Compact and Low-Profile UWB Antenna Based on Graphene-Assembled Films for Wearable Applications

Abstract

:1. Introduction

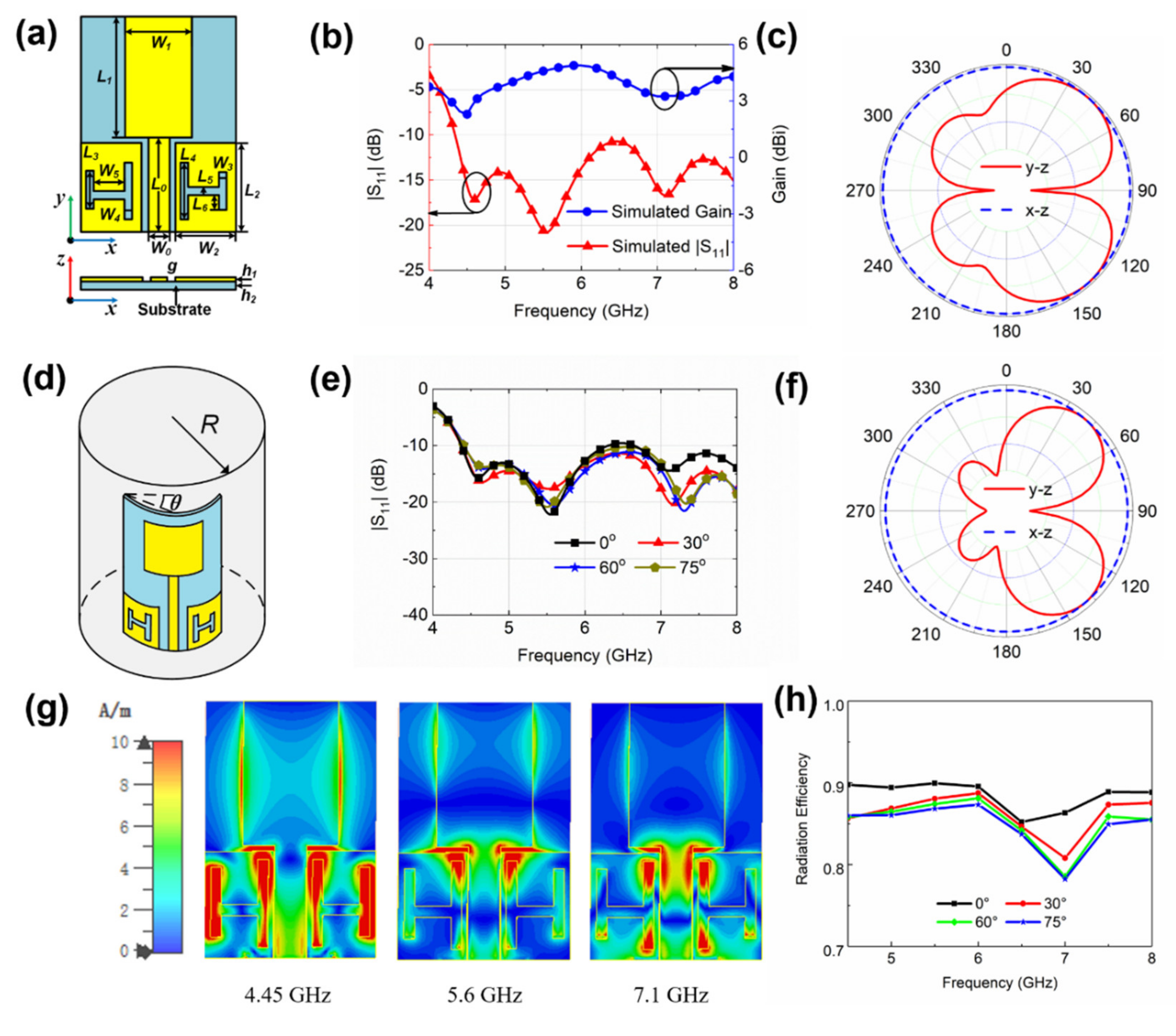

2. Preparation and Characterization of GAF

3. GAF Antenna Design and Measurement

4. Measurement of GAF Antenna in Wearable Applications

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Corchia, L.; Monti, G.; Tarricone, L. Wearable antennas: Nontextile versus fully textile solutions. IEEE Antennas Propag. Mag. 2019, 61, 71–83. [Google Scholar] [CrossRef]

- Bariya, M.; Nyein, H.Y.Y.; Javey, A. Wearable sweat sensors. Nat. Electron. 2018, 1, 160–171. [Google Scholar] [CrossRef]

- Hosseini Varkiani, S.M.; Afsahi, M. Grounded CPW multi-band wearable antenna for MBAN and WLAN applications. Microw. Opt. Technol. Lett. 2018, 60, 561–568. [Google Scholar] [CrossRef]

- Liang, T.; Yuan, Y.J. Wearable medical monitoring systems based on wireless networks: A review. IEEE Sens. J. 2016, 16, 8186–8199. [Google Scholar] [CrossRef]

- Yetisen, A.K.; Martinez-Hurtado, J.L.; Ünal, B.; Khademhosseini, A.; Butt, H. Wearables in medicine. Adv. Mater. 2018, 30, 1706910. [Google Scholar] [CrossRef]

- Agneessens, S.; Lemey, S.; Vervust, T.; Rogier, H. Wearable, small, and robust: The circular quarter-mode textile antenna. IEEE Antennas Wirel. Propag. Lett. 2015, 14, 1482–1485. [Google Scholar] [CrossRef]

- Singh, N.; Singh, A.K.; Singh, V.K. Design and performance of wearable ultrawide band textile antenna for medical applications. Microw. Opt. Technol. Lett. 2015, 57, 1553–1557. [Google Scholar] [CrossRef]

- Ashyap, A.Y.I.; Abidin, Z.Z.; Dahlan, S.H.; Majid, H.A.; Shah, S.M.; Kamarudin, M.R.; Alomainy, A. Compact and low-profile textile EBG-based antenna for wearable medical applications. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 2550–2553. [Google Scholar] [CrossRef] [Green Version]

- Nejatijahromi, M.; Naghshvarianjahromi, M.; Rahman, M. Compact CPW fed switchable UWB antenna as an antenna filter at narrow-frequency bands. Prog. Electromagn. Res. C 2018, 81, 199–209. [Google Scholar] [CrossRef] [Green Version]

- Maaref, N.; Millot, P.; Pichot, C.; Picon, O. A study of UWB FM-CW radar for the detection of human beings in motion inside a building. IEEE Trans. Geosci. Remote Sens. 2009, 47, 1297–1300. [Google Scholar] [CrossRef]

- Rahman, M.; NaghshvarianJahromi, M.; Mirjavadi, S.S.; Hamouda, A.M. Resonator based switching technique between Ultra Wide Band (UWB) and single/dual continuously tunable-notch behaviors in UWB radar for wireless vital signs monitoring. Sensors 2018, 18, 3330. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Behera, D.; Dwivedy, B.; Mishra, D.; Behera, S.K. Design of a CPW fed compact bow-tie microstrip antenna with versatile frequency tunability. IET Microw. Antennas Propag. 2017, 12, 841–849. [Google Scholar] [CrossRef]

- Abbasi, Q.H.; Rehman, M.U.; Yang, X.; Alomainy, A.; Qaraqe, K.; Serpedin, E. Ultrawideband band-notched flexible antenna for wearable applications. IEEE Antennas Wirel. Propag. Lett. 2013, 12, 1606–1609. [Google Scholar] [CrossRef]

- Ali, W.A.; Mansour, A.M.; Mohamed, D.A. Compact UWB wearable planar antenna mounted on different phantoms and human body. Microw. Opt. Technol. Lett. 2016, 58, 2531–2536. [Google Scholar] [CrossRef]

- Sun, Y.; Cheung, S.W.; Yuk, T.I. Design of a textile ultra-wideband antenna with stable performance for body-centric wireless communications. IET Microw. Antennas Propag. 2014, 8, 1363–1375. [Google Scholar] [CrossRef]

- Elobaid, H.A.E.; Rahim, S.K.A.; Himdi, M.; Castel, X.; Kasgari, M.A. A transparent and flexible polymer-fabric tissue UWB antenna for future wireless networks. IEEE Antennas Wirel. Propag. Lett. 2016, 16, 1333–1336. [Google Scholar] [CrossRef]

- Simorangkir, R.B.V.B.; Yang, Y.; Hashmi, R.M.; Björninen, T.; Esselle, K.P.; Ukkonen, L. Polydimethylsiloxane-embedded conductive fabric: Characterization and application for realization of robust passive and active flexible wearable antennas. IEEE Access 2018, 6, 48102–48112. [Google Scholar] [CrossRef]

- Gautam, A.K.; Yadav, S.; Kanaujia, B.K. A CPW-fed compact UWB microstrip antenna. IEEE Antennas Wirel. Propag. Lett. 2013, 12, 151–154. [Google Scholar] [CrossRef]

- Koohestani, M.; Moreira, A.A.; Skrivervik, A.K. A novel compact CPW-fed polarization diversity ultrawideband antenna. IEEE Antennas Wirel. Propag. Lett. 2014, 13, 563–566. [Google Scholar] [CrossRef]

- Li, Y.; Li, W.; Mittra, R. A compact CPW-fed circular slot antenna with reconfigurable dual band-notch characteristics for UWB communication applications. Microw. Opt. Technol. Lett. 2014, 56, 465–468. [Google Scholar] [CrossRef]

- Zheng, Z.-A.; Chu, Q.-X. Compact CPW-fed UWB antenna with dual band-notched characteristics. Prog. Electromagn. Res. 2009, 11, 83–91. [Google Scholar] [CrossRef] [Green Version]

- Yoon, S.J.; Jeong, S.H.; Yook, J.G.; Kim, Y.J.; Lee, S.G.; Seo, O.K.; Lim, K.S.; Kim, D.S. A novel CPW structure for high-speed interconnects. In Proceedings of the IEEE MTT-S International Microwave Symposium Digest, Phoenix, AZ, USA, 20–24 May 2001; pp. 771–774. [Google Scholar]

- Park, S.Y.; Jeong Oh, S.; Park, J.K. DUAL-BAND antenna for WLAN/UWB applications. Microw. Opt. Technol. Lett. 2010, 52, 2188–2191. [Google Scholar] [CrossRef]

- Saeed, S.M.; Balanis, C.A.; Birtcher, C.R.; Durgun, A.C.; Shaman, H.N. Wearable flexible reconfigurable antenna integrated with artificial magnetic conductor. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 2396–2399. [Google Scholar] [CrossRef]

- Li, H.; Sun, S.; Wang, B.; Wu, F. Design of compact single-layer textile MIMO antenna for wearable applications. IEEE Trans. Antennas Propag. 2018, 66, 3136–3141. [Google Scholar] [CrossRef]

- Paracha, K.N.; Rahim, S.K.A.; Soh, P.J.; Kamarudin, M.R.; Tan, K.G.; Lo, Y.C.; Islam, M.T. A low profile, dual-band, dual polarized antenna for indoor/outdoor wearable application. IEEE Access 2019, 7, 33277–33288. [Google Scholar] [CrossRef]

- Inui, T.; Koga, H.; Nogi, M.; Komoda, N.; Suganuma, K. A miniaturized flexible antenna printed on a high dielectric constant nanopaper composite. Adv. Mater. 2015, 27, 1112–1116. [Google Scholar] [CrossRef]

- Manna, S.; Bose, T.; Bera, R. Microstrip Patch Antenna with Fractal Structure Using Superstrate Operating in ISM Band. In Advances in Communication, Devices and Networking; Springer: Verlag Berlin Heidelberg, Germany, 2018; pp. 321–328. [Google Scholar]

- Agarwal, K.; Guo, Y.X.; Salam, B. Wearable AMC backed near-endfire antenna for on-body communications on latex substrate. IEEE Trans. Compon. Packag. Manuf. Technol. 2016, 6, 346–358. [Google Scholar] [CrossRef]

- Zhu, J.; Cheng, H. Recent development of flexible and stretchable antennas for bio-integrated electronics. Sensors 2018, 18, 4364. [Google Scholar] [CrossRef] [Green Version]

- Salvado, R.; Loss, C.; Gonçalves, R.; Pinho, P. Textile materials for the design of wearable antennas: A survey. Sensors 2012, 12, 15841–15857. [Google Scholar] [CrossRef] [PubMed]

- Zhong, J.; Kiourti, A.; Sebastian, T.; Bayram, Y.; Volakis, J.L. Conformal load-bearing spiral antenna on conductive textile threads. IEEE Antennas Wirel. Propag. Lett. 2016, 16, 230–233. [Google Scholar] [CrossRef]

- Janeczek, K.; Jakubowska, M.; Młożniak, A.; Kozioł, G. Thermal characterization of screen printed conductive pastes for RFID antennas. Mater. Sci. Eng. B 2012, 177, 1336–1342. [Google Scholar] [CrossRef]

- Mehdipour, A.; Rosca, I.D.; Sebak, A.R.; Trueman, C.W.; Hoa, S.V. Carbon nanotube composites for wideband millimeter-wave antenna applications. IEEE Trans. Antennas Propag. 2011, 59, 3572–3578. [Google Scholar] [CrossRef]

- Elmobarak, H.A.; Rahim, S.K.A.; Abedian, M.; Soh, P.J.; Vandenbosch, G.A.E.; Yew Chiong, L. Assessment of multilayered graphene technology for flexible antennas at microwave frequencies. Microw. Opt. Technol. Lett. 2017, 59, 2604–2610. [Google Scholar] [CrossRef]

- Hamouda, Z.; Wojkiewicz, J.-L.; Pud, A.A.; Kone, L.; Belaabed, B.; Bergheul, S.; Lasri, T. Dual-band elliptical planar conductive polymer antenna printed on a flexible substrate. IEEE Trans. Antennas Propag. 2015, 63, 5864–5867. [Google Scholar] [CrossRef]

- Huang, X.; Leng, T.; Zhu, M.; Zhang, X.; Chen, J.; Chang, K.; Aqeeli, M.; Geim, A.K.; Novoselov, K.S.; Hu, Z. Highly flexible and conductive printed graphene for wireless wearable communications applications. Sci. Rep. 2015, 6, 18298. [Google Scholar] [CrossRef] [Green Version]

- Yimdjo Poffelie, L.A.; Soh, P.J.; Yan, S.; Vandenbosch, A.E.G. A high-fidelity all-textile UWB antenna with low back radiation for off-body WBAN applications. IEEE Trans. Antennas Propag. 2016, 654, 757–760. [Google Scholar] [CrossRef]

- Locher, I.; Klemm, M.; Kirstein, T.; Trster, G. Design and characterization of purely textile patch antennas. IEEE Trans. Adv. Packag. 2006, 29, 777–788. [Google Scholar] [CrossRef] [Green Version]

- Zhou, W.; Liu, C.; Song, R.; Zeng, X.; Li, B.W.; Xia, W.; Zhang, J.; Huang, G.L.; Wu, Z.P.; He, D. Flexible radiofrequency filters based on highly conductive graphene assembly films. Appl. Phys. Lett. 2019, 114, 113503. [Google Scholar] [CrossRef]

- Song, R.; Wang, Q.; Mao, B.; Wang, Z.; Tang, D.; Zhang, B.; Zhang, J.; Liu, C.; He, D.; Wu, Z.; et al. Flexible graphite films with high conductivity for radio-frequency antennas. Carbon N.Y. 2018, 130, 164–169. [Google Scholar] [CrossRef]

- Simorangkir, R.B.V.B.; Kiourti, A.; Esselle, K.P. UWB wearable antenna with a full ground plane based on pdms-embedded conductive fabric. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 493–496. [Google Scholar] [CrossRef]

- Xu, L.J.; Wang, H.; Chang, Y.; Bo, Y. A flexible UWB inverted-F antenna for wearable application. Microw. Opt. Technol. Lett. 2017, 59, 2514–2518. [Google Scholar] [CrossRef]

- Tang, D.; Wang, Q.; Wang, Z.; Liu, Q.; Zhang, B.; He, D.; Wu, Z.; Mu, S. Highly sensitive wearable sensor based on a flexible multi-layer graphene film antenna. Sci. Bull. 2018, 63, 574–579. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, M.M. An UWB antenna design with dual band notched characteristic using U-shaped slots. In Proceedings of the 2016 International Conference on Signal Processing and Communication (ICSC), Noida, India, 26–28 December 2016; pp. 470–473. [Google Scholar]

- El Hamraoui, A.; Abdelmounim, E.; Zbitou, J.; Tajmouati, A.; El Abdellaoui, L.; Errkik, A.; Latrach, M. Compact CPW-fed dual-band uniplanar antenna for RFID applications. In Proceedings of the 2015 Third International Workshop on RFID And Adaptive Wireless Sensor Networks (RAWSN), Agadir, Morocco, 13–15 May 2015; pp. 73–77. [Google Scholar]

- Chang, K. Encyclopedia of RF and microwave engineering. Choice Rev. Online 2005, 43, 43-0665-43-0665. [Google Scholar]

- Balanis, C.A. Antenna theory: Analysis and design. IEEE Antennas Propag. Soc. Newsl. 2003, 24, 28–29. [Google Scholar]

| Ref. | Size (mm) | Frequency (GHz) | Conductive Material (S/m) | Substrate Material (ɛr) | 𝜂 (%) |

|---|---|---|---|---|---|

| [42] | 80 × 67 × 3.4 | 3.7–10.3 | nickel–copper–silver-coated nylon (1.02 × 105) | PDMS (2.7) | 27 |

| [38] | 80 × 61 × 4.51 | 2–12 | ShieldIt conductive textile (1.18 × 105) | Felt (1.45) | N/A |

| [43] | 13 × 38 × 1.8 | 3–12 | Copper (107) | Polyimide (3.5) | N/A |

| [15] | 30 × 40 × 1.15 | 2.8–16 | Copper (107) | Cotton (1.75) | 50 |

| This work | 32 × 52 × 0.28 | 4–8 | GAF (106) | Ceramic (3.2) | 90 |

| Parameters | Value (mm) | Parameters | Value (mm) |

|---|---|---|---|

| W0 | 6 | W3 | 2 |

| L0 | 23 | L3 | 8 |

| W1 | 18 | W4 | 2 |

| L1 | 29 | L4 | 15 |

| W2 | 13 | W5 | 7 |

| L2 | 20 | L5 | 2 |

| h1 | 0.025 | h2 | 0.255 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, R.; Song, R.; Zhao, X.; Wang, Z.; Qian, W.; He, D. Compact and Low-Profile UWB Antenna Based on Graphene-Assembled Films for Wearable Applications. Sensors 2020, 20, 2552. https://doi.org/10.3390/s20092552

Fang R, Song R, Zhao X, Wang Z, Qian W, He D. Compact and Low-Profile UWB Antenna Based on Graphene-Assembled Films for Wearable Applications. Sensors. 2020; 20(9):2552. https://doi.org/10.3390/s20092552

Chicago/Turabian StyleFang, Ran, Rongguo Song, Xin Zhao, Zhe Wang, Wei Qian, and Daping He. 2020. "Compact and Low-Profile UWB Antenna Based on Graphene-Assembled Films for Wearable Applications" Sensors 20, no. 9: 2552. https://doi.org/10.3390/s20092552