Location Determination of Impact on the Wind Turbine Blade Surface Based on the FBG and the Time Difference

Abstract

1. Introduction

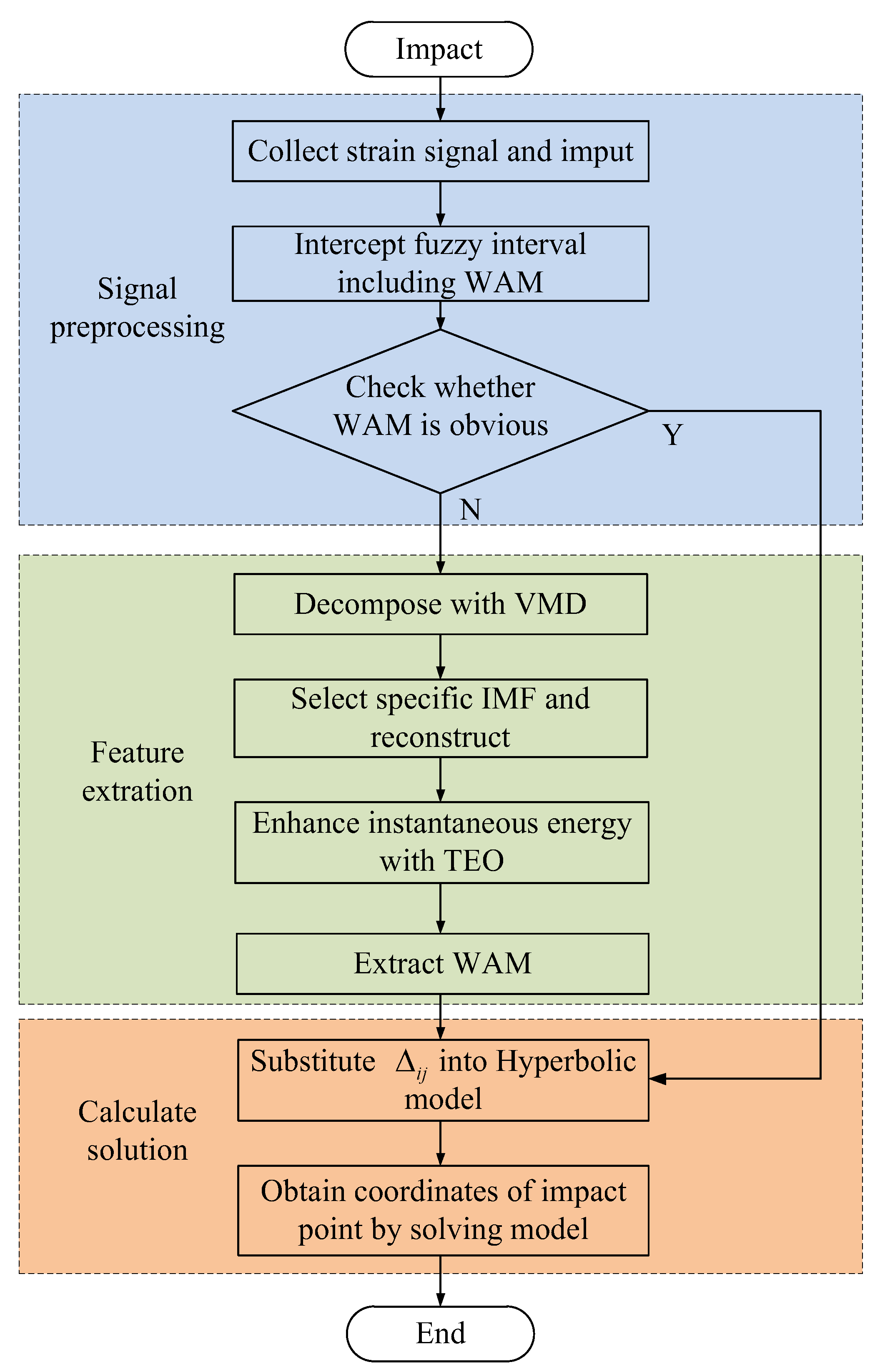

2. Proposed Approach

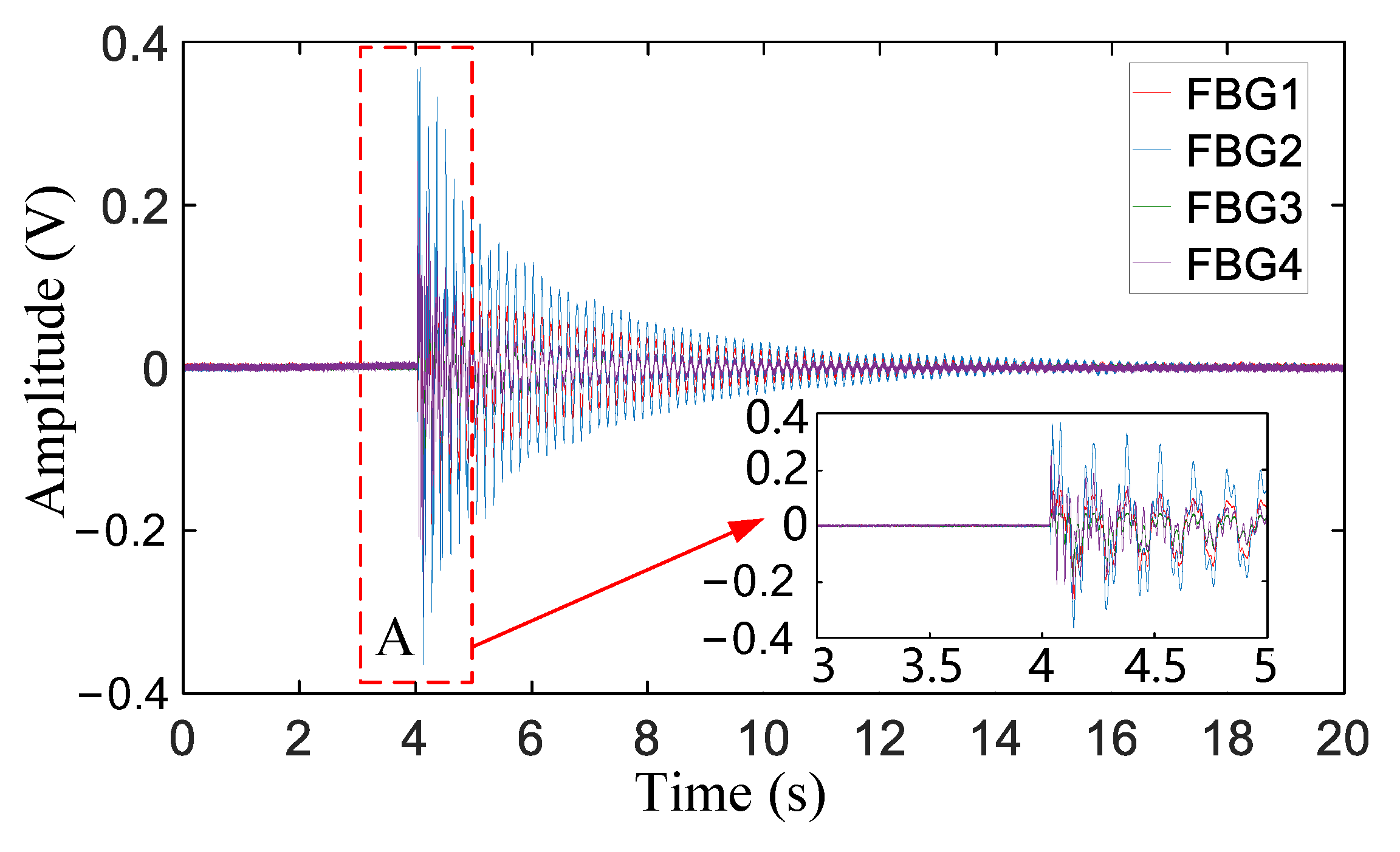

2.1. Strain Signal Acquisition and Preprocessing

2.2. Feature Parameter Extraction

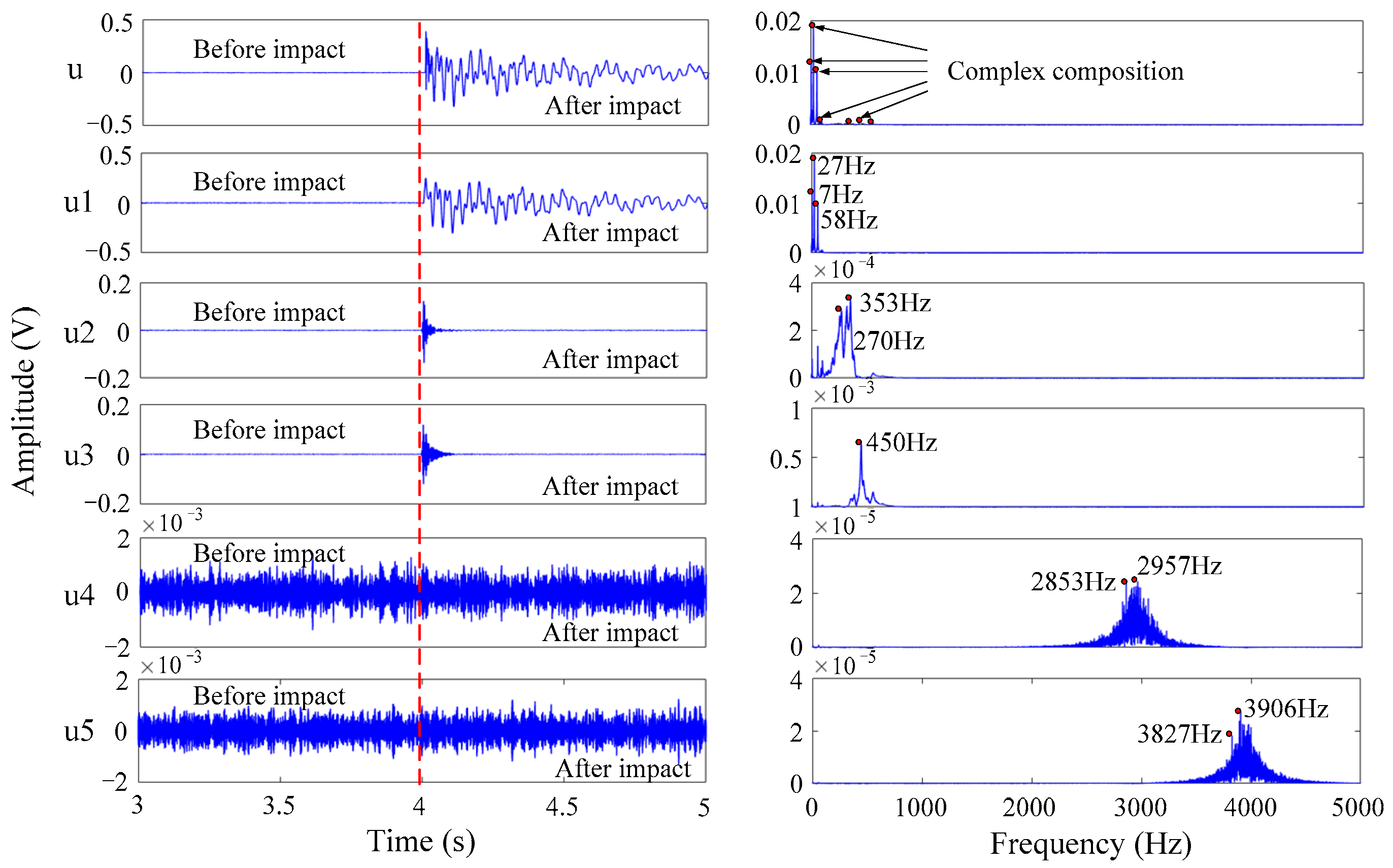

2.2.1. Identification of the Impact Signal with VMD

- (1)

- Hilbert transform is performed on each IMF component to obtain its analytical signal.

- (2)

- The center frequency of each analytical signal is estimated, and the frequency spectrum of each analytical signal is modulated to the corresponding baseband via frequency-shifting.

- (3)

- The Gaussian smoothing index of the frequency-shifted signal is used to estimate the bandwidth of each IMF component to obtain a constrained variational model. The model is expressed aswhere indicates the K IMF components obtained by decomposition, and is the center frequency of each component.

- (4)

- The quadratic penalty function term and the Lagrange multiplier are used to transform Equation (2) into an unconstrained problem expressed aswhere is a penalty factor and is the Lagrange multiplier. The final solution is obtained by the alternate direction method of multipliers, and the adaptive decomposition of the frequency band is realized [22].

2.2.2. Demodulation of the Signal with the TEO

- Define as a TEO; for any continuous impact response signal, it is defined aswhere and are respectively the first- and second-order integrals of the impact response signal . However, the signals collected in practice are mostly discrete. Equation (4) is then discretely converted to obtain Equation (5), which is given as follows.

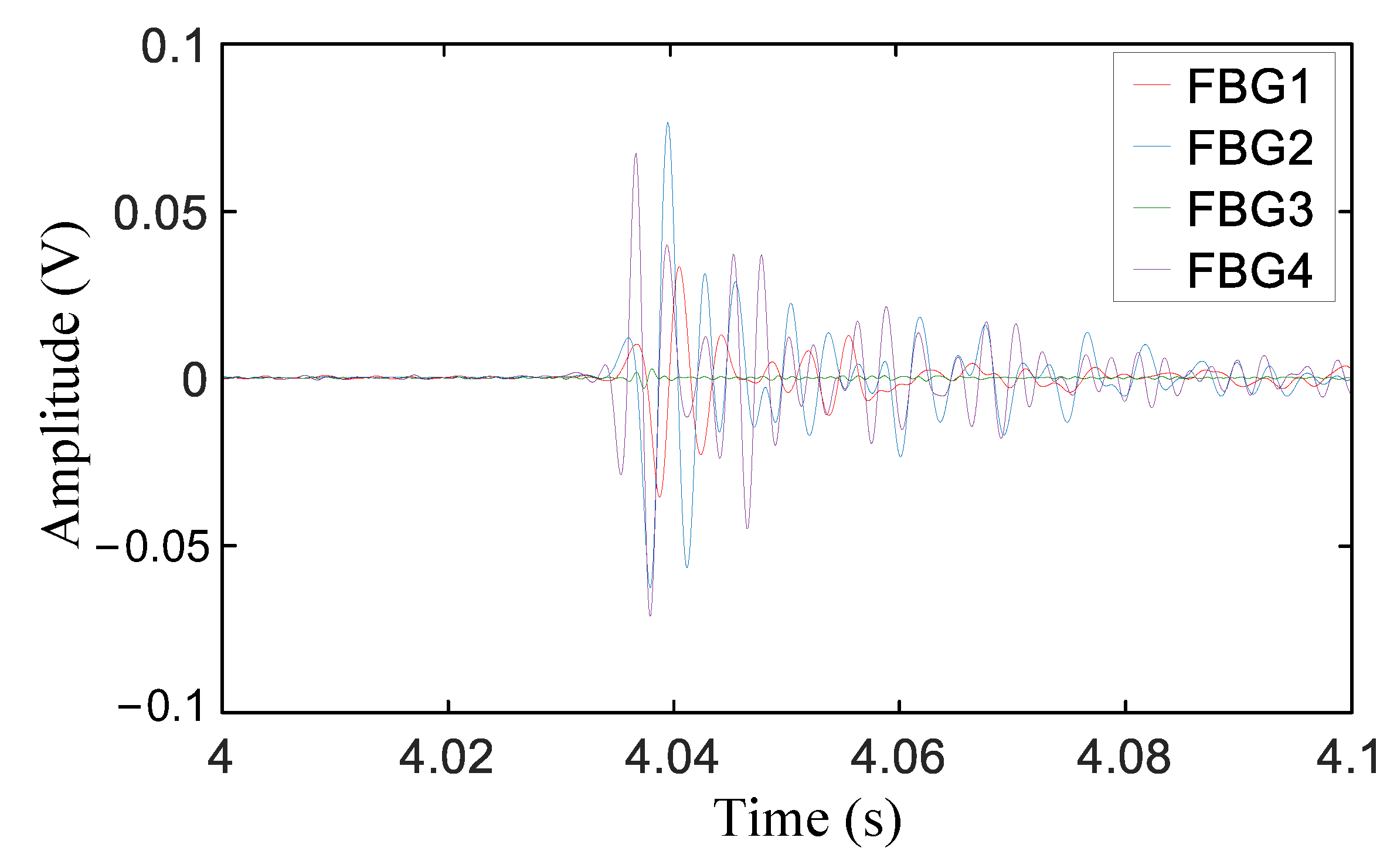

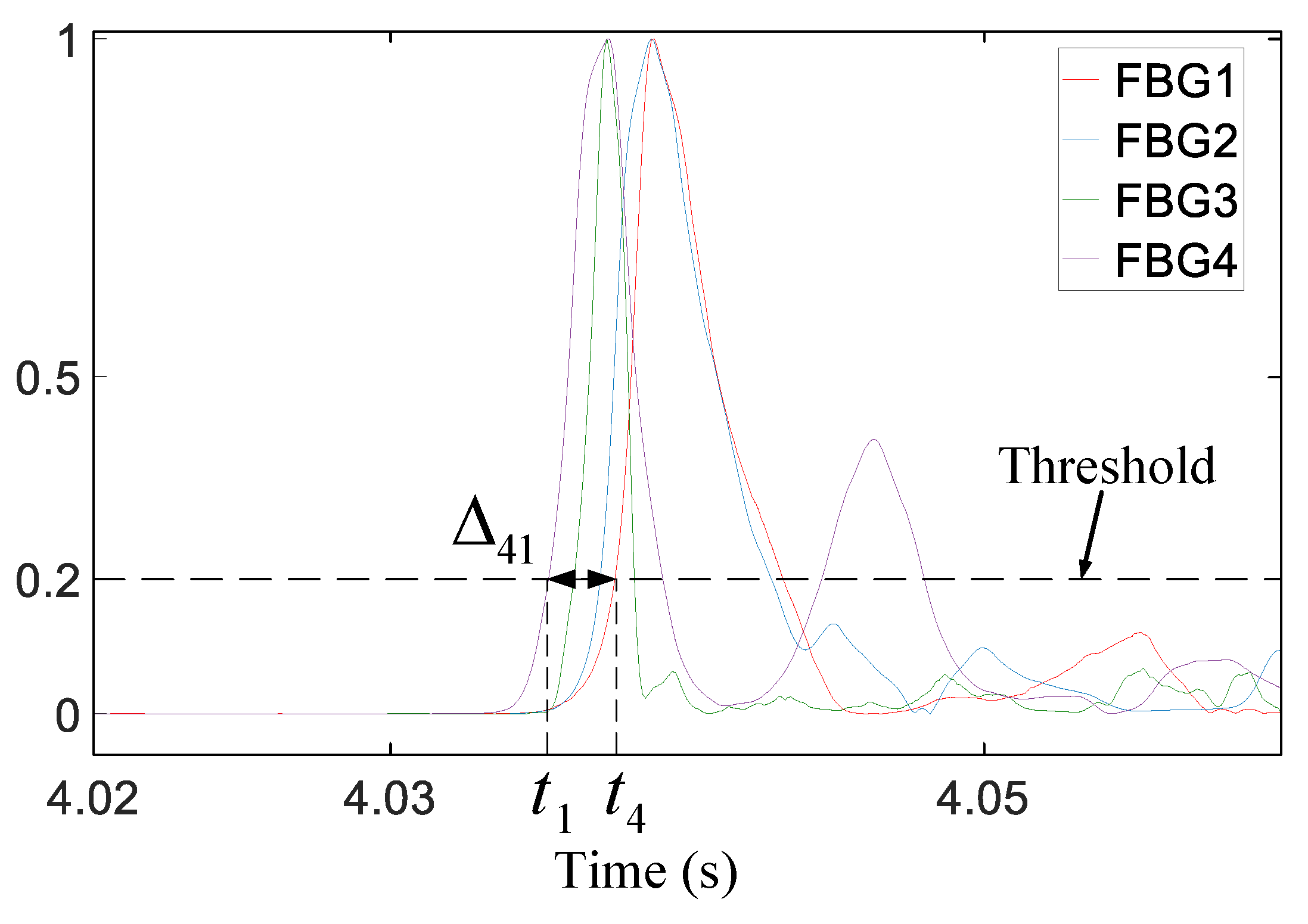

- The characteristic signal after VMD and reconstruction, described in Section 2.2.1, is introduced into Equation (5) for calculation, and an impact signal with an enhanced instantaneous energy feature is obtained. The signal has simple components and an obvious instantaneous energy feature in the time series and can therefore be directly used for the extraction of the WAM. The method of setting a threshold is adopted during the WAM extraction process. As the strain values detected by FBG sensors in different positions will be different, the energy of each group of signals will be different, and it is therefore difficult to set the threshold uniformly. Thus, the extreme value normalization formula given by Equation (6) is used to dimensionalize the data so that each group of signals is unified between 0 and 1.where is the primary data, is the maximum primary data, and is the minimum primary data. When the transient energy amplitude of the impact signal exceeds the set threshold for the first time, the corresponding time point is extracted, which is the WAM.

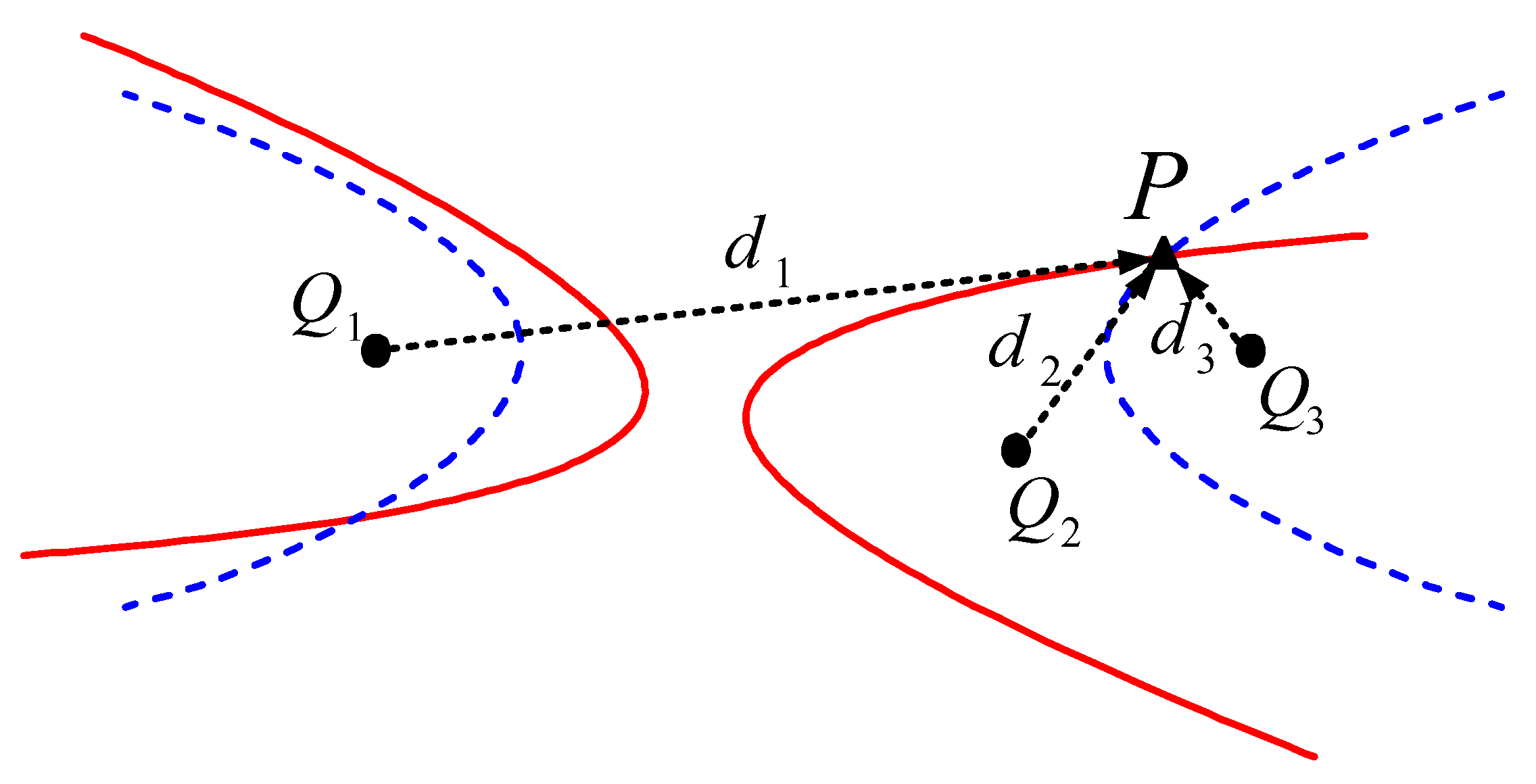

2.3. Calculation of the Solution

3. Experiment and Discussion

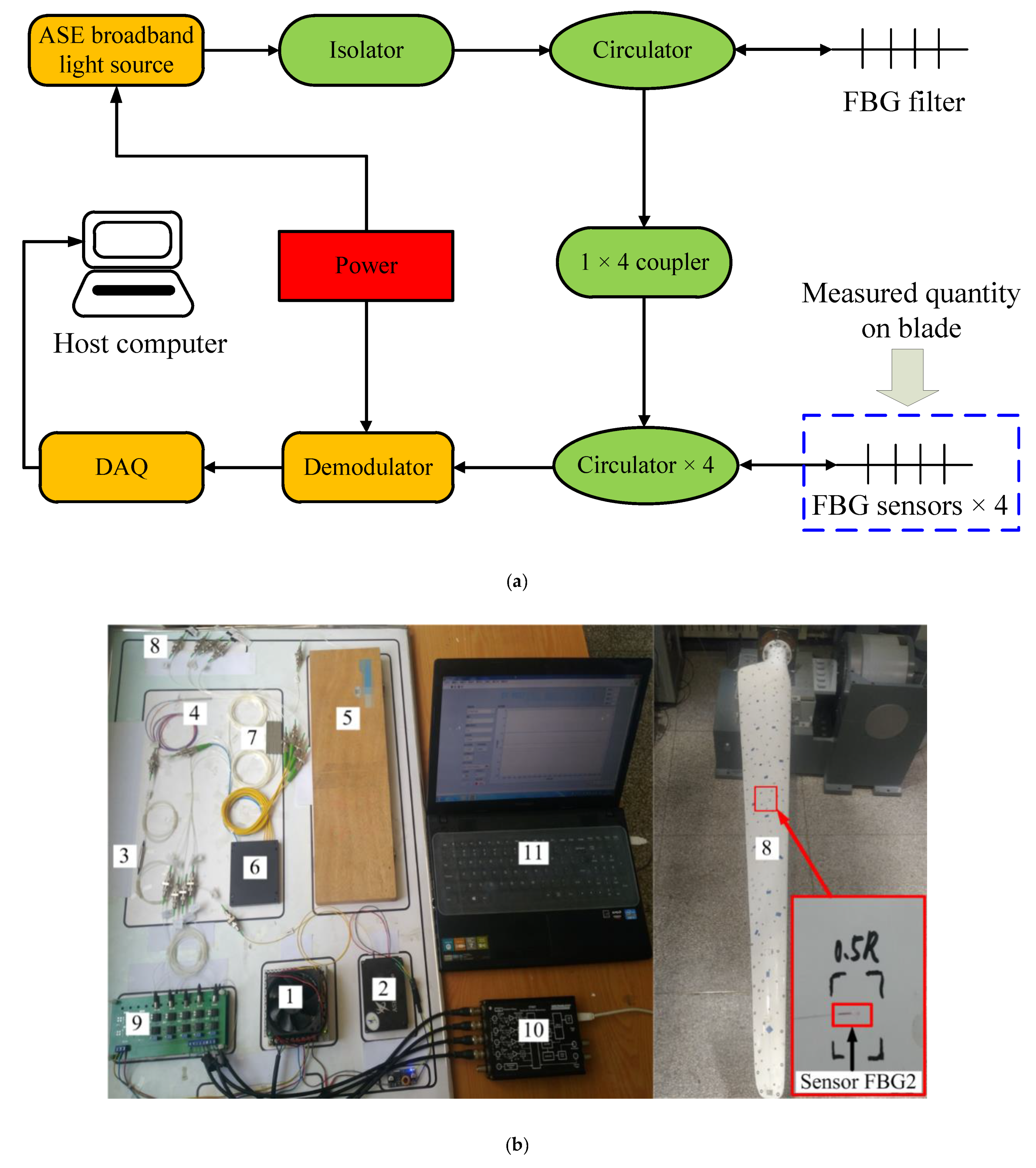

3.1. Impact Location Experiment

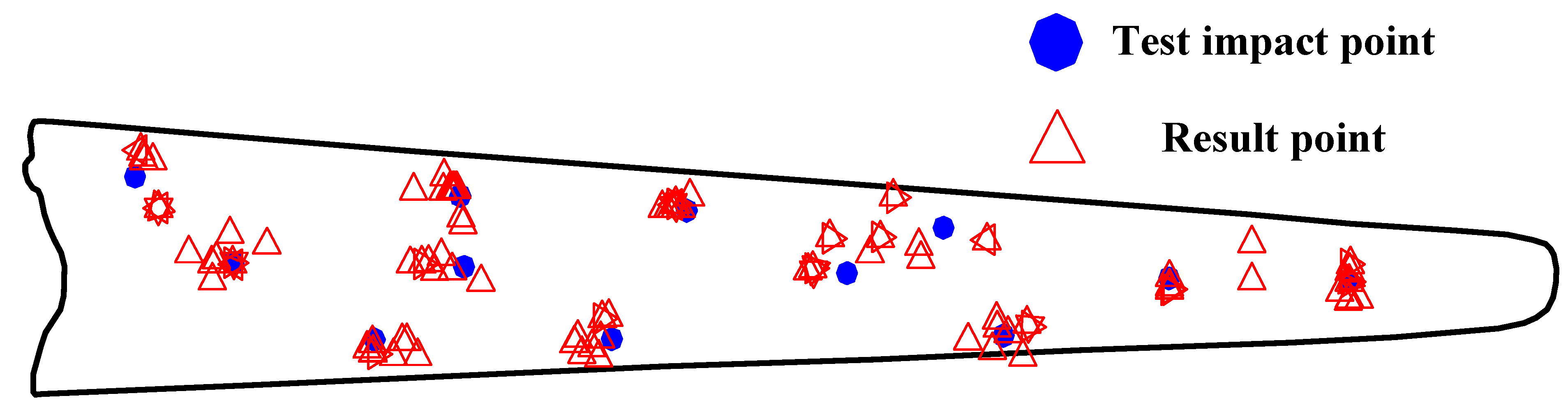

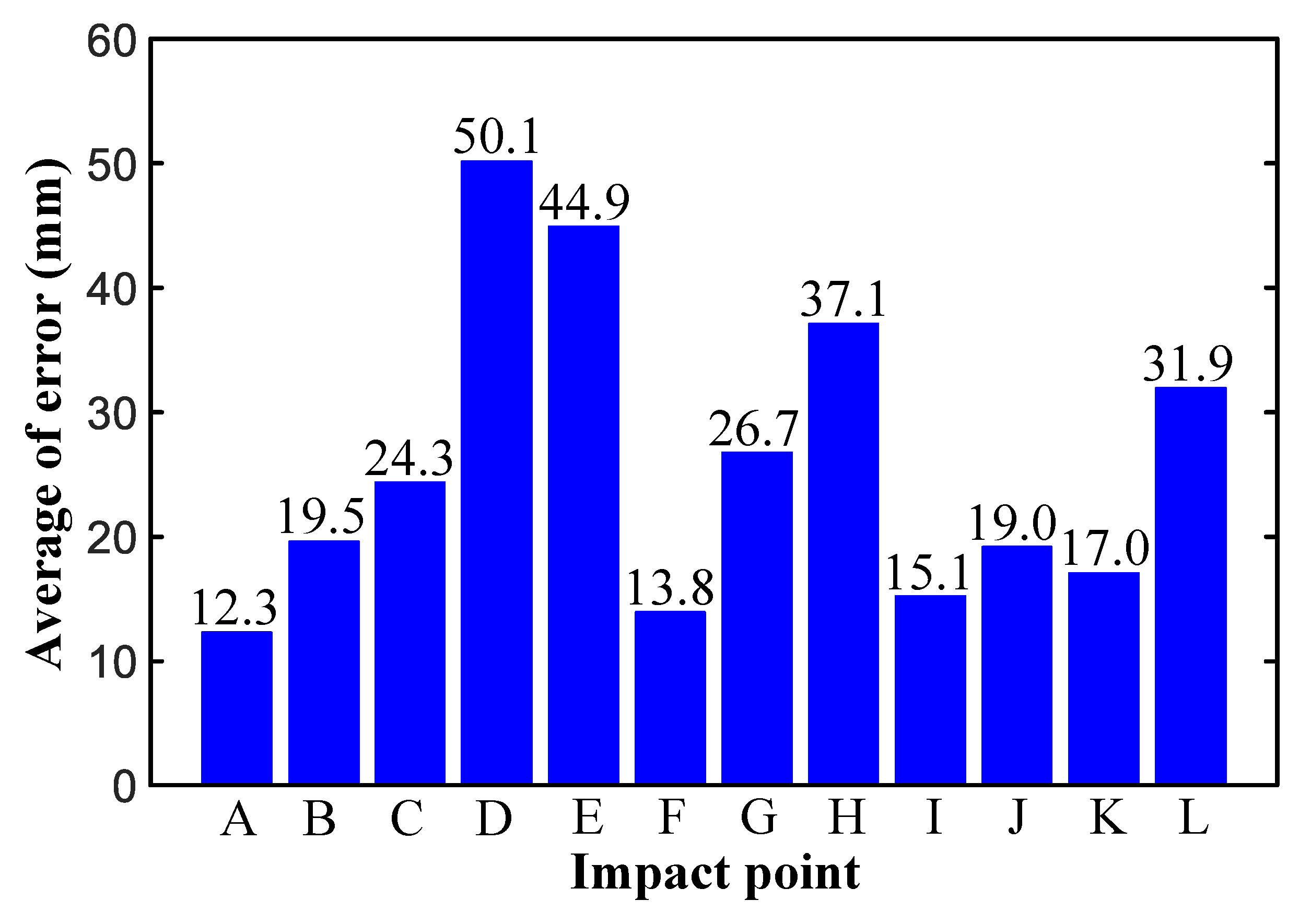

3.2. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Du, Y.; Zhou, S.; Jing, X.; Peng, Y.; Wu, H.; Kwok, N. Damage detection techniques for wind turbine blades: A review. Mech. Syst. Signal Process. 2020, 141, 106445.1–106445.23. [Google Scholar] [CrossRef]

- Chen, B.; Yu, S.; Yu, Y.; Zhou, Y. Acoustical damage detection of wind turbine blade using the improved incremental support vector data description. Renew. Energy 2020, 156. [Google Scholar] [CrossRef]

- Beale, C.; Niezrecki, C.; Inalpolat, M. An adaptive wavelet packet denoising algorithm for enhanced active acoustic damage detection from wind turbine blades. Mech. Syst. Signal Process. 2020, 142, 106754. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L.; Carrasco, J. Vibration analysis for large-scale wind turbine blade bearing fault detection with an empirical wavelet thresholding method. Renew. Energy 2020, 146, 99–110. [Google Scholar] [CrossRef]

- Sarrafi, A.; Mao, Z.; Niezrecki, C.; Poozesh, P. Vibration-based damage detection in wind turbine blades using phase-based motion estimation and motion magnification. J. Sound Vib. 2018, 421, 300–318. [Google Scholar] [CrossRef]

- Tang, J.; Soua, S.; Mares, C.; Gan, T.H. An experimental study of acoustic emission methodology for in service condition monitoring of wind turbine blades. Renew. Energy 2016, 99, 170–179. [Google Scholar] [CrossRef]

- Xu, D.; Liu, P.F.; Chen, Z.P. Damage mode identification and singular signal detection of composite wind turbine blade using acoustic emission. Compos. Struct. 2020, 255. [Google Scholar] [CrossRef]

- Yang, X.Y.; Zhang, Y.F.; Lv, W.; Wang, D. Image recognition of wind turbine blade damage based on a deep learning model with transfer learning and an ensemble learning classifier. Renew. Energy 2021, 163, 386–397. [Google Scholar] [CrossRef]

- Rizk, P.; Saleh, N.A.; Younes, R.; Ilinca, A.; Khoder, J. Hyperspectral imaging applied for the detection of wind turbine blade damage and icing. Remote Sens. Appl. Soc. Environ. 2020, 18, 100291. [Google Scholar] [CrossRef]

- Soman, R.; Balasubramaniam, K.; Golestani, A.; Karpiński, M.; Malinowski, P. A Two-Step Guided Waves Based Damage Localization Technique Using Optical Fiber Sensors. Sensors 2020, 20, 5804. [Google Scholar] [CrossRef]

- Matveenko, V.; Kosheleva, N.; Serovaev, G. Damage detection algorithm based on using surface mounted fiber-optic sensors on bragg gratings. Procedia Struct. Integr. 2019, 18, 12–19. [Google Scholar] [CrossRef]

- Jin, X.; Yuan, S.F.; Chen, J. On crack propagation monitoring by using reflection spectra of afbg and ufbg sensors. Sens. Actuators Phys. 2018, 285. [Google Scholar] [CrossRef]

- Yu, J.S.; Liang, D.K. Impact load localization by using fiber bragg gratings based on characteristics of skewness and kurtosis. Acta Opt. Sin. 2018, 38, 204–211. [Google Scholar]

- Alvarez-Montoya, J.; Alejandro, C.C.; Sierra-Pérez, J. In-flight and wireless damage detection in a uav composite wing using fiber optic sensors and strain field pattern recognition. Mech. Syst. Signal Process. 2020, 136. [Google Scholar] [CrossRef]

- Sierra-Perez, J.; Torres-Arredondo, M.A.; Gueemes, A. Damage and nonlinearities detection in wind turbine blades based on strain field pattern recognition. fbgs, obr and strain gauges comparison. Compos. Struct. 2016, 135, 156–166. [Google Scholar] [CrossRef]

- Ma, Z.Q.; Li, Y.C.; Liu, Z.; Guang, C.J. Rolling bearings’ fault feature extraction based on variational mode decomposition and teager energy operator. J. Vib. Shock 2016, 13, 134–139. [Google Scholar]

- Li, X.; Wan, S.; Huang, X.W.; Hong, J. Milling chatter detection based on vmd and difference of power spectral entropy. Int. J. Adv. Manuf. Technol. 2020, 111, 2051–2063. [Google Scholar] [CrossRef]

- Li, K.; He, S.; Luo, B.; Li, B.; Mao, X. Online chatter detection in milling process based on vmd and multiscale entropy. Int. J. Adv. Manuf. Technol. 2019, 105, 5009–5022. [Google Scholar] [CrossRef]

- Wang, L.L. Chapter 10—Elastic–Plastic Waves Propagating in Beams under Transverse Impact (Bending Wave Theory); Foundations of Stress Waves; Wang, L., Ed.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 399–451. [Google Scholar] [CrossRef]

- Al-Tallaq, K.N.; Al-Sharai, H.D.; El-Hawary, M.E. Online algorithm for removal of decaying dc-offset from fault currents. Electr. Power Syst. Res. 2011, 81, 1627–1629. [Google Scholar] [CrossRef]

- Wang, H.; Chen, J.; Zhou, Y.; Ni, G. Early fault diagnosis of rolling bearing based on noise-assisted signal feature enhancement and stochastic resonance for intelligent manufacturing. Int. J. Adv. Manuf. Technol. 2020, 107, 1017–1023. [Google Scholar] [CrossRef]

- Li, J.; Chen, Y.; Qian, Z.H.; Lu, C.G. Research on vmd based adaptive denoising method applied to water supply pipeline leakage location. Measurement 2019, 151. [Google Scholar] [CrossRef]

- Staszewski, W.J.; Mahzan, S.; Traynor, R. Health monitoring of aerospace composite structures–active and passive approach. Compos. Sci. Technol. 2009, 69, 1678–1685. [Google Scholar] [CrossRef]

| Density (kg·m−3) | Length (m) | Poisson’s Ratio | Shear Modulus (MPa) | Young’s Modulus (MPa) | Bulk Modulus (MPa) |

|---|---|---|---|---|---|

| 1950 | 2.4 | 0.22 | 5500 | 13,420 | 7988.1 |

| Order | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Frequency (Hz) | 7.32 | 18.89 | 27.61 | 58.16 | 82.73 |

| Central Wavelength (nm) | Gating Length (mm) | Bandwidth (mm) | Reflectivity (%) | Side-Mode Suppression Ratio (dB) |

|---|---|---|---|---|

| 1550 | 2.0 | 0.45 | 69.3 | 10.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Sun, W.; Wang, H.; Wan, Y.; Xu, T. Location Determination of Impact on the Wind Turbine Blade Surface Based on the FBG and the Time Difference. Sensors 2021, 21, 232. https://doi.org/10.3390/s21010232

Wang B, Sun W, Wang H, Wan Y, Xu T. Location Determination of Impact on the Wind Turbine Blade Surface Based on the FBG and the Time Difference. Sensors. 2021; 21(1):232. https://doi.org/10.3390/s21010232

Chicago/Turabian StyleWang, Bingkai, Wenlei Sun, Hongwei Wang, Yunfa Wan, and Tiantian Xu. 2021. "Location Determination of Impact on the Wind Turbine Blade Surface Based on the FBG and the Time Difference" Sensors 21, no. 1: 232. https://doi.org/10.3390/s21010232

APA StyleWang, B., Sun, W., Wang, H., Wan, Y., & Xu, T. (2021). Location Determination of Impact on the Wind Turbine Blade Surface Based on the FBG and the Time Difference. Sensors, 21(1), 232. https://doi.org/10.3390/s21010232