Smart Distribution Boards (Smart DB), Non-Intrusive Load Monitoring (NILM) for Load Device Appliance Signature Identification and Smart Sockets for Grid Demand Management

Abstract

1. Introduction

- Developing a smart distribution board (DB) with high speed CT metering sensor at >100 samples/cycle, NILM algorithm inside the smart DB home gateway can sense and disaggregate each appliance and smart sockets (SSO) with breaker controls that can turn off the load.

- Proposing a simple methodology of home load shedding system by aggregating a large number of identifiable and interruptible individual appliance load across households for utility demand management.

- Developing an HEMS that allows for easy home participation, takes in users preferences for IL while being part of a larger load shedding system, that can receive direct dispatch for grid stabilization. potentially can lead to higher IL participation.

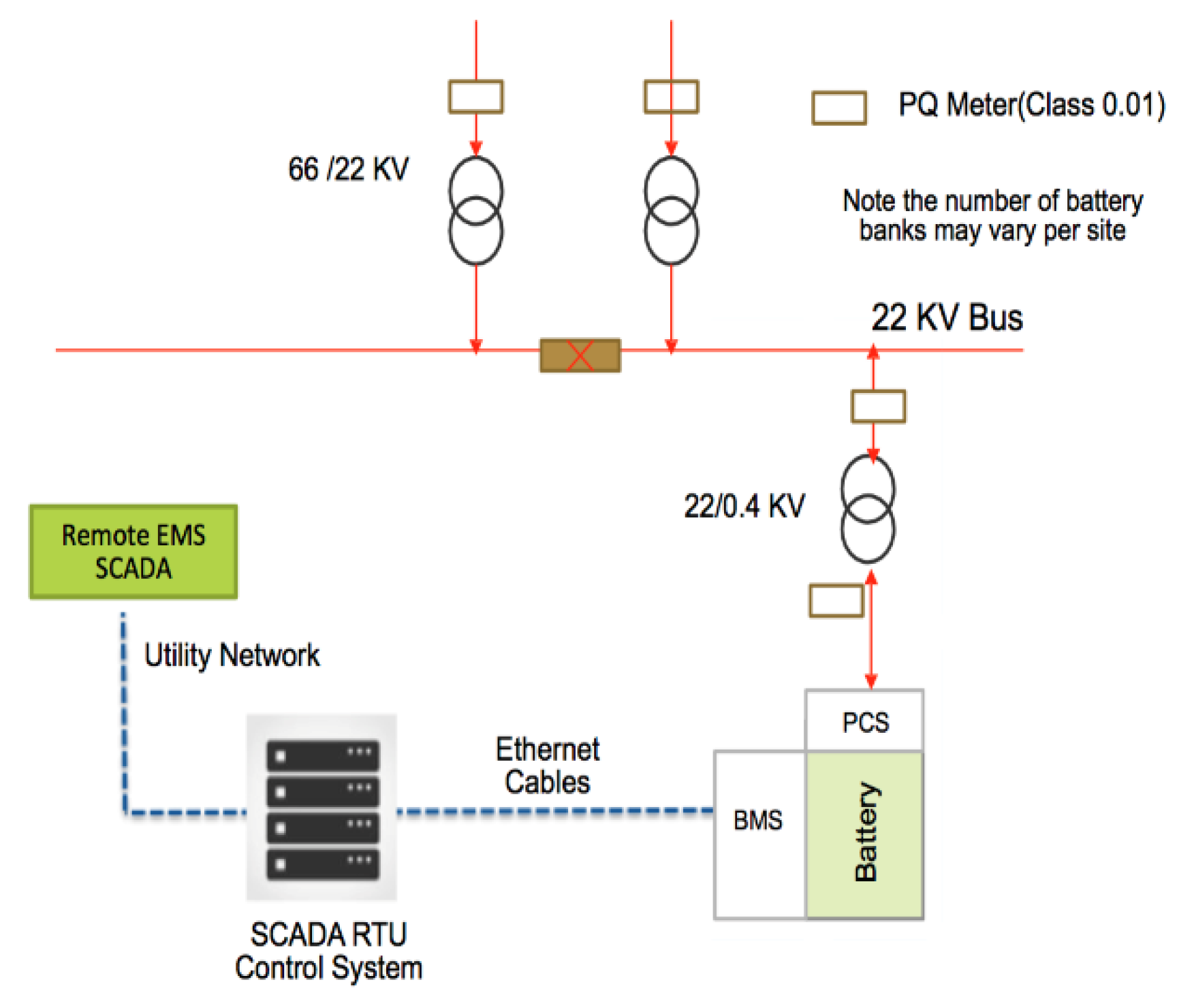

- Integrating an HESS to the smart DB, to show that by doing so can substantially increase the distributed ESS capacity throughout the utility, lowering overall cost per MW installed as compared to utility substation ESS, while working in tandem with the HEMS to minimize load interruptions, user inconvenience and providing Uninterruptible Power Supply (UPS) supply for critical applications and services.

- Designing this utility managed HEMS as part of an SCADA EMS and ILMS that can also operate autonomously and will not require real time updates and dispatch simply by sensing the grid frequency at its point of coupling to decide the amount of load shedding or energy discharge from the HESS.

2. Smart DB System Model

- system frequency

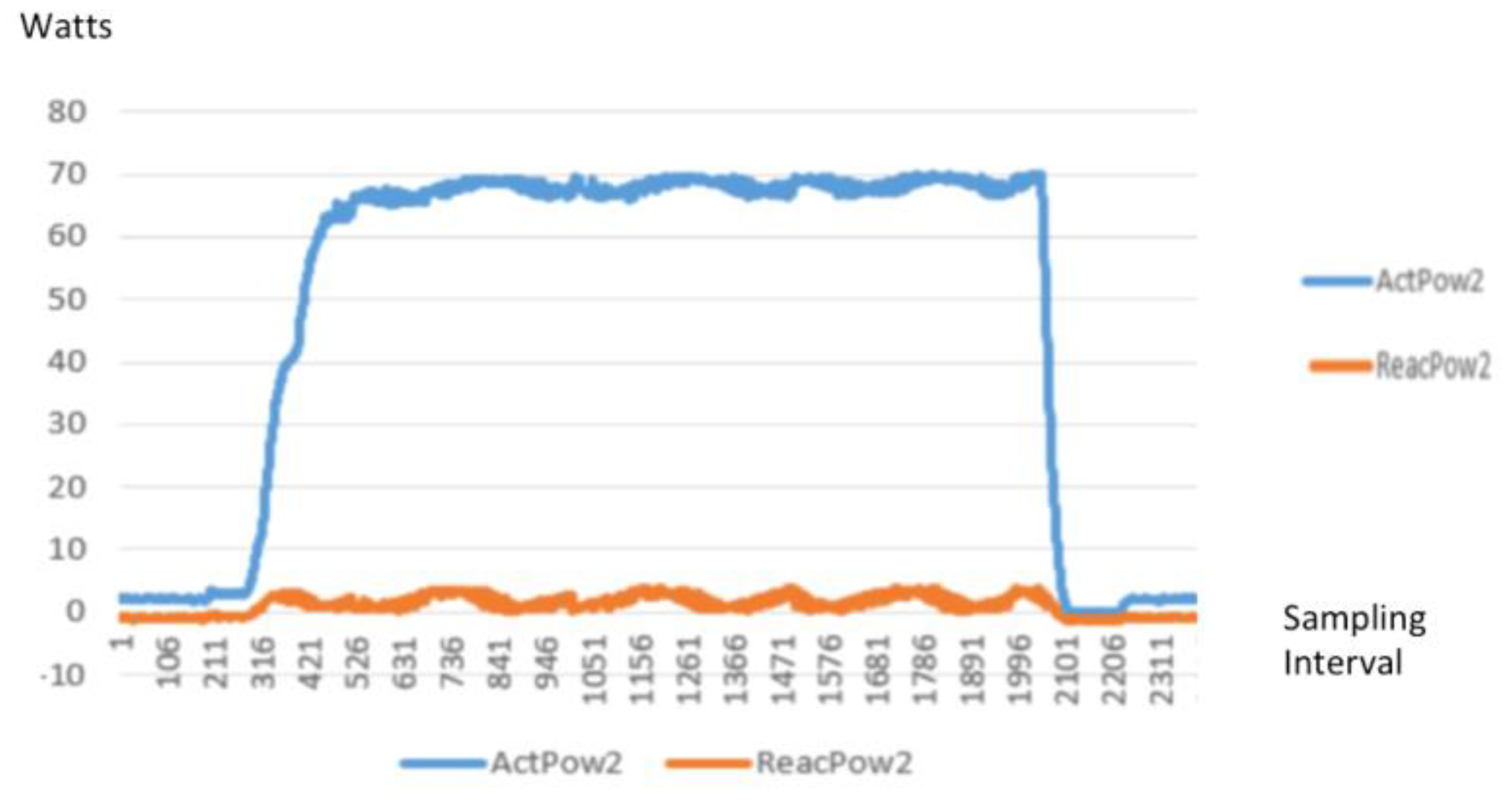

- active and reactive power

- Total and individual appliance energy usage including the aircon, heater and other loads (>150 W)

3. Home-ESS Modeling

- ESS equipment

- Space and network infrastructure

- Engineering and labor

- System setup, management and maintenance

- Part Replacements

4. HEMS Modeling

4.1. Smart DB

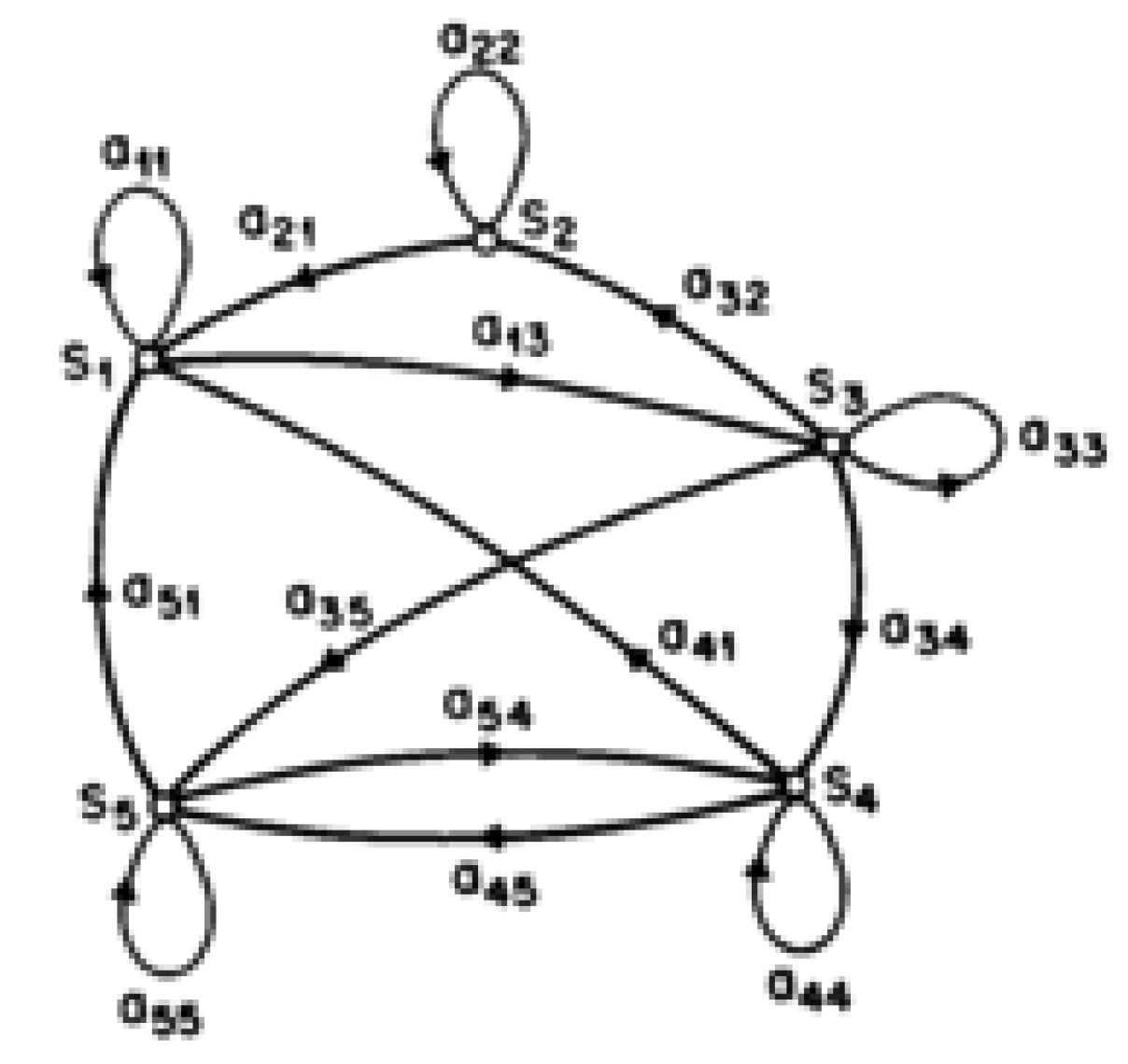

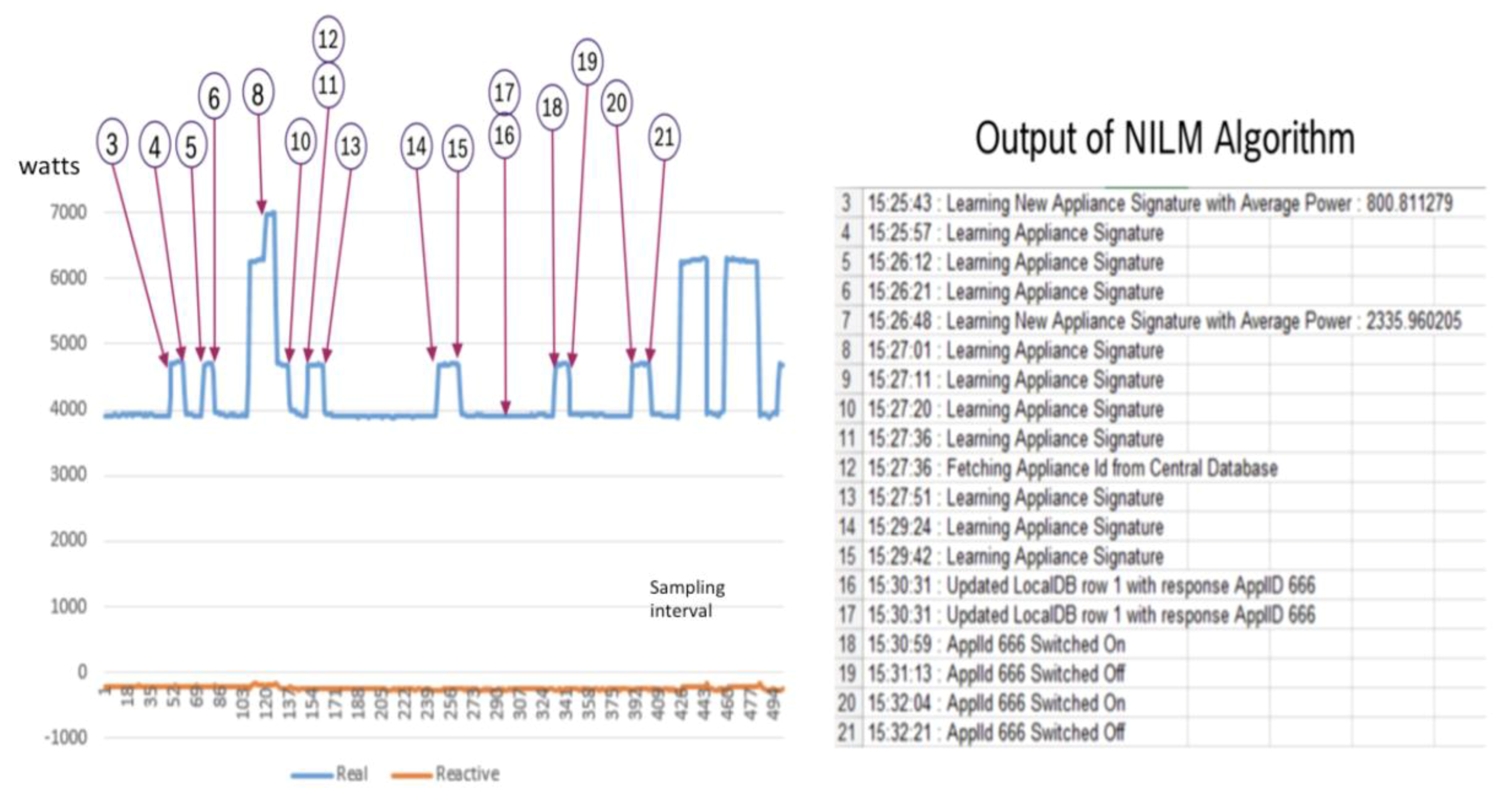

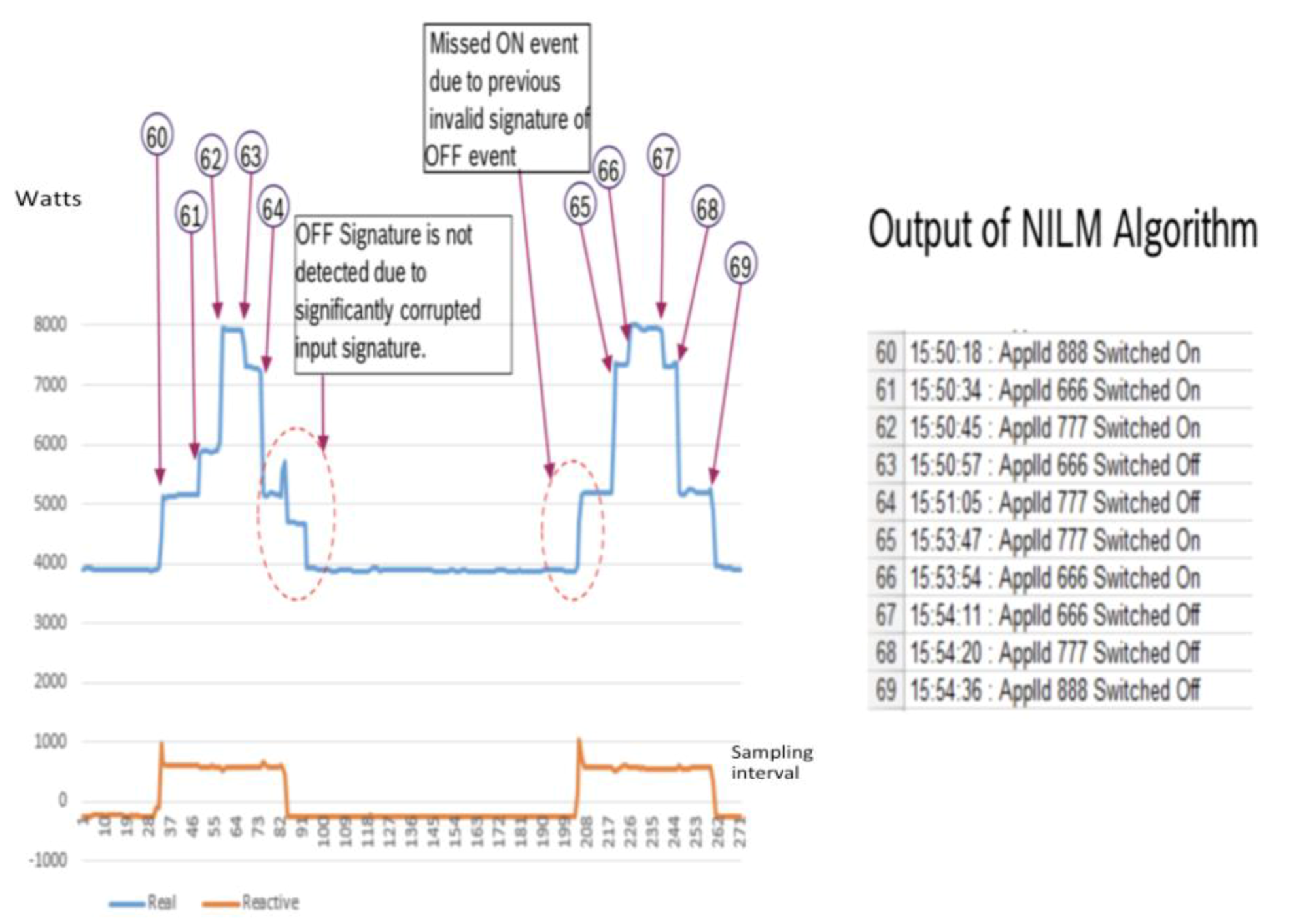

4.2. NILM

- Time complexity when the number of appliances, hidden states and the length of observation sequence need to be extended that reduces the classification performance of the model.

- Difficulty in classifying the multistate appliance requiring a long-range pattern resulting the existing models that are based on the first-order Markov process could not be trained efficiently.

- Error in classifying the appliances having similar power consumption.

- Learning and Detection of Toaster (800 watt), Kettle (2300 watt), and Vacuum Cleaner (1200 watt).

- (Sequence 1) Detection of Toaster, Kettle, and Vacuum Cleaner during Subsequent ON/OFF.

- (Sequence 2) Detection of Toaster, Kettle, and Vacuum Cleaner during Subsequent ON/OFF.

- Air conditioner—Priority 1

- Water Heater—Priority 2

- Kettle—Priority 3

- Fan—Priority 4

- Lights—Priority 5

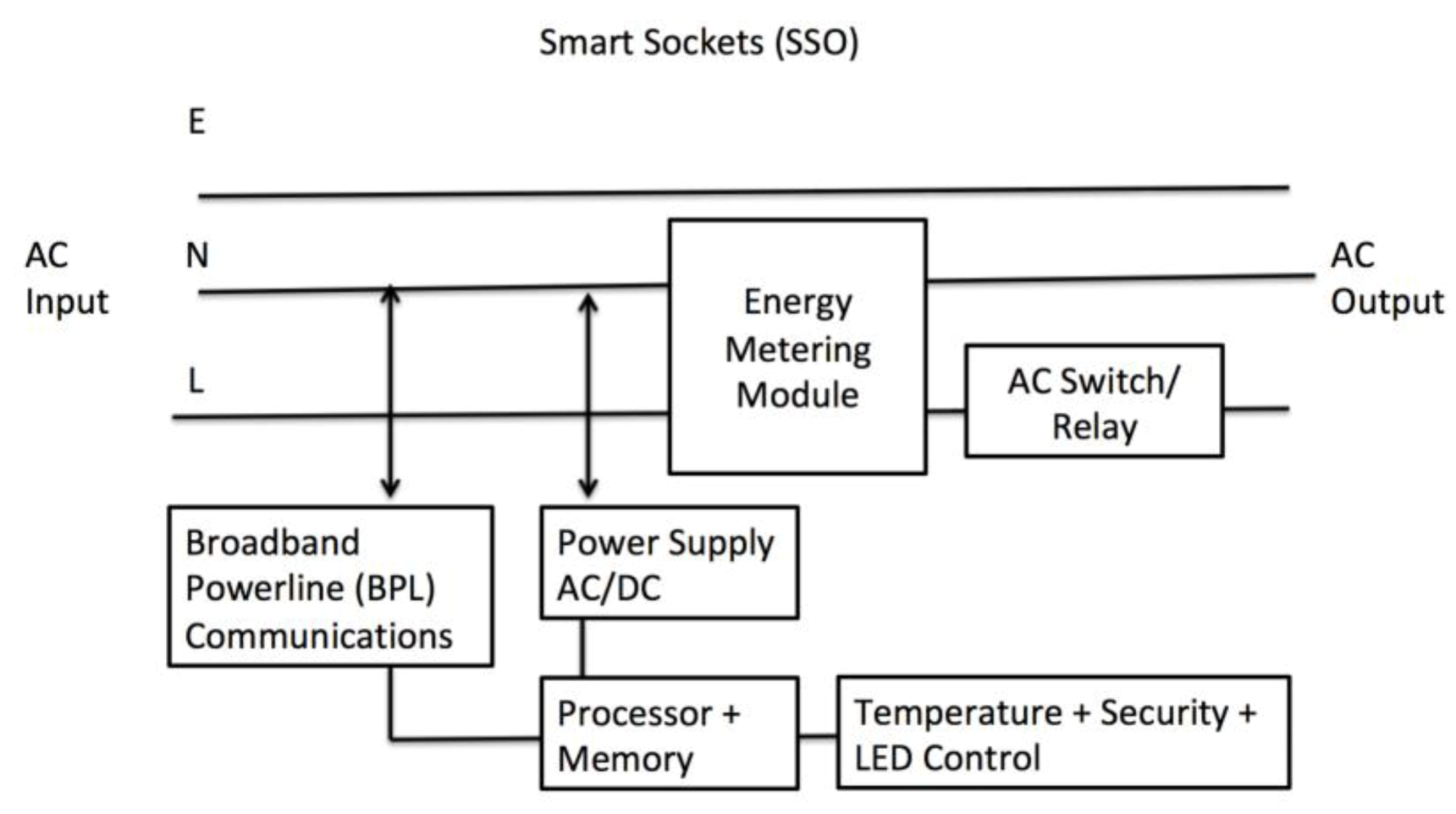

4.3. Smart Sockets (SSO)

5. HEMS Aggregation Modes for Grid Stabilization

5.1. Centralized Approach

5.2. Autonomous Approach

- 49.5 Hz—Discharge of the Home-ESS

- 49.4 Hz—Tripping of Priority 1 loads

- 49.3 Hz—Tripping of the Priority 2 loads

- 49.2 Hz—until 48.4 Hz—Tripping of the Priority 10 loads

- 48.0 Hz—Substation Relay.

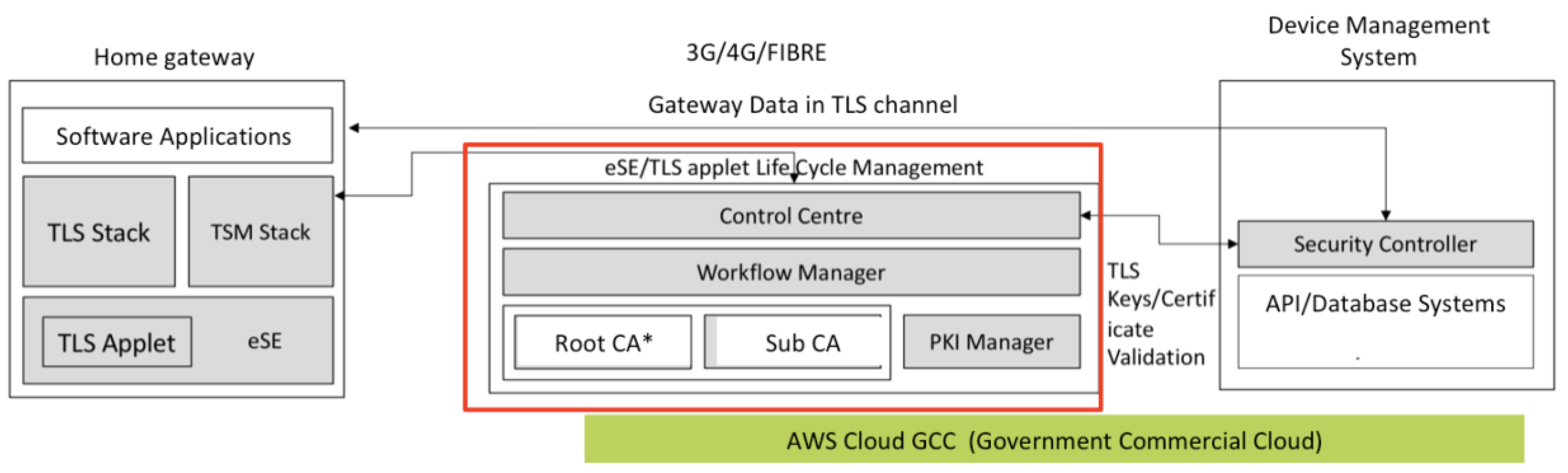

5.3. Security of This System

- PKI Infrastructure CA and PKI servers based on RSA2048 encryption on the data and Transport Layer Security TLS communication between the gateway and device data collection layer.

- Each gateway consists of a secure element (eSE) to store the signed SSL certificates in each gateway, which is tamperproof

- Use of session keys for every transaction to upload data

- SHA-256 hashing for all information.

- Reviewed by Cybersecurity Agency of Singapore (CSA) and the customer internal security department.

- All sensors also adopt the same TLS architecture

6. Case Study

- Cost of setting up the smart DB and gateway hardware in every home.

- Cost in managing and maintaining a utility wide smart home gateway and system that is “after the meter”, which is traditionally not the utility space and cost benefits must be recovered in terms of savings from having to pay for higher spinning reserve capacity to ensure the stability of the network.

- The system is highly scalable as utility revenue metering, currently recorded every 30 min or even bi-monthly for mechanical meters can now be broken down into higher resolution or even real time streaming when at home without loading on the utility server as each user will be polling its own gateway.

- Granularity of load usage profile of every appliance will lead to higher customer trusts and satisfaction on their monthly bill as it leads to higher transparency.

- Condition monitoring of appliances when compared to similar usage periods for possible degradation.

- Ability to provide additional services for new revenue stream for the utility.

- Payback model for setting up Home ESS can include other services such as providing a better quality of supply for home critical care services.

- Need to develop a custom made smart DB to house all the required components and to get the type testing approvals are not easy.

- Use of different communication protocols that must allow the offering of additional sensors and services not part of the utility space.

- Accuracy of the NILM for smaller loads (<100 W) which can be easily mixed up with the background noise.

- Designing a unified security plan for all sub-components.

- Selection of the recording and uploading interval, implementing the schema on the amount of data to upload to avoid using too much bandwidth to the end user. Hence the 6 kHz sampling interval is only locally captured and used to identified the load signature and discarded to avoid collecting too much data. V, I, kW, kVar, kWh and frequency appliances are recorded and uploaded only every 15 min to limit the amount of data. Each file is less than 1 kbyte each and only takes less than 1–2 s to upload on a typical home WIFI of around 100–200 MBits. However, when loads are turn on/off, which affects the ILMS capacity available, these status changes are uploaded immediately. On a grand scale, load changes across thousands of households changes gradually as appliances are being on/off only a few times a day. Even turning on/off the TV load 100 times a day is considered nothing to the system over 24 h.

7. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Chang, L.; Zhang, W.; Xu, S.; Spence, K. Review on Distributed Energy Storage Systems for Utility Applications. CPSS Trans. Power Electron. Appl. 2017, 2, 267–276. [Google Scholar] [CrossRef]

- Kim, J.S.; Yang, H.; Choi, S.G. Distributed real-time stochastic optimization based ESS management strategy for residential customers. In Proceedings of the 19th International Conference on Advanced Communication Technology, PyeongChang, Korea, 19–22 February 2017. [Google Scholar]

- Petrichenko, R.; Chuvychin, V. Smart load shedding system. In Proceedings of the 3rd IEEE International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Aalborg, Denmark, 25–28 June 2012. [Google Scholar]

- Syadli, H.; Abdullaha, M.P.; Hassana, I.F.M.Y.; Hussina, F. An improved load shedding scheduling strategy for solving power supply defisit. J. Tecknologi (Sci. Eng.) 2016, 78, 61–66. [Google Scholar] [CrossRef][Green Version]

- Tang, J.; Liu, J.; Ponci, F.; Monti, A. Adaptive Load Shedding Based On Combined Frequency And Voltage Stability Assessment Using Synchrophasor Measurements. IEEE Trans. Power Syst. 2013, 28, 2035–2047. [Google Scholar] [CrossRef]

- Quyen, H.A.; Bui, Q.A.; Le, T.N.; Le, T.T.T. Optimal Load Shedding Based on Frequency, Voltage Sensitivities and AHP Algorithm. In AETA 2013: Recent Advances in Electrical Engineering and Related Sciences; Springer: Berlin/Heidelberg, Germany, 2014; pp. 75–84. [Google Scholar]

- Atteya1, I.; Fahmi1, N.; Strickland, D.; Ashour, H. “Utilization of Battery Energy Storage Systems (BESS) in Smart Grid: A Review”. In Proceedings of the International Conference on Renewable Energies and Power Quality (ICREPQ’16), Madrid, Spain, 4–6 May 2016. [Google Scholar]

- Logenthiran, T.; Srinivasan, D. Intelligent Management of Distributed Storage Elements in a Smart Grid. In Proceedings of the 2011 IEEE Ninth International Conference on Power Electronics and Drive Systems, IEEE PEDS, Singapore, 5–8 December 2011. [Google Scholar]

- Tushar, W.; Chai, B.; Yuen, C.; Smith, D.B.; Wood, K.L.; Yang, Z.; Poor, H.V. Three-Party Energy Management With DistributedEnergy Resources in Smart Grid. IEEE Trans. Ind. Electron. 2015, 62, 2487–2498. [Google Scholar] [CrossRef]

- Lindahl, S.; Runvik, G.; Stranne, G. Operational experience of load shedding and new requirements on frequency relays. In Proceedings of the Sixth International Conference on Developments in Power System Protection, Nottingham, UK, 25–27 March 1997. [Google Scholar]

- Perumal, N.; Amran, A.C. Automatic load shedding in power system. In Proceedings of the National Power Engineering Conference, PECon 2003, Bangi, Malaysia, 15–16 December 2003. [Google Scholar]

- Chen, C.-S.; Ke, Y.-L.; Hsu, C.-T. Protective Relay Setting of the Tie Line Tripping and Load Shedding for the Industrial Power System. IEEE Trans. Ind. Appl. 2000, 36, 1226–1234. [Google Scholar] [CrossRef]

- Eller, A.; Gauntlett, D. Energy Storage Trends and Opportunities in Emerging Markets. Available online: https://www.ifc.org/wps/wcm/connect/ed6f9f7f-f197-4915-8ab6-56b92d50865d/7151-IFC-EnergyStorage-report.pdf?MOD=AJPERES (accessed on 13 March 2019).

- Hart, D.M.; Mason, G.; Bonvillian, B.; Nathaniel, M. Energy Storage for the Grid: An MIT Energy Initiative Working Paper; MIT Energy Initiative: Cambridge, MA, USA, 2018. [Google Scholar]

- Hesse, H.C.; Schimpe, M.; Kucevic, D.; Jossen, A. Lithium-Ion Battery Storage for the Grid—A Review of Stationary Battery Storage System Design Tailored for Applications in Modern Power Grids. Energies 2017, 10, 2107. [Google Scholar] [CrossRef]

- Schneider, M.; Biel, K.; Pfaller, S.; Schaede, H.; Rinderknecht, S.; Glock, C.H. Using inventory models for sizing energy storage systems: An interdisciplinary approach. J. Energy Storage 2016, 8, 339–348. [Google Scholar] [CrossRef]

- Borsche, T.; Ulbig, A.; Koller, M.; Andersson, G. Power and energy capacity requirements of storages providing frequency control reserve. In Proceedings of the IEEE Power and Energy Society General Meeting (PES), Vancouver, BC, Canada, 21–25 July 2013; pp. 1–5. [Google Scholar]

- Buckley, B. Putting More Energy into Peak Savings: Integrating Demand Response and Energy Efficiency Programs in the Northeast and Mid-Atlantic. In Proceedings of the 2016 ACEEE Summer Study on Energy Efficiency in Buildings, Pacific Grove, CA, USA, 21–26 August 2016. [Google Scholar]

- Thirugnanam, K.; Kerk, S.G.; Yuen, C.; Thirunavukarasu, B. Battery Integrated Solar Photovoltaic Energy Management System for Micro-Grid. In Proceedings of the IEEE ISGT-Asia 2015, Bangkok, Thailand, 3–6 November 2015. [Google Scholar]

- Hassan, N.U.; Khalid, Y.I.; Yuen, C.; Huang, S.; Pasha, M.A.; Wood, K.L.; Kerk, S.G. Framework for Minimum User Participation Rate Determination to Achieve Specific Demand Response Management Objectives in Residential Smart Grids. Int. J. Electr. Power Energy Syst. (IJEPES) 2016, 74, 91–103. [Google Scholar] [CrossRef]

- Tushar, W.; Yuen, C.; Chai, B.; Huang, S.; Wood, K.L.; Kerk, S.G.; Yang, Z. Smart Grid Testbed for Demand Focused Energy Management in End User Environments. IEEE Wirel. Commun. 2016, 23, 70–80. [Google Scholar] [CrossRef]

- Rules Modification for EMA’s “Implementing Demand Response in the National Electricity Market of Singapore”; Energy Market Authority: Singapore, 24 June 2011.

- de Mello, P.B.; Pinto, R.G.D.; Silva, P.B. Load Disaggregation of Industrial Machinery Power Consumption Monitoring Using Factorial Hidden Markov Models. In Proceedings of the NILM Workshop 2018, Duisburg, Germany, 1–2 October 2018. [Google Scholar]

- Parson, O.; Ghosh, S.; Weal, M.J.; Rogers, A. Non-intrusive load monitoring using prior models of general appliance types. In Proceedings of the Twenty-Sixth AAAI Conference on Artificial Intelligence, Toronto, ON, Canada, 22–26 July 2012. [Google Scholar]

- Kolter, J.Z.; Jaakkola, T. Approximate inference in additive factorial hmms with application to energy disaggregation. In Proceedings of the Fifteenth International Conference on Artificial Intelligence and Statistics, Ser. Proceedings of Machine Learning Research, Palma, Spain, 21–23 April 2012; Lawrence, N.D., Girolami, M., Eds.; PMLR: Palma, Spain, 2012; Volume 22, pp. 1472–1482. [Google Scholar]

- Zoha, A.; Gluhak, A.; Nati, M.; Imran, M.A. Low-power appliance monitoring using Factorial Hidden Markov Models. In Proceedings of the 2013 IEEE 8th International Conference on Intelligent Sensors, Sensor Networks and Information Processing: Sensing the Future (ISSNIP ’13), Melbourne, VIC, Australia, 2–5 April 2013; pp. 527–532. [Google Scholar]

- Rabiner, L.R. A tutorial on hidden markov models and selected applications in speech recognition. Proc. IEEE 1989, 7, 257–286. [Google Scholar] [CrossRef]

- Kim, J.; Le, T.-T.-H.; Kim, H. Non Intrusive Load Monitoring based on advanced deep learning and Novel Signature. Comput. Intell. Neurosci. 2017. [Google Scholar] [CrossRef] [PubMed]

| Types of Loads | No. of NILM Simulations | No. Error Cases | % of Error |

|---|---|---|---|

| Above 150W | |||

| Central AC for large hooms | 1000 | 298 | 29.8% |

| Room AC/Split Type | 1000 | 321 | 32.1% |

| AC Heat Pump | 1000 | 13 | 1.3% |

| Kettle/Electric heater | 1000 | 35 | 3.5% |

| Dishwasher | 1000 | 328 | 32.8% |

| Freezer | 1000 | 16 | 1.6% |

| Refrigerator | 1000 | 12 | 1.2% |

| Second refrigerator | 1000 | 15 | 1.5% |

| Hot water heater | 1000 | 18 | 1.8% |

| Tankless Hot Water Heater | 1000 | 30 | 3.0% |

| Heat Pump Water heater | 1000 | 3 | 0.3% |

| Washing Machine | 1000 | 86 | 8.6% |

| Electric Dryer/Hair dryer | 1000 | 68 | 6.8% |

| EV Charger | 1000 | 56 | 5.6% |

| LED TV | 1000 | 389 | 38.9% |

| Toaster | 1000 | 11 | 1.1% |

| Microwave Oven | 1000 | 38 | 3.8% |

| Below 150 W | |||

| Fan | 1000 | 530 | 53.0% |

| Dehumidifier | 1000 | 543 | 54.3% |

| Lights | 1000 | 679 | 67.9% |

| Aquarium Water Pump | 1000 | 235 | 23.5% |

| Number of Homes | 3000 |

|---|---|

| Available power Home-ESS | 2 kW |

| Available energy Home-ESS | 5 kWh |

| Peak power (3000 homes) | 6 MW |

| Home-ESS State of charge | 100% |

| Priority load 1-Aircon | 2 kW |

| Priority load 2-Water Heater | 1 kW |

| Priority Load 3-Kettle | 1.2 kW |

| Priority load 4-Vacuum Cleaner | 0.8 kW |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kerk, S.G.; Hassan, N.U.; Yuen, C. Smart Distribution Boards (Smart DB), Non-Intrusive Load Monitoring (NILM) for Load Device Appliance Signature Identification and Smart Sockets for Grid Demand Management. Sensors 2020, 20, 2900. https://doi.org/10.3390/s20102900

Kerk SG, Hassan NU, Yuen C. Smart Distribution Boards (Smart DB), Non-Intrusive Load Monitoring (NILM) for Load Device Appliance Signature Identification and Smart Sockets for Grid Demand Management. Sensors. 2020; 20(10):2900. https://doi.org/10.3390/s20102900

Chicago/Turabian StyleKerk, See Gim, Naveed UL Hassan, and Chau Yuen. 2020. "Smart Distribution Boards (Smart DB), Non-Intrusive Load Monitoring (NILM) for Load Device Appliance Signature Identification and Smart Sockets for Grid Demand Management" Sensors 20, no. 10: 2900. https://doi.org/10.3390/s20102900

APA StyleKerk, S. G., Hassan, N. U., & Yuen, C. (2020). Smart Distribution Boards (Smart DB), Non-Intrusive Load Monitoring (NILM) for Load Device Appliance Signature Identification and Smart Sockets for Grid Demand Management. Sensors, 20(10), 2900. https://doi.org/10.3390/s20102900