Cost-Effective Implementation of a Temperature Traceability System Based on Smart RFID Tags and IoT Services

Abstract

:1. Introduction

2. Related Work

2.1. Internet of Things: A Game Changing Factor in Traceability

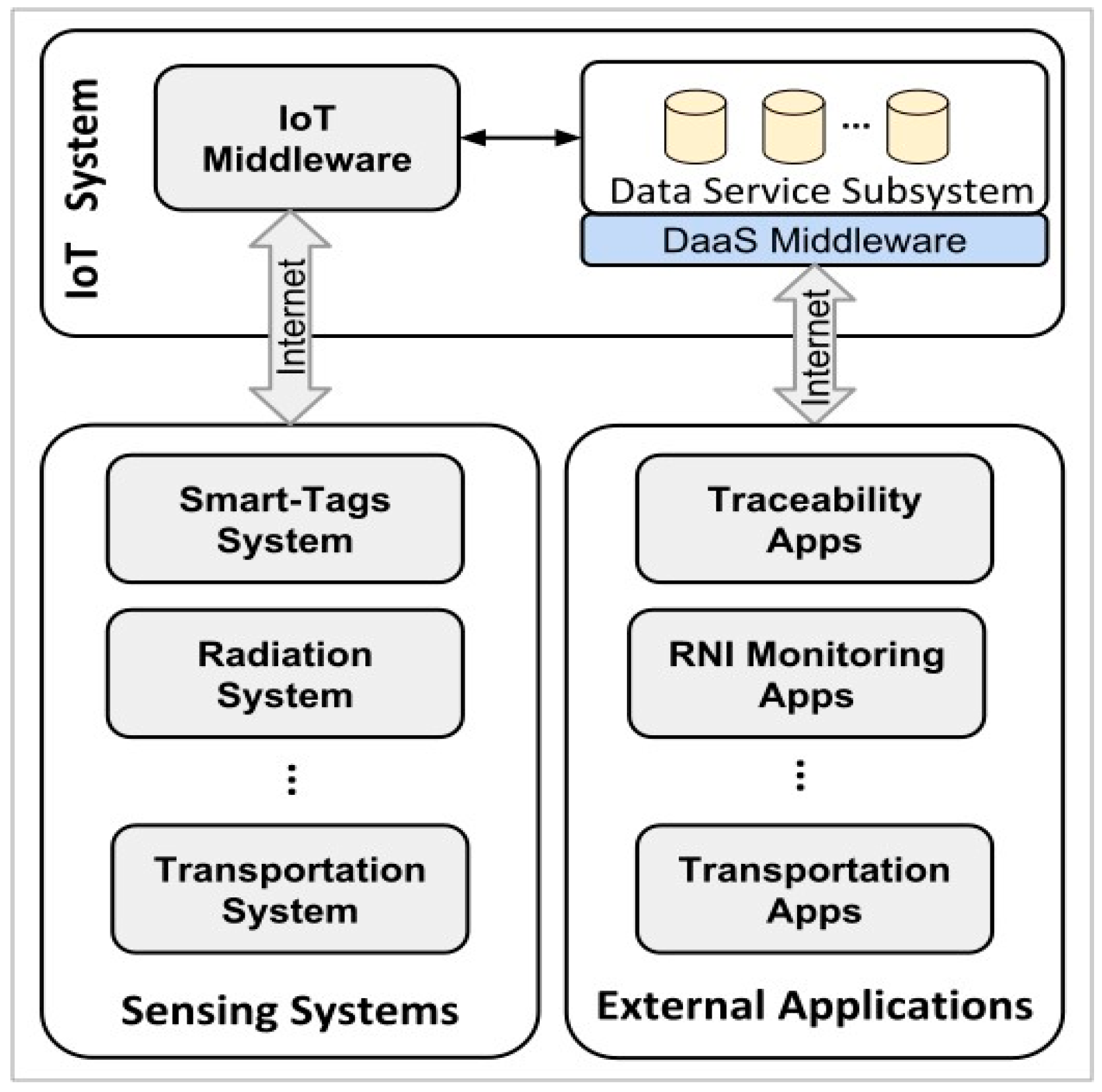

2.2. Conceptual Framework

2.3. Commercial Solutions

2.4. Orbis Traceability System

- Receiving and verifying information sent by previously registered gateways and sensors, using Rivest, Shamir y Adleman (RSA) authentication keys.

- Providing services to manage (add, modify, and remove) data sources (sensors, gateways, and users).

- Interpreting, classifying, and storing incoming information.

- Ensuring privacy and integrity of the data as well as the auto-scalability of its databases, achieved through the use of the data storage model Google Datastore—BigTable.

- Avoiding Structured Query Language (SQL) injection attacks and denial of service attacks.

- Providing services to manage (add, modify, and remove) systems to use the services of the DaaS and IoT middleware.

3. Materials and Methods

3.1. RFID Subsystem

3.1.1. Smart-Tags

3.1.2. RFID Gateway

3.2. Experimental Setup

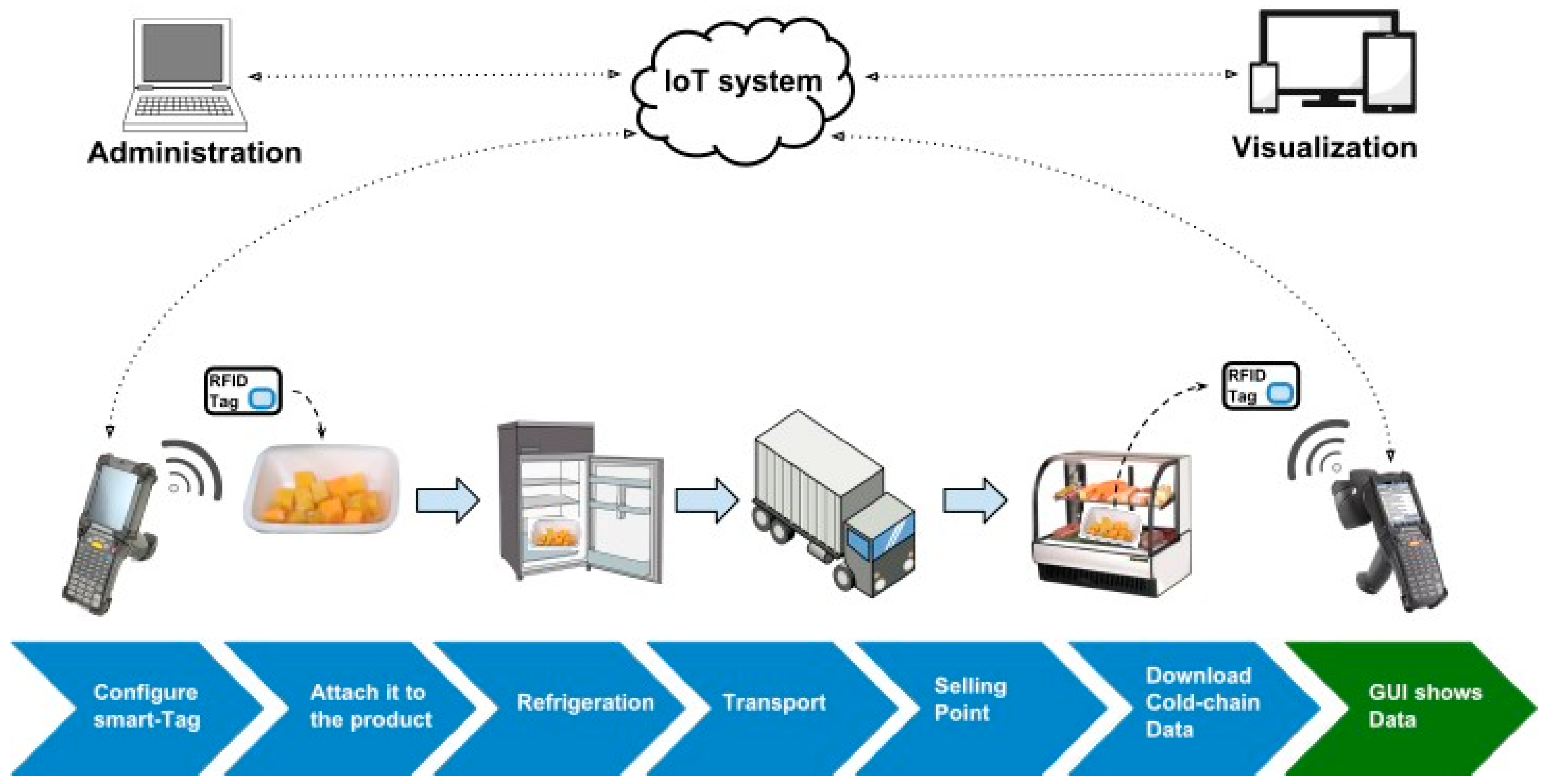

3.2.1. Pumpkin Cold-Chain Monitoring

3.2.2. Orange Temperature Monitoring

4. Results and Discussion

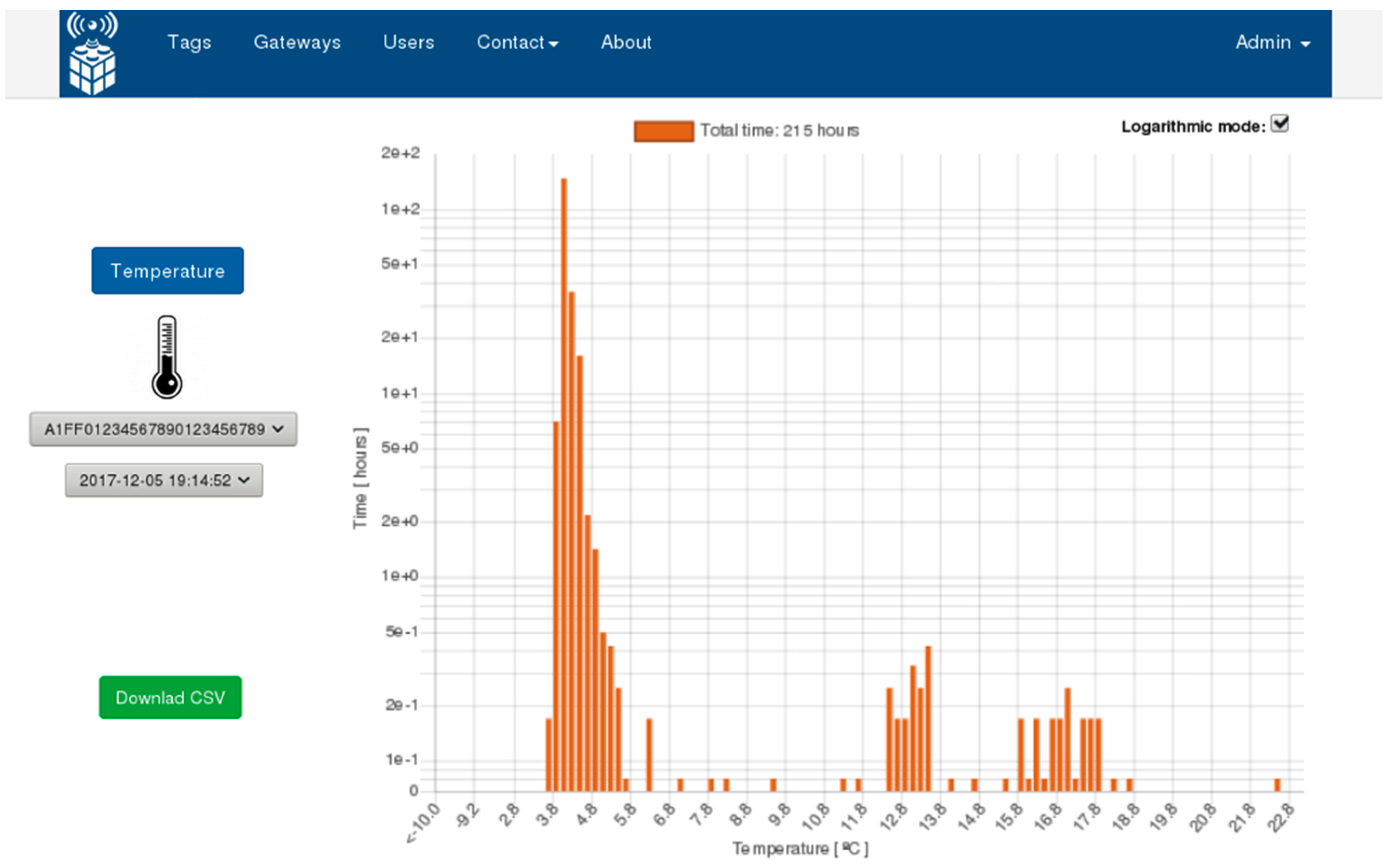

4.1. Pumpkin Cold-Chain Monitoring

4.2. Orange Temperature Monitoring

5. Conclusions and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Aung, M.M.; Chang, Y.S. Traceability in a food supply chain: Safety and quality perspectives. Food Control 2014, 39, 172–184. [Google Scholar] [CrossRef]

- Bar-Yaacov, K. Traceability and food fraud. Food fraud network administrative assistance and cooperation. In Proceedings of the Meeting of EK-FJLS Food in Iceland, Reykjavik, Iceland, 21 October 2014. [Google Scholar]

- Commission Implementing Regulation (EU) No 931/2011 of 19 September 2011 on the traceability requirements set by Regulation (EC) No 178/2002 of the European Parliament and of the Council for food of animal origin. Off. J. EU 2011, 242, 2–3.

- ISO 22005. Traceability in the Feed and Food Chain: General principles and basic requirements for system design and implementation; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- Bosona, T.; Gebresenbet, G. Food traceability as an integral part of logistics management in food and agricultural supply chain. Food Control 2013, 33, 32–48. [Google Scholar] [CrossRef]

- Bechini, A.; Cimino, M.G.C.A.; Marcelloni, F.; Tomasi, A. Patterns and technologies for enabling supply chain traceability through collaborative e-business. Inform. Software Technol. 2008, 50, 342–359. [Google Scholar] [CrossRef]

- Tracing food through the production and distribution chain to identify and address risks and protect public health. In Food Traceability; European Commission: Brussels, Belgium, 2007.

- U.S. Current Good Manufacturing Practice, Hazard Analysis, and Risk-Based Preventive Controls for Food for Animals; Food and Drug Administration: Richmond, VA, USA, 2015.

- Badia-Melis, R.; Mishra, P.; Ruiz-García, L. Food traceability: New trends and recent advances. A review. Food Control 2015, 57, 393–401. [Google Scholar] [CrossRef]

- Timestrip UK Ltd. Timestrip Visual Indicators of Time and Temperature. Available online: https://timestrip.com/ (accessed on 10 February 2020).

- Storoy, J.; Thakur, M.; Olsen, P. The TraceFood Framework—Principles and guidelines for implementing traceability in food value chains. J. Food Eng. 2013, 115, 41–48. [Google Scholar] [CrossRef]

- Pizzuti, T.; Mirabelli, G.; Sanz-Bobi, M.A.; Goméz-Gonzaléz, F. Food Track & Trace ontology for helping the food traceability control. J. Food Eng. 2014, 120, 17–30. [Google Scholar] [CrossRef]

- Aarnisalo, K.; Heiskanen, S.; Jaakkola, K.; Landor, E.; Raaska, L. Traceability of foods and foodborne hazards. In VTT Tiedotteita—Meddelanden—Research Notes 2395; VTT Technical Research Centre of Finland: Espoo, Finland, 2007. [Google Scholar]

- Landt, J. The history of RFID. IEEE Potentials 2005, 24, 8–11. [Google Scholar] [CrossRef]

- Costa, C.; Antonucci, F.; Pallottino, F.; Aguzzi, J.; Sarriá, D.; Menesatti, P. A review on agri-food supply chain traceability by means of RFID technology. Food Bioprod. Technol. 2013, 6, 353–366. [Google Scholar] [CrossRef]

- Mainetti, L.; Mele, F.; Patrono, L.; Simone, F.; Stefanizzi, M.L.; Vergallo, R. An RFID-based tracing and tracking system for the fresh vegetables supply chain. Int. J. Antennas Propag. 2013, 2013, 531364. [Google Scholar] [CrossRef] [Green Version]

- Amador, C.; Emond, J.P. Development of RFID temperature tracking systems for combat feeding logistics. In Proceedings of the XVIIth World Congress of the International Commission of Biosystems Engineering (CIGR), Québec City, QC, Canada, 13–17 June 2010. [Google Scholar]

- Catarinucci, L.; Cuiñas, I.; Expósito, I.; Colella, R.; Antonio, J.; Fernández, G.; Tarricone, L. RFID and WSNs for Traceability of Agricultural Goods from Farm to Fork: Electromagnetic and Deployment Aspects on Wine Test-Cases. In Proceedings of the 19th International Conference on Software, Telecommunications and Computer Networks (SoftCOM), Split-Hvar-Dubrovnik, Croatia, 15–17 September 2011; pp. 12–15. [Google Scholar]

- Figorilli, S.; Antonucci, F.; Costa, C.; Pallottino, F.; Raso, L.; Castiglione, M.; Pinci, E.; Del Vecchio, D.; Colle, G.; Proto, A.R.; et al. A Blockchain Implementation Prototype for the Electronic Open Source Traceability of Wood along the Whole Supply Chain. Sensors 2018, 18, 3133. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aguzzi, J.; Sbragaglia, V.; Sarriá, D.; García, J.; Costa, C.; Río, J.; Mànuel, A.; Menesatti, P.; Sardà, F. A New Laboratory Radio Frequency Identification (RFID) System for Behavioural Tracking of Marine Organisms. Sensors 2011, 11, 9532–9548. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Donelli, M. An RFID-Based Sensor for Masonry Crack Monitoring. Sensors 2018, 18, 4485. [Google Scholar] [CrossRef] [Green Version]

- De Souza, P.; Marendy, P.; Barbosa, K.; Budi, S.; Hirsch, P.; Nikolic, N.; Gunthorpe, T.; Pessin, G.; Davie, A. Low-Cost Electronic Tagging System for Bee Monitoring. Sensors 2018, 18, 2124. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Corchia, L.; Monti, G.; Tarricone, L. A Frequency Signature RFID Chipless Tag for Wearable Applications. Sensors 2019, 19, 494. [Google Scholar] [CrossRef]

- Zuffanelli, S.; Aguila, P.; Zamora, G.; Paredes, F.; Martin, F.; Bonache, J. A High-Gain Passive UHF-RFID Tag with Increased Read Range. Sensors 2016, 16, 1150. [Google Scholar] [CrossRef] [Green Version]

- Monteleone, S.; Sampaio, M.; Maia, R.F. A Novel Deployment of Smart Cold Chain System Using 2G-RFID-Sys Temperature Monitoring in Medicine Cold Chain Based on Internet of Things. In Proceedings of the 2017 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI), Bari, Italy, 18–20 September 2017; pp. 205–210. [Google Scholar] [CrossRef]

- Zou, Z.; Chen, Q.; Uysal, I.; Zheng, L. Radio frequency identification enabled wireless sensing for intelligent food logistics. Philos. Trans. R. Soc. A 2014, 372, 20140313. [Google Scholar] [CrossRef]

- Azzarelli, J.M.; Mirica, K.A.; Ravnsbæk, J.B.; Swager, T.M. Wireless gas detection with a smartphone via rf communication. Proc. Natl. Acad. Sci. USA 2014, 111, 18162–18166. [Google Scholar] [CrossRef] [Green Version]

- Pies, M.; Hajovsky, R.; Ozana, S. Wireless Measurement of Carbon Monoxide Concentration. In Proceedings of the 14th International Conference on Control, Automation and Systems (ICCAS), Gyeonggi-do, Korea, 22–25 October 2014. [Google Scholar] [CrossRef]

- Azzarà, A.; Bocchino, S.; Pagano, P.; Pellerano, G.; Petracca, M. Middleware Solutions in WSN: The IoT Oriented Approach in the ICSI Project. In Proceedings of the 21st International Conference on Software, Telecommunications and Computer Networks (SoftCOM), Split-Primošten, Croatia, 18–20 September 2013. [Google Scholar] [CrossRef]

- Ribiero, A.R.L.; Silva, F.C.S.; Freitas, L.C.; Carlos, R. SensorBus: A Middleware Model for Wireless Sensor Networks. In Proceedings of the Third International IFIP/ACM Latin American Conference on Networking (LANC), ACM, Cali, Colombia, 10–13 October 2005; pp. 1–9. [Google Scholar] [CrossRef]

- Sulc, V.; Kuchta, R.; Vrba, R. IQRF Smart House—A Case Study. In Proceedings of the Third International Conference on Advances in Mesh Networks (MESH), Venice, Italy, 18–25 July 2010; pp. 103–108. [Google Scholar] [CrossRef]

- Bhuvaneswari, V.; Porkodi, R. The Internet of Things (IOT) Applications and Communication Enabling Technology Standards: An Overview. In Proceedings of the 2014 International Conference on Intelligent Computing Applications (ICICA), Tamilnadu, India, 6–7 March 2014; pp. 324–329. [Google Scholar] [CrossRef]

- GS1 EPCglobal Inc. EPC Radio-Frequency Identity Protocols. Generation-2 UHF RFID. 2013. Available online: https://www.gs1.org/sites/default/files/docs/epc/uhfc1g2_2_0_0_standard_20131101.pdf (accessed on 2 December 2019).

- Uusitalo, M. Global vision for the future wireless world from the WWRF. IEEE Veh. Technol. Mag. 2006, 1, 4–8. [Google Scholar] [CrossRef]

- Sung, J.; Lopez, T.S.; Kim, D. The EPC Sensor Network for RFID and WSN Integration Infrastructure. In Proceedings of the Fifth Annual IEEE International Conference on Pervasive Computing and Communications Workshops (PerComW’07), New York, NY, USA, 19–23 March 2007; pp. 618–621. [Google Scholar] [CrossRef]

- Santucci, G. From Internet of Data to Internet of Things. In Proceedings of the International Conference on Future Trends of the Internet, Neumünster Abbey, Luxembourg, 28 January 2009. [Google Scholar]

- Fan, C.; Wen, Z.; Wang, F.; Wu, Y. A Middleware of Internet of Things (Iot) Based on Zigbee and RFID. In Proceedings of the IET International Conference on Communication Technology and Application (ICCTA 2011), Beijing, China, 14–16 October 2011; pp. 732–736. [Google Scholar] [CrossRef]

- Centenaro, M.; Vangelista, L.; Zanella, A.; Zorzi, M. Long-range communications in unlicensed bands: The rising stars in the IoT and smart city scenarios. IEEE Wirel. Commun. 2016, 23, 60–67. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Bolic, M.; Nayak, A.; Stojmenovi, I. Taxonomy and challenges of the integration of RFID and wireless sensor networks. IEEE Network 2008, 22, 26–35. [Google Scholar] [CrossRef]

- Bertolini, M.; Bevilacqua, M.; Massini, R. FMECA approach to product traceability in the food industry. Food Control 2006, 17, 137–145. [Google Scholar] [CrossRef]

- Zhang, M.; Li, P. RFID application strategy in agri-food supply chain based on safety and benefit analysis. Phys. Procedia 2012, 25, 636–642. [Google Scholar] [CrossRef] [Green Version]

- Engels, D.W.; Kang, Y.S.; Wang, J. On security with the new Gen2 RFID security framework. In Proceedings of the IEEE Conference on RFID (RFID), Orlando, FL, USA, 30 April 2013; pp. 144–151. [Google Scholar] [CrossRef]

- Revista de Logística. SINIEV: Un Centro Inteligente De Control De Tránsito Y Transporte Que Beneficiaría A Todo El País. 2016. Available online: https://revistadelogistica.com/actualidad/siniev-un-centro-inteligente-de-control-de-transito-y-transporte-que-beneficiara-a-todo-el-pais/ (accessed on 2 December 2019).

- Tentzeris, M.M.; Kim, S.; Traille, A.; Aubert, H.; Yoshihiro, K.; Georgiadis, A.; Collado, A. Inkjet-Printed RFID-Enabled Sensors on Paper for Iot and “Smart Skin” Applications. In Proceedings of the ICECom 2013, Dubrovnik, Croatia, 14–16 October 2013; pp. 1–4. [Google Scholar] [CrossRef]

- Neira, E.; Pantoja, J.; Figueroa, N.; Mañana, G.; Pedraza, C.; Vega, F. Development of an intelligent vehicle control platform based on radio frequency identification. In Proceedings of the Inngenio 2015, Medellin, Colombia, 22–24 August 2015. [Google Scholar]

- Vega, F.; Pantoja, J.; Morales, S.; Urbano, O.; Arevalo, A.; Muskus, E.; Pedraza, C.; Patino, M.; Suarez, M.; Hernandez, N. An IoT-based open platform for monitoring non-ionizing radiation levels in Colombia. In Proceedings of the IEEE Colombian Conference on Communications and Computing (COLCOM), Cartagena, Colombia, 27–29 April 2016. [Google Scholar] [CrossRef]

- Mitsugi, J.; Inaba, T. Architecture Development for Sensor Integration in the Epcglobal Network. In Auto-ID Labs White Paper; AUTO-ID LABS: Cambridge, UK, 2007. [Google Scholar]

- Yang, K.; Jia, X. Data storage auditing service in cloud computing: Challenges, methods and opportunities. World Wide Web 2012, 15, 409–428. [Google Scholar] [CrossRef]

- NXP Semiconductors. UCODE I2C; Technical Report; NXP: Eindhoven, The Netherlands, 2015. [Google Scholar]

- Alfian, G.; Rhee, J.; Ahn, H.; Lee, J.; Farooq, U.; Ijaz, M.F.; Syaekhoni, M.A. Integration of RFID, wireless sensor networks, and data mining in an e-pedigree food traceability system. J. Food Eng. 2017, 212, 65–75. [Google Scholar] [CrossRef]

- Chen, R.Y. Autonomous tracing system for backward design in food supply chain. Food Control 2015, 51, 70–84. [Google Scholar] [CrossRef]

- Song, J.; Wei, Q.; Wang, X.; Li, D.; Liu, C.; Zhang, M. Degradation of carotenoids in dehydrated pumpkins as affected by different storage conditions. Food Res. Int. 2018, 107, 130–136. [Google Scholar] [CrossRef]

- Montesano, D.; Rocchetti, G.; Putnik, P.; Lucini, L. Bioactive profile of pumpkin: An overview on terpenoids and their health-promoting properties. Curr. Opin. Food Sci. 2018, 22, 81–87. [Google Scholar] [CrossRef]

- Rubio-Arraez, S.; Capella, J.V.; Castelló, M.L.; Ortolá, M.D. Physicochemical characteristics of citrus jelly with non-cariogenic and functional sweeteners. J. Food Sci. Technol. 2016, 53, 3642–3650. [Google Scholar] [CrossRef] [Green Version]

- Carmona, L.; Alquezar, B.; Marques, V.V.; Peña, L. Anthocyanin biosynthesis and accumulation in blood oranges during postharvest storage at different low temperatures. Food Chem. 2017, 237, 7–14. [Google Scholar] [CrossRef]

| Product | Description | Technology |

|---|---|---|

| SensoTag NFC | Range: −40 to 60 °C Records: 4000 | Protocol: NFC Interface: Smartphone App, Cloud |

| EMERALD Temperature Recorder | Range: −40 to 85 °C Records: 4000 | Protocol: Bluetooth Interface: Smartphone App, Cloud |

| Cobalt ML3 Temperature Recorder | Range: −40 to 60 °C Records: 4000 | Protocol: LoRaWAN Interface: Smartphone App, Cloud |

| Monnit Wireless Temperature Sensor | Range: −7 to 60 °C Records: 512 | Protocol: Not Available (900 MHz) Interface: RF 900 MHz, Cloud |

| CCP Smart Tags | Range: Not Available Monitoring: Critical Points | Protocols: Wi-Fi, NFC, 4G, Sigfox, NBIoT Interface: Cloud |

| StickNTrack TEMP GPS | Range: −20 to 60 °C Monitoring: GPS and Temperature | Protocol: Sigfox Interface: Cloud |

| Stages | Temperature (°C) | Time (days) |

|---|---|---|

| Chamber | 4 | 7 |

| Transport | 7 (3 h), 4 (21 h) | 1 |

| Selling Point | 4 | 7 |

| Consumer Home | 7 | 7 |

| Description | Temperature Range (°C) |

|---|---|

| Above the optimal temperature | 9–22 |

| Optimal temperature | 2–8 |

| Low temperature break point | <−5 |

| Interpretation | Temperature Range (°C) | Time (days) |

|---|---|---|

| Chamber and selling point | 3.2–5.2 | 14.96 days |

| Transport | 5.8–8.4 | 6.86 days |

| Manipulation time | 9–22 | 3.99 h |

| Interpretation | Temperature Range (°C) | Time (days) |

|---|---|---|

| Above the optimal temperature | 9–22 | 4.25 |

| Refrigerator temperature | 6-8 | 0.76 |

| Refrigerator temperature | 1–6 | 2.92 |

| Low temperature break point | <−5 | 0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urbano, O.; Perles, A.; Pedraza, C.; Rubio-Arraez, S.; Castelló, M.L.; Ortola, M.D.; Mercado, R. Cost-Effective Implementation of a Temperature Traceability System Based on Smart RFID Tags and IoT Services. Sensors 2020, 20, 1163. https://doi.org/10.3390/s20041163

Urbano O, Perles A, Pedraza C, Rubio-Arraez S, Castelló ML, Ortola MD, Mercado R. Cost-Effective Implementation of a Temperature Traceability System Based on Smart RFID Tags and IoT Services. Sensors. 2020; 20(4):1163. https://doi.org/10.3390/s20041163

Chicago/Turabian StyleUrbano, Oscar, Angel Perles, Cesar Pedraza, Susana Rubio-Arraez, María Luisa Castelló, María Dolores Ortola, and Ricardo Mercado. 2020. "Cost-Effective Implementation of a Temperature Traceability System Based on Smart RFID Tags and IoT Services" Sensors 20, no. 4: 1163. https://doi.org/10.3390/s20041163