3.1. Background of 0.36(Bi,Sc)O3-0.64(Pb,Ti) Ceramics

Figure 1 illustrates the phase diagram for the ferroelectric (1-

x)(Bi,Sc)O

3-

x(Pb,Ti)O

3 system with a morphotropic phase boundary (MPB) observed in the vicinity of 64% PbTiO

3 content. In a previous study, the MPB region, particularly in the rhombohedral MPB region exhibited the highest piezoelectric properties in comparison with other compositions, and therefore, in this work, the 0.36(Bi,Sc)O

3-0.64(Pb,Ti)O

3 ferroelectric ceramics were selected for examination, and detailed experiments were conducted to investigate the optimized calcination and sintering conditions for this composition.

Figure 2 depicts the temperature-dependent dielectric constant

of the BS-PT ceramic sample sintered at 1200 °C. The BS-PT ceramic exhibited a significantly high Curie temperature of 394.57 °C. In comparison with the standard Pb(Zr

1-xTix)O

3 (PZT) materials, BS-PT ceramics exhibited an approximately 220 °C higher Curie temperature with a higher dielectric constant. This implies that the BS-PT ceramics can be used in more harsh environmental conditions than the PZT ceramics.

Figure 2 depicts the results obtained for the Mn-doped Pb(Zr

0.58Ti

0.42)O

3 ceramic. Mn is added to PZT to lower the sintering temperature. Generally, PZT materials exhibit Curie temperatures between 170 °C and 370 °C [

13]. Pb(Zr

0.58Ti

0.42)O

3 is frequently used because the piezoelectric charge constant tends to decrease with increasing Curie temperature [

14,

15]. Nevertheless, a higher Curie temperature is highly favorable for the use of piezoelectric materials in industrial applications. As a representative piezoelectric material PZT-5A can be employed for the electronic device applications including energy harvesters, however, BS-PT also have some merits in applications, Both of BS-PT and PZT-5A ceramics have similar Curie temperature Tc and piezoelectric charge coefficient d33, however there are strong merits in the lower lead contents for BS-PT ceramics compared with PZT-5A ceramics. In addition, with lower dielectric permittivity of BS-PT, ceramics can help to have more higher figure of merits (FOM= d

33 ∙ g

33) for energy harvester applications. Here, we have summarized the representative piezoelectric properties. As shown in the

Table 1, BS-PT ceramics have relatively higher piezoelectric charge coefficient with higher Curie temperature and lower dielectric constant.

3.2. Fabrication and Validation of 0.36(Bi,Sc)O3-0.64(Pb,Ti) Ceramics

Figure 3 illustrates the XRD pattern data for the BS-PT piezoelectric ceramics sintered at 1200 °C. As depicted in

Figure 3, the (

h00) and (

00l) reflection peaks are clearly observed, implying that BS-PT piezoelectric ceramics exhibit a tetragonal structure. Owing to their high tetragonality, the BS-PT ceramics are expected to exhibit high piezoelectric performance. Additionally, no peaks for the pyrochlore phase peaks were observed in the XRD pattern. Using Equation (1) and the measured 2θ values of the (

h00) and (00

l) peaks, the

c and

a lattice parameters can be calculated and analyzed according to the Nelson-Riley formula. Therefore, the film lattice parameter

c0 was determined by plotting

c00l versus the Nelson-Riley function [

16].

where,

ccosθ is an interplane distance calculated from the apparent 2θ Bragg peak position, and

A is a fitting coefficient. The calculated

c and

a lattice parameters were 4.09 and 3.98 Å, respectively. The inset shows the field emission scanning electron microscopy (FE-SEM) images of the BS-PT piezoelectric ceramics. The specimen was sintered at 1200 °C for 2 h after first undergoing thermal etching. As depicted in the figure, the average grain size is approximately 3.2 μm, and the grains exhibit an irregular shape but a dense structure.

Figure 4a depicts the electric field dependent polarization (P-E) hysteresis loops of the BS-PT piezoelectric ceramics sintered at 1200 °C. As observed from the figure, BS-PT ceramics exhibit an open P-E hysteresis loop with a range of 0.1 Hz. This open P-E hysteresis loop implies that the specimens require the use of a relatively high coercive electric field for removing the remnant polarization. In particular, the present specimen exhibits a high remnant polarization of 40.2 μC/cm

2. The external voltage applied to the specimen reaches ± 4 kV/mm. These high coercive electric field and remnant polarization values were similar to the values reported in the literature [

17]. This open P-E hysteresis observed for the BS-PT ceramics can be compared with the P-E loops of PZT-based materials that exhibit high piezoelectric performance for device applications [

18]. Materials with open P-E hysteresis loops with high coercive electric field and remnant polarization values can be used in piezoelectric passive damper applications, because a large area of the P-E hysteresis loop implies that a large amount of energy is accumulated under the application of a mechanical shock.

Figure 4b depicts the electric field dependent strain (S-E) curves for the BS-PT piezoelectric ceramics. As observed from the figure, the specimen exhibits non-linear S-E hysteresis loops. At an applied electric field of approximately 4 kV/mm, the strain values approaches 0.19%, whereas for an applied electric field of approximately 1 kV/mm, the strain of the BS-PT piezoelectric ceramic is 0.07%. This large strain value is comparable with those of the PZT-based materials. For example, Pb(Zr

0.6Ti

0.4) exhibits the maximum strain of 0.13% [

19]. Generally, in the mechanical-to-electrical energy conversion, some energy is dissipated as heat, raising the temperature of the material and degrading the piezoelectric performance. However, the BS-PT materials investigated in this work exhibit a high Curie temperature of 394.57 °C; because of this high Curie temperature, these ceramics are insensitive to the temperature variation due to the heating caused by energy dissipation, making them attractive materials for the passive damper system. The S-E hysteresis loops demonstrate that the BS-PT piezoelectric ceramics exhibit high strain values relative to other comparable piezoelectric materials.

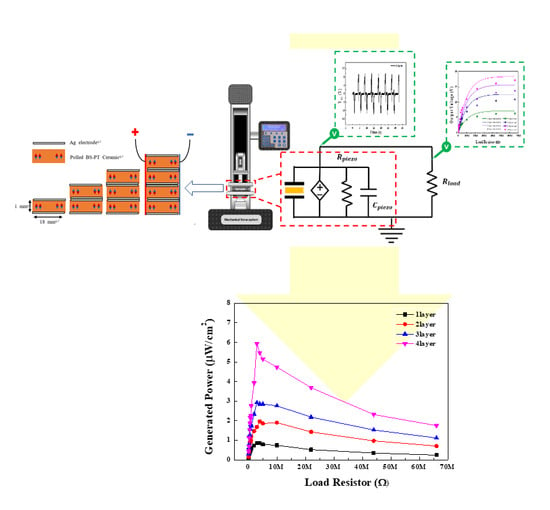

3.3. Multilayer 0.36(Bi,Sc)O3-0.64(Pb,Ti) Piezoelctric Energy Harvester Setup

Figure 5a illustrates a schematic of the 1–4 layered structured piezoelectric energy harvesters based on BS-PT multilayered ceramics. The internal electrodes of the BS-PT multilayered ceramics are connected in parallel, as depicted in

Figure 5a. To increase the generated output energy, a capacitor structure connected in parallel is designed and fabricated. Since piezoelectric ceramics are connected in the parallel structure, the output voltages are generated for a relatively long time in comparison with that generated using a single-piezoelectric structure. As a result of this extended output voltage generation time, multilayered BS-PT piezoelectric materials can generate high levels of energy. Multilayered piezoelectric devices must be connected in parallel. In the circuit, top electrode generated positive current, and the bottom electrode generate negative current, respectively. If the multilayered piezoelectric devices are connected in series, then the bottom electrode of the 1st layer and top electrode of the 2nd layer are facing each other. Therefore, the positive current in the 1st layer and negative current in the 2nd layer should be canceled. As a result, the output energy can be reduced.

Figure 5b depicts the designed output energy measurement system incorporating a load resistor. A mechanical force of 500 N was applied to the piezoelectric energy harvester at a frequency of 0.2 Hz. The piezoelectric energy harvester can be described using an equivalent circuit with the mechanical force dependent voltage sources, internal resistor R

piezo, and capacitive component C

piezo connected in parallel. As depicted in the figure, the voltage across the load resistor can be increased because the generated piezoelectric charges are accumulated in the load capacitors.

Figure 6 depicts the stored and measured capacitances of the 1–4 layer parallel connected capacitive structures for piezoelectric energy harvesters based on the BS-PT multilayered ceramics as a function of the number of layers. It is observed that the stored capacitance increases with the increasing number of layers because the internal electrodes of the BS-PT multilayered ceramics are connected in parallel. The capacitance values of the single, double, triple, quadruple layers were 2.46, 5.95, 9.25, and 11.58 nF, respectively, and the capacitance increased proportionally with the number of layers. This implies that the multilayered piezoelectric energy harvesters were successfully connected in the parallel structure. Therefore, we can expect that the output energy can be linearly increased by increasing the number of layers [

20].

3.4. Output Energy of the Multilayer 0.36(Bi,Sc)O3-0.64(Pb,Ti) Piezoelectric Energy Harvester

Figure 7a,b depicts the generated voltages of the piezoelectric energy harvesters as a function of time. This energy harvester is connected with single- and multi-layered BS-PT ceramics. A mechanical force of 500 N was applied to the piezoelectric energy harvesters at a frequency of 0.2 Hz, corresponding to a human with a weight of 50 kg walking on top of the piezoelectric energy harvesters. The positive and negative output voltages were generated when the compressive and tensile forces were applied to the piezoelectric energy harvesters. It was observed that forces of equal magnitude were applied to the devices. In every experiment, we found this small peak with applied high mechanical force condition. We believe this small peak probably come from the recovery of piezoelectric materials after removing the mechanical forces. After removing the high positive forces, then the piezoelectric material experiences a strong recovery negative force to restore the shape. Therefore, small negative peaks are always observed.

Figure 7c,d depicts the generation time of output voltage in the single- and multi-layered piezoelectric energy harvesters as a function of time. The measured generation time of output voltages were 0.77 and 1.45 s for the single- and quadruple-layer structure piezoelectric devices, respectively. This result shows that the output voltage generation time increases as the number of layers increases.

Figure 7e depicts the generated peak voltages of the 1–4 multilayered BS-PT piezoelectric ceramics with 1–4 layers measured at the load resistor. The measured generated voltages of specimens were 9.34, 12.61, 15.66, and 18.36 V for the single-, double-, triple-, and quadruple-layer structure piezoelectric energy harvesters, respectively. As shown in the

Table 2, we check the generated peak voltage for the 1–4 layer BS-PT piezoelectric energy harvesters in 500 N.

Since they were connected in parallel, the generated output voltage increased with increasing number of layers. Therefore, a voltage similar to that obtained using PZT-based materials was generated [

21].

Figure 8 depicts the generated output voltages of multilayered BS-PT piezoelectric ceramics obtained by varying the load of the resistor. As observed from the figure, the output voltage increased with increasing load of the resistor. Since the load resistor is connected to the piezoelectric energy harvester in series, the generated output voltage can be increased with a contribution of the internal resistive component. Therefore, as the load resistor value increased, the resistive component contribution in the load part increased as well. As a result, the output voltages should be increased. Using Equation (2), the relation between a resistive load and the output voltage can be expressed as follows.

where V

o is the generated output voltage applied to the load resistor, V

p is the generated peak voltage, R

L is the load resistor, and R

int is the internal resistance related to the saturated output voltage.

There are some theoretical papers, in which simulation and modeling for piezoelectric energy harvesters were employed to explain the energy converting behavior [

22,

23]. However, there are some differences that can be found. In the Junior et al. [

22] case, the authors employed a finite element model to analyze the cantilever type resonator for energy harvesters. In this analysis, they employed thermodynamics based on Hamilton’s principle for electrostatic body, which is mainly based on the mechanical and electrical energy without magnetic effects. However, in our case, we are mainly focused on the mainly input mechanical force dependent electrical energy and their configured electric load circuit. Therefore, in a practical point of view, we are more focused on the mechanical force dependent generation energy. For the Beeby et al. [

23] case, the authors employed resonant type piezoelectric generator for the energy harvester applications. They analyzed applied mechanical energies and converted energies by employing differential equation for the inertial mass system in resonators. However, in our case, we are more focused on the applied mechanical force dependent electrical input energies and system efficiencies to obtain maximum energies which we can obtain by optimizing the load circuit. The origin of Equation (2) is as follows. Considering the internal resistance of the piezoelectric element and the voltage distribution according to the internal resistance, the output voltage increases with increasing load resistance, but tends to saturate when approaching a steady state. As depicted in

Figure 8, the fitting to this equation was conducted using the iterative least mean square error minimization method. The fit values and measured values were well-matched with each other. It appears that our assumption of internal resistance related generated output voltages were related with each other. In our previous study [

23], we measured the generated output energy of a PZT-based piezoelectric energy harvester, wherein tape-casting-based multilayered structures were employed and tested. As we employed a multilayered structure, the capacitance values approached the μF level. As a result, the load impedance exhibited different values. However, the generated output voltages exhibited similar values. In this experiment as well, the generated output voltages increased with the load resistor value and then become saturated. Based on

Figure 8, the maximum generated output energy can be estimated based on the saturated output voltage values [

24].

Figure 9 depicts the generated output power of the multilayered BS-PT piezoelectric energy harvesters as a function of the resistor load. In contrast to

Figure 8, which depicts the generated output voltages, the generated output power can exhibit maximum values when the load resistor has similar internal resistance values. According to the circuit theory, an external matching circuit should have similar impedance values to the internal system; otherwise, the maximum output power cannot be obtained. To obtain the maximum power, the derivative of the equation for the total system should be considered. As a result, Equations (3) and (4) were obtained. Therefore, the external load resistor R

L should have similar values to the internal resistor value R

t. The red dashed line in the energy harvester circuit shown in

Figure 5b represents the equivalent circuit of the piezoelectric harvesters. In the equivalent circuit, R

piezo and C

piezo are the internal resistance and capacitance of the piezoelectric energy harvester, respectively. Based on the impedance matching theory, when the load resistor R

load has similar values to R

piezo, the generated output energy can be maximized. Using Equation (3), the relation between the resistive load and the generated power can be expressed as

where V

o is the generated output voltage, R

L is the load resistance, and R

piezo is the internal resistance of the energy harvesters. Using Equation (4), the maximum values of generated power can be obtained when the resistive part in the load component has the same value as that of the piezoelectric ceramic materials and other circuit components. As the load resistive component approaches 3 MΩ, the piezoelectric energy harvester system exhibits maximum power values of 5.93 μW/cm

2 for the quadruple-layer system, demonstrating high performance similar to that of the PZT-based energy harvester [

23,

24]. The load resistor values for the maximum power of energy generation decreased with increasing number of layers. Due to the parallel connection of the piezoelectric component layers, the resistive component value decreased with increasing number of layers. As shown in the

Table 3, we check the matching impedence and generated power for the 1–4 layer BS-PT piezoelectric energy harvesters in 500 N.