Steep Switching of In0.18Al0.82N/AlN/GaN MIS-HEMT (Metal Insulator Semiconductor High Electron Mobility Transistors) on Si for Sensor Applications †

Abstract

:1. Introduction

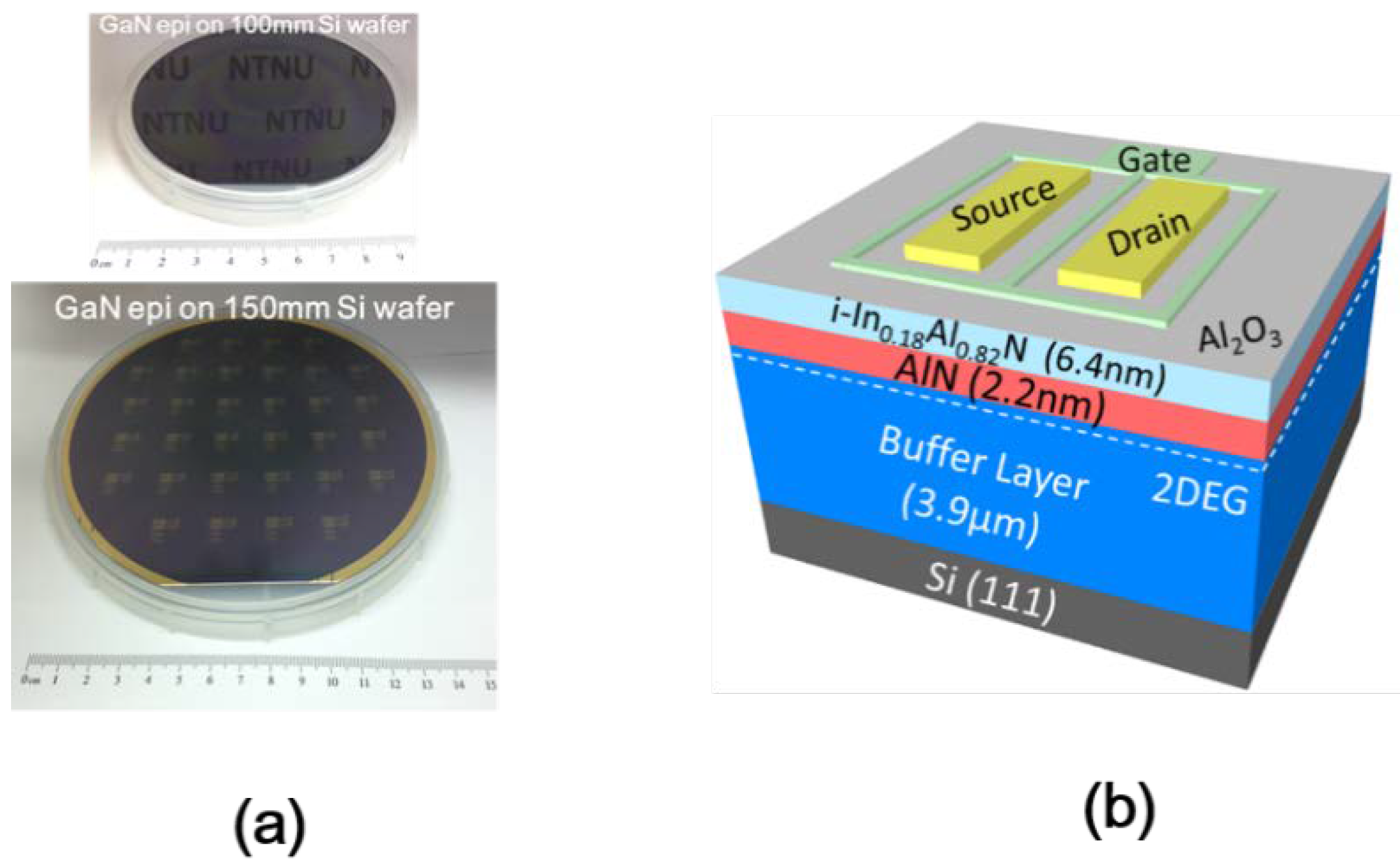

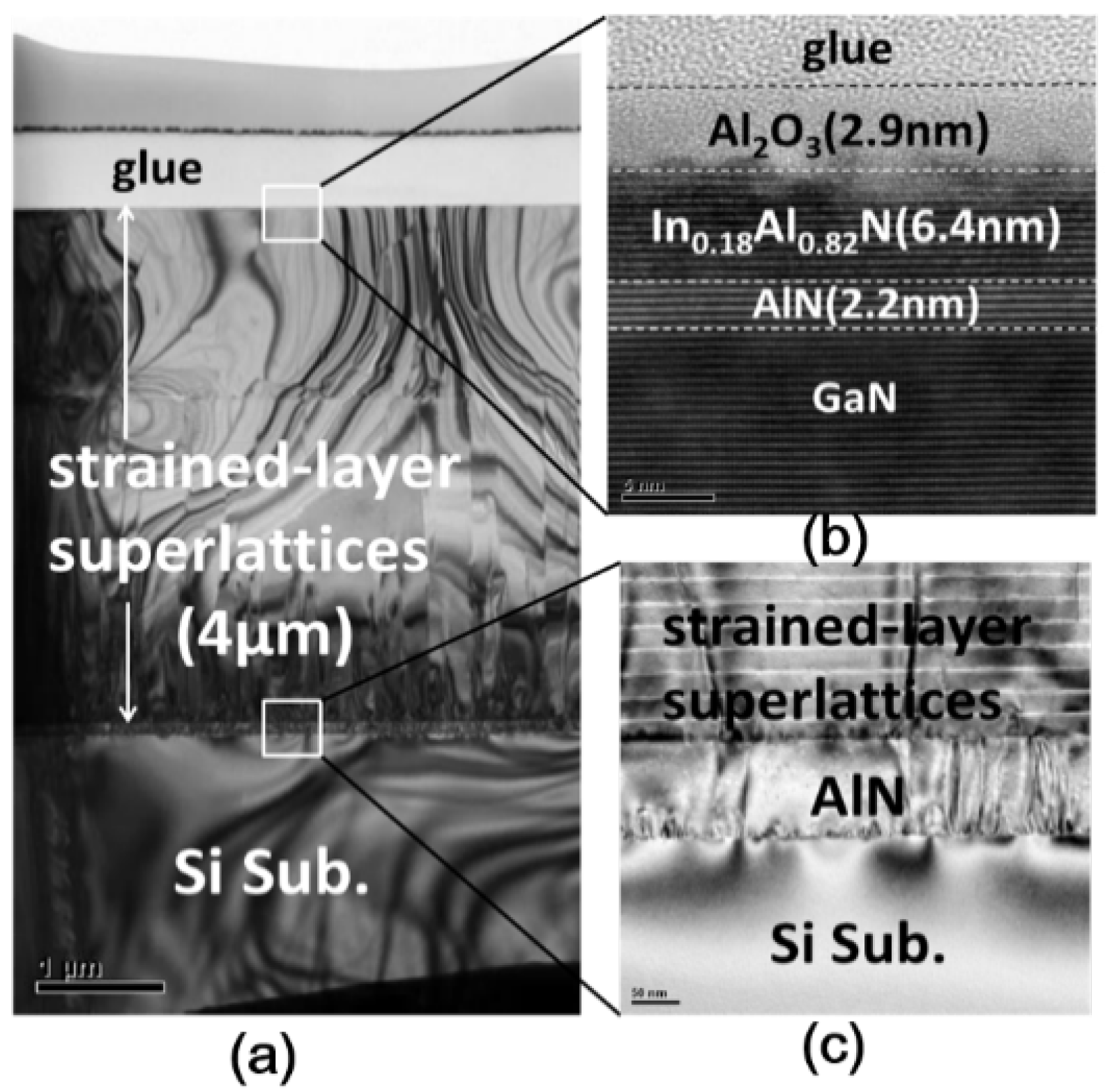

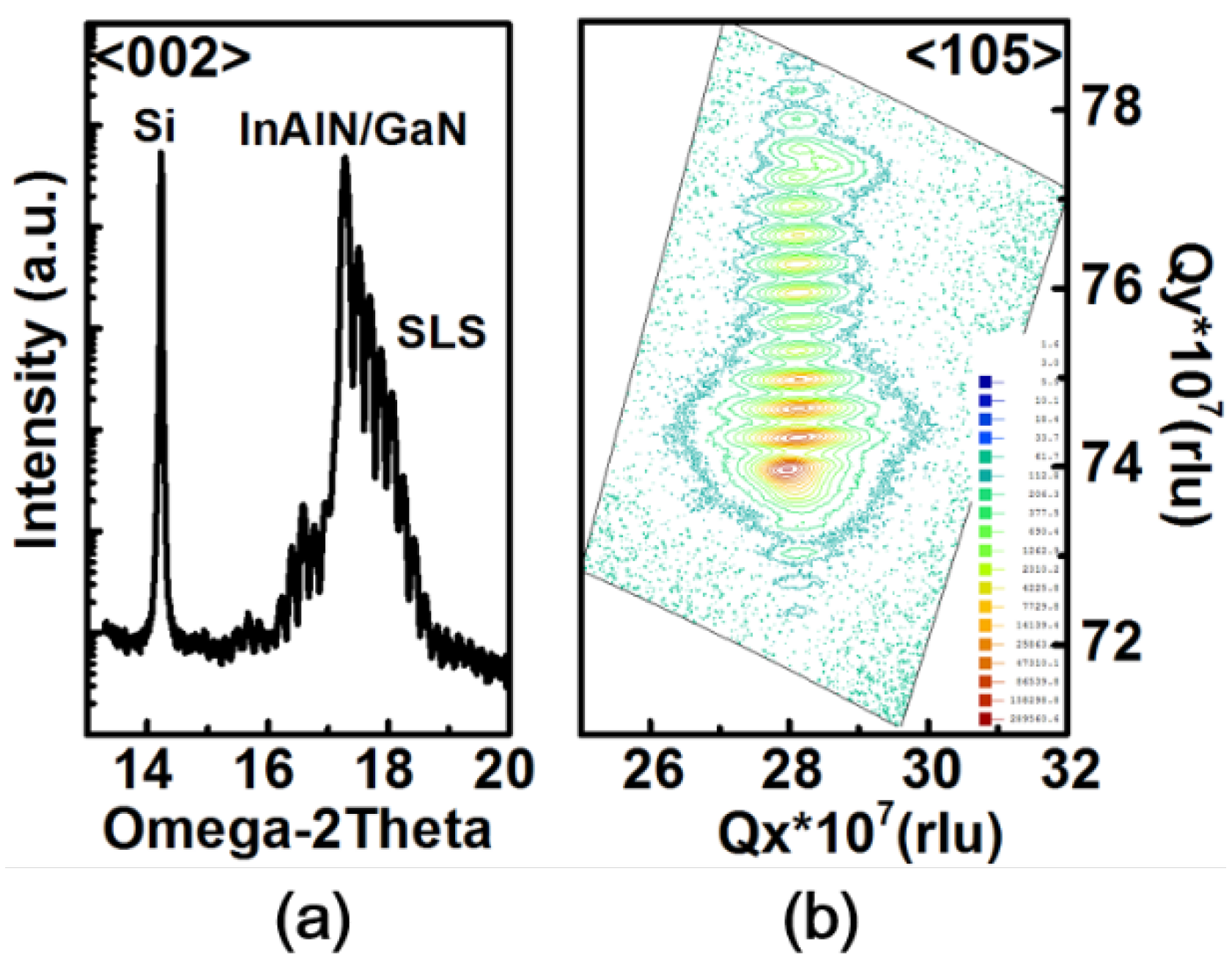

2. Device Fabrication

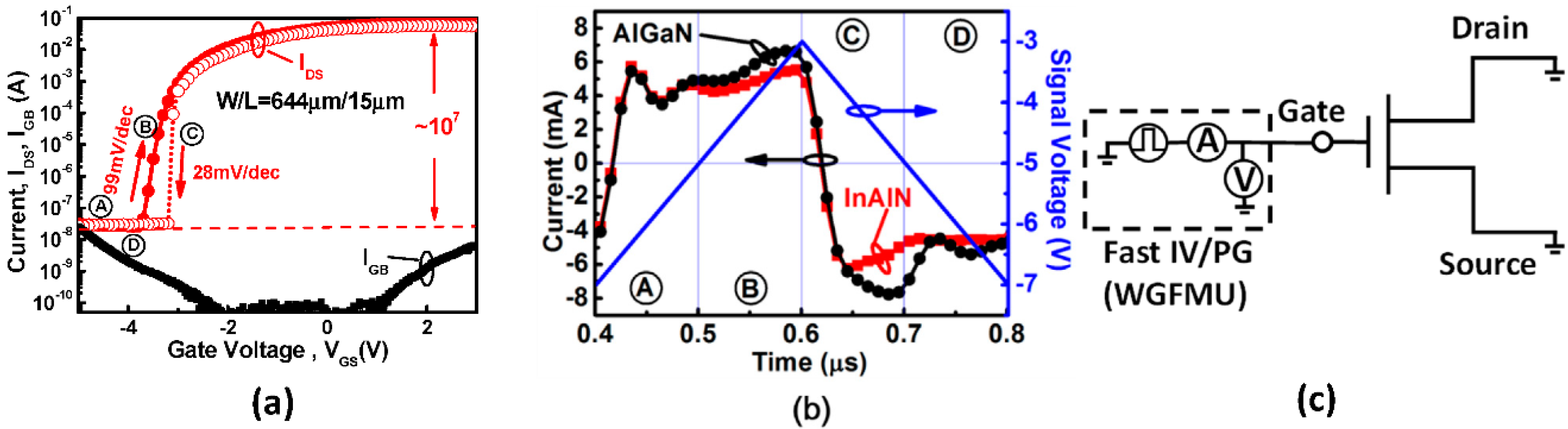

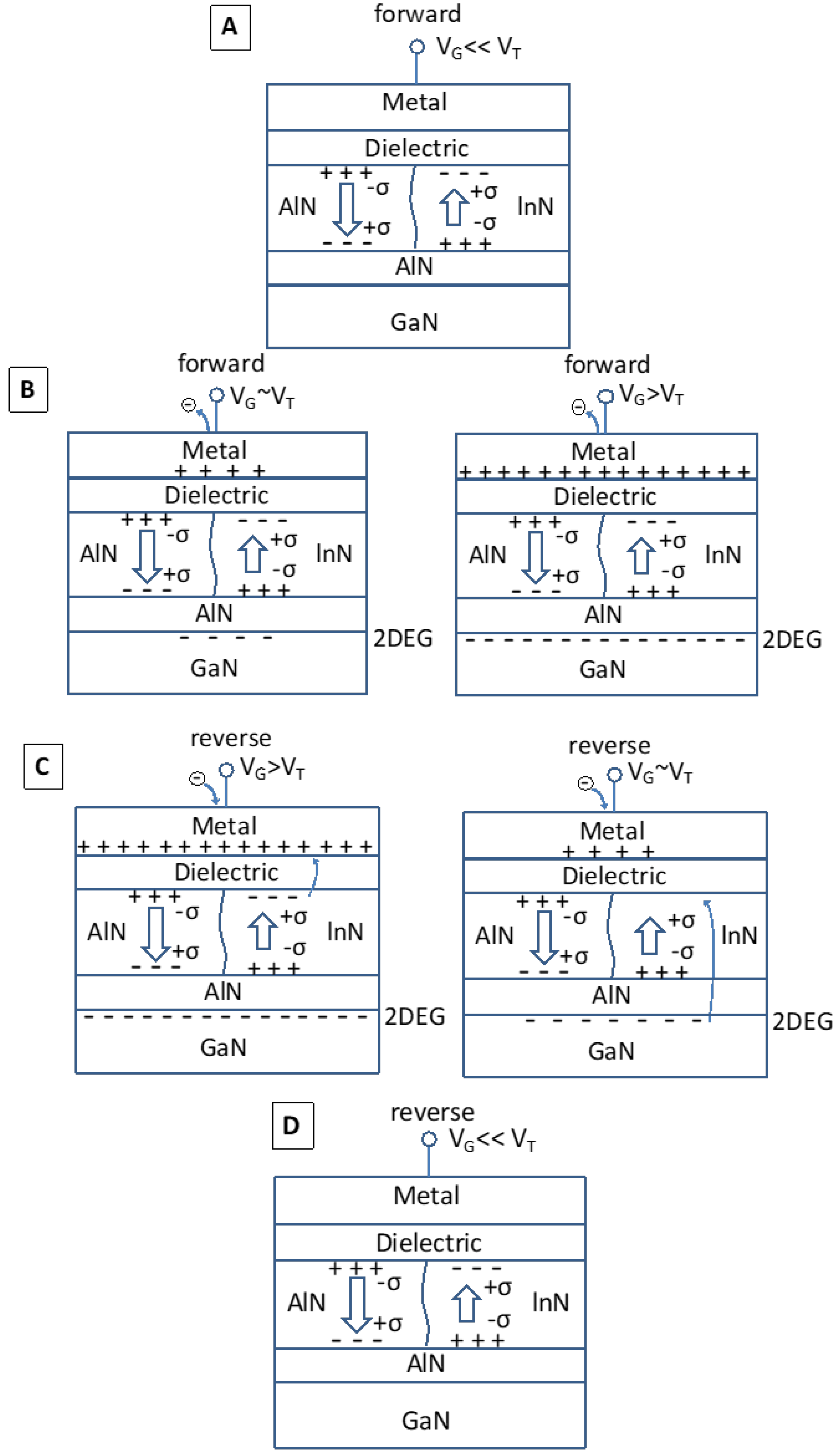

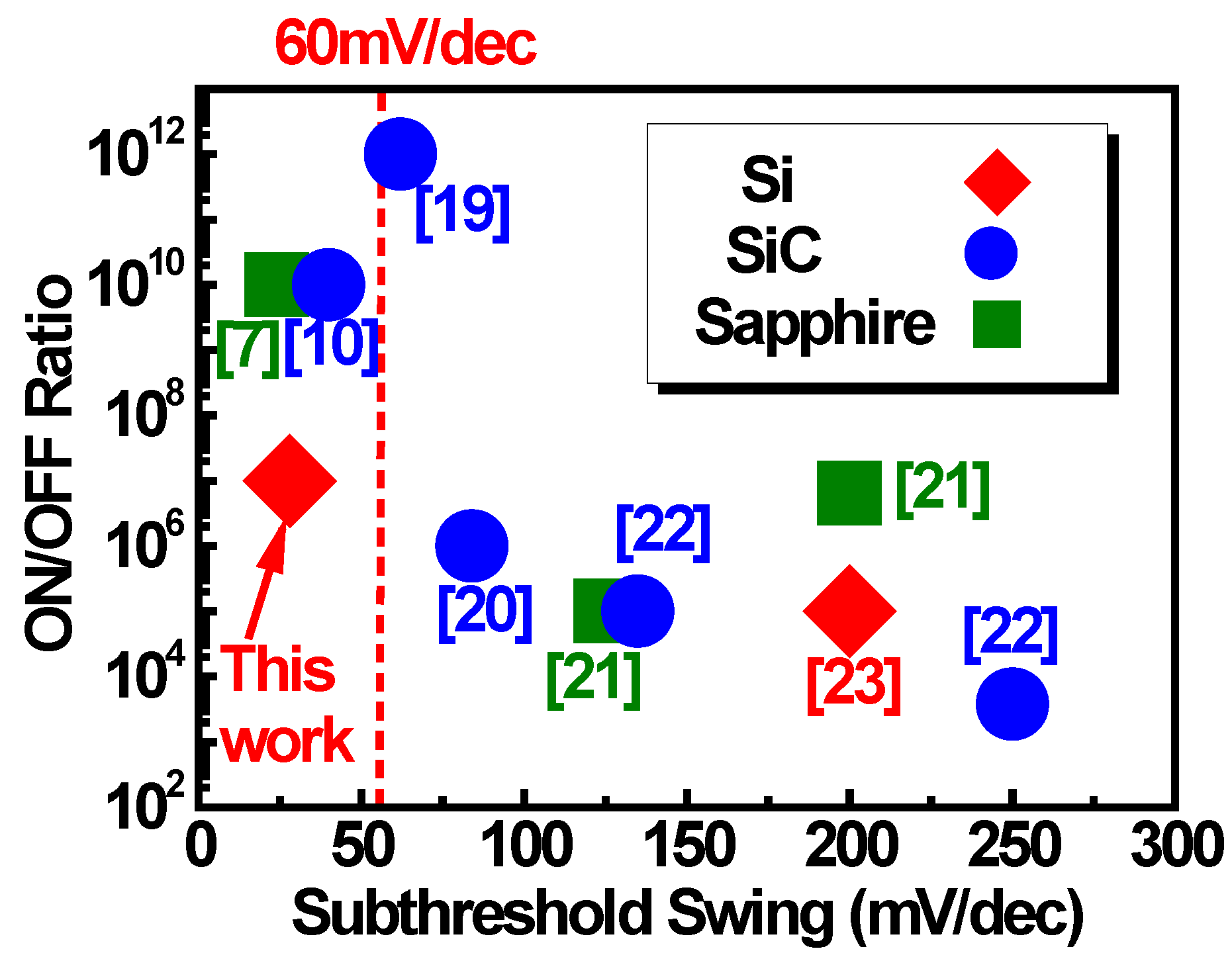

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgment

Conflicts of Interest

References

- Pearton, S.; Hull, R.; Jagadish, C.; Osgood, R.M.; Parisi, J., Jr.; Wang, Z. GaN and ZnO-Based Materials and Devices; Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2011; Chapter 6; pp. 165–203. [Google Scholar]

- Lee, D.-S.; Lee, J.-H.; Lee, Y.-H.; Lee, D.-D. GAN thin films as gas sensor. Sens. Actuators B 2003, 89, 305–310. [Google Scholar] [CrossRef]

- Lee, H.-S.; Piedra, D.; Sun, M.; Gao, X.; Guo, S.; Palacios, T. 3000-V 4.3-mΩ·cm2 InAlN/GaN MOSHEMTs With AlGaN Back Barrier. IEEE Electron Device Lett. 2012, 33, 982–984. [Google Scholar] [CrossRef]

- Chung, J.W.; Saadat, O.I.; Tirado, J.M.; Gao, X.; Guo, S.; Palacios, T. Gate-Recessed InAlN/GaN HEMTs on SiC Substrate With Al2O3 Passivation. IEEE Electron Device Lett. 2009, 30, 904–906. [Google Scholar] [CrossRef]

- Lecourt, F.; Ketteniss, N.; Behmenburg, H.; Defrance, N.; Hoel, V.; Eickelkamp, M.; Vescan, A.; Giesen, C.; Heuken, M.; de Jaeger, J.-C. InAlN/GaN HEMTs on Sapphire Substrate with 2.9-W/mm Output Power Density at 18 GHz. IEEE Electron Device Lett. 2011, 32, 1537–1539. [Google Scholar] [CrossRef]

- Maier, D.; Alomari, M.; Grandjean, N.; Carlin, J.-F.; Difforte-Poisson, M.A.; Dua, C.; Delage, S.; Kohn, E. InAlN/GaN HEMTs for Operation in the 1000 °C Regime: A First Experiment. IEEE Electron Device Lett. 2012, 33, 985–987. [Google Scholar] [CrossRef]

- Zhou, Q.; Huang, S.; Chen, H.; Zhou, C.; Feng, Z.; Cai, S.; Chen, K.J. Schottky source/drain Al2O3/InAlN/GaN MIS-HEMT with steep sub-threshold swing and high ON/OFF current ratio. In Proceedings of the 2011 International Electron Devices Meeting, Washington, DC, USA, 5–7 December 2011. [Google Scholar]

- Chen, P.-G.; Tang, M.; Lee, M.H. Indium-Based Ternary Barrier High-Electron-Mobility Transistors on Si Substrate With High ON/OFF Ratio for Power Applications. IEEE Electron Device Lett. 2015, 36, 259–261. [Google Scholar] [CrossRef]

- Chen, P.-G.; Tang, M.; Liao, M.-H.; Lee, M.H. In0.18Al0.82N/AlN/GaN MIS-HEMT on Si with Schottky-drain contact. Solid State Electron. 2017, 129, 206–209. [Google Scholar] [CrossRef]

- Then, H.W.; Dasgupta, S.; Radosavljevic, M.; Chow, L.; Chu-Kung, B.; Dewey, G.; Gardner, S.; Gao, X.; Kavalieros, J.; Mukherjee, N.; et al. Experimental observation and physics of “negative” capacitance and steeper than 40 mV/decade subthreshold swing in Al0.83In0.17N/AlN/GaN MOS-HEMT on SiC substrate. In Proceedings of the 2013 IEEE International Electron Devices Meeting, Washington, DC, USA, 9–11 December 2013. [Google Scholar]

- Ko, E.; Shin, J.; Shin, C. Steep switching devices for low power applications: Negative differential capacitance/resistance field effect transistors. Nano Converg. 2018, 5, 2. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Walukiewicz, W.; Yu, K.M.; Ager, J.W., III; Li, S.X.; Haller, E.E.; Lu, H.; Schaff, W.J. Universal bandgap bowing in group-III nitride alloys. Solid State Commun. 2003, 127, 411–414. [Google Scholar] [CrossRef] [Green Version]

- Lee, M.H.; Wei, Y.-T.; Liu, C.; Huang, J.-J.; Tang, M.; Chueh, Y.-L.; Chu, K.-Y.; Chen, M.-J.; Lee, H.-Y.; Chen, Y.-S.; et al. Ferroelectricity of HfZrO2 in Energy Landscape with Surface Potential Gain for Low-Power Steep-Slope Transistors. IEEE J. Electron Device Soc. 2015, 3, 377–381. [Google Scholar]

- Lee, M.H.; Wei, Y.-T.; Chu, K.Y.; Huang, J.J.; Chen, C.W.; Cheng, C.C.; Chen, M.J.; Lee, H.Y.; Chen, Y.S.; Lee, L.H.; et al. Steep Slope and Near Non-Hysteresis of FETs with Antiferroelectric-Like HfZrO for Low-Power Electronics. IEEE Electron Device Lett. 2015, 36, 294–296. [Google Scholar] [CrossRef]

- Song, J.; Woo, J.; Prakash, A.; Lee, D.; Hwang, H. Threshold Selector with High Selectivity and Steep Slope for Cross-Point Memory Array. IEEE Electron Device Lett. 2015, 36, 681–683. [Google Scholar] [CrossRef]

- Lee, M.H.; Lin, J.-C.; Kao, C.-Y. Hetero-Tunnel Field-Effect-Transistors with Epitaxially Grown Germanium on Silicon. IEEE Trans. Electron Device 2013, 60, 2423–2427. [Google Scholar] [CrossRef]

- Gonschorek, M.; Carlin, J.-F.; Feltin, E.; Py, M.A.; Grandjean, N.; Darakchieva, V.; Monemar, B.; Lorenz, M.; Ramm, G. Two-dimensional electron gas density in Al1−xInxN/AlN/GaN heterostructures (0.03 ≤ x ≤ 0.23). J. Appl. Phys. 2008, 103, 093714. [Google Scholar] [CrossRef]

- Lee, D.S.; Laboutin, O.; Cao, Y.; Johnson, W.; Beam, E.; Ketterson, A.; Schuette, M.; Saunier, P.; Palacios, T. Impact of Al2O3 Passivation Thickness in Highly Scaled GaN HEMTs. IEEE Electron Device Lett. 2012, 33, 976–978. [Google Scholar] [CrossRef]

- Wang, R.; Saunier, P.; Tang, Y.; Fang, T.; Gao, X.; Guo, S.; Snider, G.; Fay, P.; Jena, D.; Xing, H. Enhancement-Mode InAlN/AlN/GaN HEMTs with 10−12 A/mm Leakage Current and 1012 ON/OFF Current Ratio. IEEE Electron Device Lett. 2011, 32, 309–311. [Google Scholar] [CrossRef]

- Wang, R.; Saunier, P.; Xing, X.; Lian, C.; Gao, X.; Guo, S.; Snider, G.; Fay, P.; Jena, D.; Xing, H. Gate-Recessed Enhancement-Mode InAlN/AlN/GaN HEMTs with 1.9-A/mm Drain Current Density and 800-mS/mm Transconductance. IEEE Electron Device Lett. 2010, 31, 1383–1385. [Google Scholar] [CrossRef]

- Jurkovic, M.; Gregusova, D.; Palankovski, V.; Hascik, S.; Blaho, M.; Cico, K.; Frohlich, K.; Carlin, J.-F.; Grandjean, N.; Kuzmik, J. Schottky-Barrier Normally Off GaN/InAlN/AlN/GaN HEMT With Selectively Etched Access Region. IEEE Electron Device Lett. 2013, 34, 432–434. [Google Scholar] [CrossRef]

- Lee, D.S.; Chung, J.W.; Wang, H.; Gao, X.; Guo, S.; Fay, P.; Palacios, T. 245-GHz InAlN/GaN HEMTs With Oxygen Plasma Treatment. IEEE Electron Device Lett. 2011, 32, 755–757. [Google Scholar] [CrossRef]

- Tripathy, S.; Kyaw, L.M.; Dolmanan, S.B.; Ngoo, Y.J.; Liu, Y.; Bera, M.K.; Singh, S.P.; Tan, H.R.; Bhat, T.N.; Chor, E.F. InxAl1−xN/AlN/GaN High Electron Mobility Transistor Structures on 200 mm Diameter Si(111) Substrates with Au-Free Device Processing. ECS J. Solid State Sci. Technol. 2014, 3, 84–88. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, P.-G.; Chen, K.-T.; Tang, M.; Wang, Z.-Y.; Chou, Y.-C.; Lee, M.-H. Steep Switching of In0.18Al0.82N/AlN/GaN MIS-HEMT (Metal Insulator Semiconductor High Electron Mobility Transistors) on Si for Sensor Applications. Sensors 2018, 18, 2795. https://doi.org/10.3390/s18092795

Chen P-G, Chen K-T, Tang M, Wang Z-Y, Chou Y-C, Lee M-H. Steep Switching of In0.18Al0.82N/AlN/GaN MIS-HEMT (Metal Insulator Semiconductor High Electron Mobility Transistors) on Si for Sensor Applications. Sensors. 2018; 18(9):2795. https://doi.org/10.3390/s18092795

Chicago/Turabian StyleChen, Pin-Guang, Kuan-Ting Chen, Ming Tang, Zheng-Ying Wang, Yu-Chen Chou, and Min-Hung Lee. 2018. "Steep Switching of In0.18Al0.82N/AlN/GaN MIS-HEMT (Metal Insulator Semiconductor High Electron Mobility Transistors) on Si for Sensor Applications" Sensors 18, no. 9: 2795. https://doi.org/10.3390/s18092795

APA StyleChen, P. -G., Chen, K. -T., Tang, M., Wang, Z. -Y., Chou, Y. -C., & Lee, M. -H. (2018). Steep Switching of In0.18Al0.82N/AlN/GaN MIS-HEMT (Metal Insulator Semiconductor High Electron Mobility Transistors) on Si for Sensor Applications. Sensors, 18(9), 2795. https://doi.org/10.3390/s18092795