Instrumentation of Stratospheric Balloon Straps with Optical Fibre for Temperature and Strain Monitoring

Abstract

:1. Introduction

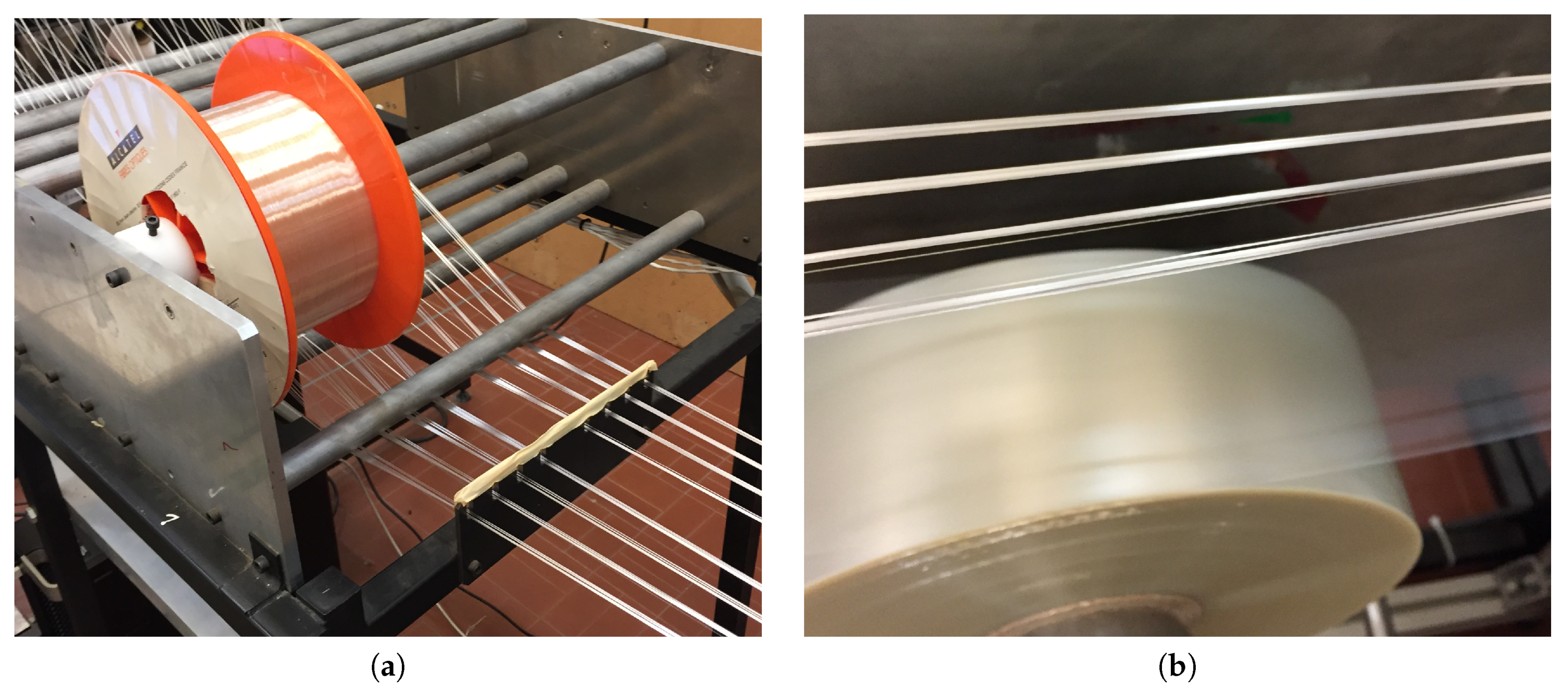

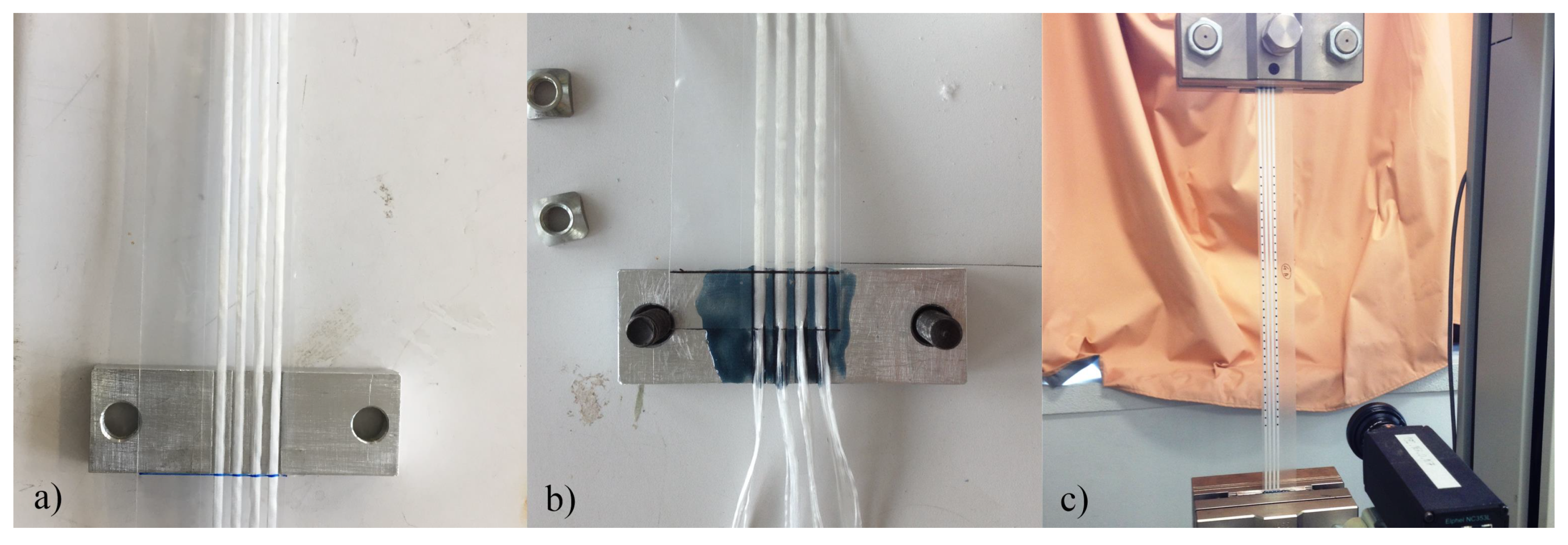

2. Insertion of Optical Fibres Inside Straps

- Alcatel-Strand-Bare: a G652 fibre from Alcatel inserted inside a strand;

- Corning-Strand-Bare: a G652 fibre from Corning inserted inside a strand;

- Draka-Strand-Bare: a G657 fibre from Draka inserted inside a strand;

- Alcatel-Strand-Polyester: a G652 fibre from Alcatel coated with polyester resin inserted inside a strand;

- Alcatel-Film-Bare: a G652 fibre from Alcatel inserted between two polymer films;

- Alcatel-Film-Polyester: a G652 fibre from Alcatel coated with polyester resin inserted between two polymer films;

- Alcatel2-Strand-Bare: two G652 fibre from Alcatel inserted in two different strands.

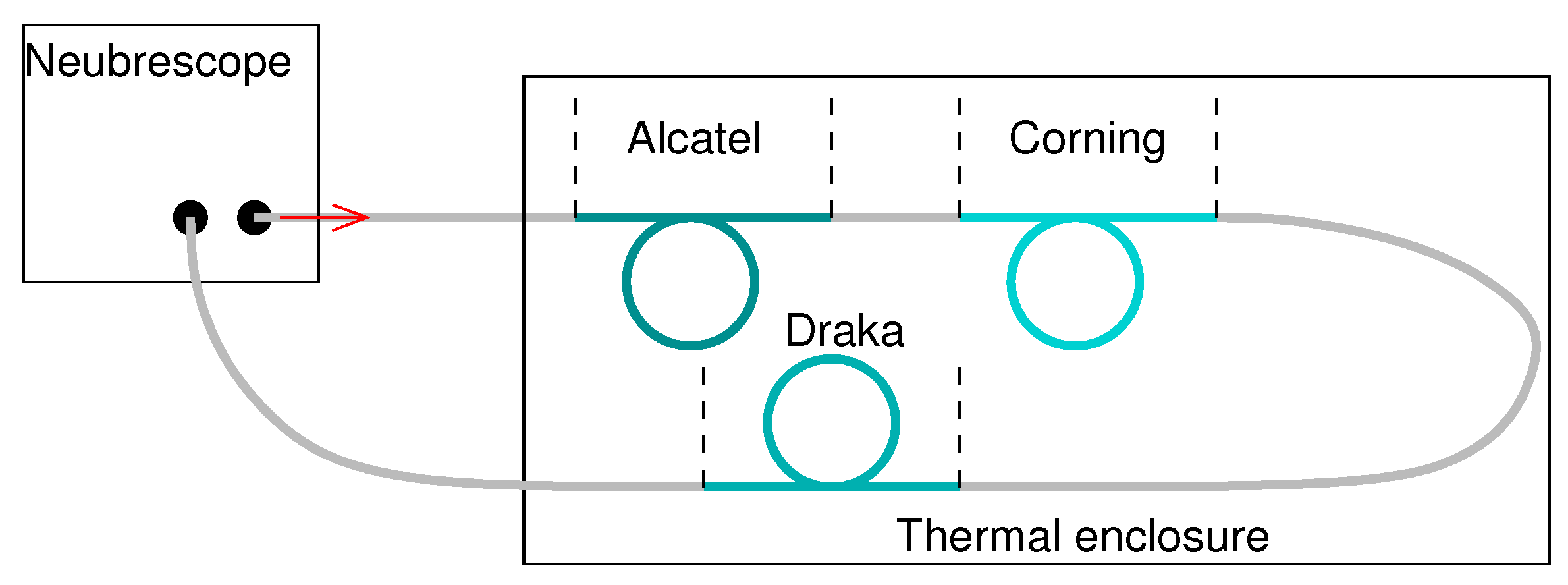

3. Thermal Tests

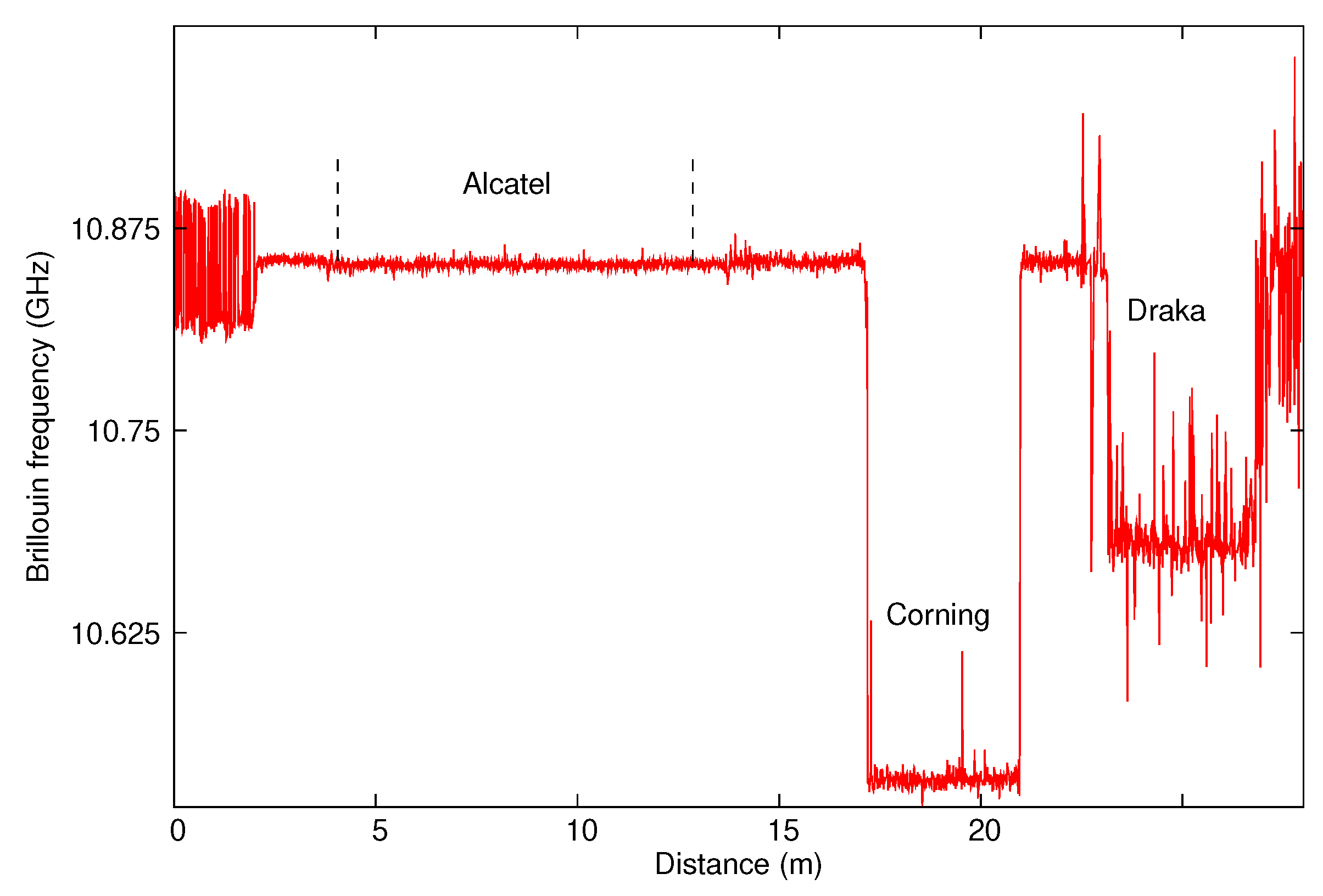

3.1. Thermal Calibration of Bare Fibres

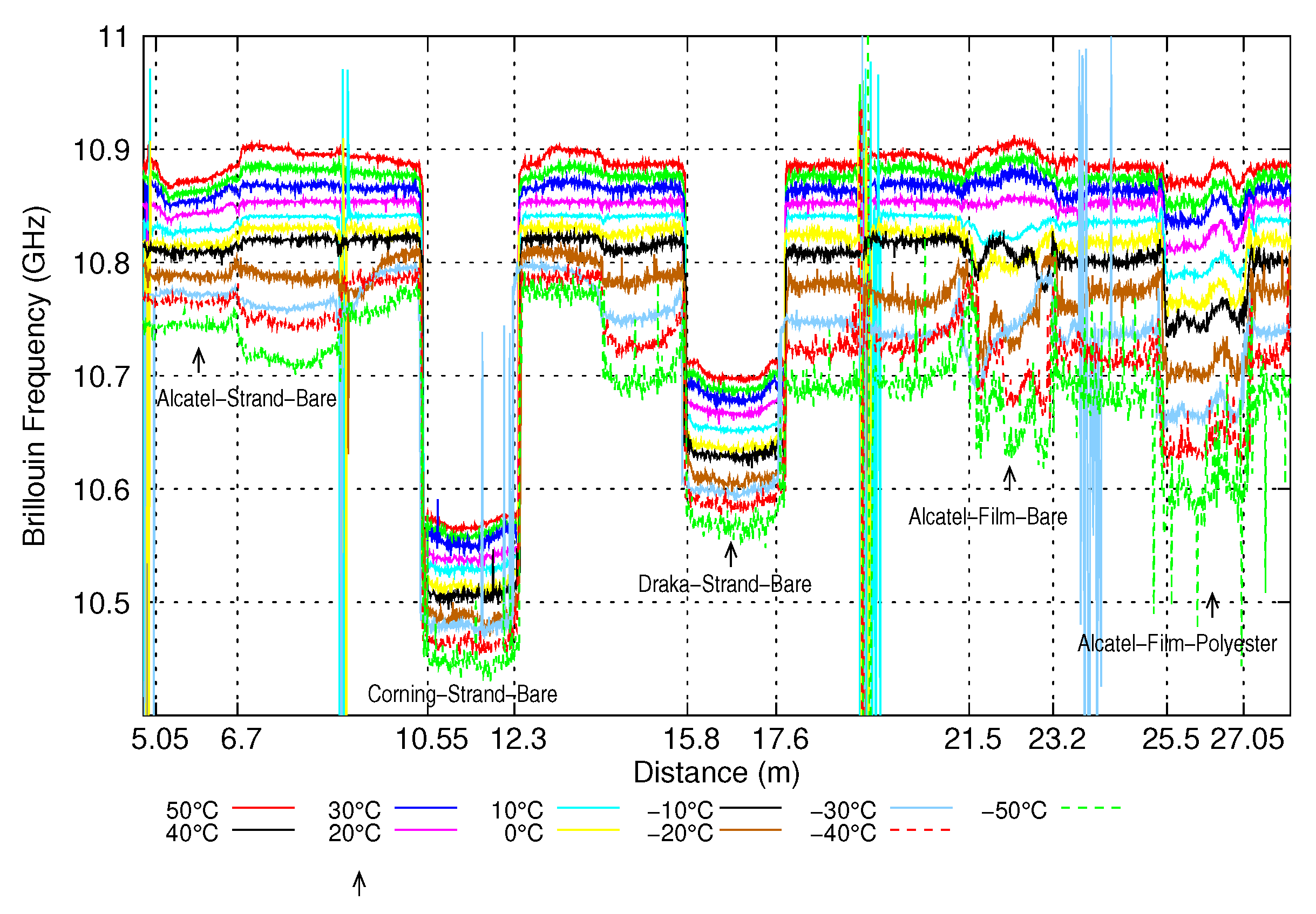

3.2. Thermal Characterization of Instrumented Straps

4. Mechanical Tests

4.1. Mechanical Calibration of Bare Fibres

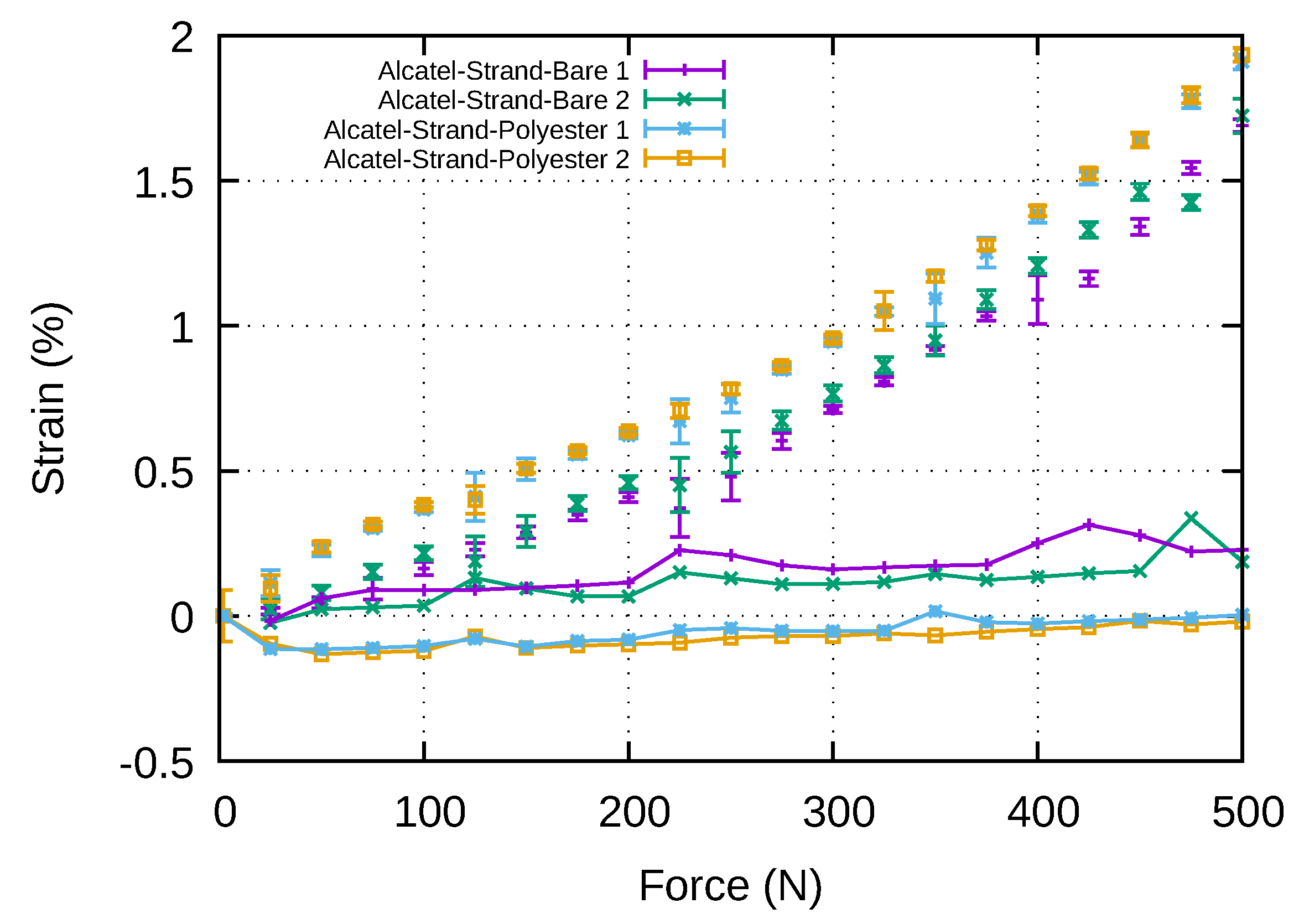

4.2. Mechanical Tests of Instrumented Straps

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nishimura, J. Scientific ballooning in the 20th century; A historical perspective. Adv. Space Res. 2002, 30, 1071–1085. [Google Scholar] [CrossRef]

- Said, M. A review on the recent progress in materials selection, development and characterization for ultra long duration balloon (ULDB) missions. Adv. Space Res. 2002, 30, 1173–1182. [Google Scholar] [CrossRef]

- Saito, Y.; Yamagami, T.; Matsuzaka, Y.; Namiki, M.; Ohta, S.; Toriumi, M.; Yokota, R.; Makino, F.; Matsumoto, T.; Hirosawa, H. High altitude balloons with ultra thin polyethylene films. Adv. Space Res. 2002, 30, 1159–1165. [Google Scholar] [CrossRef]

- Saito, Y.; Iijima, I.; Izutsu, N.; Kawasaki, T.; Matsuzaka, Y.; Namiki, M.; Toriumi, M.; Yamagami, T.; Ichimura, K.; Kobayashi, T.; et al. Development of a 2.8 μm film for scientific balloons. Adv. Space Res. 2006, 37, 2026–2032. [Google Scholar] [CrossRef]

- Gaskin, J.A.; Smith, I.S.; Jones, W.V. Introduction to the special issue on scientific balloon capabilities and instrumentation. J. Astron. Instrum. 2014, 3, 1403001. [Google Scholar] [CrossRef] [Green Version]

- Baginski, F. A mathematical model for a partially inflated balloon with periodic lobes. Adv. Space Res. 2002, 30, 1167–1171. [Google Scholar] [CrossRef]

- Schur, W. The design process for a pumpkin balloon: structural synthesis, structural analysis, and analytical assessment of some critical design issues. Adv. Space Res. 2002, 30, 1193–1198. [Google Scholar] [CrossRef]

- Winker, J. Pumpkins and onions and balloon design. Adv. Space Res. 2002, 30, 1199–1204. [Google Scholar] [CrossRef]

- Hu, J.; Li, Y.; Chen, W.; Zhang, T.; Gao, C.; Shi, T.; Yang, D. Uniaxial mechanical properties of multi-layer thin films in use for scientific balloons. Adv. Space Res. 2018, 62, 1165–1176. [Google Scholar] [CrossRef]

- Schur, W. Experimental investigation of undesired stable equilibria in pumpkin shape super-pressure balloon designs. Adv. Space Res. 2004, 33, 1682–1687. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, D.; Zhao, D.; Wu, G.; Yin, S.; Zhou, P. Change rules of a stratospheric airship’s envelope shape during ascent process. Chin. J. Aeronaut. 2017, 30, 752–758. [Google Scholar] [CrossRef]

- Horiguchi, T.; Kurashima, T.; Tateda, M. Tensile strain dependence of Brillouin frequency shift in silica optical fibers. IEEE Photonics Technol. Lett. 1989, 1, 107–108. [Google Scholar] [CrossRef]

- Kurashima, T.; Horiguchi, T.; Tateda, M. Distributed-temperature sensing using stimulated Brillouin scattering in optical silica fibers. Opt. Lett. 1990, 15, 1038–1040. [Google Scholar] [CrossRef]

- Gifford, D.K.; Kreger, S.T.; Sang, A.K.; Froggatt, M.E.; Duncan, R.G.; Wolfe, M.S.; Soller, B.J. Swept-wavelength interferometric interrogation of fiber Rayleigh scatter for distributed sensing applications. In International Society for Optics and Photonics, Proceedings of the Fiber Optic Sensors and Applications V, Boston, MA, USA, 9–12 September 2007; Udd, E., Ed.; SPIE: Bellingham, DC, USA, 2007. [Google Scholar] [CrossRef]

- Dakin, J.P.; Pratt, D.J.; Bibby, G.W.; Ross, J.N. Distributed optical fibre Raman temperature sensor using a semiconductor light source and detector. Electron. Lett. 1985, 21, 569–570. [Google Scholar] [CrossRef]

- Failleau, G.; Beaumont, O.; Razouk, R.; Delepine-Lesoille, S.; Landolt, M.; Courthial, B.; Hénault, J.; Martinot, F.; Bertrand, J.; Hay, B. A metrological comparison of Raman-distributed temperature sensors. Measurement 2018, 116, 18–24. [Google Scholar] [CrossRef]

- Barrias, A.; Casas, J.R.; Villalba, S. A review of distributed optical fiber sensors for civil engineering applications. Sensors 2019, 16, 748. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Motwani, P.; Perogamvros, N.; Taylor, S.; Sonebi, M.; Laskar, A.; Murphy, A. Experimental investigation of strain sensitivity for surface bonded fibre optic sensors. Sens. Actuators, A 2020, 303, 111833. [Google Scholar] [CrossRef]

| Sample | |||||

|---|---|---|---|---|---|

| Alcatel-Strand-Bare | Corning-Strand-Bare | Draka-Strand-Bare | Alcatel-Film-Bare | Alcatel-Film-Polyester | |

| (MHz/°C) | 1.30 | 1.22 | 1.33 | 2.3 | 2.7 |

| 0.1 | 0.3 | 0.13 | 0.95 | 1.3 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lecieux, Y.; Lupi, C.; Leduc, D.; Macé, Q.; Jeanneau, V.; Guigue, P. Instrumentation of Stratospheric Balloon Straps with Optical Fibre for Temperature and Strain Monitoring. Sensors 2020, 20, 1433. https://doi.org/10.3390/s20051433

Lecieux Y, Lupi C, Leduc D, Macé Q, Jeanneau V, Guigue P. Instrumentation of Stratospheric Balloon Straps with Optical Fibre for Temperature and Strain Monitoring. Sensors. 2020; 20(5):1433. https://doi.org/10.3390/s20051433

Chicago/Turabian StyleLecieux, Yann, Cyril Lupi, Dominique Leduc, Quentin Macé, Valentin Jeanneau, and Pascale Guigue. 2020. "Instrumentation of Stratospheric Balloon Straps with Optical Fibre for Temperature and Strain Monitoring" Sensors 20, no. 5: 1433. https://doi.org/10.3390/s20051433

APA StyleLecieux, Y., Lupi, C., Leduc, D., Macé, Q., Jeanneau, V., & Guigue, P. (2020). Instrumentation of Stratospheric Balloon Straps with Optical Fibre for Temperature and Strain Monitoring. Sensors, 20(5), 1433. https://doi.org/10.3390/s20051433