Printed Strain Sensors Based on an Intermittent Conductive Pattern Filled with Resistive Ink Droplets

Abstract

1. Introduction

2. Experimental Methods

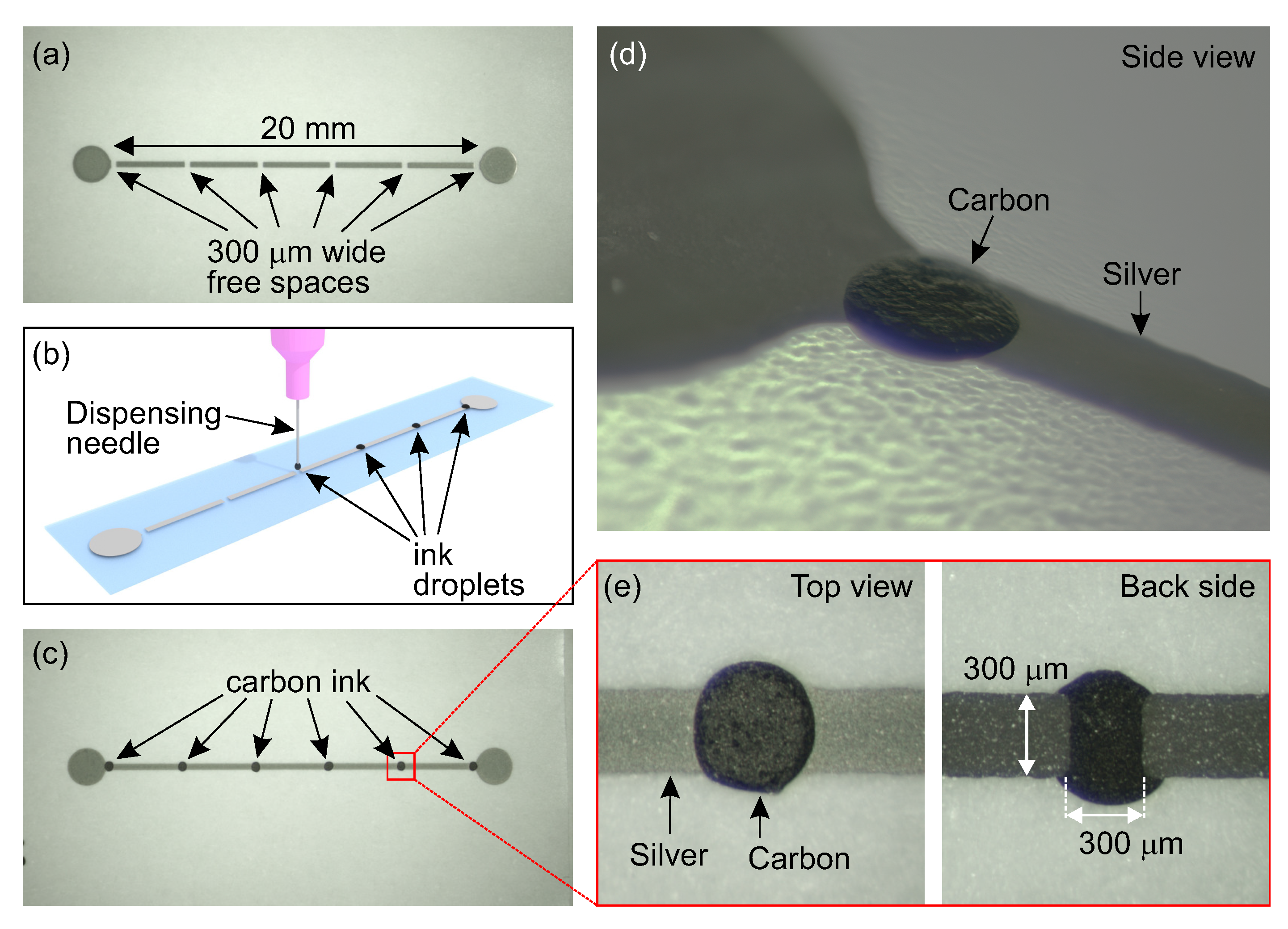

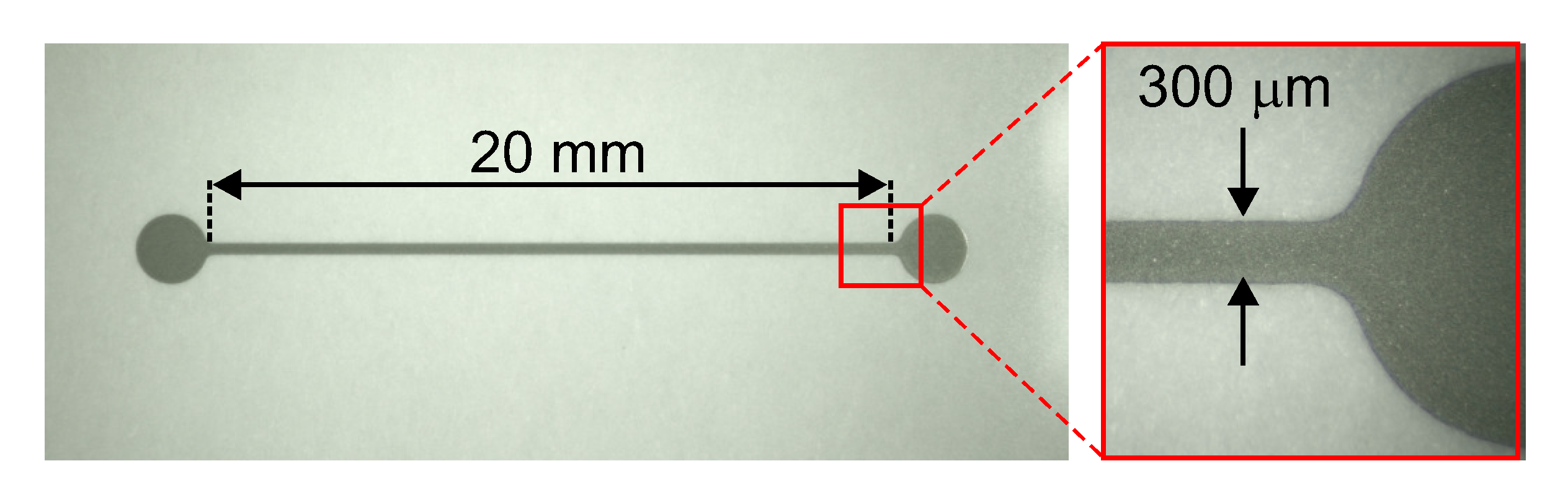

2.1. Construction of the Strain Sensor

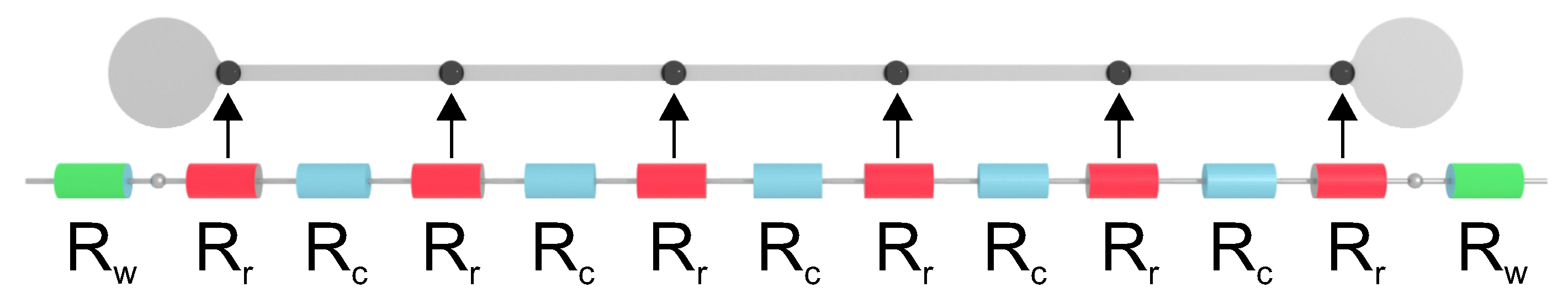

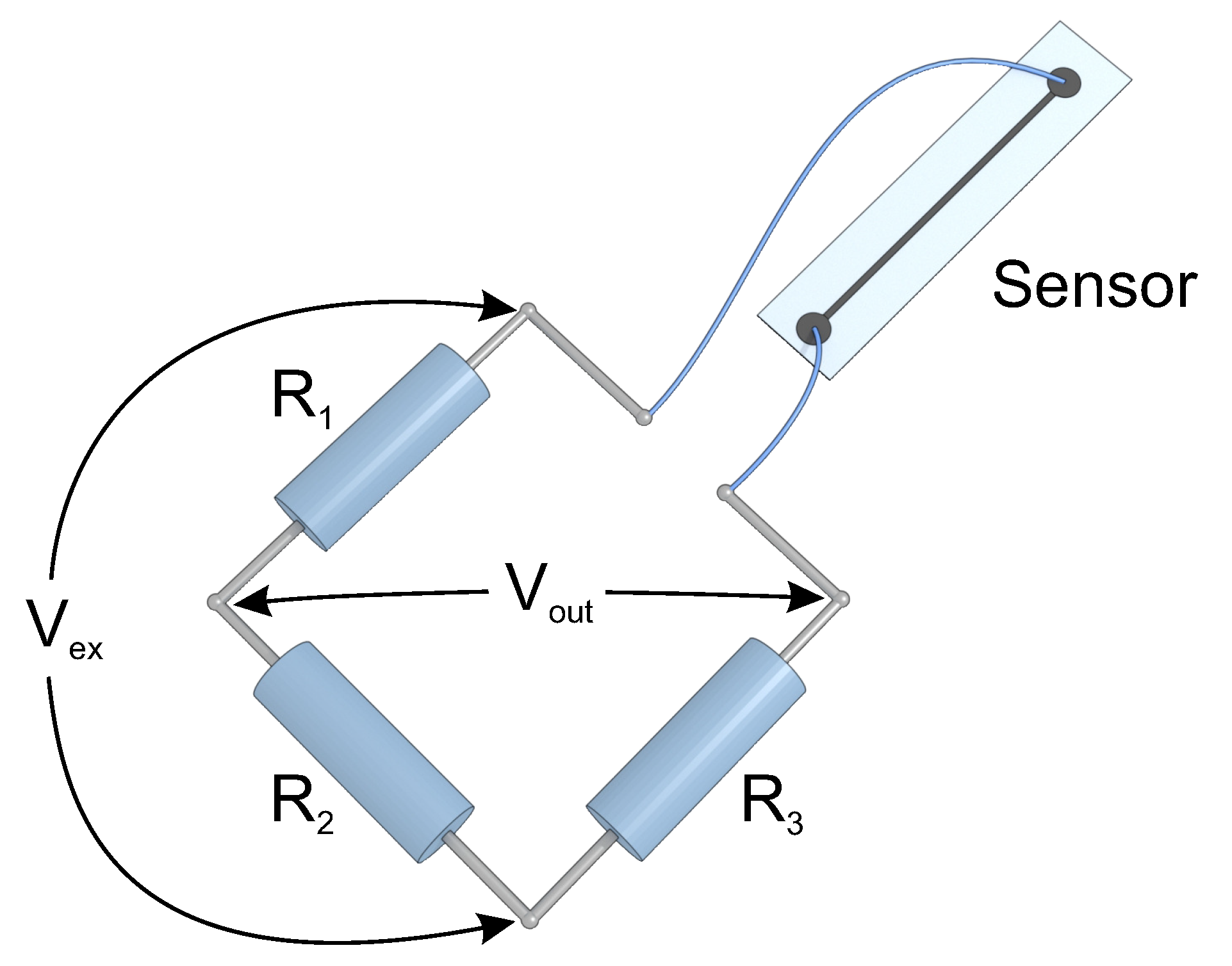

2.2. Electrical Configuration of the Sensor

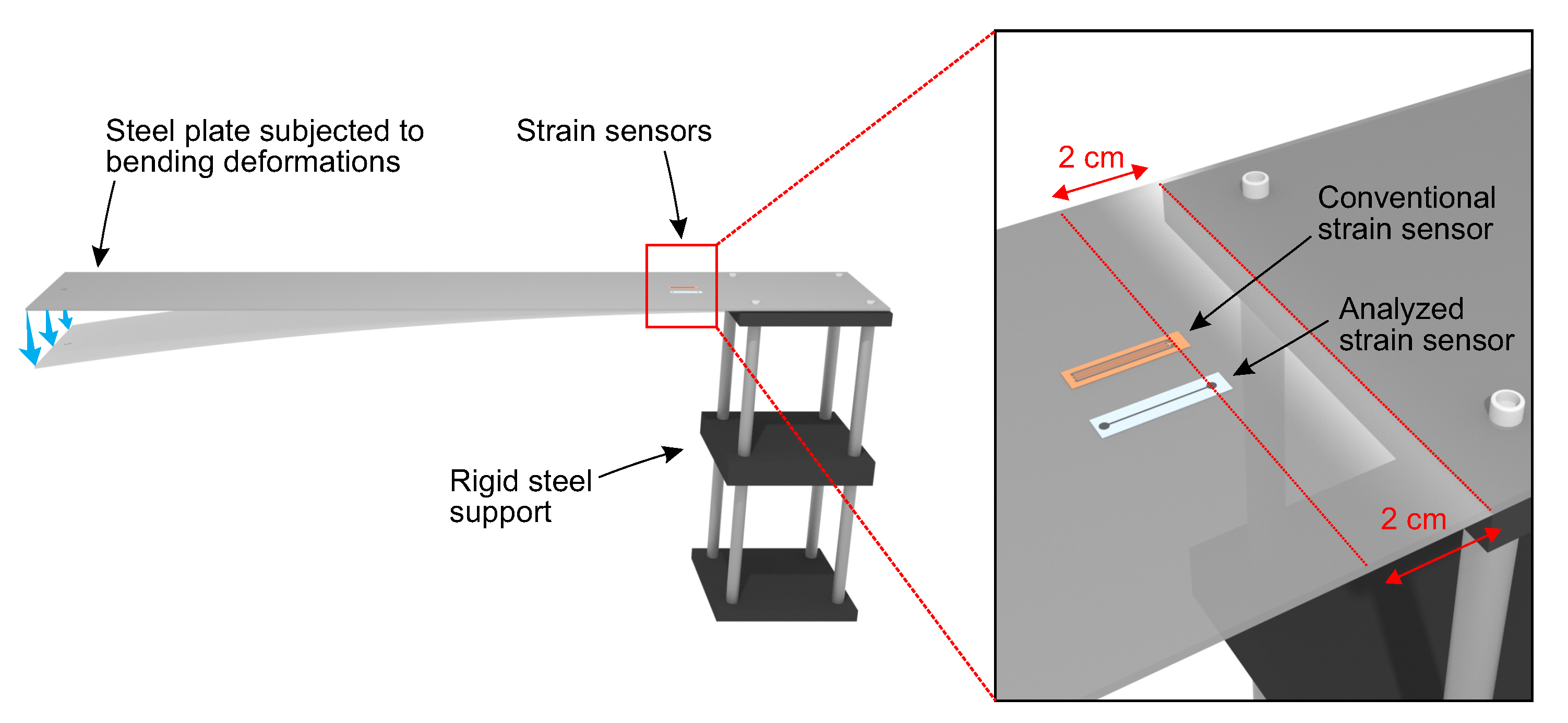

2.3. Experimental Setup and Data Acquisition System for Strain Analysis

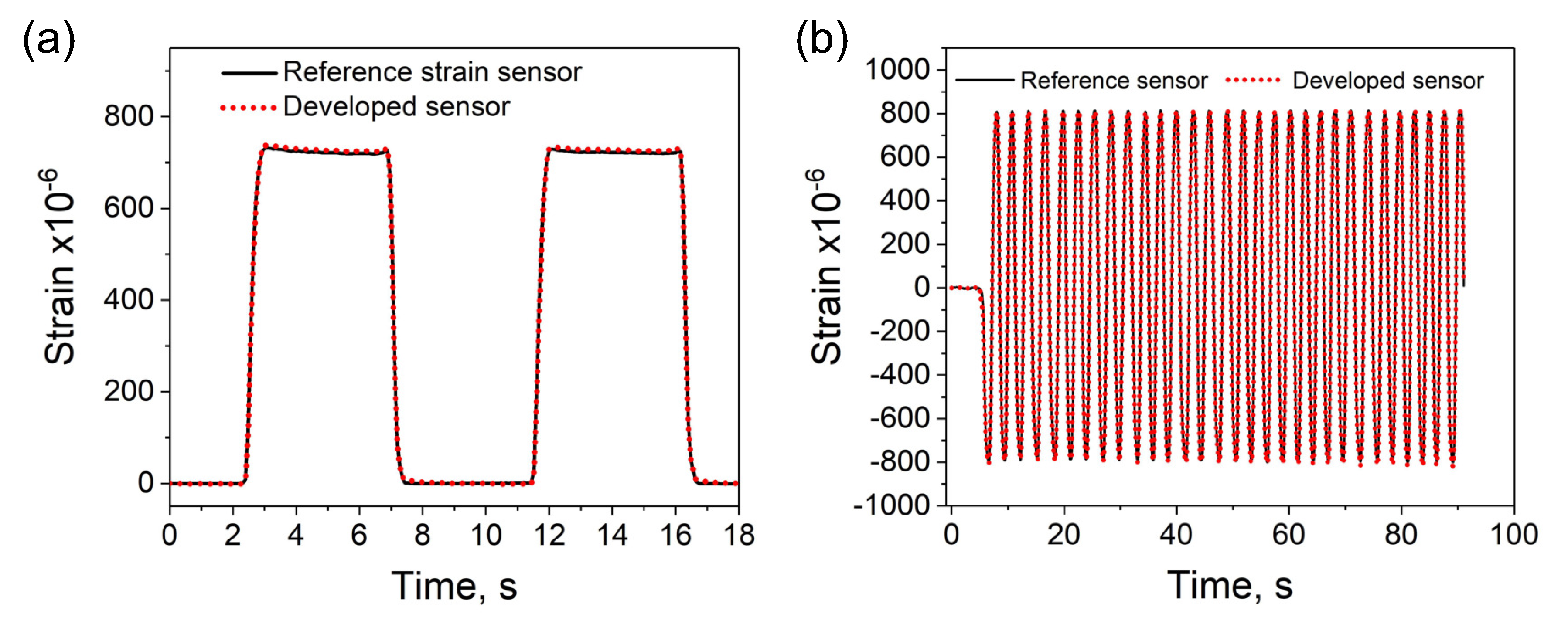

2.4. Calibration

2.5. Characterization

3. Results and Discussion

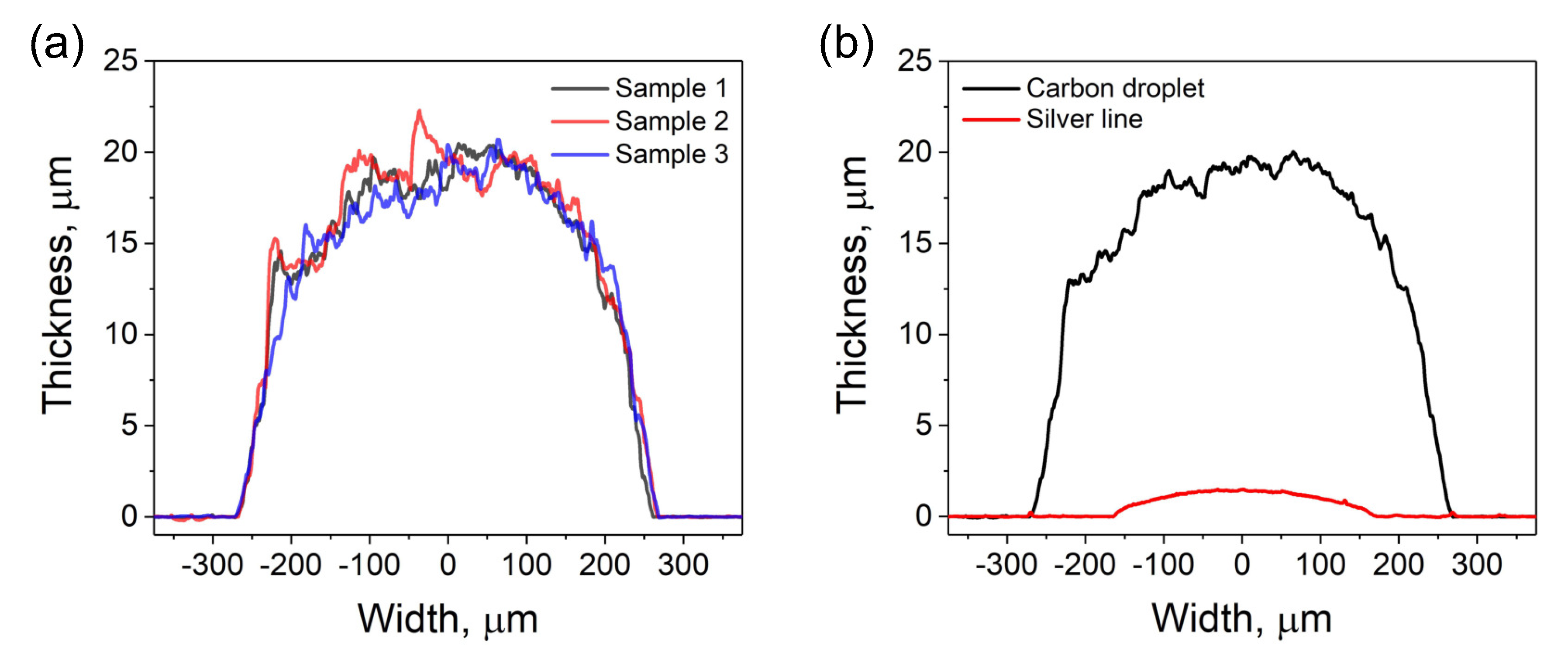

3.1. Thickness Profile Analysis

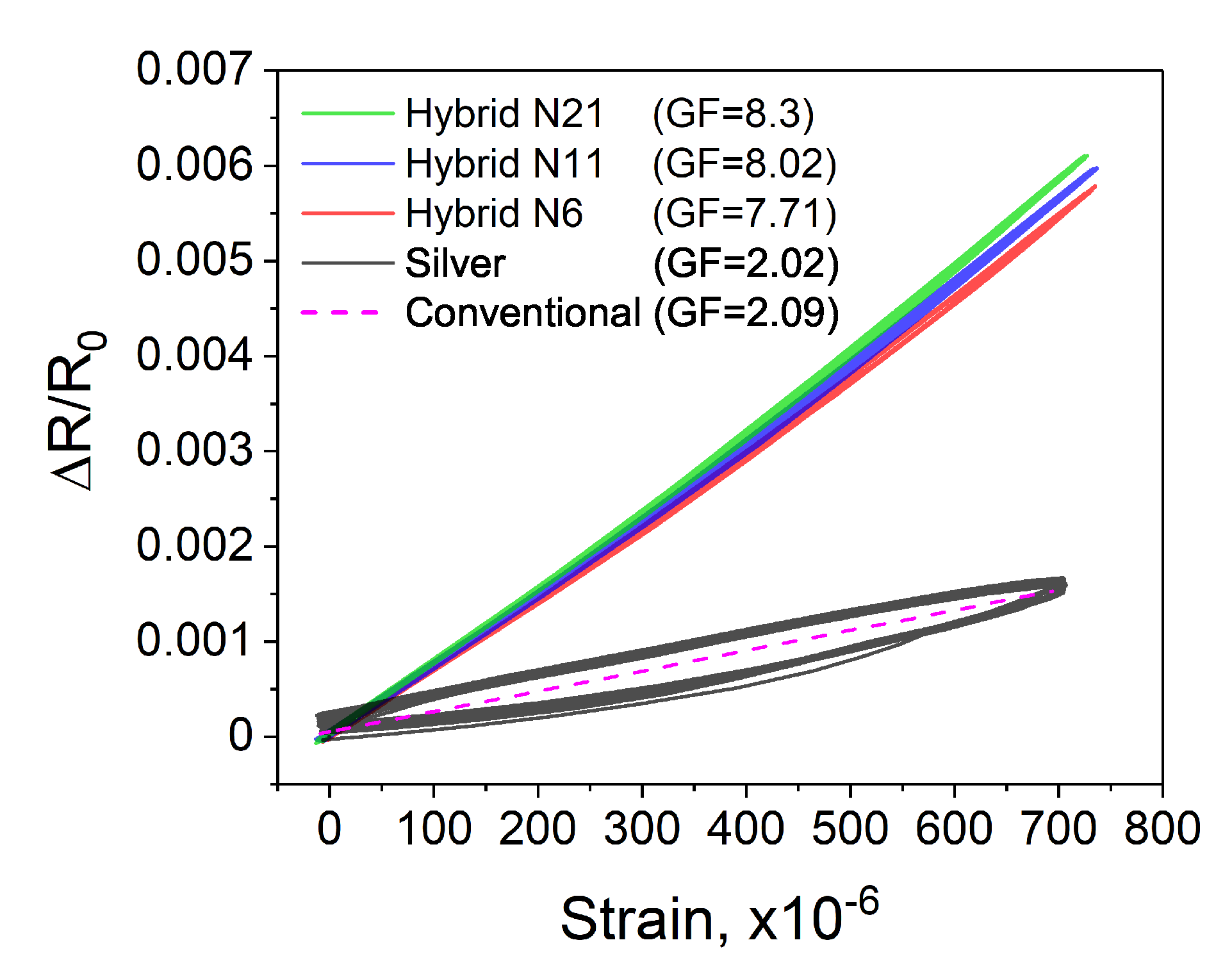

3.2. Basic Analysis of Strain Sensitivity

3.3. Discussion and Additional Analysis Concerning Strain Sensitivity

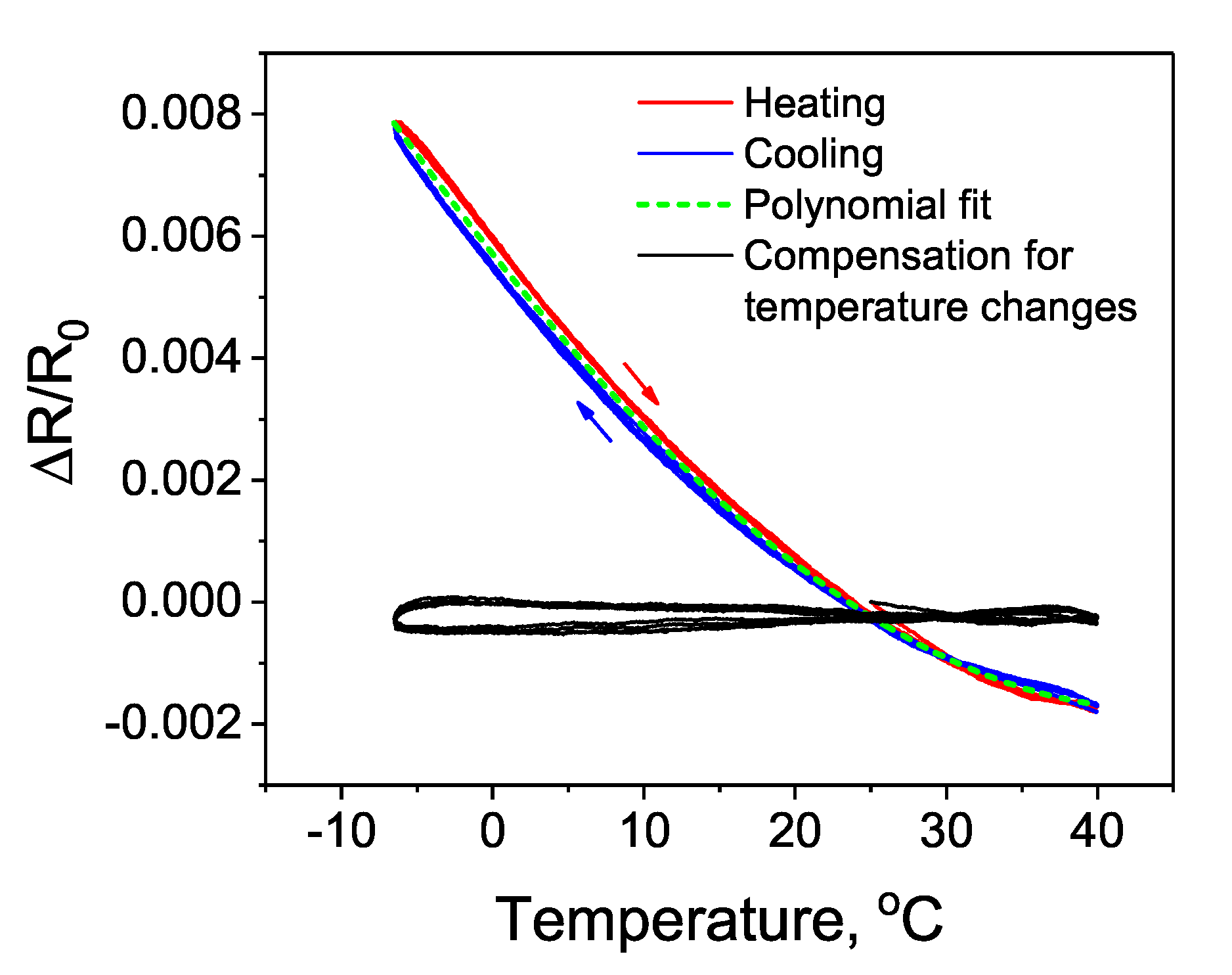

3.4. Temperature Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Farreras-Alcover, I.; Chryssanthopoulos, M.K.; Andersen, J.E. Data-based models for fatigue reliability of orthotropic steel bridge decks based on temperature, traffic and strain monitoring. Int. J. Fatigue 2017, 95, 104–119. [Google Scholar] [CrossRef]

- Treacy, M.A.; Brühwiler, E. Action effects in post-tensioned concrete box-girder bridges obtained from high-frequency monitoring. J. Civ. Struct. Health Monit. 2015, 5, 11–28. [Google Scholar] [CrossRef]

- Kunnari, E.; Valkama, J.; Keskinen, M.; Mansikkamäki, P. Environmental evaluation of new technology: Printed electronics case study. J. Clean. Prod. 2009, 17, 791–799. [Google Scholar] [CrossRef]

- Bessonov, A.; Kirikova, M.; Haque, S.; Gartseev, I.; Bailey, M.J.A. Highly reproducible printable graphite strain gauges for flexible devices. Sens. Actuators A 2014, 206, 75–80. [Google Scholar] [CrossRef]

- Hay, G.I.; Evans, P.S.A.; Harrison, D.J.; Southee, D.; Simpson, G.; Harrey, P.M. Characterization of lithographically printed resistive strain gauges. IEEE Sens. J. 2005, 5, 864–871. [Google Scholar] [CrossRef]

- Borghetti, M.; Serpelloni, M.; Sardini, E.; Pandini, S. Mechanical behavior of strain sensors based on PEDOT:PSS and silver nanoparticles inks deposited on polymer substrate by inkjet printing. Sens. Actuators A 2016, 243, 71–80. [Google Scholar] [CrossRef]

- El Zein, A.; Huppe, C.; Cochrane, C. Development of a flexible strain sensor based on PEDOT: PSS for thin film structures. Sensors 2017, 17, 1337. [Google Scholar] [CrossRef]

- Thompson, B.; Yoon, H.S. Aerosol-Printed Strain Sensor Using PEDOT:PSS. IEEE Sens. J. 2013, 13, 4256–4263. [Google Scholar] [CrossRef]

- Casiraghi, C.; Macucci, M.; Parvez, K.; Worsley, R.; Shin, Y.; Bronte, F.; Borri, C.; Paggi, M.; Fiori, G. Inkjet printed 2D-crystal based strain gauges on paper. Carbon 2018, 129, 462–467. [Google Scholar] [CrossRef]

- Wang, X.; Sparkman, J.; Gou, J.H. Strain sensing of printed carbon nanotube sensors on polyurethane substrate with spray deposition modeling. Compos. Commun. 2017, 3, 1–6. [Google Scholar] [CrossRef]

- Ali, M.M.; Maddipatla, D.; Narakathu, B.B.; Chlaihawi, A.A.; Emamian, S.; Janabi, F.; Bazuin, B.J.; Atashbar, M.Z. Printed strain sensor based on silver nanowireisilver flake composite on flexible and stretchable TPU substrate. Sens. Actuators A 2018, 274, 109–115. [Google Scholar]

- Ferreira, A.; Lanceros-Mendez, S. Piezoresistive response of spray-printed carbon nanotube/poly(vinylidene fluoride) composites. Compos. Part B Eng. 2016, 96, 242–247. [Google Scholar] [CrossRef]

- Karim, N.; Afroj, S.; Tan, S.; Novoselov, K.S.; Yeates, S.G. All inkjet-printed graphene-silver composite ink on textiles for highly conductive wearable electronics applications. Sci. Rep. 2019, 9, 8035. [Google Scholar] [CrossRef]

- Min, S.H.; Lee, G.Y.; Ahn, S.H. Direct printing of highly sensitive, stretchable, and durable strain sensor based on silver nanoparticles/multi-walled carbon nanotubes composites. Compos. Part B Eng. 2019, 161, 395–401. [Google Scholar] [CrossRef]

- Luo, C.S.; Tian, B.; Liu, Q.; Feng, Y.; Wu, W. One-step-printed, highly sensitive, textile-based, tunable performance strain sensors for human motion detection. Adv. Mater. Technol. 2020, 5, 1900925. [Google Scholar] [CrossRef]

- Tian, B.; Yao, W.J.; Zeng, P.; Li, X.; Wang, H.J.; Liu, L.; Feng, Y.; Luo, C.S.; Wu, W. All-printed, low-cost, tunable sensing range strain sensors based on Ag nanodendrite conductive inks for wearable electronics. J. Mater. Chem. C 2019, 7, 809–818. [Google Scholar] [CrossRef]

- Yao, S.; Zhu, Y. Wearable multifunctional sensors using printed stretchable conductors made of silver nanowires. Nanoscale 2014, 6, 2345–2352. [Google Scholar] [CrossRef]

- Correia, V.; Caparros, C.; Casellas, C.; Francesch, L.; Rocha, J.G.; Lanceros-Mendez, S. Development of inkjet printed strain sensors. Smart Mater. Struct. 2013, 22, 105028. [Google Scholar] [CrossRef]

- Le, M.Q.; Ganet, F.; Audigier, D.; Capsal, J.F.; Cottinet, P.J. Printing of microstructure strain sensor for structural health monitoring. Appl. Phys. A Mater. Sci. Process. 2017, 123, 354. [Google Scholar] [CrossRef]

- Hariri, H.; Kim, J.; Kim, W.S.; Frechette, L.G.; Masson, P. Performance validation of printed strain sensors for active control of intelligent tires. Appl. Acoust. 2017, 123, 73–84. [Google Scholar] [CrossRef]

- Chen, Y.H.; Lu, B.W.; Chen, Y.; Feng, X. Biocompatible and ultra-flexible inorganic strain sensors attached to skin for long-term vital signs monitoring. IEEE Electron Device Lett. 2016, 37, 496–499. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Anderson, N.; Bland, S.; Nutt, S.; Jursich, G. All-printed strain sensors: Building blocks of the aircraft structural health monitoring system. Sens. Actuators A 2017, 253, 165–172. [Google Scholar] [CrossRef]

- Zymelka, D.; Togashi, K.; Ohigashi, R.; Yamashita, T.; Takamatsu, S.; Itoh, T.; Kobayashi, T. Printed strain sensor array for application to structural health monitoring. Smart Mater. Struct. 2017, 26, 105040. [Google Scholar] [CrossRef]

- Zymelka, D.; Togashi, K.; Kobayashi, T. Concentric array of printed strain sensors for structural health monitoring. Sensors 2020, 20, 1997. [Google Scholar] [CrossRef]

- Zymelka, D.; Yamashita, T.; Takamatsu, S.; Itoh, T.; Kobayashi, T. Thin-film flexible sensor for omnidirectional strain measurements. Sens. Actuators A 2017, 263, 391–397. [Google Scholar] [CrossRef]

- Lee, H.; Seong, B.; Moon, H.; Byun, D. Directly printed stretchable strain sensor based on ring and diamond shaped silver nanowire electrodes. RSC Adv. 2015, 5, 28379–28384. [Google Scholar] [CrossRef]

- Li, Y.Q.; Huang, P.; Zhu, W.B.; Fu, S.Y.; Hu, N.; Liao, K. Flexible wire-shaped strain sensor from cotton thread for human health and motion detection. Sci. Rep. 2017, 7. [Google Scholar] [CrossRef]

- Wang, X.Z.; Sun, H.L.; Yue, X.Y.; Yu, Y.F.; Zheng, G.Q.; Dai, K.; Liu, C.T.; Shen, C.Y. A highly stretchable carbon nanotubes/thermoplastic polyurethane fiber-shaped strain sensor with porous structure for human motion monitoring. Compos. Sci. Technol. 2018, 168, 126–132. [Google Scholar] [CrossRef]

- Jang, H.; Baek, S.; Choi, G.; Oh, S.; Lim, H.S.; Jang, Y.; Lee, H.S. Crisscross-designed piezoresistive strain sensors with a cracked microtectonic architecture for direction-selective tensile perception. J. Mater. Chem. C 2018, 6, 11170–11177. [Google Scholar] [CrossRef]

- Jung, H.; Park, C.; Lee, H.; Hong, S.; Kim, H.; Cho, S.J. Nano-cracked strain sensor with high sensitivity and linearity by controlling the crack arrangement. Sensors 2019, 19, 2834. [Google Scholar] [CrossRef]

- Hong, S.K.; Yang, S.; Cho, S.J.; Jeon, H.; Lim, G. Development of a waterproof crack-based stretchable strain sensor based on PDMS shielding. Sensors 2018, 18, 1171. [Google Scholar] [CrossRef] [PubMed]

- Hay, G.I.; Southee, D.J.; Evans, P.S.A.; Harrison, D.J.; Simpson, G.; Ramsey, B.J. Examination of silver-graphite lithographically printed resistive strain sensors. Sens. Actuators A 2007, 135, 534–546. [Google Scholar] [CrossRef][Green Version]

- Jurgens, J.; Patterson, P.E. Development and evaluation of an inexpensive sensor system for use in measuring relative finger positions. Med. Eng. Phys. 1997, 19, 1–6. [Google Scholar] [CrossRef]

- Jackson, R.; Domercq, B.; Jain, R.; Kippelen, B.; Graham, S. Stability of doped transparent carbon nanotube electrodes. Adv. Funct. Mater. 2008, 18, 2548–2554. [Google Scholar] [CrossRef]

- Zhou, Y.; Shimada, S.; Saito, T.; Azumi, R. Understanding the doping effects on the structural and electrical properties of ultrathin carbon nanotube networks. J. Appl. Phys. 2015, 118, 215305. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zymelka, D.; Yamashita, T.; Sun, X.; Kobayashi, T. Printed Strain Sensors Based on an Intermittent Conductive Pattern Filled with Resistive Ink Droplets. Sensors 2020, 20, 4181. https://doi.org/10.3390/s20154181

Zymelka D, Yamashita T, Sun X, Kobayashi T. Printed Strain Sensors Based on an Intermittent Conductive Pattern Filled with Resistive Ink Droplets. Sensors. 2020; 20(15):4181. https://doi.org/10.3390/s20154181

Chicago/Turabian StyleZymelka, Daniel, Takahiro Yamashita, Xiuru Sun, and Takeshi Kobayashi. 2020. "Printed Strain Sensors Based on an Intermittent Conductive Pattern Filled with Resistive Ink Droplets" Sensors 20, no. 15: 4181. https://doi.org/10.3390/s20154181

APA StyleZymelka, D., Yamashita, T., Sun, X., & Kobayashi, T. (2020). Printed Strain Sensors Based on an Intermittent Conductive Pattern Filled with Resistive Ink Droplets. Sensors, 20(15), 4181. https://doi.org/10.3390/s20154181