A Novel Approach to Using Spectral Imaging to Classify Dyes in Colored Fibers

Abstract

:1. Introduction

- Determine the wavelength bands useful to classify natural and synthetic dyes.

- Recommend three optimal bands to achieve a reasonable accuracy.

2. Materials and Methods

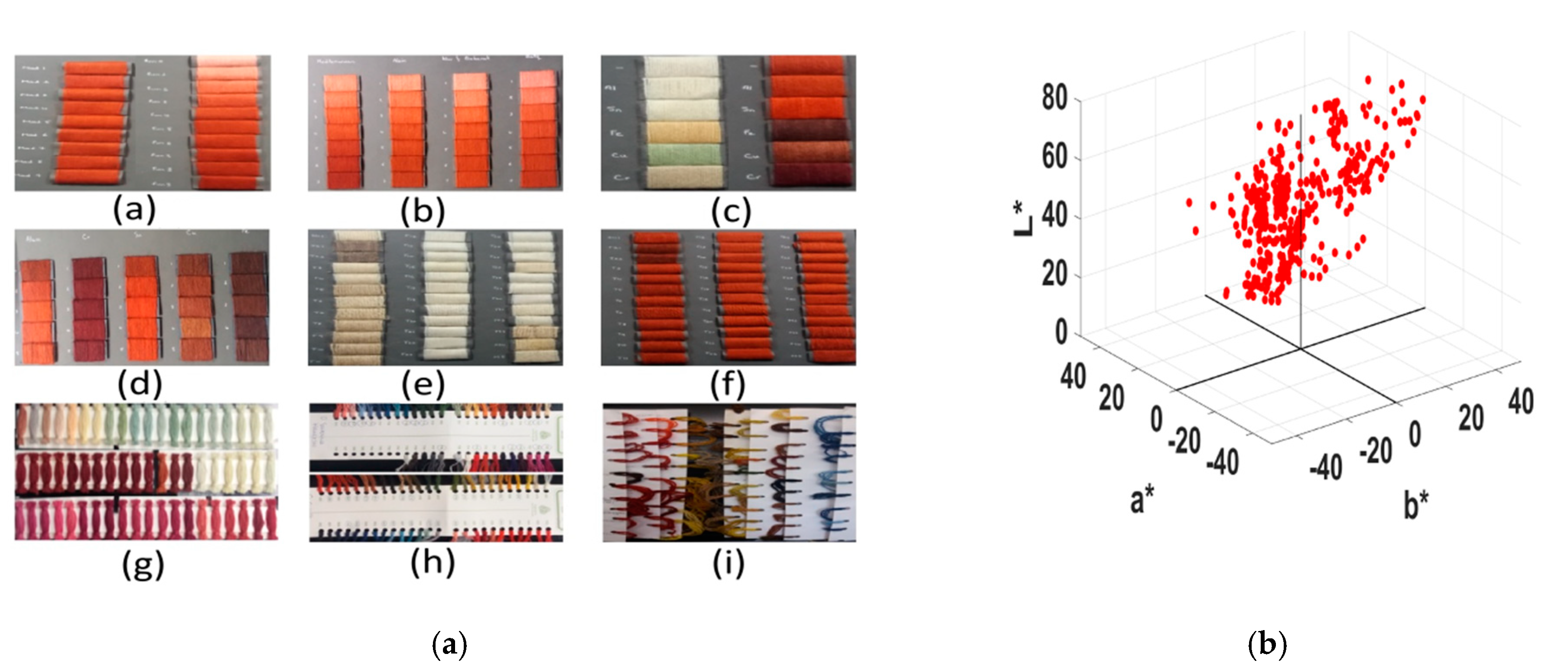

2.1. Samples of Dyed Fibers

2.2. Measurements

2.2.1. Spectral Imaging

2.2.2. Image Pre-Processing

2.3. Data Analysis

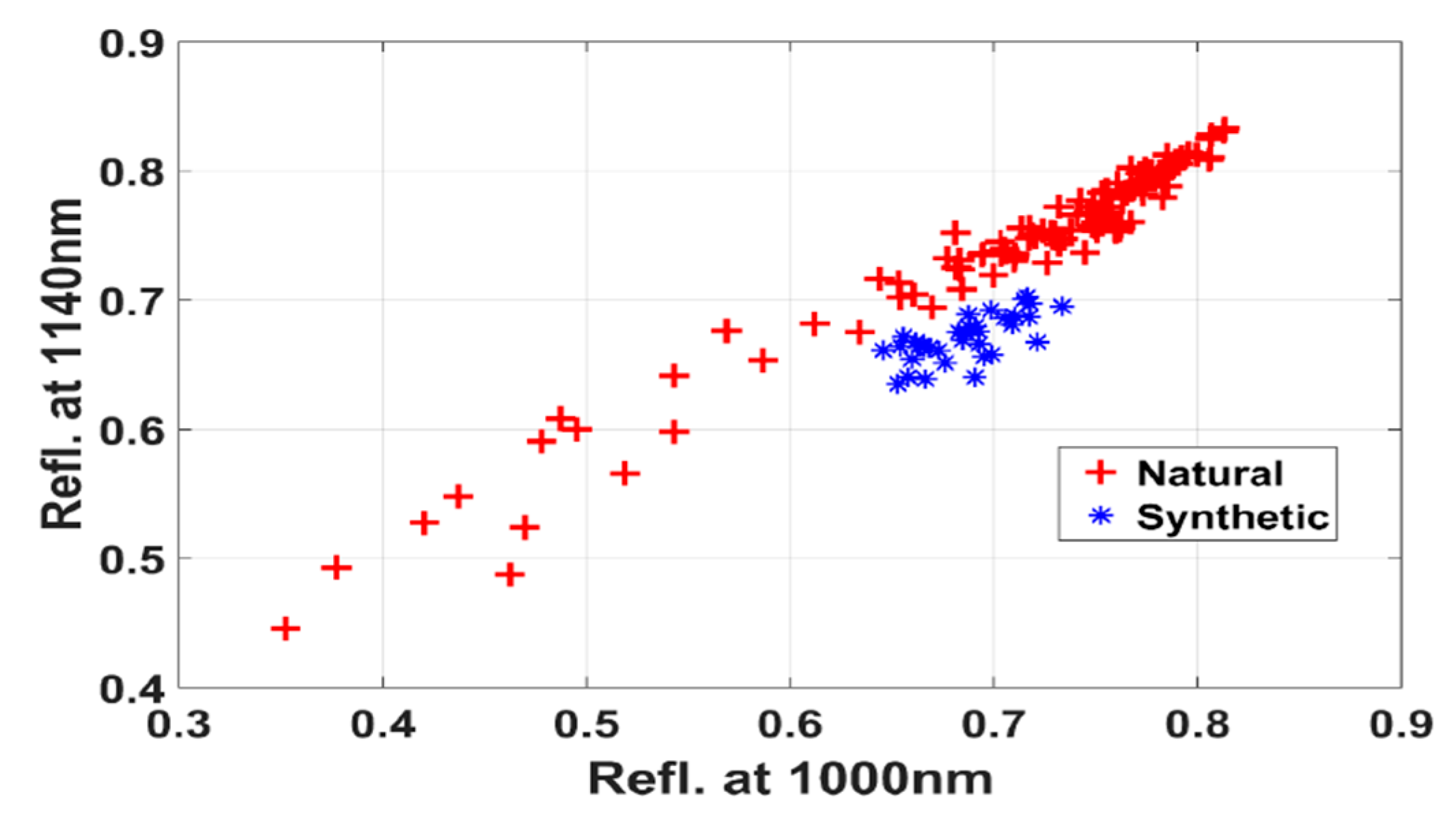

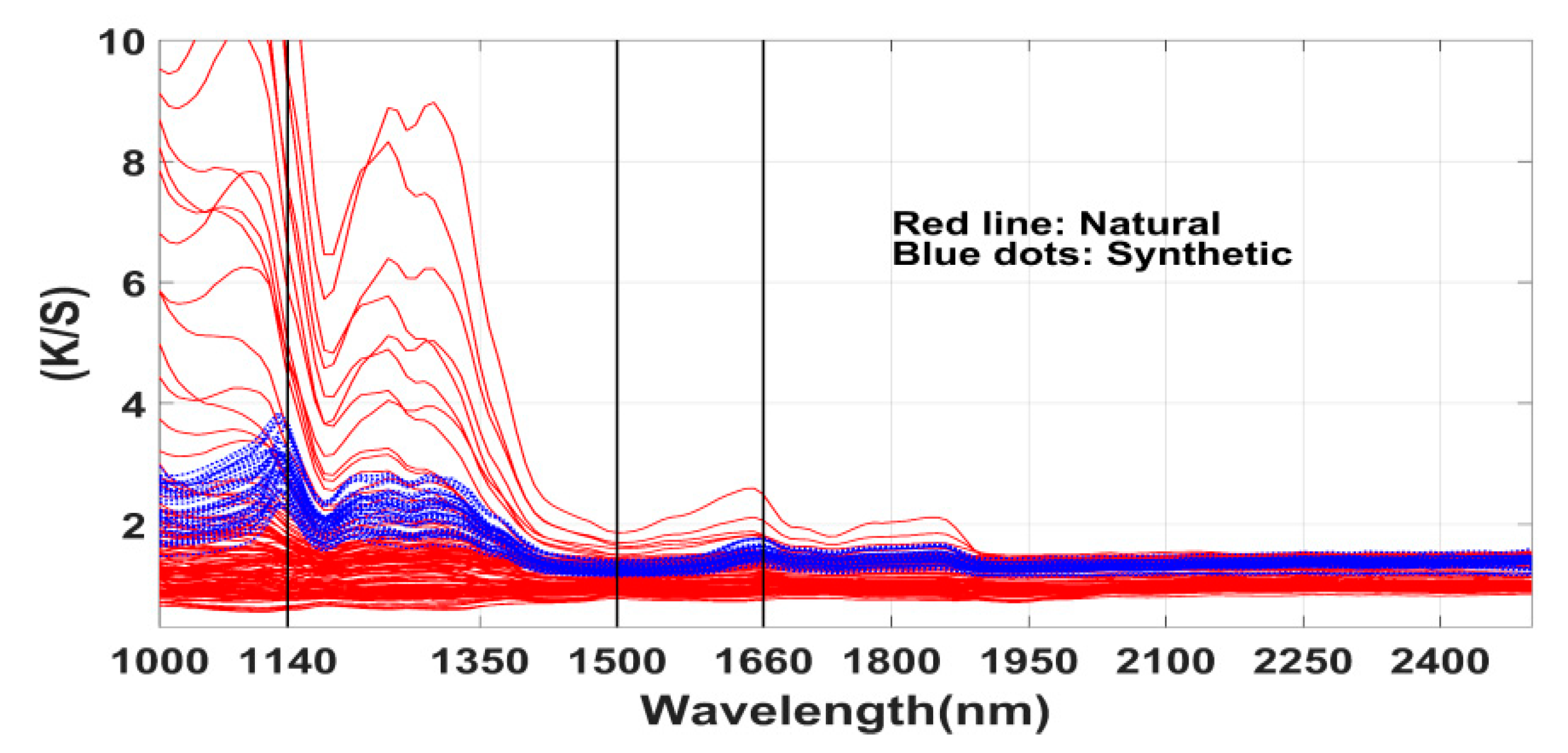

2.3.1. Reflectance Spectra

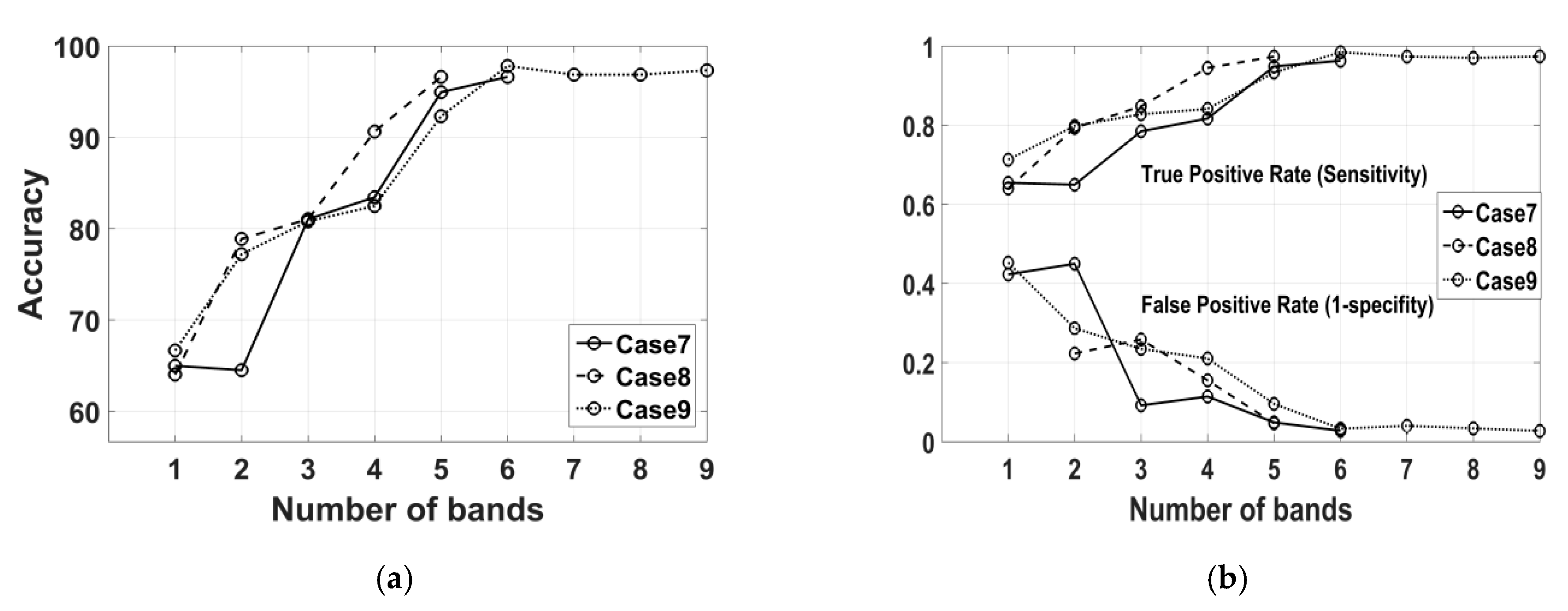

2.3.2. Spectral Band Selection Procedure

2.3.3. Classification

2.3.4. Calculation of Indexed Ratio Features

3. Results

4. Discussion

5. Limitations and Future Directions

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bell, I.M.; Clark, R.J.H.; Gibbs, P.J. Raman Spectroscopic Library of Natural and Synthetic Pigments (Pre- ≈ 1850 AD). Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 1997, 53, 2159–2179. [Google Scholar] [CrossRef]

- Villafana, T.E.; Delaney, J.K.; Warren, W.S.; Fischer, M.C. High-Resolution, Three-Dimensional Imaging of Pigments and Support in Paper and Textiles. J. Cult. Herit. 2016, 20, 583–588. [Google Scholar] [CrossRef] [Green Version]

- Casadio, F.; Leona, M.; Lombardi, J.R.; Van Duyne, R. Identification of Organic Colorants in Fibers, Paints, and Glazes by Surface Enhanced Raman Spectroscopy. Acc. Chem. Res. 2010, 43, 782–791. [Google Scholar] [CrossRef] [PubMed]

- Degano, I.; Ribechini, E.; Modugno, F.; Colombini, M.P. Analytical Methods for the Characterization of Organic Dyes in Artworks and in Historical Textiles. Appl. Spectrosc. Rev. 2009, 44, 363–410. [Google Scholar] [CrossRef]

- Buzzini, P.; Massonnet, G. The Discrimination of Colored Acrylic, Cotton, and Wool Textile Fibers Using Micro-Raman Spectroscopy. Part 1: In Situ Detection and Characterization of Dyes. J. Forensic Sci. 2013, 58, 1593–1600. [Google Scholar] [CrossRef] [PubMed]

- Nayak, R.K.; Padhye, R.; Fergusson, S. Identification of Natural Textile Fibers. In Handbook of Natural Fibers; Woodhead Publishing Limited: Cambridge, UK, 2012; pp. 314–344. [Google Scholar] [CrossRef]

- Kuffner, H.; Popescu, C. Wool Fibers. In Handbook of Natural Fibers; Woodhead Publishing Limited: Cambridge, UK, 2012; pp. 171–195. [Google Scholar] [CrossRef]

- Popescu, C.; Höcker, H. Hair—The Most Sophisticated Biological Composite Material. Chem. Soc. Rev. 2007, 36, 1282. [Google Scholar] [CrossRef] [PubMed]

- She, F.H.; Chow, S.; Wang, B.; Kong, L.X. Identification and Classification of Animal Fibers Using Artificial Neural Networks. J. Text. Eng. 2001, 47, 35–38. [Google Scholar] [CrossRef] [Green Version]

- Thiébaud, F.; Kneubühl, F.K. Infrared Properties of Quartz Fibers and Wool. Infrared Phys. 1983, 23, 131–148. [Google Scholar] [CrossRef]

- Taylor, G.W. Natural Dyes in Textile Applications. Rev. Prog. Color. Relat. Top. 2008, 16, 53–61. [Google Scholar] [CrossRef]

- Treigienė, R. The Influence of Physical Factors on Wool Fiber Colour Changes. Mater. Sci. 2010, 16, 341–345. [Google Scholar]

- Guesmi, A.; Hamadi, N.B.; Ladhari, N.; Sakli, F. Dyeing Properties and Colour Fastness of Wool Dyed with Indicaxanthin Natural Dye. Ind. Crops Prod. 2012, 37, 493–499. [Google Scholar] [CrossRef]

- Pielesz, A.; Wesełucha-Birczyńska, A. The Identification of Structural Changes in the Keratin of Wool Fiber Dyed with an Azo Dye Using the Raman and Fourier Transform Infrared Spectroscopy Methods. J. Mol. Struct. 2000, 555, 325–334. [Google Scholar] [CrossRef]

- Guesmi, A.; Hamadi, N.B.; Ladhari, N.; Saidi, F.; Maaref, H.; Sakli, F. Spectral Characterization of Wool Fabric Dyed with Indicaxanthin Natural Dye: Study of the Fluorescence Property. Ind. Crops Prod. 2013, 46, 264–267. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Y.; Zhao, F.; Peng, Z.; Wang, S. Identification of Early Synthetic Dyes in Historical Chinese Textiles of the Late Nineteenth Century by High-Performance Liquid Chromatography Coupled with Diode Array Detection and Mass Spectrometry. Color. Technol. 2016, 132, 177–185. [Google Scholar] [CrossRef]

- Ahmed, H.E.; Ziddan, Y.E. A New Approach for Conservation Treatment of a Silk Textile in Islamic Art Museum, Cairo. J. Cult. Herit. 2011, 12, 412–419. [Google Scholar] [CrossRef]

- Mantzouris, D.; Karapanagiotis, I.; Valianou, L.; Panayiotou, C. HPLC–DAD–MS Analysis of Dyes Identified in Textiles from Mount Athos. Anal. Bioanal. Chem. 2011, 399, 3065–3079. [Google Scholar] [CrossRef]

- Claro, A.; Melo, M.J.; Seixas de Melo, J.S.; van den Berg, K.J.; Burnstock, A.; Montague, M.; Newman, R. Identification of Red Colorants in van Gogh Paintings and Ancient Andean Textiles by Microspectrofluorimetry. J. Cult. Herit. 2010, 11, 27–34. [Google Scholar] [CrossRef]

- Petroviciu, I.; Van den Berghe, I.; Cretu, I.; Albu, F.; Medvedovici, A. Identification of Natural Dyes in Historical Textiles from Romanian Collections by LC-DAD and LC-MS (Single Stage and Tandem MS). J. Cult. Herit. 2012, 13, 89–97. [Google Scholar] [CrossRef]

- Coupry, C.; Sagon, G.; Gorguet-Ballesteros, P. Raman Spectroscopic Investigation of Blue Contemporary Textiles. J. Raman Spectrosc. 1997, 28, 85–89. [Google Scholar] [CrossRef]

- Massonnet, G.; Buzzini, P.; Jochem, G.; Stauber, M.; Coyle, T.; Roux, C.; Thomas, J.; Leijenhorst, H.; Van Zanten, Z.; Wiggins, K.; et al. Evaluation of Raman Spectroscopy for the Analysis of Colored Fibers: A Collaborative Study. J. Forensic Sci. 2005, 50, 1–11. [Google Scholar] [CrossRef]

- Teslova, T.; Corredor, C.; Livingstone, R.; Spataru, T.; Birke, R.L.; Lombardi, J.R.; Cañamares, M.V.; Leona, M. Raman and Surface-Enhanced Raman Spectra of Flavone and Several Hydroxy Derivatives. J. Raman Spectrosc. 2007, 38, 802–818. [Google Scholar] [CrossRef]

- Szostek, B.; Orska-Gawrys, J.; Surowiec, I.; Trojanowicz, M. Investigation of Natural Dyes Occurring in Historical Coptic Textiles by High-Performance Liquid Chromatography with UV–Vis and Mass Spectrometric Detection. J. Chromatogr. A 2003, 1012, 179–192. [Google Scholar] [CrossRef]

- Manhita, A.; Ferreira, T.; Candeias, A.; Barrocas Dias, C. Extracting Natural Dyes from Wool—An Evaluation of Extraction Methods. Anal. Bioanal. Chem. 2011, 400, 1501–1514. [Google Scholar] [CrossRef] [PubMed]

- Bisulca, C.; Picollo, M.; Bacci, M.; Kunzelman, D. UV-Vis-NIR Reflectance Spectroscopy of Red Lakes in Paintings. In Proceedings of the 9th International Conference on NDT of Art, Jerusalem, Israel, 25–30 May 2008; pp. 25–30. [Google Scholar]

- Hemingray, C.; Westland, S. A Novel Approach to Using Neural Networks to Predict the Colour of Fiber Blends. Color. Technol. 2016, 132, 297–303. [Google Scholar] [CrossRef] [Green Version]

- Swatland, H.J. Reflectance versus Transmittance: The Effects of Light Scattering on Red Colorants (Carmine, Amazonian Red Annatto, and Peruvian Cochinilla Rojo and Rosada) in Biological, Textile, and Museum Science. Color. Res. Appl. 2014, 39, 599–606. [Google Scholar] [CrossRef]

- Balas, C.; Papadakis, V.; Papadakis, N.; Papadakis, A.; Vazgiouraki, E.; Themelis, G. A Novel Hyper-Spectral Imaging Apparatus for the Non-Destructive Analysis of Objects of Artistic and Historic Value. J. Cult. Herit. 2003, 4, 330–337. [Google Scholar] [CrossRef]

- Kubik, M. Hyperspectral imaging: A new technique for the Non-Invasive study of artworks. In Physical Techniques in the Study of Art Archaeology and Cultural Heritage; Creagh, D., Bradley, D., Eds.; Elservier: Amsterdam, The Netherlands, 2007; pp. 199–259. [Google Scholar]

- Zhao, Y.; Berns, R.S.; Taplin, L.A.; Coddington, J. An Investigation of Multispectral Imaging for the Mapping of Pigments in Paintings. In Computer Image Analysis in the Study of Art; Stork, D.G., Coddington, J., Eds.; SPIE: Bellingham, WA, USA, 2008; Volume 6810, pp. 65–73. [Google Scholar] [CrossRef]

- Fischer, C.; Kakoulli, I. Multispectral and Hyperspectral Imaging Technologies in Conservation: Current Research and Potential Applications. Stud. Conserv. 2006, 51 (Suppl. S1), 3–16. [Google Scholar] [CrossRef]

- Cosentino, A. Identification of Pigments by Multispectral Imaging; a Flowchart Method. Herit. Sci. 2014, 2, 8. [Google Scholar] [CrossRef] [Green Version]

- Thomas, J.; Buzzini, P.; Massonnet, G.; Reedy, B.; Roux, C. Raman Spectroscopy and the Forensic Analysis of Black/Grey and Blue Cotton Fibers. Forensic Sci. Int. 2005, 152, 189–197. [Google Scholar] [CrossRef]

- Hearle, J.W.S.; Morton, W.E. Physical Properties of Textile Fibers; Woodhead Publishing Limited: Cambridge, UK, 2008. [Google Scholar]

- Morales, K.M.; Berrie, B.H. A Note on Characterization of the Cochineal Dyestuff on Wool Using Microspectrophotometry. E Preserv. Sci. 2015, 12, 8–14. [Google Scholar]

- Ghanean, S.; Afjeh, M.G. Using Derivative Spectrophotometry to Determine the Relation between Color Intensity and Dye Concentration of Madder. Prog. Color. Color. Coat. 2016, 9, 183–194. [Google Scholar]

- Jacobson, N.P.; Gupta, M.R. Design Goals and Solutions for Display of Hyperspectral Images. IEEE Trans. Geosci. Remote Sens. 2005, 43, 2684–2692. [Google Scholar] [CrossRef]

- Cawley, G.C.; Talbot, N.L.C. Gene Selection in Cancer Classification using Sparse Logistic Regression with Bayesian Regularization. Bioinformatics 2006, 22, 2348–2355. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shevade, S.K.; Keerthi, S.S. A Simple and Efficient Algorithm for Gene Selection Using Sparse Logistic Regression. Bioinformatics 2003, 19, 2246–2253. [Google Scholar] [CrossRef]

- Dumont, J.; Hirvonen, T.; Heikkinen, V.; Mistretta, M.; Granlund, L.; Himanen, K.; Fauch, L.; Porali, I.; Hiltunen, J.; Keski-Saari, S.; et al. Thermal and Hyperspectral Imaging for Norway Spruce (Picea Abies) Seeds Screening. Comput. Electron. Agric. 2015, 116, 118–124. [Google Scholar] [CrossRef]

- Pant, P.; Heikkinen, V.; Korpela, I.; Hauta-Kasari, M.; Tokola, T. Logistic Regression-Based Spectral Band Selection for Tree Species Classification: Effects of Spatial Scale and Balance in Training Samples. IEEE Geosci. Remote Sens. Lett. 2014, 11, 1604–1608. [Google Scholar] [CrossRef]

- Algorithms | Feature Selection @ ASU. Available online: http://featureselection.asu.edu/old/software.php (accessed on 18 July 2020).

- Ramesh, R. Near-Infrared Applications in Biotechnology; Marcel Dekker, Inc.: New York, NY, USA, 2001. [Google Scholar]

- Pauler, N. Paper Optics: Optical and Colour Science Related to the Pulp and Paper Industry; Lorentzen & Wettre: Kista, Sweden, 2007. [Google Scholar]

- Rahaman, G.A.; Parkkinen, J.; Hauta-Kasari, M. Fiber Dye Classification by Spectral Imaging. In Proceedings of the 2017 IEEE International Conference on Imaging, Vision & Pattern Recognition (icIVPR), Dhaka, Bangladesh, 13–14 February 2017; pp. 1–6. [Google Scholar] [CrossRef]

| V/NIR Range | SWIR Range | |

|---|---|---|

| Camera | Zyla 5.5 sCMOS; Andor Tech., UK | LVDS-100; Specim, Spectral Imaging Ltd. |

| Lens | V18.5 – f/2.4 091101 Specim Ltd. | OLES15-f1/2.0 052301 Specim Ltd. |

| Spectrograph | ImSpector V10E; Specim, Spectral Imaging Ltd. | ImSpector N25E; Specim Spectral Imaging Ltd. |

| Data Form | Spectral radiance, 386–998 nm at 3 nm intervals | Spectral radiance, 933-2538 nm at 6 nm intervals |

| Standard White | Spectralon® reference plate (Specim Ltd.) | Spectralon® reference plate (Specim Ltd.) |

| Light Source | 2 set halogen lamps (35 W each), 45/0° geometry | 2 set halogen lamps (35 W each), 45/0° geometry |

| Spatial Resolution | 6.5 micrometer | 30 micrometer |

| Sample distance | 395 mm | 380 mm |

| Exposure time | 9.1 ms | 1.6 ms |

| Parameter | Value |

|---|---|

| Kernel Function | polynomial |

| PolynomialOrder | 3 |

| KernelScale | 1(default) |

| Standardize | True |

| Leaveout | On |

| Solver | Sequential Minimal Optimization (SMO) |

| Case | WL Range (nm) | Selected Bands (nm) | Classification Accuracy (%) | Cohen’s Kappa | Natural Class Error (%) | Synthetic Class Error (%) |

|---|---|---|---|---|---|---|

| 1 | 400–700 | 580, 590, 400 | 90.5 | 0.73 | 6.1 | 20.6 |

| 2 | 700–1000 | 700 | ||||

| 3 | 400–1000 | 580, 400, 590 | 90.5 | 0.73 | 6.1 | 20.6 |

| 4 | 1000–1500 | 1000, 1140 | 100 | 1.0 | 0 | 0 |

| 5 | 1500–2000 | 1500, 1660 | 99.3 | 0.98 | 0 | 2.9 |

| 6 | 2000–2500 | 2000 | ||||

| 7 | 1000–2000 | 1000, 1140 | 100 | 1.0 | 0 | 0 |

| 8 | 1500–2500 | 1500, 1660 | 99.3 | 0.98 | 0 | 2.9 |

| 9 | 1000–2500 | 1000, 1140 | 100 | 1.0 | 0 | 0 |

| Case | Selected Bands (nm) | Accuracy (%) | Cohen’s Kappa | Natural Class Error (%) | Synthetic Class Error (%) |

|---|---|---|---|---|---|

| 1 | 640, 700, 570, 480, 400 | 91.6 | 0.82 | 7.5 | 10.0 |

| 2 | 810, 780, 700 | 79.9 | 0.52 | 26.6 | 8.7 |

| 3 | 640, 700, 810, 800, 560, 450, 1000, 710, 600, 400 | 94.0 | 0.87 | 6.4 | 5.3 |

| 4 | 1460, 1470, 1000, 1140 | 93.3 | 0.86 | 5.6 | 8.0 |

| 5 | 1640, 1690, 1500 | 87.3 | 0.70 | 18.7 | 2.0 |

| 6 | 2000, 2500, 2290 | 89.9 | 0.78 | 7.1 | 15.3 |

| 7 | 1470, 1460, 1730, 1000, 1140, 1980 | 96.9 | 0.93 | 3.8 | 2.7 |

| 8 | 1640, 2300, 2500, 1920, 1500 | 96.6 | 0.93 | 2.6 | 4.6 |

| 9 | 1140, 1920, 1480, 1910, 1000, 2500, 2330, 1130, 1450 | 97.4 | 0.94 | 2.6 | 2.7 |

| Case | Top Three Bands (nm) | Accuracy (%) | Cohen’s Kappa | Natural Class Error (%) | Synthetic Class Error (%) |

|---|---|---|---|---|---|

| 2 ratio indexes | 1640, 2330, 1480 | 90.1 | 0.78 | 9.8 | 10.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahaman, G.M.A.; Parkkinen, J.; Hauta-Kasari, M. A Novel Approach to Using Spectral Imaging to Classify Dyes in Colored Fibers. Sensors 2020, 20, 4379. https://doi.org/10.3390/s20164379

Rahaman GMA, Parkkinen J, Hauta-Kasari M. A Novel Approach to Using Spectral Imaging to Classify Dyes in Colored Fibers. Sensors. 2020; 20(16):4379. https://doi.org/10.3390/s20164379

Chicago/Turabian StyleRahaman, G. M. Atiqur, Jussi Parkkinen, and Markku Hauta-Kasari. 2020. "A Novel Approach to Using Spectral Imaging to Classify Dyes in Colored Fibers" Sensors 20, no. 16: 4379. https://doi.org/10.3390/s20164379