Friction and Wear Mechanism Analysis of Polymer Flexible Cable Using a High Natural Frequency Piezoelectric Sensor

Abstract

:1. Introduction

2. Experimental Details

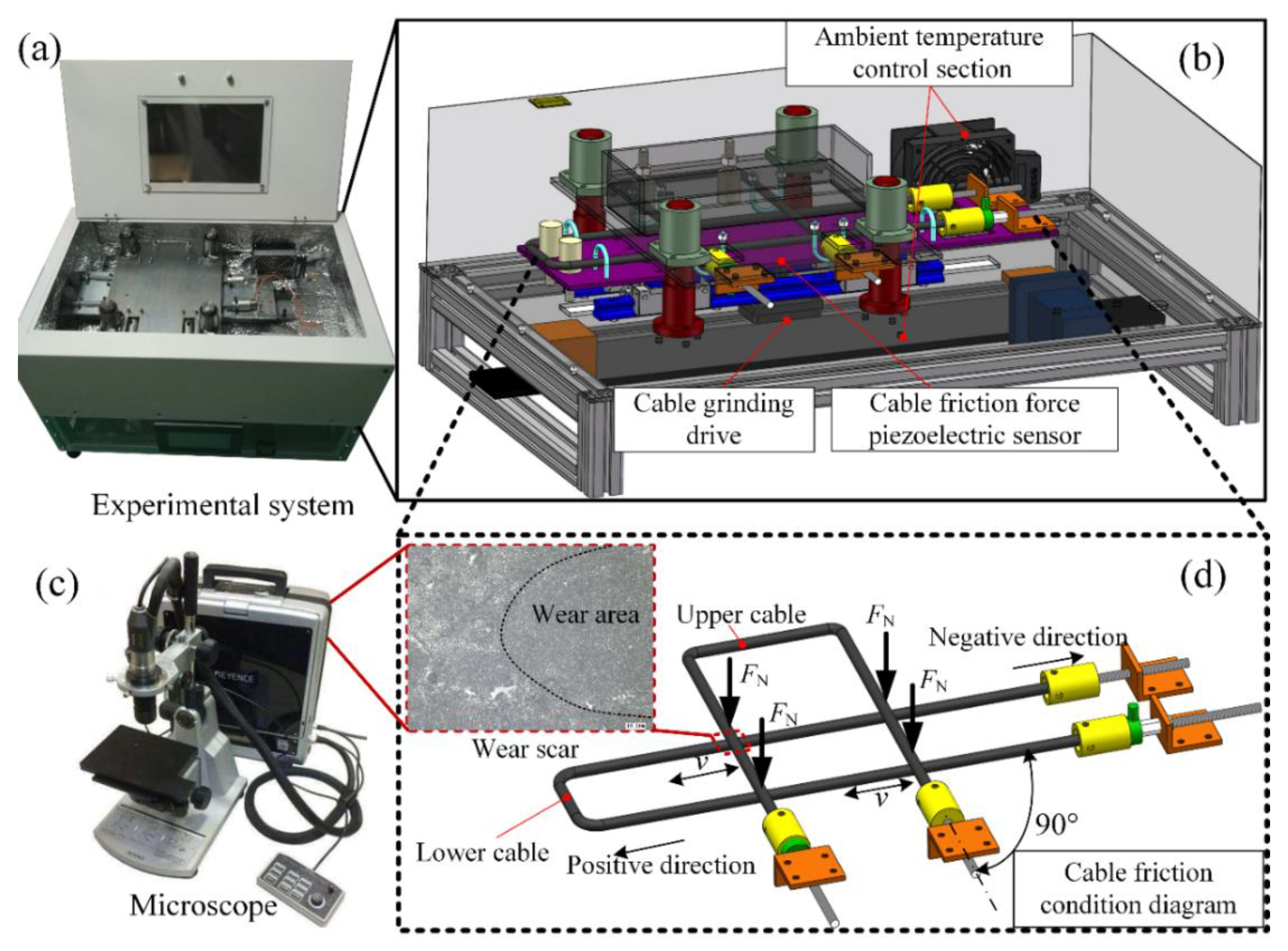

2.1. Experiment System

2.2. Test Management

3. Results and Discussions

3.1. Mechanical Force Chemical Wear Mechanism

3.2. Effect of Relative Speed on Friction at Different Temperatures

- (1)

- At 25 °C, due to the low ambient temperature, the reaction requires more energy and the reaction rate is low. The speed of 10 mm/s causes a short reaction time. Although the friction generates a certain amount of heat, it is not enough to greatly increase the reaction rate. The result shows that the friction force is minimal; when the speed is 7.5 mm/s, the heat generated by the friction increases the reaction rate, and the friction is maximized in combination with the slightly extended reaction time; slower speeds of 5 mm/s provide more reaction time, which will generate more friction force than a speed of 10 mm/s. It also shows that the friction speed has less influence on the friction in a lower temperature environment.

- (2)

- At 40 °C, the reaction rate of the mechanical force chemical is improved due to the increase of the ambient temperature. Therefore, a sufficient-force chemical effect reaction can be performed at a speed of 7.5 mm/s, and generate more friction force; and at a relative speed of 10 mm/s, the friction force is still minimal at 40 °C, due to the fact that the speed is too fast to be sufficient for the chemical reaction.

- (3)

- At 70 °C, the time required for the mechanical force chemical effect reaction becomes very short, and the reaction time at the speed of 10 mm/s can perform a sufficient-force chemical effect reaction. At this time, the faster the relative speed, the more heat will accumulate. The more intense the chemical effect, the more the friction force increases with the increase of speed.

3.3. Effect of Positive Pressure on Friction

3.4. Effect of Ambient Temperature on Friction

- (1)

- At 5 mm/s, the reaction time is the longest, and as the number of friction times increases, the accumulated energy is the largest, so this inhibition phenomenon is the most obvious. The friction force decreases most rapidly along with the increasing temperature.

- (2)

- The friction force decreases along with the increase of ambient temperature at a speed of 7.5 mm/s. Because its reaction time is shorter than the time at 5 mm/s, as the value of friction times increases, the energy accumulation is slightly less, which causes the effect to be slightly smaller, and the reduction of friction is lower.

- (3)

- At 10 mm/s, the reaction time is the shortest. The energy accumulated in the reaction process under the first 10,000 friction times cannot reach the heat required for the mechanical force chemical effect to suppress the phenomenon, so it mainly reflects the positive reaction phenomenon. The response of the acceleration is increased, and the high friction is gradually increased. It can be predicted that the friction force will gradually decrease with the increase of temperature.

4. Conclusions

- (1)

- The form of friction and wear between cables is neither commonly considered as abrasive wear, nor contact wear, but is a form of friction and wear dominated by mechanical-force chemical reactions. It has been verified by the research on relations between the friction and different conditions.

- (2)

- The relative speed between cables will greatly affect the cable friction, which will be greatly affected by the ambient temperature. When the ambient temperature is low (25 °C), the friction speed is the main factor, and the friction heat is the auxiliary influencing factor. At 40 °C, because the lower speed has sufficient reaction time, the friction is large. Friction decreases with increasing speed; in high temperature (70 °C), the ambient temperature is sufficient to provide reaction heat. The friction will increase with the increase of speed.

- (3)

- The ambient temperature will greatly affect the cable friction by affecting the activation energy of the mechanical-force chemical reaction. At 5 mm/s, the friction force decreases most rapidly along with the increasing temperature; the friction force decreases along with the increase of ambient temperature at a speed of 7.5 mm/s; at 10 mm/s, the reaction time is the shortest. The response of the acceleration is increased, and the high friction is gradually increased.

- (4)

- The effect of positive pressure on the cable friction force is mainly to increase the reaction efficiency by increasing the contact area. However, the presence of the copper wires inside the cable reduces the deformation and the contact area. The rod-shaped wear chips generated have a certain lubricating effect and reduce the friction coefficient between cables. These curb the increase in friction force.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Park, C.; Kyung, J.H.; Park, D.I. Development of an industrial robot manipulator for the easy and safe human-robot cooperation. In Proceedings of the International Conference on Control Automation & Systems, Gyeonggi-do, Korea, 27–30 October 2010. [Google Scholar]

- Wang, T. Research Status and Industrialization Development Strategy of Chinese Industrial Robot. J. Mech. Eng. 2014, 50, 1. [Google Scholar] [CrossRef]

- Wade, E.; Asada, H.H. One-Wire Smart Motors Communicating over the DC Power Bus-Line with Application to Endless Rotary Joints. In Proceedings of the 2002 IEEE International Conference on Robotics and Automation (Cat. No.02CH37292), Washington, DC, USA, 11–15 May 2002. [Google Scholar]

- Feng, B. Study on the Composition and Control of Robot Structure. Appl. Mech. Mater. 2013, 273, 646–649. [Google Scholar] [CrossRef]

- Fithri, P.; Riva, N.A.; Susanti, L.; Yuliandra, B. Safety analysis at weaving department of PT. X Bogor using Failure Mode and Effect Analysis (FMEA) and Fault Tree Analysis (FTA). In Proceedings of the 2018 5th International Conference on Industrial Engineering and Applications (ICIEA), Singapore, 26–28 April 2018. [Google Scholar]

- Hu, Y.; Chen, G.X.; Zhang, S.D.; Gao, G.Q.; Wu, G.N.; Zhang, W.H.; Zhou, Z.R. Comparative investigation into the friction and wear behaviours of a Cu-Ag contact wire/carbon strip and a pure copper contact wire/carbon strip at high speeds. Wear 2017, 376, 1552–1557. [Google Scholar] [CrossRef]

- Zhang, S.; Shen, R.; Dai, K.; Wang, L.; De Roeck, G.; Lombaert, G. A methodology for cable damage identification based on wave decomposition. J. Sound Vib. 2019, 442, 527–551. [Google Scholar] [CrossRef]

- Yang, H.J.; Chen, G.X.; Gao, G.Q.; Wu, G.N.; Zhang, W.H. Experimental research on the friction and wear properties of a contact strip of a pantograph-catenary system at the sliding speed of 350 km/h with electric current. Wear 2017, 332, 949–955. [Google Scholar] [CrossRef]

- Jia, S.G.; Liu, P.; Ren, F.Z.; Tian, B.H.; Zheng, M.S.; Zhou, G.S. Sliding wear behavior of copper alloy contact wire against copper-based strip for high-speed electrified railways. Wear 2007, 262, 772–777. [Google Scholar] [CrossRef]

- Ismailov, G.M. Flexible cable strength with regard to tribological interaction of its elements. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 233, 638–648. [Google Scholar] [CrossRef]

- Perier, V.; Dieng, L.; Gaillet, L.; Tessier, C.; Fouvry, S. Fretting-fatigue behaviour of bridge engineering cables in a solution of sodium chloride. Wear 2009, 267, 308–314. [Google Scholar] [CrossRef]

- Kotov, M.A.; Zhukov, V.A.; Chernov, R.I.; Cheryachukina, G.S. A study of the stress concentration during distension of a damaged rubber cable conveyor belt. Sov. Min. 1984, 20, 135–139. [Google Scholar] [CrossRef]

- Chang, F. Electrical properties of flexible polypropylene based cable insulation materials. J. Mater. Sci. 2006, 41, 2037–2043. [Google Scholar] [CrossRef]

- Ul-Hamid, A.; Soufi, K.Y.; Al-Hadhrami, L.M.; Shemsi, A.M. Failure investigation of an underground low voltage XLPE insulated cable. Anti Corros. Methods Mater. 2015, 62, 281–287. [Google Scholar] [CrossRef]

- Lee, M.K.; Han, S.H.; Park, K.H.; Park, J.J.; Kim, W.W.; Hwang, W.J.; Lee, G.J. Design Optimization of Bulk Piezoelectric Acceleration Sensor for Enhanced Performance. Sensors 2019, 19, 3360. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xudong, F.; Huan, L. Measuring Micro-Friction Torque in MEMS Gas Bearings. Sensors 2016, 16, 726. [Google Scholar] [CrossRef]

- Tian, B.; Liu, H.; Yang, N.; Zhao, Y.; Jiang, Z. Design of a Piezoelectric Accelerometer with High Sensitivity and Low Transverse Effect. Sensors 2016, 16, 1587. [Google Scholar] [CrossRef] [Green Version]

- Chang, X.D.; Peng, Y.X.; Zhu, Z.C.; Gong, X.S.; Yu, Z.F.; Mi, Z.T.; Xu, C.M. Experimental investigation of mechanical response and fracture failure behavior of wire rope with different given surface wear. Tribol. Int. 2018, 119, 208–221. [Google Scholar] [CrossRef]

- Minlan, J.; Hongliang, F. Mechanical Chemistry of Polymer Compounds, 1st ed.; Chemical Industry Press: Beijing, China, 1982; pp. 46–64. [Google Scholar]

- Garcia-Manyes, S.; Liang, J.; Szoszkiewicz, R.; Kuo, T.L.; Fernández, J.M. Force-activated reactivity switch in a bimolecular chemical reaction. Nat. Chem. 2009, 1, 236. [Google Scholar] [CrossRef] [PubMed]

- Casale, A. Polymer Stress Reactions, 3rd ed.; Academic Press: New York, NY, USA, 1978; pp. 154–196. [Google Scholar]

- Tongamp, W.; Zhang, Q.; Saito, F. Mechanochemical decomposition of PVC by using La2O3 as additive. J. Hazard. Mater. 2006, 137, 1226–1230. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, Y.; Zhang, Q.; Saito, F. Mechanochemical Decomposition of an Aromatic Polyamide Film. Ind. Eng. Chem. Res. 2003, 42, 5018–5023. [Google Scholar] [CrossRef]

- Zhang, S.W.; Deguo, W.; Weihua, Y. Investigation of abrasive erosion of polymers. J. Mater. Sci. 1995, 30, 4561–4566. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, D.; Ge, S. Effect of displacement amplitude on fretting fatigue behavior of hoisting rope wires in low cycle fatigue. Tribol. Int. 2012, 52, 178–189. [Google Scholar] [CrossRef]

| Ambient Temperature (°C) | Relative Speed (mm/s) | Positive Pressure (kg) |

|---|---|---|

| 25 | 5 | 2 |

| 50 | 7.5 | 8.5 |

| 70 | 10 | 15 |

| 21.5 |

| Order | Ambient Temperature (°C) | Relative Speed (mm/s) | Positive Pressure (kg) | |

|---|---|---|---|---|

| Part 1 | 1 | 25.0 | 5.0 | 2.0 |

| 2 | 25.0 | 7.5 | 2.0 | |

| 3 | 25.0 | 10.0 | 2.0 | |

| 4 | 50.0 | 5.0 | 2.0 | |

| 5 | 50.0 | 7.5 | 2.0 | |

| 6 | 50.0 | 10.0 | 2.0 | |

| 7 | 70.0 | 5.0 | 2.0 | |

| 8 | 70.0 | 7.5 | 2.0 | |

| 9 | 70.0 | 10.0 | 2.0 | |

| Part 2 | 10 | 25.0 | 5.0 | 2.0 |

| 11 | 25.0 | 5.0 | 8.5 | |

| 12 | 25.0 | 5.0 | 15.0 | |

| 13 | 25.0 | 5.0 | 21.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, J.; Ren, X.; Zheng, J. Friction and Wear Mechanism Analysis of Polymer Flexible Cable Using a High Natural Frequency Piezoelectric Sensor. Sensors 2020, 20, 1044. https://doi.org/10.3390/s20041044

Ni J, Ren X, Zheng J. Friction and Wear Mechanism Analysis of Polymer Flexible Cable Using a High Natural Frequency Piezoelectric Sensor. Sensors. 2020; 20(4):1044. https://doi.org/10.3390/s20041044

Chicago/Turabian StyleNi, Jing, Xu Ren, and Junqiang Zheng. 2020. "Friction and Wear Mechanism Analysis of Polymer Flexible Cable Using a High Natural Frequency Piezoelectric Sensor" Sensors 20, no. 4: 1044. https://doi.org/10.3390/s20041044