Chladni Figures in Modal Analysis of a Double-Panel Structure

Abstract

1. Introduction

2. Materials and Methods

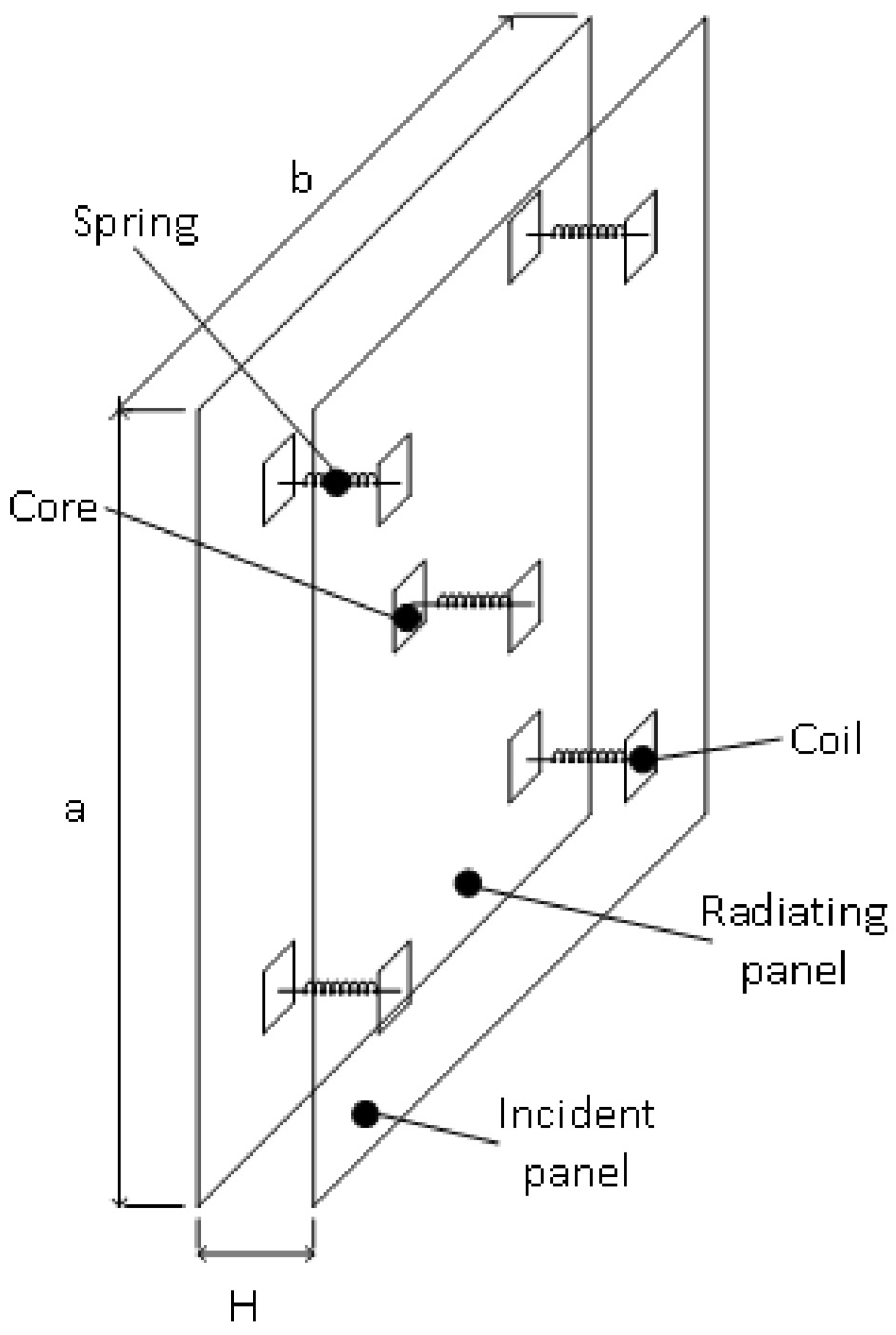

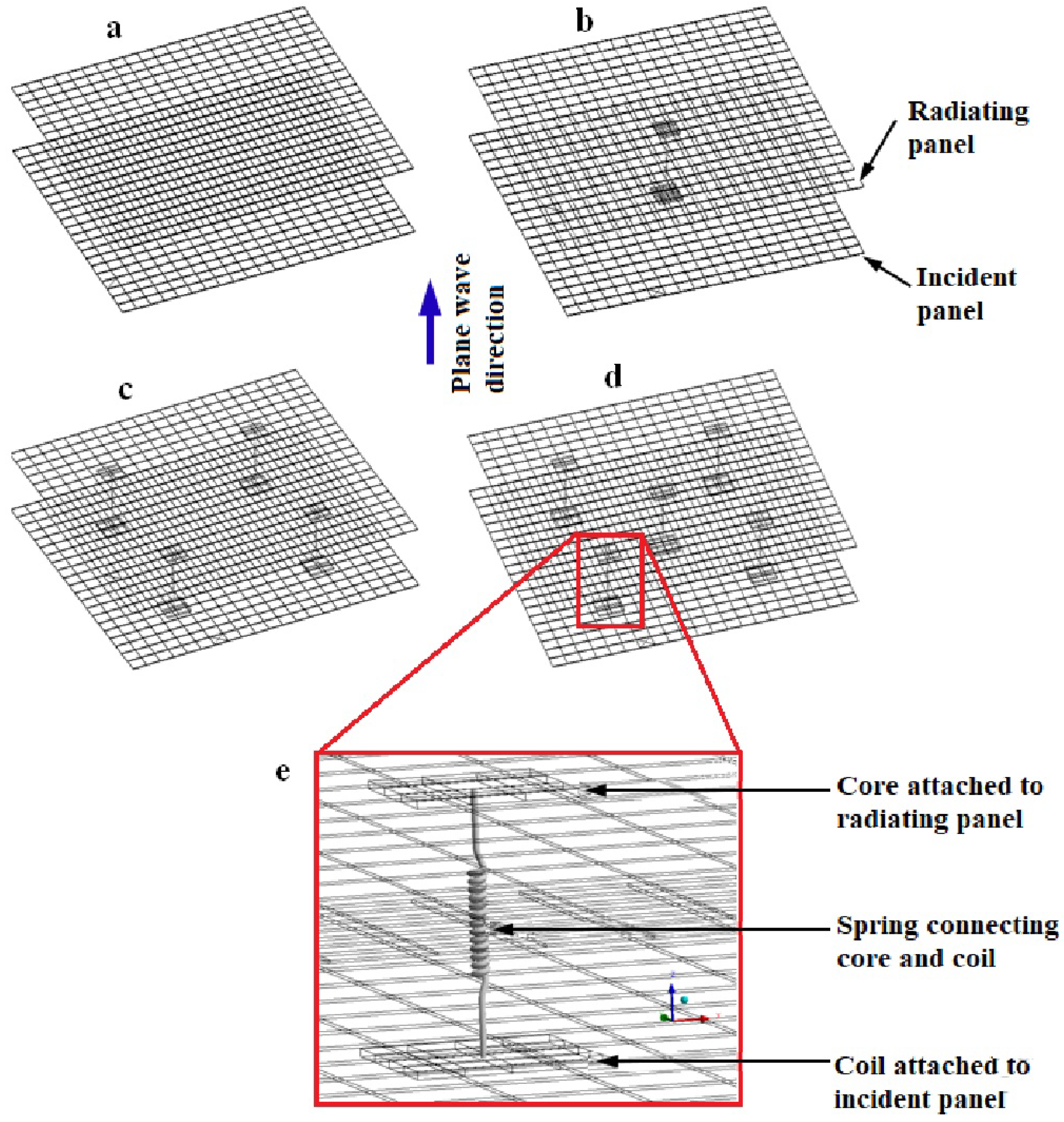

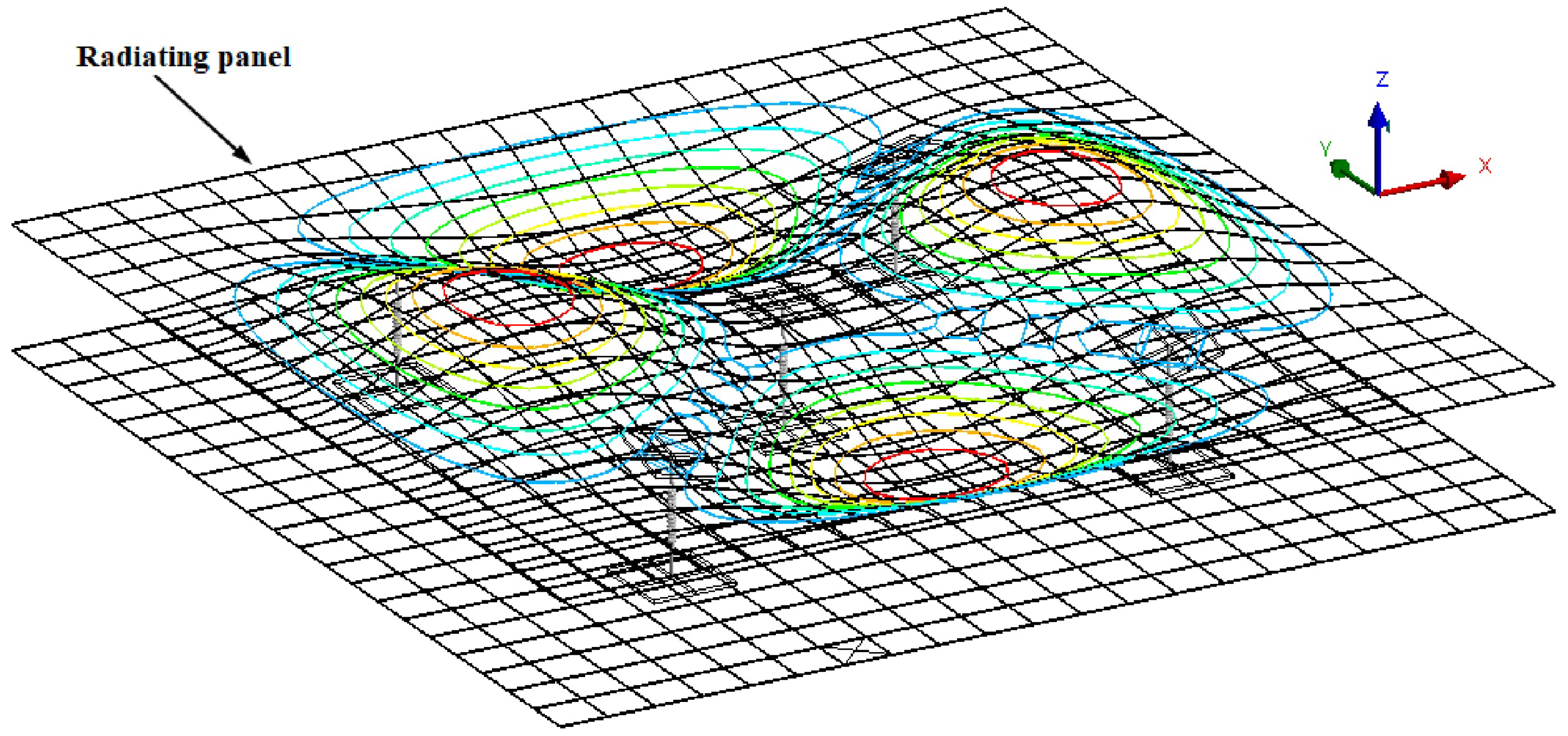

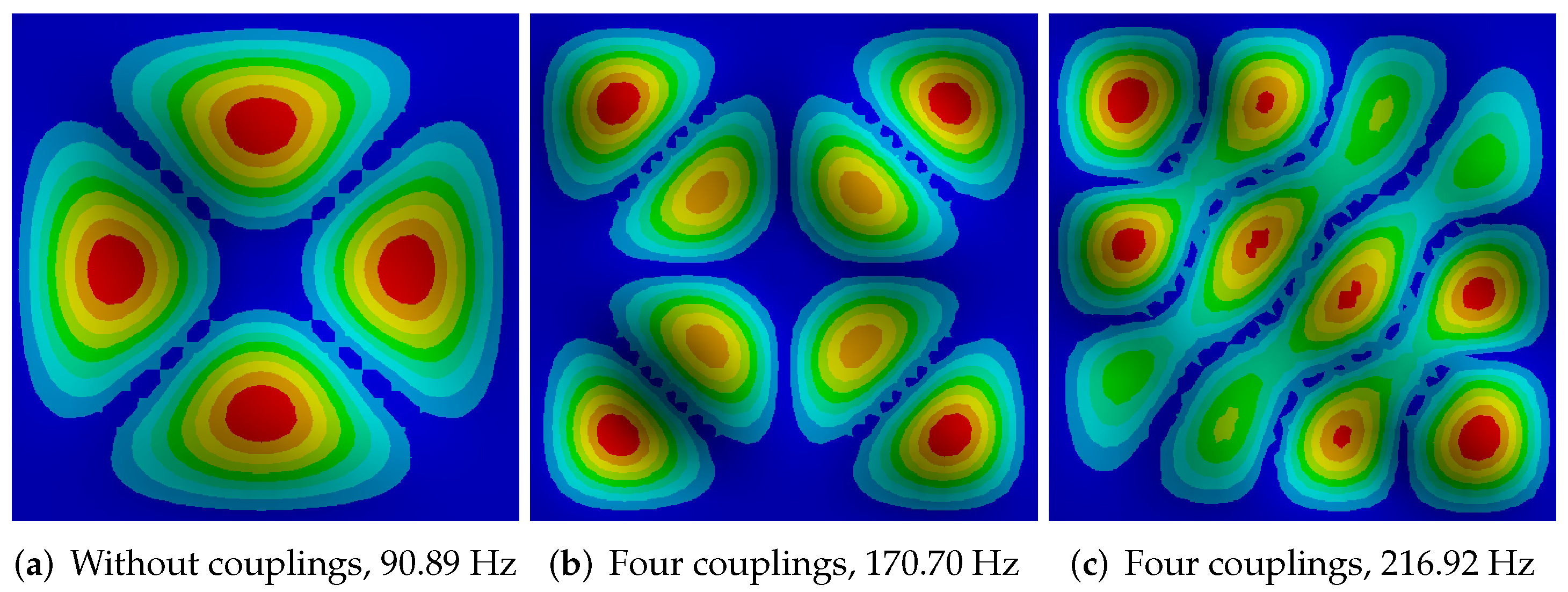

2.1. Numerical Modeling of the Double-Panel Structure

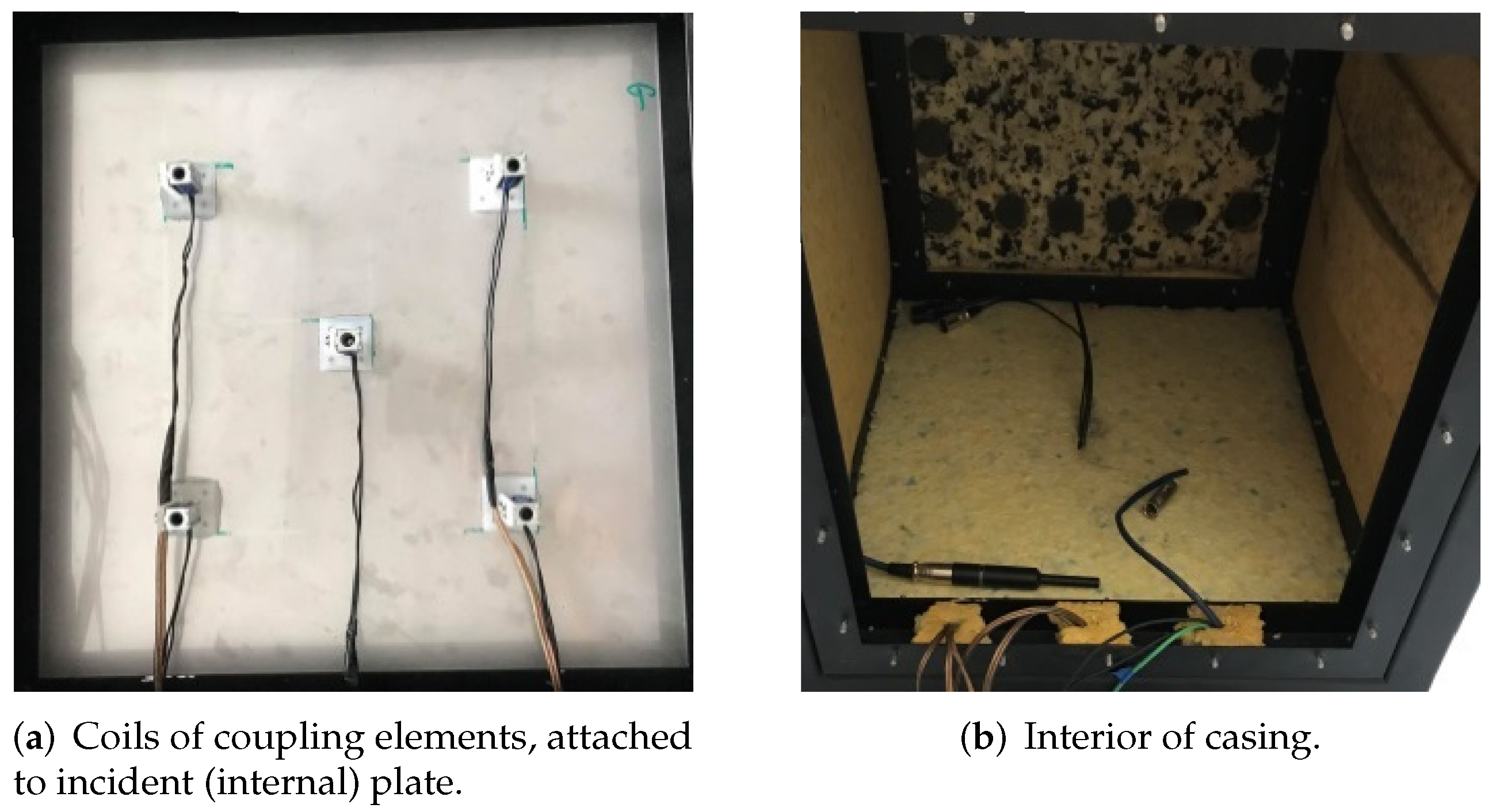

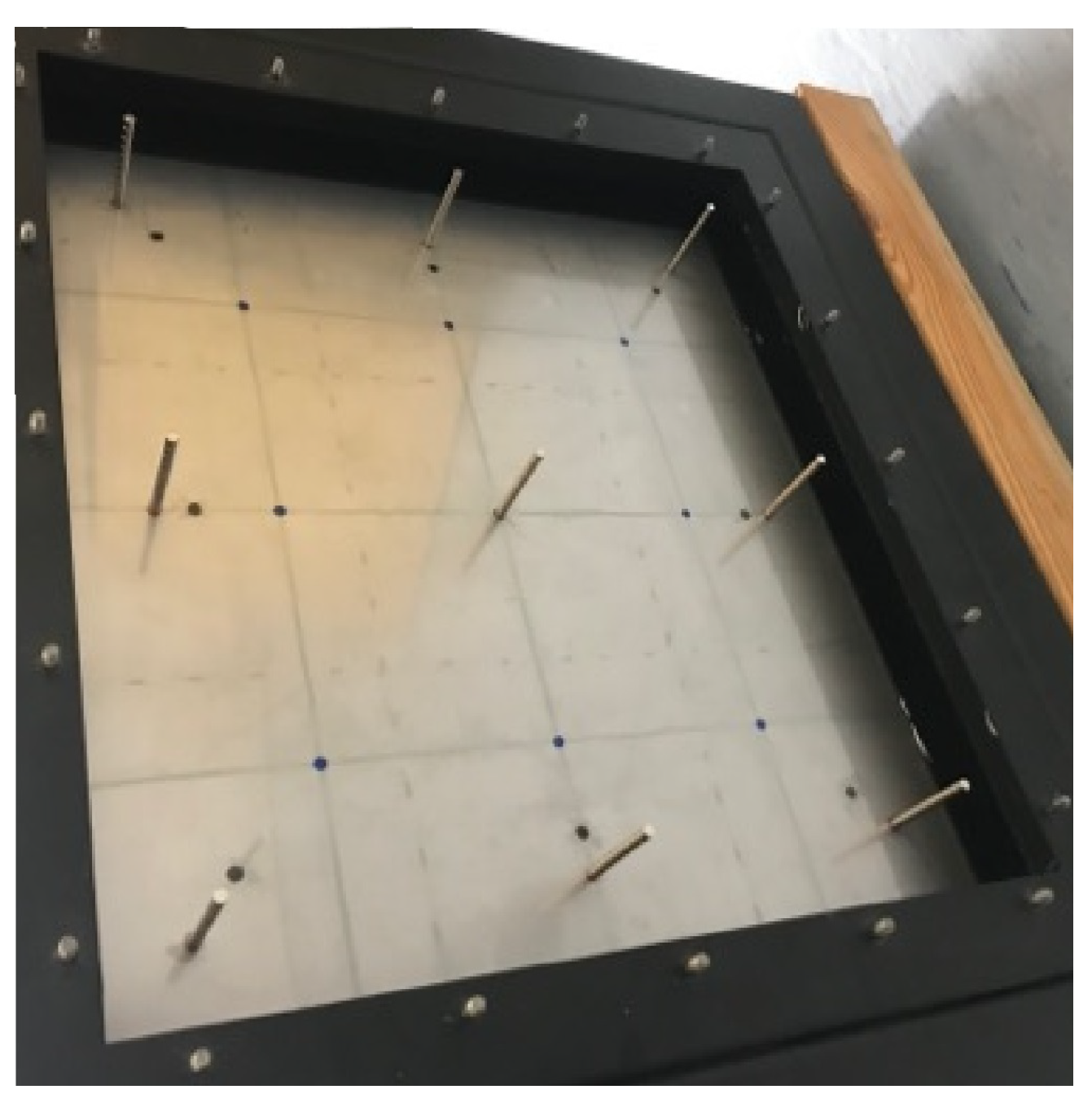

2.2. System Description

3. Results and Discussion

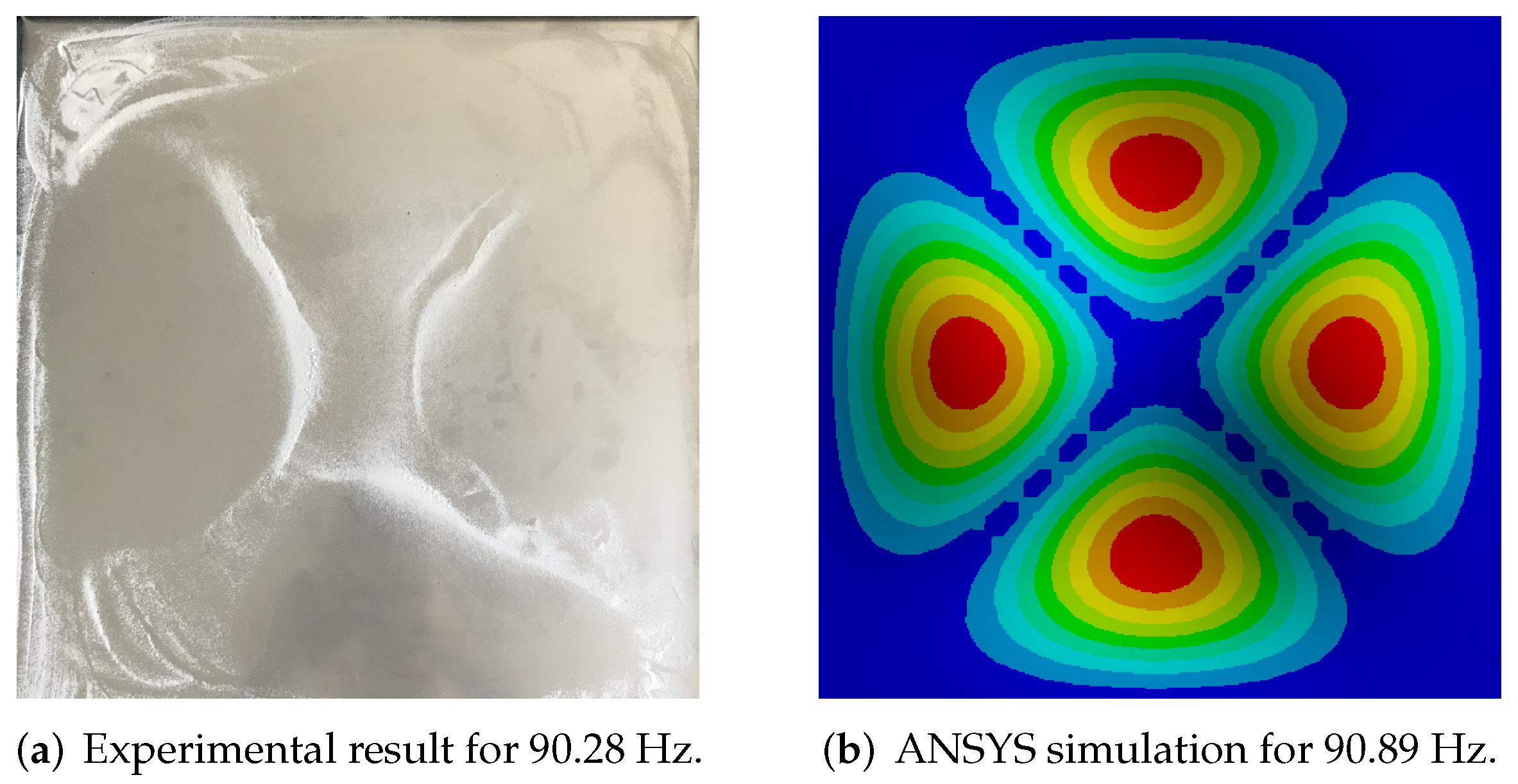

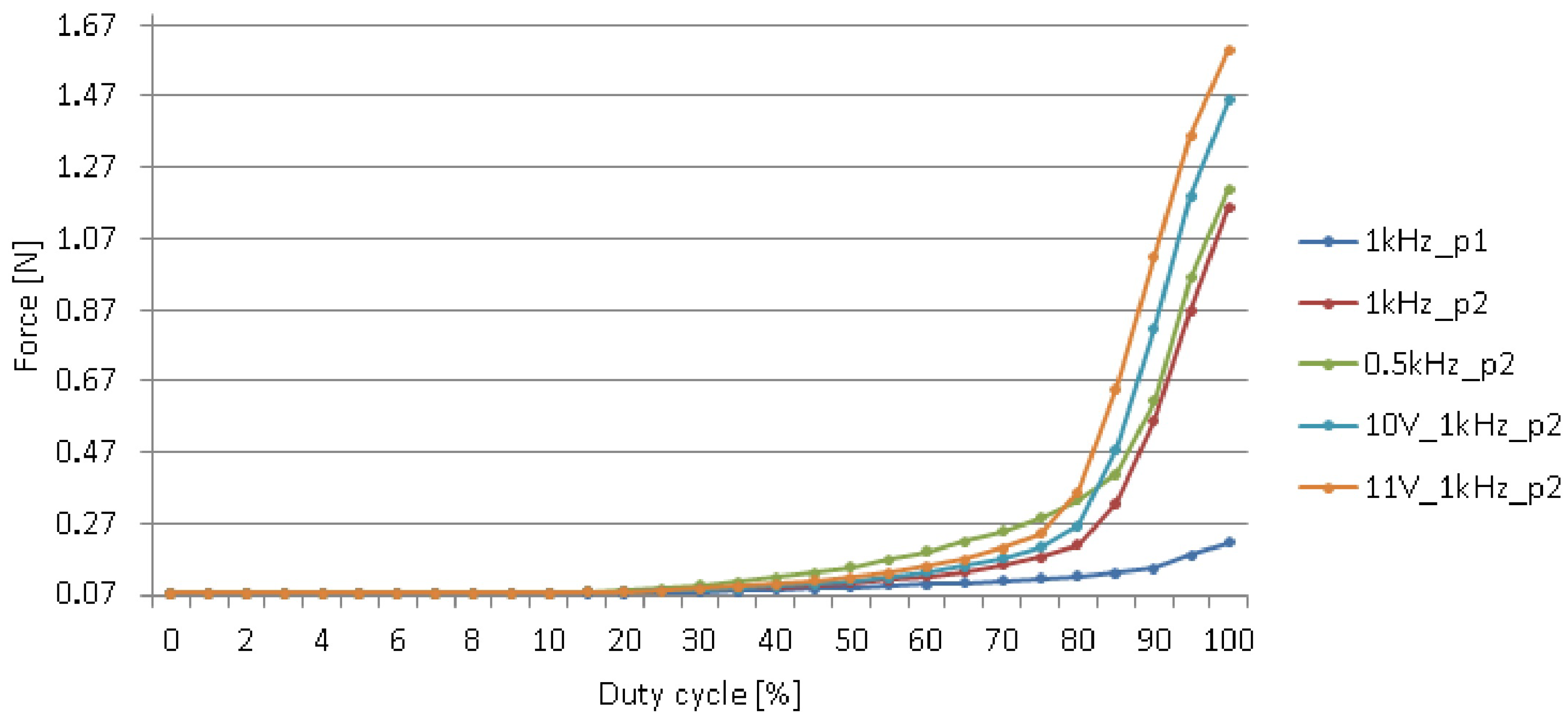

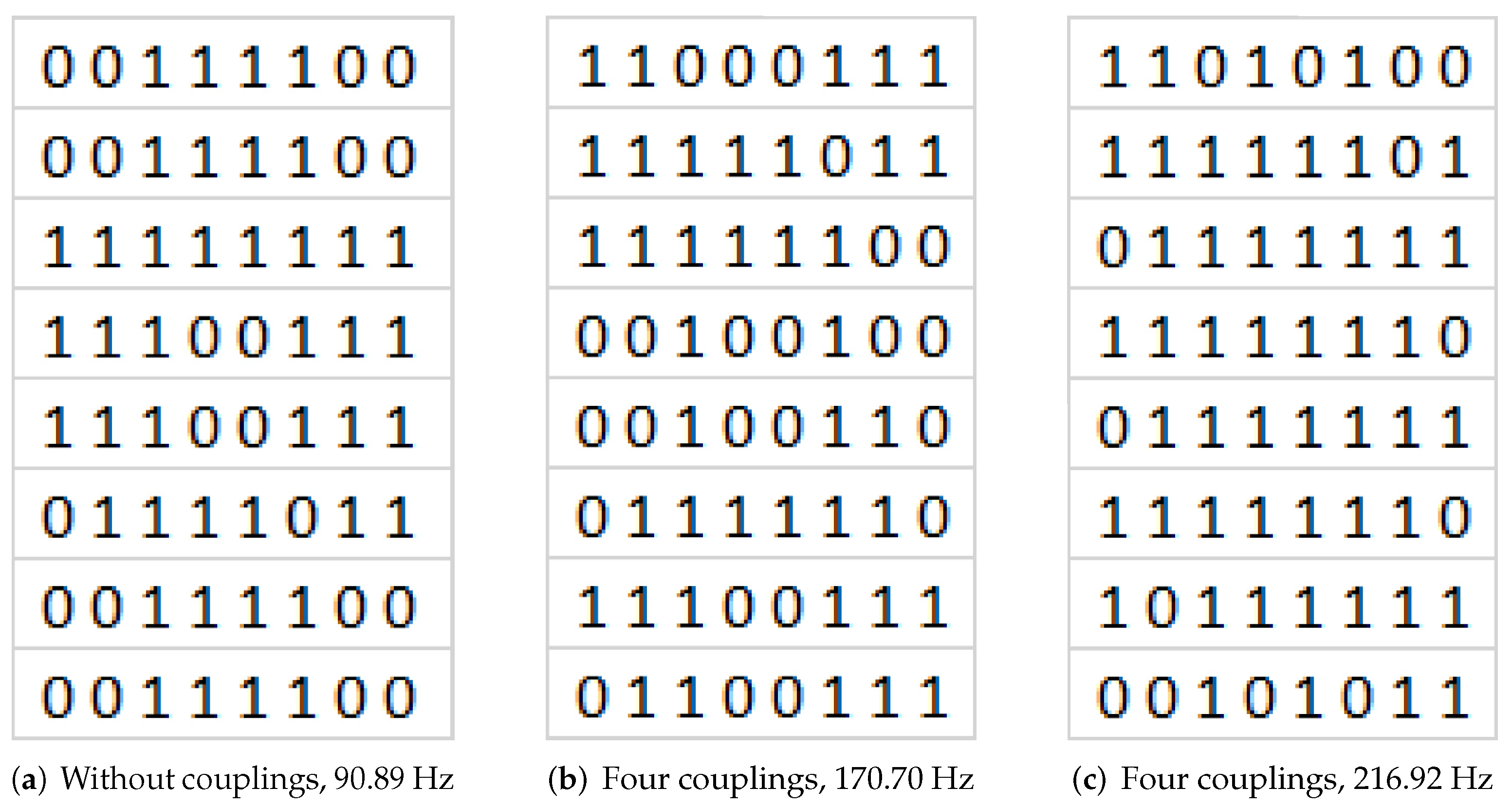

3.1. Preliminary Experiments

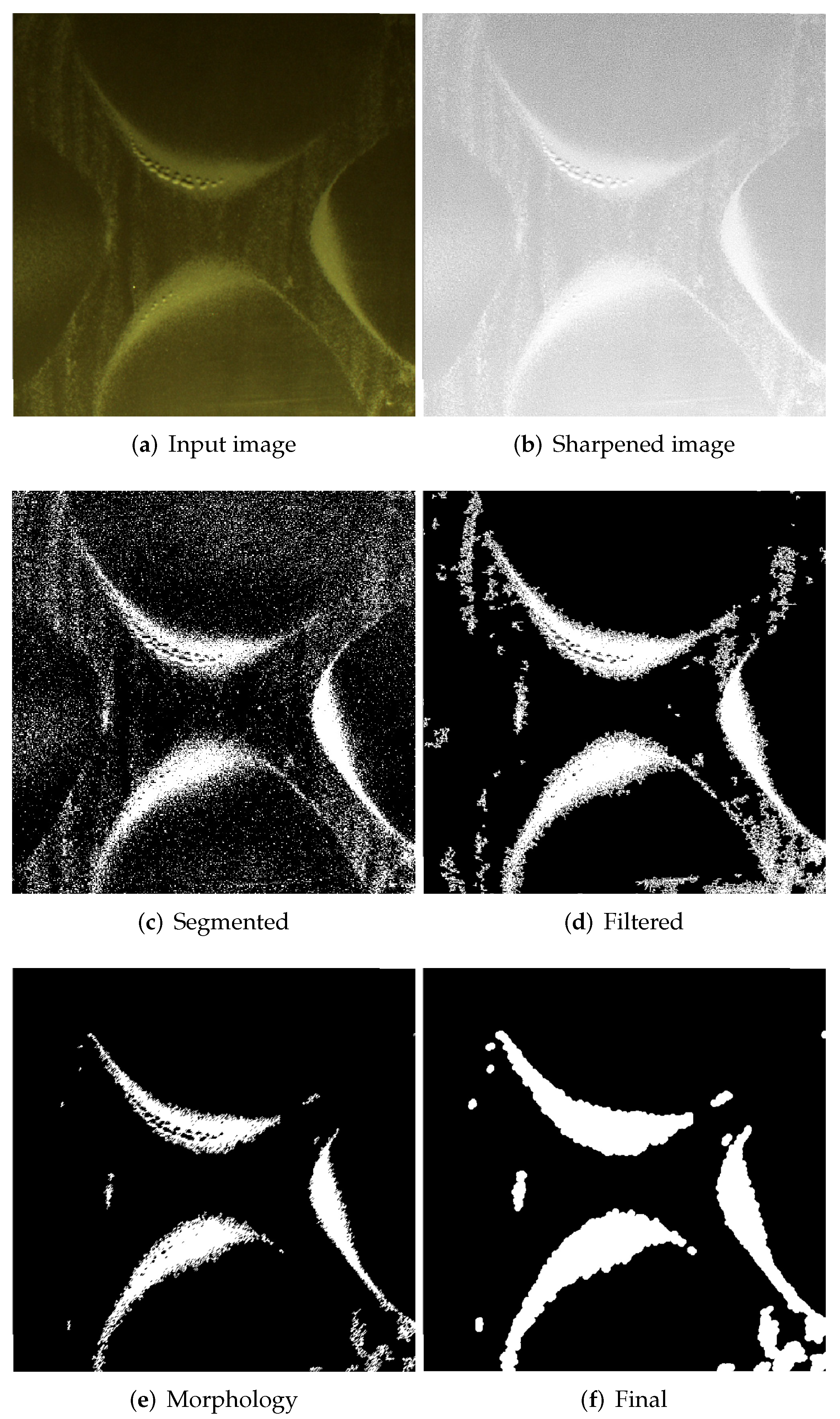

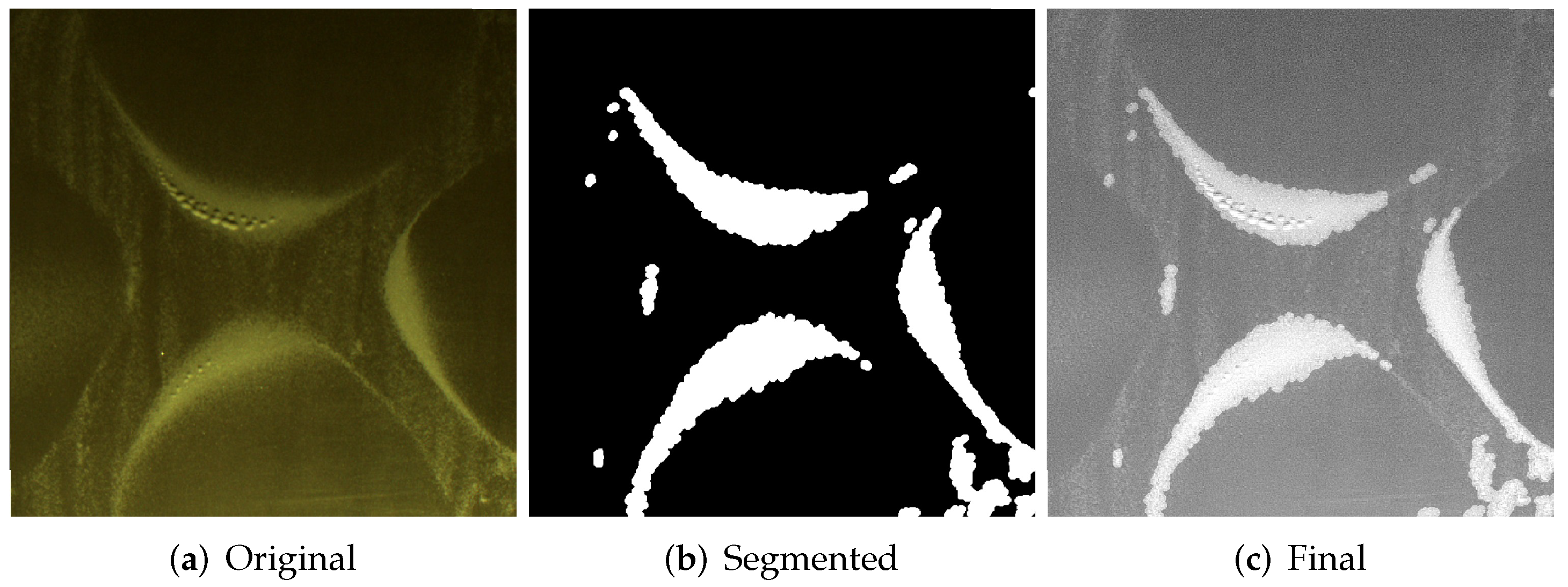

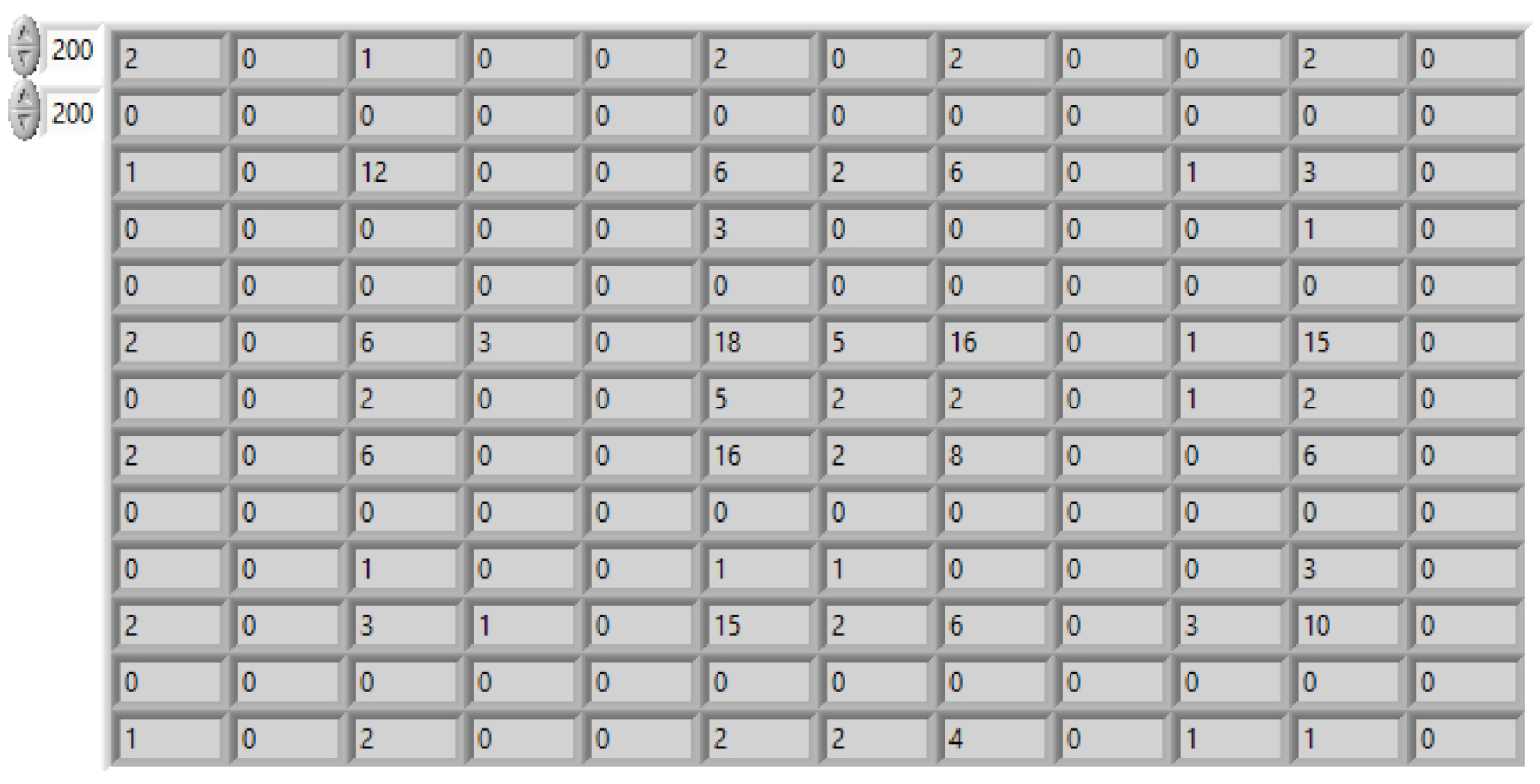

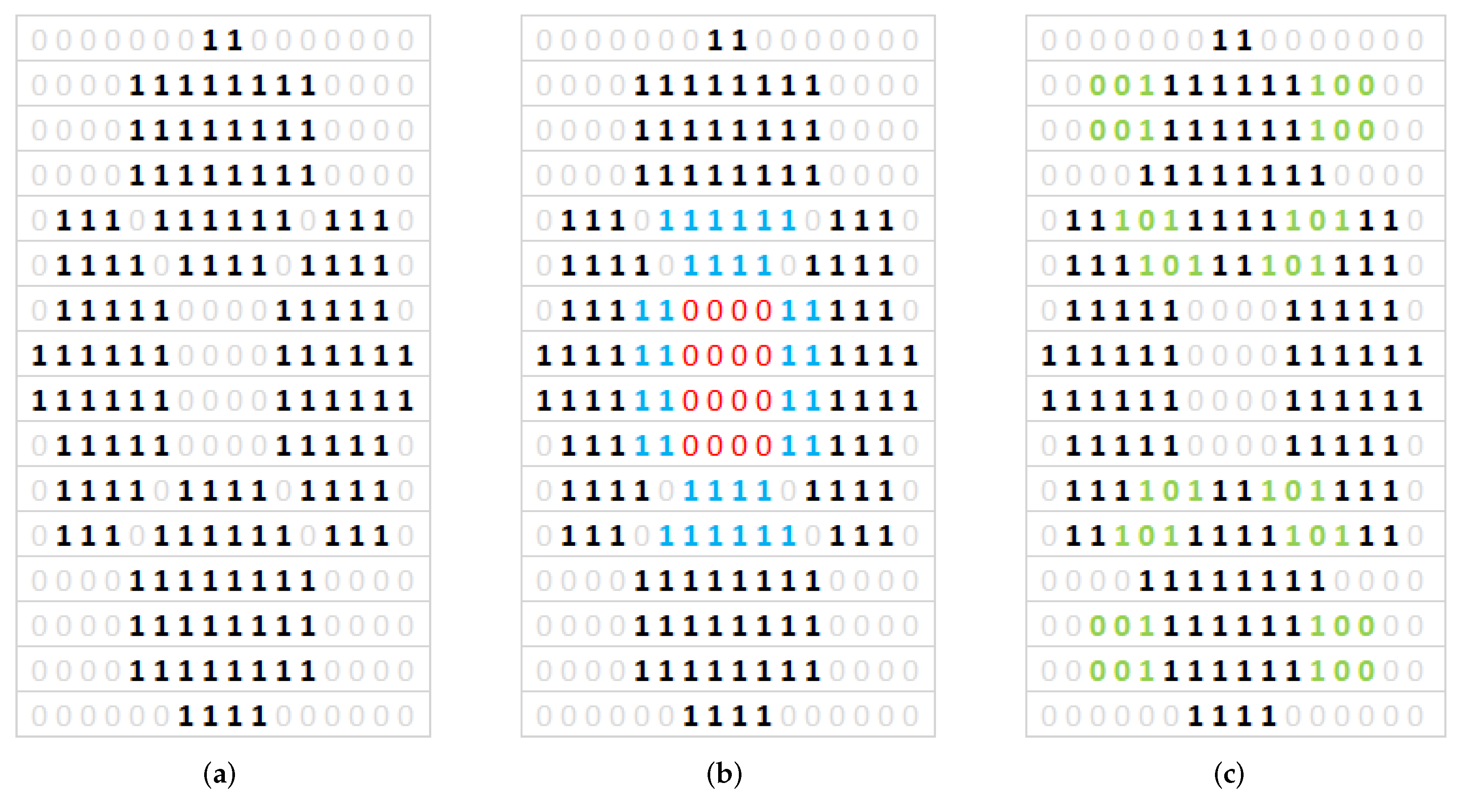

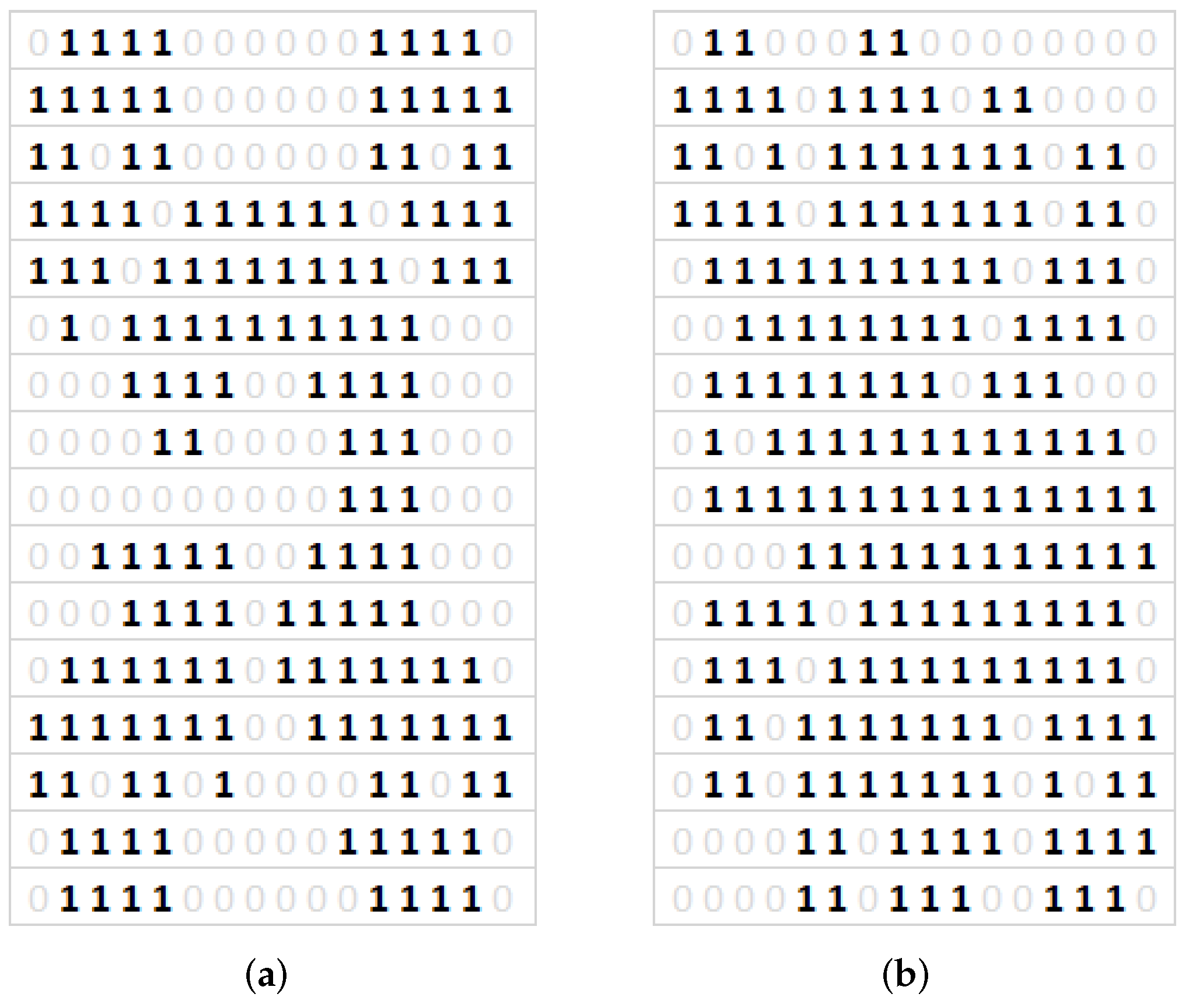

3.2. Image Based Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lai, A.; Huang, C. Effect of Occupational Exposure to Noise on the Health of Factory Workers. Procedia Manuf. 2019, 39, 942–946. [Google Scholar] [CrossRef]

- Korchut, A.; Korchut, W.; Kowalska-Koczwara, A.; Romanska-Zapala, A.; Stypula, K. The relationship between psychomotor efficiency and selected personality traits of people exposed to noise and vibration stimuli. Procedia Eng. 2017, 199, 200–205. [Google Scholar] [CrossRef]

- Krauze, P.; Kasprzyk, J.; Rzepecki, J. Experimental attenuation and evaluation of whole body vibration for an off-road vehicle with magnetorheological dampers. J. Low Freq. Noise Vib. Act. Control. 2019, 38, 852–870. [Google Scholar] [CrossRef]

- Mao, Q.; Pietrzko, S. Control of Noise and Structural Vibration: A MATLAB®-Based Approach; Springer: London, UK, 2013; p. 1. [Google Scholar]

- Kuo, S.M.; Morgan, D. Active Noise Control Systems: Algorithms and DSP Implementations; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1996; pp. 1–3. [Google Scholar]

- Kim, Y.H. Sound Propagation: An Impedance Based Approach; John Wiley & Sons (Asia), Pte Ltd.: Singapore, 2010. [Google Scholar]

- Nelson, P.A.; Elliott, S.J. Active Control of Sound; Academic Press: London, UK, 1992. [Google Scholar]

- Misol, M. Experiments on noise reduction in aircraft with active sidewall panels. In Proceedings of the 25th International Congress on Sound and Vibration, Hiroshima, Japan, 8–12 July 2018; pp. 1–7. [Google Scholar]

- Sibielak, M.; Raczka, W.; Konieczny, J.; Kowal, J. Optimal control based on a modified quadratic performance index for systems disturbed by sinusoidal signals. Mech. Syst. Signal Process. 2015, 64–65, 498–519. [Google Scholar] [CrossRef]

- Fahy, F.J.; Gardonio, P. Sound and Structural Vibration: Radiation, Transmission and Response; Academic Press: Cambridge, MA, USA, 2007; pp. 521–523. [Google Scholar]

- Alimohammadi, I.; Ebrahimi, H. Comparison Between Effects of Low and High Frequency Noise on Mental Performance. Appl. Acoust. 2017, 126, 131–135. [Google Scholar] [CrossRef]

- Chraponska, A.; Wrona, S.; Rzepecki, J.; Mazur, K.; Pawelczyk, M. Active structural acoustic control of an active casing placed in a corner. Appl. Sci. 2019, 9, 1059. [Google Scholar] [CrossRef]

- Rzepecki, J.; Chraponska, A.; Mazur, K.; Wrona, S.; Pawelczyk, M. Semi-active reduction of device casing vibration using a set of piezoelectric elements. In Proceedings of the 20th International Carpathian Control Conference (ICCC), Krakow-Wieliczka, Poland, 26–29 May 2019; pp. 1–5. [Google Scholar]

- Chraponska, A.; Rzepecki, J.; Mazur, K.; Wrona, S.; Pawelczyk, M. Influence of Double-Panel Structure Modification on Vibroacoustical Properties of a Rigid Device Casing. Arch. Acoust. 2020, 45, 119–127. [Google Scholar]

- Wrona, S.; Pawelczyk, M. Feedforward control of double-panel casing for active reduction of device noise. J. Low Freq. Noise Vib. Act. Control. 2019, 38, 787–797. [Google Scholar] [CrossRef]

- Gorman, D.J. Free Vibration Analysis of Rectangular Plates; Elsevier: New York, NY, USA, 1982; p. 14. [Google Scholar]

- Misol, M.; Haase, T.; Monner, H.P.; Sinapius, M. Causal feedforward control of a stochastically excited fuselage structure with active sidewall panel. J. Acoust. Soc. Am. 2014, 136, 1610–1618. [Google Scholar] [CrossRef]

- Sgard, F.C.; Atalla, N.; Nicolas, J. A numerical model for the low frequency diffuse field sound transmission loss of double-wall sound barriers with elastic porous linings. J. Acoust. Soc. Am. 2000, 108, 2865–2872. [Google Scholar] [CrossRef]

- Liu, G.; Liu, J.; Wang, J.; Pan, J.; Mao, H. A numerical method for double-plated structure completely filled with liquid subjected to underwater explosion. Mar. Struct. 2017, 53, 164–180. [Google Scholar] [CrossRef]

- London, A. Transmission of Reverberant Sound through Double Walls. J. Acoust. Soc. Am. 1949, 22, 270. [Google Scholar] [CrossRef]

- Beltman, W.M. Viscothermal wave propagation including acousto-elastic interaction, part I: Theory. J. Sound Vib. 1999, 227, 555–586. [Google Scholar] [CrossRef]

- Assaf, R.; Elhachem, E. Noise and vibration pollution: Analytical analysis of double-leaf partition. Energy Procedia 2015, 74, 1265–1273. [Google Scholar] [CrossRef]

- Li, X.; Yu, K.; Zha, R. Vibro-acoustic response of a clamped rectangular sandwich panel in thermal environment. Appl. Acoust. 2018, 132, 82–96. [Google Scholar] [CrossRef]

- Fu, T.; Chen, Z.; Yu, H.; Wang, Z.; Liu, X. An analytical study of sound transmission through stiffened double laminated composite sandwich plates. Aerosp. Sci. Technol. 2018, 82–83, 92–104. [Google Scholar] [CrossRef]

- Pan, J.; Bao, C. Analytical study of different approaches for active control of sound transmission through double walls. J. Acoust. Soc. Am. 1998, 103, 1916. [Google Scholar] [CrossRef]

- Isaac, C.W.; Pawelczyk, M.; Wrona, S. Comparative Study of Sound Transmission Losses of Sandwich Composite Double Panel Walls. Appl. Sci. 2020, 10, 1543. [Google Scholar] [CrossRef]

- Guo, Z.; Pan, J.; Sheng, M. Vibro-Acoustic Performance of a Sandwich Plate with Periodically Inserted Resonators. Appl. Sci. 2019, 9, 3651. [Google Scholar] [CrossRef]

- Akrout, A.; Karra, C.; Hammami, L.; Haddar, M. Viscothermal fluid effects on vibro-acoustic behaviour of double elastic panels. Int. J. Mech. Sci. 2008, 50, 764–773. [Google Scholar] [CrossRef]

- Rothberg, S.J.; Allen, M.S.; Castellini, P.; Di Maio, D.; Dirckx, J.J.J.; Ewins, D.J.; Halkon, B.J.; Muyshondt, P.; Paone, N.; Ryan, T.; et al. An international review of laser Doppler vibrometry: Making light work of vibration measurement. Opt. Lasers Eng. 2017, 99, 11–22. [Google Scholar] [CrossRef]

- Lopez-Alba, E.; Sebastian, C.M.; Santos Silva, A.C.; Patterson, E.A. Experimental study of mode shifting in an asymmetrically heated rectangular plate. J. Sound Vib. 2019, 439, 241–250. [Google Scholar] [CrossRef]

- Chladni, E.F.F.; Beyer, R.T. Treatise on Acoustics, The First Comprehensive English Translation of E.F.F. Chladni’s Traité d’Acoustique; Springer International Publishing: Cham, Switzerland, 2015; pp. 73–76. [Google Scholar]

- Grabec, I. Vibration driven random walk in a Chladni experiment. Phys. Lett. 2017, 381, 59–64. [Google Scholar] [CrossRef]

- Igea, F.; Cicirello, A. Part-to-part variability assessment of material properties for flat thin orthotropic rectangular panels using Chladni patterns. Mech. Syst. Signal Process. 2020, 139, 106559. [Google Scholar] [CrossRef]

- Escaler, X.; De La Torre, O. Axisymmetric vibrations of a circular Chladni plate in air and fully submerged in water. J. Fluids Struct. 2018, 82, 432–445. [Google Scholar] [CrossRef]

- Latifi, K.; Wijaya, H.; Zhou, Q. Motion of Heavy Particles on a Submerged Chladni Plate. Phys. Rev. Lett. 2019, 122, 184301. [Google Scholar] [CrossRef] [PubMed]

- Akl, J.; Alladkani, F.; Dumond, P. Comparing and optimizing analytical, numerical and experimental vibration models for a simply-supported ribbed plate. Structures 2020, 23, 690–701. [Google Scholar] [CrossRef]

- Luo, Y.; Feng, R.; Li, X.; Liu, D. A simple approach to determine the mode shapes of Chladni plates based on the optical lever method. Eur. J. Phys. 2019, 40, 065001. [Google Scholar] [CrossRef]

- Dunaj, P.; Bereczyński, S.; Chodźko, M.; Niesterowicz, B. Finite Element Modeling of the Dynamic Properties of Composite Steel-Polymer Concrete Beams. Materials 2020, 13, 1630. [Google Scholar] [CrossRef]

- Xin, F.X.; Lu, T.J. Analytical and experimental investigation on transmission loss of clamped double panels: Implication of boundary effects. J. Acoust. Soc. Am. 2009, 125, 1506–1517. [Google Scholar] [CrossRef]

- Rzepecki, J.; Chraponska, A.; Mazur, K.; Isaac, C.W.; Wrona, S.; Pawelczyk, M. Analysis of noise emission of a device enclosed in a rigid casing with modified double-panel wall. In Proceedings of the Annual Congress of the International Institute of Acoustics and Vibration (IIAV), Prague, Czech Republic, 12–16 July 2020. [Google Scholar]

- Zhou, Q.; Sariola, V.; Latifi, K.; Liimatainen, V. Controlling the motion of multiple objects on a Chladni plate. Nat. Commun. 2016, 7, 12764. [Google Scholar] [CrossRef] [PubMed]

- Huňady, R.; Hagara, M.; Trebuňa, F. The measurement of standing wave patterns by using high-speed digital image correlation. Am. J. Mech. Eng. 2014, 2, 247–251. [Google Scholar] [CrossRef]

- Ooi, C.H.; Kong, N.S.P.; Ibrahim, H. Bi-histogram equalization with a plateau limit for digital image enhancement. IEEE Trans. Consumer Electron. 2009, 55, 2072–2080. [Google Scholar] [CrossRef]

- Singh, K.; Kapoor, R. Image enhancement using exposure based sub image histogram equalization. Pattern Recogn. Lett. 2014, 36, 10–14. [Google Scholar] [CrossRef]

- Lai, Y.-R.; Tsai, P.-C.; Yao, C.-Y.; Ruan, S.-J. Improved local histogram equalization with gradient-based weighting process for edge preservation. Multimedia Tools Appl. 2017, 1585–1613. [Google Scholar] [CrossRef]

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cyber. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Niblack, W. An Introduction to Digital Image Processing; Prentice Hall: Englewood Cliffs, NJ, USA, 1986. [Google Scholar]

- Sauvola, J.; Pietikainen, M. Adaptive document image binarization. Pattern Recognit. 2000, 33, 225–236. [Google Scholar] [CrossRef]

- Haralick, R.M.; Shanmugan, K.; Dinstein, I. Textural Features for Image Classification. IEEE Trans. Syst. Man Cybern. 1973, SMC-3, 610–621. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Operating voltage | 6 V |

| Operating current | 0.3 A |

| Maximal force | 5 N |

| Maximal voltage | 12 V |

| Maximal current | 1.5 A |

| Maximal stroke | 10 mm |

| Time [s] | Temperature [C] |

|---|---|

| 0 | 22.1 |

| 5 | 25.9 |

| 10 | 29.6 |

| 15 | 32.6 |

| 20 | 35.9 |

| 25 | 39.8 |

| 30 | 41.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rzepecki, J.; Chraponska, A.; Budzan, S.; Isaac, C.W.; Mazur, K.; Pawelczyk, M. Chladni Figures in Modal Analysis of a Double-Panel Structure. Sensors 2020, 20, 4084. https://doi.org/10.3390/s20154084

Rzepecki J, Chraponska A, Budzan S, Isaac CW, Mazur K, Pawelczyk M. Chladni Figures in Modal Analysis of a Double-Panel Structure. Sensors. 2020; 20(15):4084. https://doi.org/10.3390/s20154084

Chicago/Turabian StyleRzepecki, Jaroslaw, Anna Chraponska, Sebastian Budzan, Chukwuemeke William Isaac, Krzysztof Mazur, and Marek Pawelczyk. 2020. "Chladni Figures in Modal Analysis of a Double-Panel Structure" Sensors 20, no. 15: 4084. https://doi.org/10.3390/s20154084

APA StyleRzepecki, J., Chraponska, A., Budzan, S., Isaac, C. W., Mazur, K., & Pawelczyk, M. (2020). Chladni Figures in Modal Analysis of a Double-Panel Structure. Sensors, 20(15), 4084. https://doi.org/10.3390/s20154084