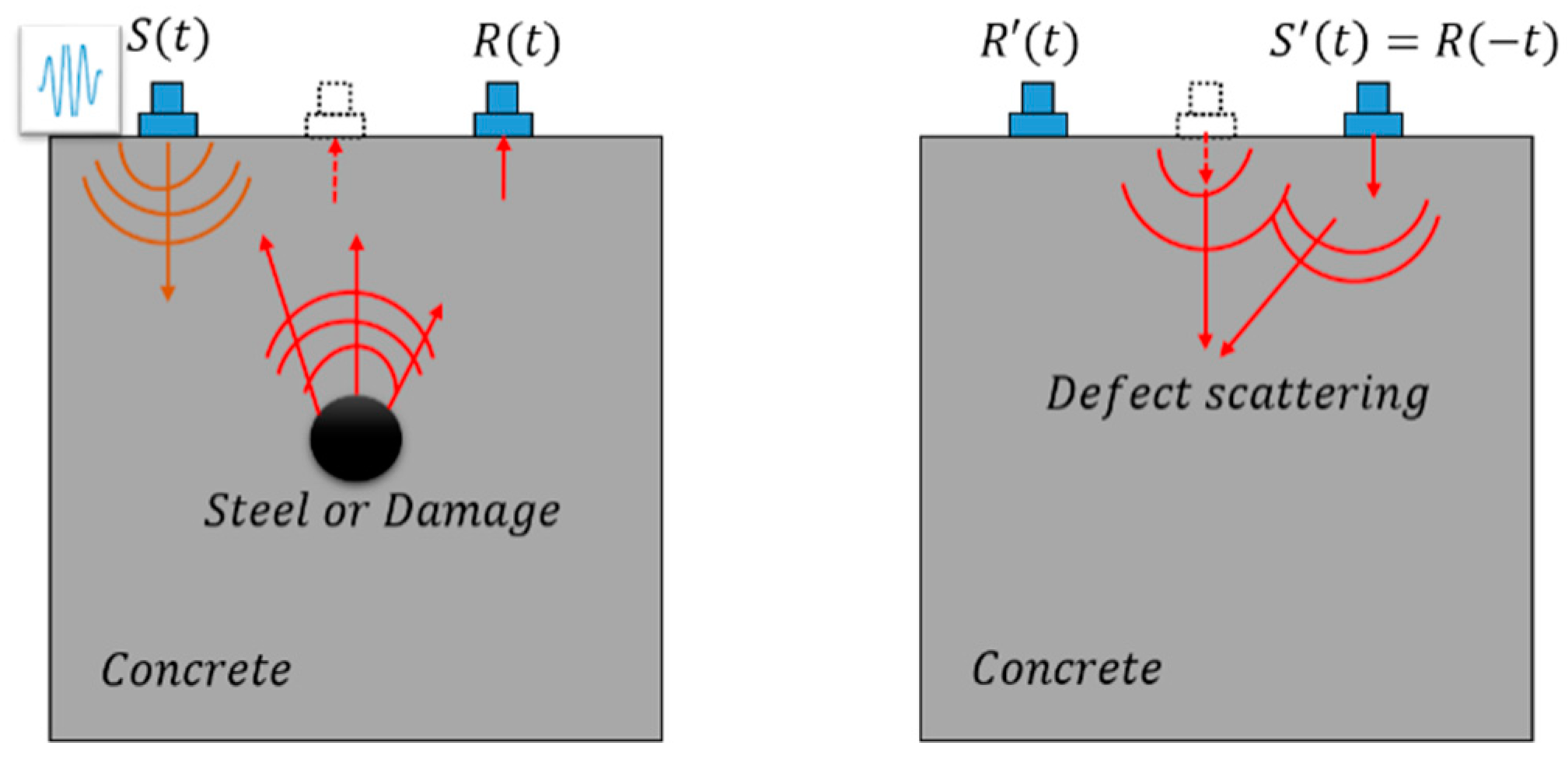

2.3. Reinforced Concrete Detecting Method Based on Time Reversed Method

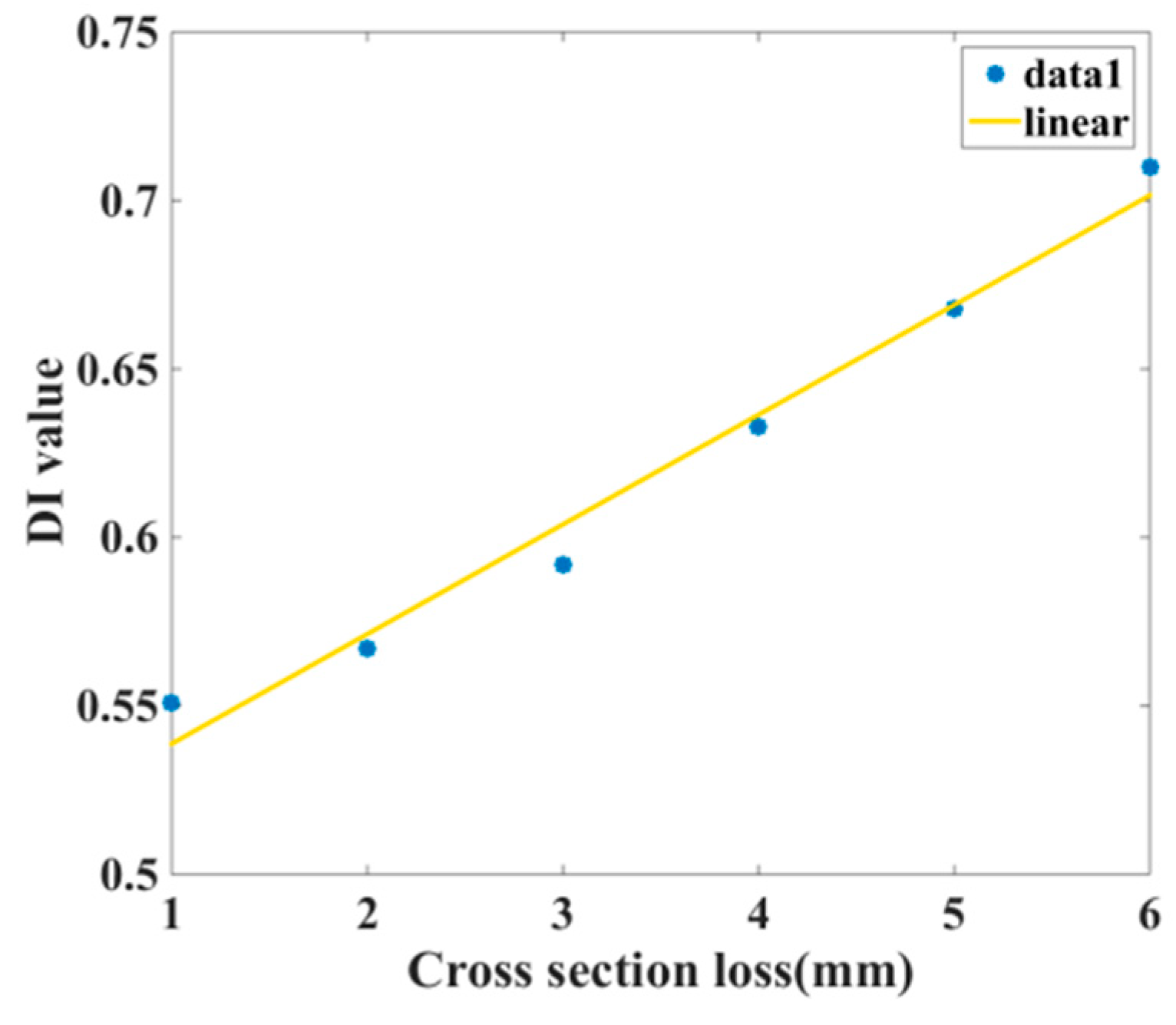

2.4. Damage Index

2.5. Imaging Algorithm

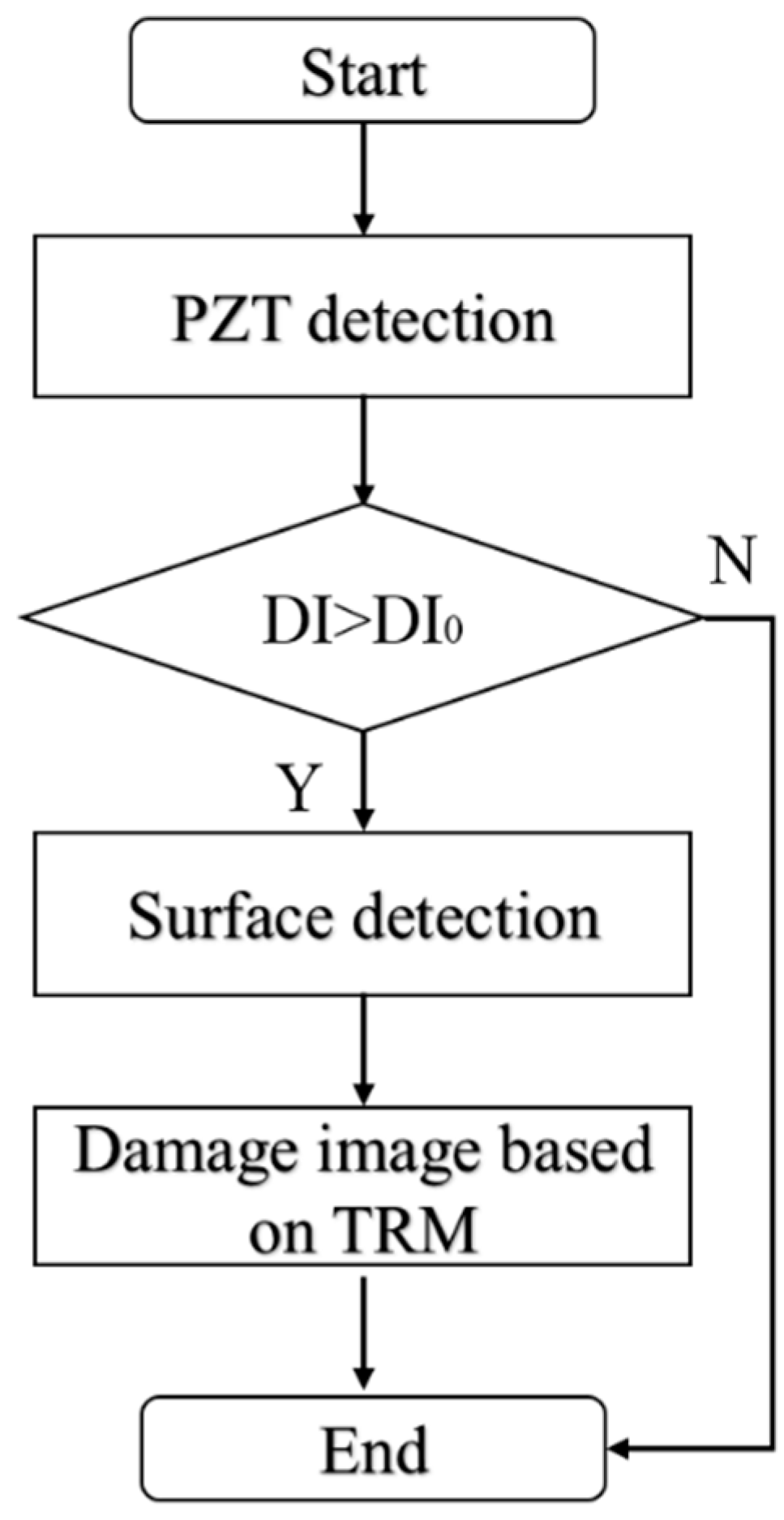

2.6. The Overall Time Reversed Method Based Defect Detection Procedure

3. Experimental Setup

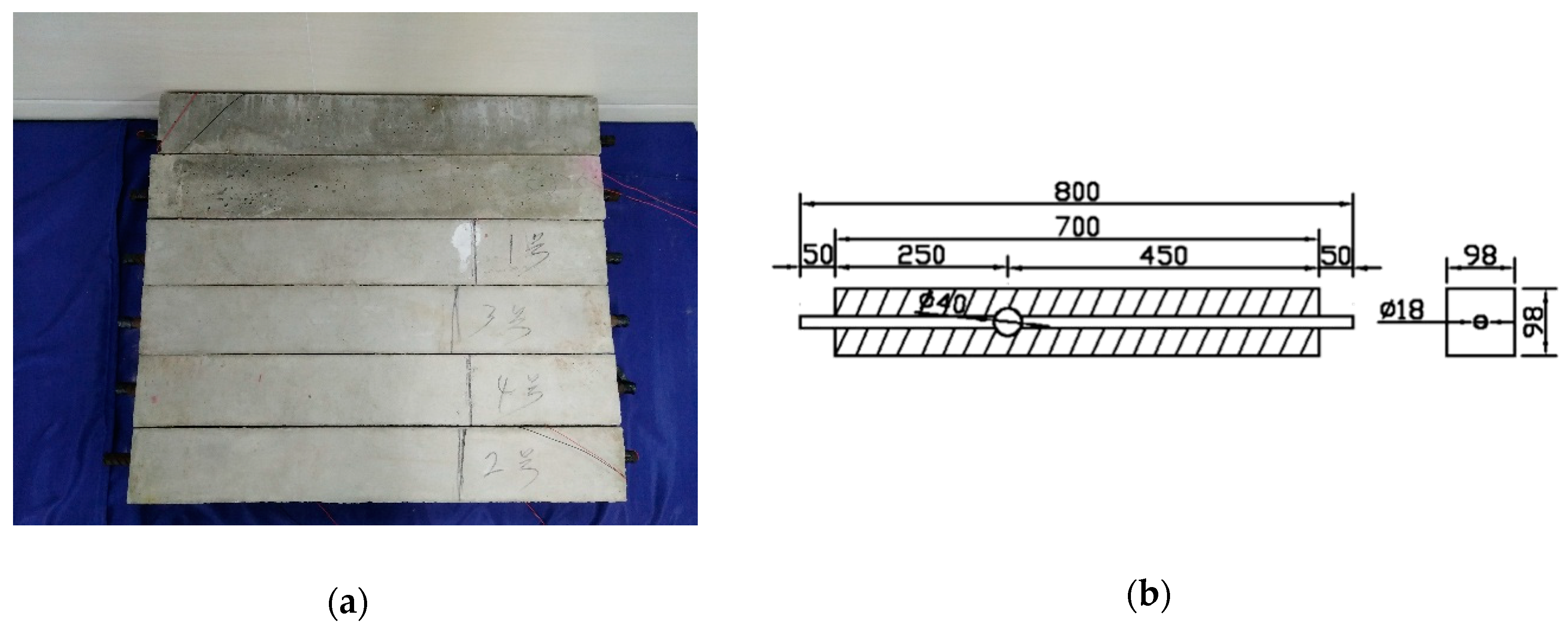

3.1. Specimens and Transducers

3.2. Experimental Setup

4. Results and Discussion

4.1. Results

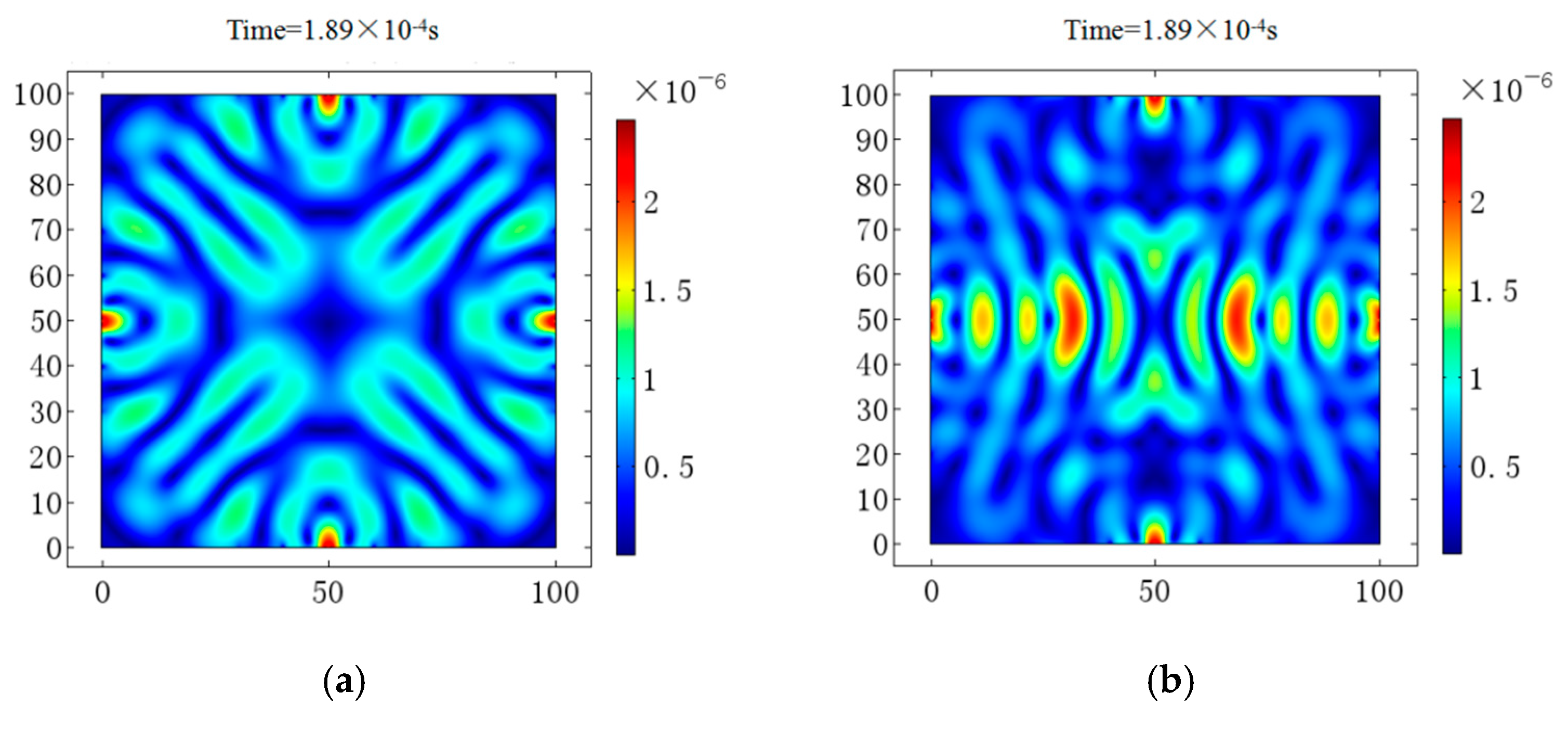

4.2. Discussion of the Two Defects Inside the Concrete Section

5. Conclusions

- The defect depths along the interface of steel and concrete can be evaluated by an L (0,1) ultrasonic guided wave actuated at one end of the steel based on time reversed method. The DI curve was linear to the cross-section loss along the interface of steel and concrete.

- After detecting the location of the defect, another time reversed method detecting system was performed at a certain “defected” boundary surface of the reinforced concrete samples to continue the time reversed method damage image. By comparing the intact cross-section and the defect cross-section, the time-reversal waves can locate the damage inside the reinforced concrete samples by focusing on the area of the damage.

- In the discussion part, the concrete without steel is simulated to apply the time reversed method to identify the two signal sources. The results showed that the two signal sources inside the concrete can also be localized using UT based on time reversed method. This work can help the engineer detect multiple damages in reinforced concrete structures if the damages are not very far from each other.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, J.; Lee, C.; Park, S. Artificial neural network-based early-age concrete strength monitoring using dynamic response signals. Sensors 2017, 17, 1319. [Google Scholar] [CrossRef] [PubMed]

- Du, G.; Kong, Q.; Wu, F.; Ruan, J.; Song, G. An experimental feasibility study of pipeline corrosion pit detection using a piezoceramic time reversal mirror. Smart Mater. Struct. 2016, 25, 037002. [Google Scholar] [CrossRef]

- Feng, Q.; Kong, Q.; Huo, L.; Song, G. Crack detection and leakage monitoring on reinforced concrete pipe. Smart Mater. Struct. 2015, 24, 115020. [Google Scholar] [CrossRef]

- Zhang, J.K.; Yan, W.; Cui, D.M. Concrete condition assessment using impact-echo method and extreme learning machines. Sensors 2016, 16, 447. [Google Scholar] [CrossRef] [PubMed]

- Kong, Q.; Robert, R.; Silva, P.; Mo, Y.L. Cyclic crack monitoring of a reinforced concrete column under simulated pseudo-dynamic loading using piezoceramic-based smart aggregates. Appl. Sci. 2016, 6, 341. [Google Scholar] [CrossRef]

- Kong, Q.; Fan, S.; Bai, X.; Mo, Y.; Song, G. A novel embeddable spherical smart aggregate for structural health monitoring Part I. Fabrication and electrical characterization. Smart Mater. Struct. 2017, 26, 095050. [Google Scholar] [CrossRef]

- Kong, Q.; Fan, S.; Mo, Y.L.; Song, G. A novel embeddable spherical smart aggregate for structural health monitoring: Part II. Numerical and experimental verifications. Smart Mater. Struct. 2017, 26, 095051. [Google Scholar] [CrossRef]

- Shao, J.; Wang, T.; Yin, H.; Yang, D.; Li, Y. Bolt looseness detection based on piezoelectric impedance frequency shift. Appl. Sci. 2016, 6, 298. [Google Scholar] [CrossRef]

- Lu, G.; Feng, Q.; Li, Y.; Wang, H.; Song, G. Characterization of ultrasound energy diffusion due to small-size damage on an aluminum plate using piezoceramic transducers. Sensors 2017, 17, 2796. [Google Scholar] [CrossRef] [PubMed]

- Yin, H.; Wang, T.; Yang, D.; Liu, S.; Shao, J.; Li, Y. A smart washer for bolt looseness monitoring based on piezoelectric active sensing method. Appl. Sci. 2016, 6, 320. [Google Scholar] [CrossRef]

- Rao, J.; Ratassepp, M.; Lisevych, D.; Hamzah, M.C.; Fan, Z. On-line corrosion monitoring of plate structures based on guided wave tomography using piezoelectric sensors. Sensors 2017, 17, 2882. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Li, Z.; Jin, W. A new corrosion sensor to determine the start and development of embedded rebar corrosion process at coastal concrete. Sensors 2013, 13, 13258–13275. [Google Scholar] [CrossRef] [PubMed]

- Jiang, T.; Kong, Q.; Patil, D.; Luo, Z.; Huo, L.; Song, G. Detection of debonding between fiber reinforced polymer bar and concrete structure using piezoceramic transducers and wavelet packet analysis. IEEE Sens. J. 2017, 17, 1992–1998. [Google Scholar] [CrossRef]

- Song, G.; Li, W.; Wang, B.; Ho, S.C.M. A review of rock bolt monitoring using smart sensors. Sensors 2017, 17, 776. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Ren, L.; Ho, S.C.; Jia, Z.; Song, G. Gas pipeline leakage detection based on pzt sensors. Smart Mater. Struct. 2017, 26, 025022. [Google Scholar] [CrossRef]

- Hong, X.; Song, G.; Ruan, J.; Zhang, Z.; Wu, S.; Liu, G. Active monitoring of pipeline tapered thread connection based on time reversal using piezoceramic transducers. Smart Struct. Syst. 2016, 18, 643–662. [Google Scholar] [CrossRef]

- Kao, H.; Shan, S.J. The source-scanning algorithm: Mapping the distribution of seismic sources in time and space. Geophys. J. R. Astron. Soc. 2004, 157, 589–594. [Google Scholar] [CrossRef]

- Gajewski, D.; Tessmer, E. Reverse modelling for seismic event characterization. Geophys. J. Int. 2005, 163, 276–284. [Google Scholar] [CrossRef] [Green Version]

- Saenger, E.H.; Kocur, G.K. Time reverse characterization of sources in 2d and 3d heterogeneous media. NDT E Int. 2011, 44, 751–759. [Google Scholar] [CrossRef]

- Pierson, D.M. Buried-Object Detection Using Time-Reversed Acoustics. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, December 2003. [Google Scholar]

- Prada, C.; Kerbrat, E.; Cassereau, D.; Fink, M. Time reversal techniques in ultrasonic nondestructive testing of scattering media. Inverse Probl. 2002, 18, 1761. [Google Scholar] [CrossRef]

- Gliozzi, A.S.; Griffa, M.; Scalerandi, M. Efficiency of time-reversed acoustics for nonlinear damage detection in solids. J. Acoust. Soc. Am. 2006, 120, 2506–2517. [Google Scholar] [CrossRef]

- Gruber, F.K.; Marengo, E.A.; Devaney, A.J. Time-reversal imaging with multiple signal classification considering multiple scattering between the targets. Acoust. Soc. Am. J. 2004, 115, 3042–3047. [Google Scholar] [CrossRef]

- Zhang, G.; Gao, W.; Song, G.; Song, Y. An imaging algorithm for damage detection with dispersion compensation using piezoceramic induced lamb waves. Smart Mater. Struct. 2017, 26, 025017. [Google Scholar] [CrossRef]

- Tian, Z.; Huo, L.; Gao, W.; Song, G.; Li, H. Grouting monitoring of post-tensioning tendon duct using pzt enabled time-reversal method. Measurement 2018, 122, 513–521. [Google Scholar] [CrossRef]

- Jiang, T.; Kong, Q.; Wang, W.; Huo, L.; Song, G. Monitoring of grouting compactness in a post-tensioning tendon duct using piezoceramic transducers. Sensors 2016, 16, 1343. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Li, D.; Kong, Q.; Song, G. Load monitoring of the pin-connected structure using time reversal technique and piezoceramic transducers—A feasibility study. IEEE Sens. J. 2016, 16, 7958–7966. [Google Scholar] [CrossRef]

- Saenger, E.H.; Kocur, G.K.; Jud, R.; Torrilhon, M. Application of time reverse modeling on ultrasonic non-destructive testing of concrete. Appl. Math. Model. 2011, 35, 807–816. [Google Scholar] [CrossRef]

- Yoon, H.; Kim, Y.J.; Kim, H.S.; Kang, J.W.; Koh, H.M. Evaluation of early-age concrete compressive strength with ultrasonic sensors. Sensors 2017, 17, 1817. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Zhu, H.; Wang, D. A study of concrete slab damage detection based on the electromechanical impedance method. Sensors 2014, 14, 19897–19909. [Google Scholar] [CrossRef] [PubMed]

- Nakahata, K.; Kawamura, G.; Yano, T.; Hirose, S. Three-dimensional numerical modeling of ultrasonic wave propagation in concrete and its experimental validation. Constr. Build. Mater. 2015, 78, 217–223. [Google Scholar] [CrossRef]

- Rucka, M.; Wilde, K. Experimental study on ultrasonic monitoring of splitting failure in reinforced concrete. J. Nondestruct. Eval. 2013, 32, 372–383. [Google Scholar] [CrossRef]

- Mustapha, S. Damage detection in rebar-reinforced concrete beams based on time reversal of guided waves. Struct. Health Monit. 2014, 13, 347–358. [Google Scholar] [CrossRef]

- Lu, Y.; Li, J.; Ye, L.; Wang, D. Guided waves for damage detection in rebar-reinforced concrete beams. Constr. Build. Mater. 2013, 47, 370–378. [Google Scholar] [CrossRef]

- Ranz, J.; Aparicio, S.; Romero, H.; Casati, M.J.; Molero, M.; González, M. Monitoring of freeze-thaw cycles in concrete using embedded sensors and ultrasonic imaging. Sensors 2014, 14, 2280–2304. [Google Scholar] [CrossRef] [PubMed]

- Rose, J.L. Ultrasonic waves in solid media. J. Acoust. Soc. Am. 2000, 107, 1807–1808. [Google Scholar] [CrossRef]

- Kohl, T.W. Ultrasonic Guided Waves in Cylinders: Theory and Experiment. Ph.D. Thesis, The University of Colorado Boulder, Boulder, CO, USA, 1993. [Google Scholar]

- Wang, D.; Ye, L.; Su, Z.; Lu, Y.; Li, F.; Meng, G. Probabilistic damage identification based on correlation analysis using guided wave signals in aluminum plates. Struct. Health Monit. 2009, 9, 133–144. [Google Scholar] [CrossRef]

| Material | Steel | Concrete |

|---|---|---|

| Young modulus | 200 GPa | 25 GPa |

| Density | 7850 kg/m3 | 2300 kg/m3 |

| Poisson ratio | 0.33 | 0.3 |

| Geometry | d = 18 mm, l = 800 mm | a = 98 mm, l = 700 mm |

| Material | Steel | Reinforced Concrete | Concrete |

|---|---|---|---|

| Central frequency | 75 kHz | 35 kHz | 100 kHz |

| Amplitude | 100 | 100 | 100 |

| Number of cycles | 5 | 5 | 5 |

| Sampling frequencies | 10 MHz | 10 MHz | 10 MHz |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, G.; Zhang, D.; Zhang, L.; Wang, B. Detection of Defects in Reinforced Concrete Structures Using Ultrasonic Nondestructive Evaluation with Piezoceramic Transducers and the Time Reversal Method. Sensors 2018, 18, 4176. https://doi.org/10.3390/s18124176

Zhao G, Zhang D, Zhang L, Wang B. Detection of Defects in Reinforced Concrete Structures Using Ultrasonic Nondestructive Evaluation with Piezoceramic Transducers and the Time Reversal Method. Sensors. 2018; 18(12):4176. https://doi.org/10.3390/s18124176

Chicago/Turabian StyleZhao, Guoqi, Di Zhang, Lu Zhang, and Ben Wang. 2018. "Detection of Defects in Reinforced Concrete Structures Using Ultrasonic Nondestructive Evaluation with Piezoceramic Transducers and the Time Reversal Method" Sensors 18, no. 12: 4176. https://doi.org/10.3390/s18124176

APA StyleZhao, G., Zhang, D., Zhang, L., & Wang, B. (2018). Detection of Defects in Reinforced Concrete Structures Using Ultrasonic Nondestructive Evaluation with Piezoceramic Transducers and the Time Reversal Method. Sensors, 18(12), 4176. https://doi.org/10.3390/s18124176