1. Introduction

Fish abundance estimation is an open problem but a necessity in fish farming. A reliable estimation of fish under cultivation aids with delivering the optimum care for fish, thus ensuing the good health as well as proper growth of the species [

1,

2,

3,

4]. Furthermore, the knowledge of fish amount helps in the proper management of inventory related to fish such as fish food and prevents under or overfeeding [

3,

4]. Another area where knowledge of the fish count would be beneficial is for the insurance companies, as they do not have any other option than believing in farmers’ words. Generally, the approximate fish count is known at the initial phase of farming. However, over time, the amount of fish decreases significantly. However, the early count or rough approximation is generally used for fish management as there is no reliable way of tracking them. Therefore, a portable device for estimating fish count in real time is proposed in this paper.

Over the past few decades, various algorithms and techniques have been proposed and used to estimate fish. To illustrate, acoustics echo-sounding, machine vision-based technique, environmental DNA based method, and resistivity counting technique are some well-known techniques [

5]. However, because of its accuracy and noninvasive nature, acoustic echo-sounding is a popular choice for fish count estimation [

6]. In a typical echosounder, the transmitter emits a ping (acoustic signal) and the received echo signals from targets are analyzed. The fundamental principle is the detection of reflected energy from a target. It is not uncommon to use sonars and fish finders to locate fish in the commercial fishing operations [

6]. The academic as well as commercial use of acoustics for estimating fish abundance have been widespread [

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19]. Although fish have been the main focus, squids and other marine organisms have also been investigated. Modern echosounder implements the echo integration to analyze fish and their behavior [

10,

11,

12,

13,

14,

15]. Even though the echo integration method has been extensively employed in open ocean, however, when the method is employed in the farming cages, it offers new challenges [

16,

17,

18,

19,

20]. Firstly, the fish are closer to transducer, therefore, classical Time Varying Gain (TVG) correction could be inappropriate [

16]. Secondly, the reverberation of the acoustical signal from the boundaries of cage need to be considered [

17,

21,

22]. Another problem that needs to be addressed is removing the cage signal from the received echo [

20]. Similarly, the stability of the transducer is another issue as the signal quality highly depends on its orientation [

17,

22].

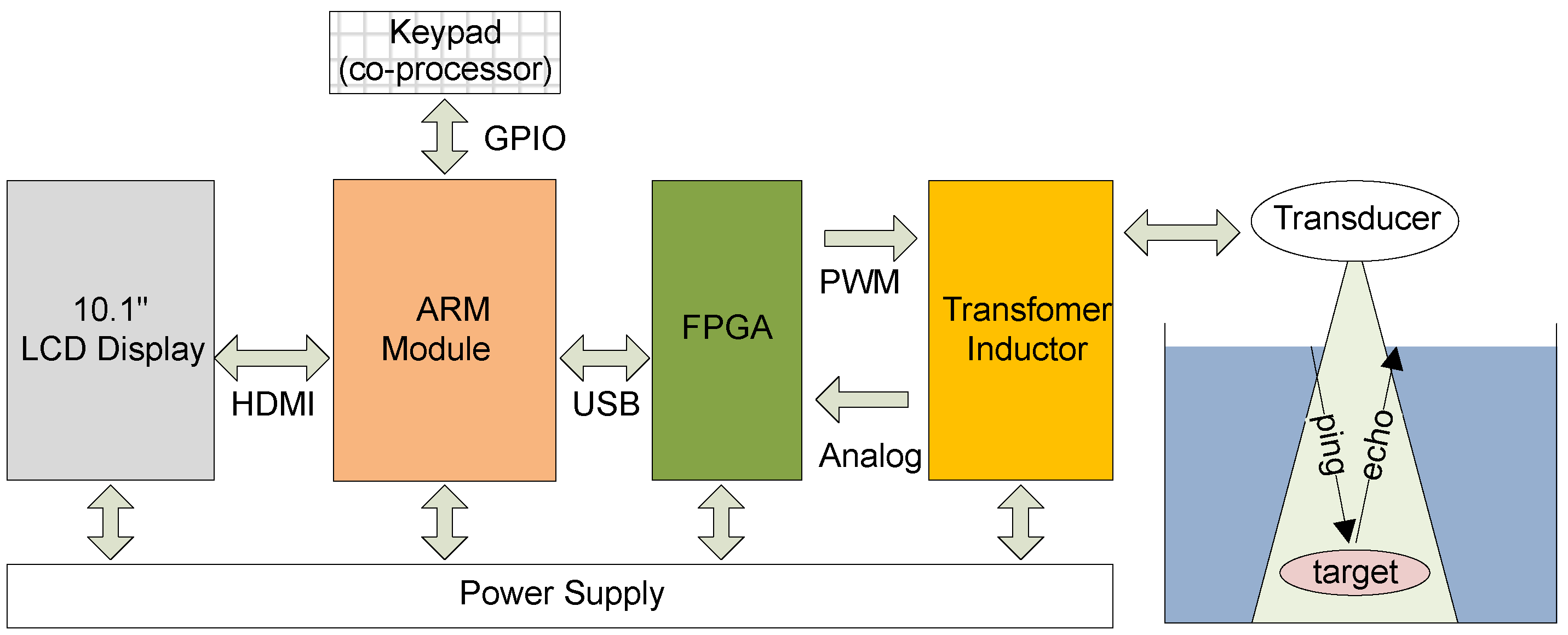

The main goal of this research is to build a cost-effective, portable, compact, and stand-alone scientific echosounder (SE) that can accurately estimate fish in a closed pen. Unlike the most state-of-the-art fish counting method, the proposed device does not need separate hardware and software for fish counting. Everything required for the fish counting is built on a single device. This paper details our novel device, its design process, the hardware and software components used, experiments performed, and the test results. Our compact design consists of a keypad, a display, FPGA, and a processing unit. Even though few ready-made commercial components are used, most of the hardware, software, and algorithms are developed and implemented in our lab. The device is built using the fundamental principles of the standard echosounder, but with enhancement. The proposed device implements programmable gain to improve dynamic range, time-variable gain to compensate transmission loss, high-speed ADC to achieve high depth resolution, bottom detection algorithm to detect net bottom and sea bed, and a novel fish counting algorithm to count fish. To our best knowledge, this is the first portable echosounder that has a built-in fish counting mechanism. The prototype device was evaluated and compared with a commercial echosounder. Our experimental results show that the performance of the device is on par with the commercial echosounder. Furthermore, our on-site experimental results show that the device could estimate the fish amount accurately. We note that even though the device has fish counting ability, it can still be used as a normal echosounder. The rest of the paper describes the design and implementation of the proposed device in detail.

2. Theoretical Aspects

2.1. Echo-Sounder

The modern echosounder device needs a personal computer (PC) to analyze and visualize data; therefore, it comes with the software. The installed software in the PC can display the received signal graphically as an “echogram”. The echosounder mainly consists of four components: transducer, transmitter, receiver, and display unit. The transmitter generates an electrical pulse that is transformed to sound waves by the transducer and propagate through the water. The reflected signal from the targets in water are sampled by the transducer again, changed back to electrical signal, and echograms are generated. SE for acoustic assessment operates on the same fundamental principles, but with the precision required for scientific study [

6,

23]. The fundamental principles of target detection in water with an echosounder are illustrated by the sonar equation as [

6]

where echo voltage (EV) is the measured echo voltage in dB, transmitted source level (SL) is in dB re

1 Pa at 1 m, receive gain (G) is in dB/Pa at 1 m, R is range in meters, is the two-way spreading loss in dB, sound attenuation coefficient (a) is in dB/m, acoustic target strength (TS) is in dB, and is the transducer directivity pattern function. In the above equation, if is larger than noise, the target can be detected. The target detection is affected by the noise produced from various sources such as a ship, electronic equipment, or sea. The ability to detect a target can be improved with less propagation loss, larger source level, and location of the target to the center of the transducer beam. The sound wave gets attenuated as it propagates. The propagation loss arises from the spreading of the beam as it propagates, and through sound absorption. Generally, sound absorption is higher with increasing salinity and sound frequencies. Generally, SE automatically corrects for the propagation loss by employing “time-varied-gain”.

2.2. Target Strength, Volume and Area Backscattering Coefficient, and Fish Density Estimation

In the fish abundance estimation, TS is used as a scaling factor [

24]. TS is scattering properties of an organism (in dB).

, where

is acoustic backscattering cross-section reflected by a target. The echo reflected from individual targets are blended to form an integrated received signal when there are many targets. The volume backscattering coefficient,

, is calculated as

, where the sampled volume is denoted by

V. The area backscattering coefficient,

, is a measurement of the reflected energy from a layer between two depths in the water column. It is the integration of

w.r.t depth through the layer

and

and is given by

If we know the total energy reflected by all fish and the energy reflected by a single fish, their ratio gives an estimation of the fish count. Assuming that all fish are of the same size, the area density () can be calculated as . However, the accuracy is dependent on the estimation of and . Furthermore, since multiple targets of various sizes and spices can exist in the water column, <> should be calculated and used.

5. Prototyping

The prototype of SFBE device is shown in

Figure 12a. It has a waterproof IP67 casing and weighs around 5 kg. The transducer is attached to the device via a connector. The operation of SFBE can be initiated by pressing the start button which runs the device in fish counting mode for 10 min (by default but configurable) while continuously displaying the echogram on the screen.

Figure 12b shows the screenshot of SFBE displaying the echogram during an experiment. Note that the device is just a prototype and in the development phase; therefore, technical information is displayed on the right side for debugging purposes. In the figure, the left and the right half of the screen shows the SV and the ADC graphs, respectively. For both the SV and ADC graphs, the

x-axis is time and the

y-axis is depth or range. The pixel intensity denotes the magnitude of the signal, white representing the lowest and red representing the highest intensity. The color scale is drawn at the lower bottom part of the figure. By analyzing the pixel intensity, fish, water, net bottom, and the seabed can be differentiated in the figure. The number pair at the bottom-right corner of the screen represents the net-bottom and the seabed depths, respectively, identified by the bottom detection algorithm. The bottom-right corner displays the fish count, and (100%) is the progress bar representing the end of the operation.

5.1. Performance Evaluation

For the performance evaluation, two types of experiments were performed: (1) lab experiment and (2) on-site experiment. The lab experiment is performed to validate the working of SFBE by comparing it with a commercial echosounder. The on-site experiment is performed to test the fish counting performance of SFBE.

5.1.1. Lab Experiment

The SFBE device was compared against Simard EK15 [

34]. Simard EK15 is selected because it shares similar characteristics with SFBE. Both the devices are single beam echosounder and operate in the 200 KHz frequency band. The experiments were performed at Korea Institute of Ocean Science and Technology (KIOST) in Busan, Korea [

35]. KIOST is a state-run research center and has all the facilities for acoustic testing as illustrated by

Figure 13. The experiments for both devices were performed under identical conditions. Both SFBE and EK15 transducers were first fitted side by side on a floating panel and the panel was placed at the center of 10 m × 10 m × 10 m tank with fresh water. At the time of the experiment, the water level was about 9.3 m. Both the devices were calibrated with the standard copper sphere of 13.7 mm and operated using the setting from

Table 6. The results presented are from two sets of experiments. In the first experiment, a single target was used, whereas, in the second experiment, multiple targets were used.

The first set of experiments performed at KOIST is illustrated in

Figure 14. A tungsten sphere of 36.4 mm was tied with a fishing line and placed at a distance of 4 m (approx. measured from the top) at first and then lower to 6 m (approx.) as shown in the figure. The experiments for EK15 and SFBE were performed separately as both the devices operate at the same frequency. The pulse duration was of 80

s and the ping interval was of 1 s for both the devices. Repetitive experiments were carried out each lasting for 5 to 10 min. The TS data of both the devices were analyzed using Octave software [

36].

Figure 15 shows the comparison of the average TS (dB) against the range (in meter) obtained from the experiment when the sphere was at 4m. Only the signal from 1 m of depth is considered to avoid near field signals. The figure clearly illustrates that the TS is high at the target position and at the bottom but low elsewhere. Furthermore, the graph shows that the signal from SFBE matches well with that of EK15. The measured TS values from the target and from the tank bottom for both devices were of a close match. Furthermore, the target and the bottom ranges detected by both devices were also the same. The experimental results verify that the performance of SFBE is on par with EK15. However, we observed significant fluctuation in TS for EK15 at the range below 3 m which was not in the case of SFBE. Furthermore, since the range resolution of SFBE is 3.75 mm, which is much higher as compared to EK15 (14 mm), SFBE has better signal resolution and characterization of targets near boundaries [

37]. The superiority of high range resolution is demonstrated by the reflected signal from the bottom of the tank in all the experiments. As can be seen in

Figure 15,

Figure 16 and

Figure 17, the range graph of the tank bottom is perpendicular for SFBE, but is slightly inclined in the case of EK15.

Similarly,

Figure 16 shows the comparison of the average TS vs. range for the sphere placed at 6 m. The results obtained were similar to the previous experiment. Furthermore, in both the experiments, the calculated average TS values of the 36.4 mm sphere were almost the same. The results from both experiments show that the noise level of SFBE is much less than that of EK15, especially at the lower depths. Since EK15 is designed to operate at higher depth, it could be the reason for the higher noise level at lower depth.

In order to further analyze the received signal from both the devices, the signals near the target are further scrutinized. The data from the target at 4 m is used for this analysis. By analyzing the data from both the devices, we observed that the target was at 4.15 m. Therefore, the TS values between 4.1 and 4.2 m were used to plot the histogram shown in

Figure 18. The left histogram is for EK15 and the right is for SFBE. As seen in the figure, the TS signal is smooth with linear growth in the case of SFBE. However, in the case of EK15, we can observe peaks and valleys. The reason for the smooth signal in the case of SFBE could be because of better range resolution, which is also illustrated by the high frequency in the histogram. The measured TS values of 36.4 mm tungsten sphere by both the devices are shown in

Table 7. The reference TS of the sphere in the freshwater is –39.8 dB [

30]. The result clearly demonstrates that the TS measured by SFBE is closer to the reference value.

In the second experiment, five tungsten spheres (17.5 mm, 33 mm 36.4 mm, and two 38 mm) were tied together with a fishing line in the ascending order of their sizes and hanged down from the middle of the floating panels as illustrated in

Figure 19. The first sphere (17.5 mm) is at the distance of 3.5 m from the top and the separation between any two adjacent spheres were of 1 m. The objective of this experiment is to compare the performance of SFBE with EK15 in the presence of multiple targets.

Figure 19 shows the comparison of the average TS (dB) against range (in meter) obtained from the second experiment. Here, also, the signal from both devices matches well. The maximum power strength at each target position of SFBE matches well with that of EK15. Similarly, the TS and the range detected for the tank bottom by both the devices were also the same. However, in this experiment, we also observed significant fluctuation of signal in EK15 at the range below 3 m, which was not the case for SFBE.

5.1.2. On Site Experiment

On-site experiments were performed on a commercial offshore fish farm in the sea, which is located in Wando of South Korea. The farm consists of many cages made on a floating grid. Five cages (named Cage1, Cage2, Cage3, cage4, and cage5) were selected for the experiment and their details are shown in

Table 8. The cages are made of nylon nets each having dimensions of 7 m × 7 m × 7 m with an 11 mm square mesh. In all five cages, rockfish were farmed. A total of 30 to 40 fish were sampled and recorded in their respective LFK tables. The fish abundance shown in

Table 8 was obtained from the farm’s records. Our findings from the previous study [

22] suggest that the accuracy of the algorithm is high during dark hours of the lowest current day at the slack time. The experiments were performed from 2020.01.19 to 2020.01.20 (low water current), for two days after sunset and during slack water [

38]. The fish in all cages were more than two years old. Before the fish counting experiment, the empty net analysis was performed on an empty net cage to estimate

. The empty net analysis was performed in a separate cage but had the same age and material as of the five cages. The same

was used for net subtraction in all experiments. The experiments were repeated five times in each cage. The fish count result was divided by the volume of the net (343 m

) to produce an estimated density (fish/m

).

The estimated fish densities were compared to actual densities using a linear mixed-effects model with cage as random effects using statsmodels (v0.11.1) Python module [

39]. In addition,

t-tests were performed to test the differences in the observed slope and the hypothesized slope = 1 and the observed intercept and the hypothesized intercept = 0. The significance was evaluated with

< 0.05. The relative standard error (RSE) was calculated from each set of five repeated measurements and was tested to determine if RSE was consistent across true fish densities using simple linear regression [

39]. Similarly, root mean square error (RMSE) for each experiment was observed.

Figure 20 compares the estimated and true density. As can be seen in the figure, the estimated density was directly proportional to true density (slope = 0.93 and intercept = 1.5). The observed slope was not significantly different from 1 (t = 0.18, d.f. = 1, P = 0.88), and the intercept was also not significantly different from 0 (t = 0.14, d.f. = 23, P = 0.88). In addition, RSE depicted in

Figure 21 did not show any trend as density is varied (F

= 0.32, P = 0.61). The observed average, maximum, and minimum RMSE were 7.36%, 13.52%, and 4.19%, respectively. The results suggest that SFBE device can accurately estimate fish count with an average error of ±7%. The estimated slopes were less than one (although not statistically different than one). This was likely caused by an underestimation of fish abundance at high densities. Since our algorithm does not consider the shadowing effect, it might have contributed to underestimation [

39].

The experimental results presented are based on a single fish species on fixed cage size. Therefore, more tests are required to validate the performance of SFBE. In the future, more experiments with different fish species and various cage sizes will be performed.