Internet of Robotic Things in Smart Domains: Applications and Challenges

Abstract

:1. Introduction

- a picture of the interaction between physical and virtual scenarios managed by the Cyber-Physical Systems technologies;

- the definition of the Internet of Robotic Things concept: its architecture and main technologies;

- the identification of various application domains, outlining the newest state-of-the-art literature based on IoRT technologies;

- open issues and challenges that are worth investigating in the future, showing how IoRT systems could represent a key role in the context of the fourth industrial revolution.

2. Smart Technologies in Industry 4.0

2.1. Cyber-Physical Systems

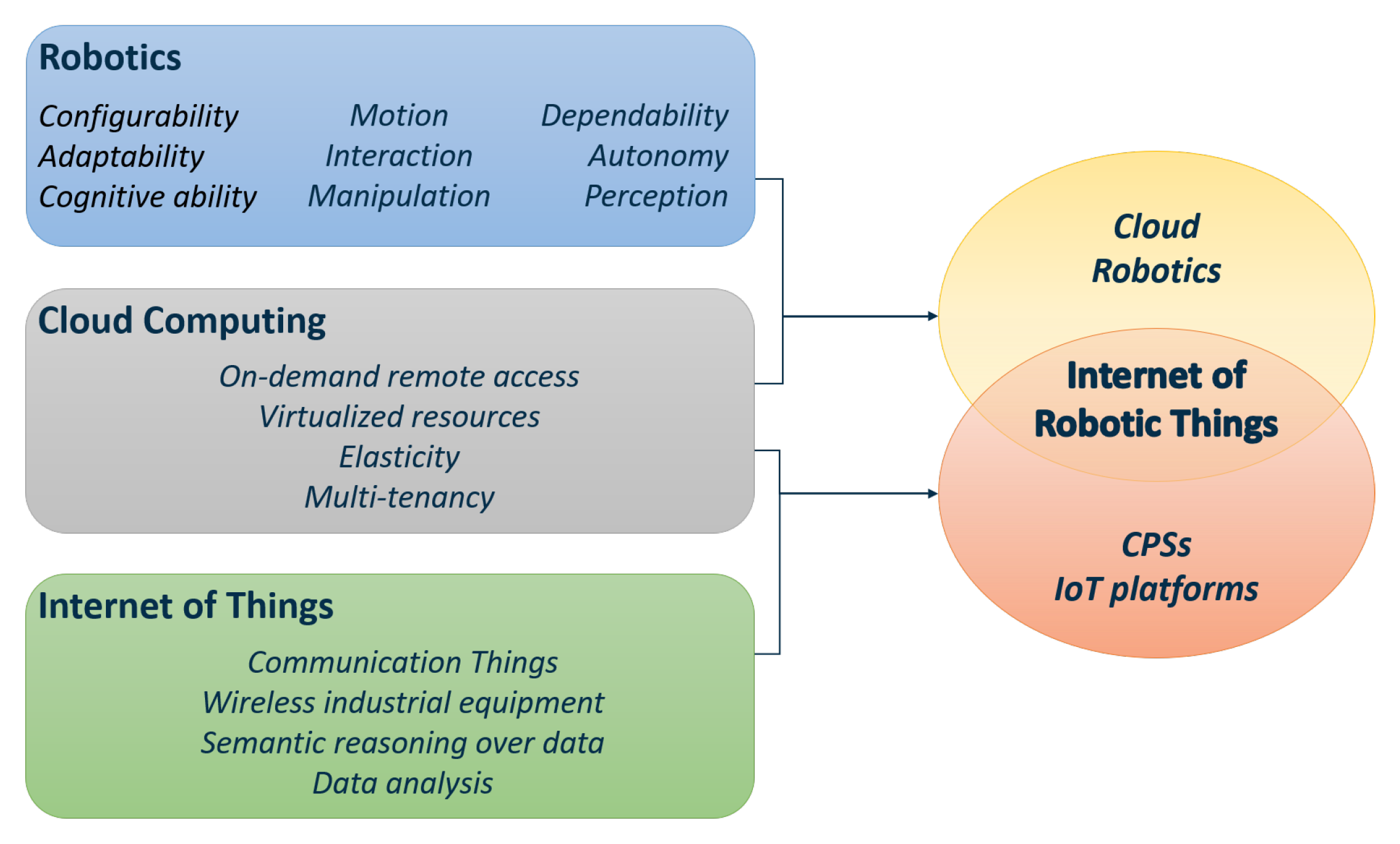

2.2. Internet of Robotic Things

3. Smart Domains and Applications in the IoRT Systems

3.1. Manufacturing

3.2. Agriculture

3.3. Further Domains: Health-Care, Education, and Surveillance

4. Issues and Challenges

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Shih, C.S.; Chou, J.J.; Reijers, N.; Kuo, T.W. Designing CPS/IoT applications for smart buildings and cities. IET Cyber Phys. Syst. Theory Appl. 2016, 1, 3–12. [Google Scholar] [CrossRef]

- Xu, H.; Yu, W.; Griffith, D.; Golmie, N. A survey on industrial Internet of Things: A cyber-physical systems perspective. IEEE Access 2018, 6, 78238–78259. [Google Scholar] [CrossRef]

- Kondratenko, Y.P. Robotics, Automation and Information Systems: Future Perspectives and Correlation with Culture, Sport and Life Science. In Decision Making and Knowledge Decision Support Systems: VIII International Conference of RACEF, Barcelona, Spain, November 2013 and International Conference MS 2013, Chania Crete, Greece, November 2013; Gil-Lafuente, A.M., Zopounidis, C., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 43–55. [Google Scholar]

- van Erp, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar]

- Ray, P.P. Internet of Robotic Things: Concept, Technologies, and Challenges. IEEE Access 2016, 4, 9489–9500. [Google Scholar] [CrossRef]

- Vermesan, O.; Bröring, A.; Tragos, E.; Serrano, M.; Bacciu, D.; Chessa, S.; Gallicchio, C.; Micheli, A.; Dragone, M.; Saffiotti, A.; et al. Internet of robotic things: Converging sensing/actuating, hypoconnectivity, artificial intelligence and IoT Platforms. In Cognitive Hyperconnected Digital Transformation: Internet of Things Intelligence Evolution; River Publishers: Gistrup, Denmark, 2017; pp. 97–155. [Google Scholar]

- Batth, R.S.; Nayyar, A.; Nagpal, A. Internet of Robotic Things: Driving Intelligent Robotics of Future-Concept, Architecture, Applications and Technologies. In Proceedings of the 2018 4th International Conference on Computing Sciences (ICCS), Jalandhar, India, 30–31 August 2018; pp. 151–160. [Google Scholar]

- Simoens, P.; Dragone, M.; Saffiotti, A. The Internet of Robotic Things: A review of concept, added value and applications. Int. J. Adv. Robot. Syst. 2018, 15. [Google Scholar] [CrossRef]

- Afanasyev, I.; Mazzara, M.; Chakraborty, S.; Zhuchkov, N.; Maksatbek, A.; Kassab, M.; Distefano, S. Towards the Internet of Robotic Things: Analysis, Architecture, Components and Challenges. In Proceedings of the 2019 12th International Conference on Developments in eSystems Engineering (DeSE), Kazan, Russia, 7–10 October 2019. [Google Scholar]

- Yao, X.; Zhou, J.; Lin, Y.; Li, Y.; Yu, H.; Liu, Y. Smart manufacturing based on cyber-physical systems and beyond. J. Intell. Manuf. 2019, 30, 2805–2817. [Google Scholar] [CrossRef] [Green Version]

- Mazzara, M.; Afanasyev, I.; Sarangi, S.; Distefano, S.; Kumar, V. A Reference Architecture for Smart and Software-defined Buildings. In Proceedings of the 2019 IEEE International Conference on Smart Computing (SMARTCOMP), Washington, DC, USA, 12–15 June 2019. [Google Scholar]

- Wan, J.; Tang, S.; Shu, Z.; Li, D.; Wang, S.; Imran, M.; Vasilakos, A.V. Software-Defined Industrial Internet of Things in the Context of Industry 4.0. IEEE Sens. J. 2016, 16, 7373–7380. [Google Scholar] [CrossRef]

- Zheng, P.; wang, H.; Sang, Z.; Zhong, R.Y.; Liu, Y.; Liu, C.; Mubarok, K.; Yu, S.; Xu, X. Smart manufacturing systems for Industry 4.0: Conceptual framework, scenarios, and future perspectives. Front. Mech. Eng. 2018, 13, 137–150. [Google Scholar] [CrossRef]

- Petitti, A.; Di Paola, D.; Milella, A.; Lorusso, A.; Colella, R.; Attolico, G.; Caccia, M. A Network of Stationary Sensors and Mobile Robots for Distributed Ambient Intelligence. IEEE Intell. Syst. 2016, 31, 28–34. [Google Scholar] [CrossRef]

- Wollschlaeger, M.; Sauter, T.; Jasperneite, J. The Future of Industrial Communication: Automation Networks in the Era of the Internet of Things and Industry 4.0. IEEE Ind. Electron. Mag. 2017, 11, 17–27. [Google Scholar] [CrossRef]

- Leitão, P.; Karnouskos, S.; Ribeiro, L.; Lee, J.; Strasser, T.; Colombo, A.W. Smart Agents in Industrial Cyber–Physical Systems. Proc. IEEE 2016, 104, 1086–1101. [Google Scholar] [CrossRef] [Green Version]

- Uhlemann, T.H.-J.; Lehmann, C.; Steinhilper, R. The Digital Twin: Realizing the Cyber-Physical Production System for Industry 4.0. Procedia CIRP 2017, 61, 335–340. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Kahlen, F.J., Flumerfelt, S., Alves, A., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 85–113. [Google Scholar]

- Tomiyama, T.; Moyen, F. Resilient architecture for cyber-physical production systems. CIRP Ann. 2018, 67, 161–164. [Google Scholar] [CrossRef]

- Garcia, C.A.; Montalvo-Lopez, W.; Garcia, M.V. Human-Robot Collaboration Based on Cyber-Physical Production System and MQTT. In Proceedings of the International Conference on Industry 4.0 and Smart Manufacturing (ISM 2019), Rende, Italy, 20–22 November 2020; Volume 42, pp. 315–321. [Google Scholar]

- Yu, M.; Zhu, M.; Chen, G.; Li, J.; Zhou, Z. A cyber-physical architecture for industry 4.0-based power equipments detection system. In Proceedings of the 2016 International Conference on Condition Monitoring and Diagnosis (CMD), Xi’an, China, 25–28 September 2016; pp. 782–785. [Google Scholar]

- Jiang, J.R. An improved cyber-physical systems architecture for Industry 4.0 smart factories. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Jiang, P. A Cyber-physical System Architecture in Shop Floor for Intelligent Manufacturing. Procedia CIRP 2016, 56, 372–377. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Peng, Y.; Wang, B.; Yao, S.; Liu, Z. Review on cyber-physical systems. IEEE/CAA J. Autom. Sin. 2017, 4, 27–40. [Google Scholar] [CrossRef]

- Drozdov, D.; Patil, S.; Dubinin, V.; Vyatkin, V. Towards formal ASM semantics of timed control systems for industrial CPS. In Proceedings of the 2019 24th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019; pp. 1682–1685. [Google Scholar]

- Cai, Y.; Tang, W.; Zhang, B.; Wang, Y. Collaborative configuration for distributed energy storages and cyber systems in low-voltage distribution networks with high penetration of PV systems. IET Cyber Phys. Syst. Theory Appl. 2019, 4, 3–12. [Google Scholar] [CrossRef]

- Hosseini, M.; Berlin, R.R.; Sha, L. A Physiology-Aware Communication Architecture for Distributed Emergency Medical CPS. In Proceedings of the 8th International Conference on Cyber-Physical Systems, ICCPS ’17, Pittsburgh, PA, USA, 18–20 April 2017; Association for Computing Machinery: New York, NY, USA, 2017; p. 83. [Google Scholar] [CrossRef]

- Koken, B. Cloud robotics platforms. Interdiscip. Descr. Complex Syst. INDECS 2015, 13, 26–33. [Google Scholar] [CrossRef]

- Razafimandimby, C.; Loscri, V.; Vegni, A.M. Towards Efficient Deployment in Internet of Robotic Things. In Integration, Interconnection, and Interoperability of IoT Systems; Gravina, R., Palau, C.E., Manso, M., Liotta, A., Fortino, G., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 21–37. [Google Scholar]

- Ramson, S.J.; Moni, D.J. Applications of wireless sensor networks—A survey. In Proceedings of the 2017 International Conference on Innovations in Electrical, Electronics, Instrumentation and Media Technology (ICEEIMT), Coimbatore, India, 3–4 February 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 325–329. [Google Scholar]

- Nathalie, M.; David, S.R. Wireless Sensor and Robot Networks: From Topology Control to Communication Aspects; World Scientific: Singapore, 2013. [Google Scholar]

- Li, T.S.; Liu, C.; Kuo, P.; Fang, N.; Li, C.; Cheng, C.; Hsieh, C.; Wu, L.; Liang, J.; Chen, C. A Three-Dimensional Adaptive PSO-Based Packing Algorithm for an IoT-Based Automated e-Fulfillment Packaging System. IEEE Access 2017, 5, 9188–9205. [Google Scholar] [CrossRef]

- Cecil, J.; Albuhamood, S.; Ramanathan, P.; Gupta, A. An Internet-of-Things (IoT) based cyber manufacturing framework for the assembly of microdevices. Int. J. Comput. Integr. Manuf. 2019, 32, 430–440. [Google Scholar] [CrossRef]

- Ke, Q.; Xiaogang, L. Internet-of-Things monitoring system of robot welding based on software defined networking. In Proceedings of the 2016 First IEEE International Conference on Computer Communication and the Internet (ICCCI), Wuhan, China, 13–15 October 2016; pp. 112–117. [Google Scholar]

- Song, D.; Goldberg, K.; Chong, N.Y. Networked Robots. In Springer Handbook of Robotics; Siciliano, B., Khatib, O., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 1109–1134. [Google Scholar]

- Rosenfeld, A.; Agmon, N.; Maksimov, O.; Kraus, S. Intelligent agent supporting human–multi-robot team collaboration. Artif. Intell. 2017, 252, 211–231. [Google Scholar] [CrossRef]

- Gaggero, M.; Di Paola, D.; Petitti, A.; Caviglione, L. When Time Matters: Predictive Mission Planning in Cyber-Physical Scenarios. IEEE Access 2019, 7, 11246–11257. [Google Scholar] [CrossRef]

- Pai, V.; Shenoy, U.K.K. 6LowPan—Performance Analysis on Low Power Networks. In International Conference on Computer Networks and Communication Technologies; Smys, S., Bestak, R., Chen, J.I.Z., Kotuliak, I., Eds.; Springer: Singapore, 2019; pp. 145–156. [Google Scholar]

- Vos, M.; Cranefield, J. RFID/Internet of Things systems on the boundary between public and private sectors: An ant study of multiplicity. In Proceedings of the 25th European Conference on Information Systems (ECIS), Guimarães, Portugal, 5–10 June 2017; pp. 1205–1216. [Google Scholar]

- Belbachir, A.; Benabid, S. Smart Communication for cooperative Wireless Sensor Network. In Proceedings of the 2016 International Conference on Applied Electronics (AE), Pilsen, Czech Republic, 6–7 September 2016; pp. 15–18. [Google Scholar]

- Mosavi, A.; Varkonyi-Koczy, A.R. Integration of Machine Learning and Optimization for Robot Learning. In Recent Global Research and Education: Technological Challenges; Jabłoński, R., Szewczyk, R., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 349–355. [Google Scholar]

- Kehoe, B.; Patil, S.; Abbeel, P.; Goldberg, K. A Survey of Research on Cloud Robotics and Automation. IEEE Trans. Autom. Sci. Eng. 2015, 12, 398–409. [Google Scholar] [CrossRef]

- Yin, S.; Li, X.; Gao, H.; Kaynak, O. Data-Based Techniques Focused on Modern Industry: An Overview. IEEE Trans. Ind. Electron. 2015, 62, 657–667. [Google Scholar] [CrossRef]

- Pedersen, M.R.; Nalpantidis, L.; Andersen, R.S.; Schou, C.; Bøgh, S.; Krüger, V.; Madsen, O. Robot skills for manufacturing: From concept to industrial deployment. Robot. Comput. Integr. Manuf. 2016, 37, 282–291. [Google Scholar] [CrossRef]

- Coronado, P.D.U.; Ahuett-Garza, H.; Morales-Menendez, R.; Castañón, P.O.; Dávila, L.D.; Escalera, M.R.F. Connectivity of a modular electric vehicle by the use of a mobile device. Adv. Mech. Eng. 2017, 9, 1687814017708087. [Google Scholar]

- Kumar, A. Methods and Materials for Smart Manufacturing: Additive Manufacturing, Internet of Things, Flexible Sensors and Soft Robotics. Industry 4.0 and Smart Manufacturing. Manuf. Lett. 2018, 15, 122–125. [Google Scholar] [CrossRef]

- Ali, M.H.; Aizat, K.; Yerkhan, K.; Zhandos, T.; Anuar, O. Vision-based Robot Manipulator for Industrial Applications. Procedia Comput. Sci. 2018, 133, 205–212. [Google Scholar] [CrossRef]

- Chang, W.; Lin, S.; Hsu, J.; Hsu, B. Automatic Path Planning of Robot for Intelligent Manufacturing Based on Network Remoted Controlling and Simulation. In Proceedings of the 2019 4th Asia-Pacific Conference on Intelligent Robot Systems (ACIRS), Nagoya, Japan, 13–15 July 2019; pp. 164–168. [Google Scholar]

- Liu, Q.; Hua, P.; Sultan, A.; Shen, L.; Mueller, E.; Boerner, F. Study of the Integration of Robot in Cyber-Physical Production Systems. In Proceedings of the 2019 International Conference on Cyber-Enabled Distributed Computing and Knowledge Discovery (CyberC), Guilin, China, 17–19 October 2019; pp. 367–370. [Google Scholar]

- Lee, Y.K.; Goh, Y.H.; Tew, Y. Cyber Physical Autonomous Mobile Robot (CPAMR) Framework in the Context of Industry 4.0. MATEC Web Conf. 2018, 167, 02005. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Z.; Xu, W.; Tang, Q.; Zhou, Z.; Pham, D.T. Human-robot collaboration in disassembly for sustainable manufacturing. Int. J. Prod. Res. 2019, 57, 4027–4044. [Google Scholar] [CrossRef]

- Mrudul, K.; Mandava, R.K.; Vundavilli, P.R. An Efficient Path Planning Algorithm for Biped Robot using Fast Marching Method. Procedia Comput. Sci. 2018, 133, 116–123. [Google Scholar] [CrossRef]

- Saraswathi, M.; Murali, G.B.; Deepak, B. Optimal Path Planning of Mobile Robot Using Hybrid Cuckoo Search-Bat Algorithm. Procedia Comput. Sci. 2018, 133, 510–517. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Imran, M.; Li, D.; Zhang, C. Cloud-based smart manufacturing for personalized candy packing application. J. Supercomput. 2018, 74, 4339–4357. [Google Scholar] [CrossRef]

- Chen, F.; Selvaggio, M.; Caldwell, D.G. Dexterous Grasping by Manipulability Selection for Mobile Manipulator With Visual Guidance. IEEE Trans. Ind. Inform. 2019, 15, 1202–1210. [Google Scholar] [CrossRef]

- Yao, B.; Zhou, Z.; Wang, L.; Xu, W.; Liu, Q.; Liu, A. Sensorless and adaptive admittance control of industrial robot in physical human- robot interaction. Robot. Comput. Integr. Manuf. 2018, 51, 158–168. [Google Scholar] [CrossRef]

- Grau, A.; Indri, M.; Bello, L.L.; Sauter, T. Industrial robotics in factory automation: From the early stage to the Internet of Things. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; pp. 6159–6164. [Google Scholar]

- Romero-Hdz, J.; Saha, B.; Toledo-Ramirez, G.; Beltran-Bqz, D. Welding sequence optimization using artificial intelligence techniques: An overview. SSRG Int. J. Comput. Sci. Eng. 2016, 3, 90–95. [Google Scholar] [CrossRef] [Green Version]

- Madhira, K.; Mehta, S.; Bollineni, R.; Kavathia, D. AGWallP—Automatic guided wall painting system. In Proceedings of the 2017 Nirma University International Conference on Engineering (NUiCONE), Ahmedabad, India, 23–25 November 2017; pp. 1–5. [Google Scholar]

- Kalpana, M.A.T.M.; Tyagi, M.A. Bellman ford shortest path algorithm using global positioning system. Int. Res. J. Eng. Technol. 2017, 4, 12. [Google Scholar]

- Qing, G.; Zheng, Z.; Yue, X. Path-planning of automated guided vehicle based on improved Dijkstra algorithm. In Proceedings of the 2017 29th Chinese control and decision conference (CCDC), Chongqing, China, 28–30 May 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 7138–7143. [Google Scholar]

- Chen, X.; Qin, S. Approach to high efficient hierarchical pathfinding of indoor mobile service robots based on grid map and Floyd-Warshall algorithm. In Proceedings of the 2017 Chinese Automation Congress (CAC), Jinan, China, 20–22 October 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 6476–6483. [Google Scholar]

- Xin, L.; Xiangyuan, H.; Ziqi, Y.; Xiaoning, Q.; Yingkui, D. The Algebraic Algorithm for Path Planning Problem of AGV in Flexible Manufacturing System. In Proceedings of the 2018 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 2396–2399. [Google Scholar]

- Huang, C.; Zhang, L.; Liu, T.; Zhang, H.Y. A control middleware for cloud robotics. In Proceedings of the 2016 IEEE International Conference on Information and Automation (ICIA), Ningbo, China, 1–3 August 2016; pp. 1907–1912. [Google Scholar]

- Yan, H.; Hua, Q.; Wang, Y.; Wei, W.; Imran, M. Cloud robotics in Smart Manufacturing Environments: Challenges and countermeasures. Comput. Electr. Eng. 2017, 63, 56–65. [Google Scholar] [CrossRef]

- Marvel, J.A.; Bostelman, R.; Falco, J. Multi-Robot Assembly Strategies and Metrics. ACM Comput. Surv. 2018, 51, 14. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, X.V.; Wang, L.; Mohammed, A.; Givehchi, M. Ubiquitous manufacturing system based on Cloud: A robotics application. Robot. Comput. Integr. Manuf. 2017, 45, 116–125. [Google Scholar] [CrossRef]

- Wan, J.; Tang, S.; Yan, H.; Li, D.; Wang, S.; Vasilakos, A. Cloud robotics: Current status and open issues. IEEE Access 2016, 4, 2797–2807. [Google Scholar] [CrossRef]

- Zimmerman, M.; Marvel, J.A. Smart Manufacturing and The Promotion of Artificially-Intelligent Human-Robot Collaborations in Small-and Medium-sized Enterprises. In Proceedings of the Association for the Advancement of Artificial Intelligence, Arlington, MA, USA, 9–11 November 2017. [Google Scholar]

- Halme, R.J.; Lanz, M.; Kämäräinen, J.; Pieters, R.; Latokartano, J.; Hietanen, A. Review of vision-based safety systems for human-robot collaboration. Procedia CIRP 2018, 72, 111–116. [Google Scholar] [CrossRef]

- Garciaa, M.A.R.; Rojasa, R.; Gualtieria, L.; Raucha, E.; Matta, D. A human-in-the-loop cyber-physical system for collaborative assembly in smart manufacturing. Procedia CIRP 2019, 81, 600–605. [Google Scholar] [CrossRef]

- Duckett, T.; Pearson, S.; Blackmore, S.; Grieve, B.; Wilson, P.; Gill, H.; Hunter, A.J.; Georgilas, I. Agricultural Robotics: The Future of Robotic Agriculture. arXiv 2018, arXiv:1806.06762. [Google Scholar]

- Wolfert, S.; Ge, L.; Verdouw, C.; Bogaardt, M.J. Big Data in Smart Farming—A review. Agric. Syst. 2017, 153, 69–80. [Google Scholar] [CrossRef]

- Saravanan, D.; Archana, G.; Parthiban, R. Voice controlled Humanoid Robotic car for smart agriculture using Arduino and Android Smart Watch. Int. J. Pure Appl. Math. 2018, 119, 829–833. [Google Scholar]

- Prasad, D.; Singla, K.; Baggan, V. System Model for Smart Precision Farming for High Crop Yielding. J. Comput. Theor. Nanosci. 2019, 16, 4406–4411. [Google Scholar] [CrossRef]

- Li, X.; Ma, Z.; Chu, X.; Liu, Y. A Cloud-Assisted Region Monitoring Strategy of Mobile Robot in Smart Greenhouse. Mob. Inf. Syst. 2019, 2019, 5846232. [Google Scholar] [CrossRef]

- Xu, X.; Li, X.; Zhang, R. Remote Configurable Image Acquisition Lifting Robot for Smart Agriculture. In Proceedings of the 2019 IEEE 4th Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chengdu, China, 20–22 December 2019; Volume 1, pp. 1545–1548. [Google Scholar]

- Zaman, S.; Comba, L.; Biglia, A.; Aimonino, D.R.; Barge, P.; Gay, P. Cost-effective visual odometry system for vehicle motion control in agricultural environments. Comput. Electron. Agric. 2019, 162, 82–94. [Google Scholar] [CrossRef]

- Ju, C.; Son, H.I. Modeling and Control of Heterogeneous Agricultural Field Robots Based on Ramadge–Wonham Theory. IEEE Robot. Autom. Lett. 2020, 5, 48–55. [Google Scholar] [CrossRef]

- Mahbub, M. A smart farming concept based on smart embedded electronics, internet of things and wireless sensor network. Internet Things 2020, 9, 100161. [Google Scholar] [CrossRef]

- Romeo, L.; Petitti, A.; Colella, R.; Valecce, G.; Boccadoro, P.; Milella, A.; Grieco, L.A. Automated Deployment of IoT Networks in Outdoor Scenarios using an Unmanned Ground Vehicle. In Proceedings of the 21st IEEE 2020 International Conference on Industrial Technology (ICIT2020), Buenos Aires, Argentina, 26–28 February 2020. [Google Scholar]

- Dharmasena, T.; de Silva, R.; Abhayasingha, N.; Abeygunawardhana, P. Autonomous Cloud Robotic System for Smart Agriculture. In Proceedings of the 2019 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 3–5 July 2019; pp. 388–393. [Google Scholar]

- Faryadi, S.; Davoodi, M.; Mohammadpour Velni, J. Agricultural Field Coverage Using Cooperating Unmanned Ground Vehicles. In Proceedings of the Dynamic Systems and Control Conference, American Society of Mechanical Engineers, Park City, UT, USA, 8–11 October 2019; Volume 59155, p. V002T25A003. [Google Scholar]

- Blaser, W.J.; Oppong, J.; Hart, S.P.; Landolt, J.; Yeboah, E.; Six, J. Climate-smart sustainable agriculture in low-to-intermediate shade agroforests. Nat. Sustain. 2018, 1, 234–239. [Google Scholar] [CrossRef]

- Campbell, B.M.; Thornton, P.; Zougmoré, R.; Van Asten, P.; Lipper, L. Sustainable intensification: What is its role in climate smart agriculture? Curr. Opin. Environ. Sustain. 2014, 8, 39–43. [Google Scholar] [CrossRef] [Green Version]

- Khatri-Chhetri, A.; Aggarwal, P.K.; Joshi, P.K.; Vyas, S. Farmers’ prioritization of climate-smart agriculture (CSA) technologies. Agric. Syst. 2017, 151, 184–191. [Google Scholar] [CrossRef]

- Mat, I.; Kassim, M.R.M.; Harun, A.N.; Yusoff, I.M. Smart Agriculture Using Internet of Things. In Proceedings of the 2018 IEEE Conference on Open Systems (ICOS), Langkawi, Malaysia, 21–22 November 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 54–59. [Google Scholar]

- McConnell, M.D.; Burger, L.W., Jr. Precision conservation to enhance wildlife benefits in agricultural landscapes. Precis. Conserv. Geospat. Tech. Agric. Nat. Resour. Conserv. 2017, 59, 285–312. [Google Scholar]

- García-Tejero, I.F.; Carbonell, R.; Ordoñez, R.; Torres, F.P.; Zuazo, V.H.D. Conservation Agriculture Practices to Improve the Soil Water Management and Soil Carbon Storage in Mediterranean Rainfed Agro-Ecosystems. In Soil Health Restoration and Management; Springer: Berlin/Heidelberg, Germany, 2020; pp. 203–230. [Google Scholar]

- Tyagi, N.K.; Joshi, P.K. Index-Based Insurance for Mitigating Flood Risks in Agriculture: Status, Challenges and Way Forward. In Climate Smart Agriculture in South Asia: Technologies, Policies and Institutions; Pal, B.D., Kishore, A., Joshi, P.K., Tyagi, N.K., Eds.; Springer: Singapore, 2019; pp. 183–204. [Google Scholar]

- Uddin, M.A.; Mansour, A.; Le Jeune, D.; Aggoune, E.H.M. Agriculture internet of things: AG-IoT. In Proceedings of the 2017 27th International Telecommunication Networks and Applications Conference (ITNAC), Melbourne, Australia, 22–24 November 2017; pp. 1–6. [Google Scholar]

- Serebrenny, V.; Shereuzhev, M.; Metasov, I. Approaches to the robotization of agricultural mobile machines. MATEC Web Conf. EDP Sci. 2018, 161, 3–14. [Google Scholar] [CrossRef] [Green Version]

- Mekala, M.S.; Viswanathan, P. A Survey: Smart agriculture IoT with cloud computing. In Proceedings of the 2017 International Conference on Microelectronic Devices, Circuits and Systems (ICMDCS), Vellore, India, 10–12 August 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–7. [Google Scholar]

- Reina, G.; Milella, A.; Rouveure, R.; Nielsen, M.; Worst, R.; Blas, M.R. Ambient awareness for agricultural robotic vehicles. Biosyst. Eng. 2016, 146, 114–132. [Google Scholar] [CrossRef]

- Milella, A.; Marani, R.; Petitti, A.; Reina, G. In-field high throughput grapevine phenotyping with a consumer-grade depth camera. Comput. Electron. Agric. 2019, 156, 293–306. [Google Scholar] [CrossRef]

- Petkovics, I.; Simon, J.; Petkovics, A.; Covic, Z. Selection of unmanned aerial vehicle for precision agriculture with multi-criteria decision making algorithm. In Proceedings of the 2017 IEEE 15th International Symposium on Intelligent Systems and Informatics (SISY), Subotica, Serbia, 14–16 September 2017. [Google Scholar]

- Valecce, G.; Micoli, G.; Boccadoro, P.; Petitti, A.; Colella, R.; Milella, A.; Alfredo Grieco, L. Robotic-aided IoT: Automated deployment of a 6TiSCH network using an UGV. IET Wirel. Sens. Syst. 2019, 9, 438–446. [Google Scholar] [CrossRef]

- Jawad, H.M.; Nordin, R.; Gharghan, S.K.; Jawad, A.M.; Ismail, M. Energy-Efficient Wireless Sensor Networks for Precision Agriculture: A Review. Sensors 2017, 17, 1781. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Basnet, B.; Bang, J. The State-of-the-Art of Knowledge-Intensive Agriculture: A Review on Applied Sensing Systems and Data Analytics. J. Sens. 2018, 2018, 1–13. [Google Scholar]

- Scilimati, V.; Petitti, A.; Boccadoro, P.; Colella, R.; Di Paola, D.; Milella, A.; Alfredo Grieco, L. Industrial Internet of things at work: A case study analysis in robotic-aided environmental monitoring. IET Wirel. Sens. Syst. 2017, 7, 155–162. [Google Scholar] [CrossRef] [Green Version]

- Adamo, F.; Attivissimo, F.; Di Nisio, A.; Carducci, C.G.C.; Spadavecchia, M.; Guagnano, A.; Goh, M. Comparison of current sensors for power consumption assessment of wireless sensors network nodes. In Proceedings of the 2017 IEEE International Workshop on Measurement and Networking (M&N), Naples, Italy, 27–29 September 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–4. [Google Scholar]

- Micoli, G.; Boccadoro, P.; Valecce, G.; Petitti, A.; Colella, R.; Milella, A.; Grieco, L.A. ASAP: A Decentralized Slot Reservation Policy for Dynamic 6TiSCH Networks in Industrial IoT. In Proceedings of the 2019 IEEE International Conference on Communications Workshops (ICC Workshops), Shanghai, China, 20–24 May 2019; pp. 1–6. [Google Scholar]

- Krishna, K.L.; Silver, O.; Malende, W.F.; Anuradha, K. Internet of Things application for implementation of smart agriculture system. In Proceedings of the 2017 International Conference on I-SMAC (IoT in Social, Mobile, Analytics and Cloud), Palladam, India, 10–11 February 2017; pp. 54–59. [Google Scholar]

- Roopaei, M.; Rad, P.; Choo, K.K.R. Cloud of things in smart agriculture: Intelligent irrigation monitoring by thermal imaging. IEEE Cloud Comput. 2017, 4, 10–15. [Google Scholar] [CrossRef]

- Cao, H.; Huang, X.; Zhuang, J.; Xu, J.; Shao, Z. CIoT-Robot Cloud and IoT Assisted Indoor Robot for Medicine Delivery. In Proceedings of the 2018 Joint International Advanced Engineering and Technology Research Conference (JIAET 2018), Xi’an, China, 26–27 May 2018; Atlantis Press: Paris, France, 2018. [Google Scholar]

- Grigorescu, S.D.; Argatu, F.C.; Paturca, S.V.; Cepisca, C.; Seritan, G.C.; Adochiei, F.C.; Enache, B. Robotic Platform with Medical Applications in the Smart City Environment. In Proceedings of the 2019 11th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 28–30 March 2019; pp. 1–6. [Google Scholar]

- Amin, R.; Islam, S.H.; Biswas, G.; Khan, M.K.; Kumar, N. A robust and anonymous patient monitoring system using wireless medical sensor networks. Future Gener. Comput. Syst. 2018, 80, 483–495. [Google Scholar] [CrossRef]

- Zhou, H.; Lv, H.; Pang, Z.; Huang, X.; Yang, H.; Yang, G. IoT-enabled Dual-arm Motion Capture and Mapping for Telerobotics in Home Care. IEEE J. Biomed. Health Inform. 2019, 24, 1541–1549. [Google Scholar] [CrossRef]

- Chen, M.; Zhou, J.; Tao, G.; Yang, J.; Hu, L. Wearable Affective Robot. IEEE Access 2018, 6, 64766–64776. [Google Scholar] [CrossRef]

- Nayyar, A.; Puri, V.; Nguyen, N.G.; Le, D.N. Smart Surveillance Robot for Real-Time Monitoring and Control System in Environment and Industrial Applications. In Information Systems Design and Intelligent Applications; Bhateja, V., Nguyen, B.L., Nguyen, N.G., Satapathy, S.C., Le, D.N., Eds.; Springer: Singapore, 2018; pp. 229–243. [Google Scholar]

- Saad, W.H.M.; Karim, S.A.A.; Azhar, N.; Manap, Z.; Soon, Y.Y.; Ibrahim, M.M. Line Follower Mobile Robot for Surveillance Camera Monitoring System. J. Telecommun. Electron. Comput. Eng. (JTEC) 2018, 10, 1–5. [Google Scholar]

- Singh, R.; Samkaria, R.; Gehlot, A.; Choudhary, S. Design and Development of IoT enabled Multi Robot System for Search and Rescue Mission. IJWA 2018, 10, 51–63. [Google Scholar] [CrossRef]

- RajKumar, K.; Kumar, C.S.; Yuvashree, C.; Murugan, M.S. Portable surveillance robot using IoT. Int. Res. J. Eng. Technol. (IRJET) 2019, 6, 94–97. [Google Scholar]

- Ashokkumar, M.; Thirumurugan, T. Integrated IOT based design and Android operated Multi-purpose Field Surveillance Robot for Military Use. In Proceedings of the International Conference for Phoenixes on Emerging Current Trends in Engineering and Management (PECTEAM 2018), Tamilnadu, India, 9–10 February 2018; Atlantis Press: Paris, France, 2018. [Google Scholar]

- Chukwuemeka, C.; Habib, M. Development of Autonomous Networked Robots (ANR) for Surveillance: Conceptual Design and Requirements. In Proceedings of the IECON 2018—44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 3757–3763. [Google Scholar]

- Bonaci, T.; Herron, J.; Yusuf, T.; Yan, J.; Kohno, T.; Chizeck, H.J. To Make a Robot Secure: An Experimental Analysis of Cyber Security Threats Against Teleoperated Surgical Robots. arXiv 2015, arXiv:1504.04339. [Google Scholar]

- Fenning, R.M.; Baker, J.K.; Baucom, B.R.; Erath, S.A.; Howland, M.A.; Moffitt, J. Electrodermal Variability and Symptom Severity in Children with Autism Spectrum Disorder. J. Autism Dev. Disord. 2017, 47, 1062–1072. [Google Scholar] [CrossRef] [PubMed]

- Saponara, S.; Pilato, L.; Fanucci, L. Exploiting CCTV camera system for advanced passenger services on-board trains. In Proceedings of the 2016 IEEE International Smart Cities Conference (ISC2), Trento, Italy, 12–15 September 2016; pp. 1–6. [Google Scholar]

- Khakimov, A.; Muthanna, A.; Kirichek, R.; Koucheryavy, A.; Muthanna, M.S.A. Investigation of methods for remote control IoT-devices based on cloud platforms and different interaction protocols. In Proceedings of the 2017 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), St. Petersburg, Russia, 1–3 February 2017; pp. 160–163. [Google Scholar]

- Raju, H.S.; Shenoy, S. Real-time remote monitoring and operation of industrial devices using IoT and cloud. In Proceedings of the 2016 2nd International Conference on Contemporary Computing and Informatics (IC3I), Noida, India, 14–17 December 2016; pp. 324–329. [Google Scholar]

- Meghana, S.; Nikhil, T.V.; Murali, R.; Sanjana, S.; Vidhya, R.; Mohammed, K.J. Design and implementation of surveillance robot for outdoor security. In Proceedings of the 2017 2nd IEEE International Conference on Recent Trends in Electronics, Information Communication Technology (RTEICT), Bangalore, India, 19–20 May 2017; pp. 1679–1682. [Google Scholar]

- Shah, M.S.; Borole, P.B. Surveillance and rescue robot using Android smartphone and the Internet. In Proceedings of the 2016 International Conference on Communication and Signal Processing (ICCSP), Melmaruvathur, India, 6–8 April 2016; pp. 1526–1530. [Google Scholar]

- Wanjari, V.; Kamargaonkar, C. A Review Paper on IoT based Cognitive Robot for Military Surveillance. Int. Res. J. Eng. Technol. (IRJET) 2019, 6, 2276–2278. [Google Scholar]

- Fierro, R.; Chaimowicz, L.; Kumar, V. Multi-robot cooperation. In Autonomous Mobile Robots; CRC Press: Boca Raton, FL, USA, 2018; pp. 417–460. [Google Scholar]

- Talebpour, Z.; Martinoli, A. Multi-Robot Coordination in Dynamic Environments Shared with Humans. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018; pp. 4593–4600. [Google Scholar]

- Cicirelli, G.; Attolico, C.; Guaragnella, C.; D’Orazio, T. A Kinect-Based Gesture Recognition Approach for a Natural Human Robot Interface. Int. J. Adv. Robot. Syst. 2015, 12, 22. [Google Scholar] [CrossRef]

- Palinko, O.; Rea, F.; Sandini, G.; Sciutti, A. Robot reading human gaze: Why eye tracking is better than head tracking for human-robot collaboration. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016; pp. 5048–5054. [Google Scholar]

- Patel, R. Human Robot Interaction with Cloud Assisted Voice Control and Vision System. Ph.D. Thesis, University of Texas at Austin, Austin, TX, USA, 2018. [Google Scholar]

- Islam, M.J.; Sattar, J. Mixed-domain biological motion tracking for underwater human-robot interaction. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 4457–4464. [Google Scholar]

- He, W.; Li, Z.; Chen, C.L.P. A survey of human-centered intelligent robots: Issues and challenges. IEEE/CAA J. Autom. Sin. 2017, 4, 602–609. [Google Scholar] [CrossRef]

- Liu, H.; Wang, L. Remote human–robot collaboration: A cyber–physical system application for hazard manufacturing environment. J. Manuf. Syst. 2020, 54, 24–34. [Google Scholar] [CrossRef]

- Hunter, P. Remote working in research: An increasing usage of flexible work arrangements can improve productivity and creativity. EMBO Rep. 2019, 20, e47435. [Google Scholar] [CrossRef]

- Stower, R. The Role of Trust and Social Behaviours in Children’s Learning from Social Robots. In Proceedings of the 2019 8th International Conference on Affective Computing and Intelligent Interaction Workshops and Demos (ACIIW), Cambridge, UK, 3–6 September 2019; pp. 1–5. [Google Scholar]

- Del Campo, G.; Calatrava, S.; Cañada, G.; Olloqui, J.; Martinez, R.; Santamaria, A. IoT Solution for Energy Optimization in Industry 4.0: Issues of a Real-life Implementation. In Proceedings of the 2018 Global Internet of Things Summit (GIoTS), Bilbao, Spain, 4–7 June 2018; pp. 1–6. [Google Scholar]

- Bukata, L.; Sucha, P.; Hanzálek, Z.; Burget, P. Energy Optimization of Robotic Cells. IEEE Trans. Ind. Inform. 2016, 13, 92–102. [Google Scholar] [CrossRef]

- Dragoni, N.; Giaretta, A.; Mazzara, M. The Internet of Hackable Things. In Proceedings of the 5th International Conference in Software Engineering for Defence Applications, Rome, Italy, 10 May 2016; Springer International Publishing: Cham, Switzerland, 2018; pp. 129–140. [Google Scholar]

- Khalid, A.; Kirisci, P.; Khan, Z.H.; Ghrairi, Z.; Thoben, K.D.; Pannek, J. Security framework for industrial collaborative robotic cyber-physical systems. Comput. Ind. 2018, 97, 132–145. [Google Scholar] [CrossRef] [Green Version]

- Wegner, A.; Graham, J.; Ribble, E. A New Approach to Cyberphysical Security in Industry 4.0. In Cybersecurity for Industry 4.0: Analysis for Design and Manufacturing; Thames, L., Schaefer, D., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 59–72. [Google Scholar]

| Outline of the Works | Robot Navigation & Path Planning | Data Gathering | Image Processing | Cloud Computing | Multi-Robots | HRI | |

|---|---|---|---|---|---|---|---|

| [50] | Implementation of a vision system on a robot manipulator (ScorBot-ER 9 Pro) to widen the proficiency of the integrated camera-robot system in industrial applications. | ✔ | ✔ | ||||

| [51] | Automatic path planning of a six-axis robot manipulator for intelligent manufacturing, using a cloud platform that monitors the system through TCP/IP protocol for networked remote controlling and simulation. | ✔ | ✔ | ✔ | |||

| [52] | Integration of robots in CPPS to manage different weight goods, combining UGVs with robot manipulator and air-move systems to built smart factory and smart manufacturing. | ✔ | ✔ | ||||

| [53] | Cyber physical autonomous mobile robot capable of performing HRI by allowing users to manage orders using a cloud platform. The robot moves following the planned route map, according to the obstacle avoidance system, until it reaches the destination and notifies the cloud platform. | ✔ | ✔ | ✔ | |||

| [54] | Systematic development framework called PCDEE-Circle, used for human–robot collaborative disassembly (HRCD) in sustainable manufacturing. A multi-modal perception platform for industrial robots system and human body is defined, by means of a bees algorithm based sequence planning method for an HRCD task. | ✔ | ✔ | ✔ | |||

| [55] | Path planning algorithm, using fast marching method (FMM) for a biped robot to move in a static environment, aiming to let it move in both known and unknown scenarios. | ✔ | ✔ | ||||

| [56] | Mobile robot path planning, combining Cuckoo Search and Bat algorithms to attain the optimal path. | ✔ | ✔ | ||||

| [57] | Prototype of a system for packing assorted candy, developing a framework to connect consumers, smart factories, and other systems through cloud and logistical networks. | ✔ | ✔ | ||||

| [58] | Error pattern transformation based on iterative closest point algorithm for object pose estimation of a robot manipulator, using point cloud data gathered from multiple stereo vision systems. | ✔ | ✔ | ✔ | |||

| [59] | Sensorless external force detection produced by human operators in physical HRI, aiming to obtain a dynamic model of an industrial robot manipulator in both dynamic and quasi-static mode. | ✔ | ✔ |

| Outline of the Works | Robot Navigation & Path Planning | Data gathering | Image Processing | Cloud Computing | Multi-Robots | HRI | |

|---|---|---|---|---|---|---|---|

| [78] | Several UAVs are used to collect data by monitoring and mapping the field to vary rate fertilizer, spraying, etc, to reduce crop diseases. | ✔ | ✔ | ✔ | ✔ | ||

| [77] | Mobile robot equipped with several sensors useful in agriculture (moisture sensor, temperature sensor, contamination sensor, damage of harvest sensor), and controlled by voice recognition, using a smart watch connected to the network. | ✔ | ✔ | ✔ | |||

| [79] | Region monitoring of plants in a smart greenhouse, using a cloud-assisted strategy of mobile robots to increase the monitoring region size and reduce time consumption. | ✔ | ✔ | ✔ | |||

| [80] | Remotely configurable crop image acquisition robot system, based on cloud computing and WSN, used to improve the flexibility and adaptation of the mobile robot. | ✔ | ✔ | ✔ | |||

| [81] | Real-time image processing algorithm, using a visual odometry system on a UGV, based on the cross-correlation approach. Low-resolution images are used to attain high accuracy in motion estimation with short computing time. | ✔ | ✔ | ✔ | |||

| [82] | Cooperation among heterogeneous agricultural field robots with a supervisory controller, using a novel approach based on discrete-event system (DES) and the Ramadge-Wonham (RW) theory, which is effective in controlling complex dynamic systems consisting of heterogeneous multi-robot for smart agriculture. | ✔ | ✔ | ✔ | |||

| [83] | Smart agri-system based on embedded electronics, IoT and WSN for agri-farm stock and livestock farms. | ✔ | ✔ | ✔ | |||

| [84] | UGV used for looking for the best suitable deploying position for a WSN system, aiming to analyze the field and gather information about the terrain condition. | ✔ | ✔ | ||||

| [85] | Automated system developed to control both climate and irrigation in a greenhouse by monitoring temperature, soil moisture, humidity and pH, using a cloud connected mobile robot. Such robot can also discover unhealthy plants using image processing. | ✔ | ✔ | ✔ | |||

| [86] | Deployment of a group of UGVs using a distributed algorithm, aiming to gather data from relevant areas of the field, selected using the Voronoi partitioning. | ✔ | ✔ | ✔ |

| Outline of the Works | Robot Navigation & Path Planning | Data Gathering | Image Processing | Cloud Computing | Multi-Robots | HRI | |

|---|---|---|---|---|---|---|---|

| [108] | Cloud and IoT Assisted Indoor Robot (CIoT) for delivery medicine, based on the multi-core embedded system, RFID and IEEE802.11 communication protocol, and cloud platforms. | ✔ | ✔ | ||||

| [112] | Architecture and design of a wearable affective robot equipped with cognitive computing, named Fitbot. Such robot can perform multi-modal data perception, aiming to recognize the emotions of the patient. | ✔ | ✔ | ✔ | |||

| [111] | Generalized IoT-enabled telerobotic architecture designed to support home-centric healthcare system, named Home-TeleBot, realized by integrating human-motion-capture subsystem with robot-control subsystem. The robot used is a dual-arm cooperative robot, named YuMi, which imitates human motion captured by a set of wearable inertial motion capture devices to complete task. | ✔ | ✔ | ✔ | |||

| [109] | Realization of a health assessment kiosk, by developing a robotic platform that ensures its functionality within the Smart City information and communication networks, and can provide specific functions by developing applications according to the needs of the patients. | ✔ | ✔ | ||||

| [113] | IoT-based robot system, named InterBot 1.0, equipped with both long-range and short-range communication systems. The robot is efficient in monitoring real-time environments for smart surveillance. | ✔ | ✔ | ||||

| [114] | Development of a mobile surveillance camera monitoring system, using a line follower to provide a mobile movement, aiming to overcome the limited coverage problem faced by conventional surveillance cameras. | ✔ | ✔ | ||||

| [115] | Multi-robot system based on swarm intelligence for surveillance and rescue missions, with real-time data uploading on cloud using IoT, exploiting wireless intercommunication between multiple agents, PID technique and ant colony optimization (ACO) algorithm, so that they can accomplish tasks synchronously. | ✔ | ✔ | ✔ | ✔ | ||

| [116] | Surveillance robot used for climbing both horizontal and vertical surfaces, while automatically controlling surface transitions, exploring space and transmitting live video through wireless channel to the remote workstation. | ✔ | ✔ | ||||

| [117] | Land mine detection and toxic gas sensing using a multi-purpose field surveillance robot. NodeMCU WiFi is used to interface the controller and do robot, which can climb on any terrains, gathering information. All robotic sensor data are sent to cloud servers. | ✔ | ✔ | ||||

| [118] | Autonomous Networked Robots (ANR) for surveillance, in which a WSN is implemented, where each sensor node comprises smoke, infrared fire, odor, and motion detector sensors, and RF transceivers for networking and communication. | ✔ | ✔ | ✔ |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romeo, L.; Petitti, A.; Marani, R.; Milella, A. Internet of Robotic Things in Smart Domains: Applications and Challenges. Sensors 2020, 20, 3355. https://doi.org/10.3390/s20123355

Romeo L, Petitti A, Marani R, Milella A. Internet of Robotic Things in Smart Domains: Applications and Challenges. Sensors. 2020; 20(12):3355. https://doi.org/10.3390/s20123355

Chicago/Turabian StyleRomeo, Laura, Antonio Petitti, Roberto Marani, and Annalisa Milella. 2020. "Internet of Robotic Things in Smart Domains: Applications and Challenges" Sensors 20, no. 12: 3355. https://doi.org/10.3390/s20123355

APA StyleRomeo, L., Petitti, A., Marani, R., & Milella, A. (2020). Internet of Robotic Things in Smart Domains: Applications and Challenges. Sensors, 20(12), 3355. https://doi.org/10.3390/s20123355