Thermoelectric Photosensor Based on Ultrathin Single-Crystalline Si Films †

Abstract

:1. Introduction

- (i)

- Photoelectric or photovoltaic effects, where photons have energies over the semiconductor band gap;

- (ii)

- Thermal-based absorption sensors, where the photon energies require the generation of mid-gap states to provide energy to the phonon bath.

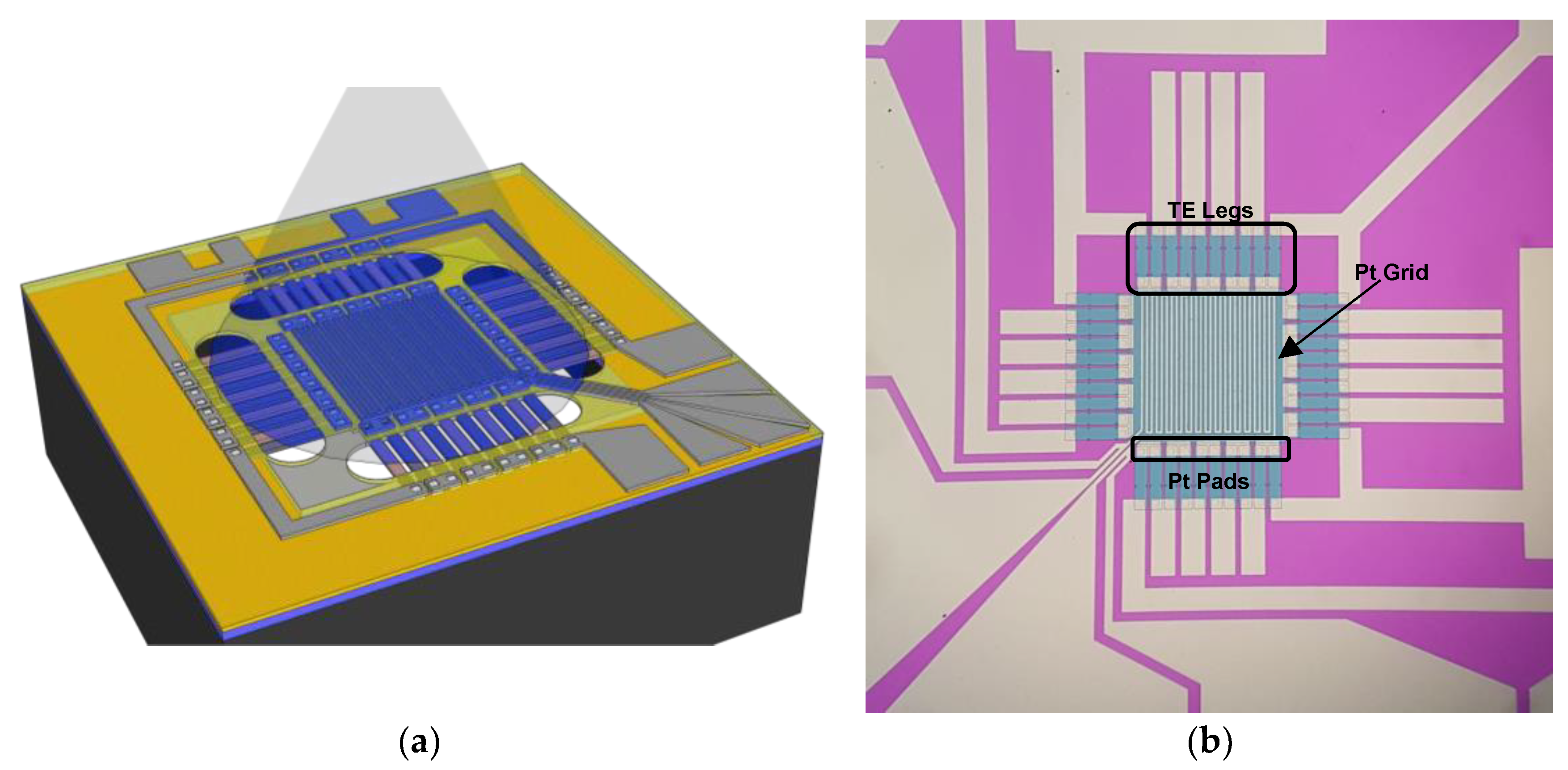

2. Materials and Methods

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Dennis, P.J.; Welch, E.F.; Alarie, J.P.; Ramsey, J.M.; Jorgenson, J.W. Development of a Photothermal Absorbance Detector for Use with Microfluidic Devices. Anal. Chem. 2010, 8, 4063–4071. [Google Scholar] [CrossRef] [PubMed]

- Patil, V.; Capone, A.; Strauf, S.; Yang, E.-H. Improved Photoresponse with Enhanced Photoelectric Contribution in Fully Suspended Graphene Photodetectors. Sci. Rep. 2013, 3, 2791. [Google Scholar] [CrossRef] [PubMed]

- García de Arquer, F.P.; Mihi, A.; Konstantatos, G. Large-Area Plasmonic-Crystal–Hot-Electron-Based Photodetectors. ACS Photonics 2015, 2, 950–957. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.Y.; Wu, X.; Liu, X.; Lancaster, D.G.; Monro, T.M.; Xu, H. Photodetector Based on Vernier-Enhanced Fabry-Perot Interferometers with a Photo-Thermal Coating. Sci. Rep. 2017, 7, 41895. [Google Scholar] [CrossRef] [PubMed]

- Boukai, A.I.; Bunimovich, Y.; Tahir-Kheli, J.; Yu, J.-K.; Goddard, W.A., III; Heath, J.R. Silicon Nanowires as Efficient Thermoelectric Materials. Nature 2008, 451, 168. [Google Scholar] [CrossRef]

- Hochbaum, A.I.; Chen, R.; Delgado, R.D.; Liang, W.; Garnett, E.C.; Najarian, M.; Majumdar, A.; Yang, P. Enhanced Thermoelectric Performance of Rough Silicon Nanowires. Nature 2008, 451, 163. [Google Scholar] [CrossRef]

- Neogi, S.; Reparaz, J.S.; Pereira, L.F.C.; Graczykowski, B.; Wagner, M.R.; Sledzinska, M.; Shchepetov, A.; Prunnila, M.; Ahopelto, J.; Sotomayor-Torres, C.M.; et al. Tuning Thermal Transport in Ultrathin Silicon Membranes by Surface Nanoscale Engineering. ACS Nano 2015, 9, 3820–3828. [Google Scholar] [CrossRef]

- Ferrando-Villalba, P.; Lopeandia, A.F.; Abad, L.; Llobet, J.; Molina-Ruiz, M.; Garcia, G.; Gerbolès, M.; Alvarez, F.X.; Goñi, A.R.; Muñoz-Pascual, F.J.; et al. In-Plane Thermal Conductivity of Sub-20 Nm Thick Suspended Mono-Crystalline Si Layers. Nanotechnology 2014, 25, 185402. [Google Scholar] [CrossRef]

- Li, Y.; Buddharaju, K.; Singh, N.; Lo, G.Q.; Lee, S.J. Chip-Level Thermoelectric Power Generators Based on High-Density Silicon Nanowire Array Prepared with Top-down CMOS Technology. IEEE Electron Device Lett. 2011, 32, 674–676. [Google Scholar] [CrossRef]

- Curtin, B.M.; Fang, E.W.; Bowers, J.E. Highly Ordered Vertical Silicon Nanowire Array Composite Thin Films for Thermoelectric Devices. J. Electron. Mater. 2012, 41, 887–894. [Google Scholar] [CrossRef]

- Perez-Marín, A.P.; Lopeandía, A.F.; Abad, L.; Ferrando-Villaba, P.; Garcia, G.; Lopez, A.M.; Muñoz-Pascual, F.X.; Rodríguez-Viejo, J. Micropower Thermoelectric Generator from Thin Si Membranes. Nano Energy 2014, 4, 73–80. [Google Scholar] [CrossRef]

- Haras, M.; Lacatena, V.; Morini, F.; Robillard, J.-F.; Monfray, S.; Skotnicki, T.; Dubois, E. Thermoelectric Energy Conversion: How Good Can Silicon Be? Mater. Lett. 2015, 157, 193–196. [Google Scholar] [CrossRef]

- Li, D.; Wu, Y.; Kim, P.; Shi, L.; Yang, P.; Majumdar, A. Thermal Conductivity of Individual Silicon Nanowires. Appl. Phys. Lett. 2003, 83, 2934–2936. [Google Scholar] [CrossRef]

- Cahill, D.G.; Braun, P.V.; Chen, G.; Clarke, D.R.; Fan, S.; Goodson, K.E.; Keblinski, P.; King, W.P.; Mahan, G.D.; Majumdar, A.; et al. Nanoscale Thermal Transport. II. 2003–2012. Appl. Phys. Rev. 2014, 1, 11305. [Google Scholar] [CrossRef]

- Malhotra, A.; Maldovan, M. Impact of Phonon Surface Scattering on Thermal Energy Distribution of Si and SiGe Nanowires. Sci. Rep. 2016, 6, 25818. [Google Scholar] [CrossRef] [Green Version]

- Dillner, U.; Kessler, E.; Meyer, H.-G. Figures of Merit of Thermoelectric and Bolometric Thermal Radiation Sensors. J. Sens. Sens. Syst. 2013, 2, 85–94. [Google Scholar] [CrossRef]

- Wang, K.; Xue, C.; Liang, T.; Jiao, B.; Zhang, W.; Chen, D.; Xiong, J. Thermopile Infrared Detector with Detectivity Greater Than 108 CmHz(1/2)/W. J. Infrared Millim. Terahertz Waves 2010, 31, 810–820. [Google Scholar] [CrossRef]

- Zhou, H.; Kropelnicki, P.; Tsai, J.M.; Lee, C. Development of a Thermopile Infrared Sensor Using Stacked Double Polycrystalline Silicon Layers Based on the {CMOS} Process. J. Micromech. Microeng. 2013, 23, 65026. [Google Scholar] [CrossRef]

- Harper, J.G.; Matthews, H.E.; Bube, R.H. Photothermoelectric Effects in Semiconductors: N- and P-Type Silicon. J. Appl. Phys. 1970, 41, 765–770. [Google Scholar] [CrossRef]

- Kwok, H.; Bube, R.H. Another Look at the Anomalous Photothermoelectric Effect in P-Type Silicon. J. Appl. Phys. 1970, 41, 5026–5027. [Google Scholar] [CrossRef]

- Okazaki, R.; Horikawa, A.; Yasui, Y.; Terasaki, I. Photo-Seebeck Effect in ZnO. J. Phys. Soc. Jpn. 2012, 81, 114722. [Google Scholar] [CrossRef] [Green Version]

- Mondal, P.S.; Okazaki, R.; Taniguchi, H.; Terasaki, I. Photo-Seebeck Effect in Tetragonal PbO Single Crystals. J. Appl. Phys. 2013, 114, 173710. [Google Scholar] [CrossRef]

- Lv, Y.; Chen, J.; Zheng, R.-K.; Song, J.; Zhang, T.; Li, X.; Shi, X.; Chen, L. Photo-Induced Enhancement of the Power Factor of Cu2S Thermoelectric Films. Sci. Rep. 2015, 5, 16291. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gonçalves Dalkiranis, G.; Ferrando-Villalba, P.; Lopeandia-Fernández, A.; Abad-Muñoz, L.; Rodríguez-Viejo, J. Thermoelectric Photosensor Based on Ultrathin Single-Crystalline Si Films †. Sensors 2019, 19, 1427. https://doi.org/10.3390/s19061427

Gonçalves Dalkiranis G, Ferrando-Villalba P, Lopeandia-Fernández A, Abad-Muñoz L, Rodríguez-Viejo J. Thermoelectric Photosensor Based on Ultrathin Single-Crystalline Si Films †. Sensors. 2019; 19(6):1427. https://doi.org/10.3390/s19061427

Chicago/Turabian StyleGonçalves Dalkiranis, Gustavo, Pablo Ferrando-Villalba, Aitor Lopeandia-Fernández, Llibertat Abad-Muñoz, and Javier Rodríguez-Viejo. 2019. "Thermoelectric Photosensor Based on Ultrathin Single-Crystalline Si Films †" Sensors 19, no. 6: 1427. https://doi.org/10.3390/s19061427

APA StyleGonçalves Dalkiranis, G., Ferrando-Villalba, P., Lopeandia-Fernández, A., Abad-Muñoz, L., & Rodríguez-Viejo, J. (2019). Thermoelectric Photosensor Based on Ultrathin Single-Crystalline Si Films †. Sensors, 19(6), 1427. https://doi.org/10.3390/s19061427