Simultaneous Electrochemical Detection of Nitrite and Hydrogen Peroxide Based on 3D Au-rGO/FTO Obtained Through a One-Step Synthesis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemical Reagents and Equipment

2.2. Preparation of 3D Au–rGO/FTO

2.3. Electrochemical Activity and the Detection of Nitrite and H2O2

3. Results and Discussion

3.1. Characteristics of the Au–rGO Nanocomposite

3.2. Electrochemical Behavior on the Modified Electrodes

3.3. Electrochemical Nitrite Sensor

3.3.1. Electrochemical Behavior of Nitrite at Different Electrodes

3.3.2. Electrochemical Mechanism of Nitrite Oxidation at the Au-rGO/FTO

3.3.3. Effect of Solution pH

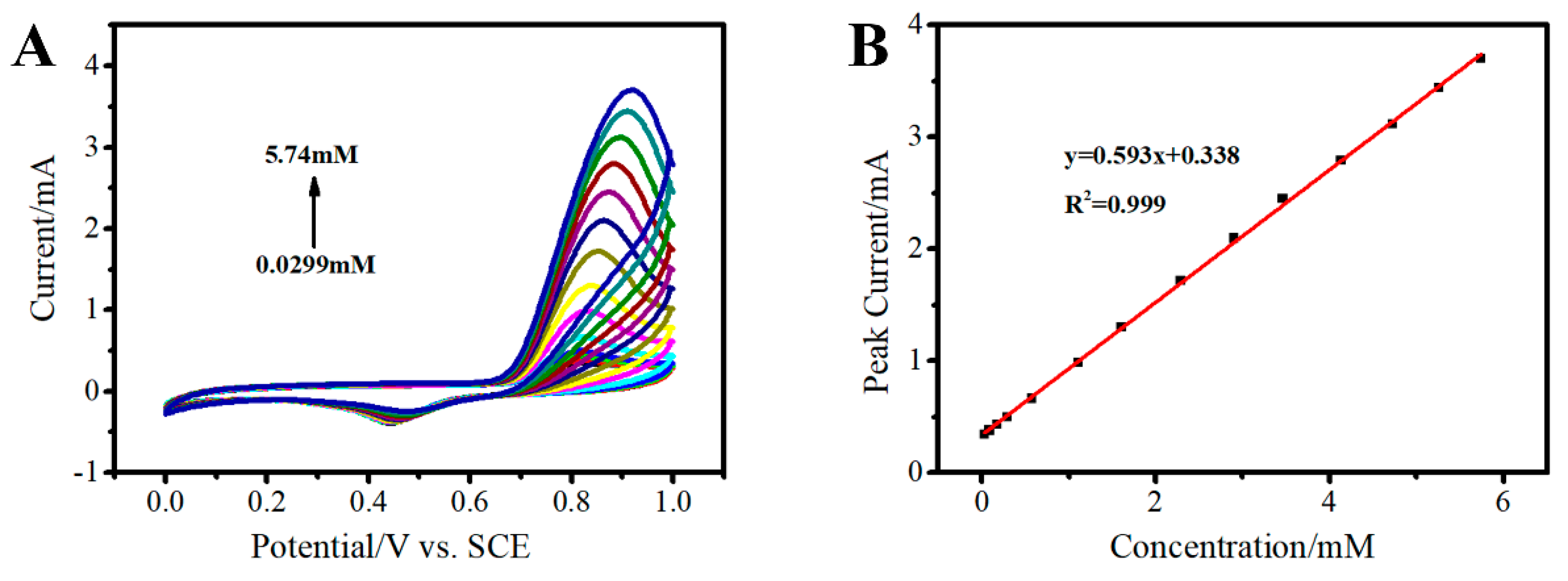

3.3.4. Determination of Nitrite on the 3D Au-rGO/FTO

3.4. Electrochemical H2O2 Sensor

3.4.1. Electrochemical Behavior of H2O2 at Different Electrodes

3.4.2. Determination of H2O2 on 3D Au-rGO/FTO

3.5. Simultaneous Electrochemical Detection of Nitrite and H2O2

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Liu, W.Q.; Wu, X.C.; Li, X.J. Gold nanorods on three-dimensional nickel foam: A non-enzymatic glucose sensor with enhanced electro-catalytic performance. RSC Adv. 2017, 7, 36744–36749. [Google Scholar] [CrossRef]

- Karthick, K.P.; Chunxiao, H.; Hywel, M.; Sekhar, R.C. One-step electrodeposition of NiCo2S4 nanosheets on patterned platinum electrodes for non-enzymatic glucose sensing. Chem. Asian J. 2016, 11, 1837–1841. [Google Scholar]

- Meng, F.; Yan, X.; Liu, J.; Gu, J.; Zou, Z. Nanoporous gold as non-enzymatic sensor for hydrogen peroxide. Electrochim. Acta 2011, 56, 4657–4662. [Google Scholar] [CrossRef]

- Li, S.; Zhu, X.; Zhang, W.; Xie, G.; Feng, W. Hydrogen peroxide biosensor based on gold nanoparticles/thionine/gold nanoparticles/multi-walled carbon nanotubes–chitosans composite film-modified electrode. Appl. Surf. Sci. 2012, 258, 2802–2807. [Google Scholar] [CrossRef]

- Afkhami, A.; Soltani-Felehgari, F.; Madrakian, T.; Ghaedi, H. Surface decoration of multi-walled carbon nanotubes modified carbon paste electrode with gold nanoparticles for electro-oxidation and sensitive determination of nitrite. Biosens. Bioelectron. 2014, 51, 379–385. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Mai, Z.; Dai, Z.; Li, Y.; Zou, X. Construction of Au nanoparticles on choline chloride modified glassy carbon electrode for sensitive detection of nitrite. Biosens. Bioelectron. 2009, 24, 3242–3247. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.Q.; Wu, L.W.; Wu, H.M.; Wang, S.F.; Ding, Y.; Feng, C.Q. Sulphides of the cobalt doped Ni7S6 type for glucose, hydrogen peroxide and nitrite sensing platform. Sens. Actuator B Chem. 2017, 250, 224–232. [Google Scholar] [CrossRef]

- Huang, S.; Si, Z.; Li, X.; Zou, J.; Yao, Y.; Weng, D. A novel Au/r-GO/TNTs electrode for H2O2, O2 and nitrite detection. Sens. Actuator B Chem. 2016, 234, 264–272. [Google Scholar] [CrossRef]

- Yuan, B.Q.; Xu, C.Y.; Liu, L.; Shi, Y.F.; Li, S.J.; Zhang, R.C.; Zhang, D.J. Polyethylenimine-bridged graphene oxide-gold film on glassy carbon electrode and its electrocatalytic activity toward nitrite and hydrogen peroxide. Sens. Actuator B Chem. 2014, 198, 55–61. [Google Scholar] [CrossRef]

- Schedin, F.; Geim, A.K.; Morozov, S.V.; Hill, E.W.; Blake, P.; Katsnelson, M.I.; Novoselov, K.S. Detection of individual gas molecules adsorbed on graphene. Nat. Mater. 2007, 6, 652. [Google Scholar] [CrossRef]

- Eissa, S.; Zourob, M. Competitive voltammetric morphine immunosensor using a gold nanoparticle decorated graphene electrode. Microchim. Acta 2017, 184, 2281–2289. [Google Scholar] [CrossRef]

- Ju, J.; Chen, W. In situ growth of surfactant-free gold nanoparticles on nitrogen-doped graphene quantum dots for electrochemical detection of hydrogen peroxide in biological environments. Anal. Chem. 2015, 87, 1903–1910. [Google Scholar] [CrossRef]

- Jiao, S.; Jin, J.; Wang, L. One-pot preparation of Au-RGO/PDDA nanocomposites and their application for nitrite sensing. Sens. Actuator B Chem. 2015, 208, 36–42. [Google Scholar] [CrossRef]

- Serra, A.; Valles, E. Advanced electrochemical synthesis of multicomponent metallic nanorods and nanowires: Fundamentals and applications. Appl. Mater. Today 2018, 12, 207–234. [Google Scholar] [CrossRef]

- Xu, G.; Li, B.; Cui, X.T.; Ling, L.; Luo, X. Electrodeposited conducting polymer PEDOT doped with pure carbon nanotubes for the detection of dopamine in the presence of ascorbic acid. Sens. Actuator B Chem. 2013, 188, 405–410. [Google Scholar] [CrossRef]

- Sanzo, G.; Taurino, I.; Antiochia, R.; Gorton, L.; Favero, G.; Mazzei, F.; De Michell, G.; Carrara, S. Bubble electrodeposition of gold porous nanocorals for the enzymatic and non-enzymatic detection of glucose. Bioelectrochemistry 2016, 112, 125–131. [Google Scholar] [CrossRef]

- Zou, C.E.; Yang, B.; Bin, D.; Wang, J.; Li, S.; Yang, P.; Wang, C.; Shiraishi, Y.; Du, Y. Electrochemical synthesis of gold nanoparticles decorated flower-like graphene for high sensitivity detection of nitrite. J. Colloid Interface Sci. 2017, 488, 135–141. [Google Scholar] [CrossRef]

- Saquib, M.; Halder, A. Reduced graphene oxide supported gold nanoparticles for electrocatalytic reduction of carbon dioxide. J. Nanopart. Res. 2018, 20, 46. [Google Scholar] [CrossRef]

- Wang, L.; Lu, X.; Wen, C.; Xie, Y.; Miao, L.; Chen, S.; Li, H.; Li, P.; Song, Y. One-step synthesis of Pt-NiO nanoplate array/reduced graphene oxide nanocomposites for nonenzymatic glucose sensing. J. Mater. Chem. A 2015, 3, 608–616. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, H.; Li, S.; Wang, R.; Sun, X.; Zhou, M.; Zhou, J.; Lou, X.W.; Xie, Y. Defect-rich MoS2 ultrathin nanosheets with additional active edge sites for enhanced electrocatalytic hydrogen evolution. Adv. Mater. 2013, 25, 5807–5813. [Google Scholar] [CrossRef]

- Merki, D.; Fierro, S.; Vrubel, H.; Hu, X. Amorphous molybdenum sulfide films as catalysts for electrochemical hydrogen production in water. Chem. Sci. 2011, 2, 1262–1267. [Google Scholar] [CrossRef] [Green Version]

- Prathap, M.U.A.; Satpati, B.; Srivastava, R. Facile preparation of β-Ni(OH)2-NiCo2O4 hybrid nanostructure and its application in the electro-catalytic oxidation of methanol. Electrochim. Acta 2014, 130, 368–380. [Google Scholar] [CrossRef]

- Lin, A.-J.; Wen, Y.; Zhang, L.-J.; Lu, B.; Li, Y.; Jiao, Y.-Z.; Yang, H.-F. Layer-by-layer construction of multi-walled carbon nanotubes, zinc oxide, and gold nanoparticles integrated composite electrode for nitrite detection. Electrochim. Acta 2011, 56, 1030–1036. [Google Scholar] [CrossRef]

- Etesami, M.; Mohamed, N. Preparation of Pt/MWCNTs catalyst by taguchi method for electrooxidation of nitrite. J. Anal. Chem. 2016, 71, 185–194. [Google Scholar] [CrossRef]

- Bharath, G.; Madhu, R.; Chen, S.-M.; Veeramani, V.; Mangalaraj, D.; Ponpandian, N. Solvent-free mechanochemical synthesis of graphene oxide and Fe3O4–reduced graphene oxide nanocomposites for sensitive detection of nitrite. J. Mater. Chem. A 2015, 3, 15529–15539. [Google Scholar] [CrossRef]

- Kung, C.-W.; Li, Y.-S.; Lee, M.-H.; Wang, S.-Y.; Chiang, W.-H.; Ho, K.-C. In situ growth of porphyrinic metal–organic framework nanocrystals on graphene nanoribbons for the electrocatalytic oxidation of nitrite. J. Mater. Chem. A 2016, 4, 10673–10682. [Google Scholar] [CrossRef]

- Aksu, Z.; Alanyalioglu, M. Fabrication of free-standing reduced graphene oxide composite papers doped with different dyes and comparison of their electrochemical performance for electrocatalytical oxidation of nitrite. Electrochim. Acta 2017, 258, 1376–1386. [Google Scholar] [CrossRef]

- Zhao, Z.; Xia, Z.; Liu, C.; Huang, H.; Ye, W. Green synthesis of Pd/Fe3O4 composite based on polyDOPA functionalized reduced graphene oxide for electrochemical detection of nitrite in cured food. Electrochim. Acta 2017, 256, 146–154. [Google Scholar] [CrossRef]

- Fu, L.; Yu, S.; Thompson, L.; Yu, A. Development of a novel nitrite electrochemical sensor by stepwise in situ formation of palladium and reduced graphene oxide nanocomposites. RSC Adv. 2015, 5, 40111–40116. [Google Scholar] [CrossRef]

- Bhat, S.A.; Pandit, S.A.; Rather, M.A.; Rather, G.M.; Rashid, N.; Ingole, P.P.; Bhat, M.A. Self-assembled AuNPs on sulphur-doped graphene: A dual and highly efficient electrochemical sensor for nitrite (NO2−) and nitric oxide (NO). New J. Chem. 2017, 41, 8347–8358. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, J.; Nie, F.; Zheng, J. Facile synthesis of TiO2-functionalized graphene nanosheet-supported Ag catalyst and its electrochemical oxidation of nitrite. J. Iran. Chem. Soc. 2015, 12, 1535–1542. [Google Scholar] [CrossRef]

- Jia, N.; Huang, B.; Chen, L.; Tan, L.; Yao, S. A simple non-enzymatic hydrogen peroxide sensor using gold nanoparticles-graphene-chitosan modified electrode. Sens. Actuators B Chem. 2014, 195, 165–170. [Google Scholar] [CrossRef]

- Chang, H.; Wang, X.; Shiu, K.-K.; Zhu, Y.; Wang, J.; Li, Q.; Chen, B.; Jiang, H. Layer-by-layer assembly of graphene, Au and poly(toluidine blue O) films sensor for evaluation of oxidative stress of tumor cells elicited by hydrogen peroxide. Biosens. Bioelectron. 2013, 41, 789–794. [Google Scholar] [CrossRef]

- Thanh, T.D.; Balamurugan, J.; Lee, S.H.; Kim, N.H.; Lee, J.H. Novel porous gold-palladium nanoalloy network-supported graphene as an advanced catalyst for non-enzymatic hydrogen peroxide sensing. Biosens. Bioelectron. 2016, 85, 669–678. [Google Scholar] [CrossRef]

- Li, D.; Meng, L.; Xiao, P.; Jiang, D.; Dang, S.; Chen, M. Enhanced non-enzymatic electrochemical sensing of hydrogen peroxide based on Cu2O nanocubes/Ag-Au alloy nanoparticles by incorporation of RGO nanosheets. J. Electroanal. Chem. 2017, 791, 23–28. [Google Scholar] [CrossRef]

- Maji, S.K.; Sreejith, S.; Mandal, A.K.; Ma, X.; Zhao, Y. Immobilizing gold nanoparticles in mesoporous silica covered reduced graphene oxide: A hybrid material for cancer cell detection through hydrogen peroxide sensing. ACS Appl. Mater. Interfaces 2014, 6, 13648–13656. [Google Scholar] [CrossRef]

- Guo, X.; Qian, C.; Yang, H.; Lin, S.; Fan, T. Silver nanograins with pore-array architecture for the electrochemical detection of hydrogen peroxide. ChemistrySelect 2017, 2, 9438–9442. [Google Scholar] [CrossRef]

- Fan, Y.; Yang, X.; Yang, C.; Liu, J. Au-TiO2/Graphene Nanocomposite Film for Electrochemical Sensing of Hydrogen Peroxide and NADH. Electroanalysis 2012, 24, 1334–1339. [Google Scholar] [CrossRef]

- Wang, M.-Q.; Zhang, Y.; Bao, S.-J.; Yu, Y.-N.; Ye, C. Ni(II)-based metal-organic framework anchored on carbon nanotubes for highly sensitive non-enzymatic hydrogen peroxide sensing. Electrochim. Acta 2016, 190, 365–370. [Google Scholar] [CrossRef]

- Yang, M.; Kim, D.S.; Lee, T.J.; Lee, S.J.; Lee, K.G.; Choi, B.G. Polyoxometalate-grafted graphene nanohybrid for electrochemical detection of hydrogen peroxide and glucose. J. Colloid Interface Sci. 2016, 468, 51–56. [Google Scholar] [CrossRef]

| Modified Electrode | Linear Range (mM) | Sensitivity (mA mM−1 cm−2) | Reference |

|---|---|---|---|

| Pt/MWCNTs/GC | 0.004–2.4 | 0.41 | [24] |

| Fe3O4/RGO/GCE | 0.010–2.882 | 0.196 | [25] |

| MOF-GNRs-50/ITO | 0.100–2.500 | 0.094 | [26] |

| Free-standing rGO/Acr paper | 0.0004–3.6 | 0.40 | [27] |

| Pd/Fe3O4/polyDOPA/RGO/GCE | 0.0025–6.47 | 0.22 | [28] |

| Pd/RGO/GCE | 0.001–1.000 | 0.298 | [29] |

| AuNPs-S-Gr/GCE | 0.0125–0.681 | 0.208 | [30] |

| TiO2/Ag/RGO/GCE | 0.001–1.1 | 0.112 | [31] |

| 3D Au-rGO/FTO | 0.0299–5.74 | 0.419 | This work |

| Modified Electrode | Linear Range (μM) | Sensitivity (μA mM−1 cm−2) | Reference |

|---|---|---|---|

| RGO-Au-PTBO/GCE | 5.0–1077 | 63.39 | [33] |

| AuPd@GR/ITO | 5–11,500 | 186.86 | [34] |

| RGO/Ag-Au/Cu2O/GCE | 50–50,750 | 0.14 | [35] |

| AuNPs-N-GQDs/GCE | 0.25–13,327 | 186.22 | [16] |

| RGO-PMS@AuNPs/GC | 0.5–50,000 | 39.2 | [36] |

| pore array-Ag/GCE | 100–40,000 | 61 | [37] |

| Au-TiO2/GR/GCE | 10–200 | 151.5 | [38] |

| Ni(II)-MOF/CNTs/GCE | 10.0–51,600 | 117.14 | [39] |

| POM-g-rGO/GCE | 100–20,000 | 95.5 | [40] |

| 3D Au-rGO/FTO | 179–10,500 | 236 | This work |

| Sample | Nitrite Concentration (mM) | H2O2 Concentration (mM) | Recovery (%) | |||

|---|---|---|---|---|---|---|

| Actual | Detectable | Actual | Detectable | Nitrite | H2O2 | |

| Sample 1 | 1.5 | 1.57 | 1.5 | 1.63 | 104 | 109 |

| Sample 2 | 3.0 | 3.20 | 3.0 | 3.02 | 107 | 101 |

| Sample 3 | 5.0 | 4.47 | 5.0 | 5.26 | 95 | 105 |

| Sample 4 | 5.0 | 5.26 | 7.5 | 7.19 | 105 | 95 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Chen, D.; Wang, Y.; Lai, X.; Peng, J.; Wang, X.; Zhang, K.; Cao, Y. Simultaneous Electrochemical Detection of Nitrite and Hydrogen Peroxide Based on 3D Au-rGO/FTO Obtained Through a One-Step Synthesis. Sensors 2019, 19, 1304. https://doi.org/10.3390/s19061304

Li C, Chen D, Wang Y, Lai X, Peng J, Wang X, Zhang K, Cao Y. Simultaneous Electrochemical Detection of Nitrite and Hydrogen Peroxide Based on 3D Au-rGO/FTO Obtained Through a One-Step Synthesis. Sensors. 2019; 19(6):1304. https://doi.org/10.3390/s19061304

Chicago/Turabian StyleLi, Chengcheng, Delun Chen, Yuanyuan Wang, Xiaoyong Lai, Juan Peng, Xiaohong Wang, Kexi Zhang, and Yang Cao. 2019. "Simultaneous Electrochemical Detection of Nitrite and Hydrogen Peroxide Based on 3D Au-rGO/FTO Obtained Through a One-Step Synthesis" Sensors 19, no. 6: 1304. https://doi.org/10.3390/s19061304