A New Paper-Based Microfluidic Device for Improved Detection of Nitrate in Water

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Greiss Assay

2.2. A New Composite Material That Improves Nitrate Conversion Efficiency

2.3. Immobilized Griess Reagent

2.4. Device Architecture

2.5. Device Preparation, Operation, and Analysis Procedure

2.6. Reagents

2.7. Testing Range and Limits of Detection and Quantification

3. Results and Discussion

3.1. Signal Uniformity

3.2. Optimization of Device Parameters

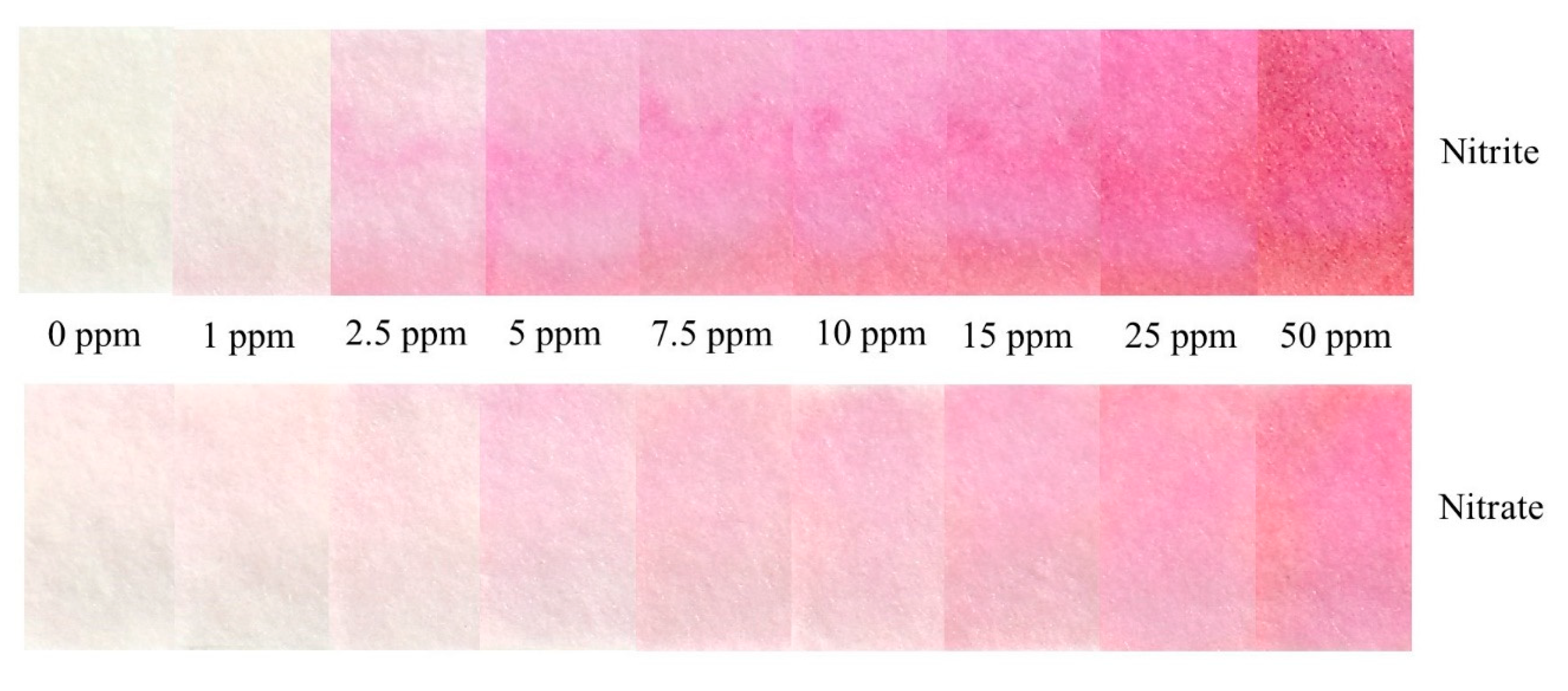

3.3. Testing in Deionized Water

3.4. Testing in Sargasso Seawater

3.5. Comparison of Results

3.6. Device Portability, Longevity, and Commercialization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pengpumkiat, S.; Nammoonnoy, J.; Wongsakoonkan, W.; Konthonbut, P.; Kongtip, P. A Microfluidic Paper-Based Analytical Device for Type-II Pyrethroid Targets in an Environmental Water Sample. Sensors 2020, 20, 4107. [Google Scholar] [CrossRef]

- Racicot, J.M.; Mako, T.L.; Olivelli, A.; Levine, M. A Paper-Based Device for Ultrasensitive, Colorimetric Phosphate Detection in Seawater. Sensors 2020, 20, 2766. [Google Scholar] [CrossRef]

- Kumar, S.; Nehra, M.; Mehta, J.; Dilbaghi, N.; Marrazzabd, G.; Kaushik, A. Point-of-Care Strategies for Detection of Waterborne Pathogens. Sensors 2019, 19, 4476. [Google Scholar] [CrossRef] [Green Version]

- Gutiérrez-Capitán, M.; Baldi, A.; Fernández-Sánchez, C. Electrochemical Paper-Based Biosensor Devices for Rapid Detection of Biomarkers. Sensors 2020, 20, 967. [Google Scholar] [CrossRef] [Green Version]

- Hristov, D.R.; Rodriguez-Quijada, C.; Gómez-Márquez, J.; Hamad-Schifferli, K. Designing Paper-Based Immunoassays for Biomedical Applications. Sensors 2019, 19, 554. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Islam, N.; Ahmed, I.; Anik, M.I.; Ferdous, S.; Khan, M.S. Developing Paper Based Diagnostic Technique to Detect Uric Acid in Urine. Front. Chem. 2018, 6, 496. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gao, H.; Yan, C.; Wu, W.; Li, J. Application of Microfluidic Chip Technology in Food Safety Sensing. Sensors 2020, 20, 1792. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choi, J.R.; Yong, K.W.; Choi, J.Y.; Cowie, A.C. Emerging Point-of-care Technologies for Food Safety Analysis. Sensors 2019, 19, 817. [Google Scholar] [CrossRef] [Green Version]

- Shriver-Lake, L.; Zabetakis, D.; Dressick, W.J.; Stenger, D.; Trammell, S.A. Paper-Based Electrochemical Detection of Chlorate. Sensors 2018, 18, 328. [Google Scholar] [CrossRef] [Green Version]

- Singh, A.T.; Lantigua, D.; Meka, A.; Taing, S.; Pandher, M.; Camci-Unal, G. Paper-Based Sensors: Emerging Themes and Applications. Sensors 2018, 18, 2838. [Google Scholar] [CrossRef] [Green Version]

- Qi, A.; Yeo, L.; Friend, J.R.; Ho, J. The extraction of liquid, protein molecules and yeast cells from paper through surface acoustic wave atomization. Lab Chip 2010, 10, 470–476. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Demirev, P.A. Dried Blood Spots: Analysis and Applications. Anal. Chem. 2013, 85, 779–789. [Google Scholar] [CrossRef] [PubMed]

- Soum, V.; Park, S.; Brilian, A.I.; Kwon, O.-S.; Shin, K. Programmable Paper-Based Microfluidic Devices for Biomarker Detections. Micromachines 2019, 10, 516. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, X.; Ballerini, D.R.; Shen, W. A perspective on paper-based microfluidics: Current status and future trends. Biomicrofluidics 2012, 6, 011301–1130113. [Google Scholar] [CrossRef] [Green Version]

- Muller, R.H.; Clegg, D.L. Automatic Paper Chromatography. Anal. Chem. 1949, 21, 1123–1125. [Google Scholar] [CrossRef]

- Martinez, A.W.; Phillips, S.T.; Butte, M.J.; Whitesides, G.M. Patterned Paper as a Platform for Inexpensive, Low-Volume, Portable Bioassays. Angew. Chem. Int. Ed. 2007, 46, 1318–1320. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, G.M.; Silva, W.R.; Barreto, D.N.; Lamarca, R.S.; Gomes, P.C.F.L.; Petruci, J.F.D.S.; Batista, A.D. Novel approaches for colorimetric measurements in analytical chemistry—A review. Anal. Chim. Acta 2020, 1135, 187–203. [Google Scholar] [CrossRef]

- Almeida, M.I.G.; Jayawardane, B.M.; Kolev, S.D.; McKelvie, I.D. Developments of microfluidic paper-based analytical devices (μPADs) for water analysis: A review. Talanta 2018, 177, 176–190. [Google Scholar] [CrossRef]

- Fernandes, S.C.; Walz, J.A.; Wilson, D.J.; Brooks, J.C.; Mace, C.R. Beyond Wicking: Expanding the Role of Patterned Paper as the Foundation for an Analytical Platform. Anal. Chem. 2017, 89, 5654–5664. [Google Scholar] [CrossRef] [Green Version]

- Cate, D.M.; Adkins, J.A.; Mettakoonpitak, J.; Henry, C.S. Recent Developments in Paper-Based Microfluidic Devices. Anal. Chem. 2015, 87, 19–41. [Google Scholar] [CrossRef]

- World Health Organization. Guidelines for Drinking-Water Quality, 4th ed.; WHO: Geneva, Switzerland, 2017; Available online: https://www.who.int/publications/i/item/9789241549950 (accessed on 22 October 2020).

- U.S. Geological Survey. Nitrogen and Water. Available online: https://www.usgs.gov/special-topic/water-science-school/science/nitrogen-and-water?qt-science_center_objects=0#qt-science_center_objects (accessed on 22 October 2020).

- Silva, C.G.; Pereira, M.F.R.; Órfão, J.J.M.; Faria, J.L.; Soares, O.S.G.P. Catalytic and Photocatalytic Nitrate Reduction Over Pd-Cu Loaded Over Hybrid Materials of Multi-Walled Carbon Nanotubes and TiO2. Front. Chem. 2018, 6, 632. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gupta, S.; Gupta, R.C.; Gupta, A.B.; Eskiocak, S.; Rao, E.V.S.P.; Puttanna, K.; Singhvi, A. Pathophysiology of Nitrate Toxicity in Human and its Mitigation Measures. Bull. Reg. Assess. React. Nitrogen 2010, 20, 1–78. [Google Scholar]

- Ward, M.H.; Jones, R.R.; Brender, J.D.; De Kok, T.M.; Weyer, P.J.; Nolan, B.T.; Villanueva, C.M.; Van Breda, S.G. Drinking Water Nitrate and Human Health: An Updated Review. Int. J. Environ. Res. Public Health 2018, 15, 1557. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Estimated Nitrate Concentrations in Groundwater Used for Drinking. Nutrient Pollution Policy and Data. US EPA. Available online: https://www.epa.gov/nutrient-policy-data/estimated-nitrate-concentrations-groundwater-used-drinking (accessed on 7 October 2020).

- De Acha, N.; Elosua, C.; Corres, J.M.; Arregui, F.J. Fluorescent Sensors for the Detection of Heavy Metal Ions in Aqueous Media. Sensors 2019, 19, 599. [Google Scholar] [CrossRef] [Green Version]

- Alahi, E.E.; Mukhopadhyay, S.C. Detection methods of nitrate in water: A review. Sens. Actuators A Phys. 2018, 280, 210–221. [Google Scholar] [CrossRef]

- Wierzbicka, E. Novel methods of nitrate and nitrite determination—A review. J. Elementol. 2019, 25, 97–106. [Google Scholar] [CrossRef]

- Kapoor, A.; Balasubramanian, S.; Muthamilselvi, P.; Vaishampayan, V.; Prabhakar, S. Lab-on-a-Chip Devices for Water Quality Monitoring; Springer: Cham, Switzerland, 2020; pp. 455–469. [Google Scholar]

- Jaywant, S.A.; Arif, K.M. A Comprehensive Review of Microfluidic Water Quality Monitoring Sensors. Sensors 2019, 19, 4781. [Google Scholar] [CrossRef] [Green Version]

- Khanfar, M.F.; Al-Faqheri, W.; Al-Halhouli, A. Low Cost Lab on Chip for the Colorimetric Detection of Nitrate in Mineral Water Products. Sensors 2017, 17, 2345. [Google Scholar] [CrossRef] [Green Version]

- Jayawardane, B.M.; Wei, S.; McKelvie, I.D.; Kolev, S.D. Microfluidic Paper-Based Analytical Device for the Determination of Nitrite and Nitrate. Anal. Chem. 2014, 86, 7274–7279. [Google Scholar] [CrossRef]

- Teepoo, S.; Arsawiset, S.; Chanayota, P. One-Step Polylactic Acid Screen-Printing Microfluidic Paper-Based Analytical Device: Application for Simultaneous Detection of Nitrite and Nitrate in Food Samples. Chemosensors 2019, 7, 44. [Google Scholar] [CrossRef] [Green Version]

- Ratnarathorn, N.; Dungchai, W. Paper-based Analytical Device (PAD) for the Determination of Borax, Salicylic Acid, Nitrite, and Nitrate by Colorimetric Methods. J. Anal. Chem. 2020, 75, 487–494. [Google Scholar] [CrossRef]

- Thongkam, T.; Hemavibool, K. An Environmentally Friendly Microfluidic Paper-Based Analytical Device for Simultaneous Colorimetric Detection of Nitrite and Nitrate in Food Products. Microchem. J. 2020, 159, 105412. [Google Scholar] [CrossRef]

- Ferreira, F.T.; Mesquita, R.B.R.; Rangel, A.O. Novel microfluidic paper-based analytical devices (μPADs) for the determination of nitrate and nitrite in human saliva. Talanta 2020, 219, 121183. [Google Scholar] [CrossRef] [PubMed]

- Charbaji, A.; Smith, W.; Anagnostopoulos, C.; Faghri, M. Zinculose: A new fibrous material with embedded zinc particles. Eng. Sci. Technol. Int. J. 2020. [Google Scholar] [CrossRef]

- Mako, T.L.; Levenson, A.M.; Levine, M. Ultrasensitive Detection of Nitrite through Implementation of N-(1-Naphthyl)ethylenediamine-Grafted Cellulose into a Paper-Based Device. ACS Sens. 2020, 5, 1207–1215. [Google Scholar] [CrossRef]

- Fox, J.B. Kinetics and mechanisms of the Griess reaction. Anal. Chem. 1979, 51, 1493–1502. [Google Scholar] [CrossRef]

- Wang, Q.-H.; Yu, L.-J.; Liu, Y.; Lin, L.; Lu, R.-G.; Zhu, J.-P.; He, L.; Lu, Z.-L. Methods for the detection and determination of nitrite and nitrate: A review. Talanta 2017, 165, 709–720. [Google Scholar] [CrossRef]

- Mahmud, M.A.P.; Ejeian, F.; Azadi, S.; Myers, M.; Pejcic, B.; Abbassi, R.; Alizadeh, A.; Asadnia, M. Recent progress in sensing nitrate, nitrite, phosphate, and ammonium in aquatic environment. Chemosphere 2020, 259, 127492. [Google Scholar] [CrossRef]

- Jaikang, P.; Wangkarn, S.; Paengnakorn, P.; Grudpan, K. Microliter Operation for Determination of Nitrate-Nitrogen via Simple Zinc Reduction and Color Formation in a Well Plate with a Smartphone. Anal. Sci. 2019, 35, 421–425. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Murray, E.; Nesterenko, E.P.; McCaul, M.; Morrin, A.; Diamond, D.; Moore, B. A colorimetric method for use within portable test kits for nitrate determination in various water matrices. Anal. Methods 2017, 9, 680–687. [Google Scholar] [CrossRef]

- Goals & Expected Outcomes—RI NSF EPSCoR. Available online: https://web.uri.edu/rinsfepscor/expected-outcomes-2/ (accessed on 23 November 2020).

- Kudo, H.; Yamada, K.; Watanabe, D.; Suzuki, K.; Citterio, D. Paper-Based Analytical Device for Zinc Ion Quantification in Water Samples with Power-Free Analyte Concentration. Micromachines 2017, 8, 127. [Google Scholar] [CrossRef]

- Shimada, Y.; Kaneta, T. Highly Sensitive Paper-based Analytical Devices with the Introduction of a Large-Volume Sample via Continuous Flow. Anal. Sci. 2018, 34, 65–70. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fawcett, S.E.; Johnson, K.S.; Riser, S.C.; Van Oostende, N.; Sigman, D.M. Low-nutrient organic matter in the Sargasso Sea thermocline: A hypothesis for its role, identity, and carbon cycle implications. Mar. Chem. 2018, 207, 108–123. [Google Scholar] [CrossRef]

- Weng, C.-H.; Weng, C.-H.; Shen, C.-H.; Yang, R.-J. Colored wax-printed timers for two-dimensional and three-dimensional assays on paper-based devices. Biomicrofluidics 2014, 8, 066502. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, X.; Tian, J.; Shen, W. Quantitative biomarker assay with microfluidic paper-based analytical devices. Anal. Bioanal. Chem. 2009, 396, 495–501. [Google Scholar] [CrossRef] [PubMed]

- Klasner, S.A.; Price, A.K.; Hoeman, K.W.; Wilson, R.S.; Bell, K.J.; Culbertson, C.T. Paper-based microfluidic devices for analysis of clinically relevant analytes present in urine and saliva. Anal. Bioanal. Chem. 2010, 397, 1821–1829. [Google Scholar] [CrossRef] [PubMed]

- Blicharz, T.M.; Rissin, D.M.; Bowden, M.; Hayman, R.B.; Dicesare, C.; Bhatia, J.; Grand-Pierre, N.; Siqueira, W.L.; Helmerhorst, E.J.; Loscalzo, J.; et al. Use of Colorimetric Test Strips for Monitoring the Effect of Hemodialysis on Salivary Nitrite and Uric Acid in Patients with End-Stage Renal Disease: A Proof of Principle. Clin. Chem. 2008, 54, 1473–1480. [Google Scholar] [CrossRef]

- Cardoso, T.M.G.; Garcia, P.T.; Coltro, W.K.T. Colorimetric determination of nitrite in clinical, food and environmental samples using microfluidic devices stamped in paper platforms. Anal. Methods 2015, 7, 7311–7317. [Google Scholar] [CrossRef]

- Miller, J.N.; Miller, J.C. Statistics and Chemometrics for Analytical Chemistry, 5th ed.; Pearson: London, UK, 2005. [Google Scholar]

- Heidari-Bafroui, H.; Ribeiro, B.; Charbaji, A.; Anagnostopoulos, C.; Faghri, M. Infrared Lightbox and iPhone App for Improving Detection Limit of Phosphate Detecting Dip Strips. Int. J. Chem. Mol. Eng. 2020, 14, 179–185. [Google Scholar]

- Heidari-Bafroui, H.; Ribeiro, B.; Charbaji, A.; Anagnostopoulos, C.; Faghri, M. Portable infrared lightbox for improving the detection limits of paper-based phosphate devices. Measurement 2020, 108607. [Google Scholar] [CrossRef]

- Kim, S.C.; Jalal, U.M.; Im, S.B.; Ko, S.; Shim, J.S. A smartphone-based optical platform for colorimetric analysis of microfluidic device. Sens. Actuators B Chem. 2017, 239, 52–59. [Google Scholar] [CrossRef]

- Bhakta, S.A.; Borba, R.; Taba, M.; Garcia, C.D.; Carrilho, E. Determination of nitrite in saliva using microfluidic paper-based analytical devices. Anal. Chim. Acta 2014, 809, 117–122. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lai, Y.-T.; Tsai, C.-H.; Hsu, J.; Lu, Y.-W. Microfluidic Time-Delay Valve Mechanism on Paper-Based Devices for Automated Competitive ELISA. Micromachines 2019, 10, 837. [Google Scholar] [CrossRef] [Green Version]

- Toley, B.J.; Wang, J.A.; Gupta, M.; Buser, J.R.; LaFleur, L.K.; Lutz, B.R.; Fu, E.; Yager, P. A versatile valving toolkit for automating fluidic operations in paper microfluidic devices. Lab Chip 2015, 15, 1432–1444. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Parameter | Range Tested | Optimum Value |

|---|---|---|

| Sample volume (µL) | 80–100 | 95 |

| Reduction time (minutes) | 10–15 | 11 |

| Zinc content (mg/cm2) | 0–30 | 20 |

| Color development time (minutes) | 1–15 | 10 |

| Reference | Nutrient | Media | Sample Volume (µL) | Testing Time (min) | Testing Range (ppm) | LOD (ppm) | LOQ (ppm) |

|---|---|---|---|---|---|---|---|

| This work | Nitrite | Water | 95 | 21 | 0.01–50 | 0.018 | 0.061 |

| Nitrate | 0.533 | 1.765 | |||||

| [33] | Nitrite | Water | 20 | 4.5–8.5 | 0.46–6.9 | 0.046 | 0.359 |

| Nitrate | 3.1–62 | 1.178 | 2.976 | ||||

| [34] | Nitrite | Food sample | 80 | 12 | 2–10 | 1.2 | 4 |

| Nitrate | 10–50 | 3.6 | 12 | ||||

| [35] | Nitrite * | Food sample | 25 | 10 | 0.4–20 | 0.4 | NA |

| Nitrate | |||||||

| [36] | Nitrite | Food sample | 20 | 5 | 0.5–40 | 0.1 | 1.2 |

| Nitrate | 10 | 0.4 | 1.4 | ||||

| [37] | Nitrite | Saliva | 15 | 20–120 | 0.23–11.5 | 0.002 | 0.008 |

| Nitrate | 12.4–74.4 | 4.96 | 16.74 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Charbaji, A.; Heidari-Bafroui, H.; Anagnostopoulos, C.; Faghri, M. A New Paper-Based Microfluidic Device for Improved Detection of Nitrate in Water. Sensors 2021, 21, 102. https://doi.org/10.3390/s21010102

Charbaji A, Heidari-Bafroui H, Anagnostopoulos C, Faghri M. A New Paper-Based Microfluidic Device for Improved Detection of Nitrate in Water. Sensors. 2021; 21(1):102. https://doi.org/10.3390/s21010102

Chicago/Turabian StyleCharbaji, Amer, Hojat Heidari-Bafroui, Constantine Anagnostopoulos, and Mohammad Faghri. 2021. "A New Paper-Based Microfluidic Device for Improved Detection of Nitrate in Water" Sensors 21, no. 1: 102. https://doi.org/10.3390/s21010102