Hydrodynamic Tweezers: Trapping and Transportation in Microscale Using Vortex Induced by Oscillation of a Single Piezoelectric Actuator

Abstract

:1. Introduction

2. Concept of Hydrodynamic Tweezers

3. Design and Analysis

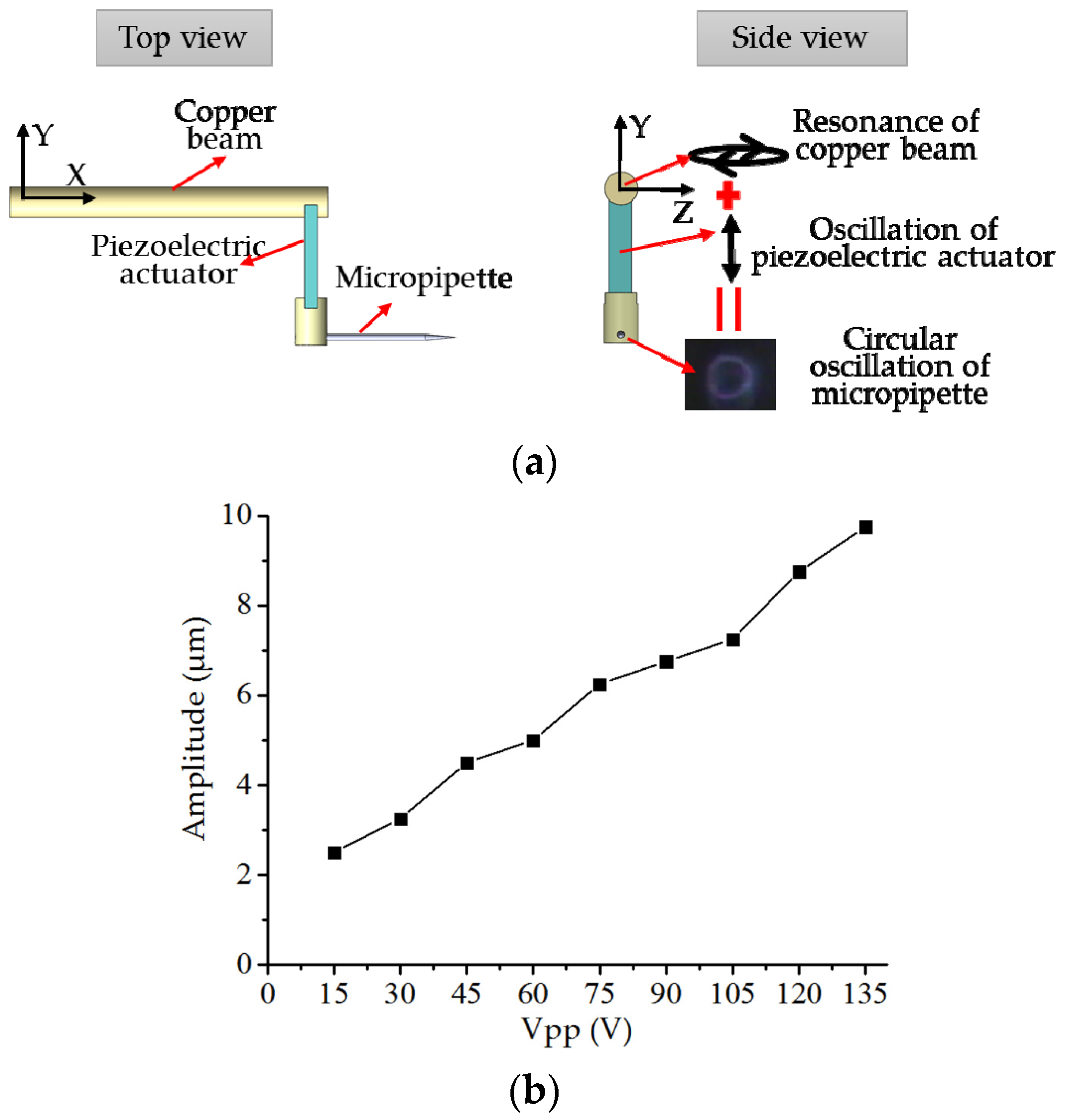

3.1. Circular Oscillation by Single Piezoelectric Actuator

3.2. Induced Vortex Analysis by Simulation

3.3. Trapping and Transportation by Vortex

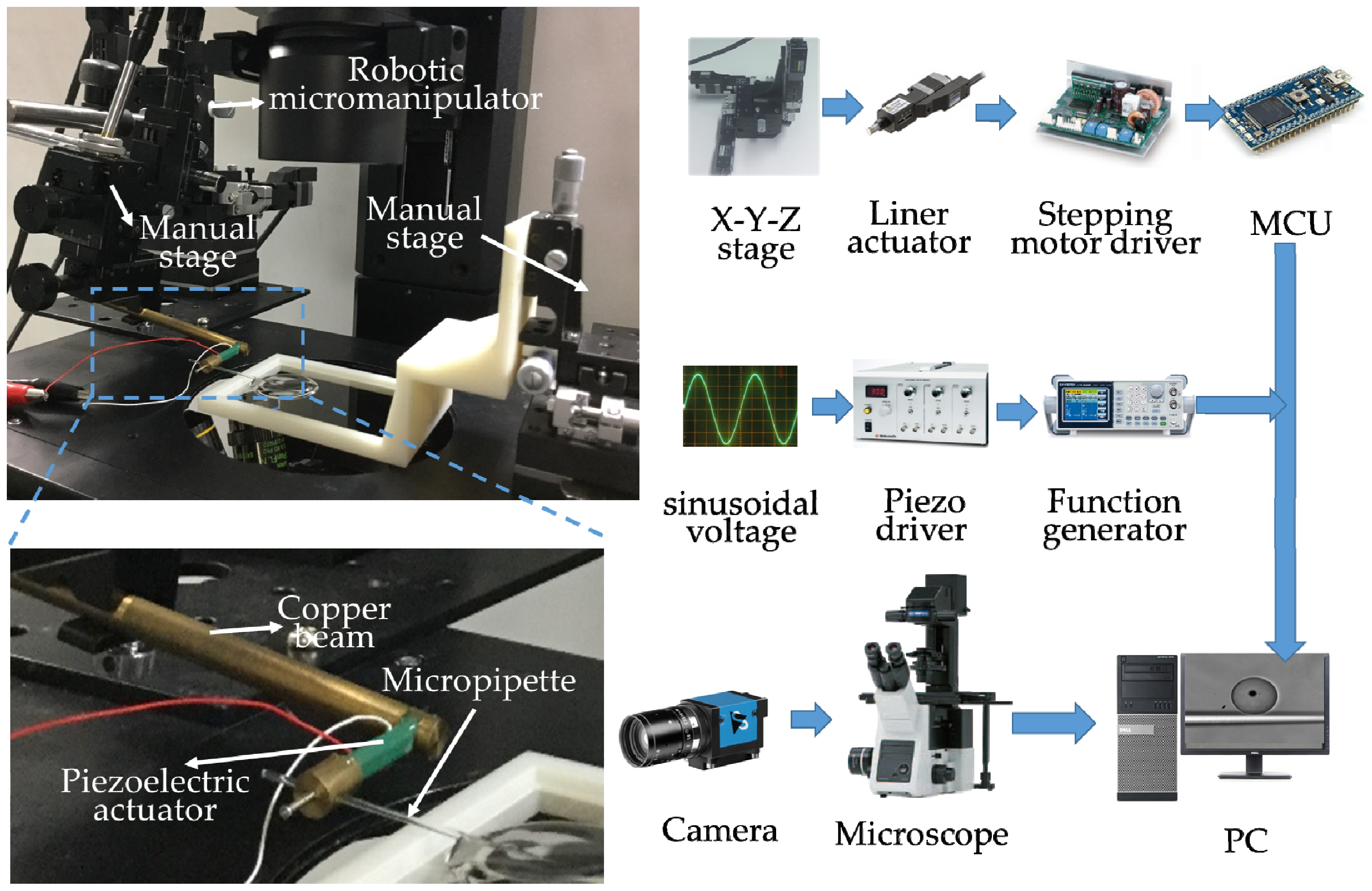

4. Experimental Setup

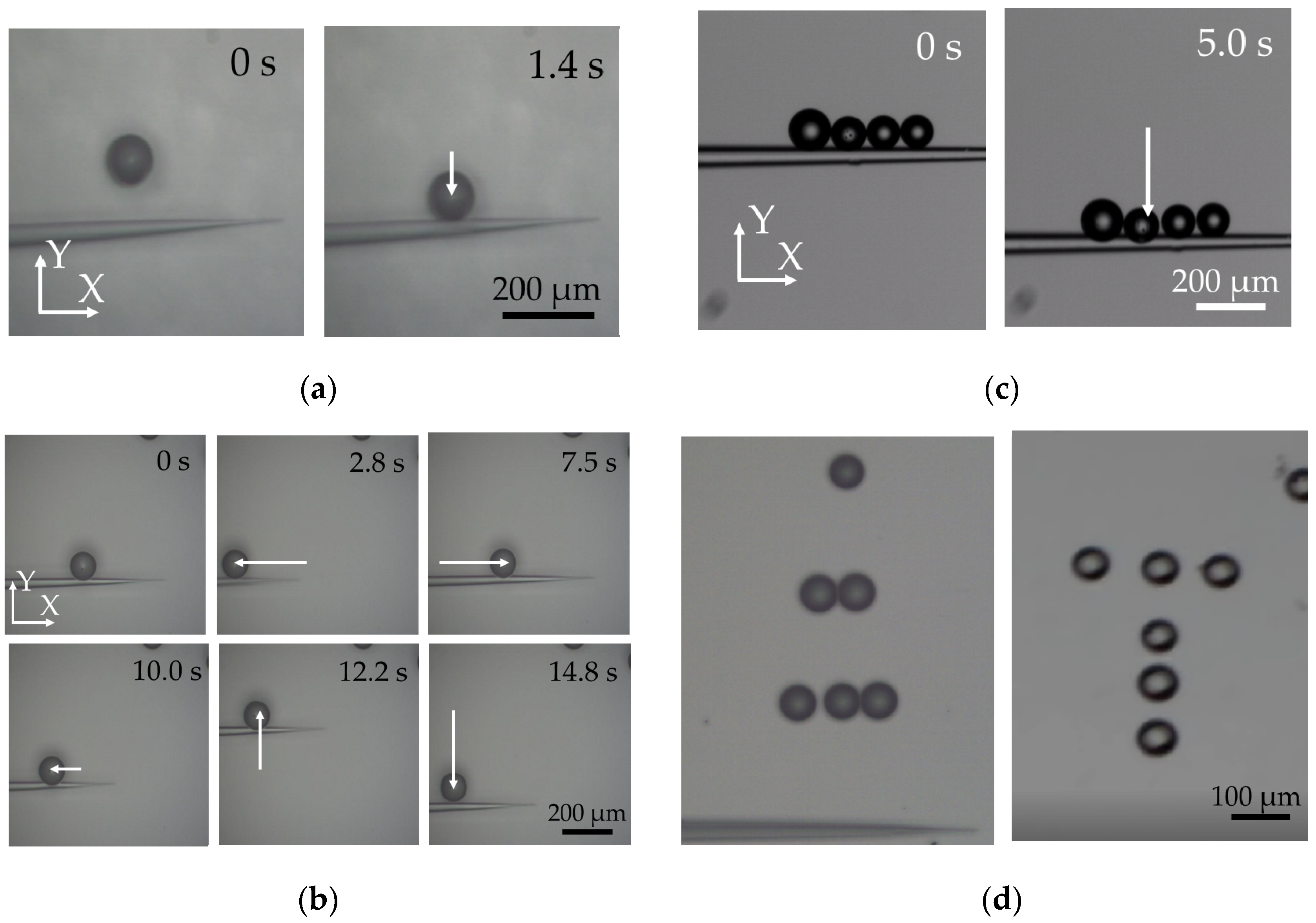

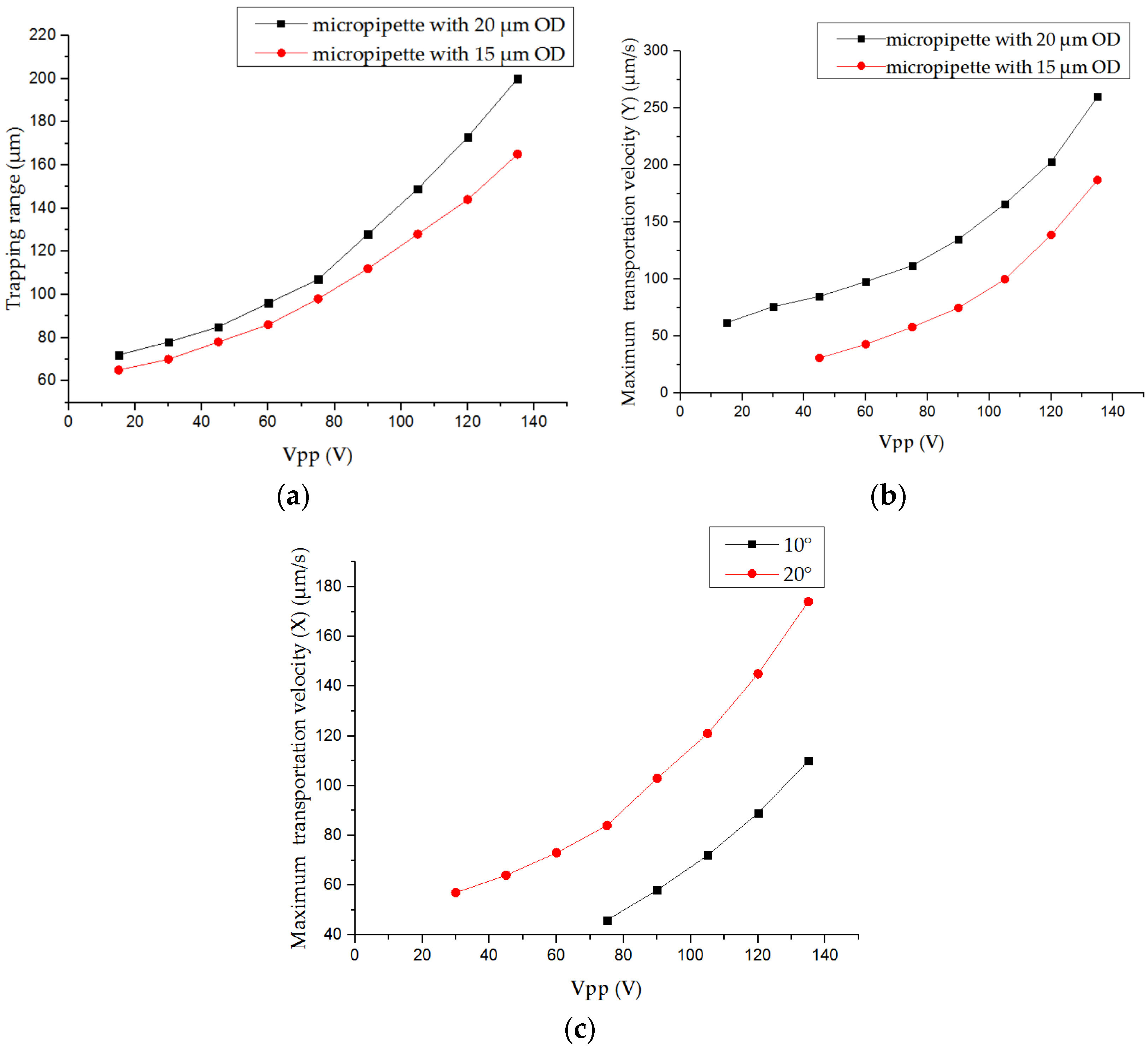

5. Experiments and Results

6. Discussion

7. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Wang, D.; Bodovitz, S. Single cell analysis: The new frontier in ‘omics’. Trends Biotechnol. 2010, 28, 281–290. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Wan, W.; Zhang, L.; Yong, L.; Lu, H.; Ding, W. Multidirectional image sensing for microscopy based on a rotatable robot. Sensors 2015, 15, 31566–31580. [Google Scholar] [CrossRef] [PubMed]

- Hayakawa, T.; Sakuma, S.; Fukuhara, T.; Yokoyama, Y.; Arai, F. A Single Cell Extraction Chip Using Vibration-Induced Whirling Flow and a Thermo-Responsive Gel Pattern. Micromachines 2014, 5, 681–696. [Google Scholar] [CrossRef] [Green Version]

- Shen, Y.; Wan, W.; Lu, H.; Fukuda, T.; Shang, W. Automatic sample alignment under microscopy for 360° imaging based on the nanorobotic manipulation system. IEEE Trans. Robot. 2017, 99, 1–7. [Google Scholar] [CrossRef]

- Hu, W.; Ishii, K.S.; Ohta, A.T. Micro-assembly using optically controlled bubble microrobots. Appl. Phys. Lett. 2011, 99, 1077. [Google Scholar] [CrossRef]

- Pawashe, C.; Floyd, S.; Sitti, M. Modeling and Experimental Characterization of an Untethered Magnetic Micro-Robot; Sage Publications, Inc.: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Hagiwara, M.; Kawahara, T.; Arai, F. Local streamline generation by mechanical oscillation in a microfluidic chip for noncontact cell manipulations. Appl. Phys. Lett. 2012, 101, 074102. [Google Scholar] [CrossRef]

- Xie, H.; Régnier, S. Three-dimensional automated micromanipulation using a nanotip gripper with multi-feedback. J. Micromech. Microeng. 2009, 19, 75009. [Google Scholar] [CrossRef]

- Savia, M.; Koivo, H.N. Contact micromanipulation—Survey of strategies. IEEE/ASME Trans. Mechatron. 2009, 14, 504–514. [Google Scholar] [CrossRef]

- Avci, E.; Hattori, T.; Kamiyama, K.; Kojima, M.; Horade, M.; Mae, Y.; Arai, T. Piezo-actuated parallel mechanism for biological cell release at high speed. Biomed. Microdevices 2015, 17, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Ashkin, A. Acceleration and Trapping of Particles by Radiation Pressure. Phys. Rev. Lett. 1970, 24, 156–159. [Google Scholar] [CrossRef]

- Ashkin, A.; Dziedzic, J.M. Optical trapping and manipulation of viruses and bacteria. Science 1987, 235, 1517–1520. [Google Scholar] [CrossRef] [PubMed]

- Eriksson, E.; Sott, K.; Lundqvist, F.; Sveningsson, M.; Scrimgeour, J.; Hanstorp, D.; Goksör, M.; Granéli, A. A microfluidic device for reversible environmental changes around single cells using optical tweezers for cell selection and positioning. Lab Chip 2010, 10, 617–625. [Google Scholar] [CrossRef] [PubMed]

- Fuhr, G.; Arnold, W.M.; Hagedorn, R.; Muller, T.; Benecke, W.; Wagner, B.; Zimmermann, U. Levitation, holding, and rotation of cells within traps made by high-frequency fields. Biochim. Biophys. Acta 1992, 1108, 215–223. [Google Scholar] [CrossRef]

- Schnelle, T.; Hagedorn, R.; Fuhr, G.; Fiedler, S.; Muller, T. Schnelle Three-dimensional electric field traps for manipulation of cells--calculation and experimental verification. Biochim. Biophys. Acta 1993, 1157, 127–140. [Google Scholar] [CrossRef]

- Wu, J.R. Acoustical tweezers. J. Acoust. Soc. Am. 1991, 89, 2140. [Google Scholar] [CrossRef] [PubMed]

- Takeuchi, M.; Abe, H.; Yamanouchi, K. Ultrasonic micromanipulation of small particles in liquid using VHF-range leaky wave transducers. Ultrasonics Symposium 1994. Proc. IEEE 1994, 1, 607–610. [Google Scholar]

- Collins, D.J.; Ma, Z.; Han, J.; Ai, Y. Continuous micro-vortex-based nanoparticle manipulation via focused surface acoustic waves. Lab Chip 2016, 17, 91. [Google Scholar] [CrossRef] [PubMed]

- Lieu, V.H.; House, T.A.; Schwartz, D.T. Hydrodynamic tweezers: Impact of design geometry on flow and microparticle trapping. Anal. Chem. 2012, 84, 1963. [Google Scholar] [CrossRef] [PubMed]

- Yue, T.; Nakajima, M.; Takeuchi, M.; Hu, C.; Huang, Q.; Fukuda, T. On-chip self-assembly of cell embedded microstructures to vascular-like microtubes. Lab Chip 2014, 14, 1151–1161. [Google Scholar] [CrossRef] [PubMed]

- Tan, W.H.; Takeuchi, S. A trap-and-release integrated microfluidic system for dynamic microarray applications. Proc. Natl. Acad. Sci. USA 2007, 104, 1146–1151. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Su, E.C.; Park, W.; Shin, S.; Lee, S.A.; Kwon, S. Guided and fluidic self-assembly of microstructures using railed microfluidic channels. Nat. Mater. 2008, 7, 581–587. [Google Scholar]

- Pieters, R.; Tung, H.W.; Charreyron, S.; Sargent, D.F.; Nelson, B.J. Rodbot: A rolling microrobot for micromanipulation. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 4042–4047. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Shi, Q.; Lin, Y.; Kojima, M.; Mae, Y.; Huang, Q.; Fukuda, T.; Arai, T. Hydrodynamic Tweezers: Trapping and Transportation in Microscale Using Vortex Induced by Oscillation of a Single Piezoelectric Actuator. Sensors 2018, 18, 2002. https://doi.org/10.3390/s18072002

Liu X, Shi Q, Lin Y, Kojima M, Mae Y, Huang Q, Fukuda T, Arai T. Hydrodynamic Tweezers: Trapping and Transportation in Microscale Using Vortex Induced by Oscillation of a Single Piezoelectric Actuator. Sensors. 2018; 18(7):2002. https://doi.org/10.3390/s18072002

Chicago/Turabian StyleLiu, Xiaoming, Qing Shi, Yuqing Lin, Masaru Kojima, Yasushi Mae, Qiang Huang, Toshio Fukuda, and Tatsuo Arai. 2018. "Hydrodynamic Tweezers: Trapping and Transportation in Microscale Using Vortex Induced by Oscillation of a Single Piezoelectric Actuator" Sensors 18, no. 7: 2002. https://doi.org/10.3390/s18072002

APA StyleLiu, X., Shi, Q., Lin, Y., Kojima, M., Mae, Y., Huang, Q., Fukuda, T., & Arai, T. (2018). Hydrodynamic Tweezers: Trapping and Transportation in Microscale Using Vortex Induced by Oscillation of a Single Piezoelectric Actuator. Sensors, 18(7), 2002. https://doi.org/10.3390/s18072002