Sensitivity Improvement of a Surface Plasmon Resonance Sensor Based on Two-Dimensional Materials Hybrid Structure in Visible Region: A Theoretical Study

Abstract

:1. Introduction

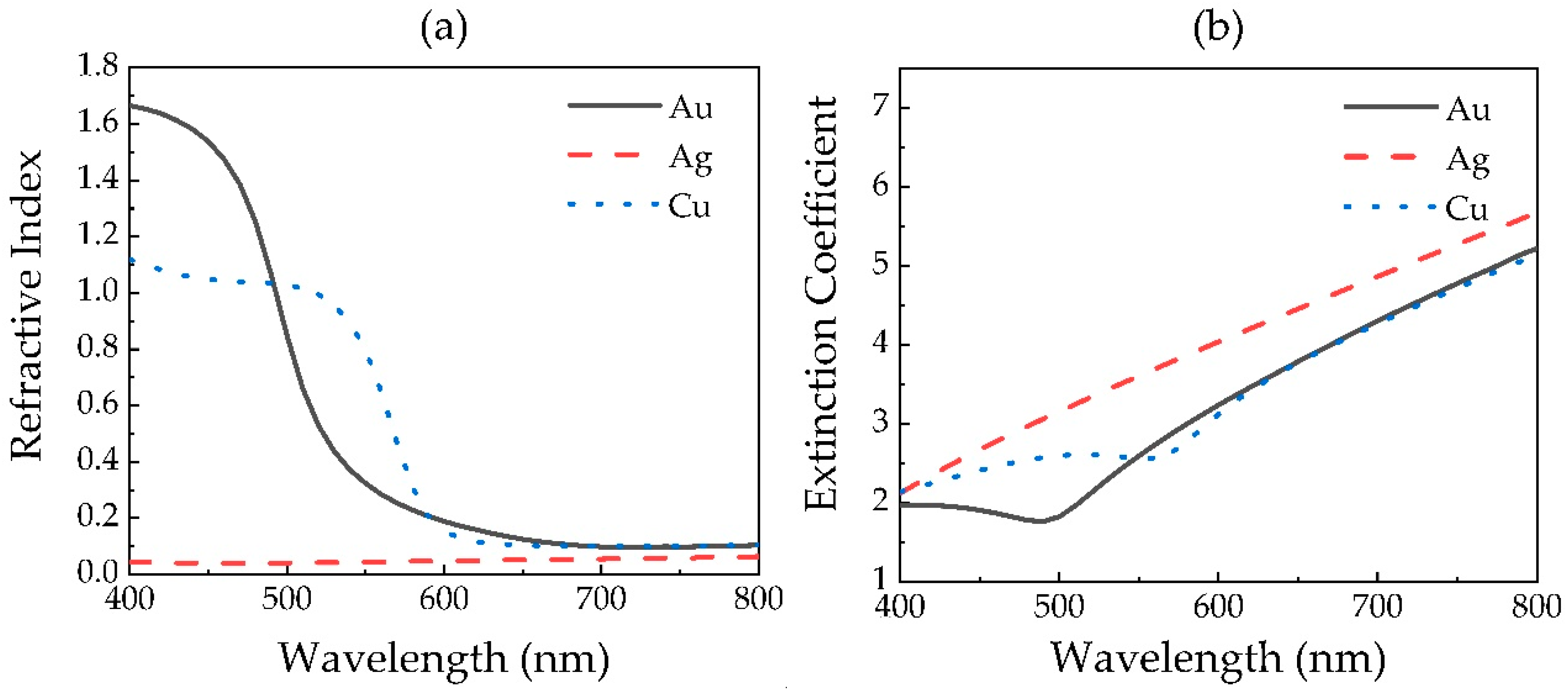

2. Materials and Methods

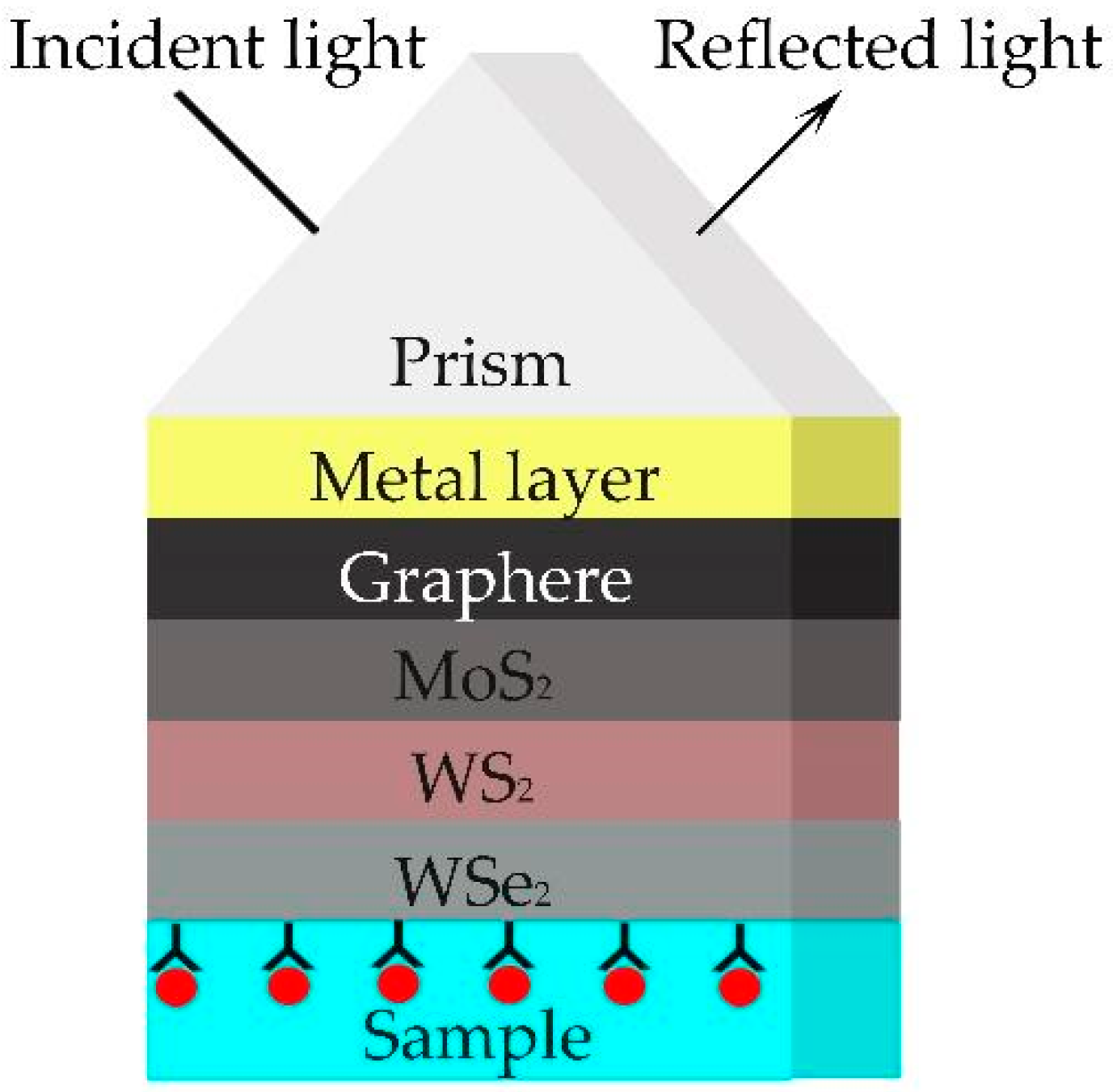

2.1. Structure of Proposed SPR Sensor

2.2. Transfer Matrix Method

2.3. Genetic Algorithm

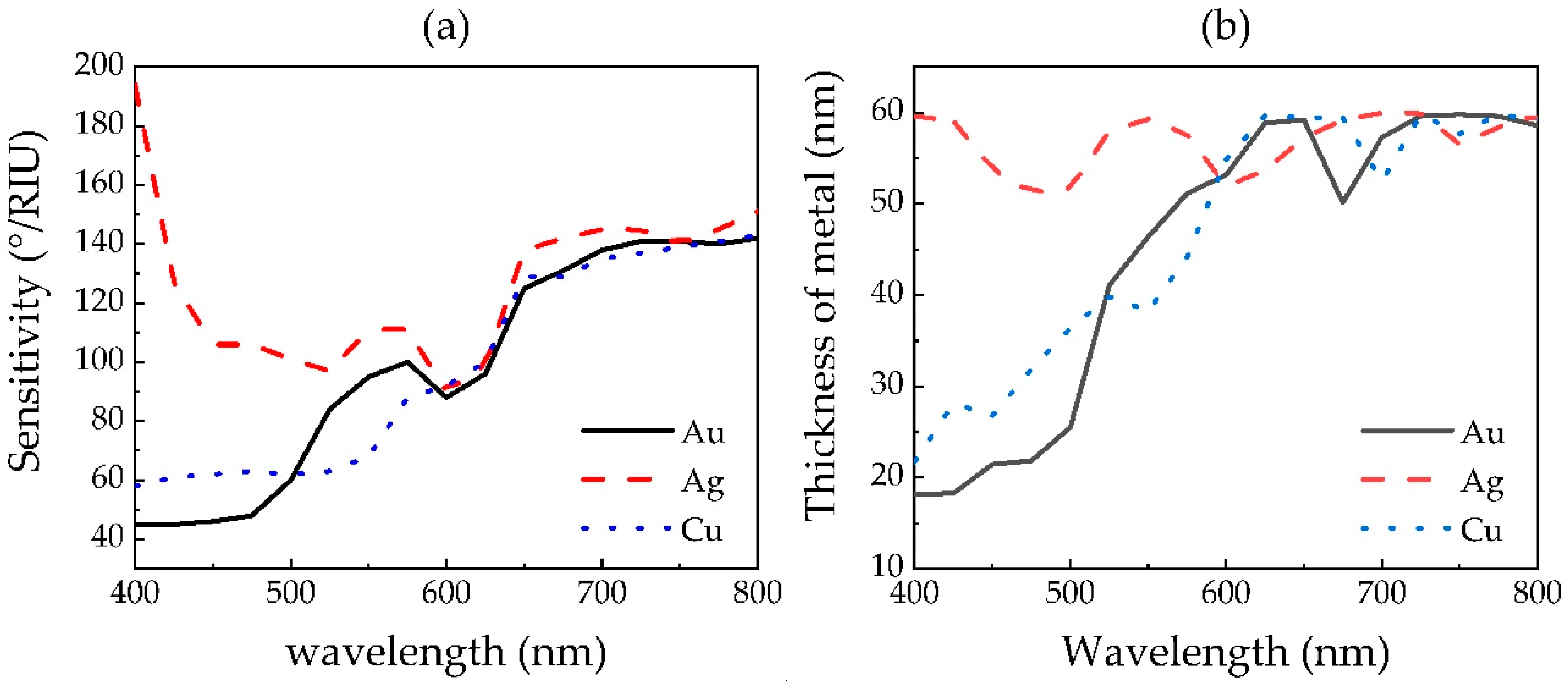

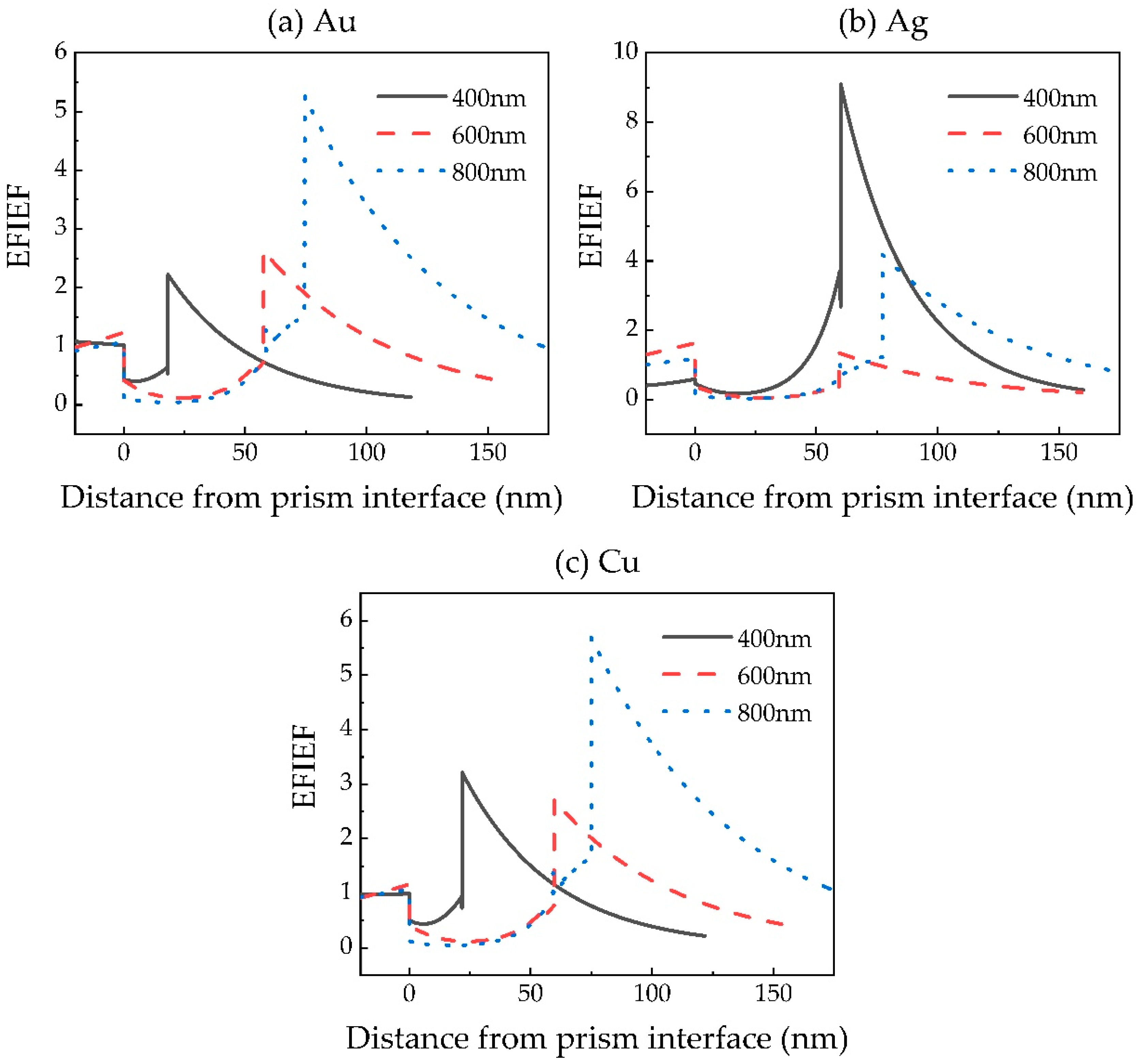

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kumar, R.; Kushwaha, A.S.; Srivastava, M.; Mishra, H.; Srivastava, S.K. Enhancement in sensitivity of graphene-based zinc oxide assisted bimetallic surface plasmon resonance (SPR) biosensor. Appl. Phys. A-Mater. 2018, 124, 235. [Google Scholar] [CrossRef]

- Béland, P.; Berini, P. Viability assessment of bacteria using long-range surface plasmon waveguide biosensors. Appl. Phys. A-Mater. 2017, 123, 31. [Google Scholar] [CrossRef]

- Piliarik, M.; Parova, L.; Homola, J. High-throughput SPR sensor for food safety. Biosens. Bioelectron. 2008, 24, 1399–1404. [Google Scholar] [CrossRef] [PubMed]

- Farré, M.; Kantiani, L.; Barceló, D. Advances in immunochemical technologies for analysis of organic pollutants in the environment. Trends Anal. Chem. 2007, 26, 1100–1112. [Google Scholar] [CrossRef]

- Heckmann, J.; Pufahl, K.; Franz, P.; Grosse, N.B.; Li, X.; Woggon, U. Plasmon-enhanced nonlinear yield in the Otto and Kretschmann configurations. Phys. Rev. B 2018, 98, 115415. [Google Scholar] [CrossRef]

- McPhedran, R.; Nicorovici, N.A.; Alleyne, C.J.; Kirk, A.G.; Maystre, D. Enhanced SPR sensitivity using periodic metallic structures. Opt. Express 2007, 15, 8163–8169. [Google Scholar] [CrossRef]

- Kapoor, V.; Sharma, N.K.; Sajal, V. Effect of zinc oxide overlayer on the sensitivity of fiber optic SPR sensor with indium tin oxide layer. Optik 2019, 185, 464–468. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, H.; Dong, J.; Hu, S.; Zhu, W.; Qiu, W.; Lu, H.; Yu, J.; Guan, H.; Gao, S.; et al. Sensitivity-enhanced surface plasmon resonance sensor utilizing a tungsten disulfide (WS2) nanosheets overlayer. Photonics Res. 2018, 6, 485–491. [Google Scholar] [CrossRef]

- Shukla, S.; Sharma, N.K.; Sajal, V. Sensitivity enhancement of a surface plasmon resonance based fiber optic sensor using ZnO thin film: A theoretical study. Sens. Actuators B 2015, 206, 463–470. [Google Scholar] [CrossRef]

- Maharana, P.K.; Jha, R.; Palei, S. Sensitivity enhancement by air mediated graphene multilayer based surface plasmon resonance biosensor for near infrared. Sens. Actuators B 2014, 190, 494–501. [Google Scholar] [CrossRef]

- Sheng, X.; Liu, J.; Yang, H.; Chen, L.; Li, J.; Liu, H. Optimization of tunable symmetric SPR sensor based on Ag-graphene. Optik 2019, 184, 339–347. [Google Scholar] [CrossRef]

- Verma, A.; Prakash, A.; Tripathi, R. Sensitivity enhancement of surface plasmon resonance biosensor using graphene and air gap. Opt. Commun. 2015, 357, 106–112. [Google Scholar] [CrossRef]

- Maharana, P.K.; Jha, R.; Padhy, P. On the electric field enhancement and performance of SPR gas sensor based on graphene for visible and near infrared. Sens. Actuators B 2015, 207, 117–122. [Google Scholar] [CrossRef]

- Rifat, A.A.; Mahdiraji, G.A.; Ahmed, R.; Chow, D.M.; Sua, Y.M.; Shee, Y.G.; Adikan, F.R.M. Copper-graphene-based photonic crystal fiber plasmonic biosensor. IEEE Photonics J. 2016, 8, 4800408. [Google Scholar] [CrossRef]

- Zakaria, R.; Zainuddin, N.A.A.M.; Leong, T.C.; Rosli, R.; Rusdi, M.F.; Harun, S.W.; Sadegh Amiri, I. Investigation of surface plasmon resonance (SPR) in MoS2-and WS2-protected titanium side-polished optical fiber as a humidity sensor. Micromachines 2019, 10, 465. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rahman, M.S.; Anower, M.S.; Abdulrazak, L.F. Utilization of a phosphorene-graphene/TMDC heterostructure in a surface plasmon resonance-based fiber optic biosensor. Photonic Nanostruct. 2019, 35, 100711. [Google Scholar] [CrossRef]

- Rahman, M.S.; Anower, M.S.; Hasan, M.R.; Hossain, M.B.; Haque, M.I. Design and numerical analysis of highly sensitive Au-MoS2-graphene based hybrid surface plasmon resonance biosensor. Opt. Commun. 2017, 396, 36–43. [Google Scholar] [CrossRef]

- Kushwaha, A.S.; Kumar, A.; Kumar, R.; Srivastava, S.K. A study of surface plasmon resonance (SPR) based biosensor with improved sensitivity. Photonic Nanostruct. 2018, 31, 99–106. [Google Scholar] [CrossRef]

- Wu, L.; Jia, Y.; Jiang, L.; Guo, J.; Dai, X.; Xiang, Y.; Fan, D. Sensitivity improved SPR biosensor based on the MoS2/graphene–aluminum hybrid structure. J. Lightwave Technol. 2017, 35, 82–87. [Google Scholar] [CrossRef]

- Meshginqalam, B.; Barvestani, J. Performance enhancement of SPR biosensor based on phosphorene and transition metal dichalcogenides for sensing DNA hybridization. IEEE Sens. J. 2018, 18, 7537–7543. [Google Scholar] [CrossRef]

- Guo, X.; Zhou, C.; Jin, S.; Huang, C.; Xing, J.; Liu, Z. Sensitivity enhancement of two-dimensional materials based on genetic optimization in surface plasmon resonance. Sensors 2019, 19, 1198. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.; Chen, S. Design of high-performance Au-Ag-dielectric-graphene based surface plasmon resonance biosensors using genetic algorithm. J. Appl. Phys. 2019, 125, 113101. [Google Scholar] [CrossRef]

- Lin, C.; Chen, S. Design of highly sensitive guided-wave surface plasmon resonance biosensor with deep dip using genetic algorithm. Opt. Commun. 2019, 445, 155–160. [Google Scholar] [CrossRef]

- Bahrami, F.; Maisonneuve, M.; Meunier, M.; Aitchison, J.S.; Mojahedi, M. An improved refractive index sensor based on genetic optimization of plasmon waveguide resonance. Opt. Express 2013, 21, 20863–20872. [Google Scholar] [CrossRef]

- Fu, P.H.; Lo, S.C.; Tsai, P.C.; Lee, K.L.; Wei, P.K. Optimization for gold nanostructure-based surface plasmon biosensors using a microgenetic algorithm. ACS Photonics 2018, 5, 2320–2327. [Google Scholar] [CrossRef]

- Jha, R.; Sharma, A.K. Chalcogenide glass prism based SPR sensor with Ag–Au bimetallic nanoparticle alloy in infrared wavelength region. J. Opt. A Pure Appl. Opt. 2009, 11, 045502. [Google Scholar] [CrossRef]

- Xu, H.; Wu, L.; Dai, X.; Gao, Y.; Xiang, Y. An ultra-high sensitivity surface plasmon resonance sensor based on graphene-aluminum-graphene sandwich-like structure. J. Appl. Phys. 2016, 120, 053101. [Google Scholar] [CrossRef]

- Aray, A.; Ranjbar, M. SPR-based fiber optic sensor using IMO thin film: Towards wide wavelength tunability from visible to NIR. IEEE Sens. J. 2019, 19, 2540–2546. [Google Scholar] [CrossRef]

- Chen, S.; Lin, C. Sensitivity comparison of graphene based surface plasmon resonance biosensor with Au, Ag and Cu in the visible region. Mater. Res. Express 2019, 6, 056503. [Google Scholar] [CrossRef]

- McPeak, K.M.; Jayanti, S.V.; Kress, S.J.P.; Meyer, S.; Iotti, S.; Rossinelli, A.; Norris, D.J. Plasmonic films can easily be better: Rules and recipes. ACS Photonics 2015, 2, 326–333. [Google Scholar] [CrossRef]

- Weber, J.W.; Calado, V.E.; van de Sanden, M.C.M. Optical constants of graphene measured by spectroscopic ellipsometry. Appl. Phys. Lett. 2010, 97, 091904. [Google Scholar] [CrossRef]

- Jung, G.H.; Yoo, S.; Park, Q.H. Measuring the optical permittivity of two-dimensional materials without a priori knowledge of electronic transitions. Nanophotonics 2019, 8, 263–270. [Google Scholar] [CrossRef]

- Ouyang, Q.; Zeng, S.; Jiang, L.; Hong, L.; Xu, G.; Dinh, X.Q.; Qian, J.; He, S.; Qu, J.; Coquet, P. Sensitivity enhancement of transition metal dichalcogenides/silicon nanostructure-based surface plasmon resonance biosensor. Sci. Rep. 2016, 6, 28190. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Chu, H.S.; Koh, W.S.; Li, E.P. Highly sensitive graphene biosensors based on surface plasmon resonance. Opt. Express 2010, 18, 14395–14400. [Google Scholar] [CrossRef]

- Shalabney, A.; Abdulhalim, I. Electromagnetic fields distribution in multilayer thin film structures and the origin of sensitivity enhancement in surface plasmon resonance sensors. Sens. Actuators A 2010, 159, 24–32. [Google Scholar] [CrossRef]

- Aksimsek, S.; Jussila, H.; Sun, Z. Graphene–MoS2–metal hybrid structures for plasmonic biosensors. Opt. Commun. 2018, 428, 233–239. [Google Scholar] [CrossRef]

- Maharana, P.K.; Jha, R. Chalcogenide prism and graphene multilayer based surface plasmon resonance affinity biosensor for high performance. Sens. Actuators B 2012, 169, 161–166. [Google Scholar] [CrossRef]

- Ouyang, Q.; Zeng, S.; Dinh, X.-Q.; Coquet, P.; Yong, K.-T. Sensitivity enhancement of MoS2 nanosheet based surface plasmon resonance biosensor. Procedia Eng. 2016, 140, 134–139. [Google Scholar] [CrossRef] [Green Version]

| 2D Materials | Thickness of Monolayer (nm) |

|---|---|

| Graphene | 0.34 |

| MoS2 | 0.65 |

| WS2 | 0.8 |

| WSe2 | 0.7 |

| Metal | Wavelength (nm) | Thickness (nm) | K | L | M | N | Rres | θres | S |

|---|---|---|---|---|---|---|---|---|---|

| Au | 400 | 18.14 | 0 | 0 | 0 | 0 | 0.013 | 61.26 | 45 |

| 600 | 53.18 | 0 | 0 | 1 | 5 | 0.479 | 64.89 | 88 | |

| 800 | 58.58 | 0 | 1 | 12 | 8 | 0.433 | 76.07 | 142 | |

| Ag | 400 | 59.63 | 1 | 0 | 0 | 0 | 0.603 | 71.09 | 194 |

| 600 | 51.92 | 0 | 0 | 4 | 6 | 0.723 | 64.76 | 90 | |

| 800 | 59.78 | 0 | 12 | 12 | 0 | 0.574 | 76.65 | 151 | |

| Cu | 400 | 21.72 | 0 | 0 | 0 | 0 | 0.001 | 59.66 | 58 |

| 600 | 54.86 | 0 | 0 | 6 | 0 | 0.493 | 65.82 | 92 | |

| 800 | 59.20 | 0 | 6 | 13 | 2 | 0.417 | 75.56 | 143 |

| Reference | Wave Length (nm) | Configuration | Layer Number of 2D Materials | Sensitivity (°/RIU) | |||

|---|---|---|---|---|---|---|---|

| Graphene | MoS2 | WS2 | WSe2 | ||||

| [1] | 632.8 | BK7/ZnO/Ag/Au/graphene | l | — | — | — | 66 |

| [15] | 633 | SF11/Au/graphene | 1 | — | — | — | 71 |

| [17] | 633 | SF10/Au/Graphene/MoS2 | 1 | 2 | — | — | 89.29 |

| [34] | 633 | SF10/Au/graphene | 1 | — | — | — | 53.2 |

| [36] | 632.8 | SF11/Ag/MoS2/graphene | 1 | 5 | — | — | 73.5 |

| [37] | 632.8 | 2S2G /Au/graphene | 6 | — | — | — | 46 |

| [38] | 633 | SF10/Au/ MoS2 | 6 | — | — | 75.34 | |

| This paper | 400 | SF11/Ag/graphene | 1 | — | — | — | 194 |

| This paper | 600 | SF11/Cu/WSe2 | — | — | — | 6 | 92 |

| This paper | 800 | SF11/Au/MoS2/WS2/WSe2 | — | 1 | 12 | 8 | 142 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Z.; Chen, S.; Lin, C. Sensitivity Improvement of a Surface Plasmon Resonance Sensor Based on Two-Dimensional Materials Hybrid Structure in Visible Region: A Theoretical Study. Sensors 2020, 20, 2445. https://doi.org/10.3390/s20092445

Lin Z, Chen S, Lin C. Sensitivity Improvement of a Surface Plasmon Resonance Sensor Based on Two-Dimensional Materials Hybrid Structure in Visible Region: A Theoretical Study. Sensors. 2020; 20(9):2445. https://doi.org/10.3390/s20092445

Chicago/Turabian StyleLin, Zhining, Shujing Chen, and Chengyou Lin. 2020. "Sensitivity Improvement of a Surface Plasmon Resonance Sensor Based on Two-Dimensional Materials Hybrid Structure in Visible Region: A Theoretical Study" Sensors 20, no. 9: 2445. https://doi.org/10.3390/s20092445