Non-Destructive Methodology to Determine Modulus of Elasticity in Static Bending of Quercus mongolica Using Near-Infrared Spectroscopy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. NIR Spectra Measurements

2.3. Detemination of MOE in Static Bending

2.4. Calibration Set and Predition Set Partitioning Using Improved Kennard-Stone Method

2.5. Pretreatment of NIR Spectra

2.6. Characteristic Spectrum Extraction

2.6.1. SiPLS

2.6.2. SPA

2.7. Model Evaluation Standard

3. Results and Discussion

3.1. Determination of the MOE and Dataset Partitioning

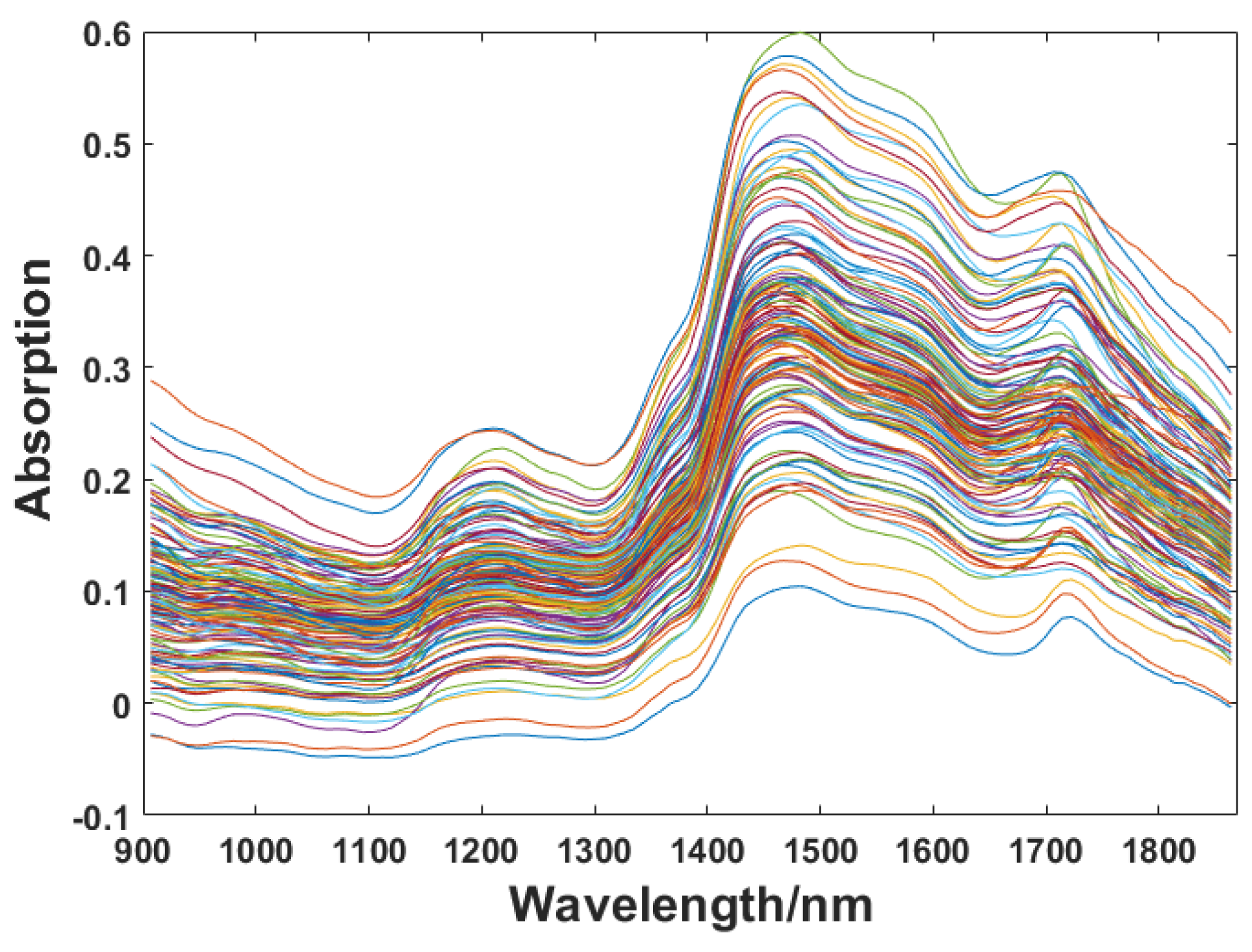

3.2. Near-Infrared Spectra of Specimens and Spectral Pretreatment

3.3. Characteristic Spectrum Selection

3.3.1. Optimal Spectra Intervals Selected by SiPLS

3.3.2. Characteristic Wavelengths Selected by SPA

3.4. Analysis of the Predictive Models

4. Conclusions

- (1)

- The improved K-S method can make the sample distribution uniform, and ensure that the calibration set is widely distributed

- (2)

- By pretreating with MSC and the SG smoothing and differentiation filter, the overall variation trend of spectra was more consistent, and the contour of spectra was more clear. Moreover, the absorption peak is more obvious. When the window size of SG was of 11, the effect of pretreatment was the best

- (3)

- SiPLS combined with SPA could extract characteristic wavelengths that had the closest relevance with the MOE of Quercus mongolica. It reduced the dimensions of the original data, decreasing the computation and reducing the complexity of the modelling process.

- (4)

- Compared with the prediction results, BPNN was better capable of predicting the MOE of the specimens by using the characteristic wavelengths to establish the calibration model. The rp, RMSEP, and RPD of BPNN were 0.91, 0.76, and 2.93, respectively. The quantitative prediction effects of the model can meet the needs of actual industrial activities.

Author Contributions

Funding

Conflicts of Interest

References

- Rakotovololonalimanana, H.; Chaix, G.; Brancheriau, L.; Ramamonjisoa, L.; Ramananantoandro, T.; Thevenon, M.F. A novel method to correct for wood MOE ultrasonics and NIRS measurements on increment cores in Liquidambar styraciflua L. Ann. For. Sci. 2015, 72, 753–761. [Google Scholar] [CrossRef]

- Tsuchikawa, S. A review of recent near infrared research for wood and paper. Appl. Spectrosc. Rev. 2007, 42, 43–71. [Google Scholar] [CrossRef]

- Eom, C.D.; Park, J.H.; Choi, I.G.; Choi, J.W.; Han, Y.; Yeo, H. Determining surface emission coefficient of wood using theoretical methods and near-infrared spectroscopy. Wood Fiber Sci. 2013, 4, 76–83. [Google Scholar]

- Watanabe, K.; Kobayashi, I.; Saito, S.; Kuroda, N.; Noshiro, S. Nondestructive evaluation of drying stress level on wood surface using near-infrared spectroscopy. Wood Sci. Technol. 2013, 47, 299–315. [Google Scholar] [CrossRef]

- Santos, A.; Alves, A.; Simões, R.; Pereira, H.; Rodrigues, J.; Schwanninger, M. Estimation of wood basic density of Acacia melanoxylon (r. br.) by near infrared spectroscopy. J. Near Infrared Spectrosc. 2012, 20, 267–274. [Google Scholar] [CrossRef]

- Schimleck, L.; Matos, J.L.M.; Trianoski, R.; Prata, J. Comparison of methods for estimating mechanical properties of wood by NIR spectroscopy. J. Spectrosc. 2018, 2018, 4823285. [Google Scholar] [CrossRef]

- Todorović, N.; Popović, Z.; Milić, G. Estimation of quality of thermally modified beech wood with red heartwood by FT-NIR spectroscopy. Wood Sci. Technol. 2015, 49, 527–549. [Google Scholar] [CrossRef]

- Acquah, G.E.; Essien, C.; Via, B.K.; Billor, N.; Eckhardt, L.G. Estimating the basic density and mechanical properties of elite loblolly pine families with near infrared spectroscopy. For. Sci. 2018, 64, 149–158. [Google Scholar] [CrossRef]

- Andrade, C.R.; Trugilho, P.F.; Napoli, A.; Vieira, R.D.S.; Lima, J.T.; Sousa, L.C.D. Estimation of the mechanical properties of wood from Eucalyptus urophylla using near infrared spectroscopy. Cerne 2010, 16, 291–298. [Google Scholar] [CrossRef]

- Liang, H.; Cao, J.; Tu, W.; Lin, X.; Zhang, Y. Nondestructive determination of the compressive strength of wood using near-infrared spectroscopy. Bioresources 2016, 11, 7205–7213. [Google Scholar] [CrossRef]

- Horvath, L.; Peszlen, I.; Peralta, P.; Kelley, S. Use of transmittance near-infrared spectroscopy to predict the mechanical properties of 1- and 2-year-old transgenic aspen. Wood Sci. Technol. 2011, 45, 303–314. [Google Scholar] [CrossRef]

- Singh, K.R.; Chaudhury, S. Efficient technique for rice grain classification using back-propagation neural network and wavelet decomposition. IET Comput. Vis. 2017, 10, 780–787. [Google Scholar] [CrossRef]

- Brereton, R.G.; Lloyd, G.R. Support vector machines for classification and regression. Analyst 2010, 135, 230–267. [Google Scholar] [CrossRef] [PubMed]

- Schimleck, L.R.; Mora, C.; Daniels, R.F. Estimation of the physical wood properties of green Pinus taeda radial. Can. J. For. Res. 2003, 33, 2297–2305. [Google Scholar] [CrossRef]

- Shetty, N.; Rinnan, Å.; Gislum, R. Selection of representative calibration sample sets for near-infrared reflectance spectroscopy to predict nitrogen concentration in grasses. Chemom. Intell. Lab. Syst. 2012, 111, 59–65. [Google Scholar] [CrossRef]

- Kennard, R.W.; Stone, L.A. Computer aided design of experiments. Technometrics 1969, 11, 137–148. [Google Scholar] [CrossRef]

- Macho, S.; Rius, A.; Callao, M.P.; Larrechi, M.S. Monitoring ethylene content in heterophasic copolymers by near-infrared spectroscopy: Standardisation of the calibration model. Anal. Chim. Acta 2001, 44, 213–220. [Google Scholar] [CrossRef]

- Macdougall, D.; Martens, H.; Geladi, P. Linearization and scatter-correction for near-infrared reflectance spectra of meat. Appl. Spectrosc. 1985, 39, 491–500. [Google Scholar]

- Steinier, J.; Termonia, Y.; Deltour, J. Smoothing and differentiation of data by simplified least square procedure. Anal. Chem. 1972, 44, 1906–1909. [Google Scholar] [CrossRef] [PubMed]

- Saudland, A.; Wagner, J.; Nielsen, J.P.; Munck, L.; Norgaard, L.; Engelsen, S.B. Interval partial least-squares regression (IPLS): A comparative chemometric study with an example from near-infrared spectroscopy. Appl. Spectrosc. 2000, 54, 413–419. [Google Scholar]

- Leardi, R.; Nørgaard, L. Sequential application of backward interval partial least squares and genetic algorithms for the selection of relevant spectral regions. J. Chemom. 2004, 18, 486–497. [Google Scholar] [CrossRef]

- Zou, X.; Zhao, J.; Povey, M.J.; Holmes, M.; Mao, H. Variables selection methods in near-infrared spectroscopy. Anal. Chim. Acta 2010, 667, 14–32. [Google Scholar]

- Araújo, M.C.U.; Saldanha, T.C.B.; Galvão, R.K.H.; Yoneyama, T.; Chame, H.C.; Visani, V. The successive projections algorithm for variable selection in spectroscopic multicomponent analysis. Chemom. Intell. Lab. Syst. 2001, 57, 65–73. [Google Scholar] [CrossRef]

- Soares, S.; Gomes, A.A. The successive projections algorithm. TrAC-Trends Anal. Chem. 2013, 42, 84–98. [Google Scholar] [CrossRef]

- Ye, S.; Wang, D.; Min, S. Successive projections algorithm combined with uninformative variable elimination for spectral variable selection. Chemom. Intell. Lab. Syst. 2008, 91, 194–199. [Google Scholar] [CrossRef]

- Schimleck, L.R.; Doran, J.C.; Rimbawanto, A. Near infrared spectroscopy for cost effective screening of foliar oil characteristics in a Melaleuca cajuputi breeding population. J. Agric. Food Chem. 2003, 51, 2433–2437. [Google Scholar] [CrossRef] [PubMed]

- Gierlinger, N.; Schwanninger, M.; Hinterstoisser, B.; Wimmer, R. Rapid determination of heartwood extractives in Larix sp. by means of fourier transform near infrared spectroscopy. J. Near Infrared Spectrosc. 2002, 10, 203–214. [Google Scholar] [CrossRef]

- Schwanninger, M.; Rodrigues, J.C.; Fackler, K. A review of band assignments in near infrared spectra of wood and wood components. J. Near Infrared Spectrosc. 2011, 19, 287–308. [Google Scholar] [CrossRef]

| Sample Set | Serial Number of Samples | ||||||

|---|---|---|---|---|---|---|---|

| Calibration set | 2 | 3 | 4 | 6 | 9 | 11 | 12 |

| 15 | 16 | 17 | 18 | 19 | 20 | 21 | |

| 22 | 23 | 25 | 26 | 27 | 28 | 29 | |

| 30 | 32 | 35 | 36 | 37 | 40 | 41 | |

| 43 | 44 | 45 | 47 | 48 | 49 | 50 | |

| 52 | 53 | 54 | 56 | 60 | 63 | 64 | |

| 66 | 67 | 69 | 72 | 74 | 75 | 76 | |

| 77 | 78 | 79 | 80 | 82 | 83 | 84 | |

| 85 | 86 | 87 | 88 | 92 | 93 | 94 | |

| 95 | 96 | 97 | 98 | 100 | 101 | 104 | |

| 105 | 106 | 107 | 108 | 111 | 112 | 113 | |

| 114 | 115 | 118 | 120 | 122 | 123 | 125 | |

| Prediction set | 1 | 5 | 7 | 8 | 10 | 13 | 14 |

| 24 | 31 | 33 | 34 | 38 | 39 | 42 | |

| 46 | 51 | 55 | 57 | 58 | 59 | 61 | |

| 62 | 65 | 68 | 70 | 71 | 73 | 81 | |

| 89 | 90 | 91 | 99 | 102 | 103 | 109 | |

| 110 | 116 | 117 | 119 | 121 | 124 | ||

| Samples | Maximum (GPa) | Minimum (GPa) | Mean (GPa) | Standard Deviation (GPa) |

|---|---|---|---|---|

| Calibration set (n = 84) | 19.25 | 10.43 | 16.00 | 3.05 |

| Prediction set (n = 41) | 18.96 | 11.22 | 16.41 | 2.23 |

| Number of Intervals | PCs | Selected Subintervals | RMSECV |

|---|---|---|---|

| 5 | 8 | [1 3 5] | 1.439 |

| 6 | 7 | [1 2 3 6] | 1.431 |

| 7 | 6 | [1 5 7 9] | 1.354 |

| 8 | 8 | [1 6 7] | 1.388 |

| 9 | 8 | [1 2 6 8] | 1.355 |

| 10 | 6 | [1 5 7 9] | 1.354 |

| 11 | 7 | [1 2 8 10] | 1.374 |

| 12 | 8 | [1 2 9 11] | 1.360 |

| 13 | 6 | [1 6 9 11] | 1.387 |

| 14 | 7 | [1 7 10 12] | 1.388 |

| 15 | 7 | [1 7 12 13] | 1.389 |

| Types of model | rc | RMSEC | SECV | rp | RMSEP | RPD |

|---|---|---|---|---|---|---|

| PLSR | 0.90 | 1.35 | 1.34 | 0.84 | 1.08 | 2.06 |

| BPNN | 0.94 | 1.00 | 1.04 | 0.89 | 0.76 | 2.93 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, H.; Zhang, M.; Gao, C.; Zhao, Y. Non-Destructive Methodology to Determine Modulus of Elasticity in Static Bending of Quercus mongolica Using Near-Infrared Spectroscopy. Sensors 2018, 18, 1963. https://doi.org/10.3390/s18061963

Liang H, Zhang M, Gao C, Zhao Y. Non-Destructive Methodology to Determine Modulus of Elasticity in Static Bending of Quercus mongolica Using Near-Infrared Spectroscopy. Sensors. 2018; 18(6):1963. https://doi.org/10.3390/s18061963

Chicago/Turabian StyleLiang, Hao, Meng Zhang, Chao Gao, and Yandong Zhao. 2018. "Non-Destructive Methodology to Determine Modulus of Elasticity in Static Bending of Quercus mongolica Using Near-Infrared Spectroscopy" Sensors 18, no. 6: 1963. https://doi.org/10.3390/s18061963

APA StyleLiang, H., Zhang, M., Gao, C., & Zhao, Y. (2018). Non-Destructive Methodology to Determine Modulus of Elasticity in Static Bending of Quercus mongolica Using Near-Infrared Spectroscopy. Sensors, 18(6), 1963. https://doi.org/10.3390/s18061963