A New Logging-While-Drilling Method for Resistivity Measurement in Oil-Based Mud †

Abstract

:1. Introduction

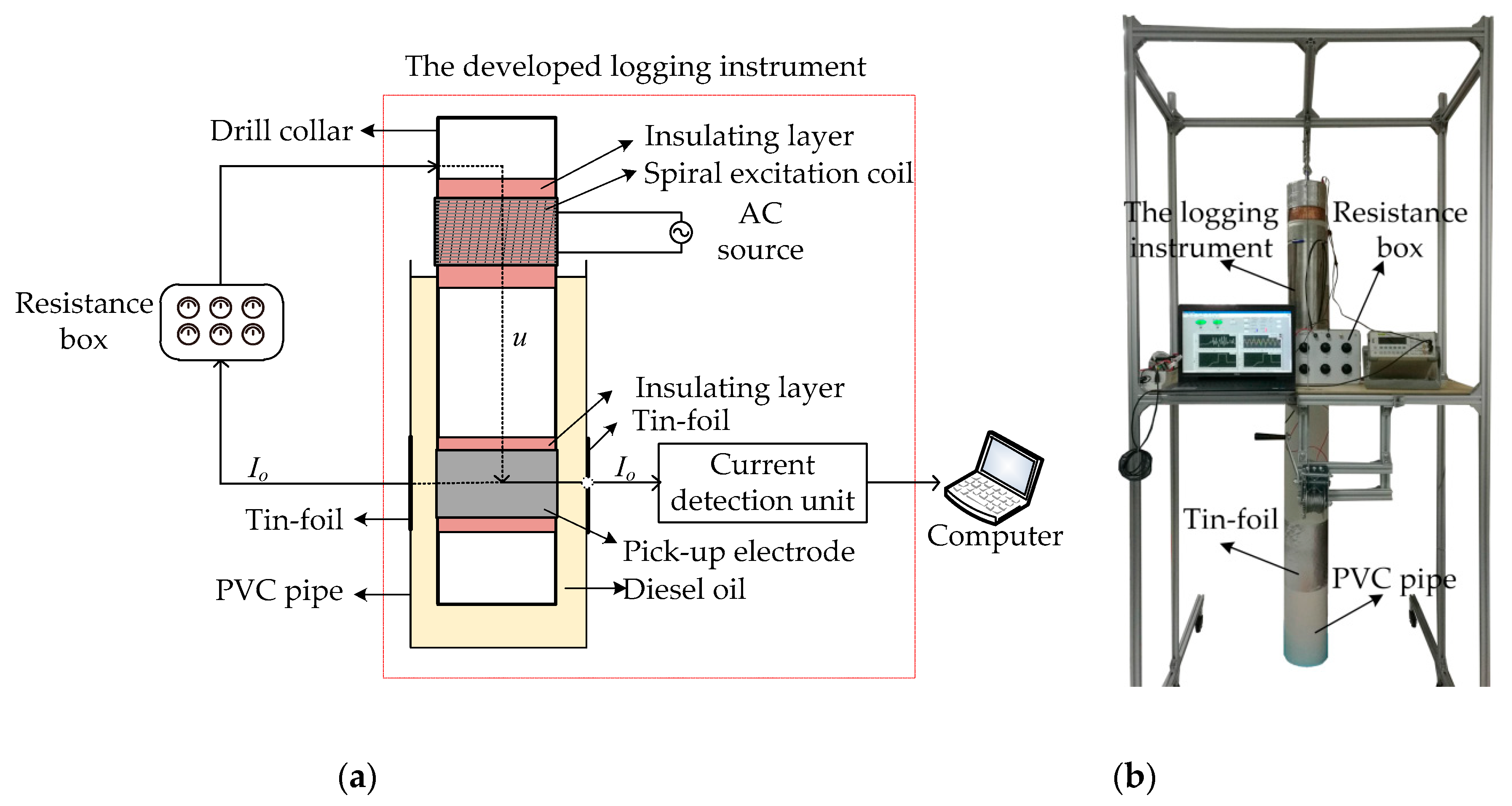

2. Methods

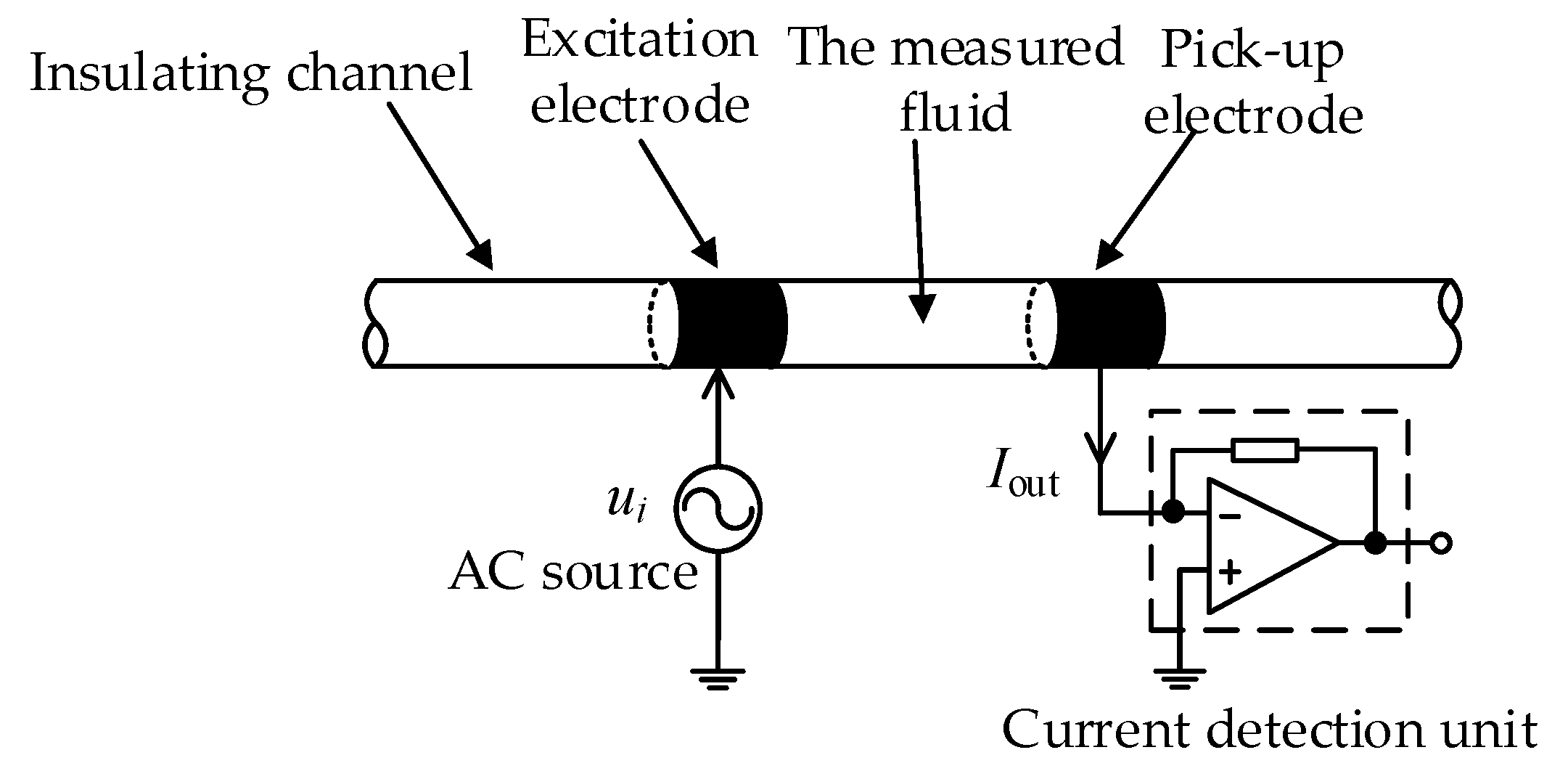

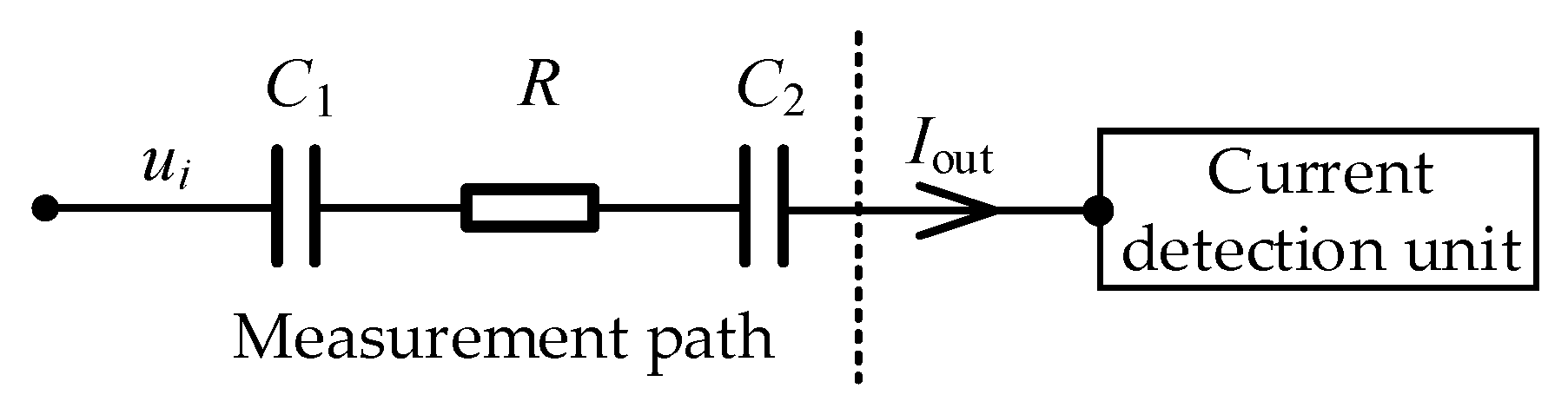

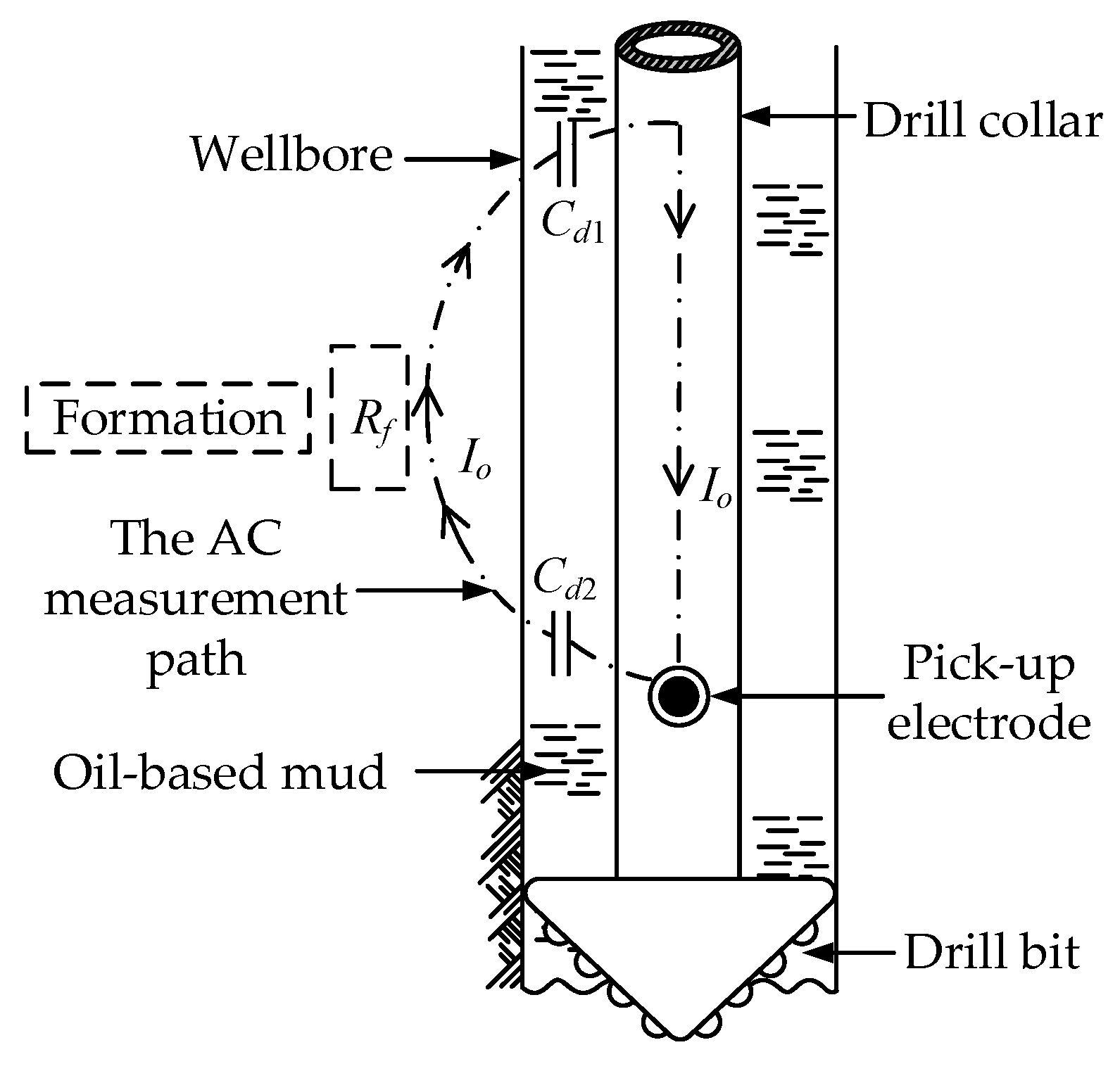

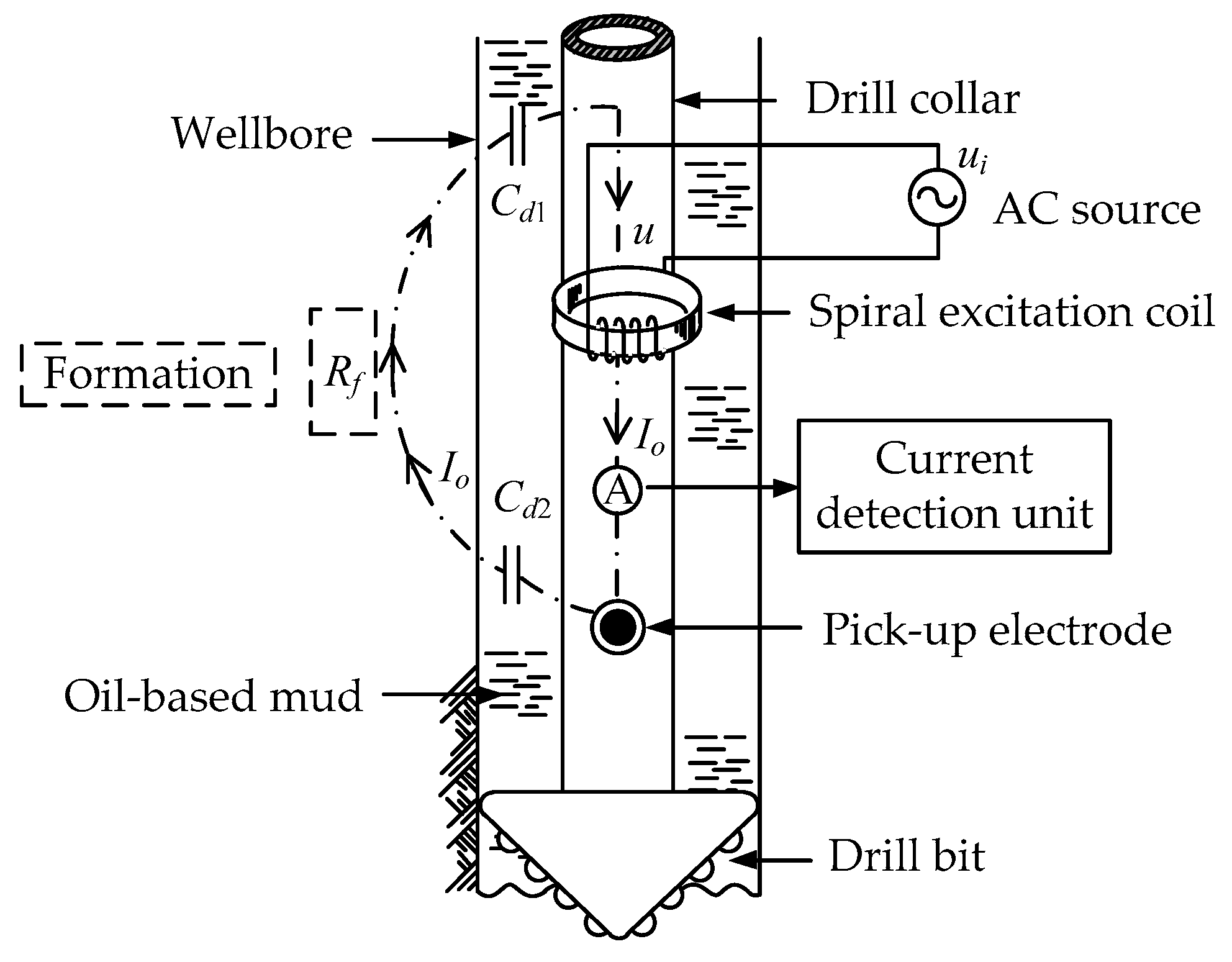

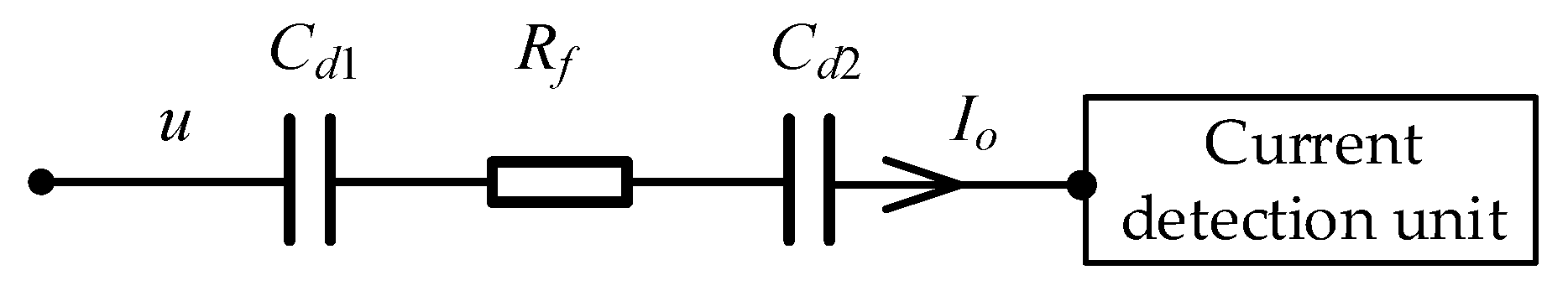

2.1. Application of C4D Technique in LWD

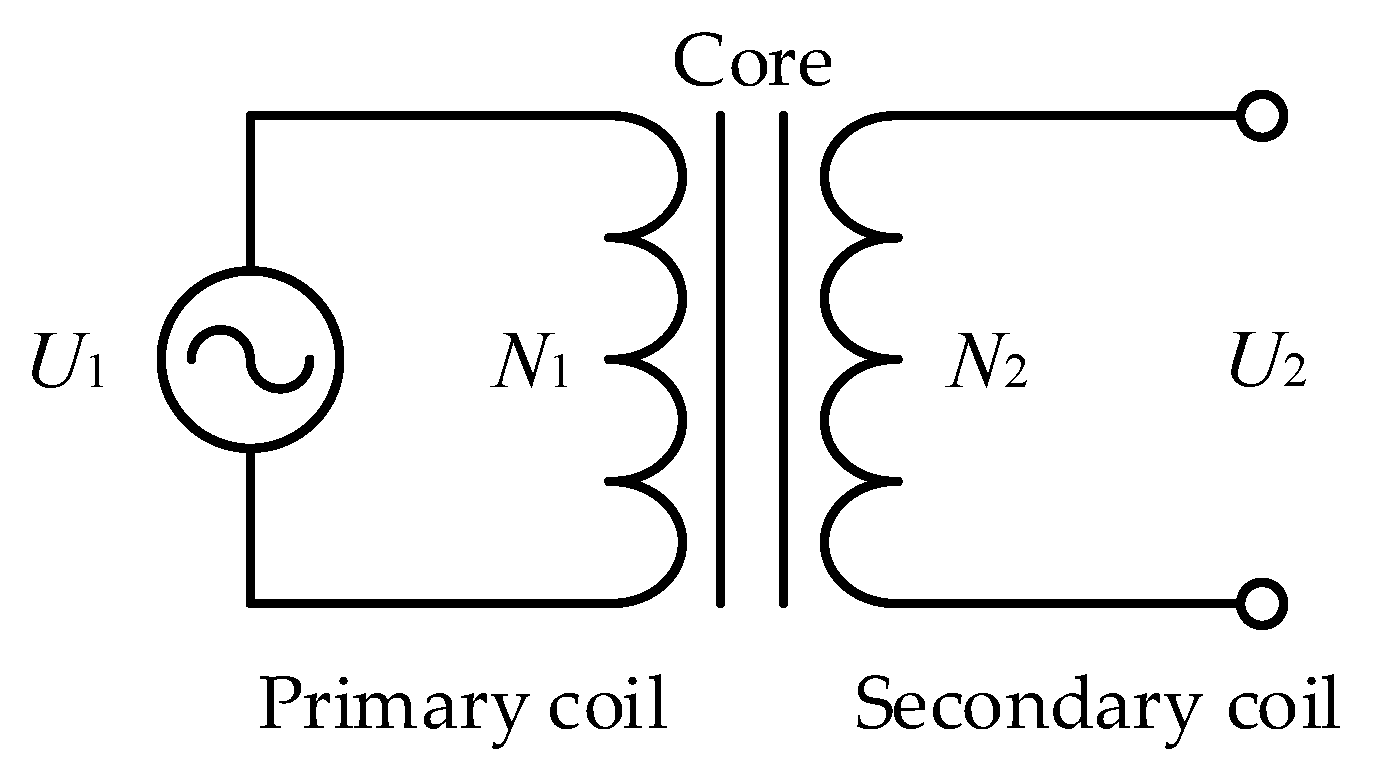

2.2. Application of Inductive Coupling Principle in LWD

2.3. The New Oil-Based LWD Method

3. Results

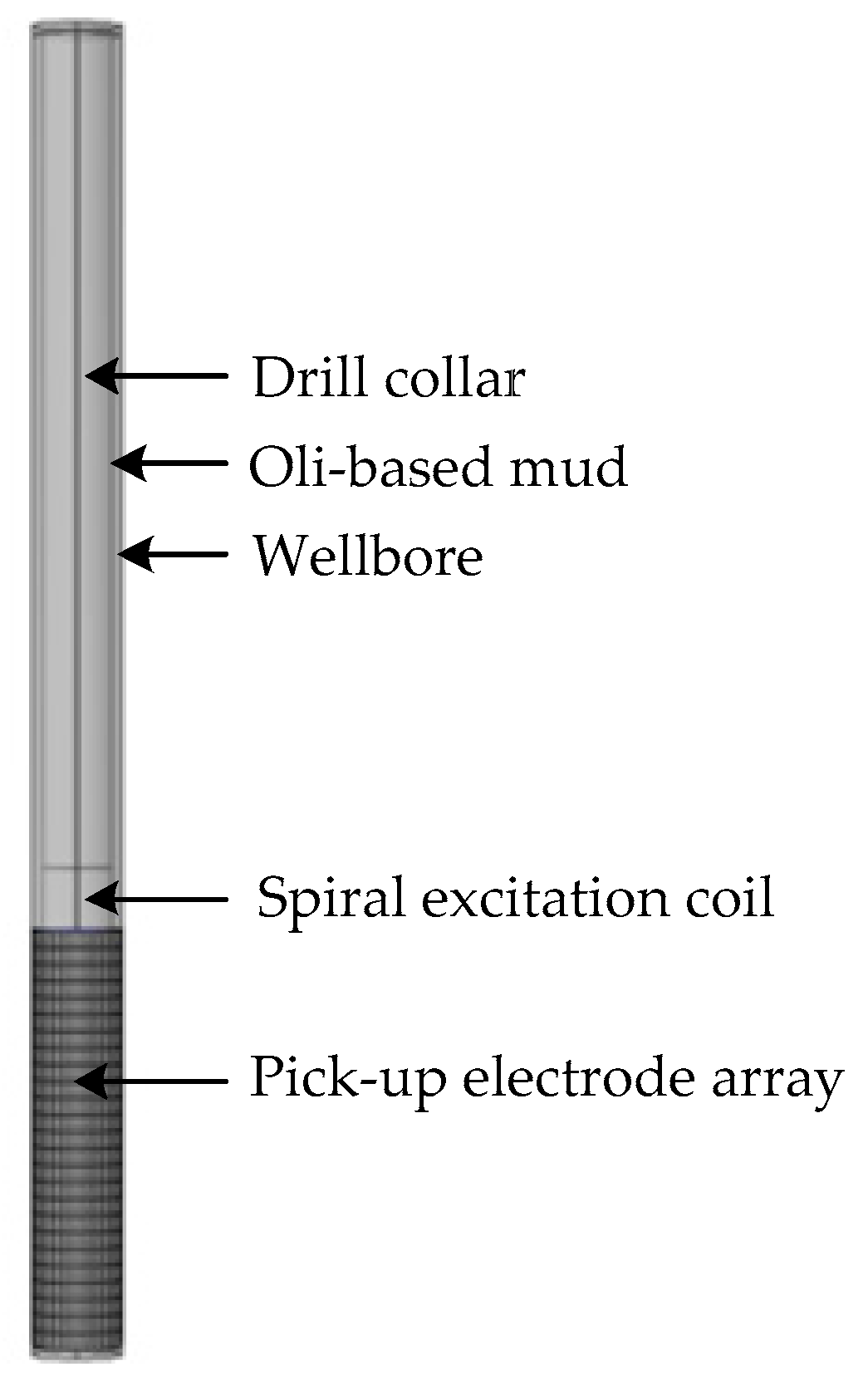

3.1. Numerical Simulation

3.1.1. Numerical Simulation Setup

3.1.2. Numerical Simulation Results

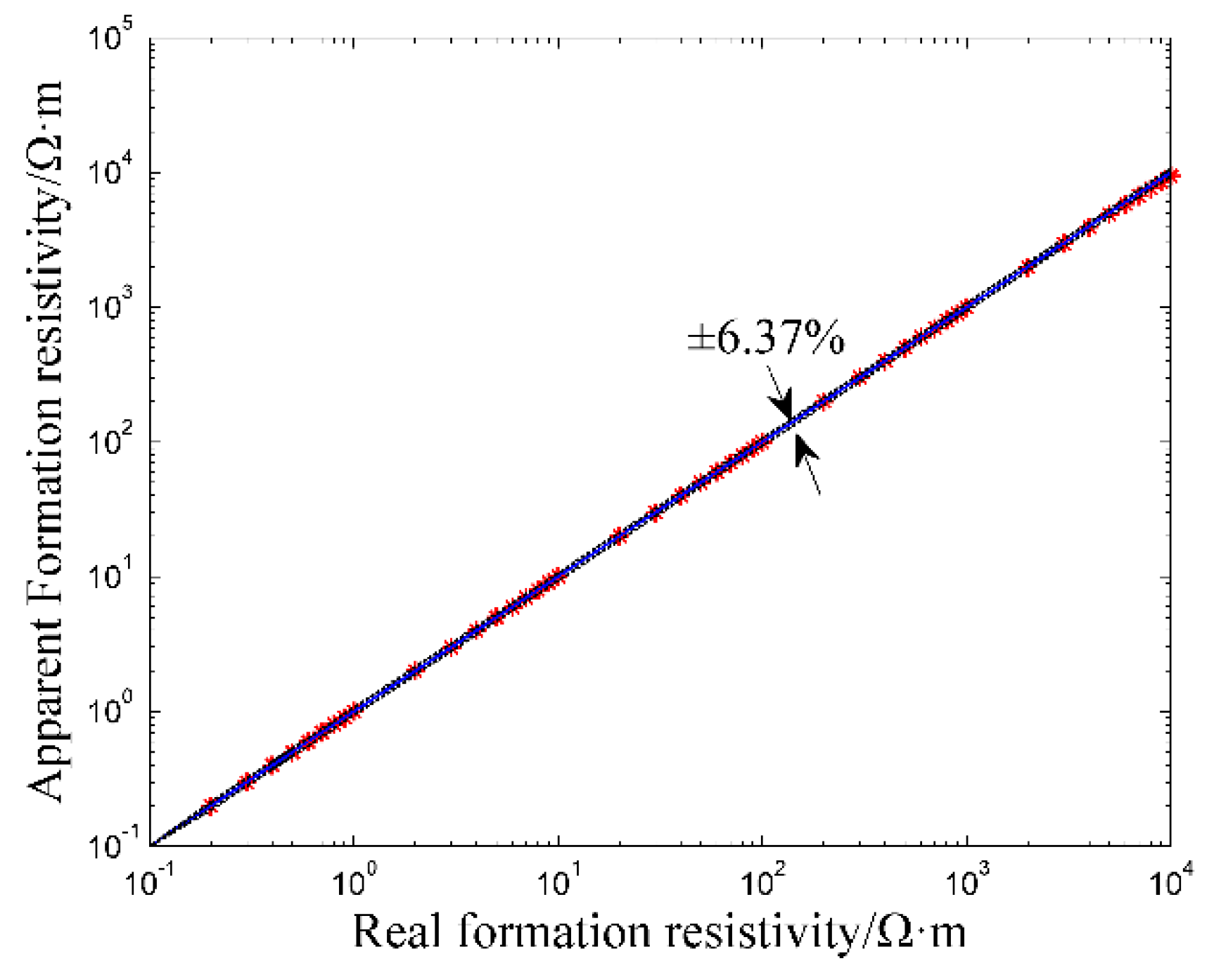

- Measurement Accuracy of Formation ResistivityAccording to the relevant published literatures, the range of oil-based logging instrument is generally between 0.2 Ω·m and 10,000 Ω·m [6,17,18]. In the numerical simulation, the formation resistivity is set between 0.2 Ω·m and 10,000 Ω·m. The relative dielectric constant of OBM is set to 3 and the resistivity of OBM is set to 1e11 Ω·m.In this work, the relative error is introduced to evaluate the measurement accuracy of the logging instrument. The relative error σR can be determined by the following equation:where Ra is the measured apparent resistivity of the logging instrument, Rt is the real resistivity of the measured formation.The resistivity measurement result of the logging instrument is shown in Figure 11.As is shown in Figure 11, the measured apparent formation resistivity is very close to the real formation resistivity. For the range of 0.2 Ω·m to 2000 Ω·m, the maximum relative error σR is ± 0.56% and for the range of 2000 Ω·m to 10,000 Ω·m, the maximum relative error σR is ± 6.37%. The simulation result shows that the logging instrument has good measurement accuracy in the common range of 0.2 Ω·m to 10,000 Ω·m.

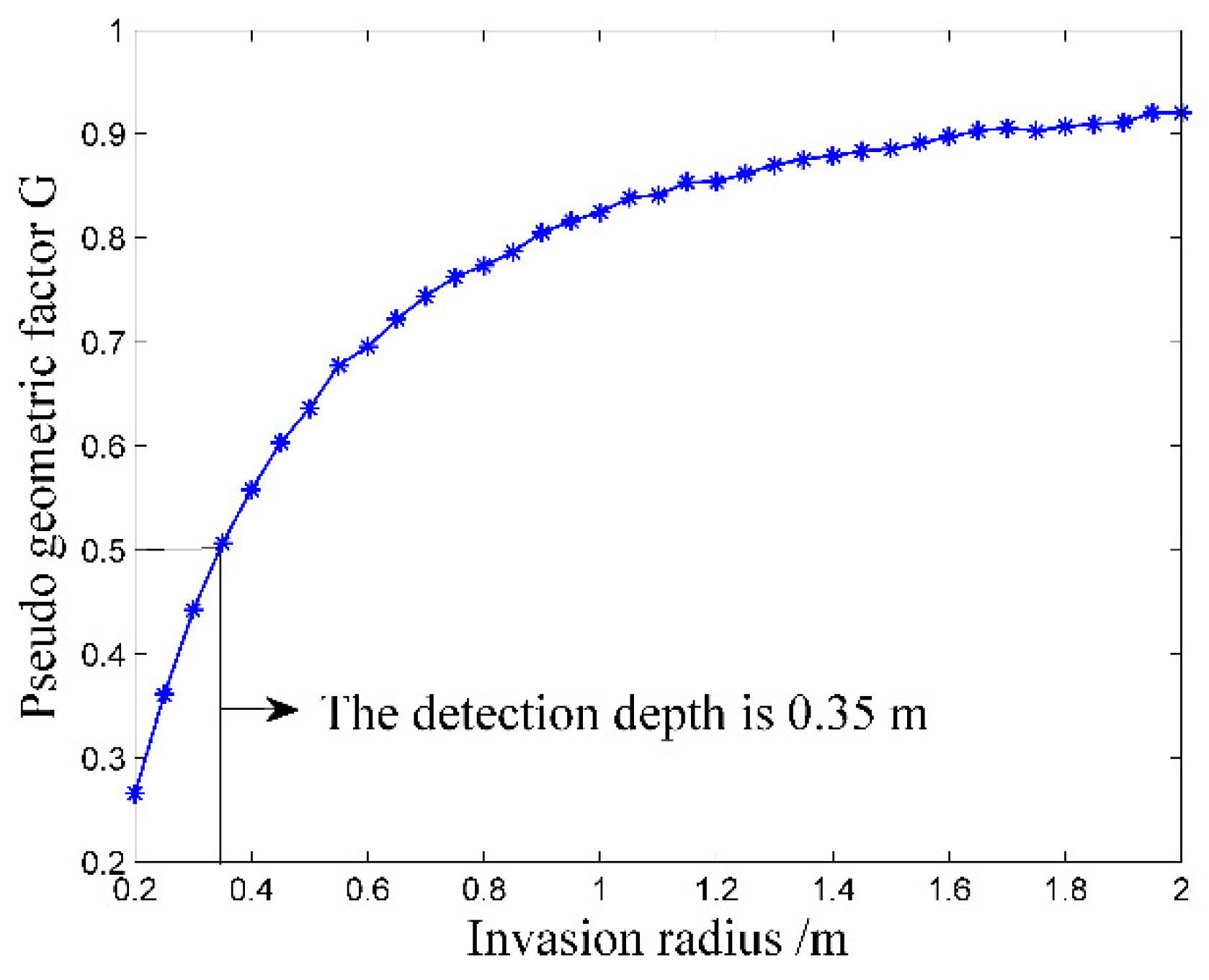

- Detection Depth and Invasion RadiusIn the well logging field, detection depth refers to the horizontal range of the detectable formation that affects the measurement results, while invasion radius means the invasion degree of the OBM into the formation while drilling [36,37]. The detection depth of the logging instrument is generally determined by the pseudo geometric factor, i.e. the detection depth equals to the invasion radius where the pseudo geometric factor is 0.5 [36,37]. The pseudo geometric factor G is determined by the following equation:where Ra is the apparent resistivity of the formation, Rt is the real resistivity of the formation, Rx is the apparent resistivity of the formation when the invasion radius is infinite.As is shown in Figure 12, the pseudo geometric factor G increases with the increase of the invasion radius. When the invasion radius is large enough, the pseudo geometric factor G is almost unchanged. At G = 0.5, the invasion radius is 0.35 m, so the detection depth of the logging instrument is 0.35 m.

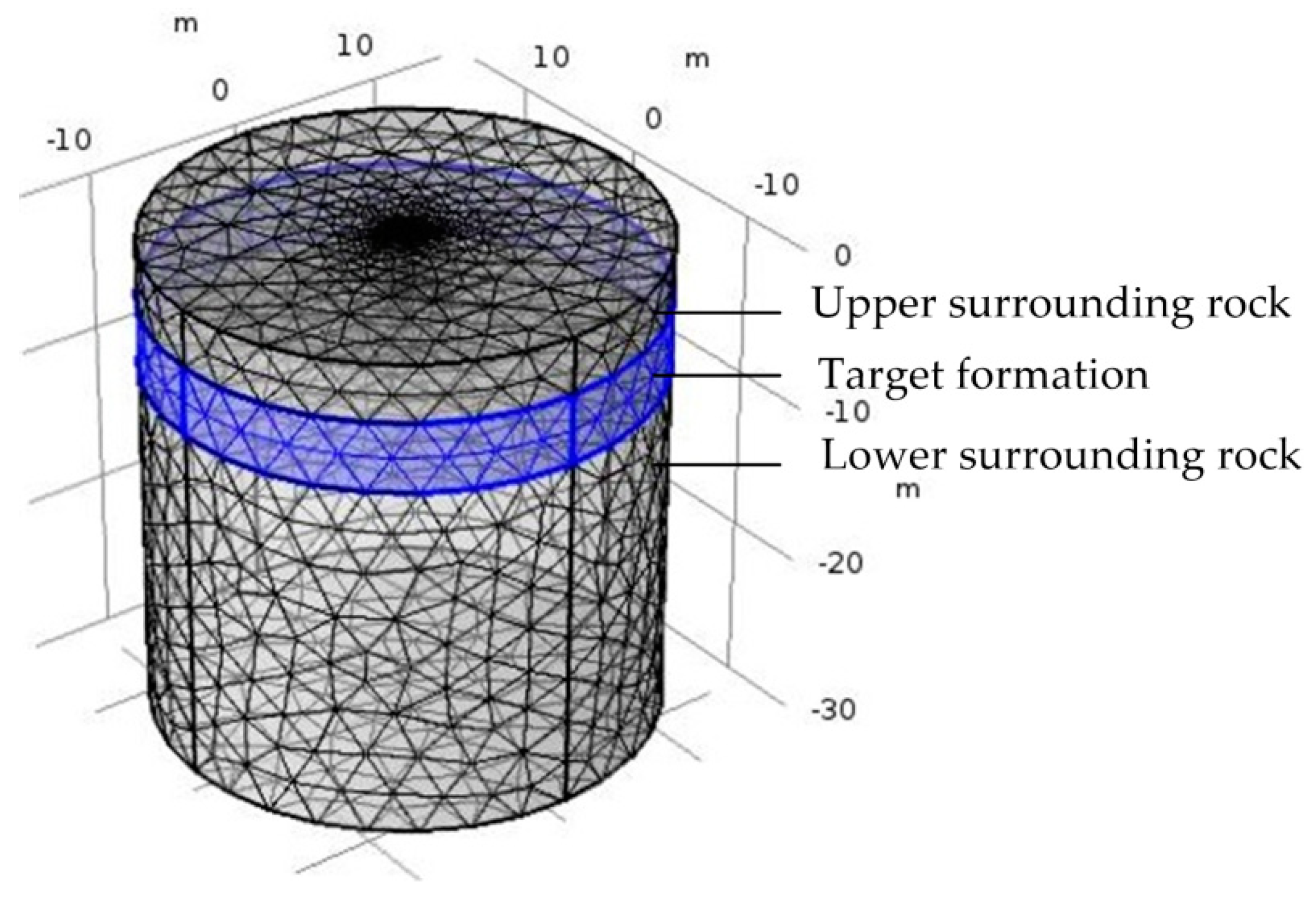

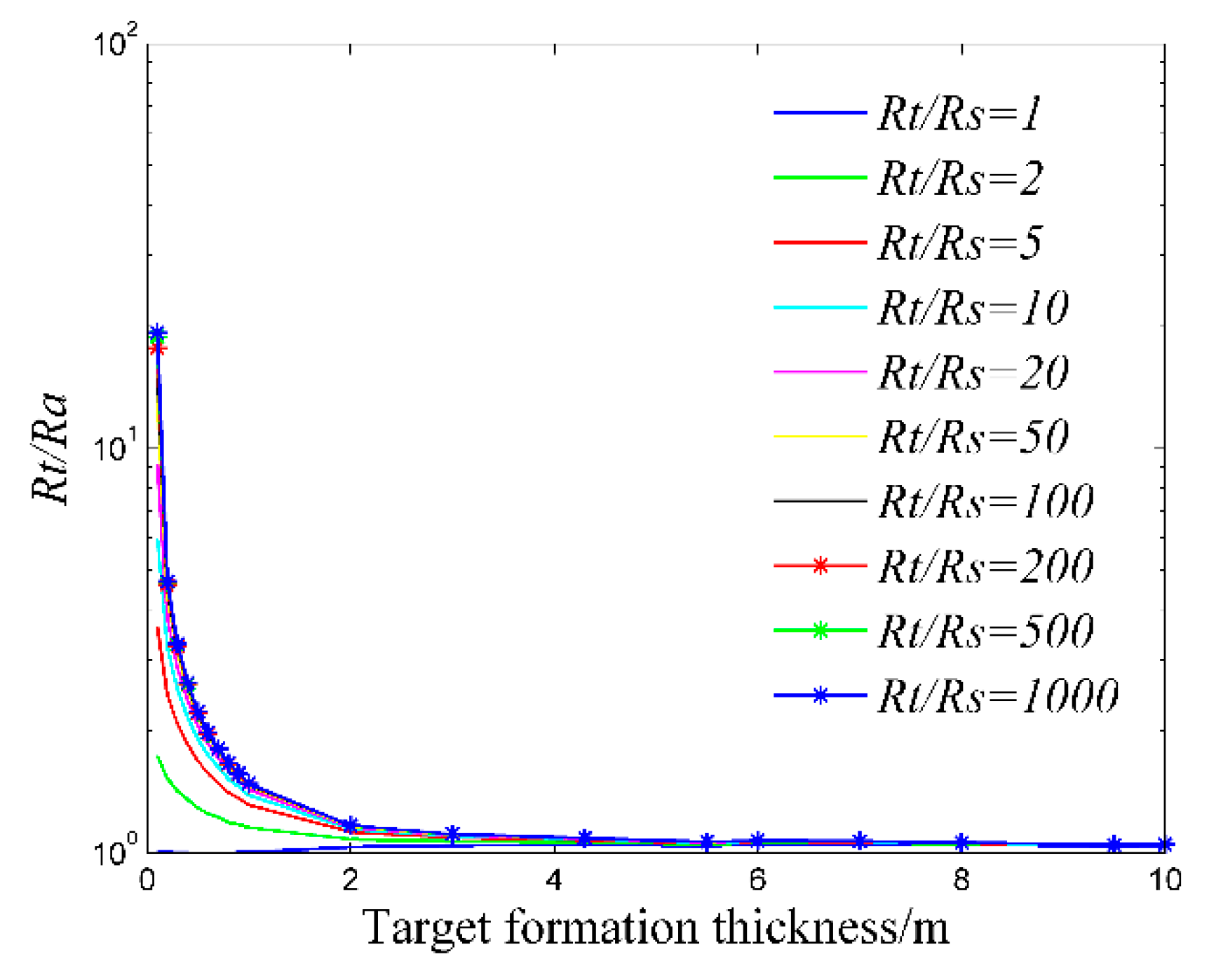

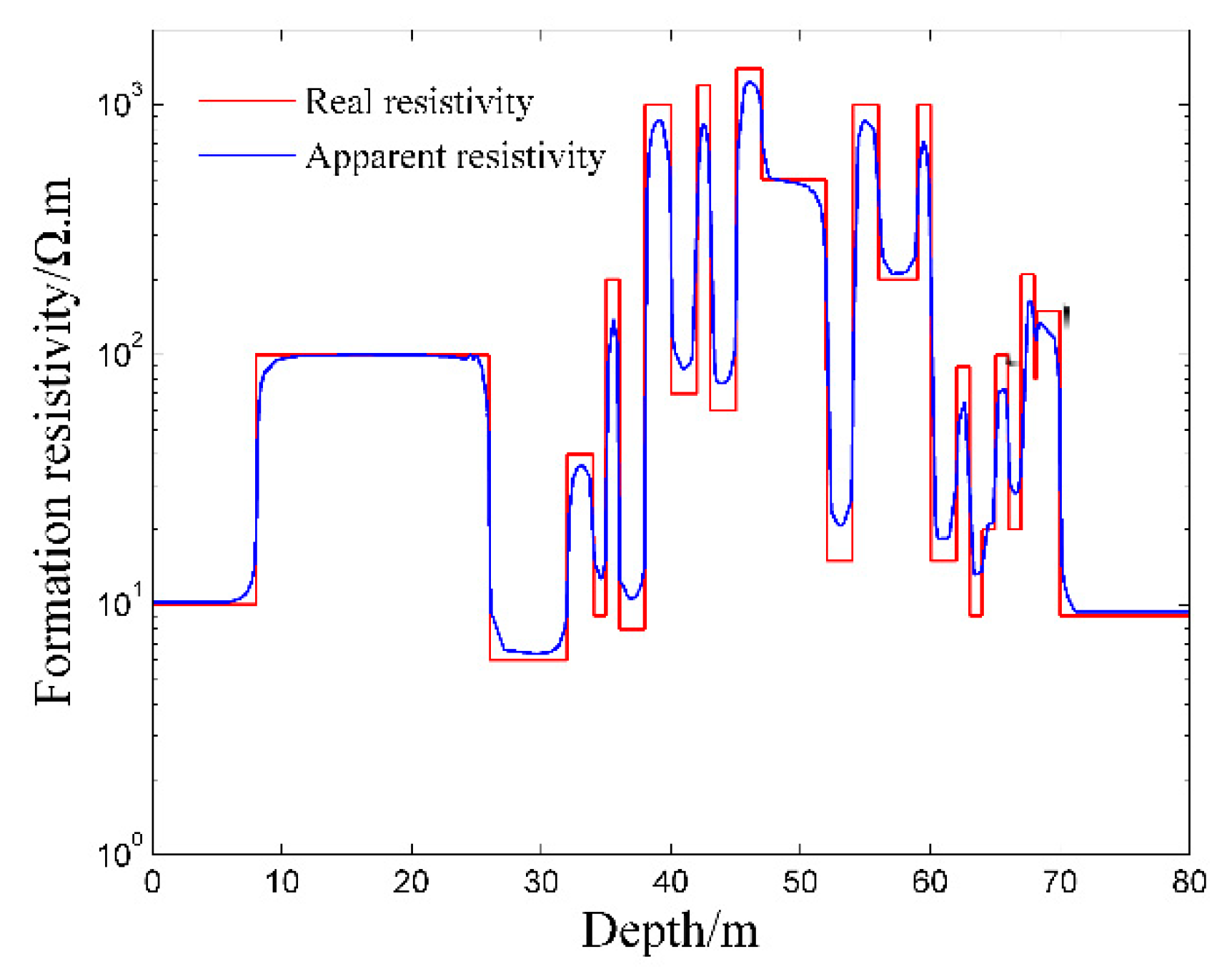

- Influence of Surrounding Rock and Vertical ResolutionInfluence of surrounding rock refers to the influence of upper and lower surrounding rock resistivity (Rs) on the target formation resistivity (Rt). The three-layer formation model is shown in Figure 13.Correction coefficient Rt/Ra is generally used to describe the influence of surrounding rock [36,37]. The closer Rt/Ra is to 1, the smaller the influence of surrounding rock is. As is shown in Figure 14, correction coefficient Rt/Ra is negatively correlated with the thickness of the target formation and positively correlated with Rt/Rs, which is consistent with the theory of well logging [36,37].Oklahoma formation model is a classic isotropic model used to test electric logging methods [36,38,39]. It has a large change in resistivity and thickness, and the thinnest formation thickness is only 0.2 m, which can fully reflect the complex situation of the real formation and evaluate the performance of the logging instrument. As is shown in Figure 15, the vertical depth of the Oklahoma formation is 80 m and the diameter of the Oklahoma formation is 30 m. In the Oklahoma formation model, the grid density reflects the thickness of the formation. The thickness of formation changes greatly, which can test the vertical resolution of the logging instrument.Figure 16 shows the logging response of the logging instrument to the Oklahoma formation. As is shown in Figure 16, the measured apparent resistivity of the logging instrument is close to the real formation resistivity. Further, the variation trend of the apparent resistivity is basically consistent with that of the real formation resistivity, indicating that the logging instrument can accurately reflect the resistivity change of the Oklahoma formation. Besides, the logging instrument can reflect the thickness change of the Oklahoma formation and even detect the formation with the thickness of 0.2 m at the vertical depth range of 68 m to 68.2 m, showing that the logging instrument has a high vertical resolution of thin formation layers.

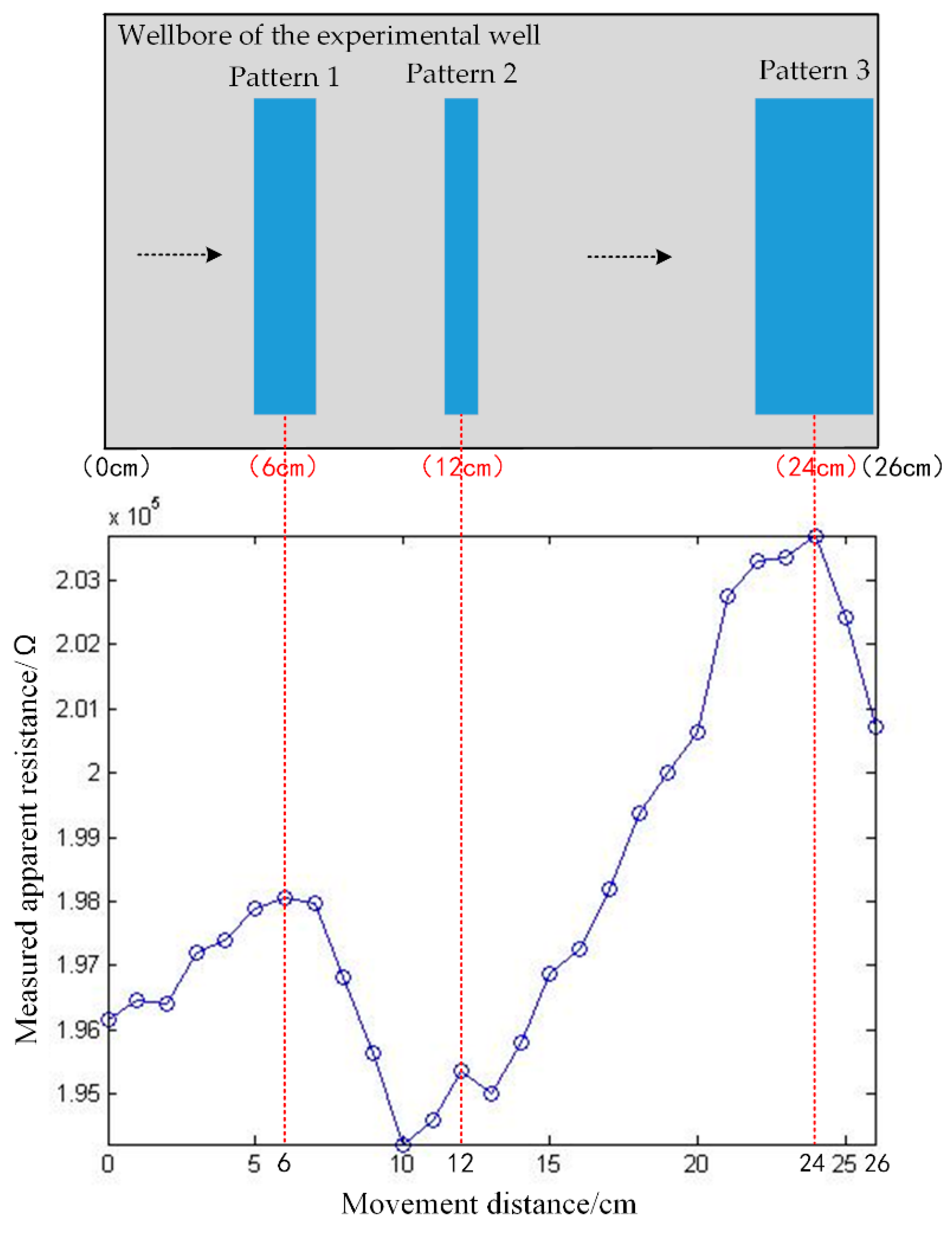

3.2. Practical Experiments

3.2.1. Resistance Box Experiment

3.2.2. Well Logging Experiment

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ekstrom, M.P.; Dahan, C.A.; Chen, M.Y. Formation imaging with microelectrical scanning arrays. In Proceedings of the SPWLA 27th Annual Logging Symposium, Houston, TX, USA, 9–13 June 1986. [Google Scholar]

- Gao, J.S.; Liu, X.; Zhao, J.P. A new electrical imaging logging method in oil-based mud for low-resistivity formation based on concave electrode couples. J. Petrol. Sci. Eng. 2020, 185, 106675. [Google Scholar] [CrossRef]

- Færgestad, I.M.; Strachan, C.R. Developing a high-performance oil-base fluid for exploration drilling. Oilfield Review. 2014, 26, 26–33. [Google Scholar]

- Gao, J.S.; Sun, J.M.; Jiang, Y.J. A novel quantitative imaging method for oil-based mud: the full-range formation resistivity. J. Petrol. Sci. Eng. 2018, 162, 844–851. [Google Scholar] [CrossRef]

- Habashy, T.; Hayman, A.; Chen, Y.H. System and method for imaging properties of subterranean formations. US patent No. US8754651B2, 7 June 2012. [Google Scholar]

- Gao, J.S.; Jiang, L.M.; Liu, Y.P. Review and Analysis on the Development and Applications of Electrical Imaging Logging in Oil-Based Mud. J. Appl. Geophy. 2019, 171, 1–11. [Google Scholar] [CrossRef]

- Yang, J.; Garcia, A.R.; Arensdorf, J.J.; Clapper, D.K.; Darugar, Q.A. Electrically Conductive Oil-Based Fluids. US patent No. US10280356B2, 7 May 2019. [Google Scholar]

- Halliday, W.S.; Schwertner, D.W.; Strickland, S.D. Drilling Fluids Comprising Sized Graphite Particles. US patent No. 7087555B2, 8 August 2006. [Google Scholar]

- Thaemlitz, C.J. Electrically Conductive Oil-Based Mud. US patent No. 7112557B2, 26 September 2006. [Google Scholar]

- Jones, T.G.J.; Tustin, G.J. Electrically Conductive Non-Aqueous Wellbore Fluid. US patent No. 7399731B2, 15 July 2008. [Google Scholar]

- Palmer, B.J.; Fu, D.; Card, R. Wellbore Fluids and Their Application. US patent 6608005B2, 19 August 2003. [Google Scholar]

- Monteiro, O.; Quintero, L. Graphene-Containing Fluids for Oil and Gas Exploration and Production. US patent 20120245058A1, 27 September 2012. [Google Scholar]

- Hoelscher, B.K.P.; Bovet, C.; Friedheim, J. Electrically Conductive Wellbore Fluids and Methods of Use. US patent No. 20150284619A1, 8 October 2015. [Google Scholar]

- Quintero, L.; Cardenas, A.E.; Clark, D.E. Nanofluids and Methods of Use for Drilling and Completion Fluids. US patent No. 8822386B2, 2 September 2014. [Google Scholar]

- Zanten, R.V. Electrically Conductive Oil-Based Drilling Fluids. US patent No. 8763695B2, 1 July 2014. [Google Scholar]

- Clark, B.O.; Kleinberg, R.L.; Seleznev, N.V. Electrical Heating of Oil Shale and Heavy Oil Formations. US patent No. 9410408B2, 9 August 2016. [Google Scholar]

- Williams, P.; McQuown, S.; Palacio, M.D.B. A new small diameter, memory based, microresistivity imaging tool engineered for oil-based mud: Design and applications. In Proceedings of the SPWLA 57th Annual Logging Symposium, Reykjavik, Iceland, 25–29 June 2016. [Google Scholar]

- Liu, Y.; Yu, Y.; Wu, D. Development and application of oil base mud resistivity imaging logging instrument OBIT. In Proceedings of the 18th Annual Logging Symposium, Urumchi, China, 7 October 2013. [Google Scholar]

- Sun, J.M.; Gao, J.S.; Jiang, Y.J. Resistivity and relative permittivity imaging for oil-based mud: A method and numerical simulation. J. Petrol. Sci. Eng. 2016, 147, 24–33. [Google Scholar] [CrossRef]

- Gas, B.; Demjanenko, M.; Vacik, J. High-frequency contactless conductivity detection in isotachophoresis. J. Chromatogr. 1980, 192, 253–257. [Google Scholar] [CrossRef]

- Zemann, A.J.; Schnell, E.; Volgger, D. Contactless conductivity detection for capillary electrophoresis. Anal. Chem. 1998, 70, 563–567. [Google Scholar] [CrossRef]

- Da Silva, J.A.K.; Do Lago, C.L. An oscillometric detector for capillary electrophoresis. Anal. Chem. 1998, 70, 4339–4343. [Google Scholar] [CrossRef]

- Rosthal, R.A. Formation evaluation and geological interpretation from the Resistivity-at-the-Bit Tool. Eukaryot. Cell 1995, 7, 268–278. [Google Scholar]

- Gas, B.; Zuska, J.; Coufal, P. Optimization of the high-frequency contactless conductivity detector for capillary electrophoresis. Electrophoresis. 2002, 23, 3520–3527. [Google Scholar] [CrossRef]

- Pumera, M. Contactless conductivity detection for microfluidics: designs and applications. Talanta. 2007, 74, 358–364. [Google Scholar] [CrossRef] [PubMed]

- Kuban, P.; Hauser, P.C. A review of the recent achievements in capacitively coupled contactless conductivity detection. Anal. Chem. 2008, 607, 15–29. [Google Scholar]

- Kuban, P.; Hauser, P.C. Ten years of axial capacitively coupled contactless conductivity detection for CZE-a review. Electrophoresis. 2009, 30, 176–188. [Google Scholar] [CrossRef] [PubMed]

- Kuban, P.; Hauser, P.C. Capacitively Coupled Contactless Conductivity Detection for Microseparation Techniques–Recent Developments. Electrophoresis. 2011, 32, 30–42. [Google Scholar] [CrossRef] [PubMed]

- Arps, J.J. Inductive resistivity guard logging apparatus including toroidal coils mounted on a conductive stem. US patent No. 3305771A, 21 February 1967. [Google Scholar]

- Bonner, S.; Burgess, T.; Clark, B. Measurements at the bit: a new generation of MWD tools. Oilfield Review. 1993, 5, 44–54. [Google Scholar]

- Bonner, S.; Fredette, M.; Lovell, J. Resistivity while drilling-images from the string. Oilfield Review. 1996, 8, 4–19. [Google Scholar]

- Wu, Y.K.; Ni, W.N.; Li, X. Research on characteristics of a new oil-based logging-while-drilling instrument. In Proceedings of the 11th International Symposium on Measurement Techniques for Multiphase Flow, Zhenjiang, China, 3–7 November 2019. [Google Scholar]

- Ji, H.F.; Lyu, Y.C.; Wang, B.L. An improved capacitively coupled contactless conductivity detection sensor for industrial applications. Sens. Actuator A Phys. 2015, 235, 273–280. [Google Scholar] [CrossRef]

- Scott, R.J.; Leichti, R.J.; Miller, T.H. Finite-element modeling of log wall lateral force resistance. Forest Prod. J. 2005, 55, 48–54. [Google Scholar]

- Xing, G.L.; Wang, H.J.; Ding, Z. New Combined Measurement Method of the Electromagnetic Propagation Resistivity Logging. IEEE Trans. Geosci. Remote Sens. 2008, 5, 430–432. [Google Scholar] [CrossRef]

- Kang, Z.M.; Ke, S.Z.; Jiang, M. Environmental corrections of a dual-induction logging while drilling tool in vertical wells. J. Appl. Geophy. 2018, 151, 309–317. [Google Scholar] [CrossRef]

- Xu, W.; Ke, S.Z.; Li, A.Z. Response simulation and theoretical calibration of a dual-induction resistivity LWD tool. J. Appl. Geophy. 2014, 11, 31–40. [Google Scholar] [CrossRef]

- Li, K.S.; Gao, J.; Ju, X.D. Study on ultra-deep azimuthal electromagnetic resistivity LWD tool by influence quantification on azimuthal depth of investigation and real signal. Pure Appl. Geophys. 2018, 175, 4465–4482. [Google Scholar] [CrossRef]

- Davydycheva, S. 3D modeling of new-generation (1999-2010) resistivity logging tools. Lead. Edge 2010, 29, 780–789. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Lu, B.; Zhang, W.; Jiang, Y.; Wang, B.; Huang, Z. A New Logging-While-Drilling Method for Resistivity Measurement in Oil-Based Mud. Sensors 2020, 20, 1075. https://doi.org/10.3390/s20041075

Wu Y, Lu B, Zhang W, Jiang Y, Wang B, Huang Z. A New Logging-While-Drilling Method for Resistivity Measurement in Oil-Based Mud. Sensors. 2020; 20(4):1075. https://doi.org/10.3390/s20041075

Chicago/Turabian StyleWu, Yongkang, Baoping Lu, Wei Zhang, Yandan Jiang, Baoliang Wang, and Zhiyao Huang. 2020. "A New Logging-While-Drilling Method for Resistivity Measurement in Oil-Based Mud" Sensors 20, no. 4: 1075. https://doi.org/10.3390/s20041075

APA StyleWu, Y., Lu, B., Zhang, W., Jiang, Y., Wang, B., & Huang, Z. (2020). A New Logging-While-Drilling Method for Resistivity Measurement in Oil-Based Mud. Sensors, 20(4), 1075. https://doi.org/10.3390/s20041075