Unified Chassis Control of Electric Vehicles Considering Wheel Vertical Vibrations

Abstract

:1. Introduction

2. System Modeling

2.1. Nonlinear Vehicle Model

2.2. Nonlinear Tire Model

2.3. Driver Model

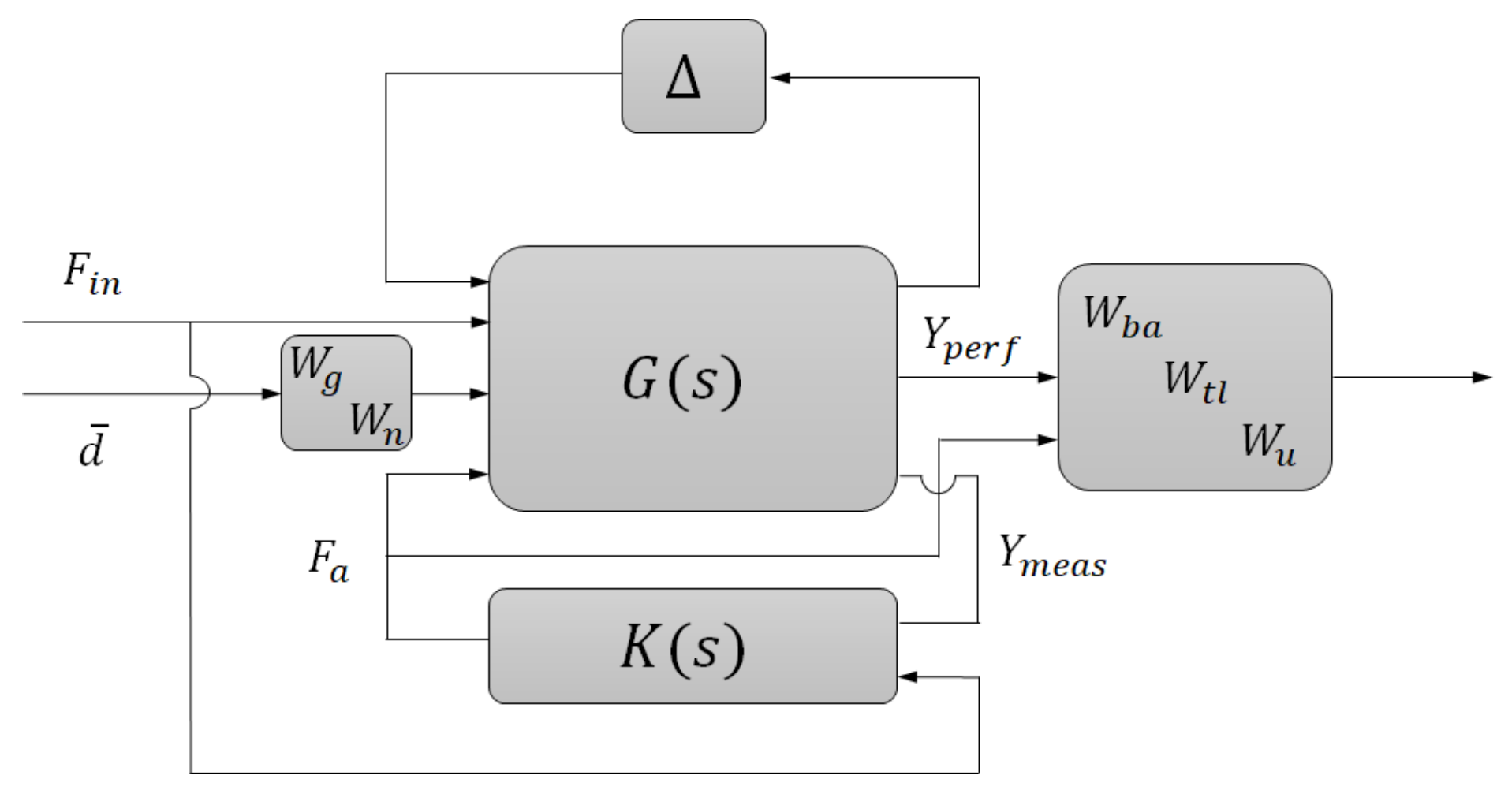

3. Design of the Control System

3.1. High-Level Robust Controller Design

3.2. Control Allocation Algorithm

3.3. Tire Normal Forces Robust Tracking Control

- (1)

- In practical use, the wheel motions are under the effect of road roughness, especially considering the high unsprung mass introduced by the electric propulsion system, such as the in-wheel motor. This kind of motion instability will cause the inaccuracy of tire load tracking.

- (2)

- Quarter car model is the classic model which was widely utilized in suspension analysis and control synthesis. However, the spatial kinematics and dynamics considering the suspension geometry are relatively complicated, leading to the inaccuracy and uncertainty of model parameters. Though some analytic model of suspension geometry is presented and realized in simulation [33], the complex computation makes them less efficient in real-car implements.

- (3)

- The active suspension control algorithm is always a trade-off between the vehicle ride comfort and tire-road adhesion stability, which is hard to be optimized simultaneously. Moreover, the tracking control requirement makes the problem more complex and increases the difficulty of controller design.

- (1)

- Controller 1: For the state of tire contact force cannot reflect the dynamic behavior of sprung mass, only the sprung mass acceleration was selected as the feedback signal of the comfort-orientated control scheme.

- (2)

- Controller 2: In the tire-stability-orientated control scheme, both the unsprung mass acceleration and tire contact force work as the feedback signals, with the former signal reflecting the desired tire normal force and the latter one providing the real normal force. The sensor reflects the DL could be tire-pressure based, for example.

4. Simulation Studies

4.1. High-Speed Double Lane-Changing (DLC) on a Rough Road Surface

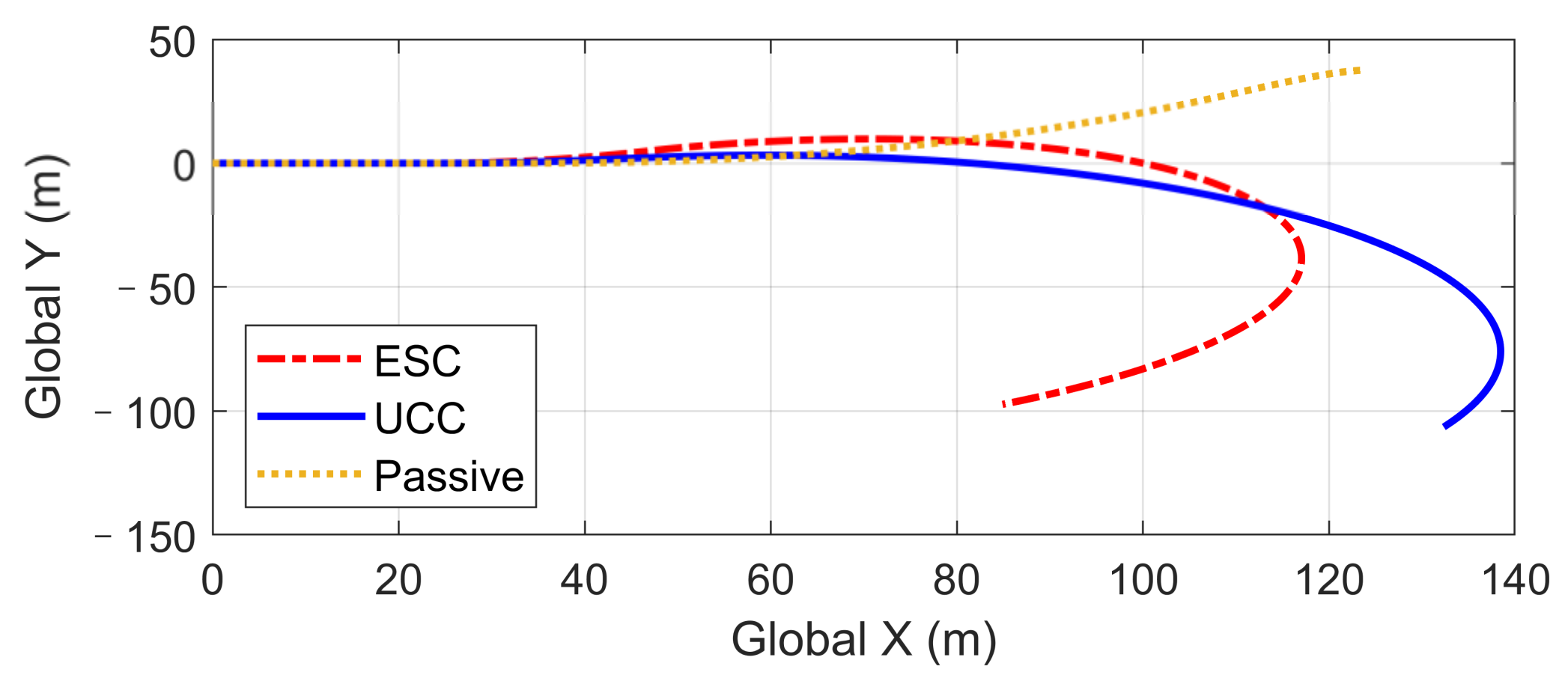

4.2. High-Speed Double Lane-Changing (DLC) on a Flat Road Surface (Compared with ESC)

4.3. High-Speed Fishhook Maneuver

- (1)

- The body altitude control function of UCC reduced the vehicle roll angle, indicated in Figure 23.

- (2)

- The braking force was triggered to inhibit the increase of lateral acceleration, which is shown in Figure 21.

4.4. Tire Blow-Out in the Hard-Braking Process (Re-Configurable Control)

5. Conclusions

- (1)

- For a four-wheel independent drive–independent steering configuration, the proposed UCC method can effectively realize the tire planar force distribution and the desired vehicle motion, which proves to be a practical solution due to its simple feedback control rules and reconfigurable allocation.

- (2)

- Considering the wheel vertical vibrations, we present a robust tire normal force tracking controller to address the tire contact stability issue. This work provides an innovative method for improving the vehicle driving stability and maintaining the desired body attitude simultaneously.

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| UCC | Unified Chassis Control | ESC | Electric Stability Control |

| CG | Center of Gravity | RI | Rollover Index |

| BA | Body Acceleration | DL | Tire Dynamic Load |

| DLC | Doubel Lane Change | CA | Control Allocation |

References

- Murata, S. Innovation by in-wheel-motor drive unit. Veh. Syst. Dyn. 2012, 50, 807–830. [Google Scholar] [CrossRef]

- Koehn, P.; Eckrich, M. Active steering-the BMW approach towards modern steering technology. SAE Tech. Pap. 2004. [Google Scholar] [CrossRef]

- Gysen, B.L.; Paulides, J.J.; Janssen, J.L.; Lomonova, E.A. Active electromagnetic suspension system for improved vehicle dynamics. IEEE Trans. Veh. Technol. 2010, 59, 1156–1163. [Google Scholar] [CrossRef] [Green Version]

- Hoehn, B.R.; Stahl, K.; Gwinner, P.; Wiesbeck, F. Torque-vectoring driveline for electric vehicles. In Proceedings of the International Federation of Automotive Engineering Societies FISITA 2012 World Automotive Congress; Springer: Berlin/Heidelberg, Germany, 2013; pp. 585–593. [Google Scholar] [CrossRef]

- Bouvin, J.L.; Hamrouni, E.; Moreau, X.; Benine-Neto, A.; Hernette, V.; Serrier, P.; Oustaloup, A. Hierarchical approach for global chassis control. In Proceedings of the 2018 European Control Conference (ECC), Limassol, Cyprus, 12–15 June 2018; pp. 2555–2560. [Google Scholar] [CrossRef]

- Vivas-Lopez, C.A.; Tudon-Martinez, J.C.; Hernandez-Alcantara, D.; Morales-Menendez, R. Global chassis control system using suspension, steering, and braking subsystems. Math. Probl. Eng. 2015, 2015, 263424. [Google Scholar] [CrossRef] [Green Version]

- Chokor, A.; Talj, R.; Doumiati, M.; Charara, A. A global chassis control system involving active suspensions, direct yaw control and active front steering. IFAC-PapersOnLine 2019, 52, 444–451. [Google Scholar] [CrossRef]

- Cho, W.; Yoon, J.; Kim, J.; Hur, J.; Yi, K. An investigation into unified chassis control scheme for optimised vehicle stability and manoeuvrability. Veh. Syst. Dyn. 2008, 46, 87–105. [Google Scholar] [CrossRef]

- Cho, W.; Choi, J.; Kim, C.; Choi, S.; Yi, K. Unified chassis control for the improvement of agility, maneuverability, and lateral stability. IEEE Trans. Veh. Technol. 2012, 61, 1008–1020. [Google Scholar] [CrossRef]

- Yoon, J.; Cho, W.; Koo, B.; Yi, K. Unified chassis control for rollover prevention and lateral stability. IEEE Trans. Veh. Technol. 2009, 58, 596–609. [Google Scholar] [CrossRef]

- Poussot-Vassal, C.; Sename, O.; Dugard, L.; Savaresi, S.M. Vehicle dynamic stability improvements through gain-scheduled steering and braking control. Veh. Syst. Dyn. 2011, 49, 1597–1621. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Crolla, D.A.; Levesley, M.C.; Manning, W.J. Coordination of active steering, driveline, and braking for integrated vehicle dynamics control. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2006, 220, 1401–1420. [Google Scholar] [CrossRef]

- Ono, E.; Hattori, Y.; Muragishi, Y.; Koibuchi, K. Vehicle dynamics integrated control for four-wheel-distributed steering and four-wheel-distributed traction/braking systems. Veh. Syst. Dyn. 2006, 44, 139–151. [Google Scholar] [CrossRef]

- Zhao, J.; Wong, P.K.; Ma, X.; Xie, Z. Chassis integrated control for active suspension, active front steering and direct yaw moment systems using hierarchical strategy. Veh. Syst. Dyn. 2017, 55, 72–103. [Google Scholar] [CrossRef]

- Mousavinejad, E.; Han, Q.L.; Yang, F.; Zhu, Y.; Vlacic, L. Integrated control of ground vehicles dynamics via advanced terminal sliding mode control. Veh. Syst. Dyn. 2017, 55, 268–294. [Google Scholar] [CrossRef]

- Cheng, S.; Li, L.; Liu, C.Z.; Wu, X.; Fang, S.N.; Yong, J.W. Robust LMI-Based H-Infinite Controller Integrating AFS and DYC of Autonomous Vehicles with Parametric Uncertainties. IEEE Trans. Syst. Man Cybern. Syst. 2020. [Google Scholar] [CrossRef]

- Sun, J.; Cong, J.; Gu, L.; Dong, M. Fault-tolerant control for vehicle with vertical and lateral dynamics. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2019, 233, 3165–3184. [Google Scholar] [CrossRef]

- Wang, R.; Wang, J. Fault-tolerant control for electric ground vehicles with independently-actuated in-wheel motors. J. Dyn. Syst. Meas. Control. 2012, 134. [Google Scholar] [CrossRef]

- Ataei, M.; Khajepour, A.; Jeon, S. Model Predictive Control for integrated lateral stability, traction/braking control, and rollover prevention of electric vehicles. Veh. Syst. Dyn. 2020, 58, 49–73. [Google Scholar] [CrossRef]

- Guo, J.; Luo, Y.; Li, K.; Dai, Y. Coordinated path-following and direct yaw-moment control of autonomous electric vehicles with sideslip angle estimation. Mech. Syst. Signal Process. 2018, 105, 183–199. [Google Scholar] [CrossRef]

- Peng, H.; Wang, W.; An, Q.; Xiang, C.; Li, L. Path tracking and direct yaw moment coordinated control based on robust MPC with the finite time horizon for autonomous independent-drive vehicles. IEEE Trans. Veh. Technol. 2020, 69, 6053–6066. [Google Scholar] [CrossRef]

- Pylypchuk, V.; Chen, S.K.; Moshchuk, N.; Litkouhi, B. Slip-Based Holistic Corner Control. In Proceedings of the ASME 2011 International Mechanical Engineering Congress and Exposition, Denver, CO, USA, 11–17 November 2011; pp. 337–342. [Google Scholar] [CrossRef]

- Chen, S.K.; Ghoneim, Y.; Moshchuk, N.; Litkouhi, B.; Pylypchuk, V. Tire-Force Based Holistic Corner Control. In Proceedings of the ASME 2012 International Mechanical Engineering Congress and Exposition, Volume 11: Transportation Systems, Houston, TX, USA, 9–15 November 2012; pp. 133–140. [Google Scholar] [CrossRef]

- Wang, J.; Longoria, R.G. Coordinated and reconfigurable vehicle dynamics control. IEEE Trans. Control. Syst. Technol. 2009, 17, 723–732. [Google Scholar] [CrossRef]

- Shim, T.; Margolis, D. Dynamic normal force control for vehicle stability enhancement. Int. J. Veh. Auton. Syst. 2005, 3, 1–14. [Google Scholar] [CrossRef]

- Gáspár, P.; Szabó, Z.; Bokor, J. The design of an integrated control system in heavy vehicles based on an LPV method. In Proceedings of the 44th IEEE Conference on Decision and Control, Seville, Spain, 12–15 December 2005; pp. 6722–6727. [Google Scholar] [CrossRef] [Green Version]

- Poussot-Vassal, C.; Sename, O.; Dugard, L.; Gaspar, P.; Szabo, Z.; Bokor, J. Attitude and handling improvements through gain-scheduled suspensions and brakes control. Control. Eng. Pract. 2011, 19, 252–263. [Google Scholar] [CrossRef] [Green Version]

- Hrovat, D. Influence of unsprung weight on vehicle ride quality. J. Sound Vib. 1988, 124, 497–516. [Google Scholar] [CrossRef]

- Besselink, I.J.M.; Vos, R.; Nijmeijer, H. Influence of in-wheel motors on the ride comfort of electric vehicles. In Proceedings of the 10th International Symposium on Advanced Vehicle Control (AVEC10), Loughborough, UK, 22–26 August 2010; pp. 835–840. [Google Scholar]

- Zhang, L.; Li, L.; Qi, B. Rollover prevention control for a four in-wheel motors drive electric vehicle on an uneven road. Sci. China Technol. Sci. 2018, 61, 934–948. [Google Scholar] [CrossRef]

- Tan, D.; Wang, H.; Wang, Q. Study on the rollover characteristic of in-wheel-motor-driven electric vehicles considering road and electromagnetic excitation. Shock Vib. 2016, 2016, 1–13. [Google Scholar] [CrossRef]

- Pacejka, H.B.; Bakker, E. The magic formula tyre model. Veh. Syst. Dyn. 1992, 21, 1–18. [Google Scholar] [CrossRef]

- Hurel, J.; Mandow, A.; García-Cerezo, A. Kinematic and dynamic analysis of the McPherson suspension with a planar quarter-car model. Veh. Syst. Dyn. 2013, 51, 1422–1437. [Google Scholar] [CrossRef]

- Wang, W.; Chen, X.; Wang, J. Unsprung Mass Effects on Electric Vehicle Dynamics based on Coordinated Control Scheme. In Proceedings of the 2019 American Control Conference (ACC), Philadelphia, PA, USA, 10–12 July 2019; pp. 971–976. [Google Scholar] [CrossRef]

- Doyle, J.; Glover, K.; Khargonekar, P.; Francis, B. State-space solutions to standard H2 and H∞ control problems. In Proceedings of the 1988 American Control Conference, Atlanta, GA, USA, 15–17 June 1988; pp. 1691–1696. [Google Scholar] [CrossRef] [Green Version]

| Suspension Performances | Passive Suspension (without Control) | Comfort-Orientated Control | Stability-Orientated Control |

|---|---|---|---|

| Body acceleration (m/s2) | 0.6732 | 0.2795 (↓58%) | 0.9067 (↑35%) |

| Tire dynamic load (N) | 242.7421 | 377.5729 (↑56%) | 204.7990 (↓16%) |

| Symbol | Description | Values and Units |

|---|---|---|

| m | Vehicle mass | 1140 kg |

| CD | Aerodynamic drag coefficient | 0.34 |

| a | Distance of front wheel axle from C.G. | 1.165 m |

| b | Distance of rear wheel axle from C.G. | 1.165 m |

| d | Half of the wheel base | 0.7405 m |

| Izz | Yaw inertia | 996 kg m2 |

| ms | Vehicle sprung mass | 1020 kg |

| ks | Suspension stiffness | 33,972 N/m |

| bs | Suspension damping | 2000 N s/m |

| kt | Tire stiffness | 200,000 N/m |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Wang, M.; Wang, W. Unified Chassis Control of Electric Vehicles Considering Wheel Vertical Vibrations. Sensors 2021, 21, 3931. https://doi.org/10.3390/s21113931

Chen X, Wang M, Wang W. Unified Chassis Control of Electric Vehicles Considering Wheel Vertical Vibrations. Sensors. 2021; 21(11):3931. https://doi.org/10.3390/s21113931

Chicago/Turabian StyleChen, Xinbo, Mingyang Wang, and Wei Wang. 2021. "Unified Chassis Control of Electric Vehicles Considering Wheel Vertical Vibrations" Sensors 21, no. 11: 3931. https://doi.org/10.3390/s21113931

APA StyleChen, X., Wang, M., & Wang, W. (2021). Unified Chassis Control of Electric Vehicles Considering Wheel Vertical Vibrations. Sensors, 21(11), 3931. https://doi.org/10.3390/s21113931