Fault Diagnosis in the Slip–Frequency Plane of Induction Machines Working in Time-Varying Conditions

Abstract

:1. Introduction

- Cyclic faults in the outer or inner races of bearings, which generate fault harmonics at frequencies that depend on the fault localization (inner or outer race), and on the bearing characteristics (number of balls, ball diameter, bearing pitch diameter, and the contact angle) [21,22], given byfor the outer and inner race, respectively, where is the number of bearing balls.

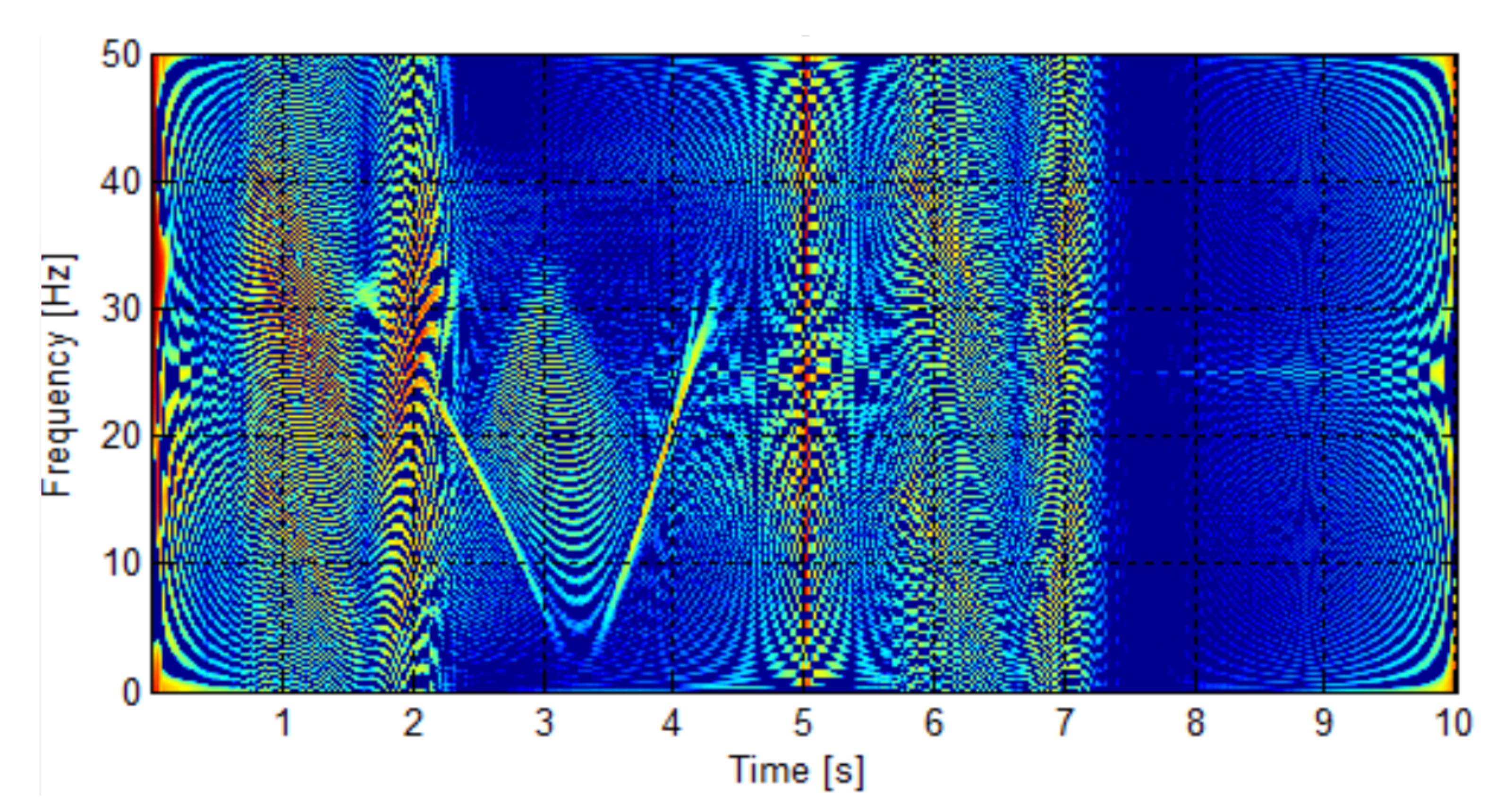

- The choice of the tool for calculating the IF of the fault harmonics in variable speed conditions. It is needed to replace the FFT, used in steady state regime, with specialized transient regime techniques (time-frequency transforms, analytic signals, etc.), which are more complex and computationally intensive. Therefore, it is necessary to select a method with a good trade-off between computational burden and accuracy.

- The definition of suitable fault signatures in the time-frequency domain. It is needed to replace the analysis of fault harmonics amplitudes at fixed frequencies (steady state) with the analysis of their complex 2D trajectories in the time-frequency domain. Therefore, it is necessary to define time-frequency fault signatures with a good trade-off between complexity and sensitivity.

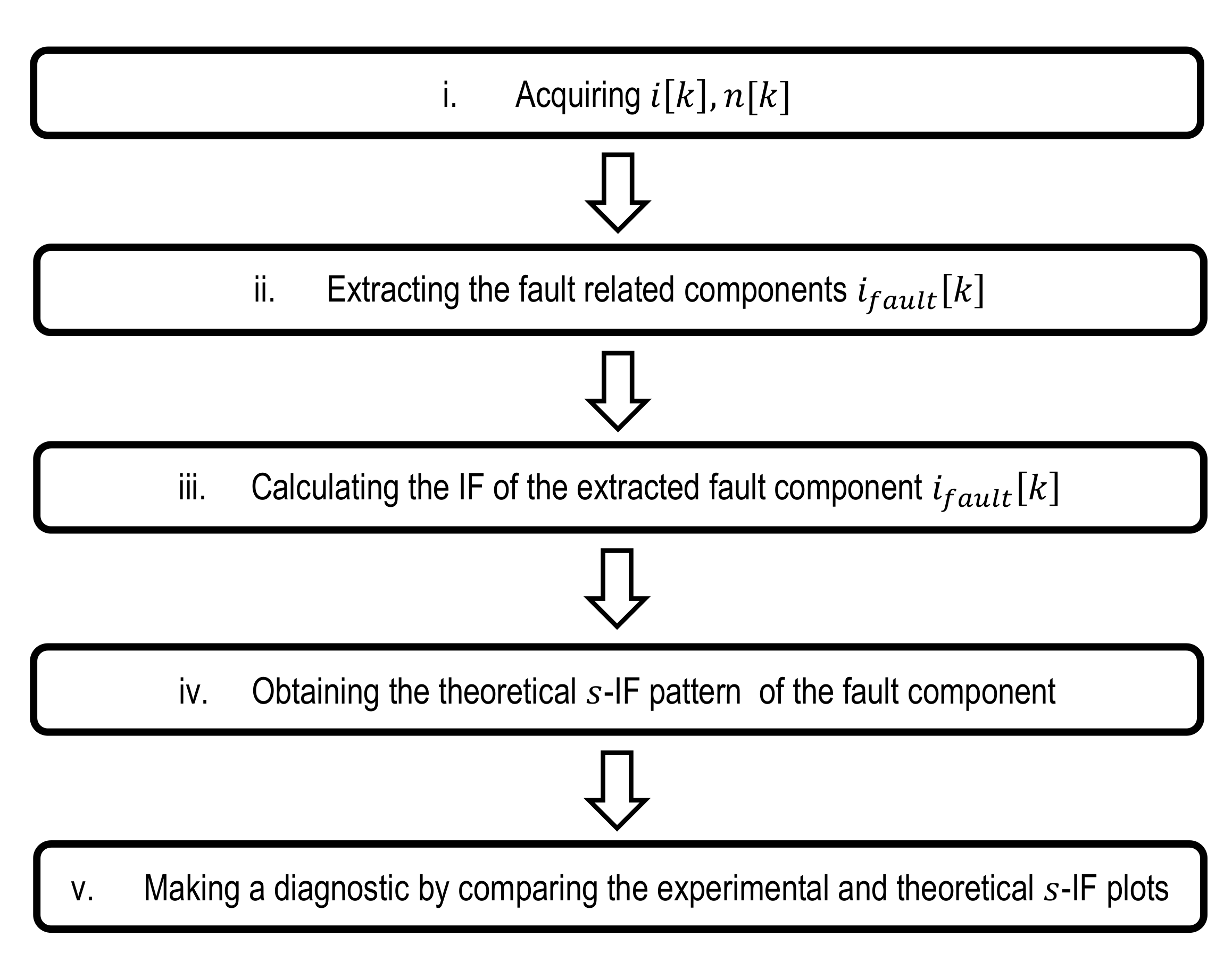

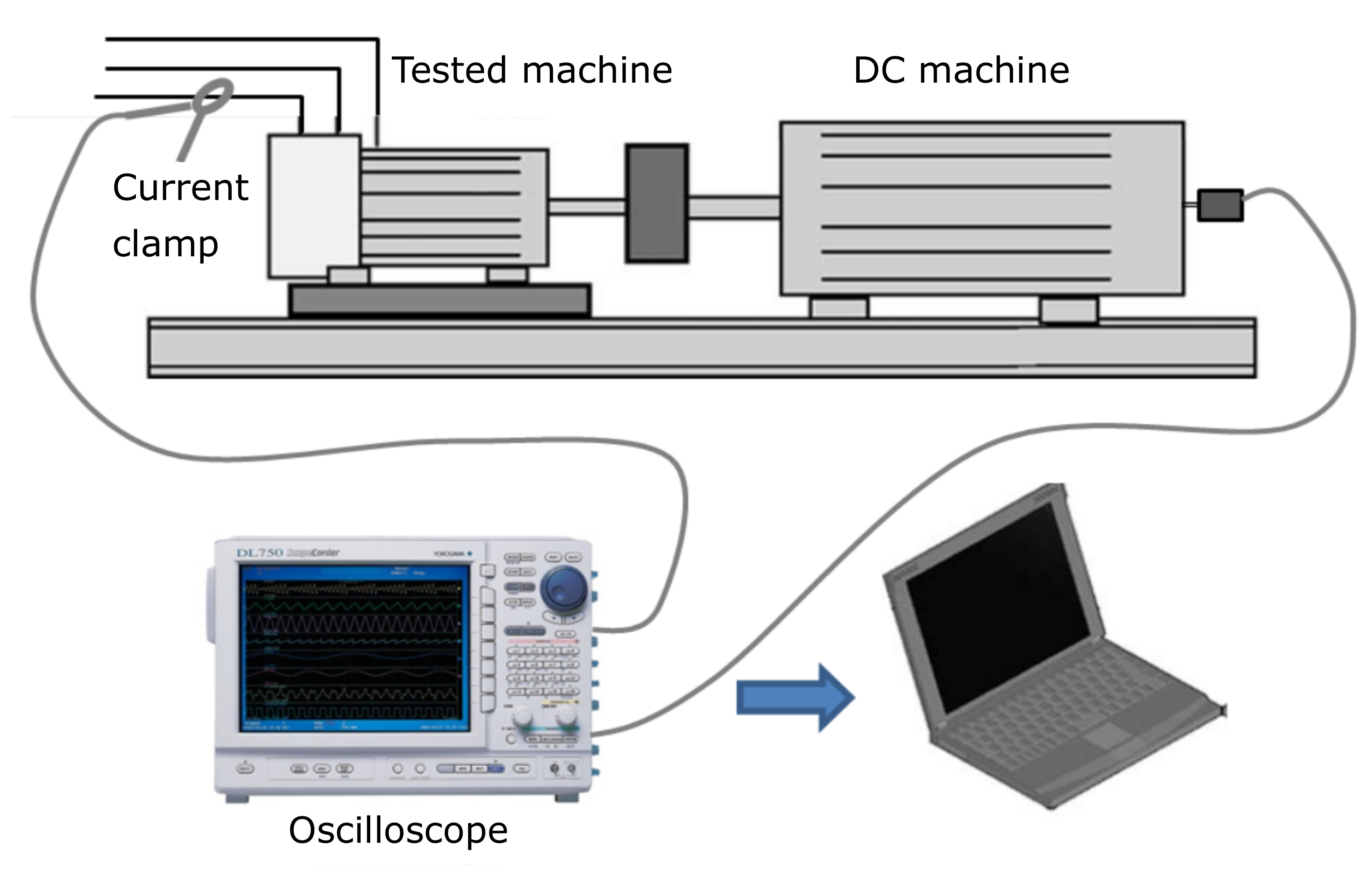

- Capturing one of the IM line currents and the rotor speed, sampling them with a suitable frequency .

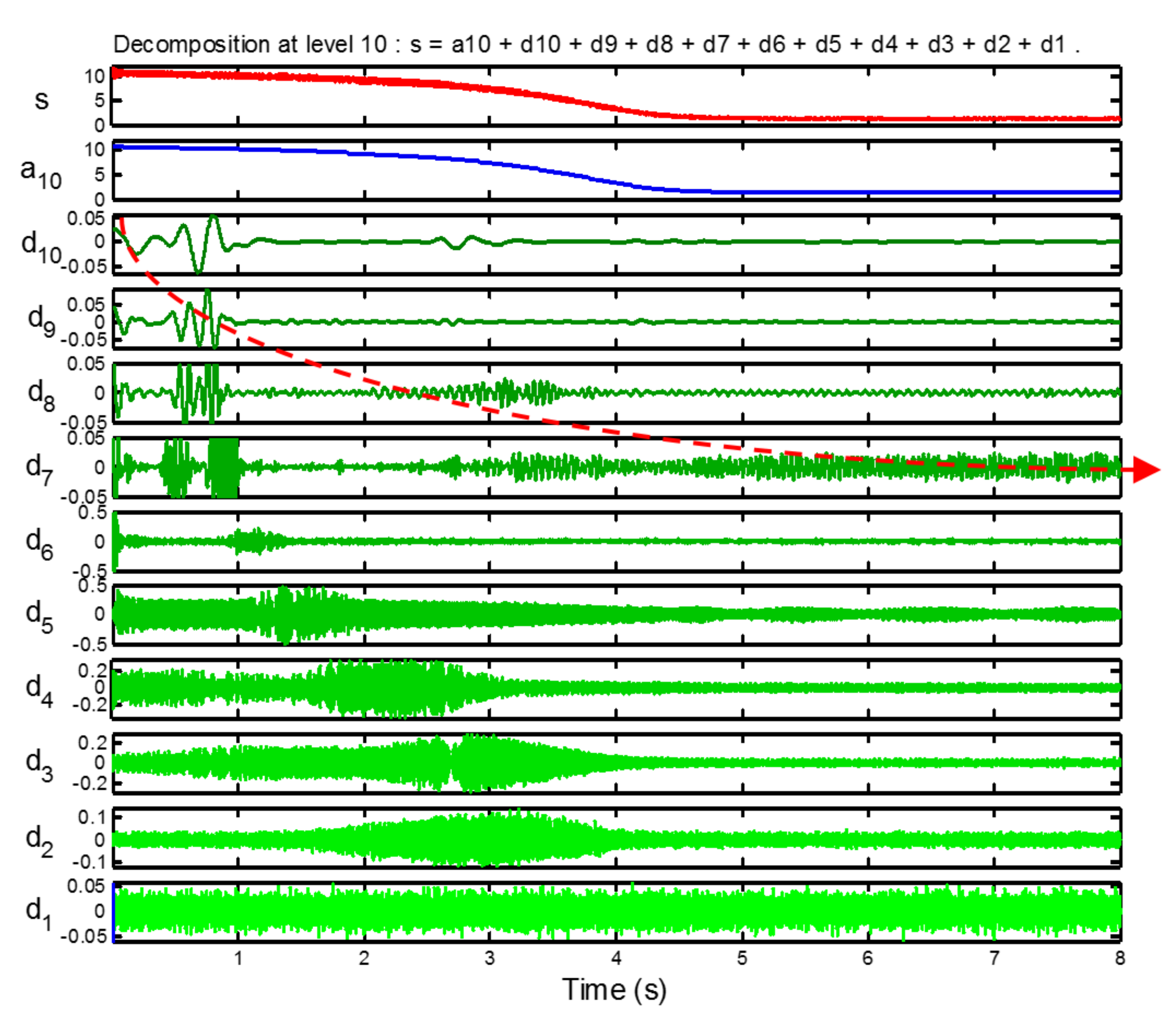

- Extracting the fault component related to the type of fault under study. The extraction of the fault component from the tested current is unavoidable, since the concept of IF is meaningless if one intent to apply it to complex multicomponent signals. The extraction process basically consists on filtering the tested current, keeping the part of the tested signal included in a frequency band that contains the range of frequencies that can be spanned by the fault component during the transient, and where it is predominant when the fault arises. There are different methods for the extraction of the fault components that basically consist on filtering techniques. In this work, the DWT is used for this purpose, since it enables in a simple an efficient way to take out frequency bands suitable for isolating the fault components.

- Calculating the IF of the subsignal extracted previously using a suitable mathematical tool.

- Obtaining the theoretical pattern s-IF corresponding to the fault component under study.

- Comparing the experimental s-IF plot with the corresponding theoretical pattern and formulating a diagnostic assessment. This comparison can be carried out in qualitative manner, but it is advisable to define a numerical parameter for fault severity assessment.

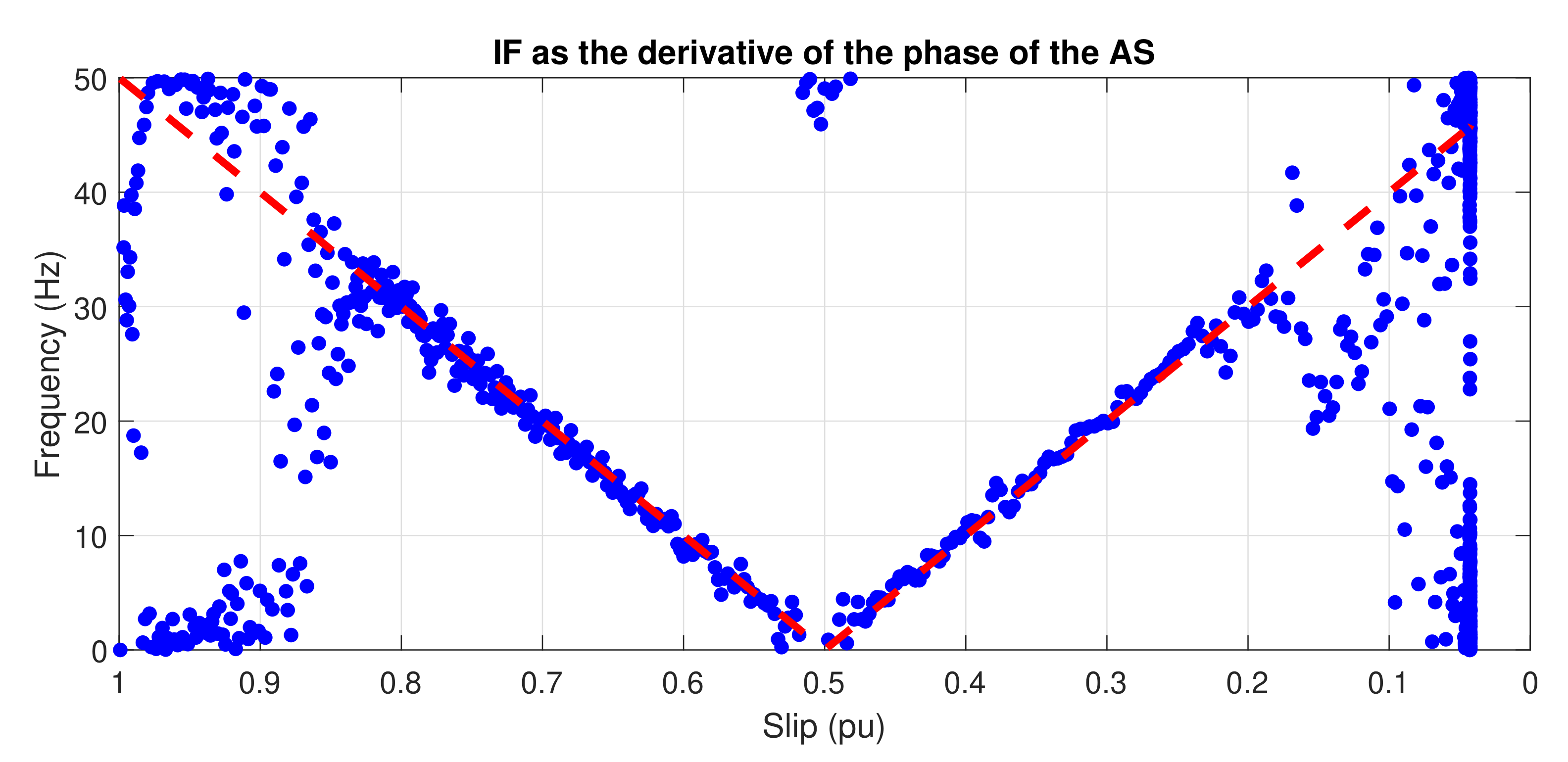

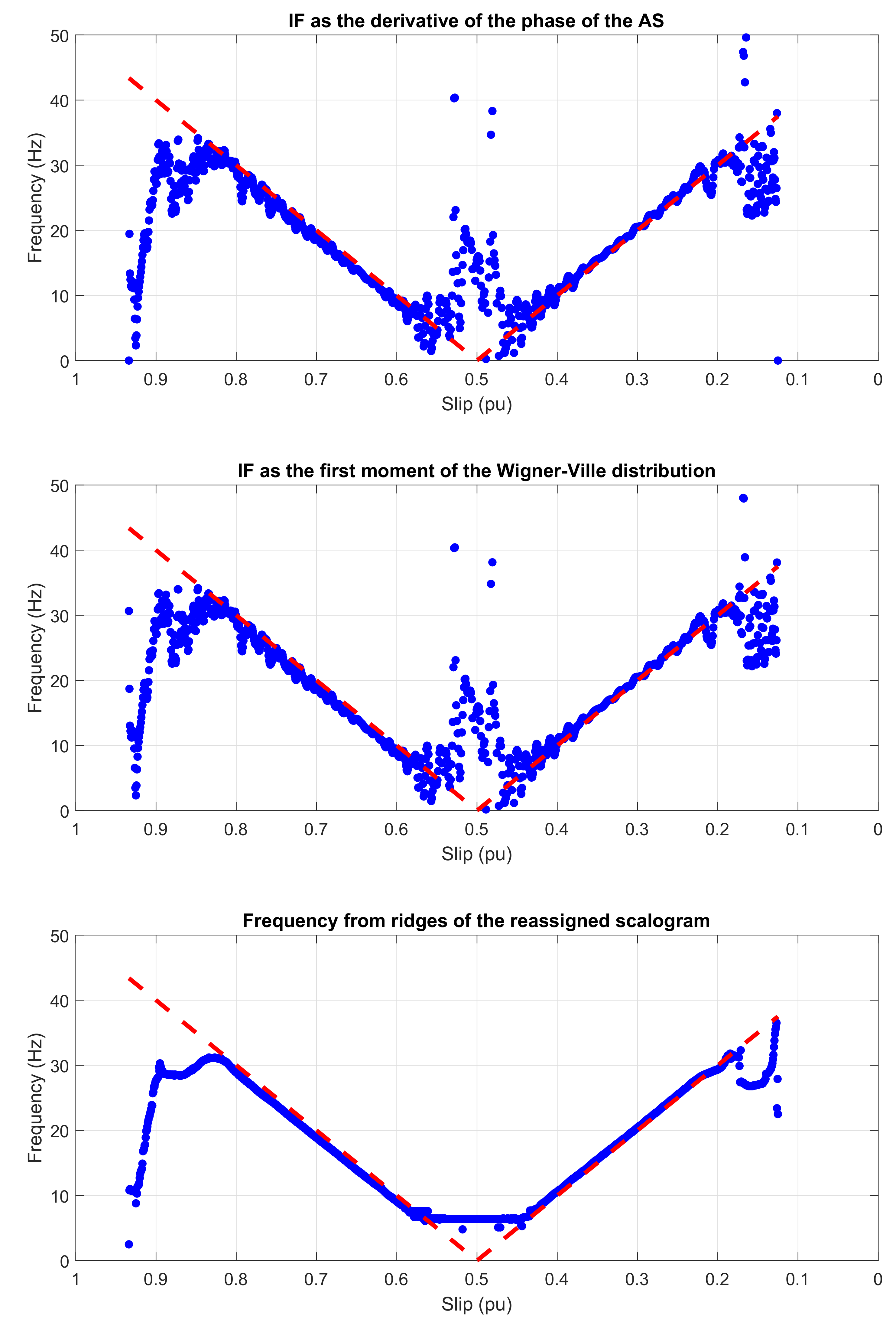

- Regarding step iii, as the proposed signatures are based on calculating the IF of the fault components along a transient functioning, a contribution of this paper is a thorough study comparing the main families of techniques for calculating the IF (linear time-frequency transform, quadratic time-frequency transform and the analytical function method). Three different techniques for extracting the IF are compared from a theoretical point of view, and also in a practical way, applying them to experimental tested currents of IM with different kinds of faults. This analysis allows conclusions to be drawn regarding the computational burden, the calculation time, and the precision of these techniques.

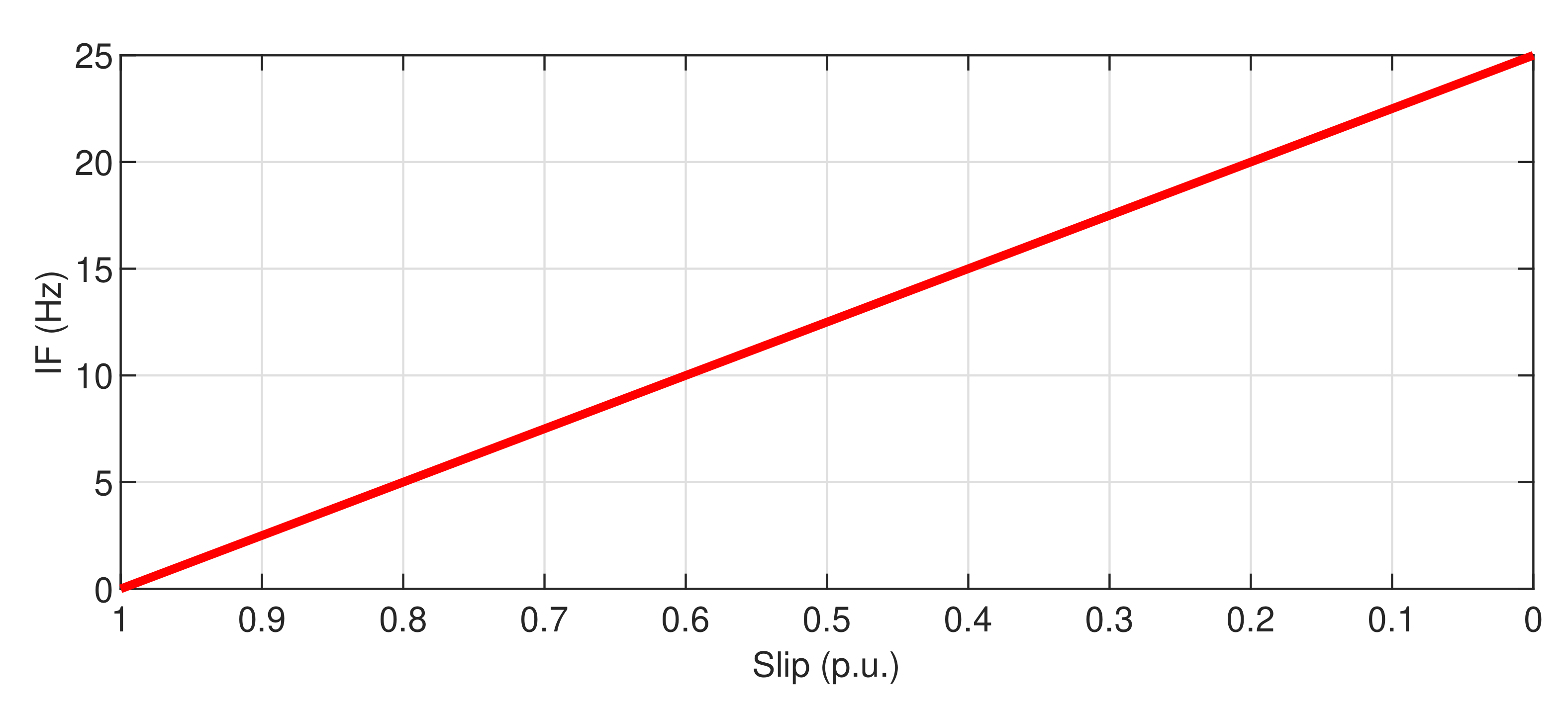

- Regarding step iv, the main contribution of this paper is to introduce new fault related signatures designed for transient functioning. Unlike the signatures currently used by diagnosis methods based on the above mentioned time-frequency approaches, the signatures here introduced are unique for every kind of fault. This means that they are the same for any induction machine, and do not depend on the way in which the load and speed vary. In fact, the fault signatures introduced in this paper are very simple, since they are straight lines, obtained by representing the IF of the fault harmonics given by Equations (1), (2), (3), and (4) not in the time-frequency domain, but in the slip–frequency domain; the slope of these straight lines is equal to the coefficient of the slip in Equations (1), (2), (3), and (4). This slope is different for each type of fault, and, therefore, Equations (1), (2), (3), and (4), understood as functions of slip, constitute suitable signatures not depending on IM or transient characteristics. The use of the proposed signatures significantly simplifies the diagnostic task, which can be carried out by non-specialized staff, and make easier the application of automatic diagnostic algorithms based on IA techniques. These signatures are theoretically justified and experimentally tested.

2. Presentation of the Methods for Obtaining the IF of the Fault Components in the Slip–Frequency Domain

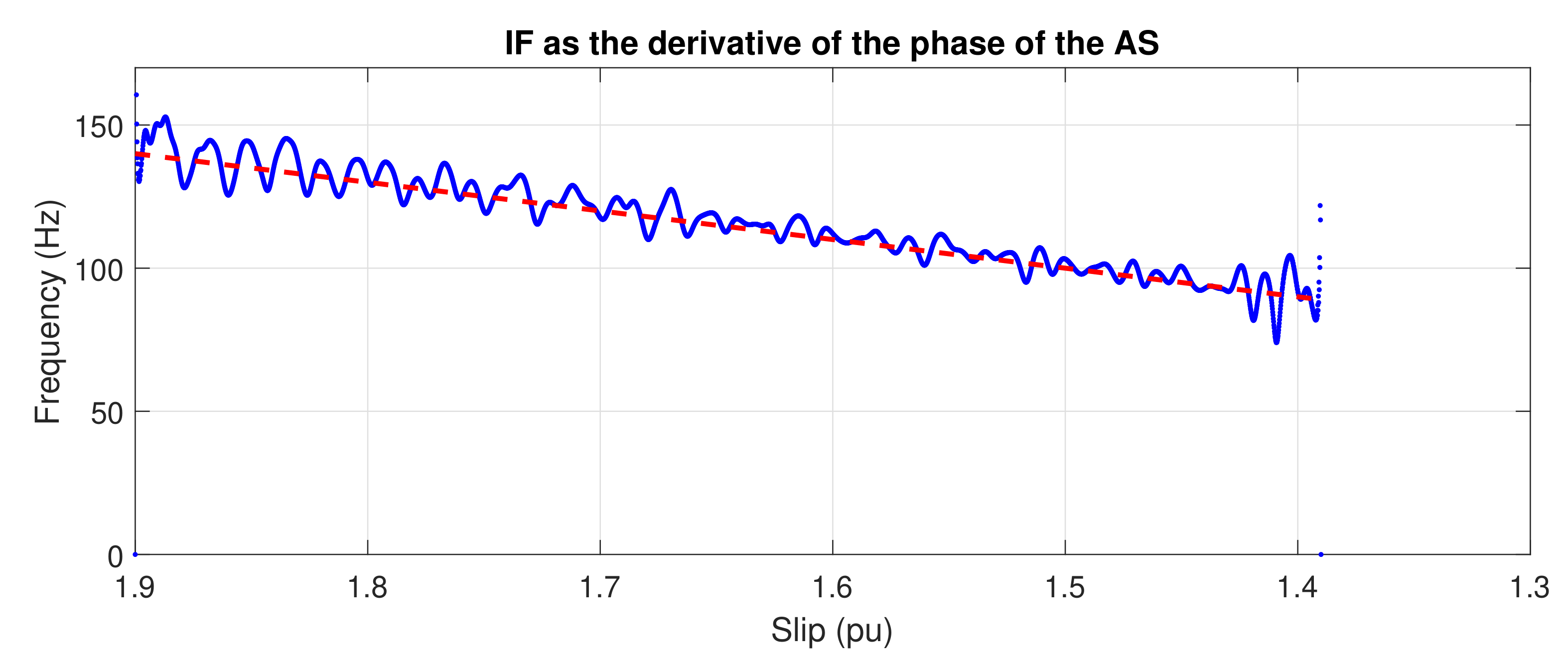

- The derivative of the phase of the analytic signal (AS) of the stator current component.

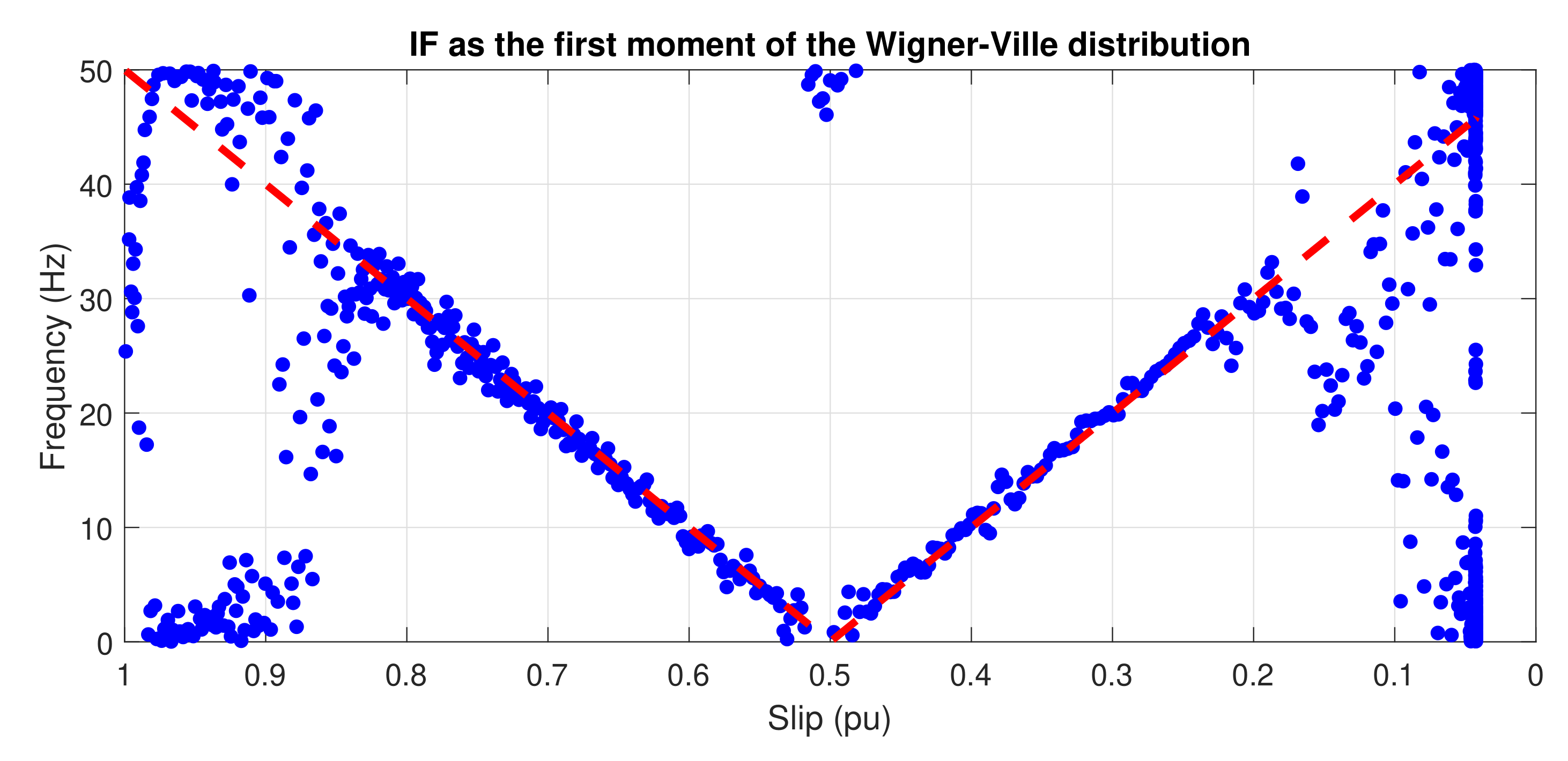

- The first conditional moment of frequency for a given time, obtained from quadratic time-frequency energy distributions, such as the Wigner–Ville distribution (WVD).

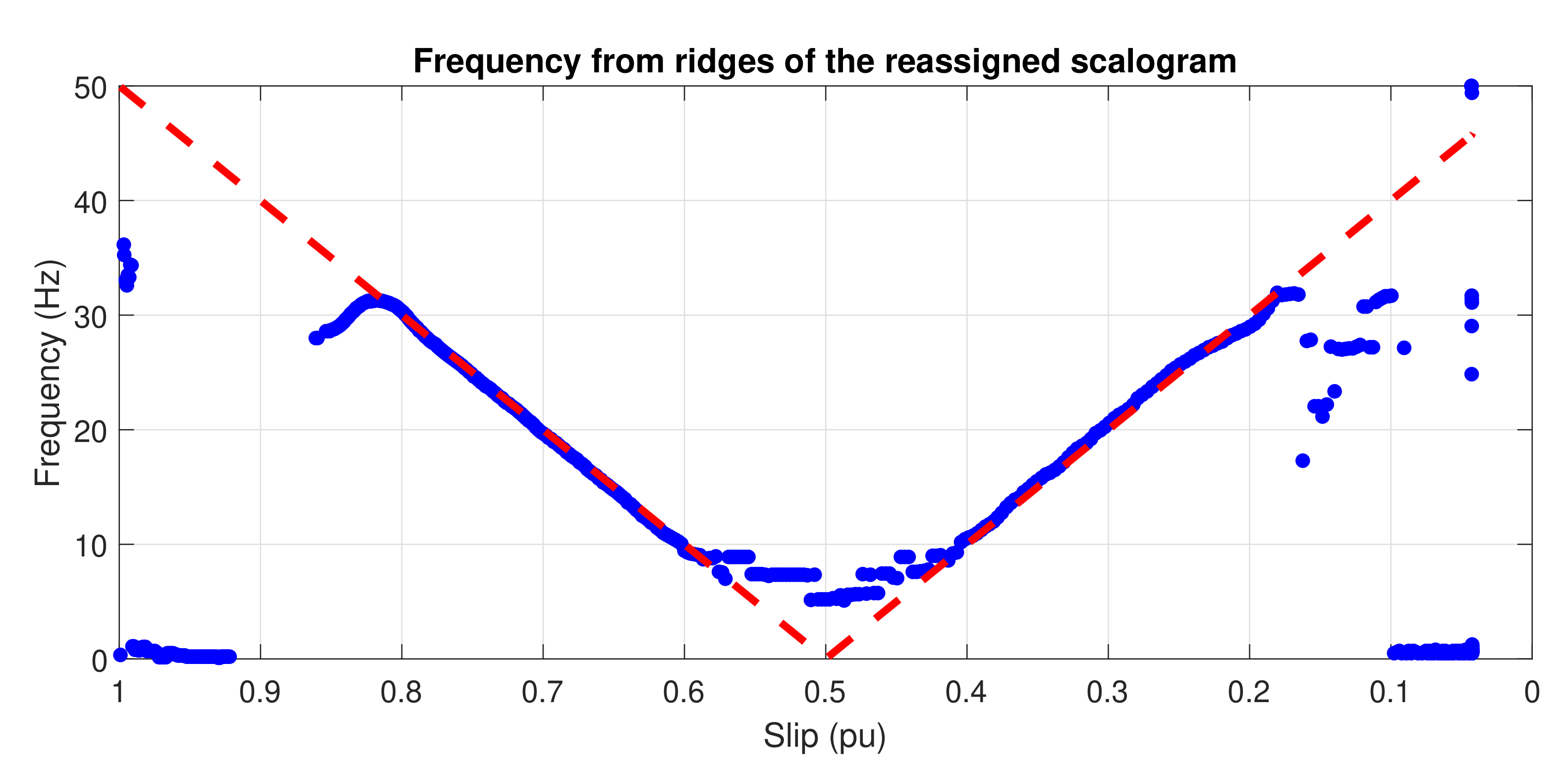

- The evaluation of the ridges in linear time-frequency transforms (CWT with the Morlet Wavelet).

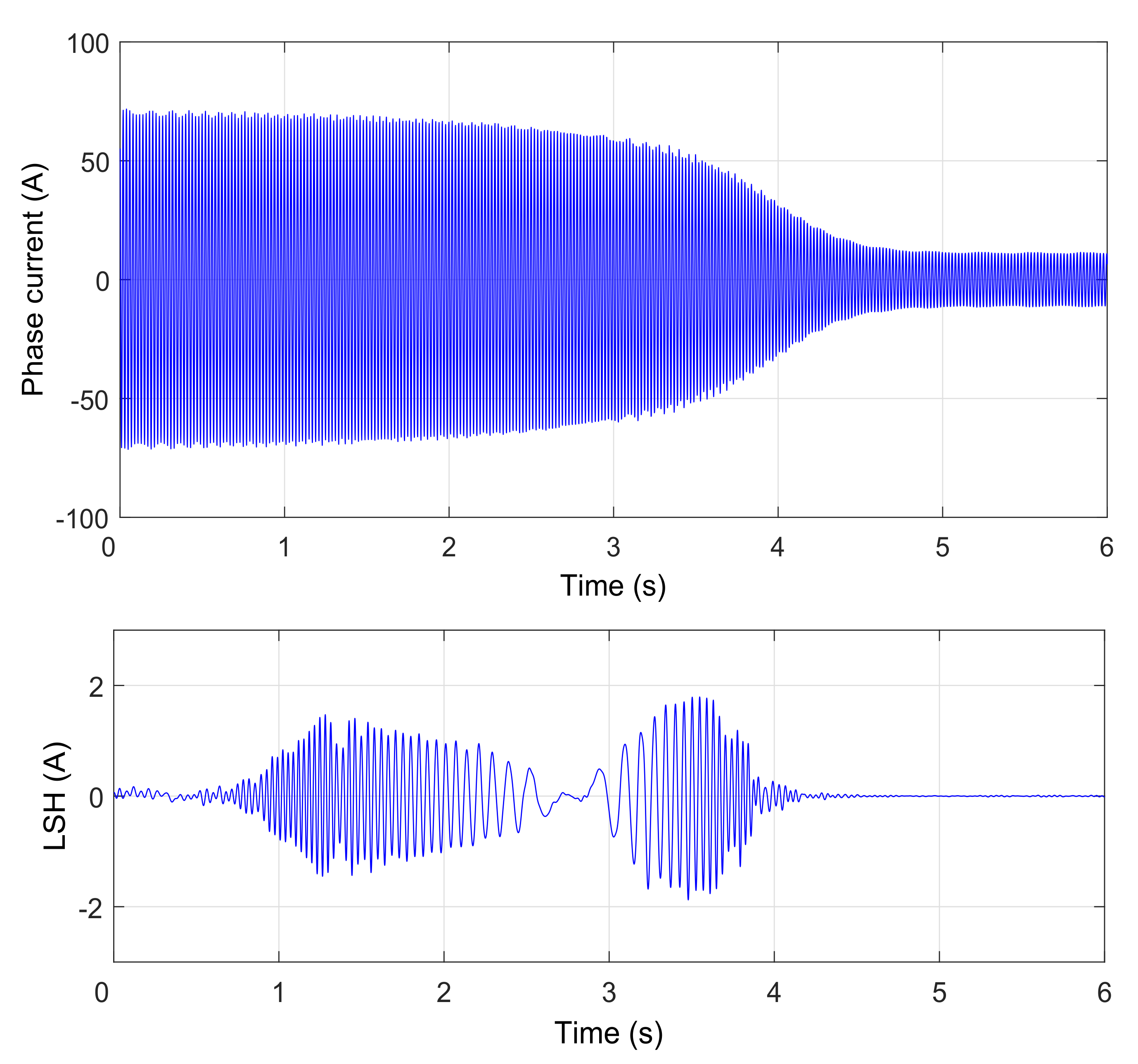

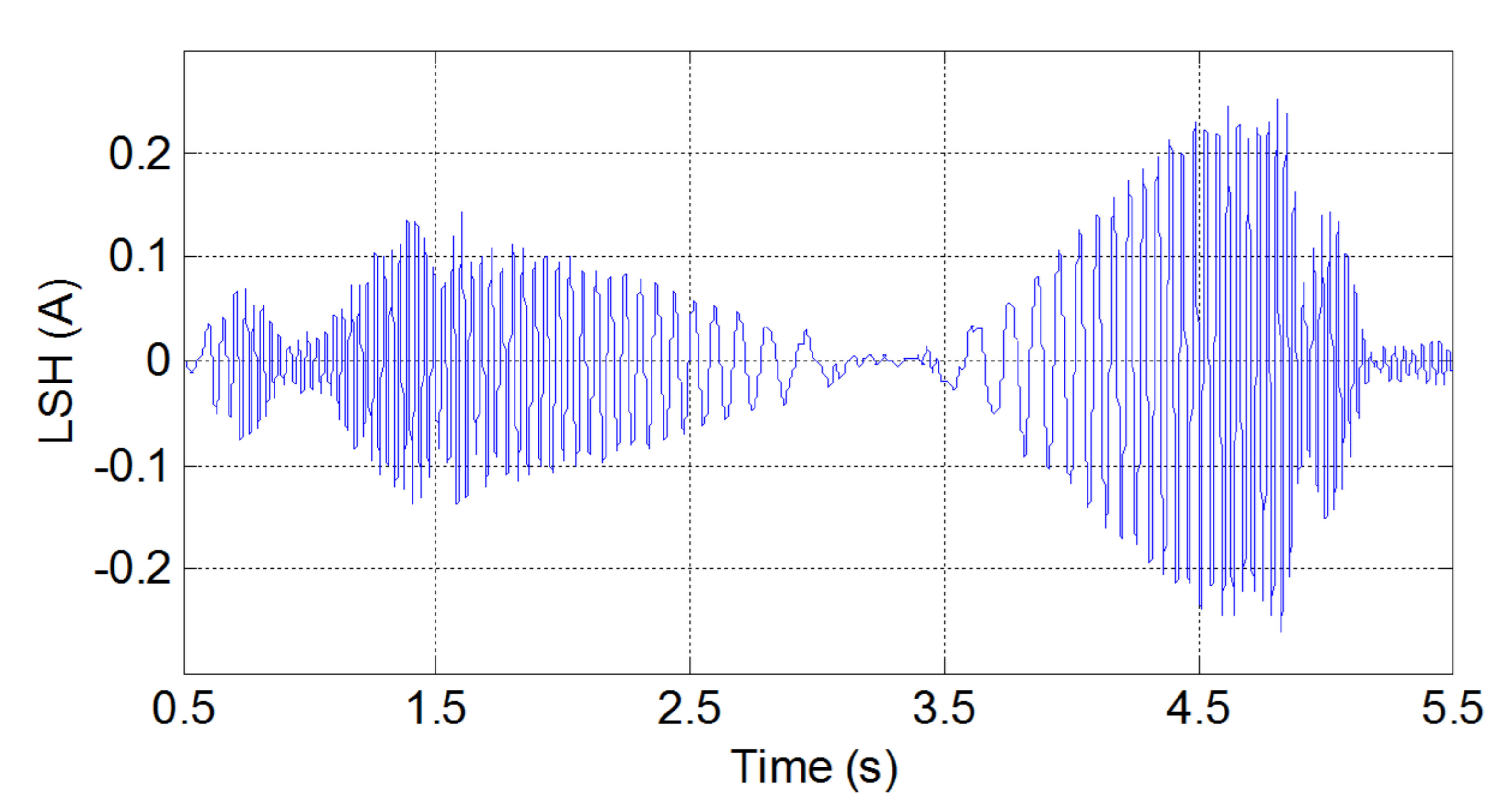

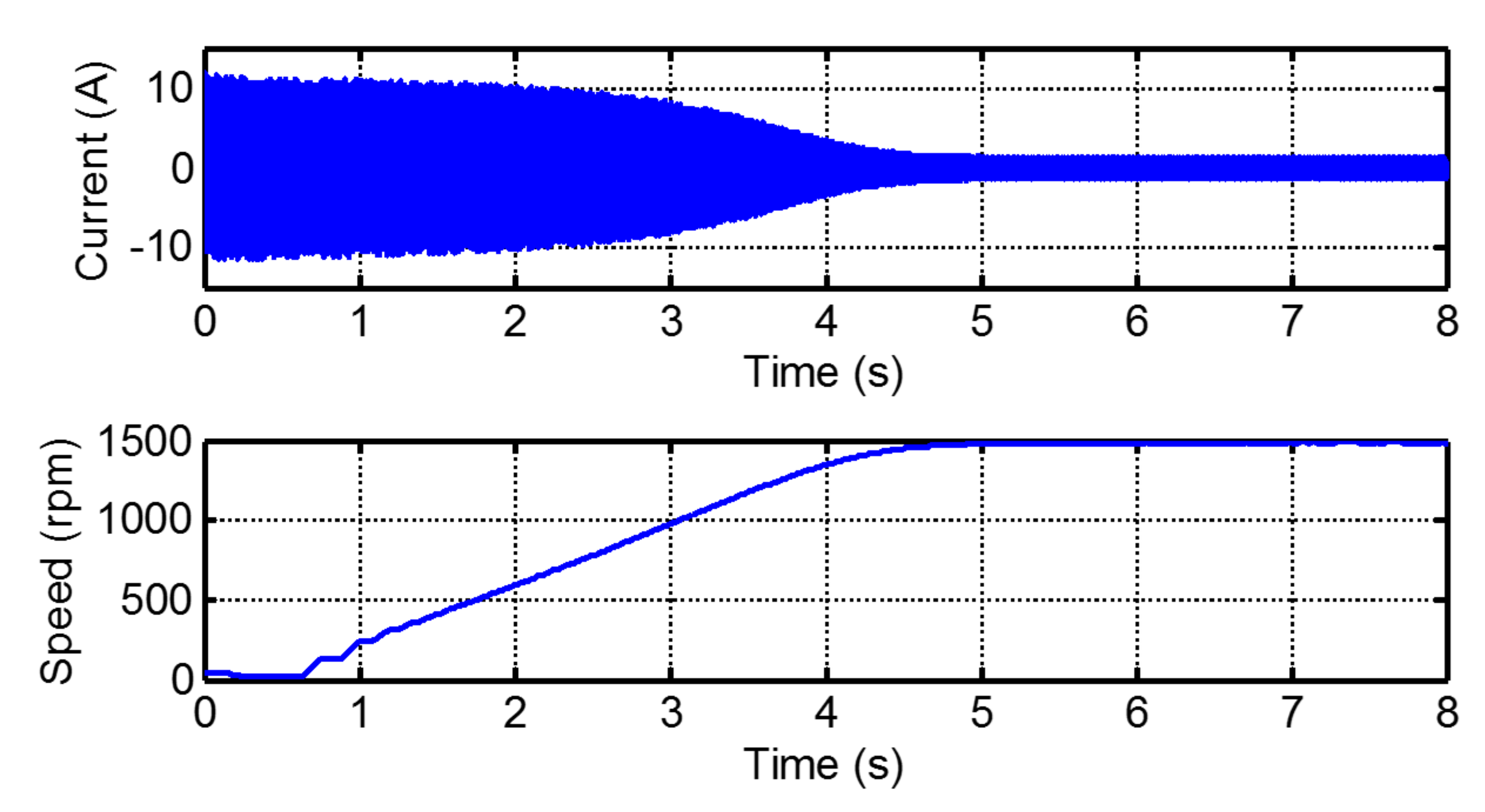

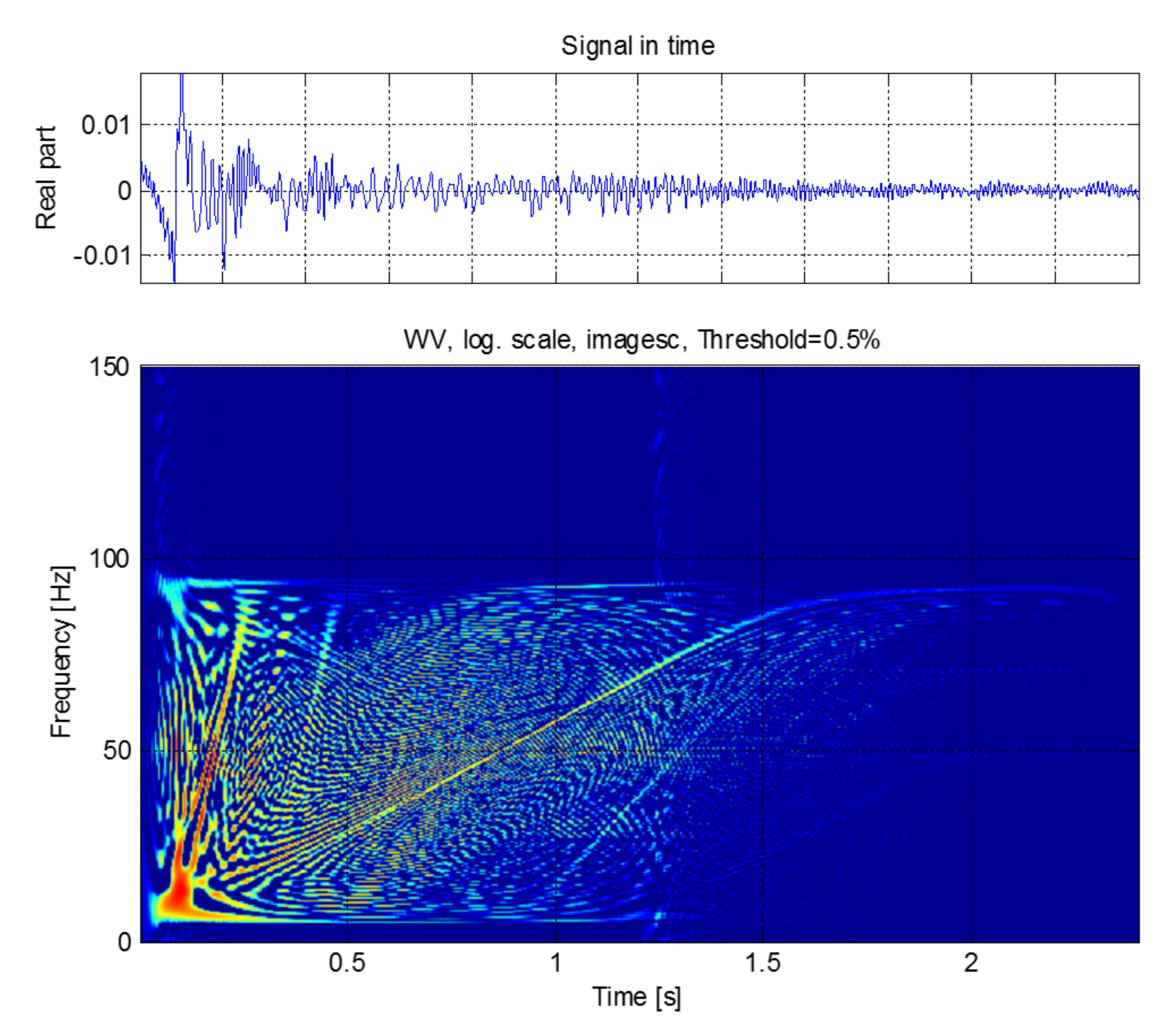

- First, the start-up of a 4-pole, 4 kW cage motor with a broken bar is simulated using the commercial finite-elements software Flux-2D. Figure 2 (top) shows the simulated current. More details about the characteristics of the induction motor are given in Appendix A.

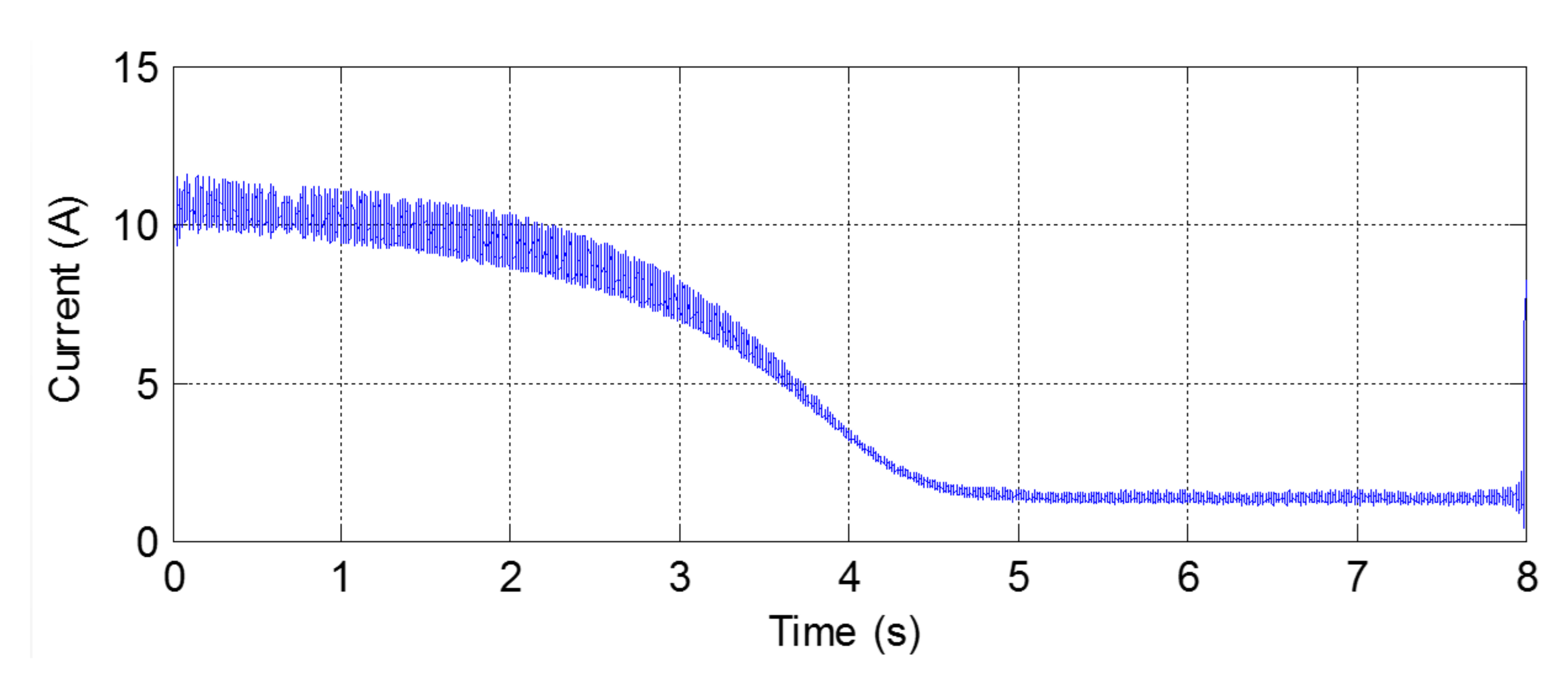

- Second, the LSHst is isolated from the current signal using the DWT [54]. More accurately, the signal of Figure 2 (bottom) is the approximation of level 4 (a4) of the wavelet decomposition of the current of Figure 2 (top), using Daubechies-44 as mother wavelet. Since the time increment used in the simulation is = 0.001 s, the sub-signal is formed by the components of the current included in the interval [0, 31.25] Hz; since in a machine with broken bars, the LSHst is by far the more prominent component in the frequency band below the supply frequency ( = 50 Hz) [54], Figure 2 (bottom), can be taken as a good representation of the LSHst in that interval.

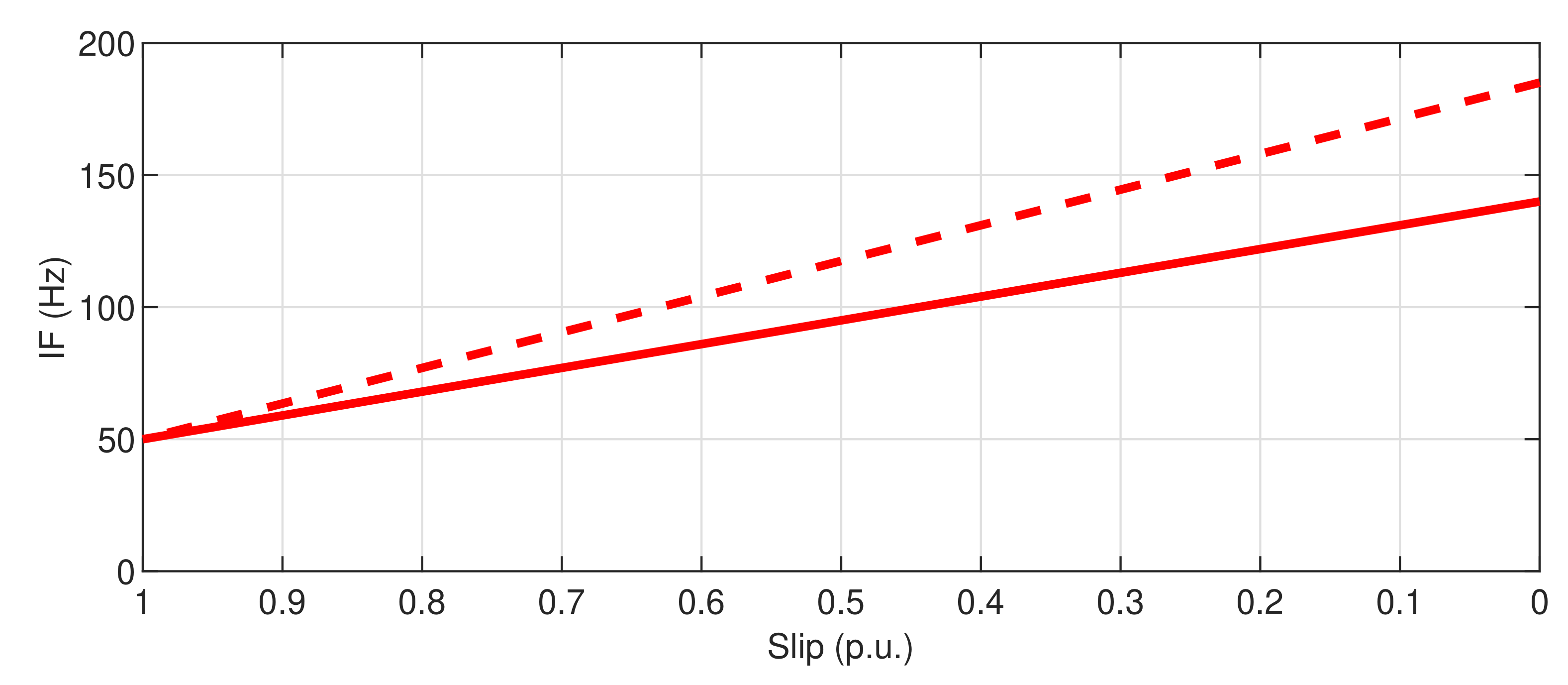

2.1. Theoretical IF of the LSHst in the Slip–Frequency Plane

2.2. IF of the LSHst Using the Hilbert Transform of the Current

- Application of the Hilbert transform to the LSHst fault harmonic, a current signal designed as :

- Construction of the analytic signal of the LSHst, . It is a complex signal with a real part equal to the original signal , and an imaginary part equal to its HT:

- Once obtained the complex AS, the derivative of its phase gives the IF of the LSHst:

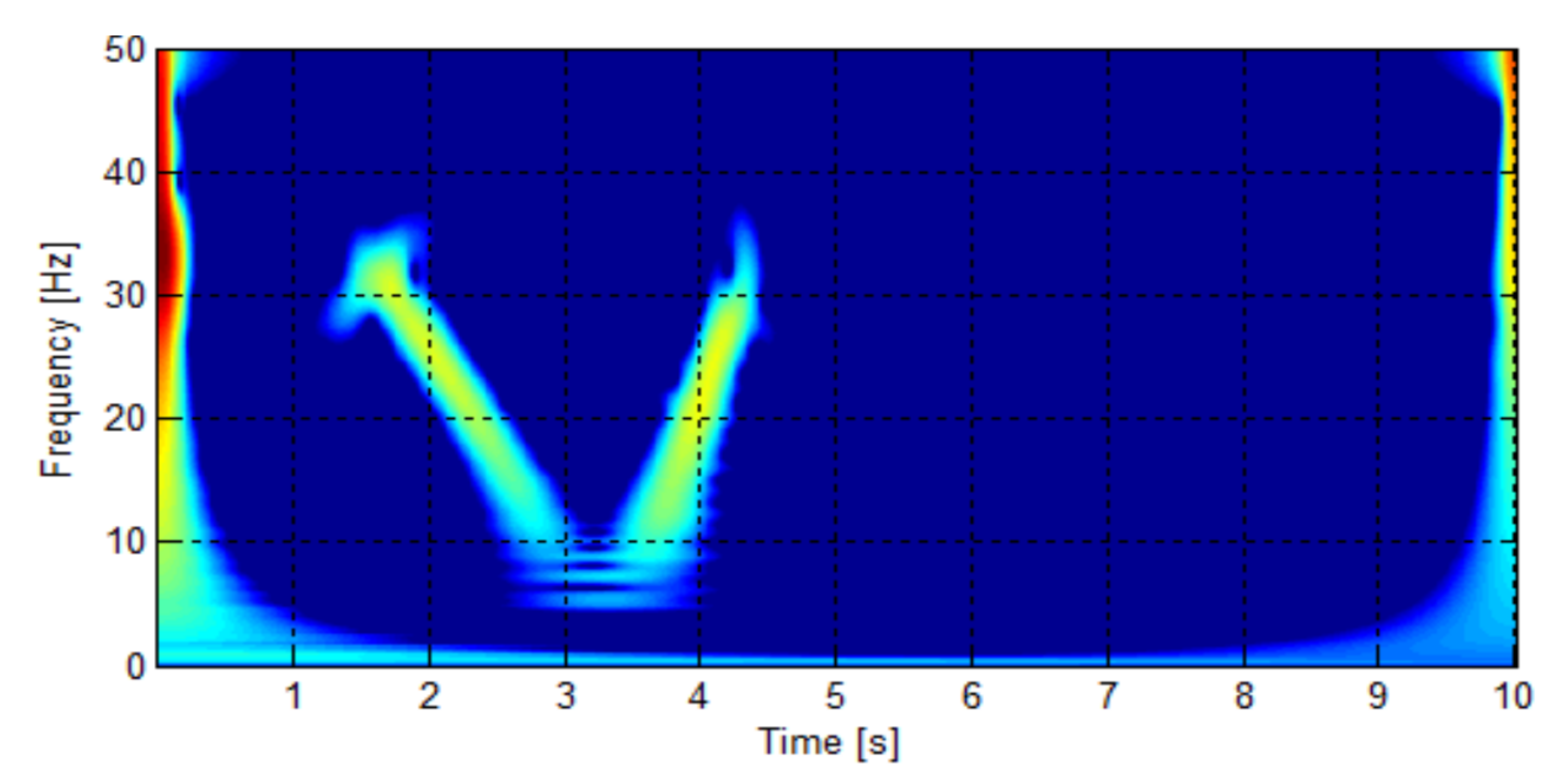

2.3. IF of the LSHst Using the Wigner–Ville Distribution

2.4. IF of the LSHst Using the Continuous Wavelet Transform

3. Experimental Comparison of the Methods for Calculating the IF of the Fault Components in the Slip–Frequency Domain

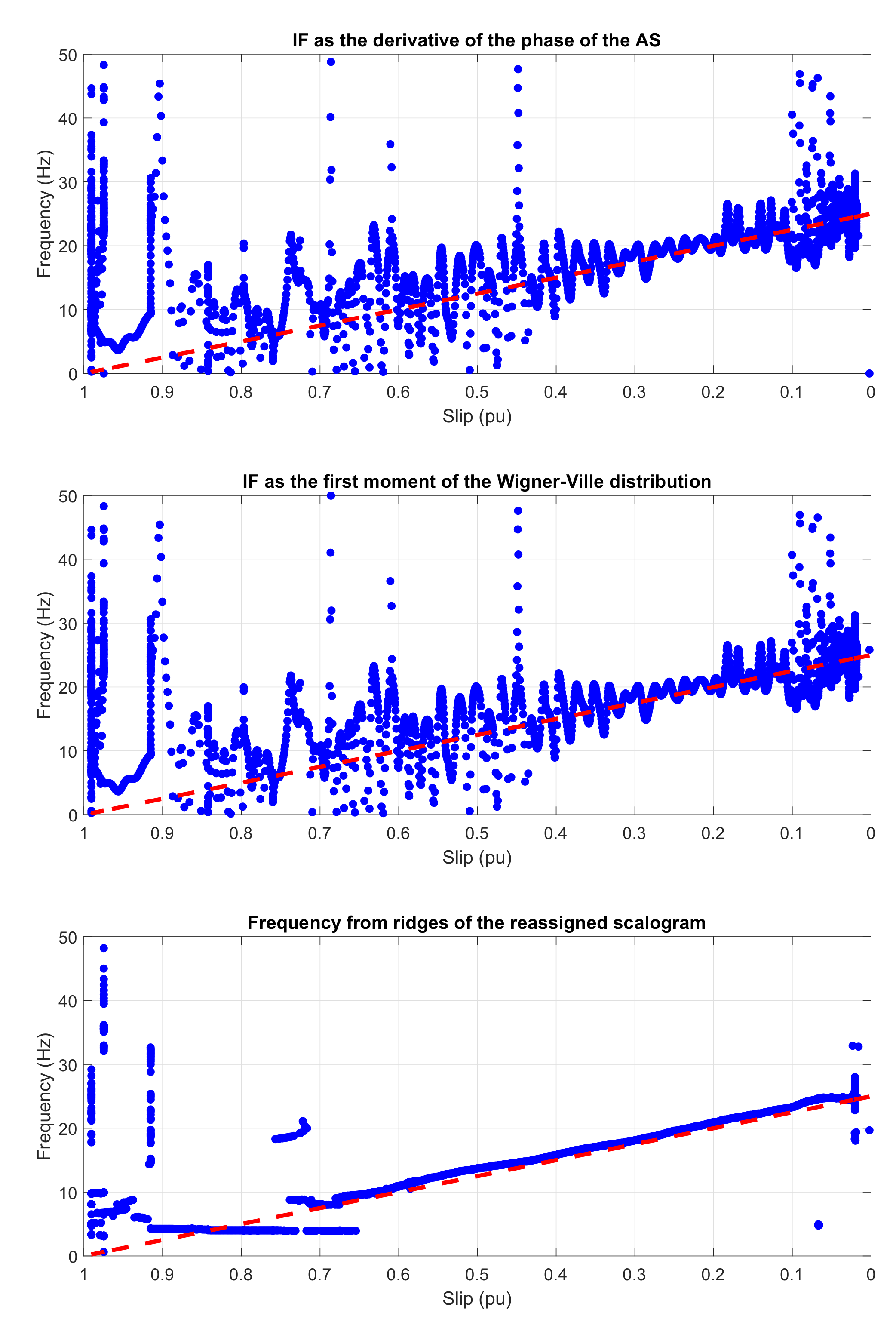

3.1. IF of the LSHst Extracted from the Tested Startup Current of a Machine with Broken Bars

3.2. IF of the Fault Component Extracted from the Tested Startup Current of a Machine with Mixed Eccentricity

3.2.1. Theoretical IF of the Mixed Eccentricity Fault Related Harmonics in the Slip–Frequency Plane

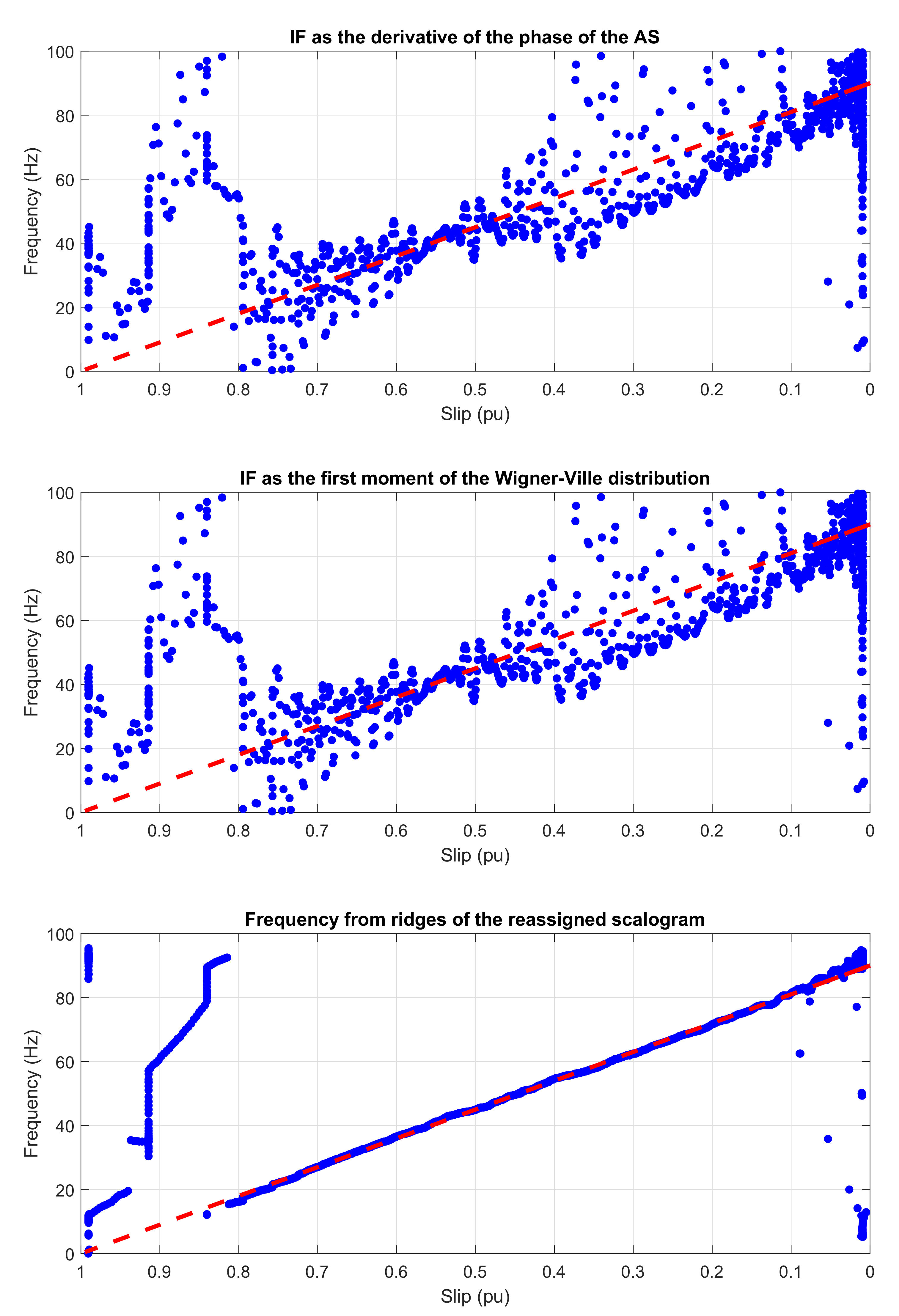

3.2.2. Experimental IF of the Mixed Eccentricity Harmonics in the Slip–Frequency Plane

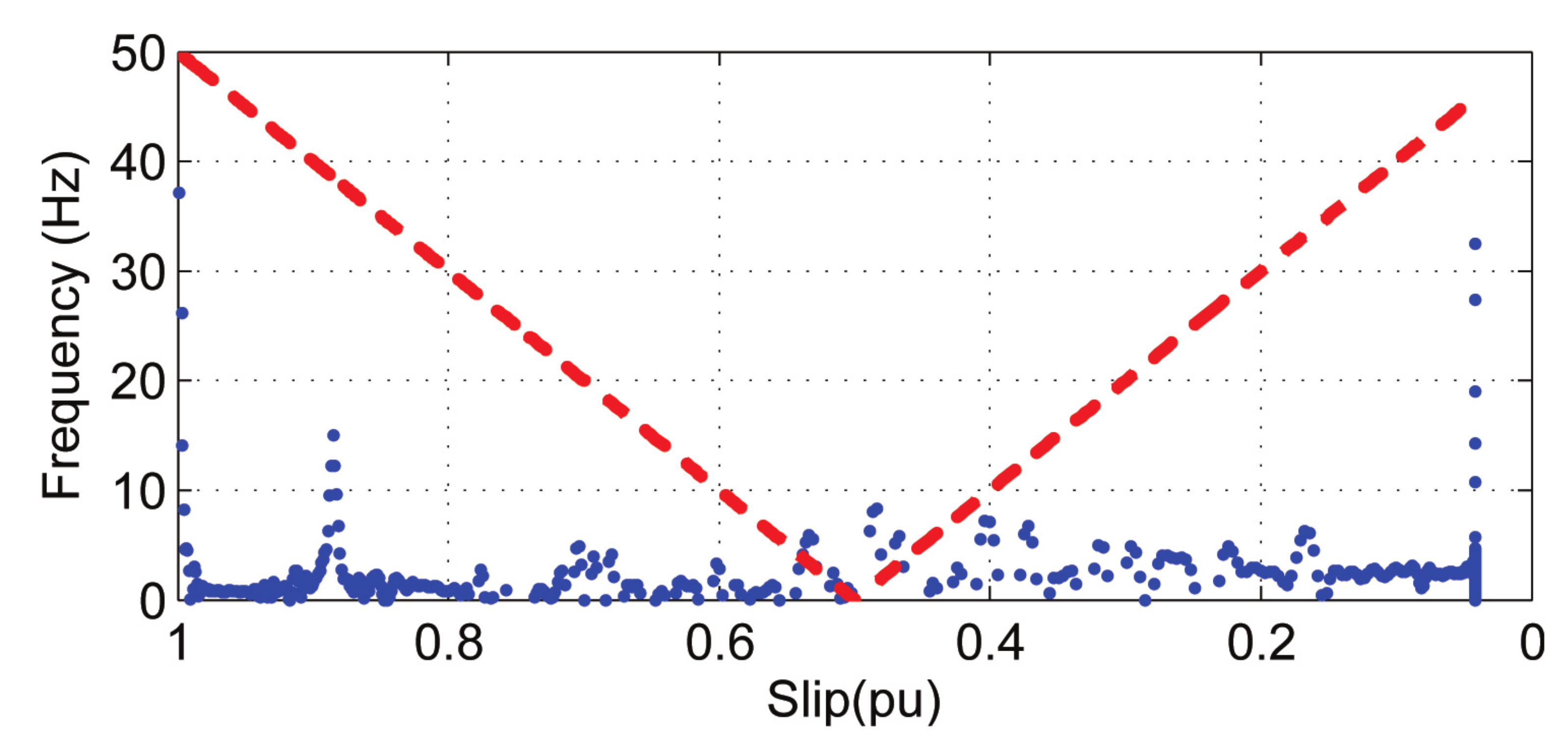

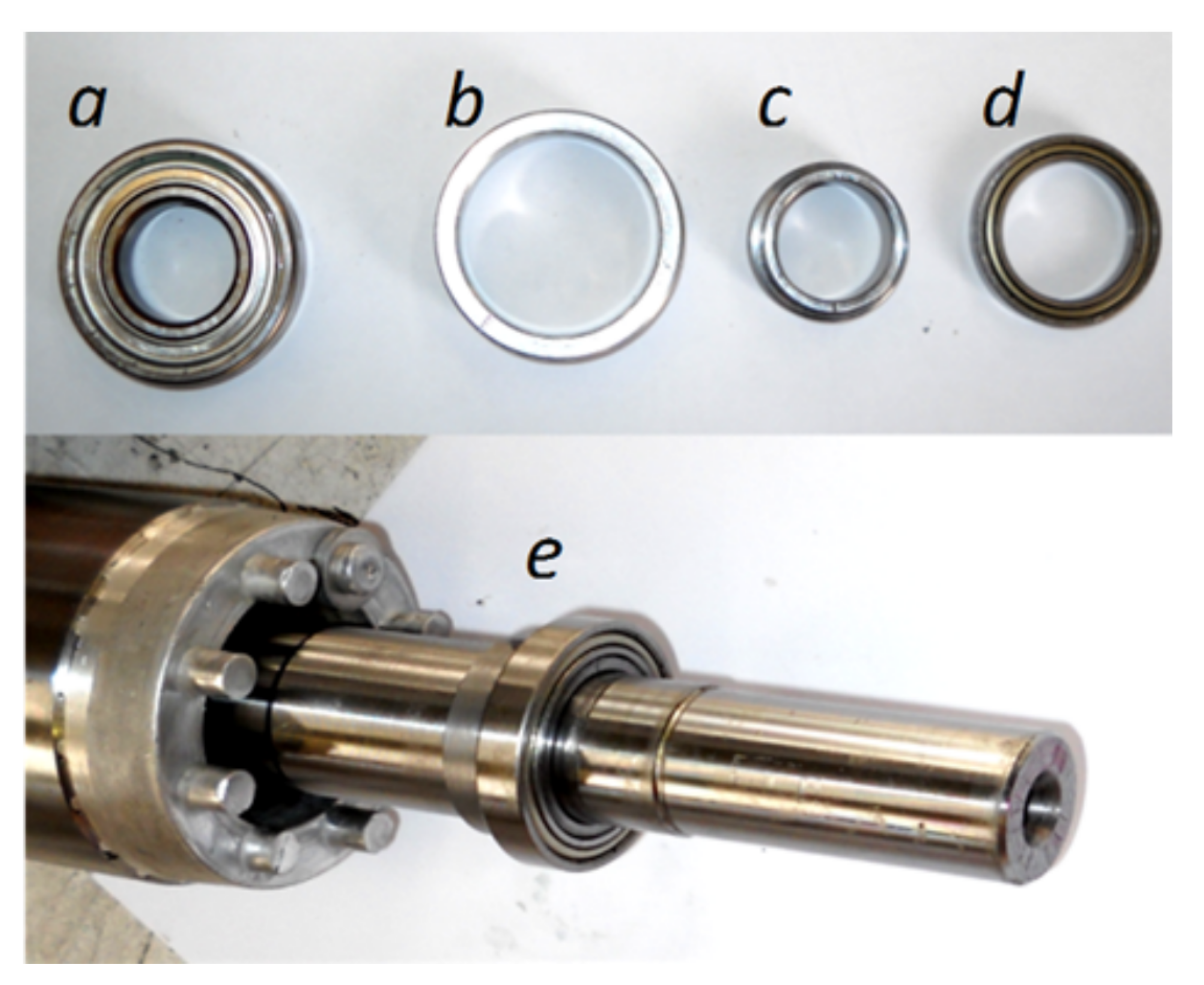

3.3. IF of the Fault Component Extracted from the Tested Startup Current of a Machine with a Bearing Fault

3.3.1. Theoretical IF of the Bearing Fault Harmonics in the Slip–Frequency Plane

3.3.2. Experimental IF of the Bearing Fault Harmonics in the Slip–Frequency

4. Definition of a Fault Signature Based on the IF of the Fault Components

5. Practical Remarks

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| A | Modulus of the analytic signal |

| a | Scale parameter |

| Approximation of level i obtained from the discrete wavelet transform | |

| Detail of level i obtained from the discrete wavelet transform | |

| f | Frequency |

| Phase of the analytic signal | |

| Supply frequency | |

| Bandwidth parameter of a wavelet | |

| Frequency of the fault harmonic related to an inner race cyclic defect | |

| Frequency of the fault harmonic related to an outer race cyclic defect | |

| Frequency of the fault harmonic related to a bar breakage fault | |

| Central frequency of a wavelet | |

| Frequency of the fault harmonic related to a mixed eccentricity fault | |

| Frequency of the fault harmonic related to load torque pulsation | |

| Rotation frequency of the rotor | |

| Sampling frequency | |

| Frequency of a load torque pulsation | |

| Analytic signal obtained from Hilbert transform | |

| Current signal which contains the mixed eccentricity component, obtained through discrete wavelet filtering of tested stator current | |

| Low sideband component of the stator current | |

| Number of bearing balls | |

| p | Number of pole pairs |

| Distribution of the energy of a signal x | |

| Correlation parameter | |

| s | Slip, rotor relative speed related to magnetic field speed, in pu |

| t | Time |

| Generic signal defined in the time domain | |

| Conjugate of x | |

| Y | Hilbert transform of a signal |

| Mother wavelet |

Appendix A. Motor Type I

Appendix B. Motor Type II

Appendix C. Current Clamp

Appendix D. Computer Characteristics

References

- Pang, B.; Tang, G.; Tian, T.; Zhou, C. Rolling Bearing Fault Diagnosis Based on an Improved HTT Transform. Sensors 2018, 18, 1203. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, G.; Deng, C.; Wu, J.; Xu, X.; Shao, X.; Wang, Y. Sensor Data-Driven Bearing Fault Diagnosis Based on Deep Convolutional Neural Networks and S-Transform. Sensors 2019, 19, 2750. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Burriel-Valencia, J.; Puche-Panadero, R.; Martinez-Roman, J.; Sapena-Baño, A.; Riera-Guasp, M.; Pineda-Sánchez, M. Multi-Band Frequency Window for Time-Frequency Fault Diagnosis of Induction Machines. Energies 2019, 12, 3361. [Google Scholar] [CrossRef] [Green Version]

- Murcia-Sepúlveda, N.; Cruz-Duarte, J.M.; Martin-Diaz, I.; Garcia-Perez, A.; Rosales-García, J.J.; Avina-Cervantes, J.G.; Correa-Cely, C.R. Fractional Calculus-Based Processing for Feature Extraction in Harmonic-Polluted Fault Monitoring Systems. Energies 2019, 12, 3736. [Google Scholar] [CrossRef] [Green Version]

- Burriel-Valencia, J.; Puche-Panadero, R.; Martinez-Roman, J.; Sapena-Bano, A.; Pineda-Sanchez, M. Fault Diagnosis of Induction Machines in a Transient Regime Using Current Sensors with an Optimized Slepian Window. Sensors 2018, 18, 146. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Tang, T.; Chen, M.; Hu, T. Self-Adaptive Spectrum Analysis Based Bearing Fault Diagnosis. Sensors 2018, 18, 3312. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Calva, T.A.; Morinigo-Sotelo, D.; Garcia-Perez, A.; Camarena-Martinez, D.; de Jesus Romero-Troncoso, R. Demodulation Technique for Broken Rotor Bar Detection in Inverter-Fed Induction Motor Under Non-Stationary Conditions. IEEE Trans. Energy Convers. 2019, 34, 1496–1503. [Google Scholar] [CrossRef]

- Shao, S.; Yan, R.; Lu, Y.; Wang, P.; Gao, R. DCNN-based Multi-signal Induction Motor Fault Diagnosis. IEEE Trans. Instrum. Meas. 2019, 69, 2658–2669. [Google Scholar] [CrossRef]

- Liu, C.; Cheng, G.; Chen, X.; Pang, Y. Planetary Gears Feature Extraction and Fault Diagnosis Method Based on VMD and CNN. Sensors 2018, 18, 1523. [Google Scholar] [CrossRef] [Green Version]

- Riera-Guasp, M.; Antonino-Daviu, J.; Pineda-Sanchez, M.; Puche-Panadero, R.; Perez-Cruz, J. A General Approach for the Transient Detection of Slip-Dependent Fault Components Based on the Discrete Wavelet Transform. IEEE Trans. Ind. Electron. 2008, 55, 4167–4180. [Google Scholar] [CrossRef]

- Rivera-Guillen, J.R.; Santiago-Perez, J.D.; Amezquita-Sanchez, J.P.; Valtierra-Rodriguez, M.; Romero-Troncoso, R.J. Enhanced FFT-based method for incipient broken rotor bar detection in induction motors during the startup transient. Measurement 2018, 124, 277–285. [Google Scholar] [CrossRef]

- Li, H.; Wang, Z.; Zhen, D.; Gu, F.; Ball, A. Modulation Sideband Separation Using the Teager–Kaiser Energy Operator for Rotor Fault Diagnostics of Induction Motors. Energies 2019, 12, 4437. [Google Scholar] [CrossRef] [Green Version]

- Burriel-Valencia, J.; Puche-Panadero, R.; Martinez-Roman, J.; Sapena-Bano, A.; Pineda-Sanchez, M. Cost-Effective Reduced Envelope of the Stator Current via Synchronous Sampling for the Diagnosis of Rotor Asymmetries in Induction Machines Working at Very Low Slip. Sensors 2019, 19, 3471. [Google Scholar] [CrossRef] [Green Version]

- Pires, V.F.; Kadivonga, M.; Martins, J.; Pires, A. Motor square current signature analysis for induction motor rotor diagnosis. Measurement 2013, 46, 942–948. [Google Scholar] [CrossRef]

- Ottewill, J.; Orkisz, M. Condition monitoring of gearboxes using synchronously averaged electric motor signals. Mech. Syst. Signal Process. 2013, 38, 482–498. [Google Scholar] [CrossRef]

- Hassan, O.E.; Amer, M.; Abdelsalam, A.K.; Williams, B.W. Induction motor broken rotor bar fault detection techniques based on fault signature analysis – a review. IET Electr. Power Appl. 2018, 12, 895–907. [Google Scholar] [CrossRef]

- Bellini, A.; Filippetti, F.; Franceschini, G.; Tassoni, C.; Kliman, G. Quantitative evaluation of induction motor broken bars by means of electrical signature analysis. IEEE Trans. Ind. Appl. 2001, 37, 1248–1255. [Google Scholar] [CrossRef]

- Nandi, S.; Bharadwaj, R.; Toliyat, H. Performance analysis of a three-phase induction motor under mixed eccentricity condition. IEEE Trans. Energy Convers. 2002, 17, 392–399. [Google Scholar] [CrossRef]

- Sapena-Bano, A.; Martinez-Roman, J.; Puche-Panadero, R.; Pineda-Sanchez, M.; Perez-Cruz, J.; Riera-Guasp, M. Induction machine model with space harmonics for the diagnosis of rotor eccentricity, based on the convolution theorem. Int. J. Electr. Power Energy Syst. 2020, 117, 105625. [Google Scholar] [CrossRef]

- Sapena-Bano, A.; Chinesta, F.; Pineda-Sanchez, M.; Aguado, J.; Borzacchiello, D.; Puche-Panadero, R. Induction machine model with finite element accuracy for condition monitoring running in real time using hardware in the loop system. Int. J. Electr. Power Energy Syst. 2019, 111, 315–324. [Google Scholar] [CrossRef]

- Contreras-Hernandez, J.L.; Almanza-Ojeda, D.L.; Ledesma-Orozco, S.; Garcia-Perez, A.; Romero-Troncoso, R.J.; Ibarra-Manzano, M.A. Quaternion Signal Analysis Algorithm for Induction Motor Fault Detection. IEEE Trans. Ind. Electron. 2019, 66, 8843–8850. [Google Scholar] [CrossRef]

- Schoen, R.; Habetler, T.; Kamran, F.; Bartfield, R. Motor bearing damage detection using stator current monitoring. IEEE Trans. Ind. Appl. 1995, 31, 1274–1279. [Google Scholar] [CrossRef]

- Pineda-Sanchez, M.; Riera-Guasp, M.; Antonino-Daviu, J.; Roger-Folch, J.; Perez-Cruz, J.; Puche-Panadero, R. Instantaneous Frequency of the Left Sideband Harmonic During the Start-Up Transient: A New Method for Diagnosis of Broken Bars. IEEE Trans. Ind. Electron. 2009, 56, 4557–4570. [Google Scholar] [CrossRef]

- Khan, N.; Jönsson, P.; Sandsten, M. Performance Comparison of Time-Frequency Distributions for Estimation of Instantaneous Frequency of Heart Rate Variability Signals. Appl. Sci. 2017, 7, 221. [Google Scholar] [CrossRef] [Green Version]

- Feng, Z.; Liang, M.; Chu, F. Recent advances in time–frequency analysis methods for machinery fault diagnosis: A review with application examples. Mech. Syst. Signal Process. 2013, 38, 165–205. [Google Scholar] [CrossRef]

- Bouchikhi, E.; Choqueuse, V.; Benbouzid, M. Current Frequency Spectral Subtraction and Its Contribution to Induction Machines’ Bearings Condition Monitoring. IEEE Trans. Energy Convers. 2013, 28, 135–144. [Google Scholar] [CrossRef] [Green Version]

- Guo, Y.; Chen, X.; Wang, S.; Sun, R.; Zhao, Z. Wind Turbine Diagnosis under Variable Speed Conditions Using a Single Sensor Based on the Synchrosqueezing Transform Method. Sensors 2017, 17, 1149. [Google Scholar]

- Bessous, N.; Zouzou, S.E.; Bentrah, W.; Sbaa, S.; Sahraoui, M. Diagnosis of bearing defects in induction motors using discrete wavelet transform. Int. J. Syst. Assur. Eng. Manag. 2018, 9, 335–343. [Google Scholar] [CrossRef]

- Khodja, M.E.A.; Aimer, A.F.; Boudinar, A.H.; Benouzza, N.; Bendiabdellah, A. Bearing Fault Diagnosis of a PWM Inverter Fed-Induction Motor Using an Improved Short Time Fourier Transform. J. Electr. Eng. Technol. 2019, 14, 1201–1210. [Google Scholar] [CrossRef]

- Hu, Y.; Tu, X.; Li, F.; Meng, G. Joint High-Order Synchrosqueezing Transform and Multi-Taper Empirical Wavelet Transform for Fault Diagnosis of Wind Turbine Planetary Gearbox under Nonstationary Conditions. Sensors 2018, 18, 150. [Google Scholar] [CrossRef] [Green Version]

- Zhen, D.; Wang, Z.; Li, H.; Zhang, H.; Yang, J.; Gu, F. An Improved Cyclic Modulation Spectral Analysis Based on the CWT and Its Application on Broken Rotor Bar Fault Diagnosis for Induction Motors. Appl. Sci. 2019, 9, 3902. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Feng, Z. Time-frequency space vector modulus analysis of motor current for planetary gearbox fault diagnosis under variable speed conditions. Mech. Syst. Signal Process. 2019, 121, 636–654. [Google Scholar] [CrossRef]

- Pineda-Sanchez, M.; Riera-Guasp, M.; Antonino-Daviu, J.; Roger-Folch, J.; Perez-Cruz, J.; Puche-Panadero, R. Diagnosis of Induction Motor Faults in the Fractional Fourier Domain. IEEE Trans. Instrum. Meas. 2010, 59, 2065–2075. [Google Scholar] [CrossRef]

- Chen, X.; Feng, Z. Induction motor stator current analysis for planetary gearbox fault diagnosis under time-varying speed conditions. Mech. Syst. Signal Process. 2020, 140, 106691. [Google Scholar] [CrossRef]

- Delgado-Arredondo, P.A.; Morinigo-Sotelo, D.; Osornio-Rios, R.A.; Avina-Cervantes, J.G.; Rostro-Gonzalez, H.; de Jesus Romero-Troncoso, R. Methodology for fault detection in induction motors via sound and vibration signals. Mech. Syst. Signal Process. 2017, 83, 568–589. [Google Scholar] [CrossRef]

- el Malek, M.B.A.; Abdelsalam, A.K.; Hassan, O.E. Novel approach using Hilbert Transform for multiple broken rotor bars fault location detection for three phase induction motor. ISA Trans. 2018, 80, 439–457. [Google Scholar] [CrossRef]

- Amirat, Y.; Benbouzid, M.; Wang, T.; Bacha, K.; Feld, G. EEMD-based notch filter for induction machine bearing faults detection. Appl. Acoust. 2018, 133, 202–209. [Google Scholar] [CrossRef]

- Boashash, B. Estimating and interpreting the instantaneous frequency of a signal. I. Fundamentals. Proc. IEEE 1992, 80, 520–538. [Google Scholar] [CrossRef]

- Nho, W.; Loughlin, P. When is instantaneous frequency the average frequency at each time? Signal Process. Lett. IEEE 1999, 6, 78–80. [Google Scholar]

- Khan, N.; Boashash, B. Instantaneous Frequency Estimation of Multicomponent Nonstationary Signals Using Multiview Time-Frequency Distributions Based on the Adaptive Fractional Spectrogram. Signal Process. Lett. IEEE 2013, 20, 157–160. [Google Scholar] [CrossRef]

- Kijewski-Correa, T.; Kareem, A. Nonlinear Signal Analysis: Time-Frequency Perspectives. J. Eng. Mech. 2007, 133, 238–245. [Google Scholar] [CrossRef] [Green Version]

- Stanković, L.; Daković, M.; Thayaparan, T. A real-time time-frequency based instantaneous frequency estimator. Signal Process. 2013, 93, 1392–1397. [Google Scholar] [CrossRef]

- Qin, Y. Multicomponent AM-FM demodulation based on energy separation and adaptive filtering. Mech. Syst. Signal Process. 2013, 38, 440–459. [Google Scholar] [CrossRef]

- Toole, J.O.; Boashash, B. Fast and memory-efficient algorithms for computing quadratic time–frequency distributions. Appl. Comput. Harmon. Anal. 2013, 35, 350–358. [Google Scholar] [CrossRef]

- Sadeghi, R.; Samet, H.; Ghanbari, T. Detection of Stator Short-Circuit Faults in Induction Motors Using the Concept of Instantaneous Frequency. IEEE Trans. Ind. Informatics 2019, 15, 4506–4515. [Google Scholar] [CrossRef]

- Song, X.; Hu, J.; Zhu, H.; Zhang, J. A bearing outer raceway fault detection method in induction motors based on instantaneous frequency of the stator current. IEEJ Trans. Electr. Electron. Eng. 2018, 13, 510–516. [Google Scholar] [CrossRef]

- Ouanas, A.; Medoued, A.; Mordjaoui, M.; Lebaroud, A.; Sayad, D. Fault diagnosis in yaw drive induction motor for wind turbine. Wind. Eng. 2018, 42, 576–595. [Google Scholar] [CrossRef]

- Vedreño-Santos, F.; Riera-Guasp, M.; Henao, H.; Pineda-Sánchez, M.; Puche-Panadero, R. Diagnosis of Rotor and Stator Asymmetries in Wound-Rotor Induction Machines Under Nonstationary Operation Through the Instantaneous Frequency. IEEE Trans. Ind. Electron. 2014, 61, 4947–4959. [Google Scholar] [CrossRef]

- Vedreño-Santos, F.; Riera-Guasp, M.; Henao, H.; Pineda-Sánchez, M. Diagnosis of faults in induction generators under fluctuating load conditions through the instantaneous frequency of the fault components. In Proceedings of the 2012 XXth International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; pp. 1653–1659. [Google Scholar]

- Pineda-Sanchez, M.; Riera-Guasp, M.; Pons-Llinares, J.; Climente-Alarcon, V.; Perez-Cruz, J. Diagnosis of induction machines under transient conditions through the Instantaneous Frequency of the fault components. In Proceedings of the The XIX International Conference on Electrical Machines - ICEM 2010, Rome, Italy, 6–8 September 2010; pp. 1–6. [Google Scholar]

- Feng, Z.; Chen, X.; Zuo, M.J. Induction Motor Stator Current AM-FM Model and Demodulation Analysis for Planetary Gearbox Fault Diagnosis. IEEE Trans. Ind. Informatics 2019, 15, 2386–2394. [Google Scholar] [CrossRef]

- Blodt, M.; Chabert, M.; Regnier, J.; Faucher, J. Mechanical Load Fault Detection in Induction Motors by Stator Current Time-Frequency Analysis. IEEE Trans. Ind. Appl. 2006, 42, 1454–1463. [Google Scholar] [CrossRef]

- Boashash, B. Estimating and interpreting the instantaneous frequency of a signal. II. Algorithms and applications. Proc. IEEE 1992, 80, 540–568. [Google Scholar] [CrossRef]

- Riera-Guasp, M.; Antonino-Daviu, J.; Roger-Folch, J.; Molina Palomares, M. The Use of the Wavelet Approximation Signal as a Tool for the Diagnosis of Rotor Bar Failures. IEEE Trans. Ind. Appl. 2008, 44, 716–726. [Google Scholar] [CrossRef] [Green Version]

- Hlawatsch, F.; Boudreaux-Bartels, G. Linear and quadratic time-frequency signal representations. Signal Process. Mag. IEEE 1992, 9, 21–67. [Google Scholar] [CrossRef]

- O’Toole, J.; Mesbah, M.; Boashash, B. A New Discrete Analytic Signal for Reducing Aliasing in the Discrete Wigner-Ville Distribution. IEEE Trans. Signal Process. 2008, 56, 5427–5434. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Song, W.; Wu, F.; Zio, E.; Zhang, Y. Spectral Kurtosis of Choi–Williams Distribution and Hidden Markov Model for Gearbox Fault Diagnosis. Symmetry 2020, 12, 285. [Google Scholar] [CrossRef] [Green Version]

- Mallat, S. A Wavelet Tour of Signal Processing, 2nd ed.; Academic Press: San Diego, CA, USA, 1999; p. 636. [Google Scholar]

- Zhang, Z.; Ren, Z.; Huang, W. A novel detection method of motor broken rotor bars based on wavelet ridge. IEEE Trans. Energy Convers. 2003, 18, 417–423. [Google Scholar] [CrossRef]

- Puche-Panadero, R.; Pineda-Sanchez, M.; Riera-Guasp, M.; Roger-Folch, J.; Antonino-Daviu, J.; Perez-Cruz, J. Diagnosis of rotor bar breakages based on the Hilbert Transform of the current during the startup transient. In Proceedings of the 2009 IEEE International Electric Machines and Drives Conference, Miami, FL, USA, 3–6 May 2009; pp. 1434–1440. [Google Scholar]

- Puche-Panadero, R.; Pineda-Sanchez, M.; Riera-Guasp, M.; Roger-Folch, J.; Hurtado-Perez, E.; Perez-Cruz, J. Improved Resolution of the MCSA Method Via Hilbert Transform, Enabling the Diagnosis of Rotor Asymmetries at Very Low Slip. IEEE Trans. Energy Convers. 2009, 24, 52–59. [Google Scholar] [CrossRef]

| Machine | Fault Tested | HT | WVD | CWT |

|---|---|---|---|---|

| Faulty | Broken bar | 0.97804 | 0.97804 | 0.9839 |

| (simulated) | (Figure 3) | (Figure 5) | (Figure 7) | |

| Broken bar | 0.973 | 0.973 | 0.984 | |

| (Figure 11 top) | (Figure 11 middle) | (Figure 11 bottom) | ||

| Eccentricity | 0.912 | 0.919 | 0.926 | |

| (Figure 19 top) | (Figure 19 middle) | (Figure 19 bottom) | ||

| Outer race | 0.909 | 0.909 | 0.998 | |

| (Figure 23 top) | (Figure 23 middle) | (Figure 23 bottom) | ||

| Healthy | Broken bar | 0.007 | 0.007 | 0 |

| (Figure 12) | ||||

| Eccentricity | 0.147 | 0.143 | 0.009 | |

| Outer race | 0.050 | 0.046 | 0.097 |

| Method | Time (Relative to AS) |

|---|---|

| Analytic signal (AS) | 1 |

| Wigner–Ville Distribution (WVD) | 18.4 |

| Reassigned Scalogram | 4023 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puche-Panadero, R.; Martinez-Roman, J.; Sapena-Bano, A.; Burriel-Valencia, J.; Riera-Guasp, M. Fault Diagnosis in the Slip–Frequency Plane of Induction Machines Working in Time-Varying Conditions. Sensors 2020, 20, 3398. https://doi.org/10.3390/s20123398

Puche-Panadero R, Martinez-Roman J, Sapena-Bano A, Burriel-Valencia J, Riera-Guasp M. Fault Diagnosis in the Slip–Frequency Plane of Induction Machines Working in Time-Varying Conditions. Sensors. 2020; 20(12):3398. https://doi.org/10.3390/s20123398

Chicago/Turabian StylePuche-Panadero, Ruben, Javier Martinez-Roman, Angel Sapena-Bano, Jordi Burriel-Valencia, and Martin Riera-Guasp. 2020. "Fault Diagnosis in the Slip–Frequency Plane of Induction Machines Working in Time-Varying Conditions" Sensors 20, no. 12: 3398. https://doi.org/10.3390/s20123398

APA StylePuche-Panadero, R., Martinez-Roman, J., Sapena-Bano, A., Burriel-Valencia, J., & Riera-Guasp, M. (2020). Fault Diagnosis in the Slip–Frequency Plane of Induction Machines Working in Time-Varying Conditions. Sensors, 20(12), 3398. https://doi.org/10.3390/s20123398